Rotatable hydraulic expanding type tail pipe hanger

A liner hanger, expansion type technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc. The inner diameter of the column is large, the hanging success rate is high, and the sealing quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

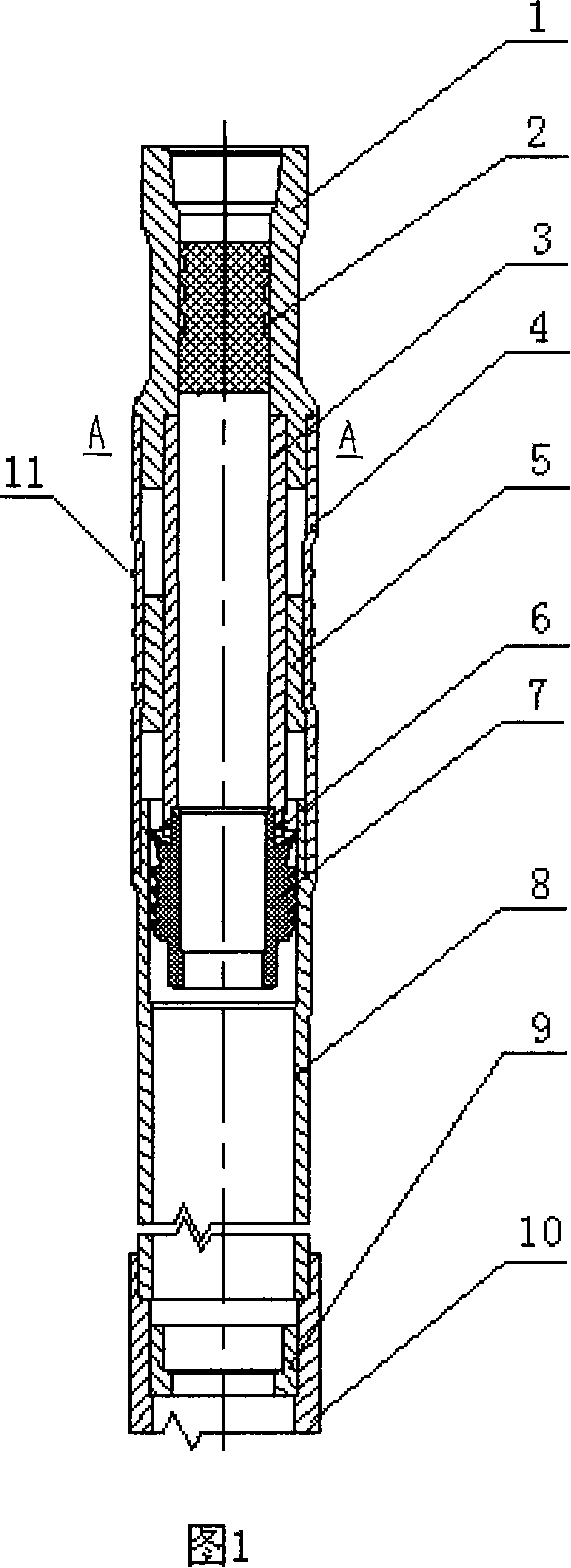

[0015] Embodiment 1: Refer to Fig. 1. Taking the 9-5 / 8" rotatable hydraulic expansion liner hanger as an example, it will be described in detail.

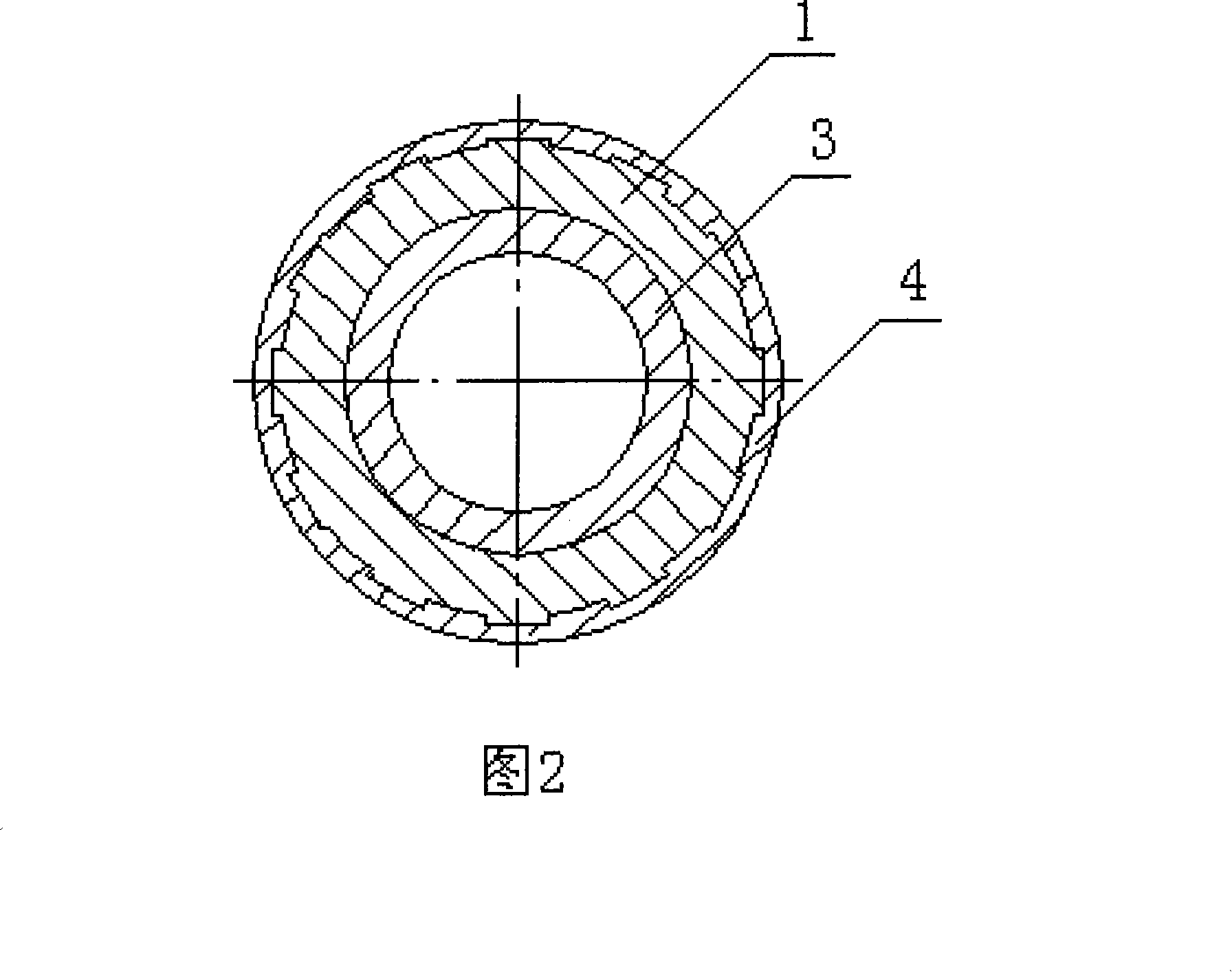

[0016] The rotatable hydraulic expansion liner hanger has an NC50 drill pipe threaded joint at the upper end of the feeding joint 1, which can be connected to a 5-1 / 2″ drill string. The cement rubber plug 2 can be a conventional drill pipe rubber plug. The length of the center pipe 3 is 1320mm , the inner diameter is the same as the inner diameter of the upper drill pipe. The outer diameter of both ends of the expansion tube 4 is ¢210mm, and there are 10 annular protrusions on the outside, and the outer edge diameter of the annular protrusions is the same as the diameter of the end of the expansion tube 4. The expansion plug 5 adopts an annular expansion plug The shear nail 6 has a shearing pressure of 8MPa. The size and specification of the sealant plug 7 is equivalent to that of the casing plug. The plug conduit 8 is the casing t...

Embodiment 2

[0019] Embodiment 2: Refer to Fig. 1. Embodiment 2 is basically the same as Embodiment 1, with the difference that: the outer wall of the expansion section of the expansion tube 4 is covered with a metal-rubber sealing ring. There are five annular protrusions 11 on the outside of the expansion tube 4 , the cross section of the annular protrusions 11 is trapezoidal, and the diameter of the outer edge of the annular protrusions 11 is the same as that of the end of the expansion tube 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com