An upper laid sealing and fixture device for spiral lamp and the corresponding sealing techniques

A sealing fixture device and spiral lamp technology, which is applied in the direction of electric tube/light off, etc., can solve the problems of broken glass tube bent feet, reduced product qualification rate, easy to generate stress, etc. Improve product qualification rate and reduce the effect of high temperature heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

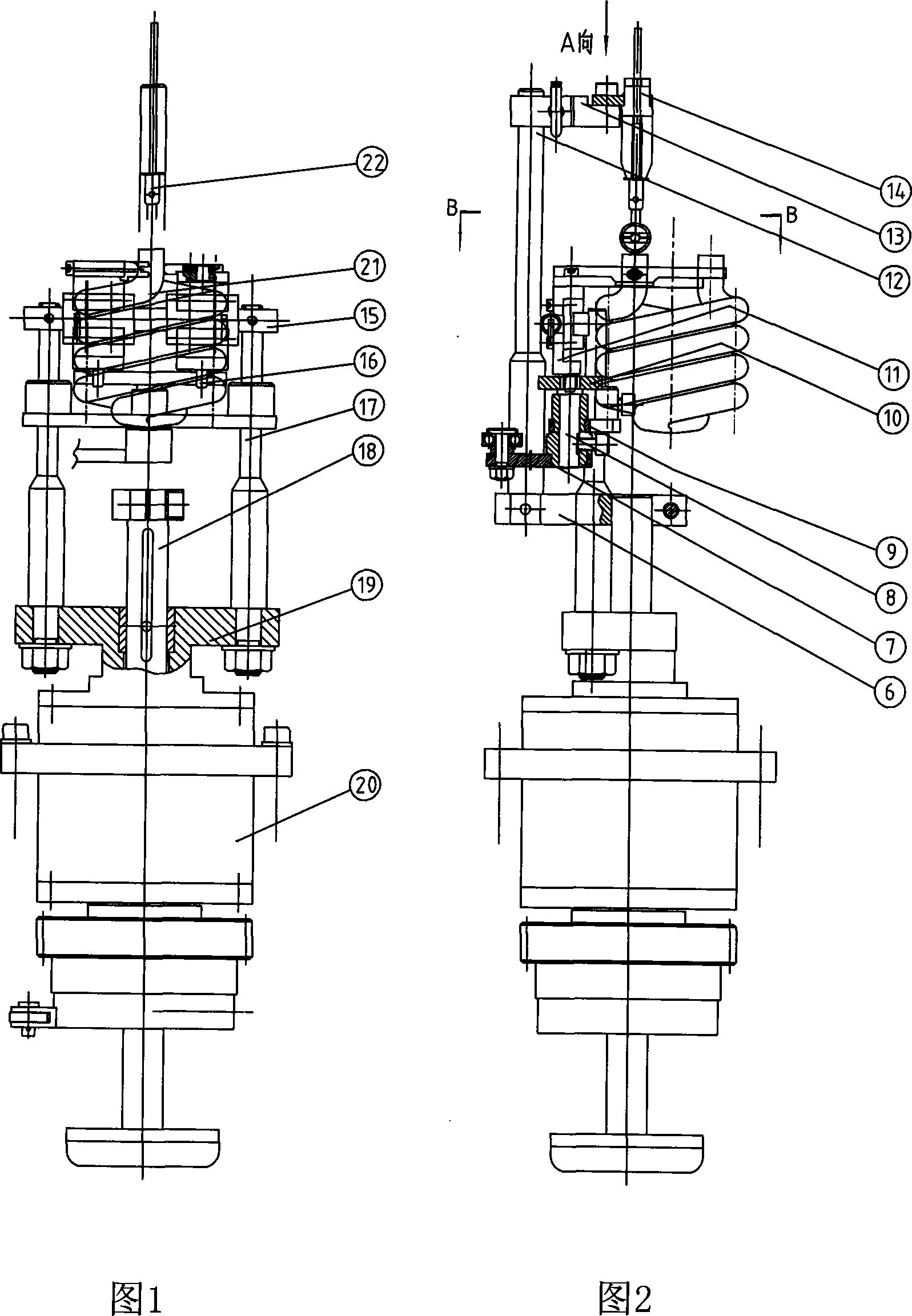

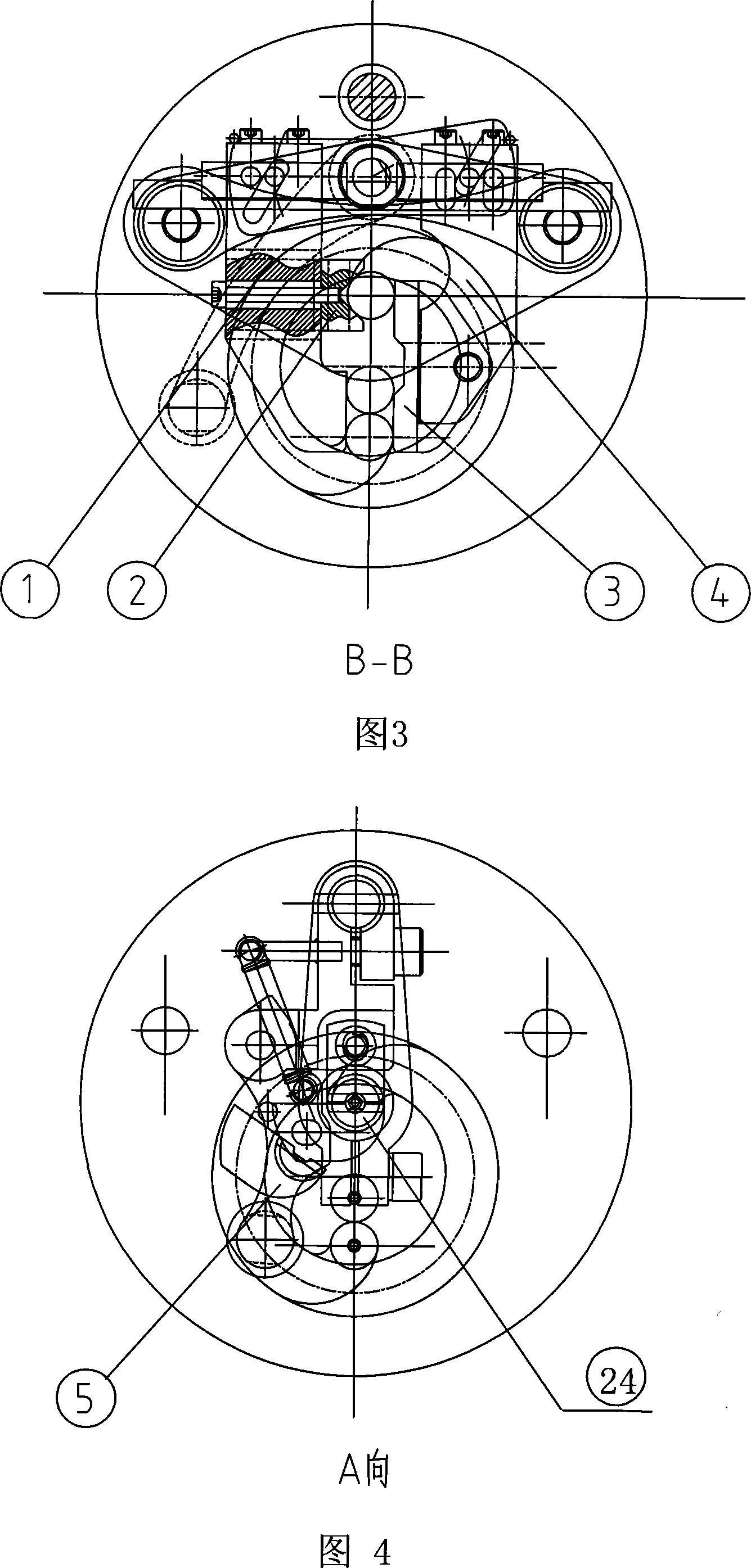

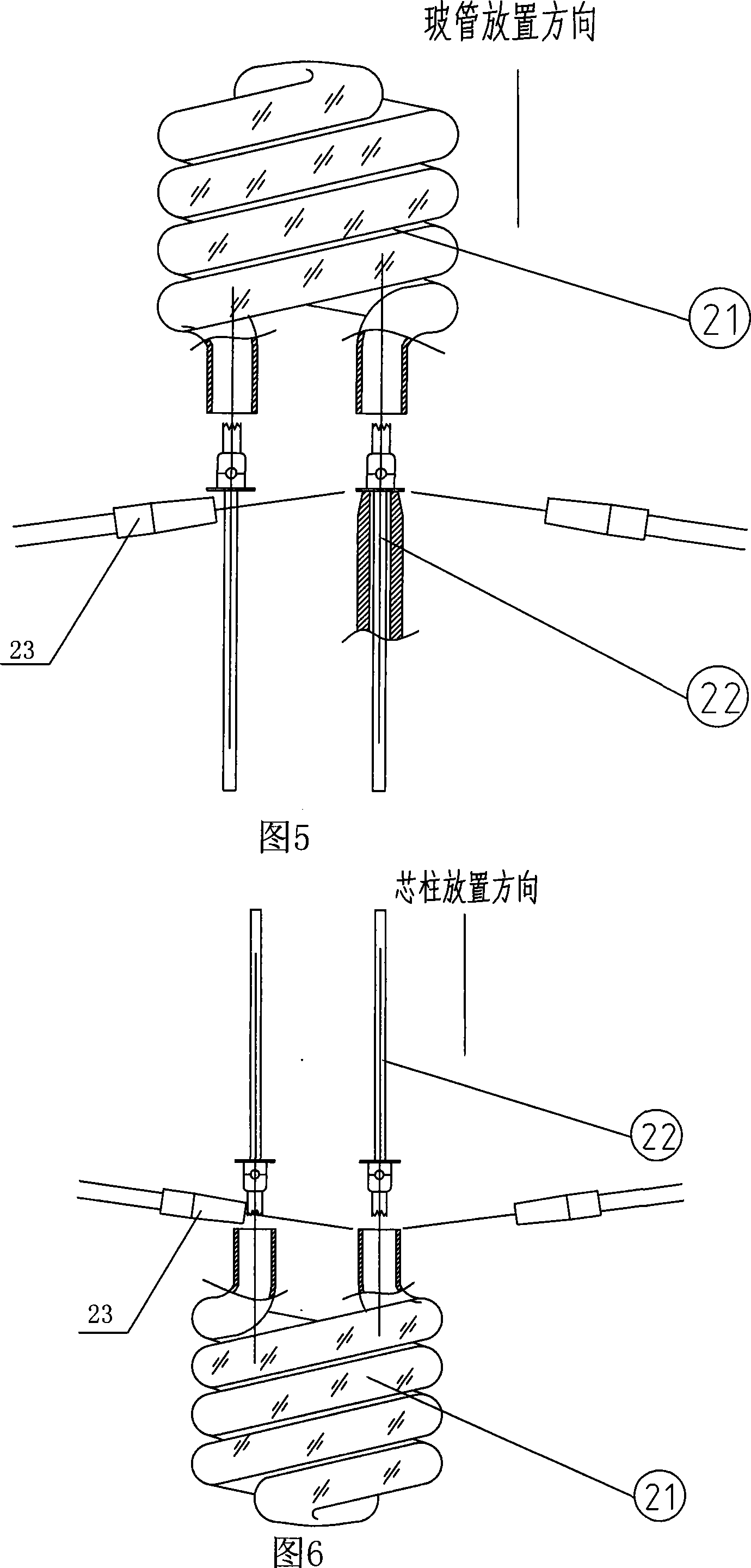

[0019] The sealing clamp device of the present invention consists of a left clamp piece 1, a V-shaped block 2, a movable clamp piece 3, a right clamp piece 4, a rotating arm 5, a connecting block 6, a rotating arm 7, a supporting shaft 8, and an arc support plate 9 , plate-shaped groove cam 10, square block 11, main shaft 12, support block 13, Huff fixed clamp 14, Huff movable clamp 24, slide rail assembly 15, small support shaft 16, two vertical rods 17, connecting lifting shaft 18. Composed of rotating T-shaped shaft 19 and rotating assembly 20.

[0020] The spiral tube of the present invention is clamped and positioned by the left clamp piece 1, the V-shaped block 2 and the movable clamp piece 3 mounted on the right clamp piece 4, and the left clamp piece 1 and the right clamp piece 4 are respectively installed on the slide On the left and right sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com