Construction control method for large direct-buried steel anchor fluke embedded part

A control method and technology of embedded parts, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of shortening installation time and low accuracy, and achieve shortening installation time, simple method, and simple installation and positioning process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

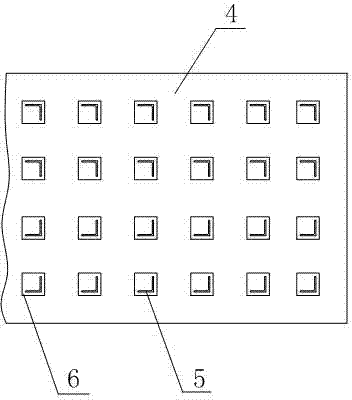

[0032] Such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the construction control method of large directly buried steel anchor fluke embedded parts includes the following steps:

[0033] (a) Set up corbel reinforcement cages or frame beams, and pour concrete under the corbel reinforcement cages 13 or frame beams, and bury the bottom ends of several supporting angle steels 10 in the concrete, and the height of the tops of the supporting angle steels is higher than that of the corbel reinforcement cages Or the upper surface of the frame beam, after the reinforcement binding of the corbel reinforcement cage 13 or the frame beam is completed, put out the elevation control point 12 of the bottom surface of the embedded steel plate 4 on each support angle steel 10 with a level gauge, then use flame cutting to The angle steel 11 above the elevation control point is cut off. In this way, after the embedded part is installed, the top of the supporting angle steel 10 ca...

Embodiment 2

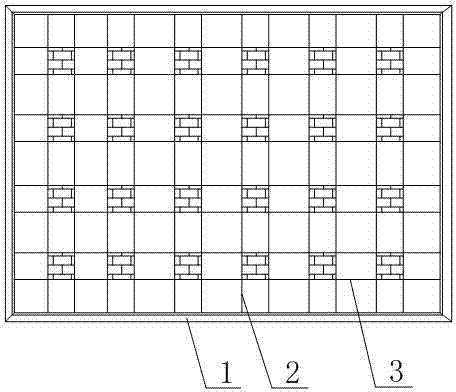

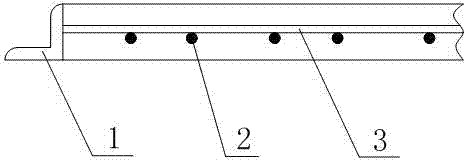

[0039] Such as figure 1 , figure 2 As shown, on the basis of Example 1, the positioning frame includes a rectangular structure composed of four positioning angle steels 1 welded end to end in sequence and a positioning device arranged inside the rectangular structure, both ends of the positioning device are connected to the positioning angle steel 1 . The edge width of the positioning angle steel 1 is 50mm and the thickness is 3mm. The positioning angle steel 1 of this size is used as a preferred size, and other sizes can also be selected according to the situation of the abandoned angle steel on each construction site. The size of the rectangle formed by the positioning angle steel 1 is the same as the size of the embedded part, and the outer wall of the rectangle is correspondingly arranged in the same plane as the outer wall of the corbel reinforcement cage, so that when the iron wire is tightened to form the position of the steel anchor, it can A uniform distribution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com