Detachable liner plate device for FCB method welding and application method of detachable liner plate device

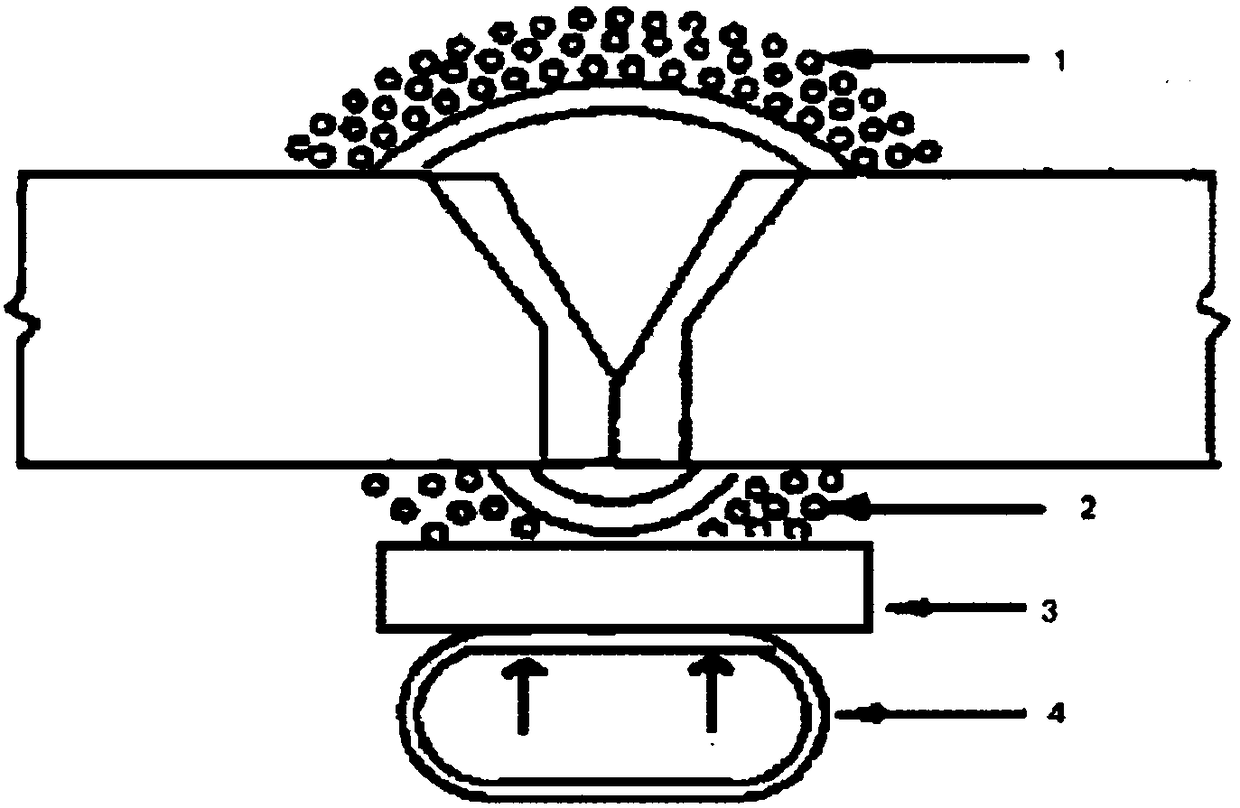

A backing plate, welding steel plate technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of inability to flexibly change welding positions, construction site restrictions, and high maintenance costs, and achieve easy installation, positioning, and stress. The effect of uniformity and improved welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

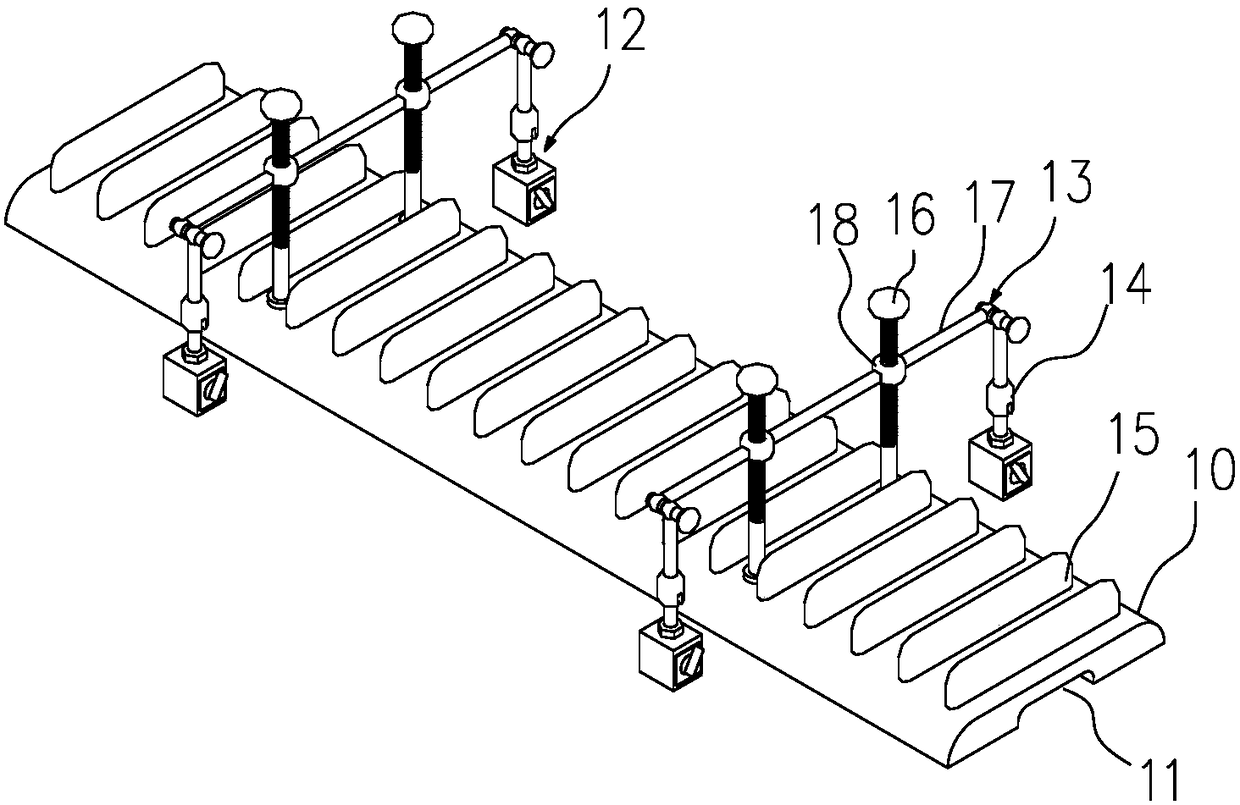

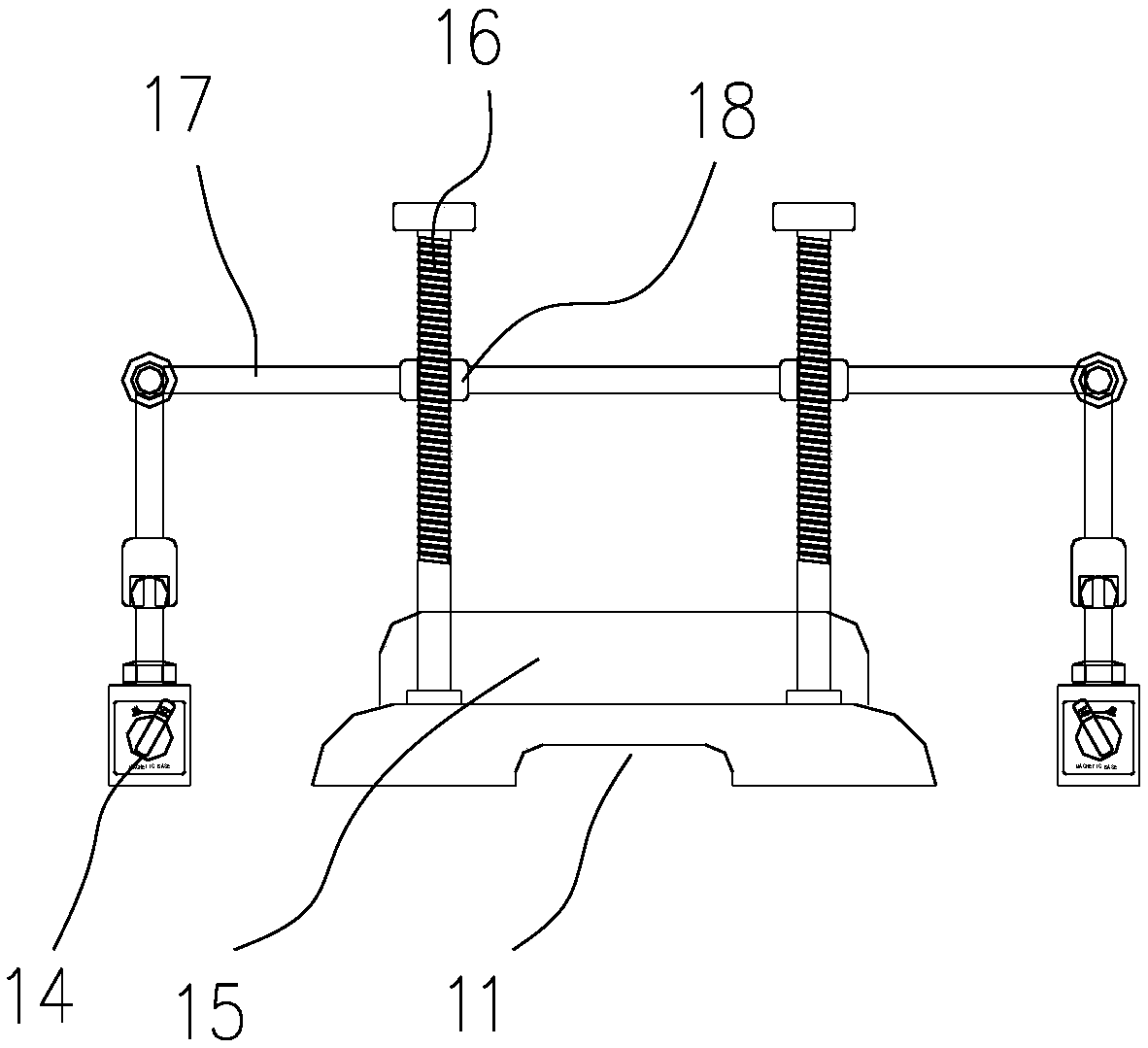

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0025] see figure 2 and image 3 As shown, the embodiment of the present invention provides a detachable liner plate device for FCB welding, including:

[0026] The backing plate 10, the material of the backing plate 10 is copper, the backing plate 10 is provided with a groove-shaped supporting surface 11 for bearing and supporting the root flux, and in the welding process, the groove structure of the supporting surface 11 It can effectively prevent molten iron from flowing. The other side of the backing plate 10 opposite to the support surface 11 is provided with a number of cooling grids 15 side by side along the length direction of the backing plate 10. The cooling grids 15 prevent the copper backing plate 10 from overheating.

[0027] Fixing device 12, fixing device 12 comprises the support 13 that is installed on the opposite side of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com