Tempered/semi-tempered vacuum glass and method for manufacturing same

A technology of vacuum glass and manufacturing method, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve the problems of poor wettability, small width of flow and wetting, low fluidity of low-melting glass powder, etc., to achieve sealing effect Reliable, Intensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Embodiments of the present invention will be described below with reference to the accompanying drawings.

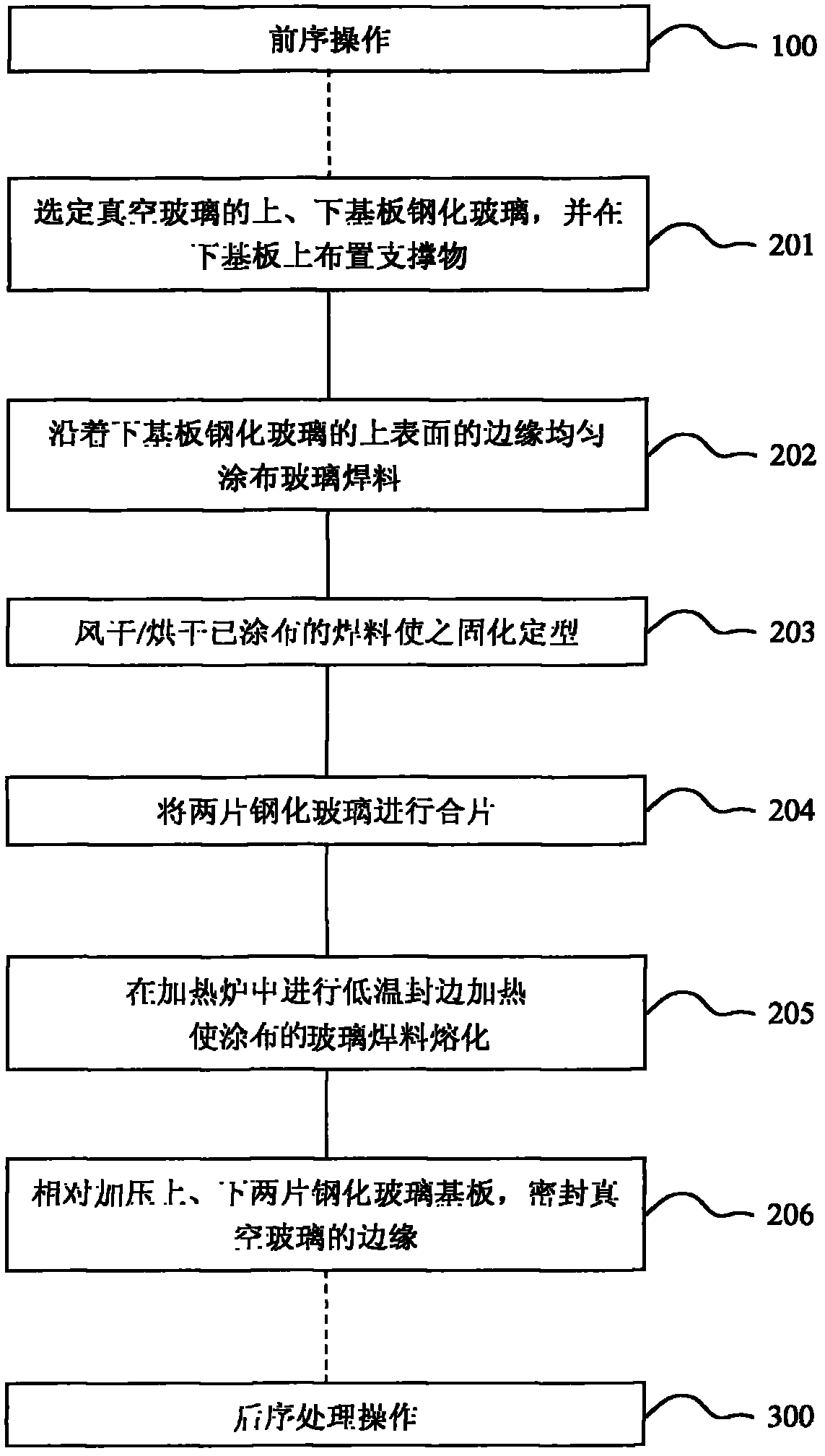

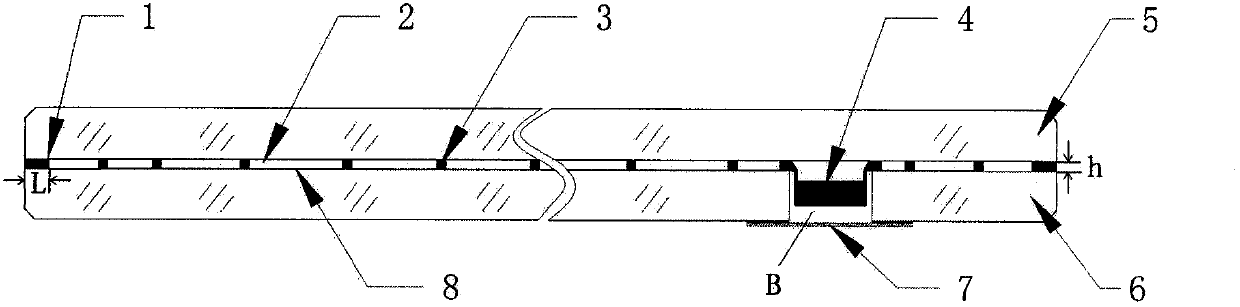

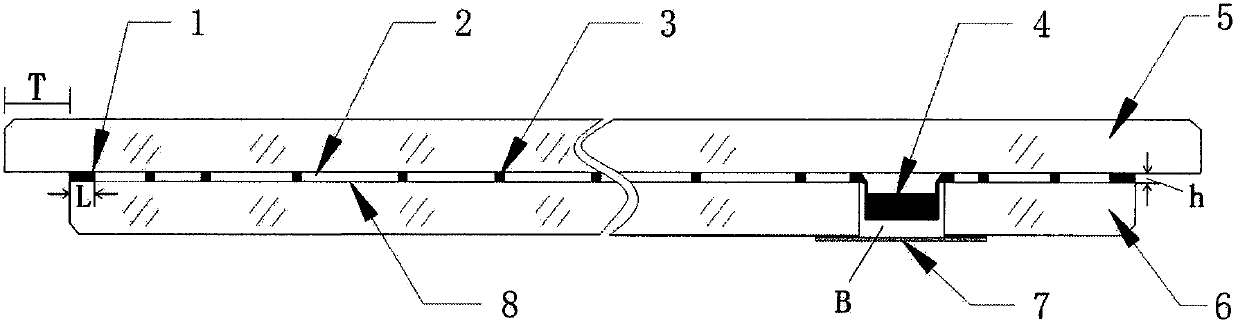

[0026] figure 1 A flowchart showing a method for manufacturing tempered and semi-tempered vacuum glass according to the technical solution of the present invention. Figure 2a is adopted figure 1 Schematic diagram of the structure of tempered and semi-tempered vacuum glass manufactured by the method shown. see figure 1 and Figure 2a , in step 100 a series of pre-order operation processing steps are completed. For example, inspect, decontaminate, remove sharp edges, arrange low-emissivity film 8, prefabricate vacuum suction port, place encapsulated getter, etc. on the tempered flat glass used. Although these steps are closely related to the present invention, they are not the core steps of the present invention, but are similar to the corresponding steps in the prior art.

[0027] In step 201 , the support 3 is placed on the selected lower substrate toughe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com