Automatic sealing device of spiral tubes

An automatic sealing and lamp tube technology, applied in the direction of electric tube/lamp closing, etc., can solve the problems of poor working conditions and low quality of sealing of spiral lamp tubes, and achieve the effects of compact structure, improved work efficiency, and improved sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and embodiments.

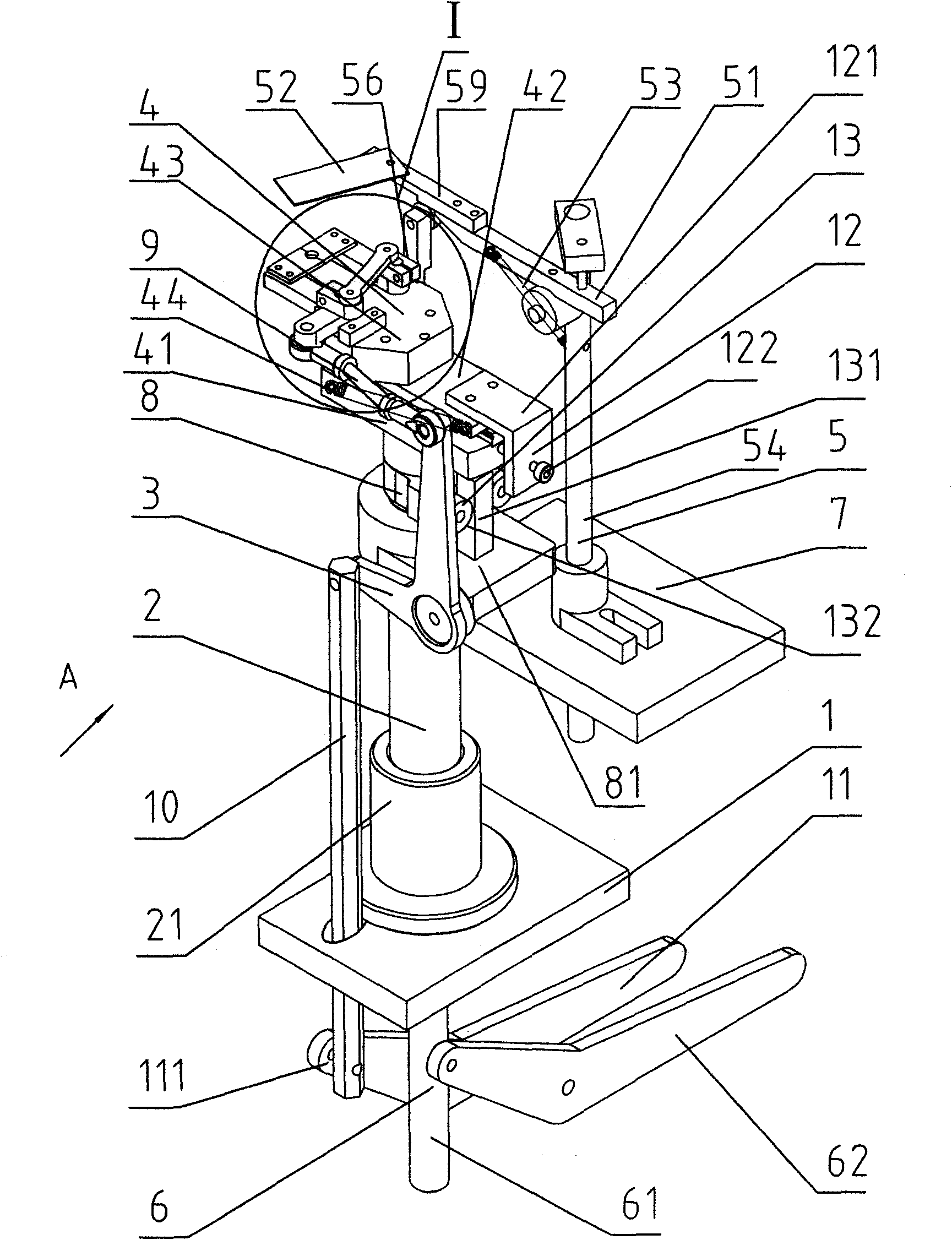

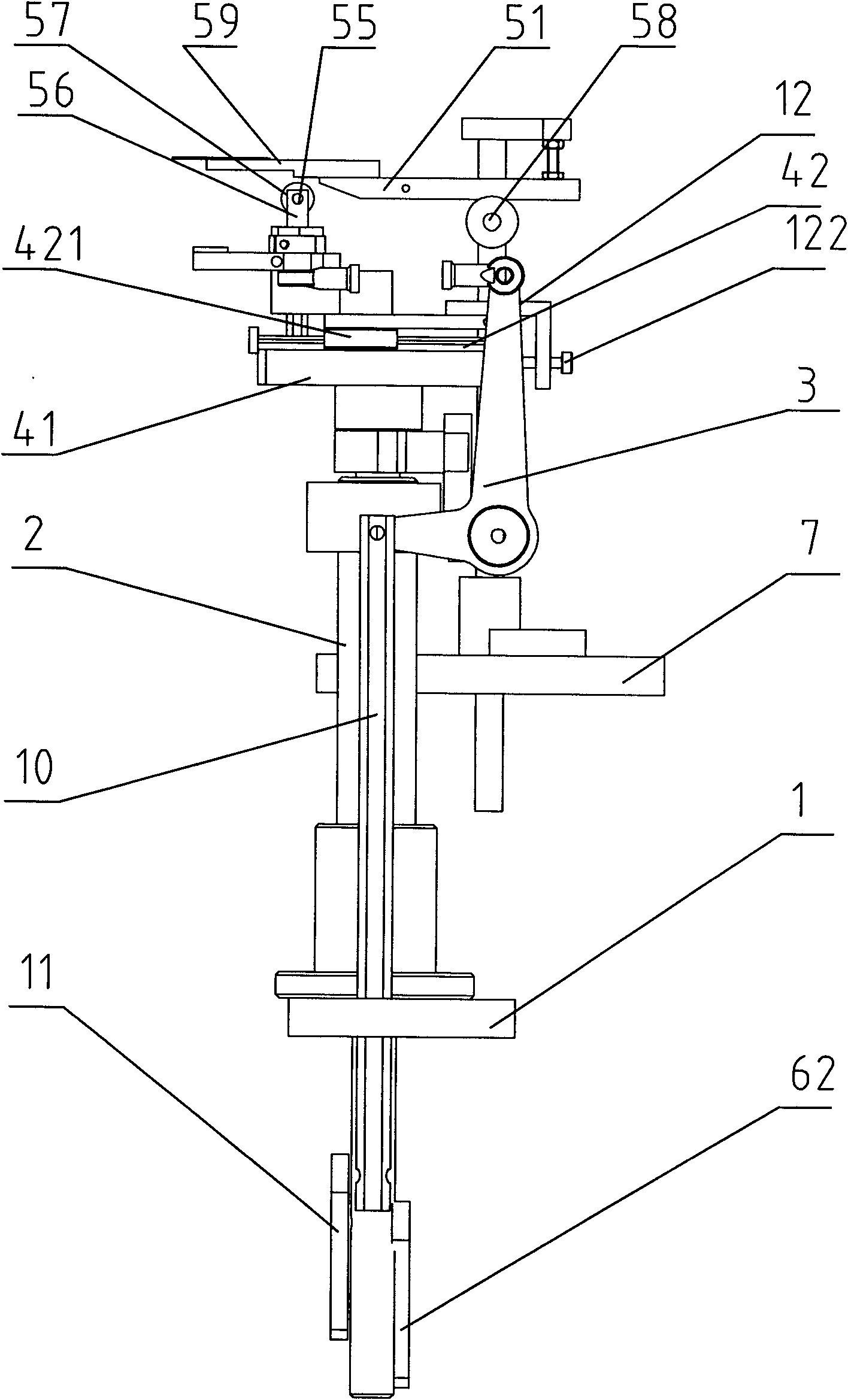

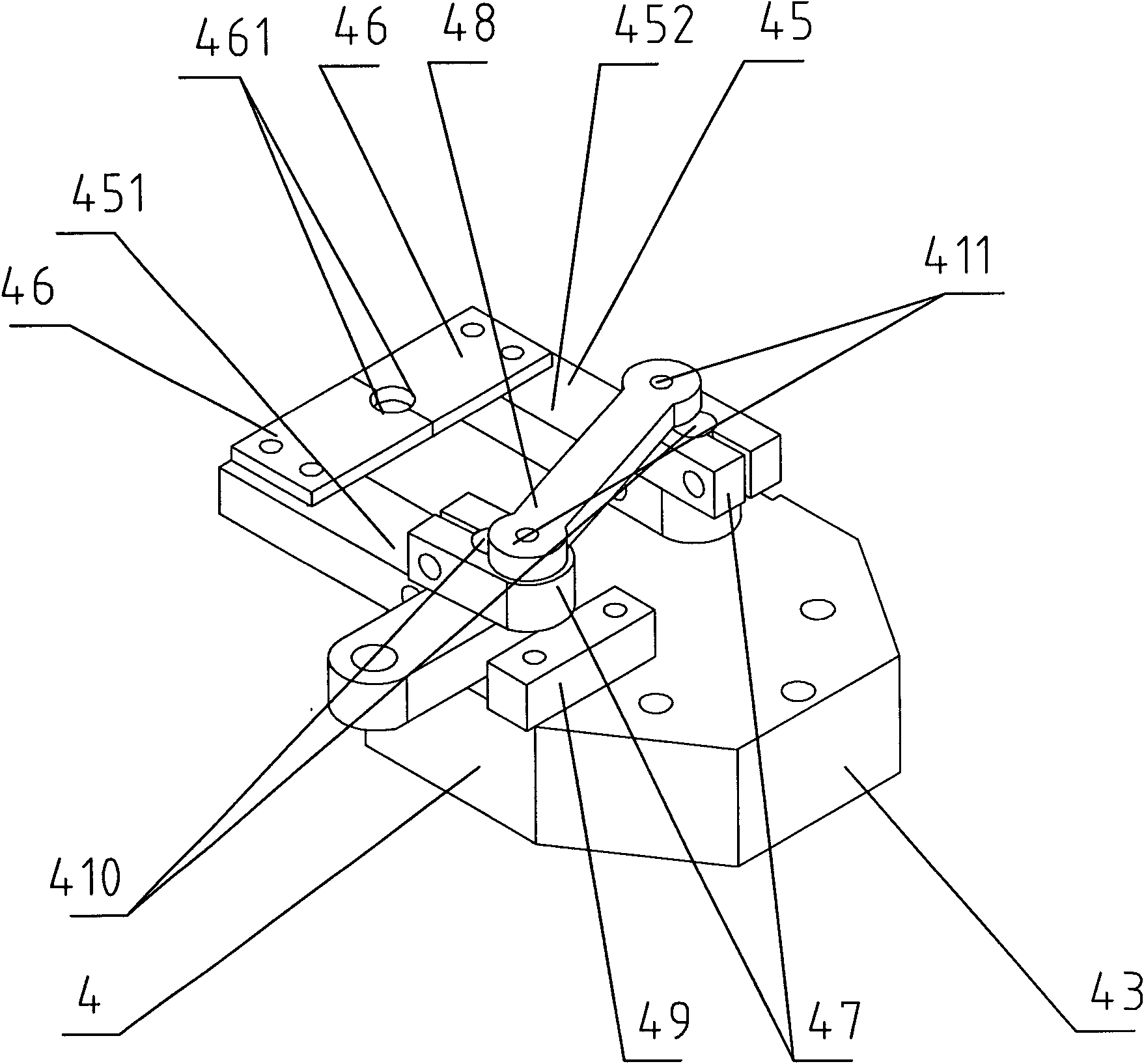

[0019] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a base 1, a column 2, a driving arm 3, a clamping and moving mechanism 4, a lamp tube mechanism 5, a base lifting mechanism 6, a limit mechanism 12, and an anti-rotation mechanism 13; the column 2 is sleeved in France In the flange tube 21, the flange tube 21 is fixedly installed on the base 1, the fixed plate 7 is arranged on the base 1, and the front side of the flange tube 21 supports the clamping and moving mechanism 4 through the supporting column 8. The driving arm 3 is a curved arm with the center lines of the two ends at 90°, and is arranged on one side of the fixed plate 7. The middle part is hinged with one side of the extension section 81 of the support column 8, the upper end is hinged with one end of the connecting rod 9, the lower end is hinged with the upper end of the tie rod 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com