Plane balance positioning device for lathe machining

A lathe processing and positioning device technology, applied in auxiliary devices, metal processing equipment, turning equipment, etc., can solve the problems of reducing product processing qualification rate, low clamping efficiency, and inability to realize clamping, etc., to avoid uncertainty and Instability, easy installation and positioning, avoid the effect of bad size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

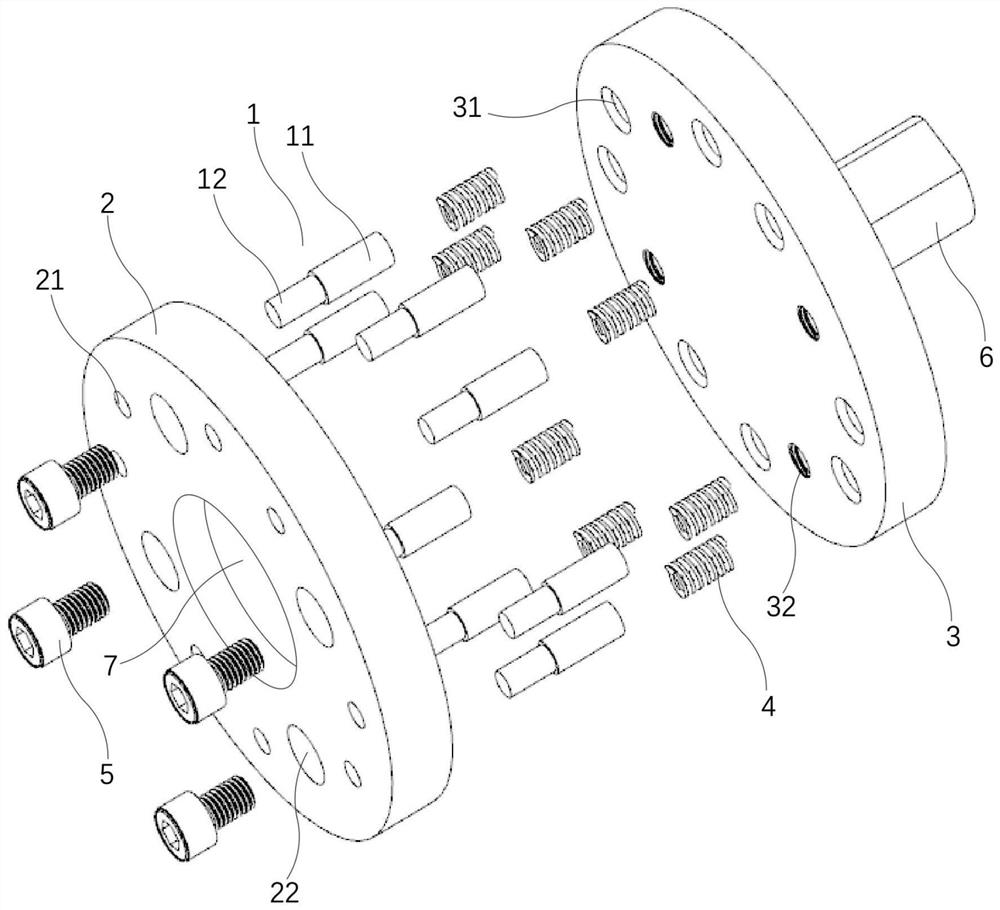

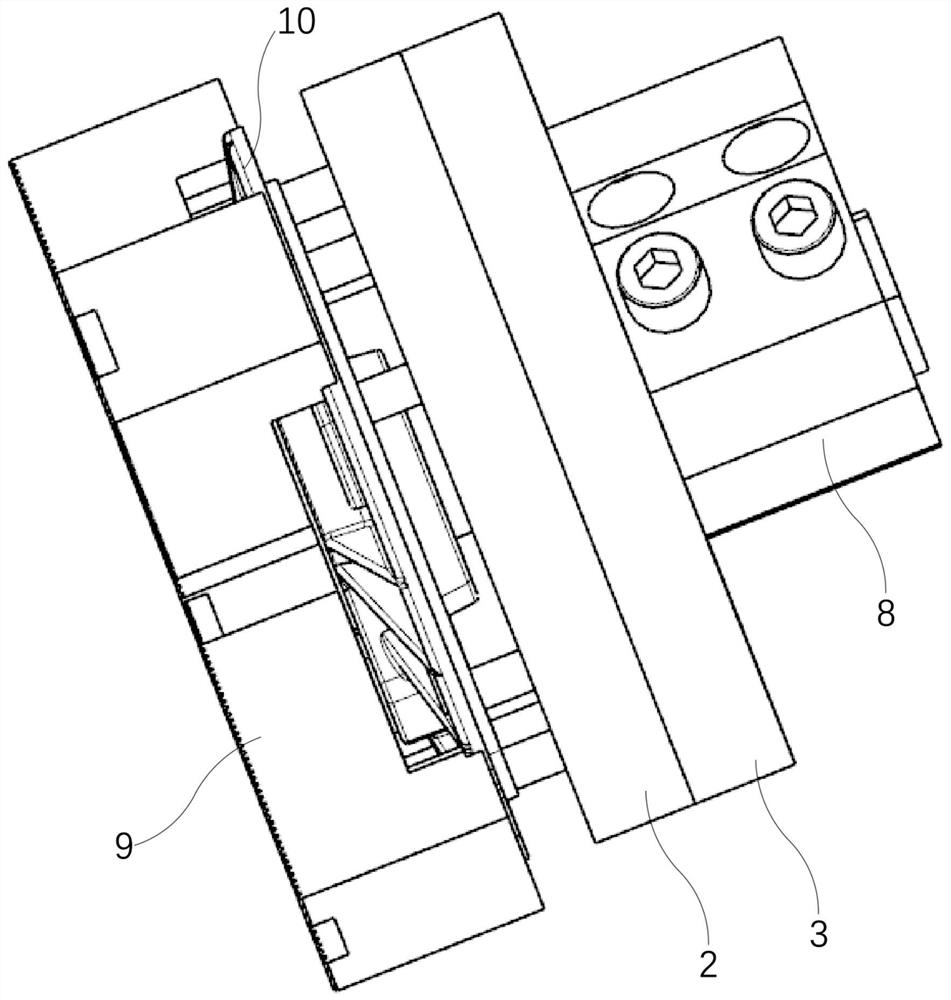

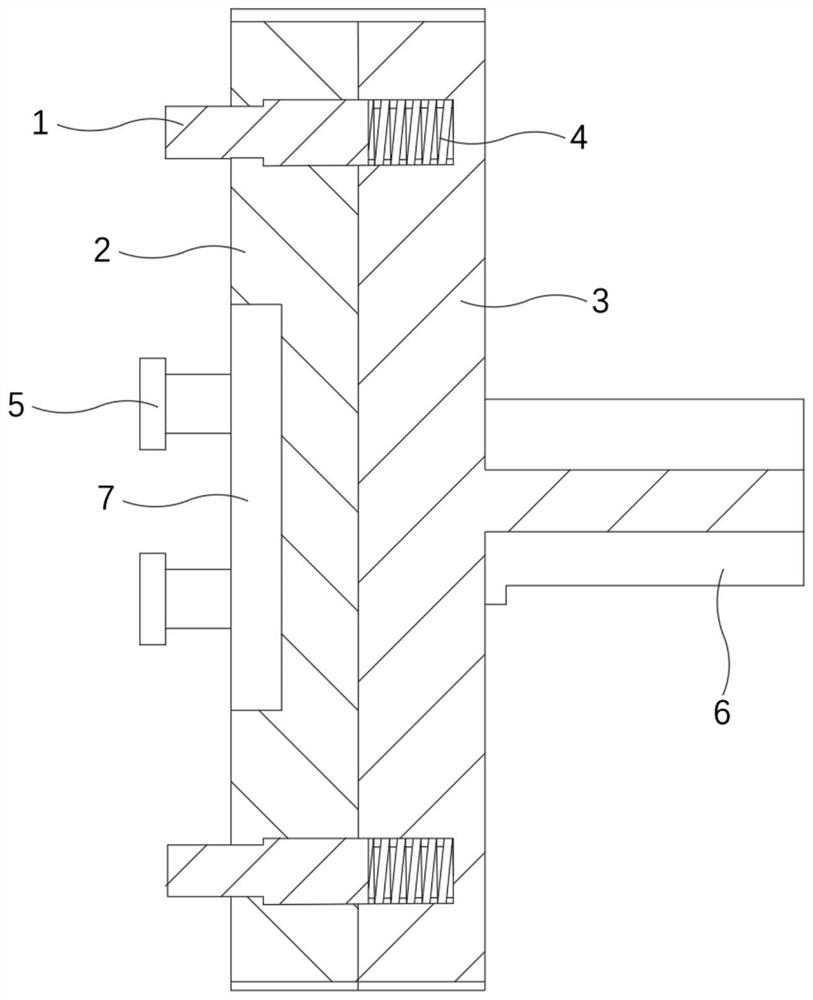

[0045] like Figure 1-6 As shown, the present invention provides a flat balancing positioning device for a lathe machining comprising a first restricted device 2 and a second limit device 3, wherein the first limit device 2 and the second limit device 3 pass through the fixture 5. A plurality of top column holes 21 are provided on the first restricted device 2, wherein a top post 1 is mounted in the top pillar 21; a support mounting groove 31 having one end opening is provided on the second limit device 3. Wherein, the support mounting groove 31 is mounted having an elastic support 4, a top column hole 21, a support mounting groove 31, a top post 1, and an elastic support 4, and one or one correspondence, a fixed device 5. For the screw, where the fixing device 5 and the fixing hole 22 and the threaded holes 32 mounted thereto are provided with at least 4, and the support member 31 of the second limit device 3 of the elastic support 4 is used, and will The top column 1 is loaded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com