Patents

Literature

32results about How to "Efficient trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

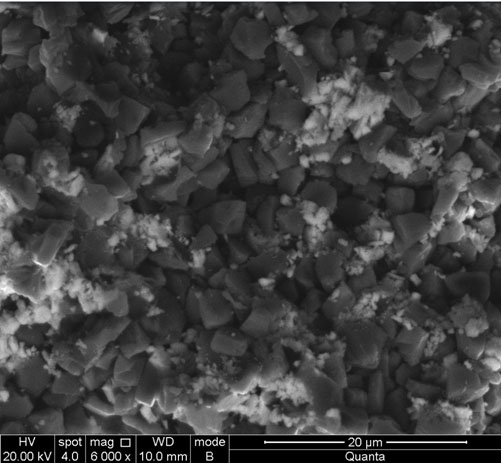

Method for roughly trimming diamond grinding wheel

InactiveCN103042468AReduce the gripQuick removalGrinding feed controlAbrasive surface conditioning devicesMicrometerPulsed laser beam

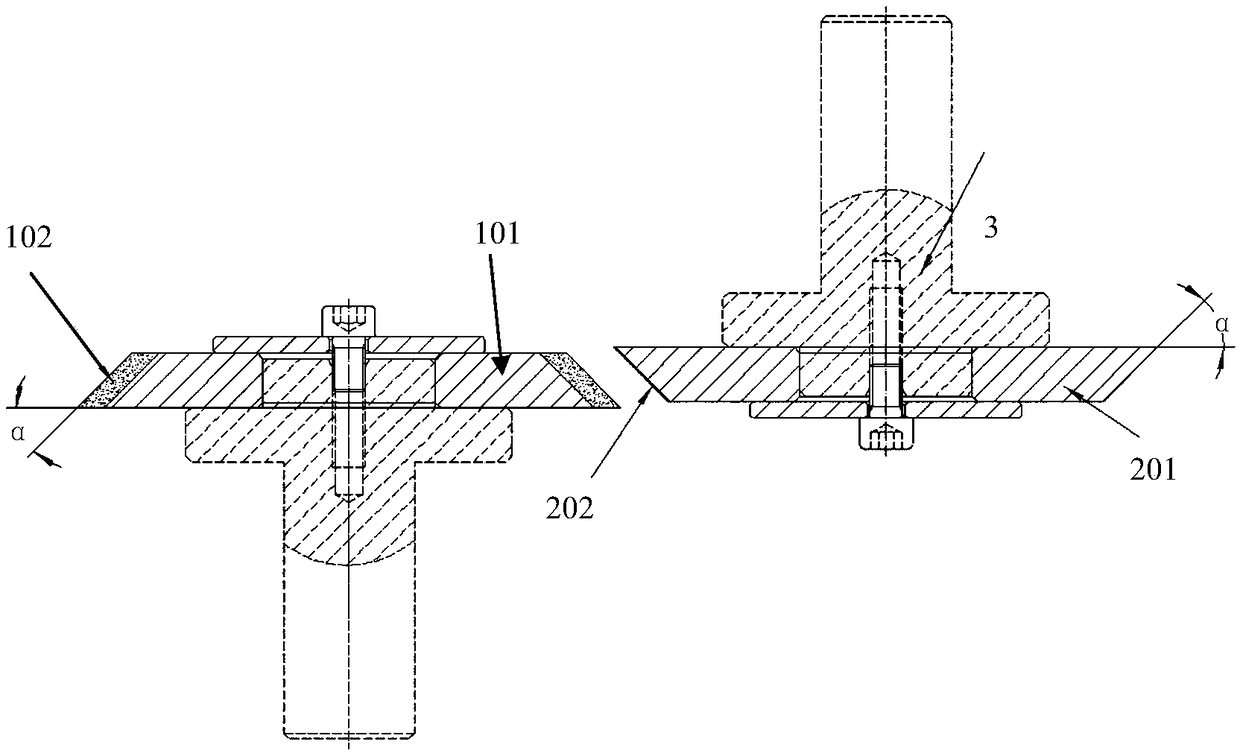

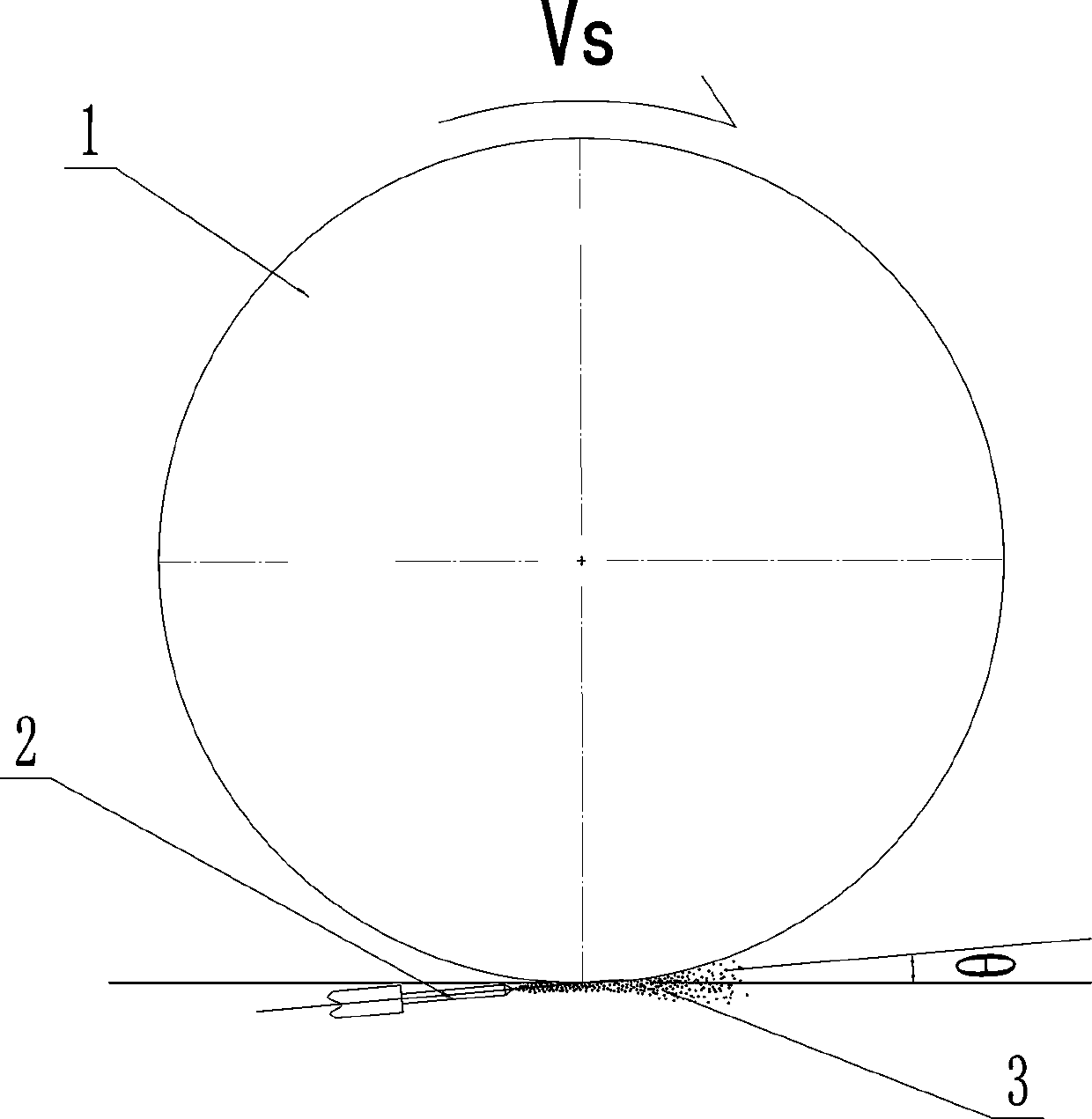

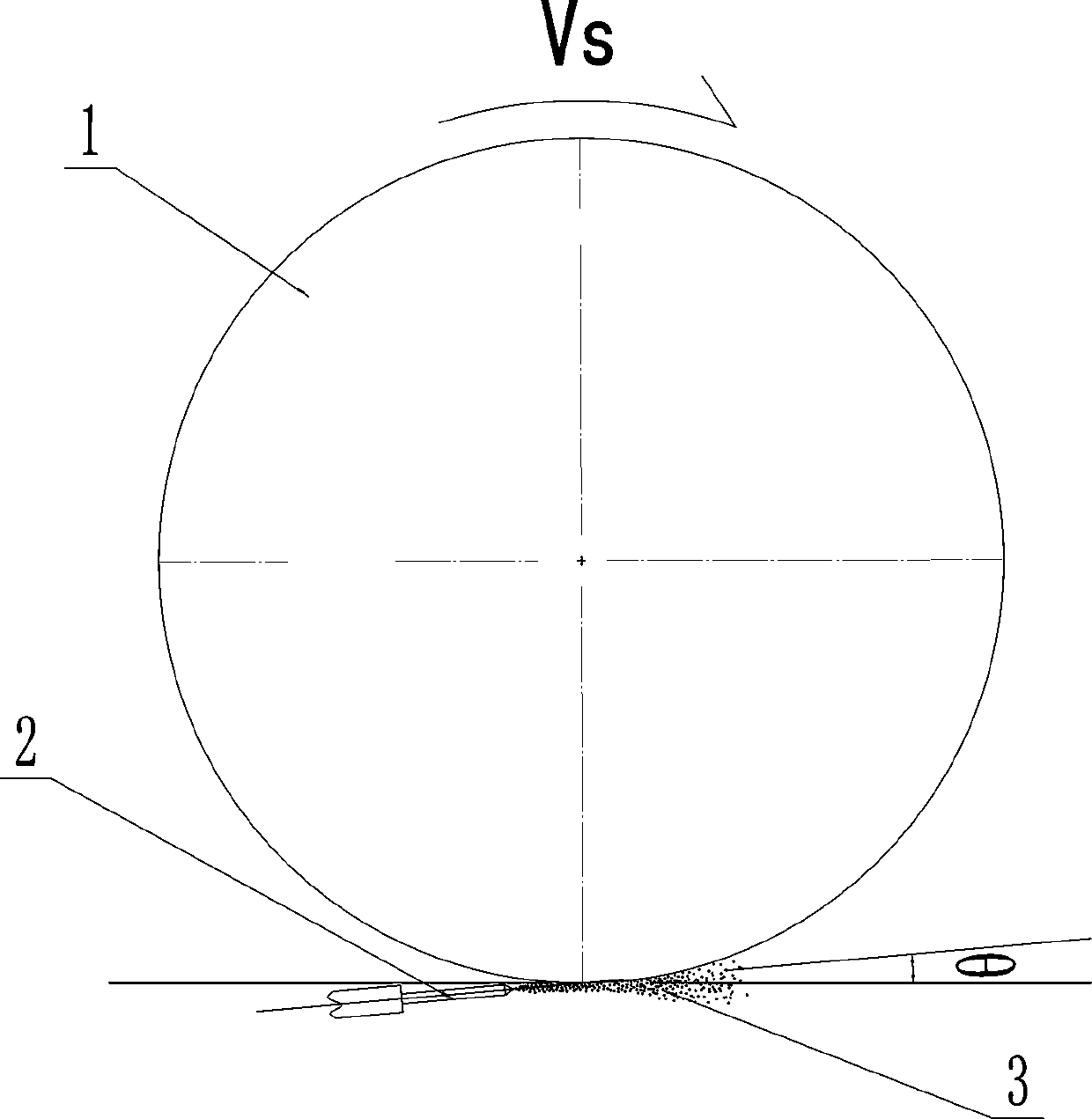

The invention provides a method for roughly trimming a diamond grinding wheel. The method includes steps of A, scanning the surface of the diamond grinding wheel, acquiring the highest point of the surface of the grinding wheel and determining the position of the highest point in radial, axial and generating line directions; B, emitting a focused pulse laser beam along the inner normal direction of the surface of the grinding wheel and enabling the position of a focal spot of the focused pulse laser beam to be coincided with the position of the highest point of the grinding wheel in the radial, axial and generating line directions; C, erecting a silicon carbide roller at a position opposite to a generating line of the grinding wheel and setting the cutting depth as 0.005mm; and D, repeating the steps once after the grinding wheel is trimmed for 3 to 5 minutes until a circle run-out error of the grinding wheel is not larger than 20 micrometers. The method has the advantages that diamond grains are ablated and directly removed by the focused pulse laser beam, remaining diamond grains are removed by the silicon carbide roller, deteriorative layers of surfaces of the grains which are ablated by laser, grains without holding force and the like are mechanically peeled off, and the method is applicable to efficiently roughly trimming diamond grinding wheels with large grains.

Owner:HUNAN UNIV

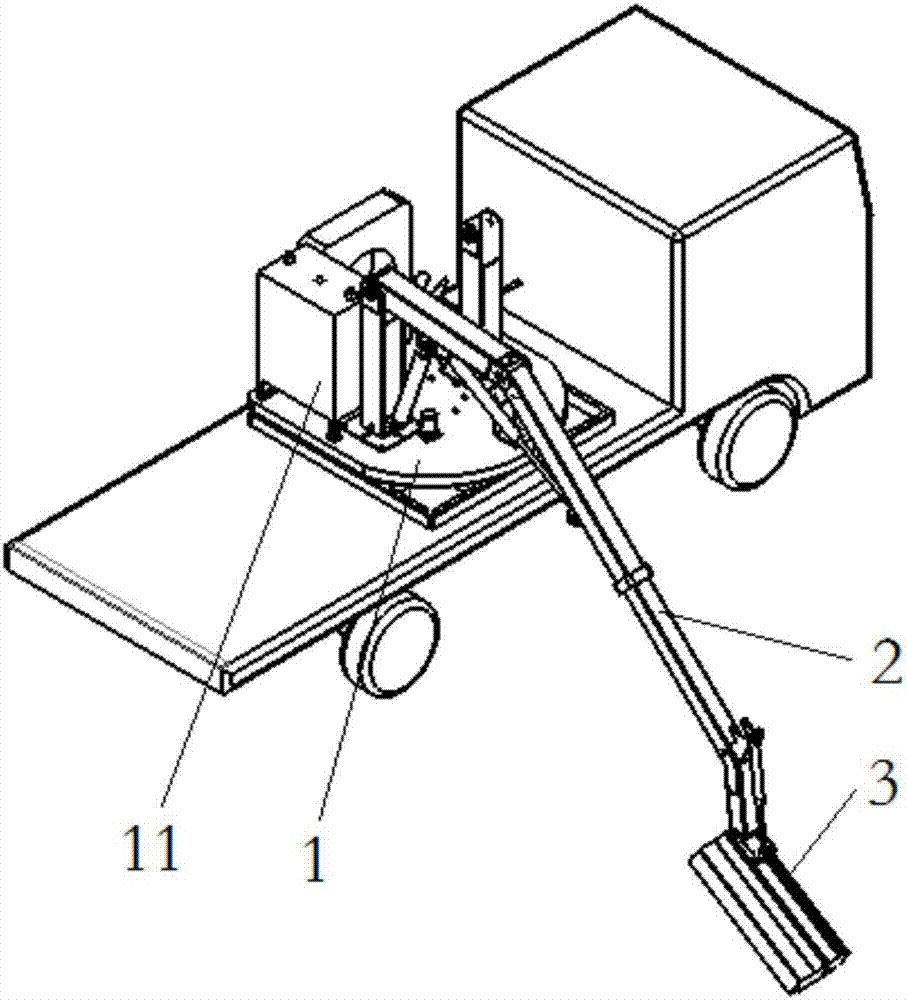

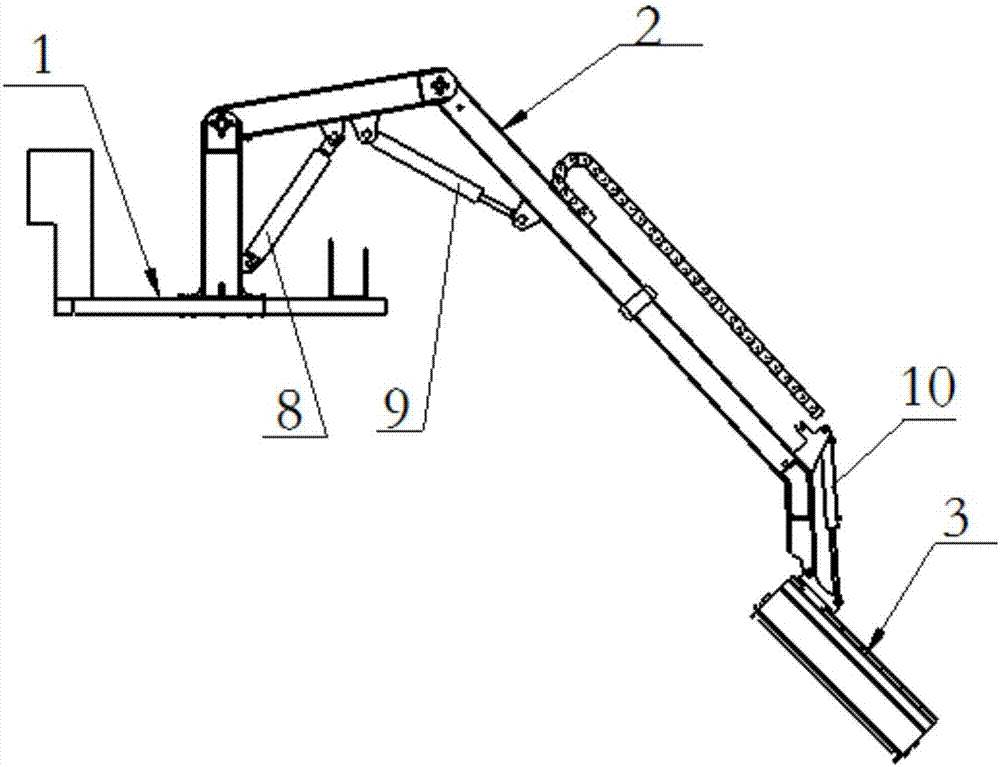

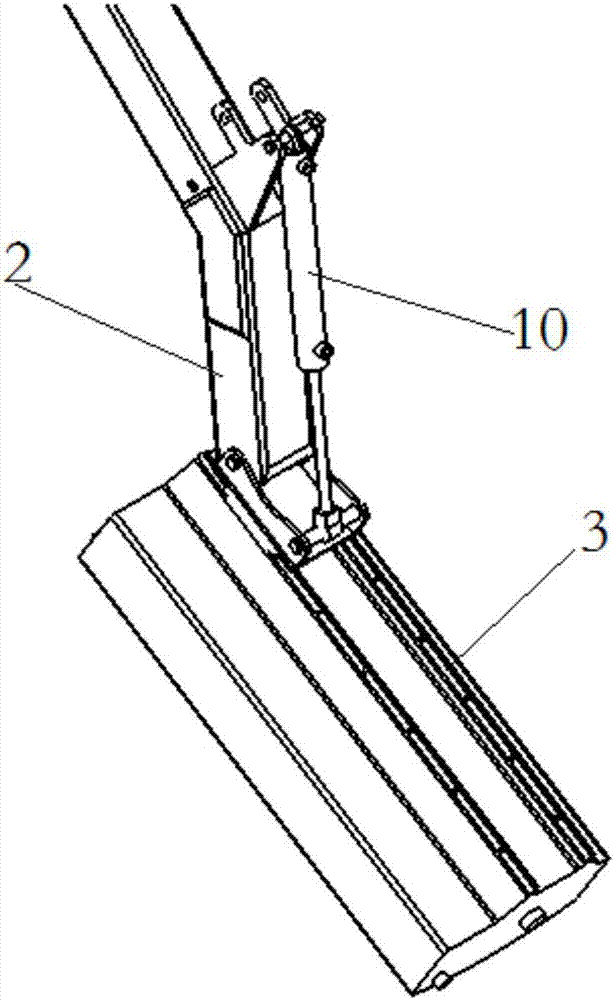

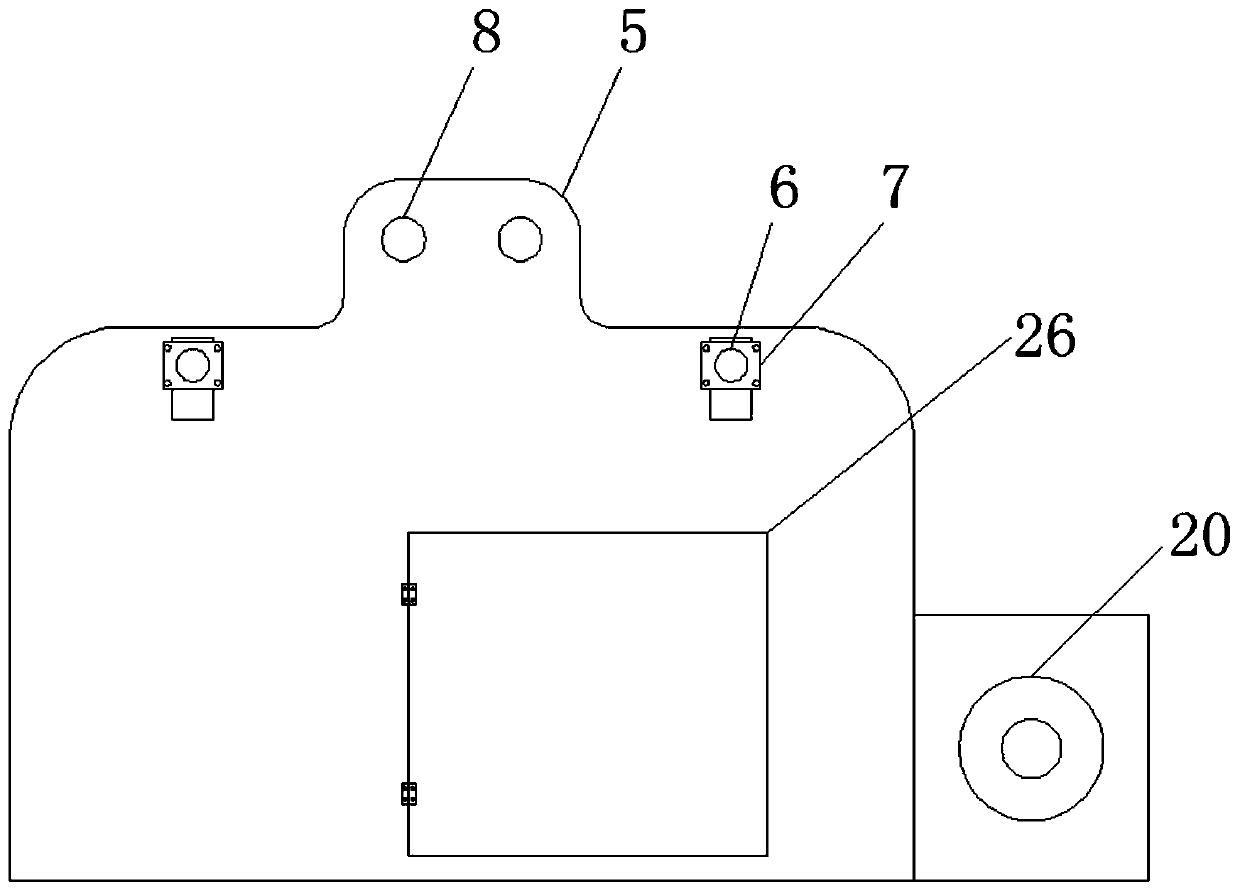

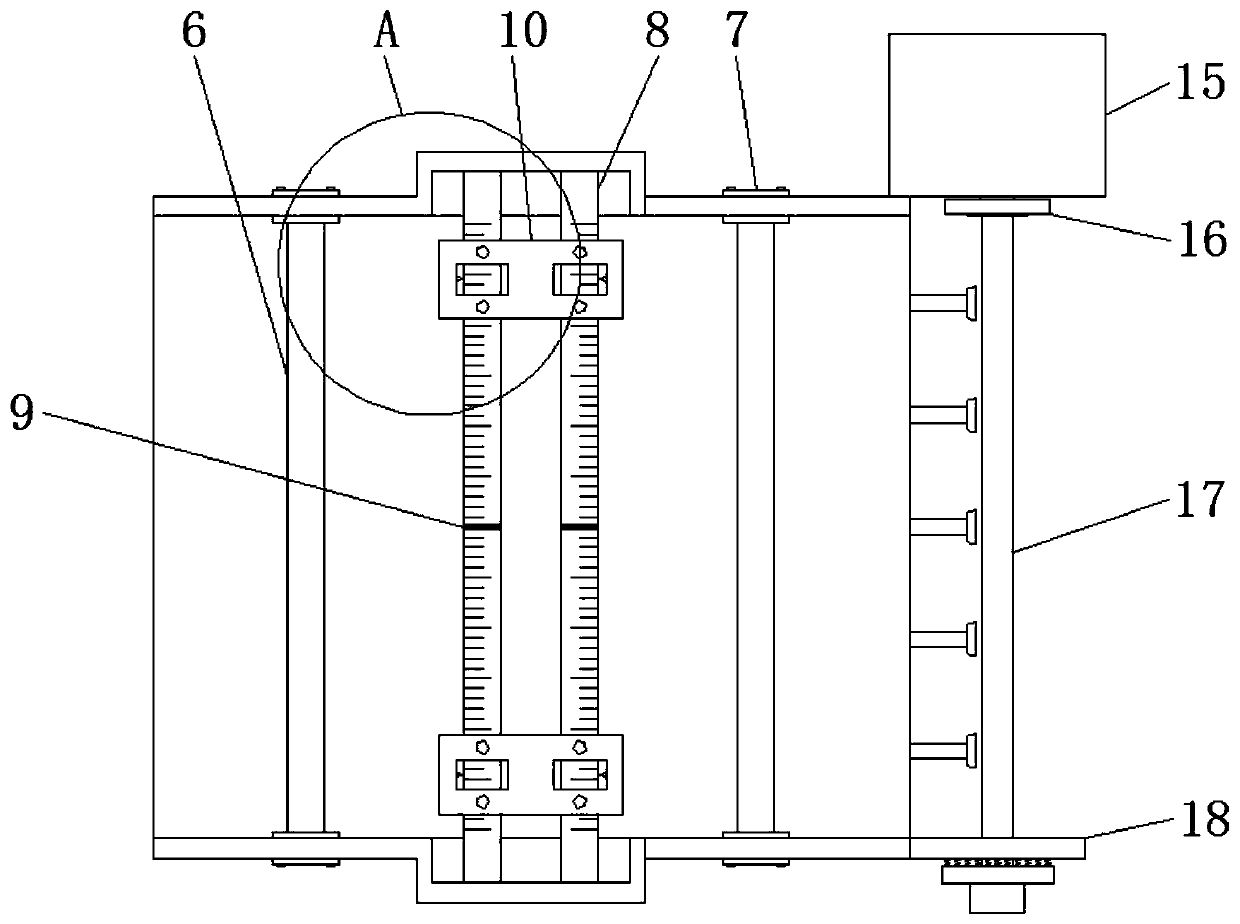

Automatic obstacle-avoiding device of hedge trimmer

The invention discloses an automatic obstacle-avoiding device of a hedge trimmer. The automatic obstacle-avoiding device comprises a rotary table for installing a boom structure, wherein the rotary table is fixedly installed on a trimmer body, one end of the boom structure is hinged to the upper end of the rotary table, a cutter is fixedly installed at the other end of the boom structure, a base is fixed on one side of the cutter, a buffer plate is connected to the base through a screw, a pressure sensor is installed on the buffer plate, and the screw between the base and the buffer plate is sleeved with a damping spring. The automatic obstacle-avoiding device further comprises a control module for controlling a rotary table driving motor and connected with the pressure sensor. A pressure sensor and a buffer device are installed on a hedge trimmer cutter. The automatic obstacle-avoiding device can avoid the phenomenon that the working cutter is damaged due to non-timely eluding when an obstacle is encountered, the hedge trimmer can achieve the purpose of a traditional hedge trimmer and can also automatically avoid obstacles and efficiently and intelligently complete trimming operation, and the device is simple in structure and can effectively achieve the purposes of trimming green belts and meanwhile protecting the cutter.

Owner:CHANGAN UNIV

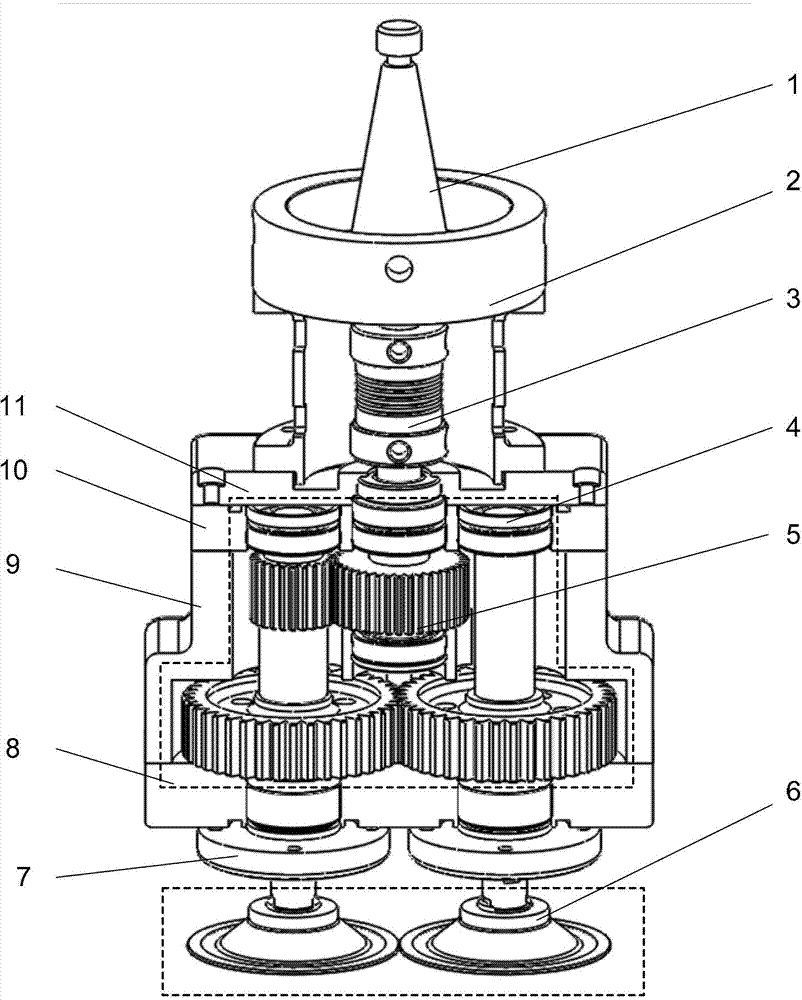

Grinding and edge cutting device of composite material

ActiveCN103042459ATrim stableThe cutting speed of the trimming mechanism is stabilized by the machine feedGrinding drivesGrinding machinesNumerical controlGear wheel

A grinding and edge cutting device of a composite material is composed of a casing connection part, a casing part, a power input part, a motion transformation part and a tool part. The casing connection part is located at the top of the device, the casing part is connected with a machine tool spindle casing through the casing connection part, the power input part is located between a machine tool spindle and a casing upper end cover, three transmission shafts of the motion transformation part are installed in the casing part through bearings, an input gear shaft of the motion transformation part is connected with the power input part through a coupling, output ends of two output gear shafts are used for being connected with a tool part and driving two tools to perform opposite rotation motion of the same size, and the tool part is located below a casing and fixed on two output gear shafts of the motion transformation part through a group of compression nuts. The grinding and edge cutting device of the composite material can be connected with a numerical control machine tool directly and is light and compact in structure, cutting grinding disks can rotate at the same speed synchronously, and accurate outline cutting can be performed on the upper surface and the lower surface of a carbon fiber reinforced composite material.

Owner:BEIHANG UNIV +1

Diamond grinding wheel dressing method

InactiveCN108838890AGood shape retentionImprove trimming accuracyAbrasive surface conditioning devicesDiamond grindingDressing method

The invention relates to a diamond grinding wheel dressing method, and belongs to the technical field of grinding apparatuses. The diamond grinding wheel dressing method comprises the following stepsthat an electroplating diamond grinding wheel and a diamond grinding wheel to be dressed are relatively ground, then the relatively ground grinding wheel to be dressed is subjected to surface cleaning, and the diamond grinding wheel is obtained. According to the diamond grinding wheel dressing method, the diamond grinding wheel and the diamond grinding wheel are relatively ground, the diamond grinding wheel is dressed, and the problem that when a silicon carbide grinding wheel is used for dressing the diamond grinding wheel in the prior art, the silicon carbide grinding wheel is consumed too fast is avoided. Meanwhile, the diamond grinding wheel is adopted as the dressing grinding wheel, the shape retention performance is good, profile modeling dressing can be adopted for the diamond grinding wheel as the grinding wheel to be dressed, and the dressing precision of the diamond grinding wheel is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

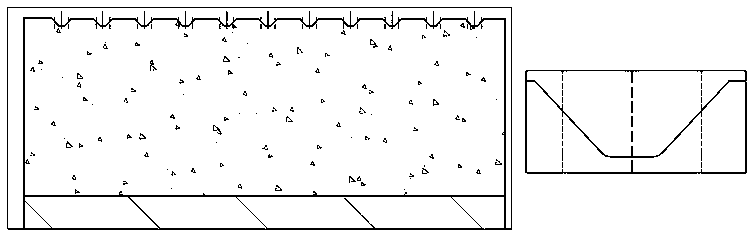

Ultrahard abrasive grinding wheel compounded efficient and precise finishing method

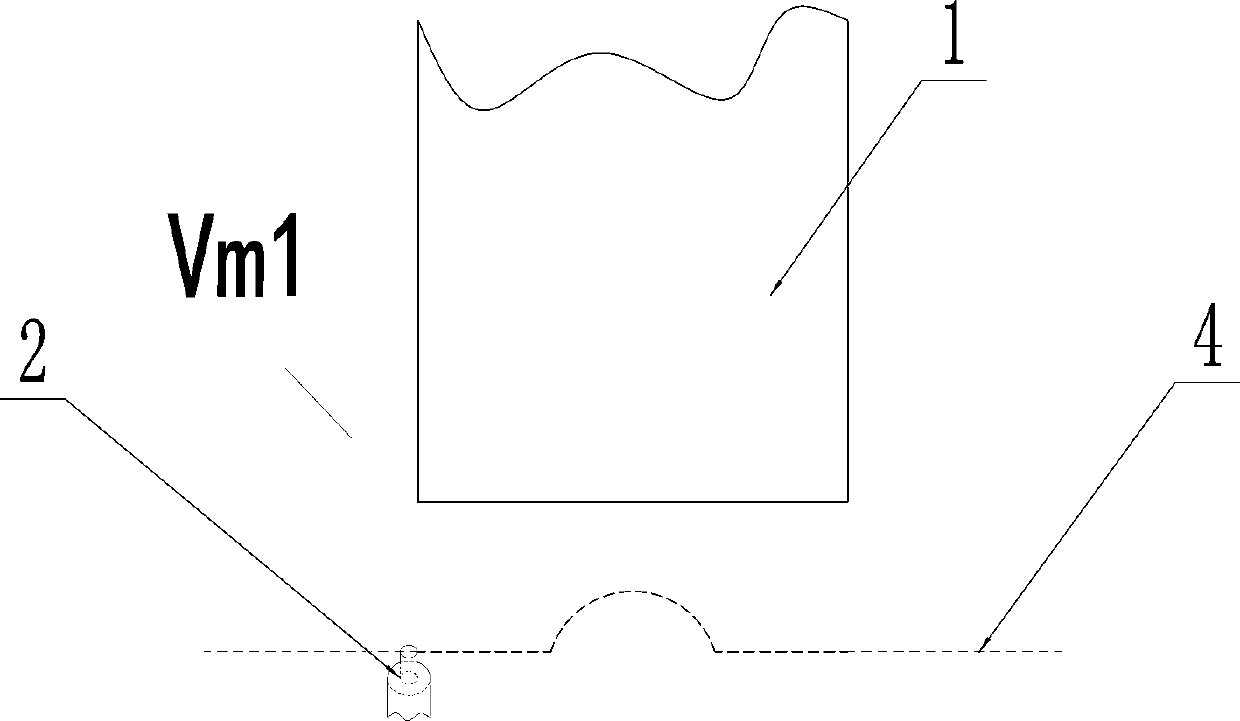

ActiveCN110116372ARealize finishing workPrecision trimming of shape accuracyAbrasive surface conditioning devicesReciprocating motionGrinding wheel

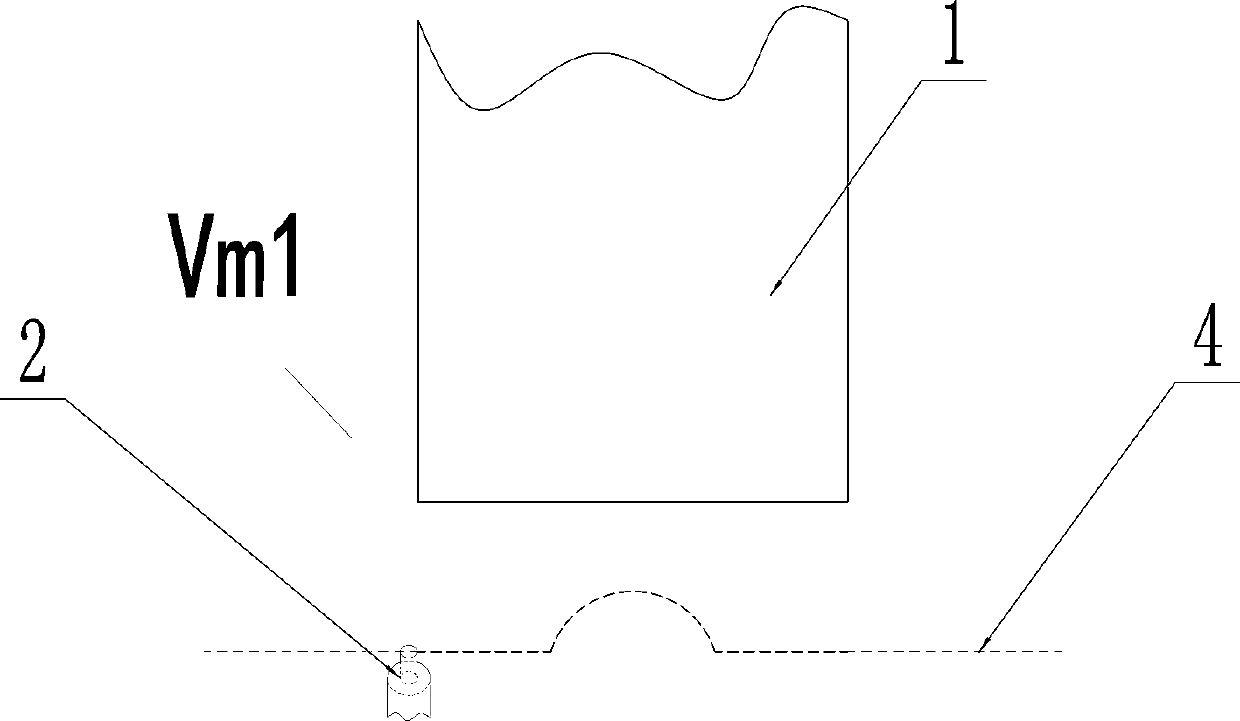

The invention provides an ultrahard abrasive grinding wheel compounded efficient and precise finishing method. The method comprises the following steps: (1) abrasive water jet rough finishing: abrasive water jet is sprayed to a direction with a certain angle; meanwhile, an abrasive water jet nozzle performs a reciprocating motion along a section profile trajectory of a molded surface needed by a grinding wheel; and an ultrahard abrasive grinding wheel is radially fed to realize rough finishing; (2) a finishing roller and a free abrasive are used for extrusion and finishing; abrasive water jetspray heads are arranged in a row; and the jet flow of each spray head is controlled to match with a finishing roller for finishing; and (3) the abrasive water jet is used for finishing sharpness. Theultrahard abrasive grinding wheel compounded efficient and precise finishing method is simple in process, high in finishing precision and suitable for the finishing work of ultrahard abrasive grinding wheels with complex molded surfaces.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

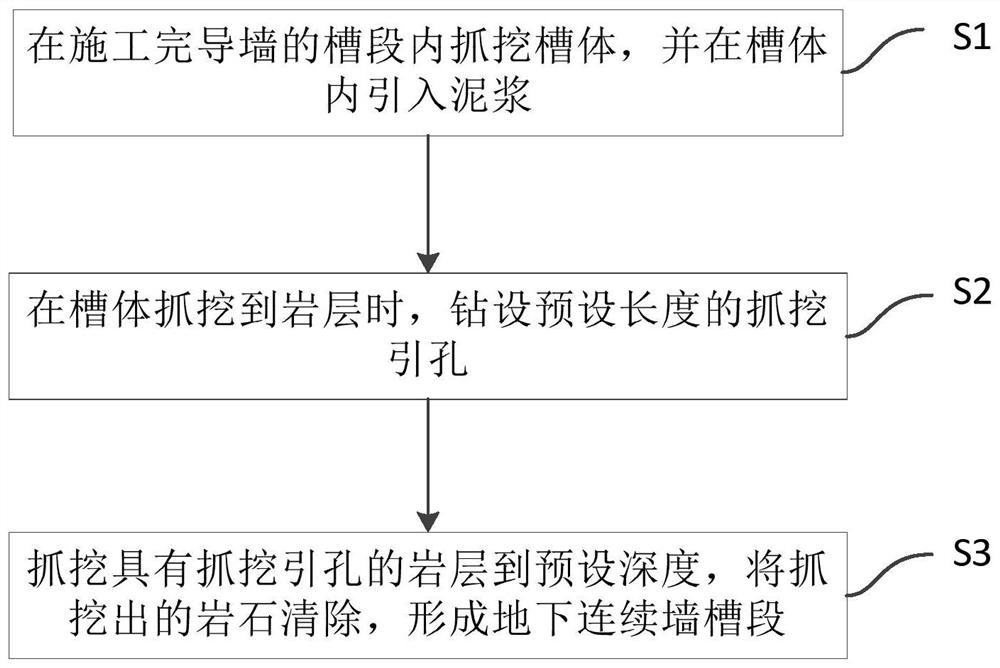

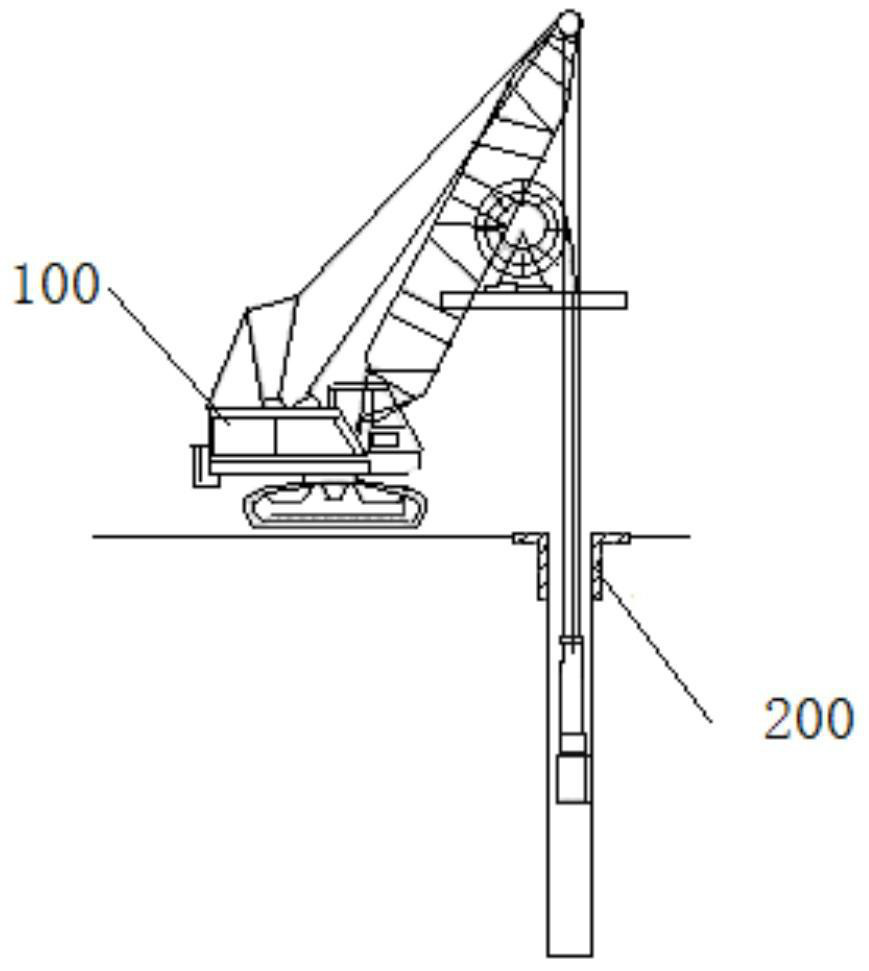

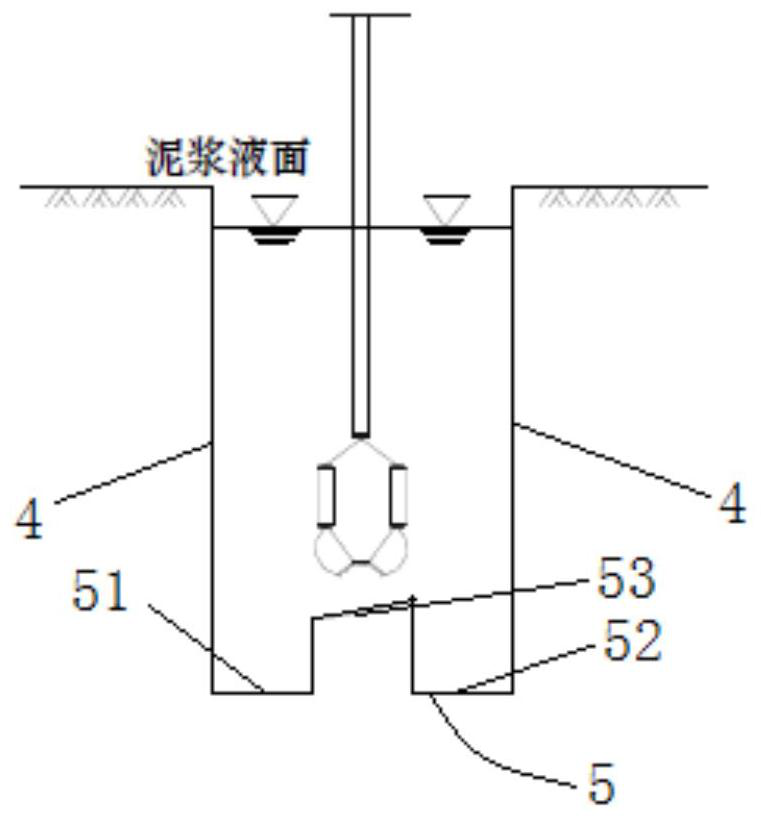

Grooving method for underground diaphragm wall

InactiveCN111705785AReduce construction costsImprove work abilitySoil-shifting machines/dredgersBulkheads/pilesDrill holeGeotechnical engineering

The invention relates to a grooving method for an underground diaphragm wall. The grooving method comprises the steps that a groove body is grabbed and dug in a groove section of a constructed guide wall, and slurry is introduced into the groove body; when the groove body grabs and digs a rock stratum, a grabbing and digging guide hole with a preset length is drilled; and the rock stratum with thegrabbing and digging guide hole is grabbed and dug to a preset depth, and the grabbed and dug rock is removed to form the groove section of the underground diaphragm wall. When the underground diaphragm wall is grooved to the rock stratum, a rotary drilling machine is adopted to drill the grabbing and digging guide hole, and finally the rock stratum with the grabbing and digging guide hole is grabbed by a grab machine, so that the construction capacity of various common machines is fully utilized, the use of machines with high cost is avoided, the construction cost is reduced, and meanwhile,the operation capacity of the grab machine is improved, and the construction progress and quality of grooving are guaranteed; and the rotary drilling machine is adopted to drill the grabbing and digging guide hole, so that the vibration generated when a drilling machine or a punching machine is adopted for drilling is avoided, and the influence of punching or drilling vibration on the surroundingenvironment is reduced.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

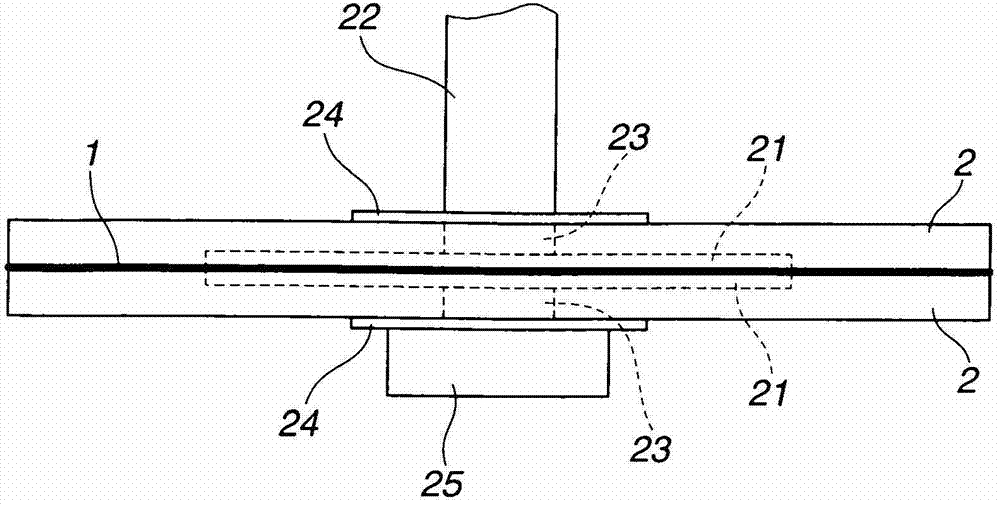

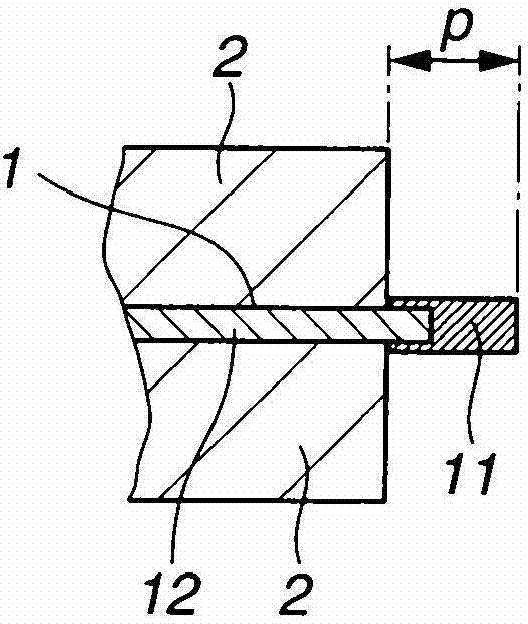

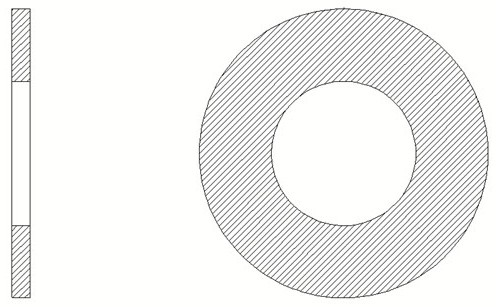

Dressing and manufacture of outer blade cutting wheel

ActiveCN103192322AEfficient trimmingSatisfied with trimmingElectrolytic coatingsBonded abrasive wheelsAlloyKnife blades

An outer blade cutting wheel (1) comprising a base and a blade section (11) of metal or alloy-bonded abrasive grains is dressed by clamping the cutting wheel between a pair of circular jigs (2) such that the blade section (11) projects beyond the jigs, immersing the cutting wheel in an electropolishing liquid, positioning counter electrodes (4, 5, 6) relative to the blade section, and effecting electropolishing for thereby removing part of the metal or alloy bond and chips received in chip pockets until abrasive grains are exposed on the blade section surface.

Owner:SHIN ETSU CHEM IND CO LTD

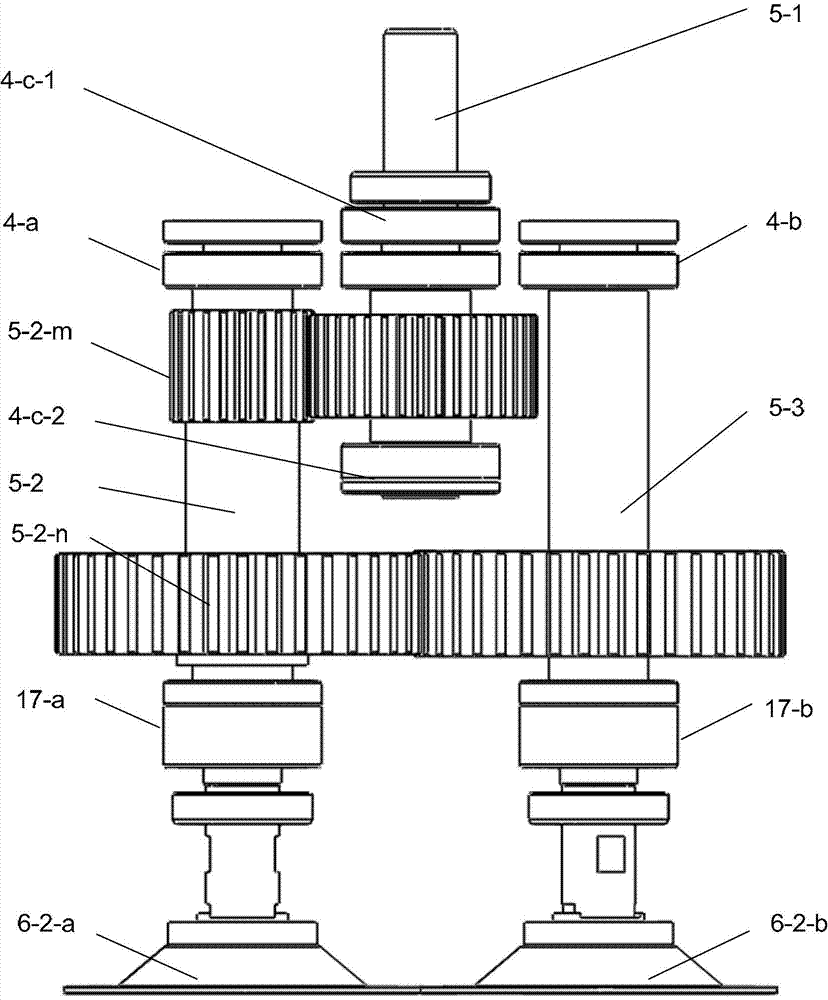

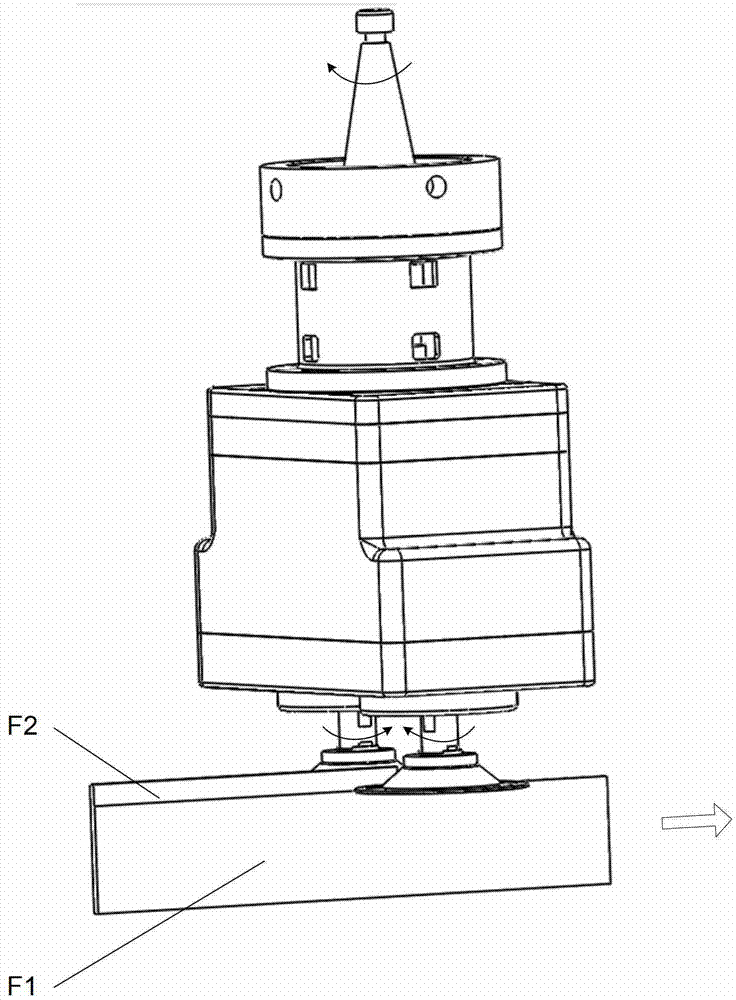

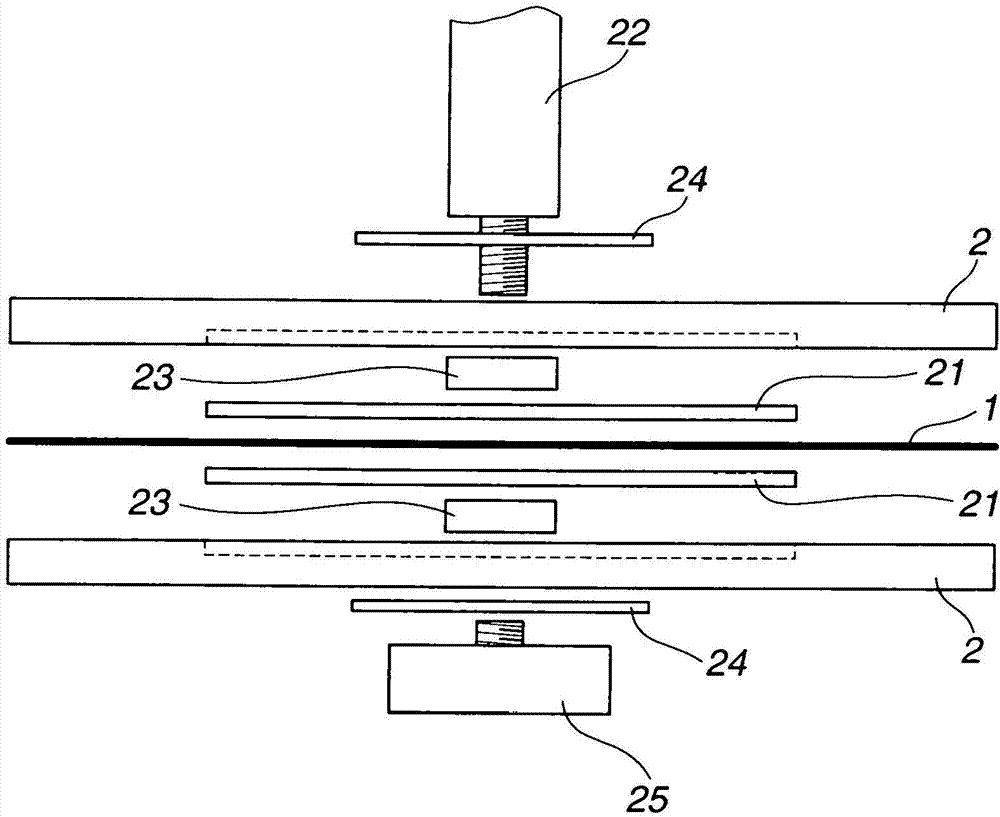

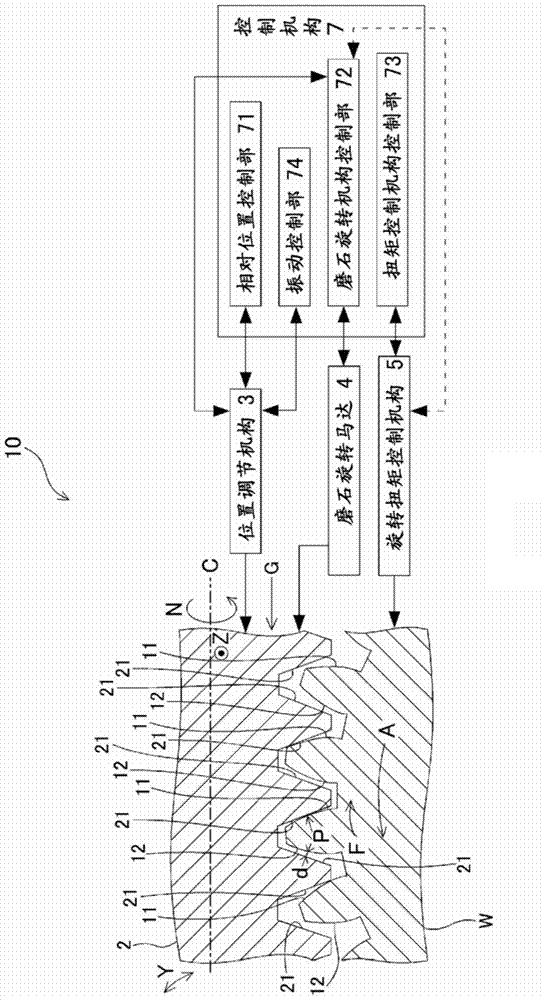

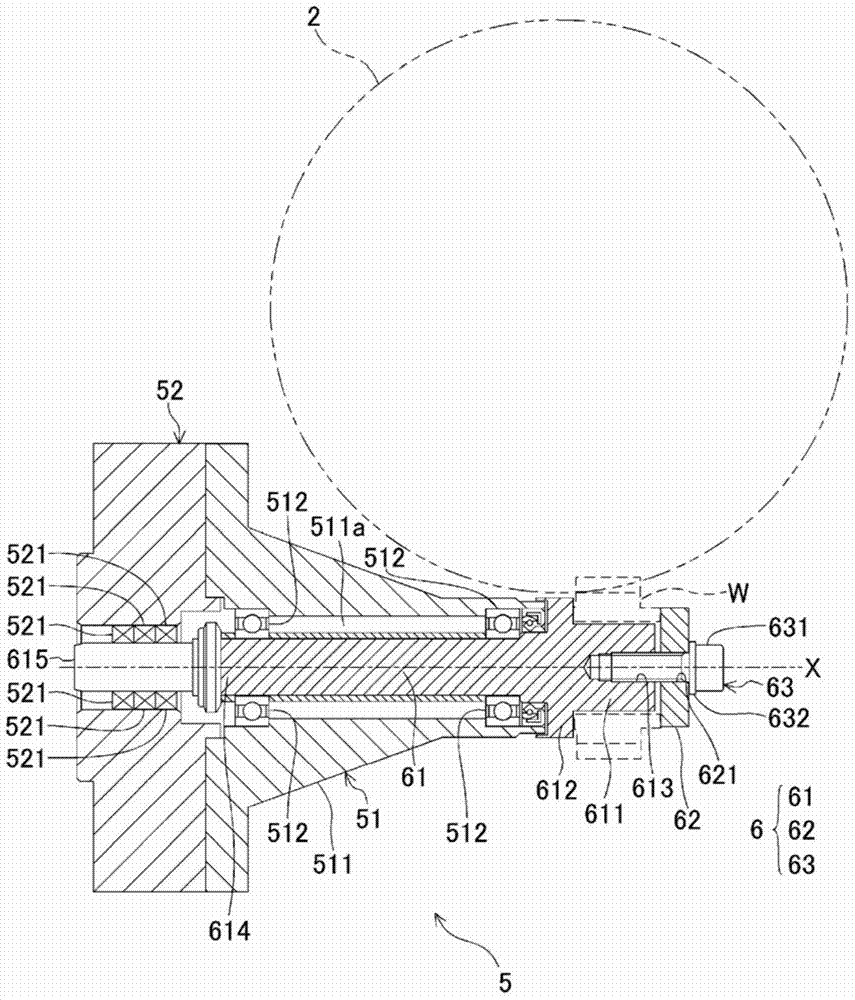

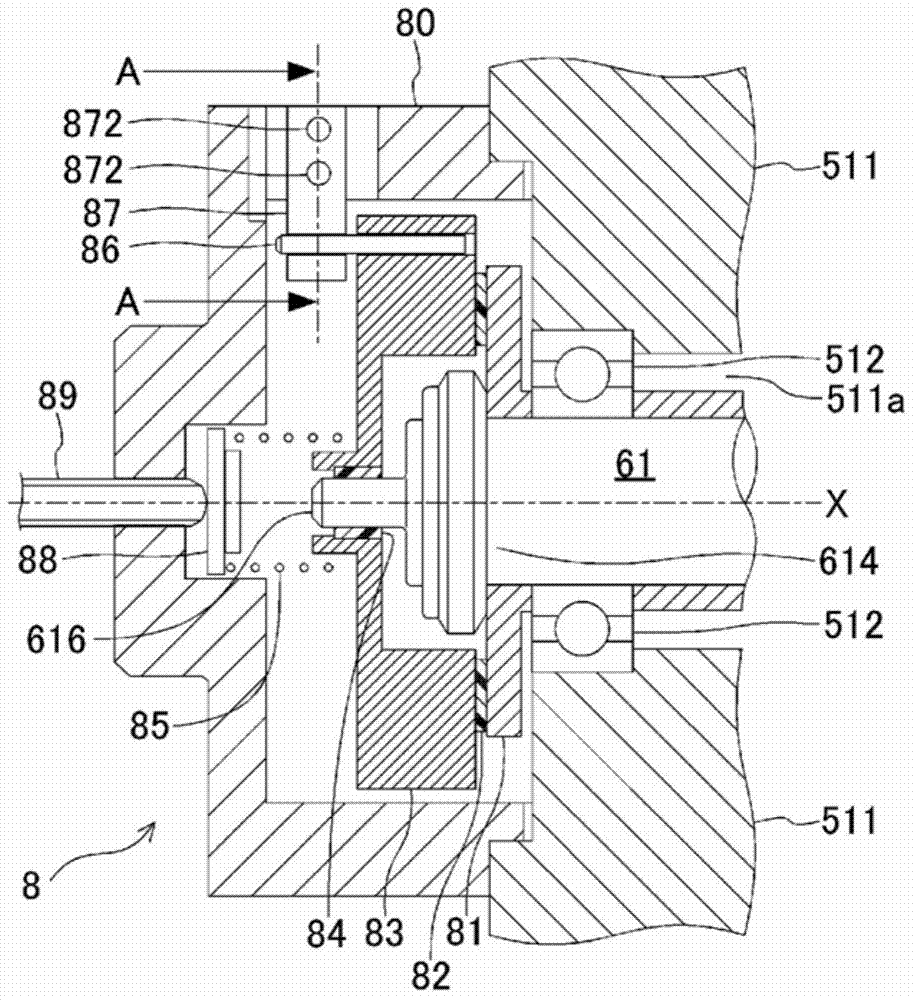

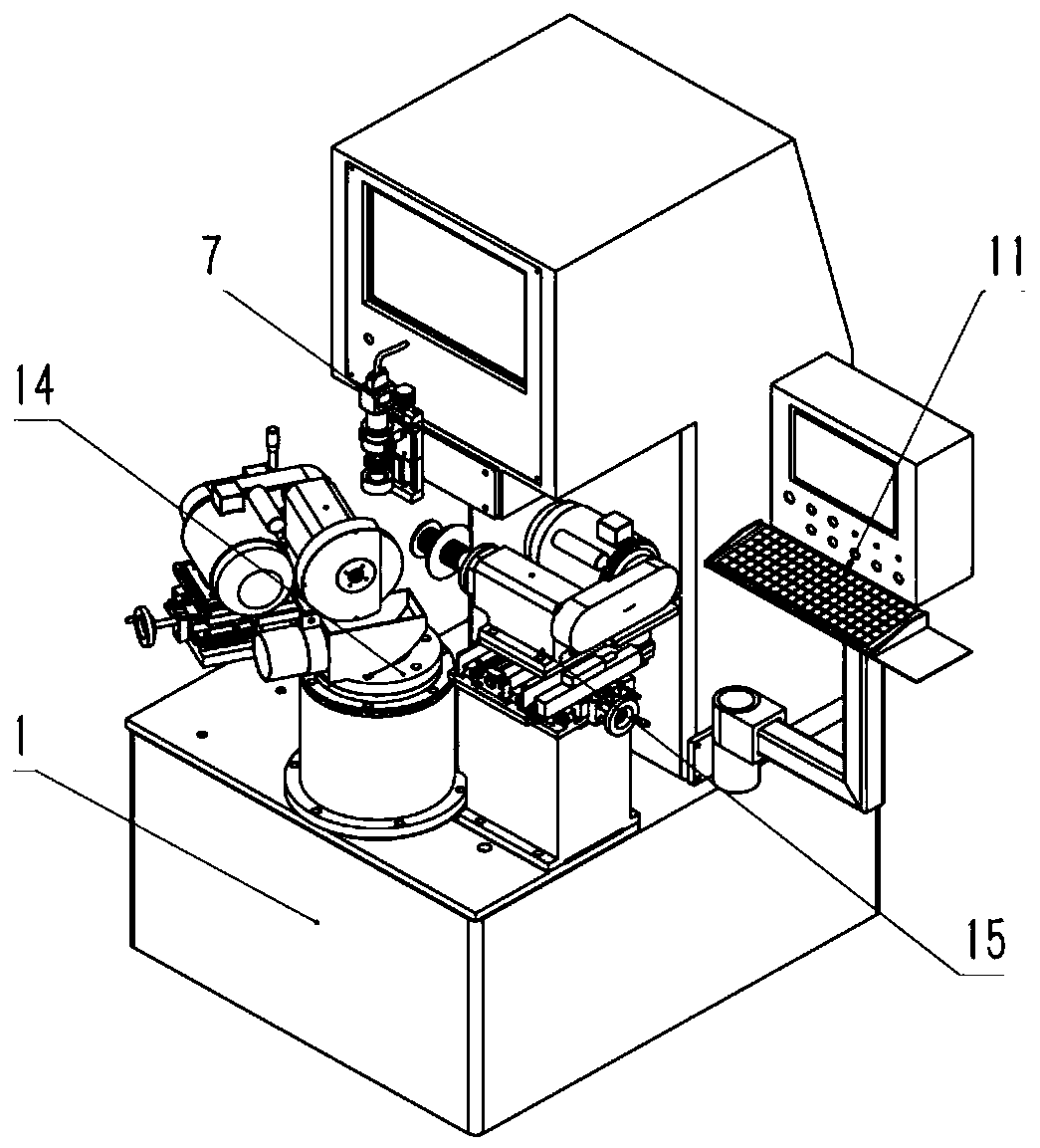

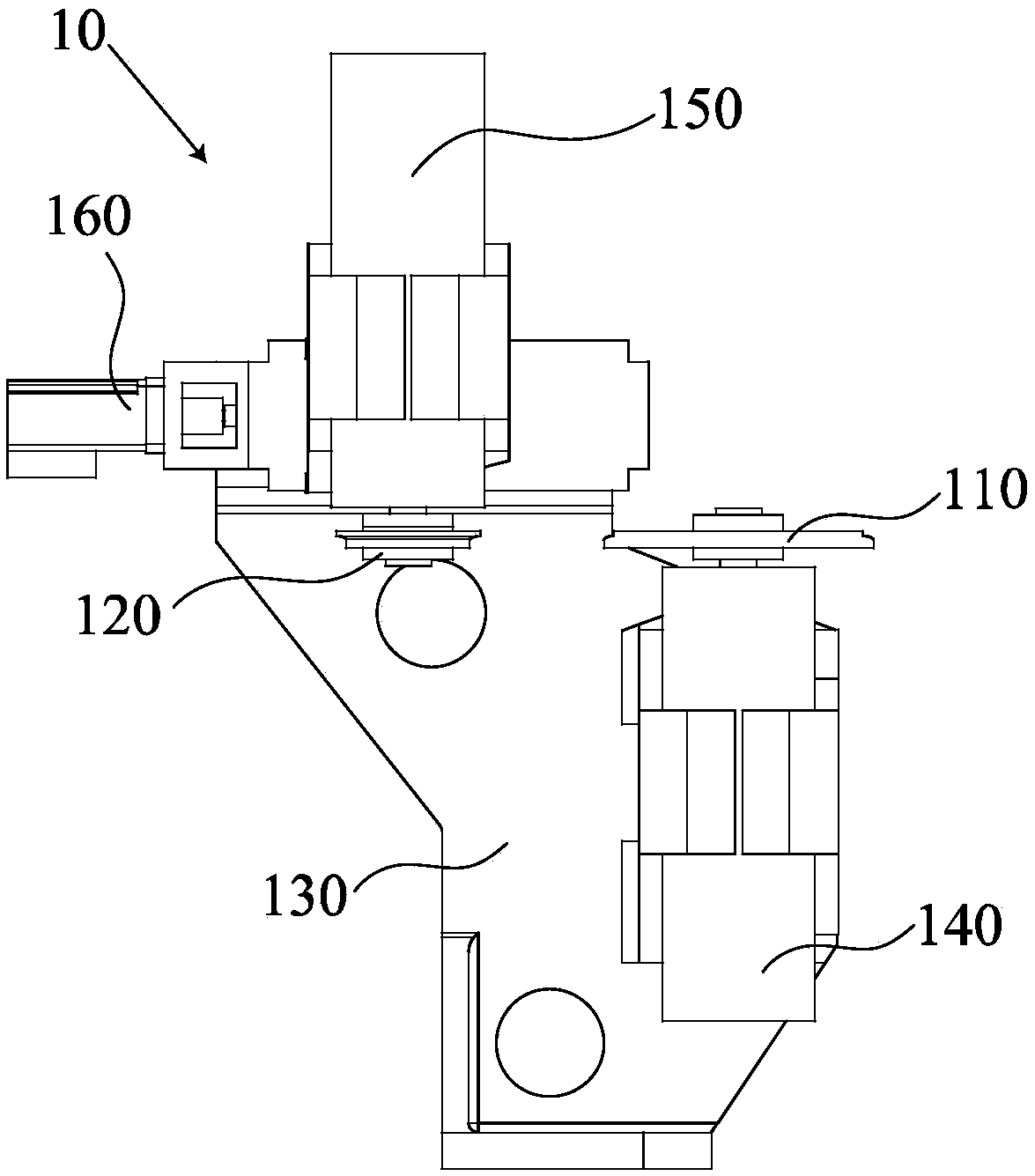

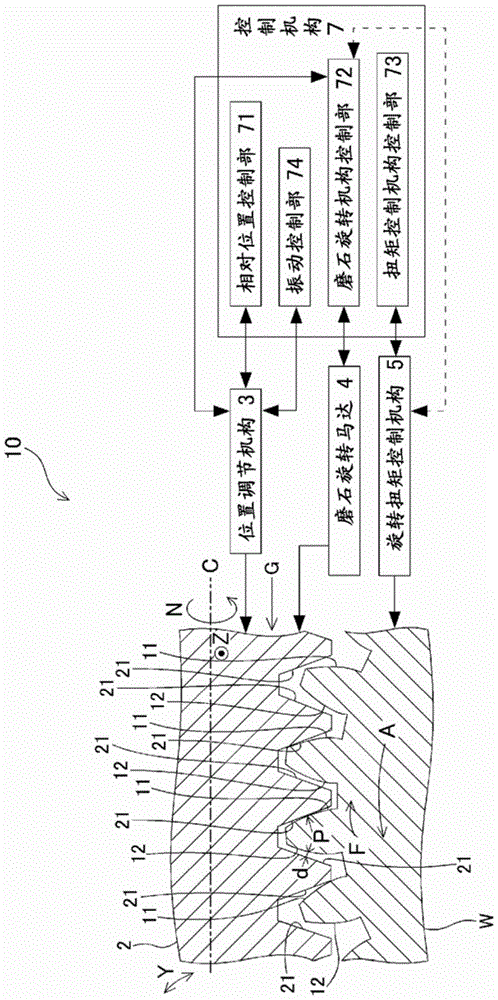

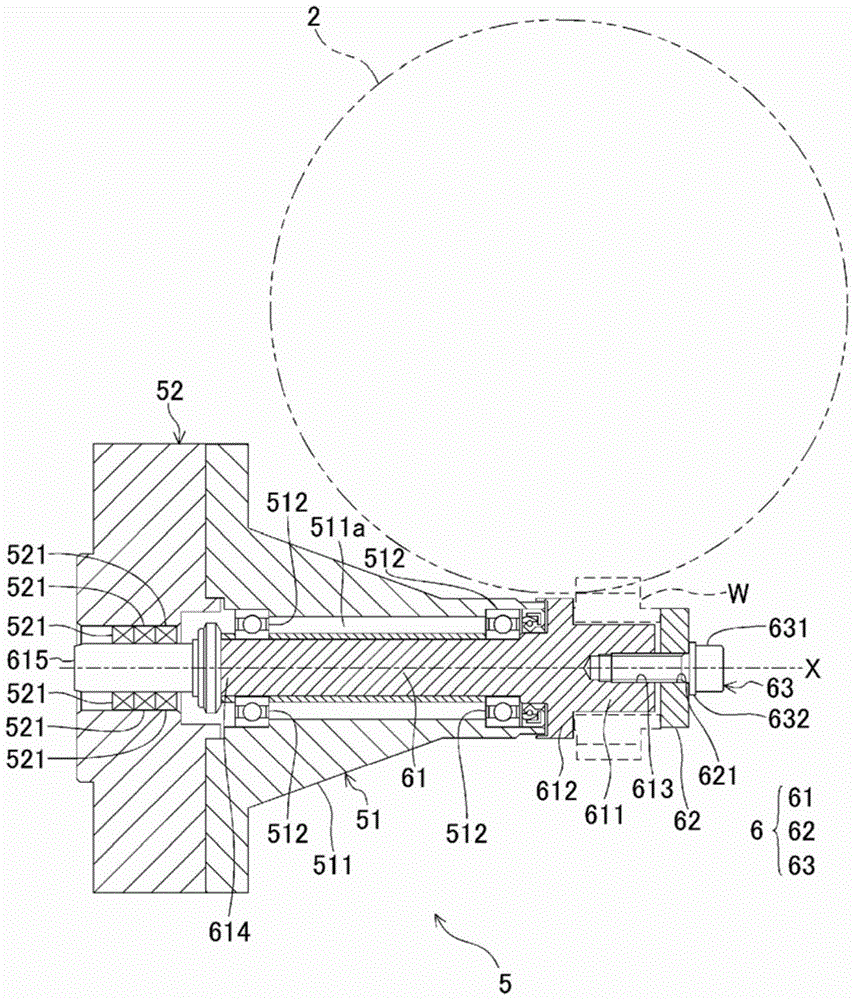

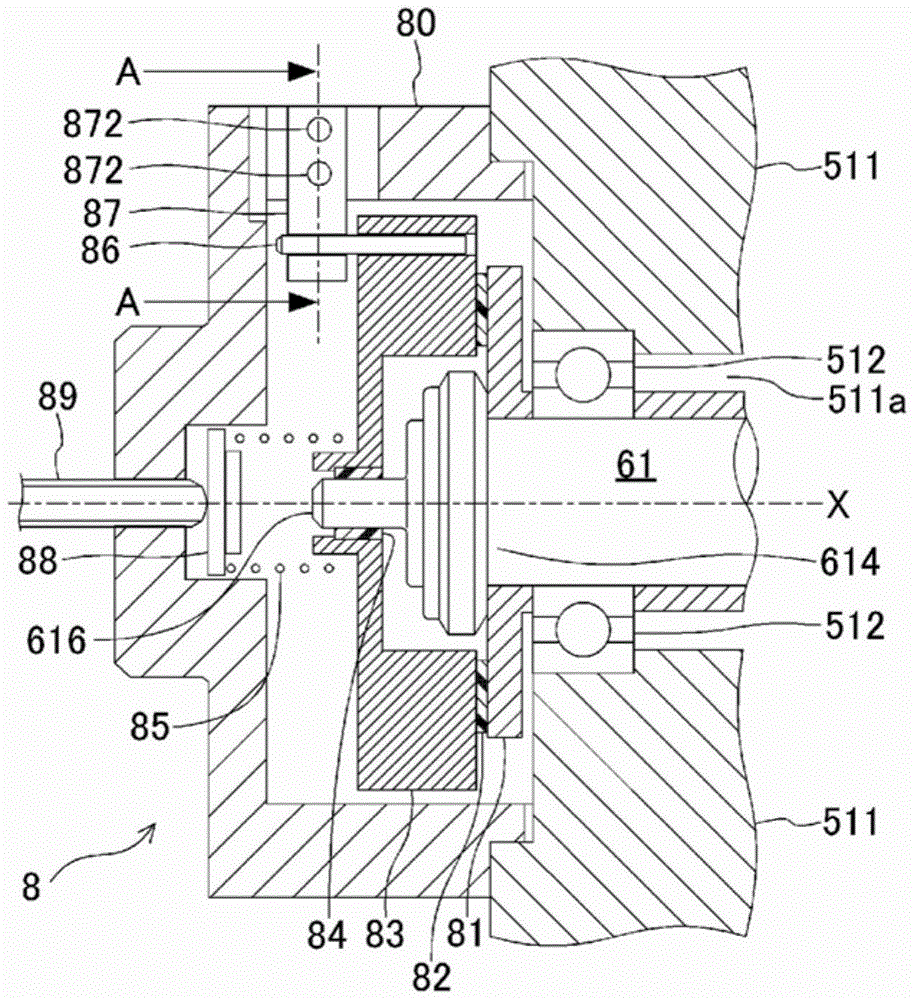

Gear tooth surface processing device and gear manufacturing method

ActiveCN104507613AAvoid Grinding BurnsImprove surface roughnessGrinding feed controlBonded abrasive wheelsGrindstoneGear manufacturing

A gear tooth surface processing device and a gear manufacturing method are provided which are capable of adjusting processing pressure for the purpose of improving the surface roughness of high-hardness gears and the like. The gear tooth processing device (10) has: a helical grindstone (2); a position adjusting means (3) which is capable of moving the relative positions of a rotary axis (C) of the helical grindstone (2) and a rotary axis (X) of a gear to be processed (W); and a control means (7). The control means (7) includes: a position control unit (71) which operates the position adjusting means (3) so as to adjust the relative positions of the rotary axis (C) of the helical grindstone (2) and the rotary axis (X) of the gear to be processed (W) to cause only one of the tooth surfaces to be processed (11), from among the gear tooth surfaces that form a single tooth of the gear to be processed (W), to make contact with a grindstone tooth surface (21) of the helical grindstone (2) such that the helical grindstone (2) and the gear to be processed (W) are engaged; a grindstone rotation means control unit (72) for operating a grindstone rotation means (4); and a torque control means control unit (73) for operating a rotation torque control means (5) so as to adjust the rotation torque within a predetermined range.

Owner:AISIN AI CO LTD +1

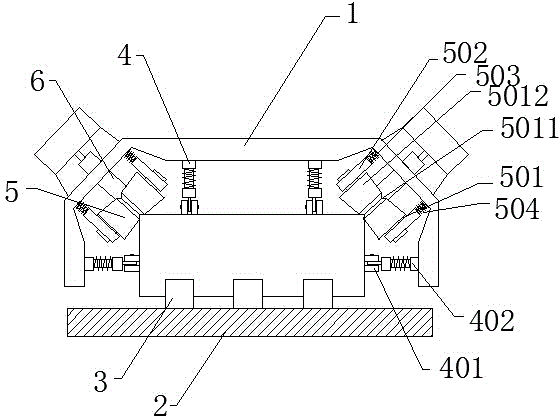

High-efficiency flash trimming device

The invention provides a high-efficiency flash trimming device. The high-efficiency flash trimming device comprises a stander and a workpiece pedestal, wherein the workpiece pedestal is provided with a clamping buckle for clamping a to-be-machined workpiece, the stander is arranged above the workpiece pedestal, the stander is provided with a pressing wheel device which is used for pressing the to-be-machined workpiece and enabling the stander to move relative to the to-be-machined workpiece, the stander is also provided with a heat melting and trimming device which is tightly clung to the surface of a flash position of the to-be-machined workpiece, used for heating for melting the flash and used for trimming the flash of the to-be-machined workpiece in a rolling manner, and an adhesive replenishing device which is used for filling a recess in the surface of the to-be-machined workpiece is arranged in front of the heat melting trimming device in the rolling direction. According to the high-efficiency flash trimming device, the flash of the workpiece is trimmed in a hot melting manner, and the flaw on the surface of the workpiece also can be repaired.

Owner:ZHEJIANG BAIZHIJIA FURNITURE

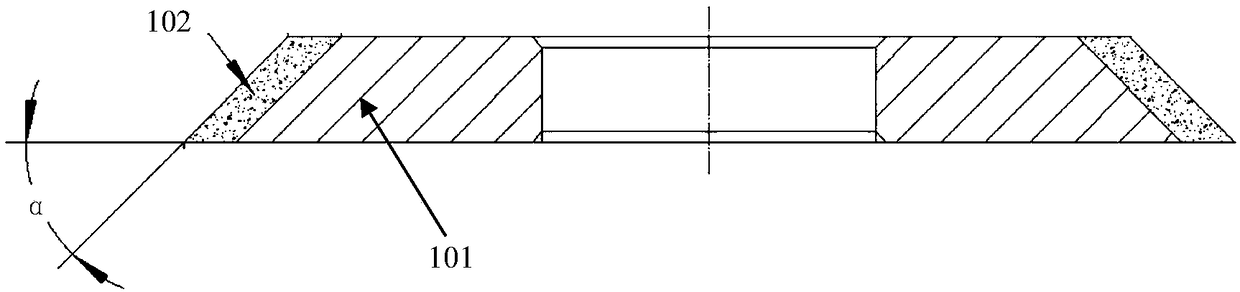

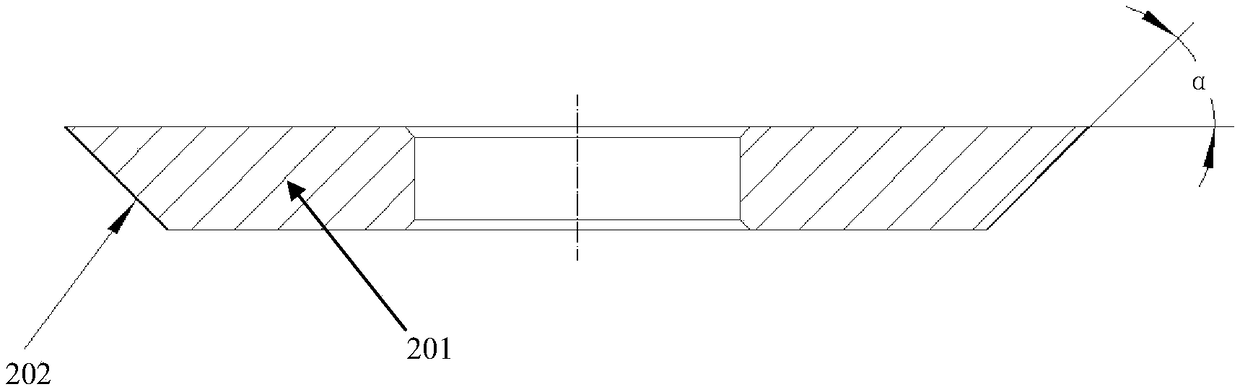

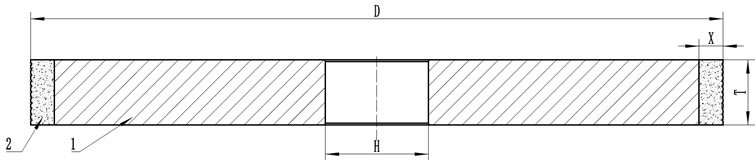

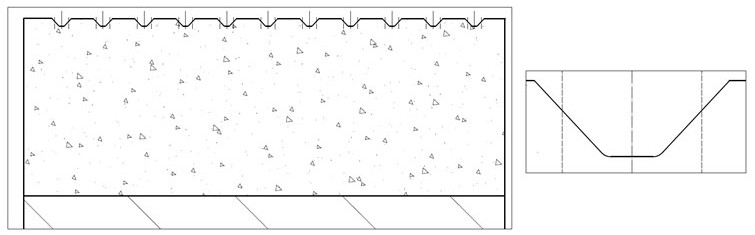

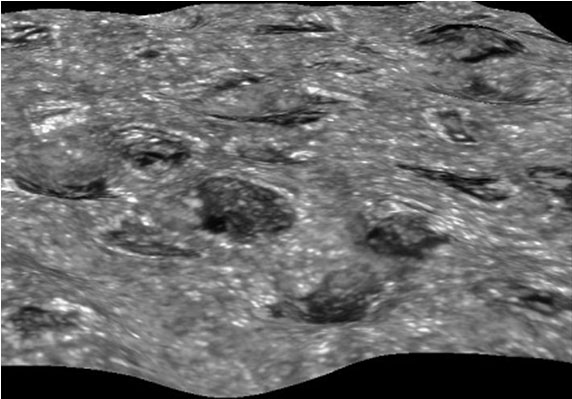

Optical curve grinding wheel and preparing method thereof

ActiveCN111496699ALess prone to loss of precisionGood for heat transferTransportation and packagingAbrasion apparatusMachining processMetal binding

The invention belongs to the technical field of ultra-hard grinding wheel dressing, and particularly relates to an optical curve grinding wheel for metal bonding agent ultra-hard material chamfering grinding wheel dressing. The optical curve grinding wheel comprises a base body and a grinding material layer. The grinding material layer comprises following raw materials including, by weight, 30-40parts of grinding materials and 60-70 parts of a metal bonding agent. The metal bonding agent comprises following raw materials including, by weight, 30-55 parts of copper powder, 25-50 parts of tin powder and 5-10 parts of silver powder. The grinding wheel is simple in formula and machining technology and simple and convenient to operate. Dressing can be conducted on a metal bonding agent ultra-hard material chamfering grinding wheel, the machining effect is good, the size of a chamfering grinding wheel tiny groove can reach the precision of + / - 0.01 mm.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

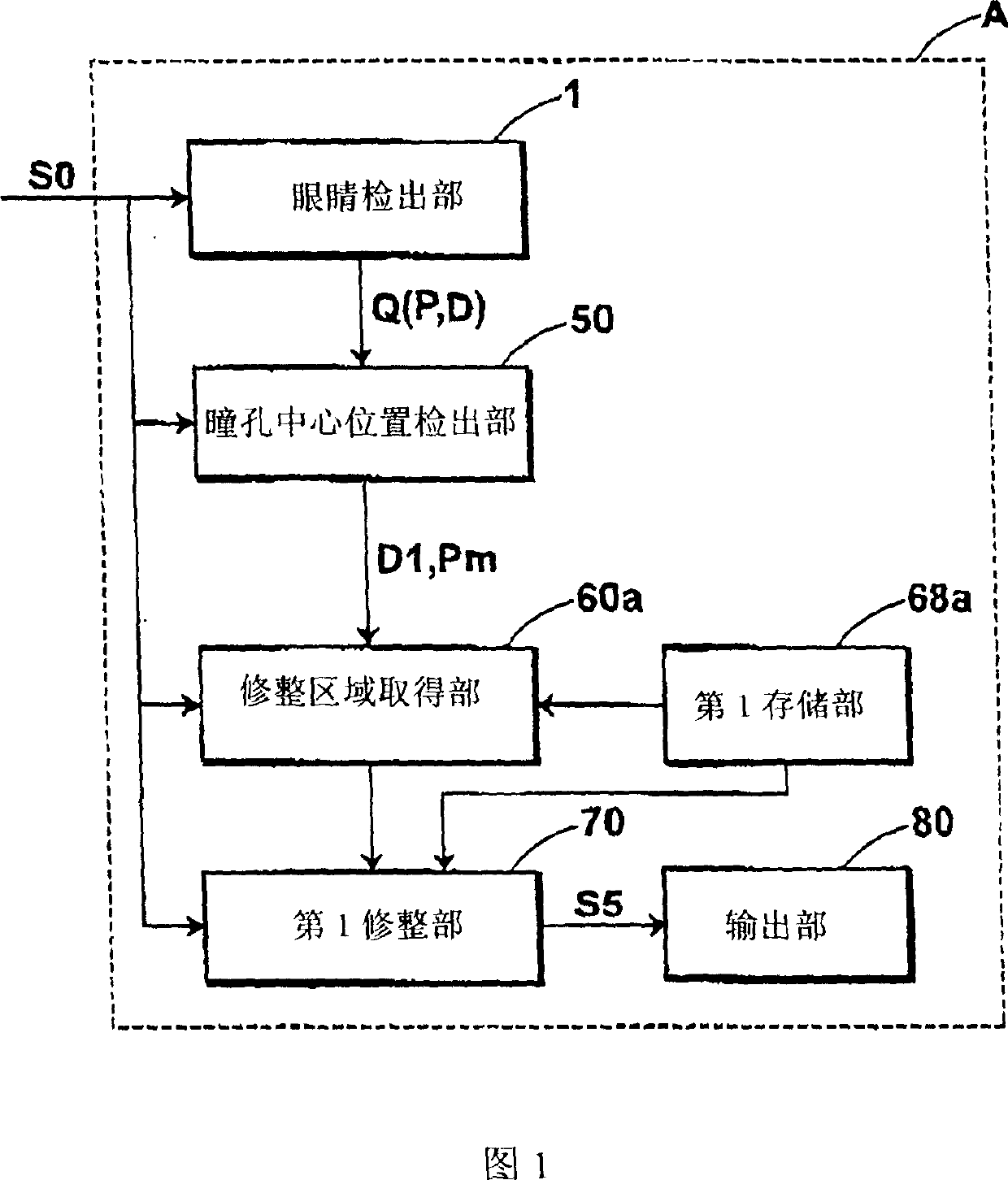

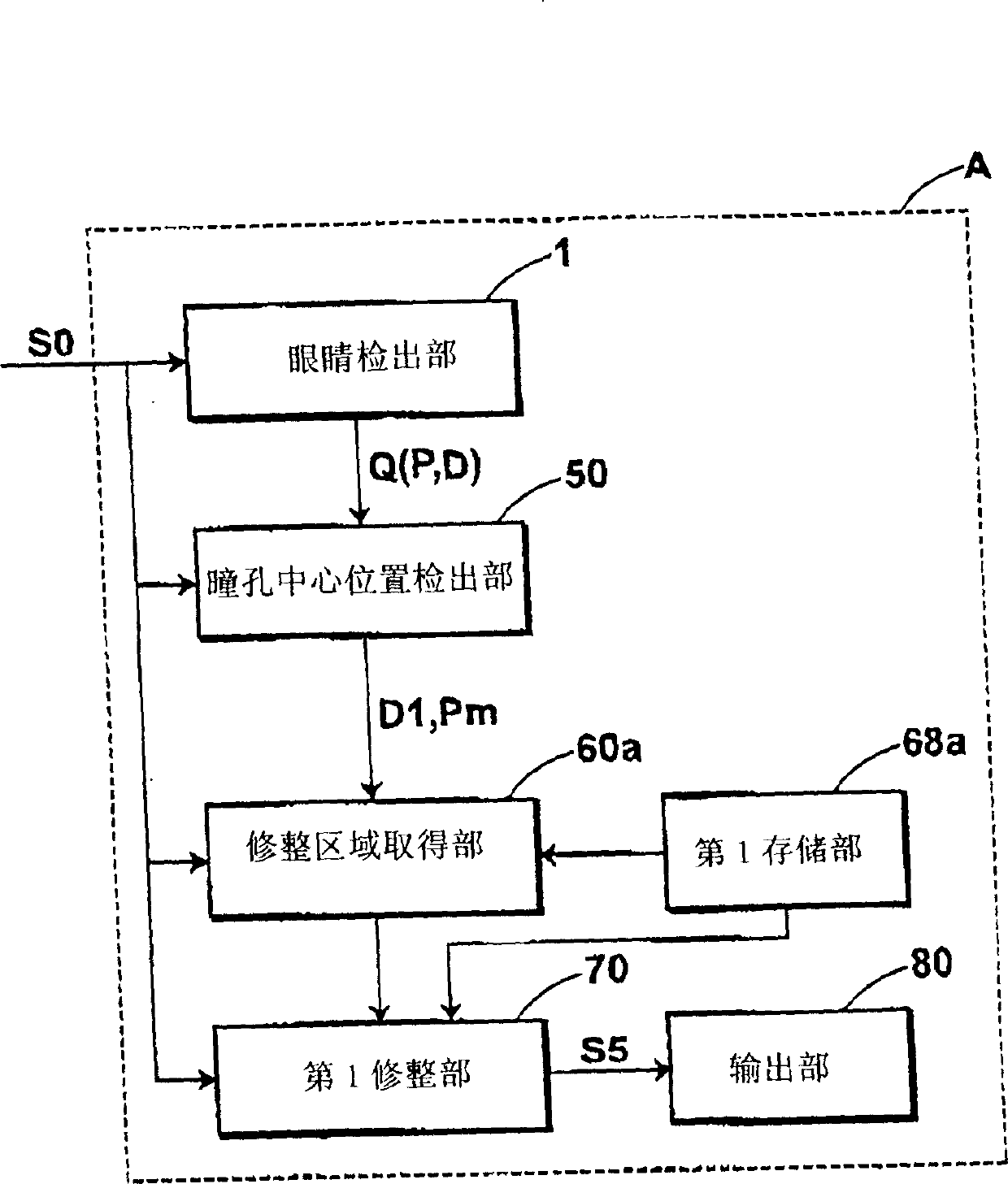

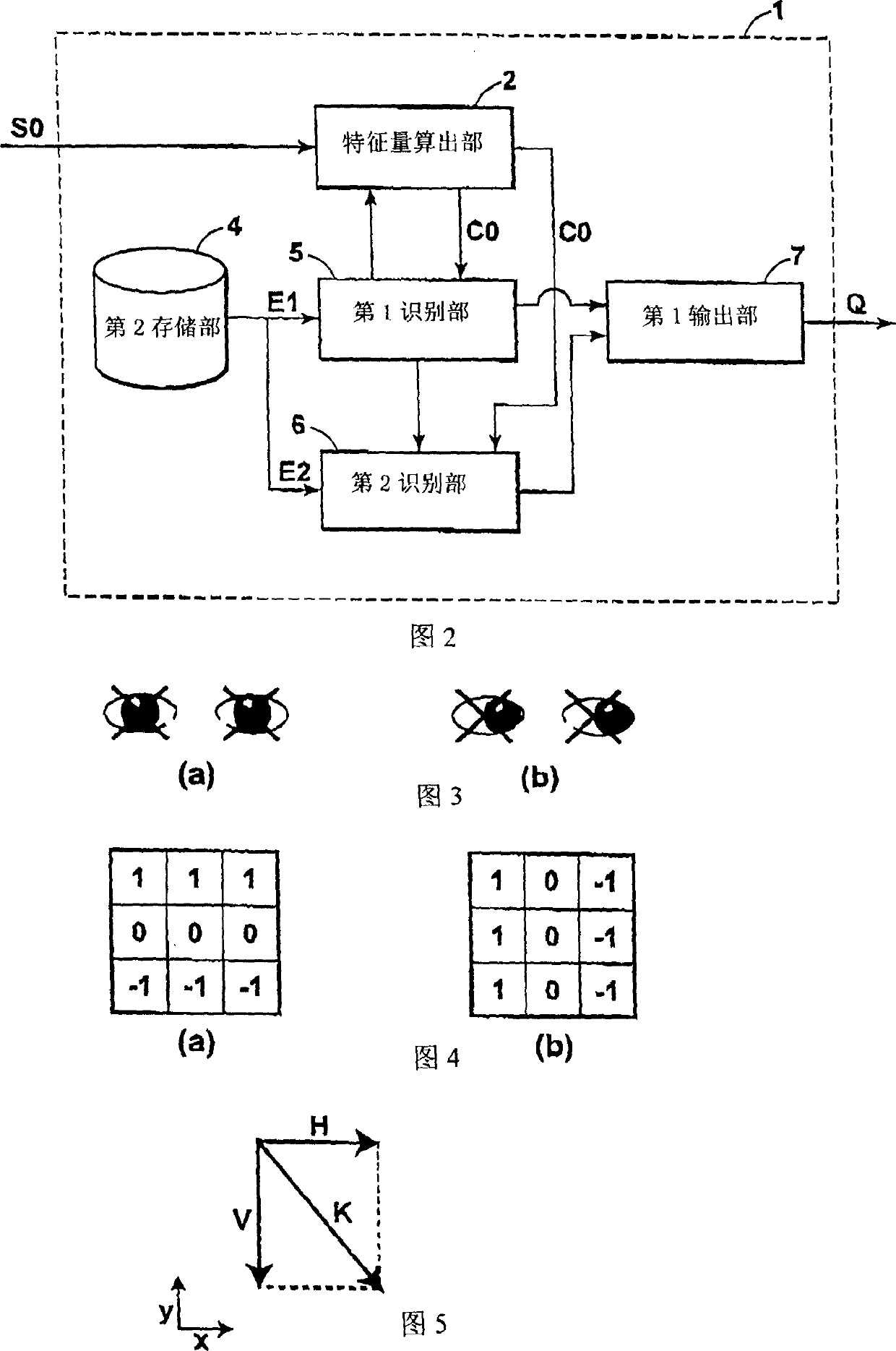

Image processing method and device and its program

InactiveCN1599406AEasy to handleImprove efficiencyTelevision system detailsCharacter and pattern recognitionImaging processingComputer graphics (images)

Owner:FUJIFILM CORP

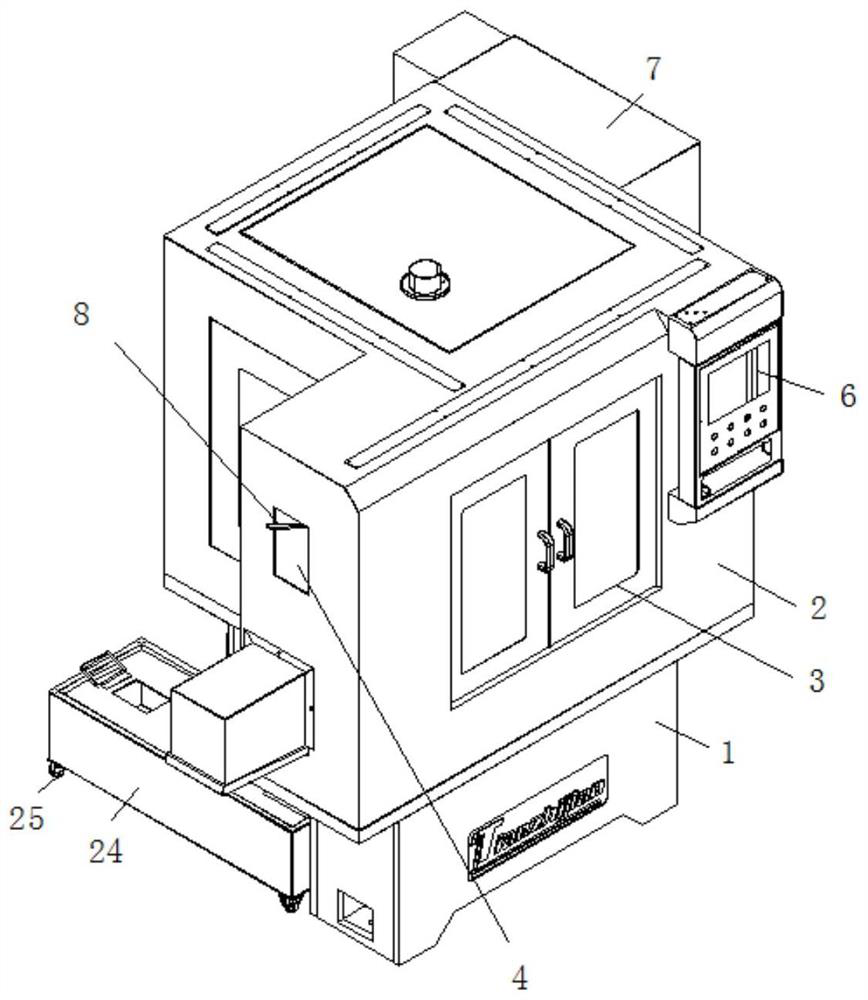

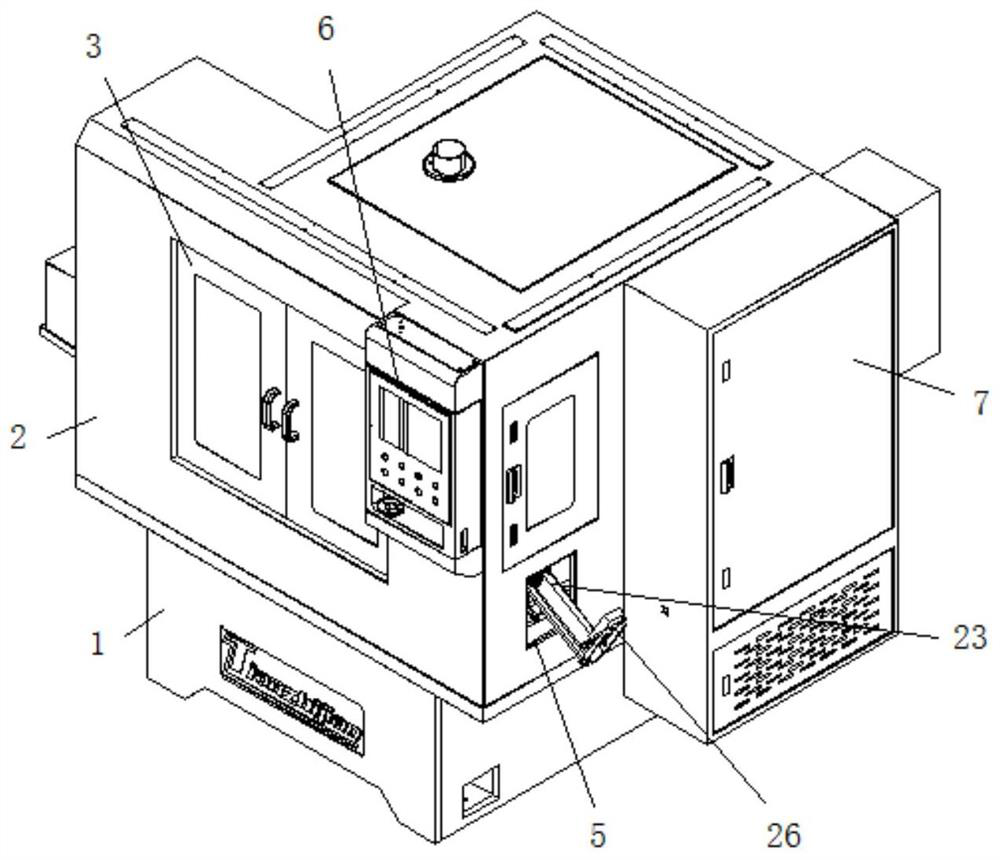

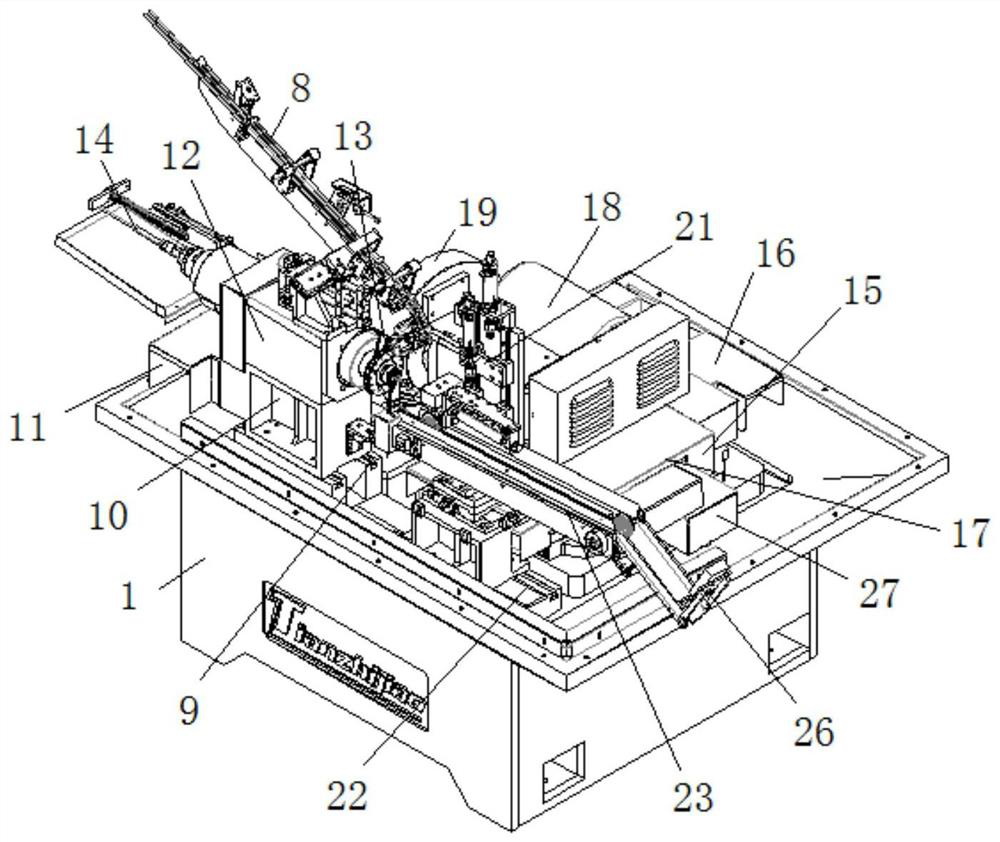

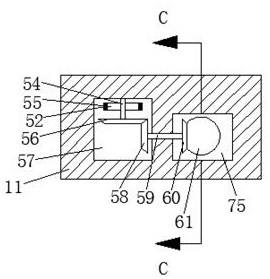

CBN valve accurate grinding conical surface grinding machine

PendingCN112658834AEasy to processFast processingRevolution surface grinding machinesAbrasive surface conditioning devicesElectrical controlEngineering

The invention discloses a CBN valve fine grinding conical surface grinding machine, which comprises a machine tool body; a machine tool protective cover is fixedly connected to the upper end of the machine tool body; a left-right moving door is movably connected to the front end of the machine tool protective cover; a feeding port is formed in the left end of the machine tool protective cover, and a discharging port is formed in the right end of the machine tool protective cover; the front end of the machine tool protective cover is fixedly connected with an operation control box, and the operation control box is located on the outer side of the left-right sliding door; the right end of the machine tool protective cover is fixedly connected with an electric control cabinet, and the electric control cabinet is electrically connected with the machine tool body and the operation control box; the outer side of the machine tool body is detachably connected with a cooling grinding fluid water tank; and universal trundles are fixedly installed at the lower end of the cooling grinding fluid water tank. According to the CBN valve accurate grinding conical surface grinding machine provided by the invention, overall rapid and stable clamping is guaranteed, the overall clamping stability is improved, overall trimming is facilitated, and therefore the overall good using effect is guaranteed.

Owner:SUZHOU TIANZHIJIAO PRECISION MACHINERY CO LTD

A composite high-efficiency and precise dressing method for superabrasive grinding wheels

ActiveCN110116372BRealize finishing workPrecision trimming of shape accuracyAbrasive surface conditioning devicesReciprocating motionAbrasive water jet

The invention provides an ultrahard abrasive grinding wheel compounded efficient and precise finishing method. The method comprises the following steps: (1) abrasive water jet rough finishing: abrasive water jet is sprayed to a direction with a certain angle; meanwhile, an abrasive water jet nozzle performs a reciprocating motion along a section profile trajectory of a molded surface needed by a grinding wheel; and an ultrahard abrasive grinding wheel is radially fed to realize rough finishing; (2) a finishing roller and a free abrasive are used for extrusion and finishing; abrasive water jetspray heads are arranged in a row; and the jet flow of each spray head is controlled to match with a finishing roller for finishing; and (3) the abrasive water jet is used for finishing sharpness. Theultrahard abrasive grinding wheel compounded efficient and precise finishing method is simple in process, high in finishing precision and suitable for the finishing work of ultrahard abrasive grinding wheels with complex molded surfaces.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

An edge trimming device for non-woven fabric production that is convenient for position adjustment

ActiveCN109176676BEasy to rewindEasy to store and use for workMetal working apparatusWebs handlingBall bearingStructural engineering

Owner:温州恒基包装有限公司

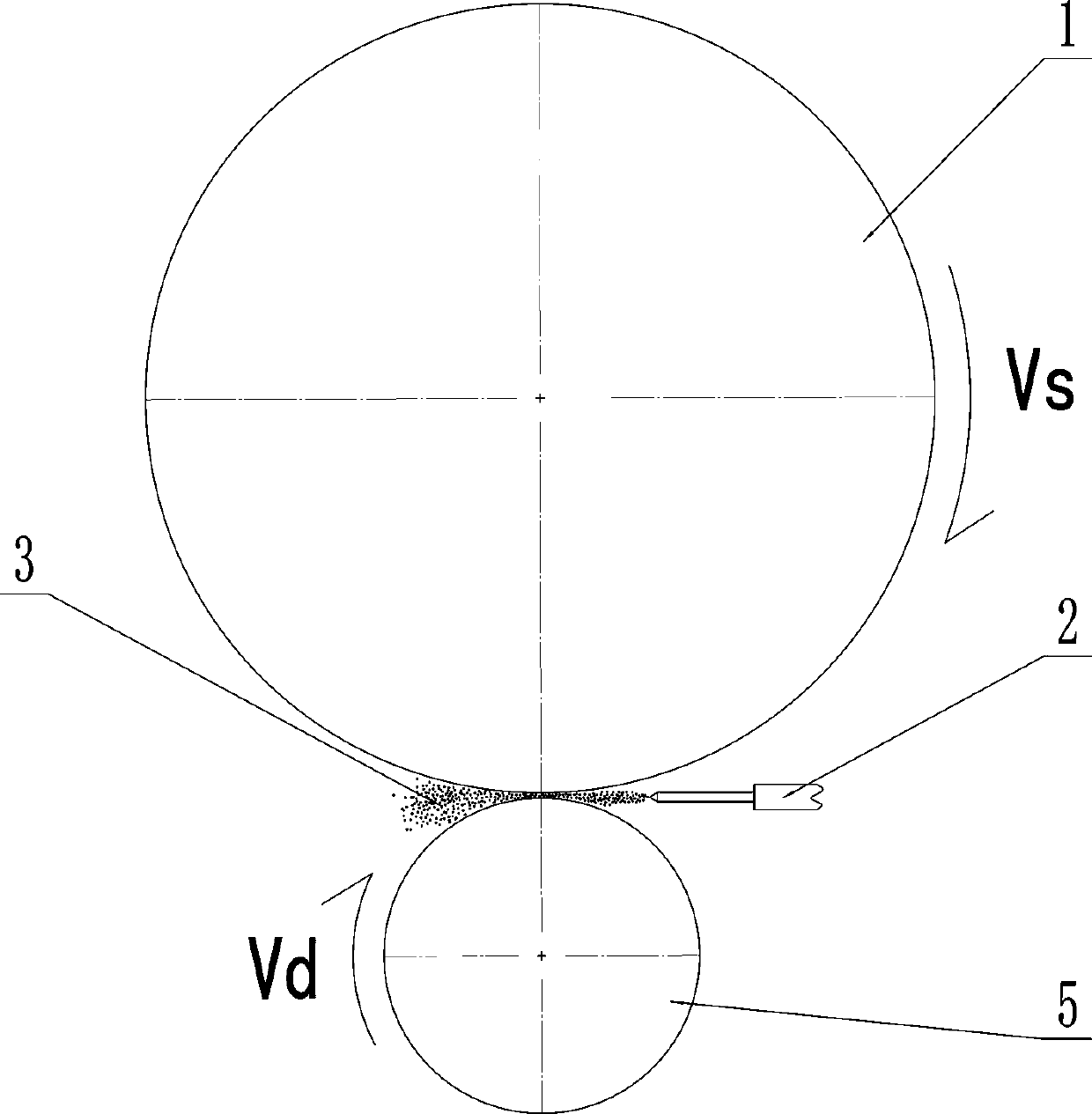

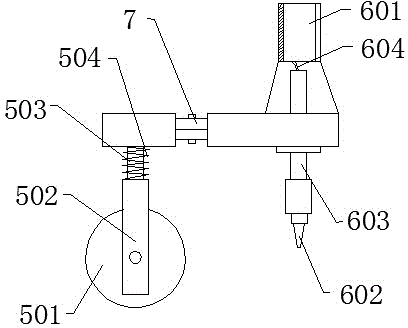

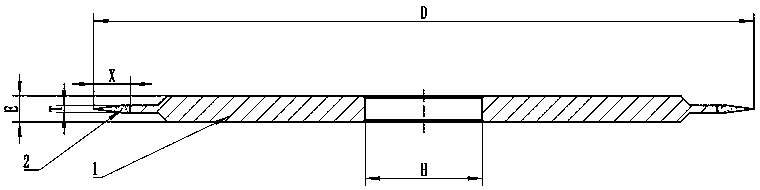

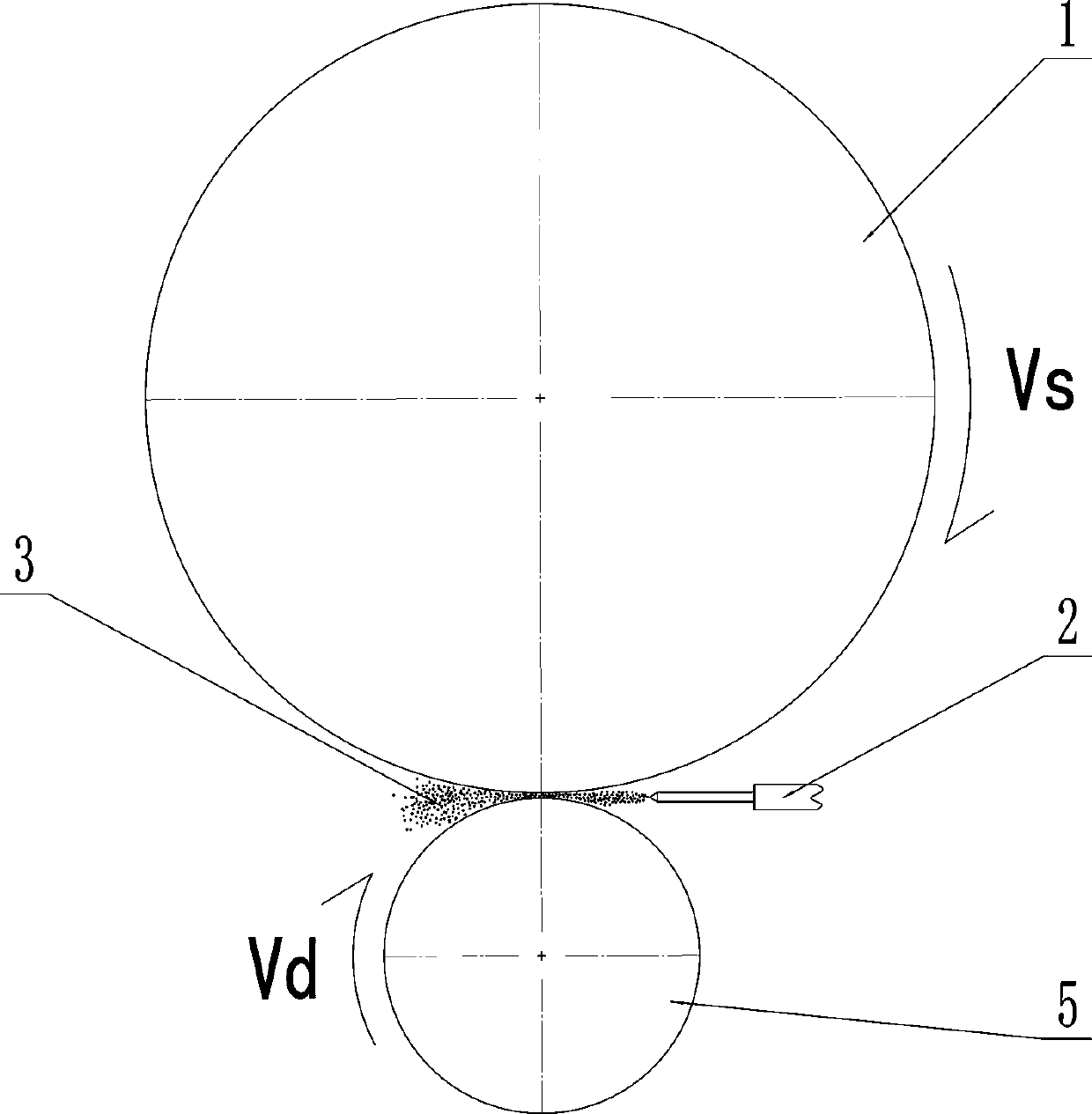

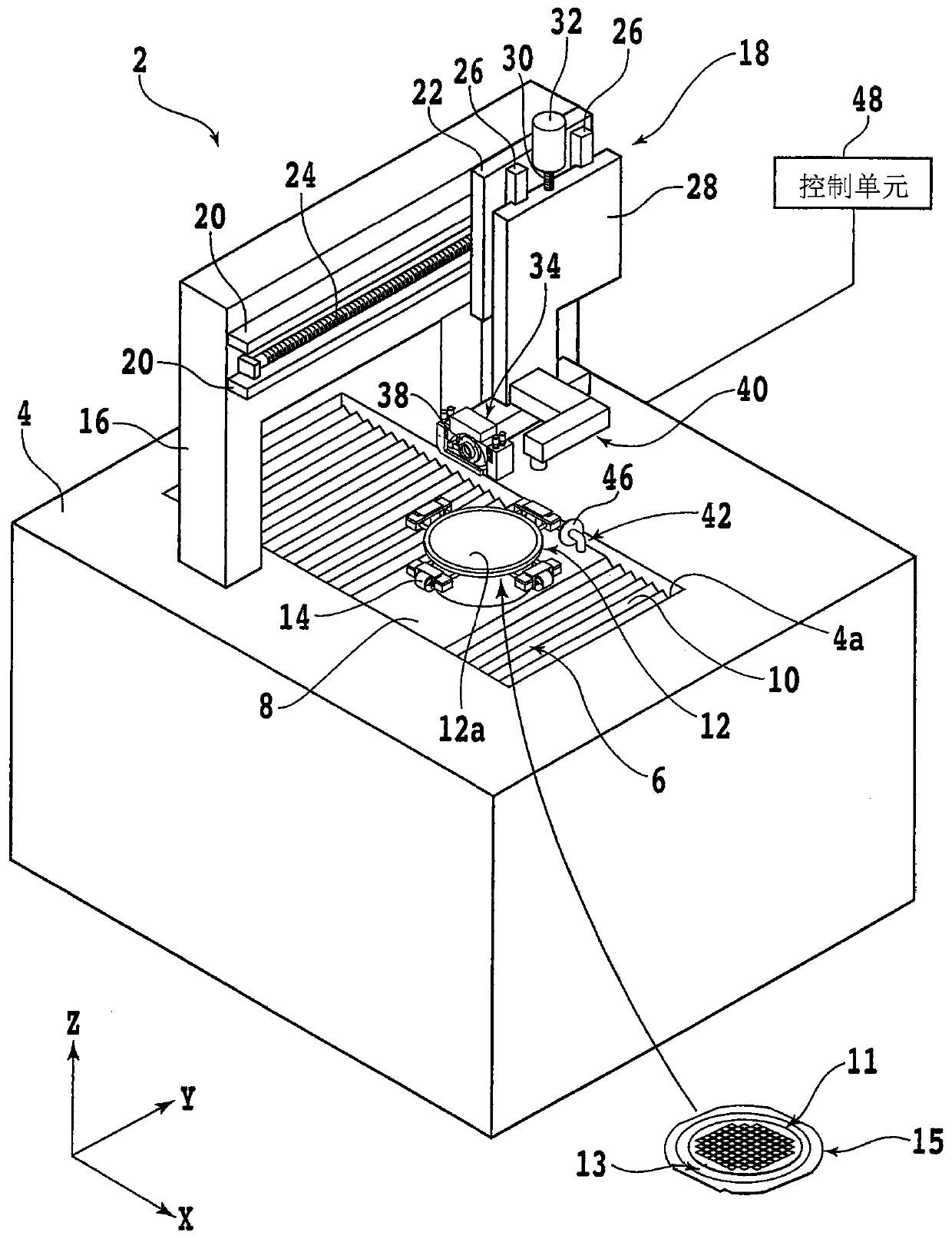

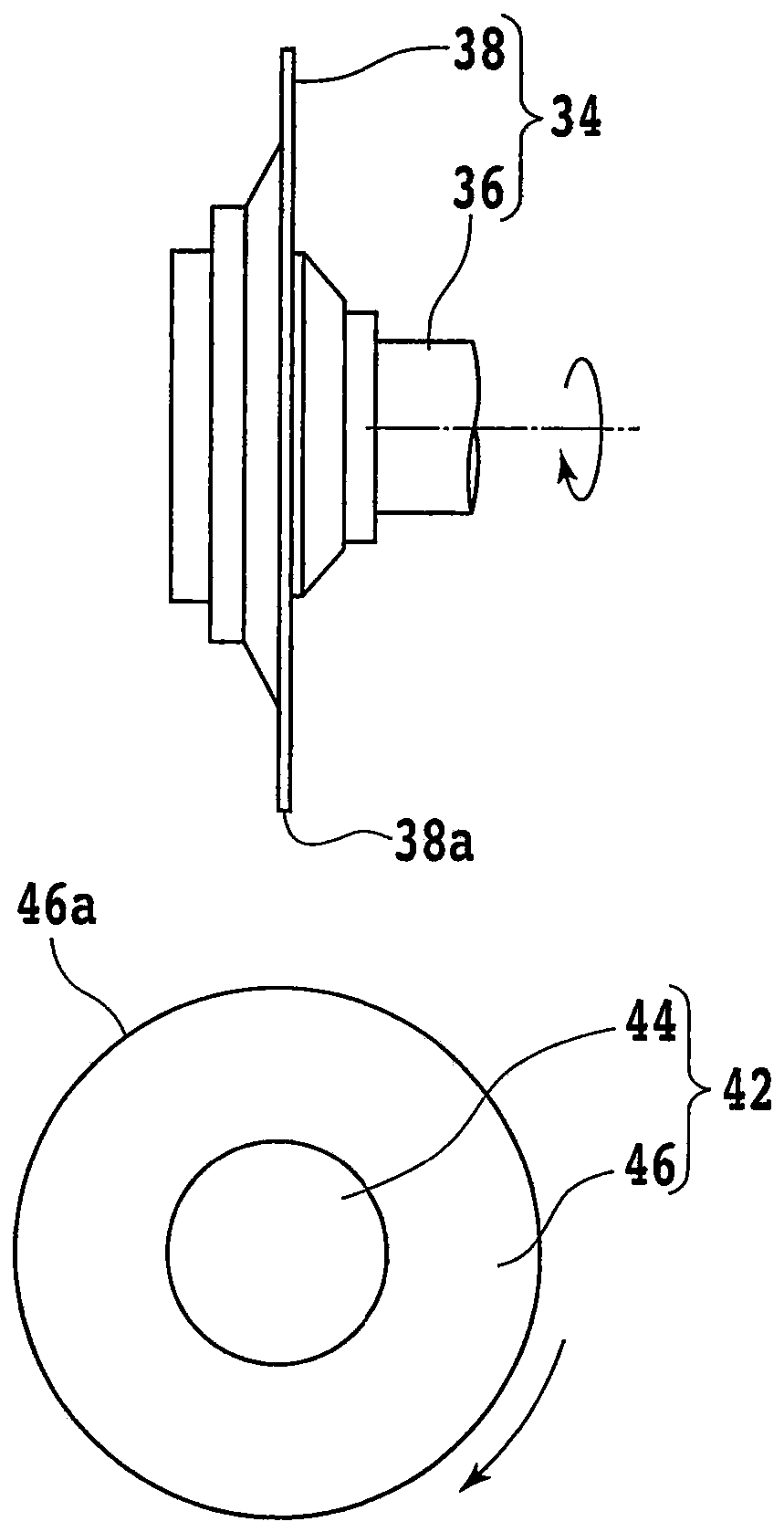

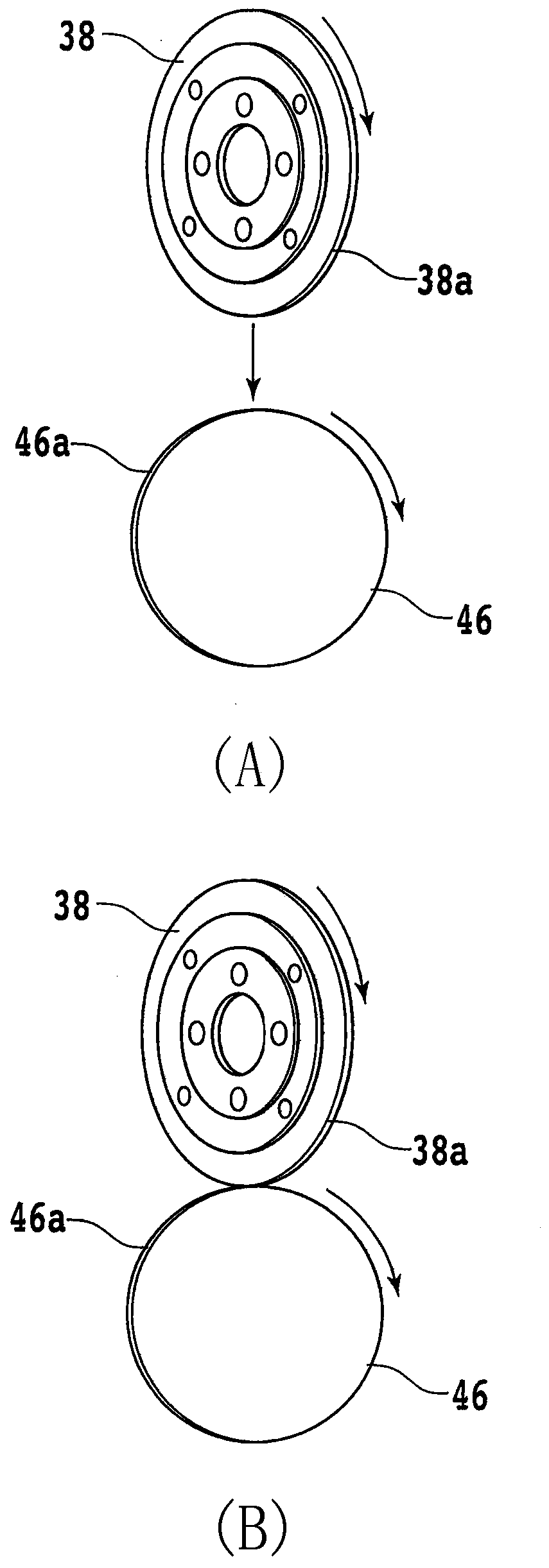

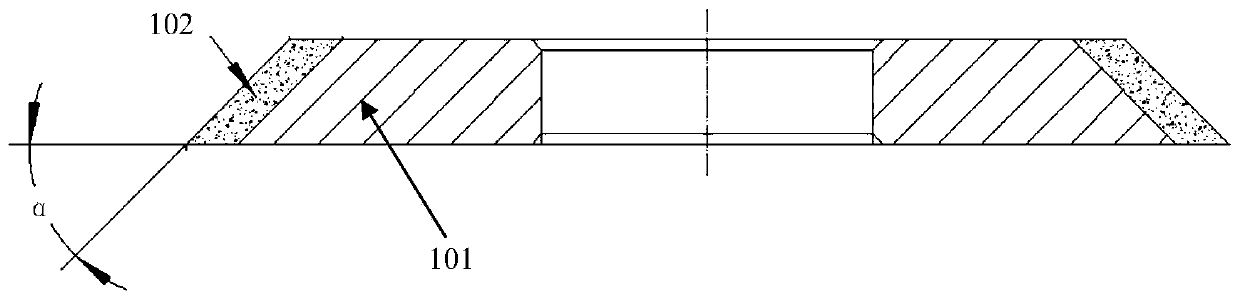

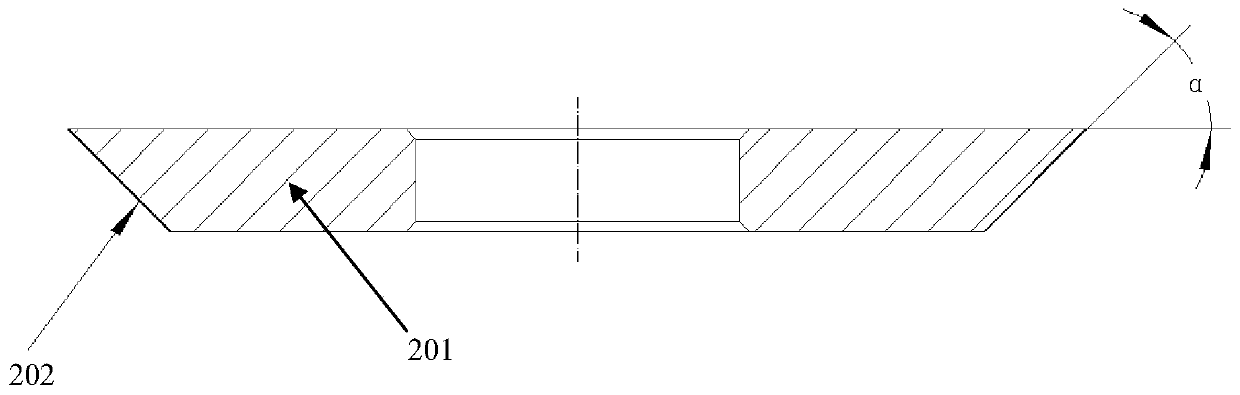

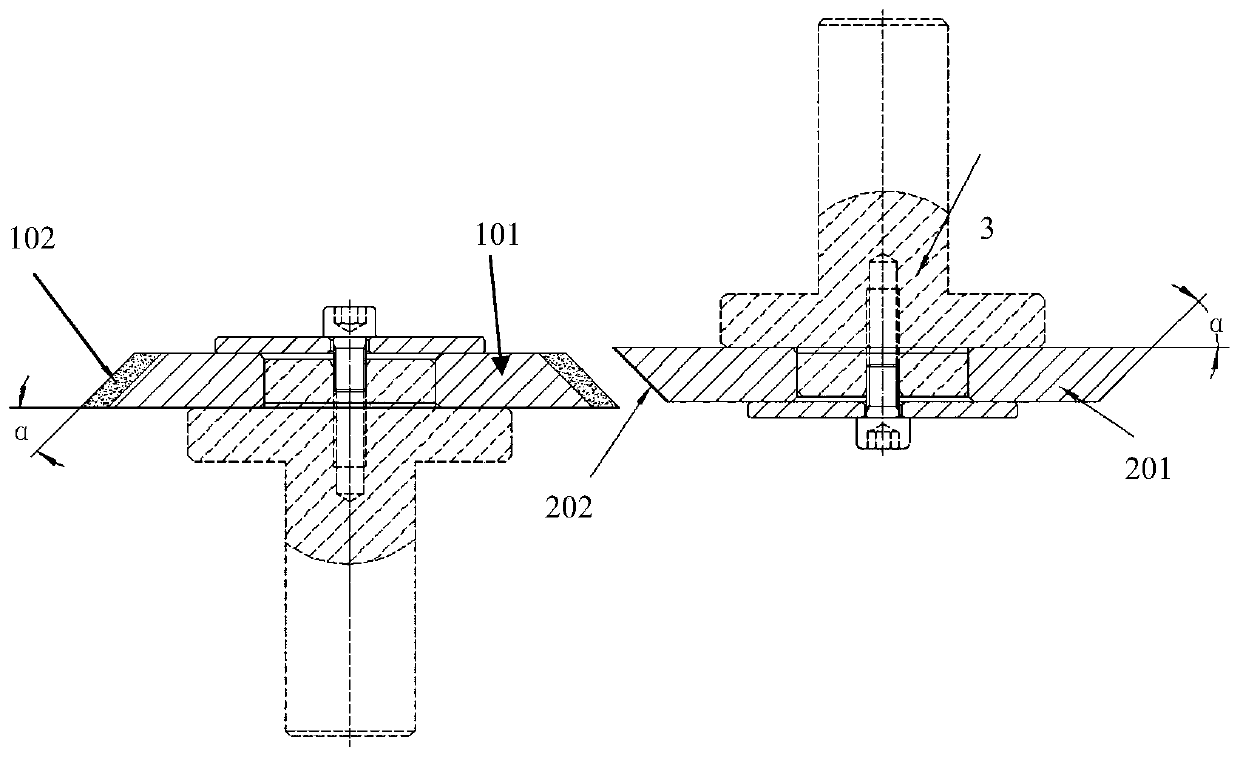

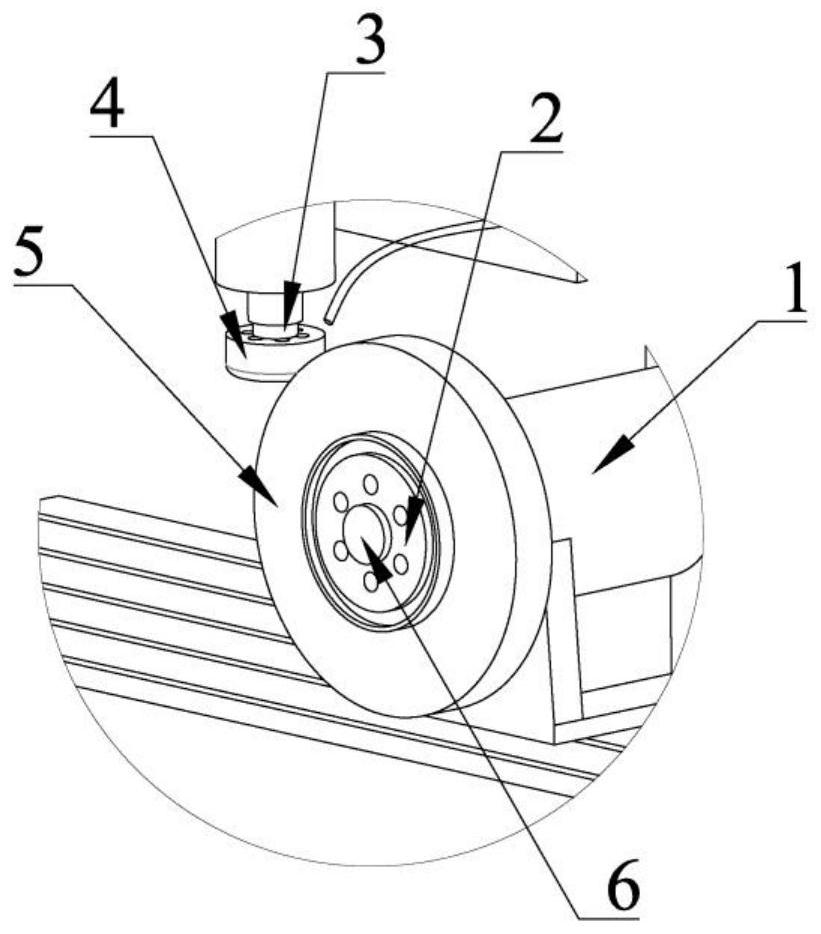

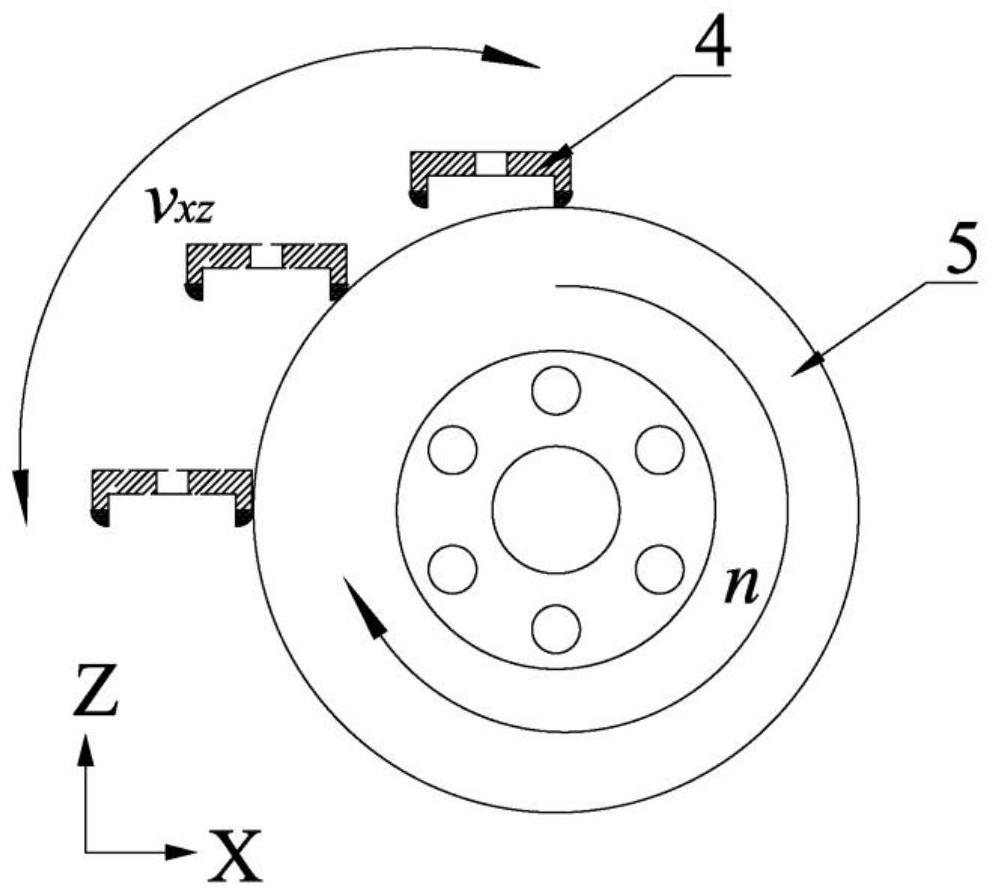

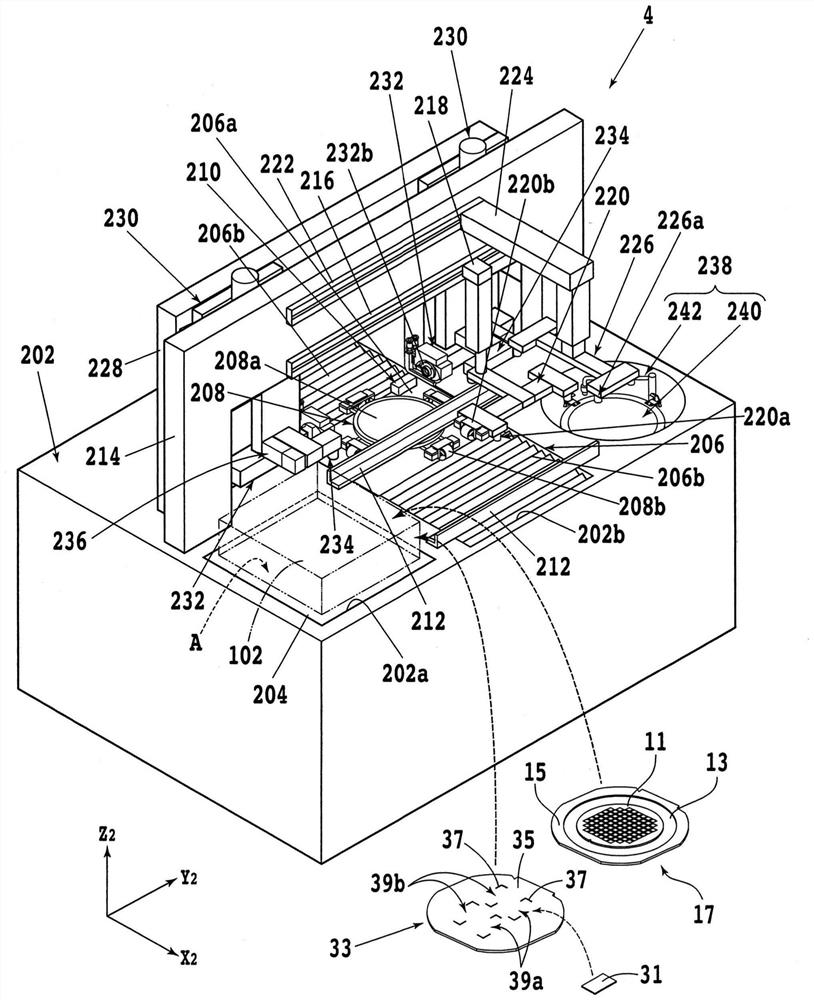

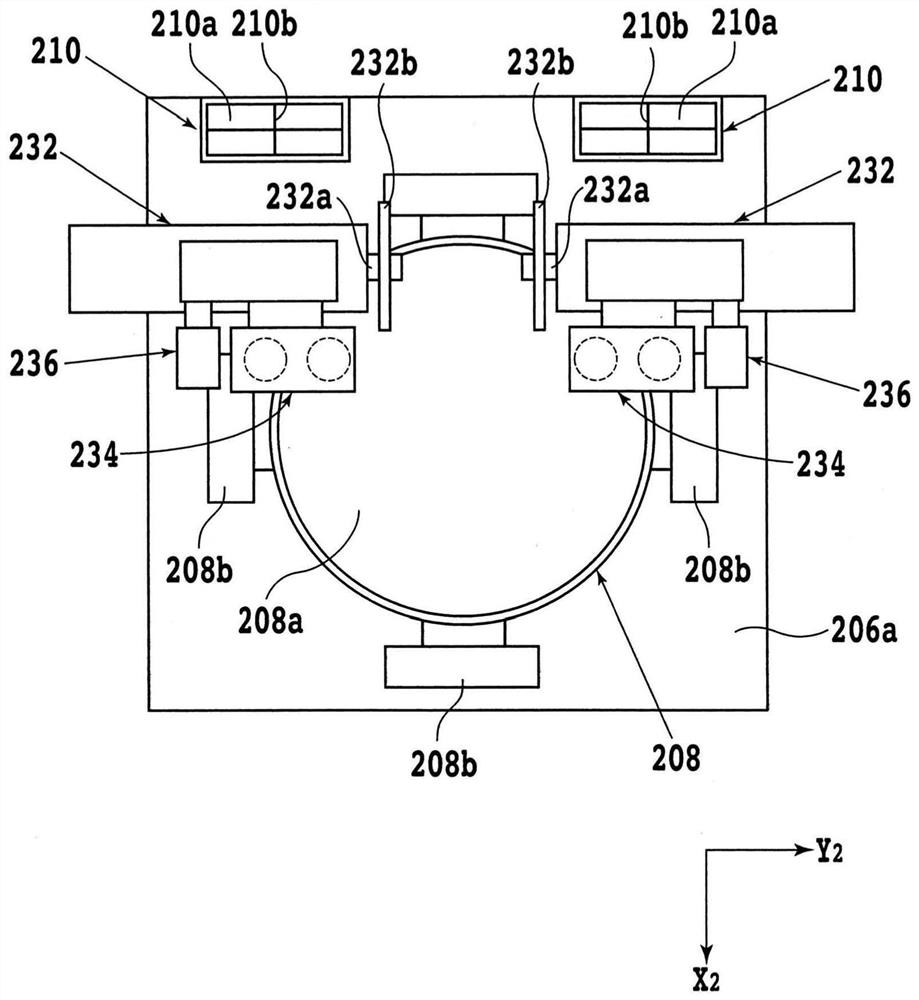

Cutting apparatus and cutting tool trimming method

PendingCN111452238AEfficient trimmingAbrasive surface conditioning devicesGrinding machinesRotational axisCircular disc

A cutting apparatus and a trimming method of a cutting tool are provided. The cutting tool can be efficiently trimmed in a short time. The cutting apparatus is used for cutting a plate-shaped workpiece, and the cutting apparatus comprises a holding table having a holding surface for holding the workpiece; a cutting unit having a rotating shaft to which a disc-shaped cutting tool having a cutting edge on the outer peripheral portion is attached, the cutting unit rotating the cutting tool together with the rotating shaft to cut the workpiece held by the holding table; a cutting mechanism that moves the cutting unit in a direction perpendicular to the holding surface; and a dressing unit having a rotating shaft to which a disc-shaped dressing plate is attached, the dressing unit dressing thecutting tool by rotating the dressing plate together with the rotating shaft, and the rotating shaft of the dressing unit being disposed non-parallel to the rotating shaft of the cutting unit.

Owner:DISCO CORP

A kind of diamond grinding wheel dressing method

InactiveCN108838890BAvoid consuming too quicklyEfficient trimmingAbrasive surface conditioning devicesCarbide siliconMetallurgy

The invention relates to a diamond grinding wheel dressing method, and belongs to the technical field of grinding apparatuses. The diamond grinding wheel dressing method comprises the following stepsthat an electroplating diamond grinding wheel and a diamond grinding wheel to be dressed are relatively ground, then the relatively ground grinding wheel to be dressed is subjected to surface cleaning, and the diamond grinding wheel is obtained. According to the diamond grinding wheel dressing method, the diamond grinding wheel and the diamond grinding wheel are relatively ground, the diamond grinding wheel is dressed, and the problem that when a silicon carbide grinding wheel is used for dressing the diamond grinding wheel in the prior art, the silicon carbide grinding wheel is consumed too fast is avoided. Meanwhile, the diamond grinding wheel is adopted as the dressing grinding wheel, the shape retention performance is good, profile modeling dressing can be adopted for the diamond grinding wheel as the grinding wheel to be dressed, and the dressing precision of the diamond grinding wheel is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Water-based Anti-corrosion coating composition

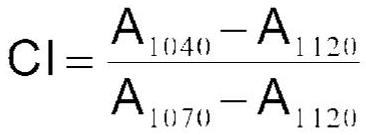

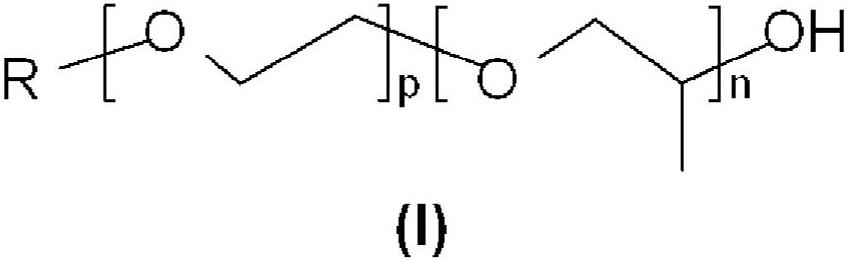

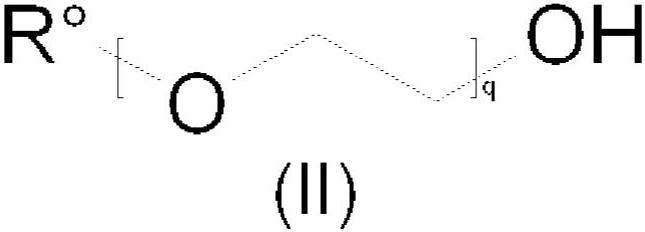

ActiveCN108884352AEfficient trimmingImprove corrosion resistanceAnti-corrosive paintsPolymer scienceMeth-

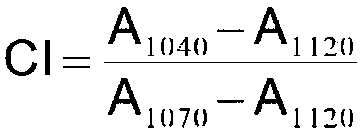

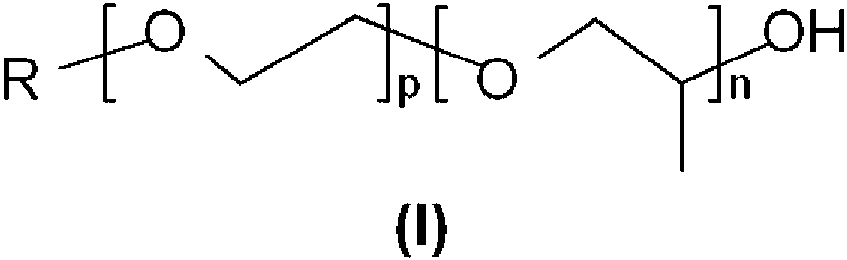

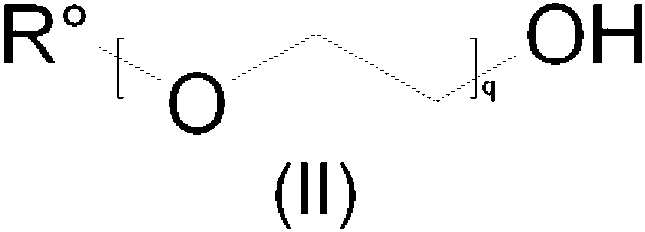

The invention pertains to an aqueous coating composition comprising: an aqueous latex of a copolymer consisting essentially of recurring units derived (i) from vinylidene chloride (VDC), (ii) from vinyl chloride (VC), (iii) from one or more than one alkyl (meth)acrylate having from 1 to 12 carbon atoms in the alkyl group [monomer (MA)] and (iv) from one or more than one aliphatic alpha-beta unsaturated carboxylic acids [monomer (AA)], the proportion of recurring units derived from monomer (AA) being of at least 1.0 wt %, with respect to the total weight of the copolymer [copolymer (A)], wherein: (A) the said copolymer (A) is stable against dehydrochlorination, in a manner such that the total chloride content of the solid residue of the aqueous latex, after thermal treatment at about 120 DEG C for 2 hours, is of less than 1000 ppm, with respect to the total weight of the copolymer (A); (B) the said copolymer (A) does not to undergo any significant crystallization upon heating, in a manner such that the ratio of (j) its crystallinity index (CI) after a thermal treatment involving heating at 60 DEG C for 48 hours to (jj) its crystallinity index before such thermal treatment (Clafter thermal treatment / CI before thermal treatment) is less than 1.15; and at least one anti-corrosion pigment comprising an aluminium salt of a (poly)phosphoric acid modified with an alkaline earth metal oxide [pigment (P)]; at least one non-ionic surfactant [surfactant (NS)]; and at least one inorganic filler [filler (I)] different from pigment (P), in an amount such that the overall pigment volume concentration (PVC), comprehensive of pigment (P) and filler (I), is comprised from 20 to 40 % vol., when determined with respect to the dried coating composition.

Owner:SOLVAY SA

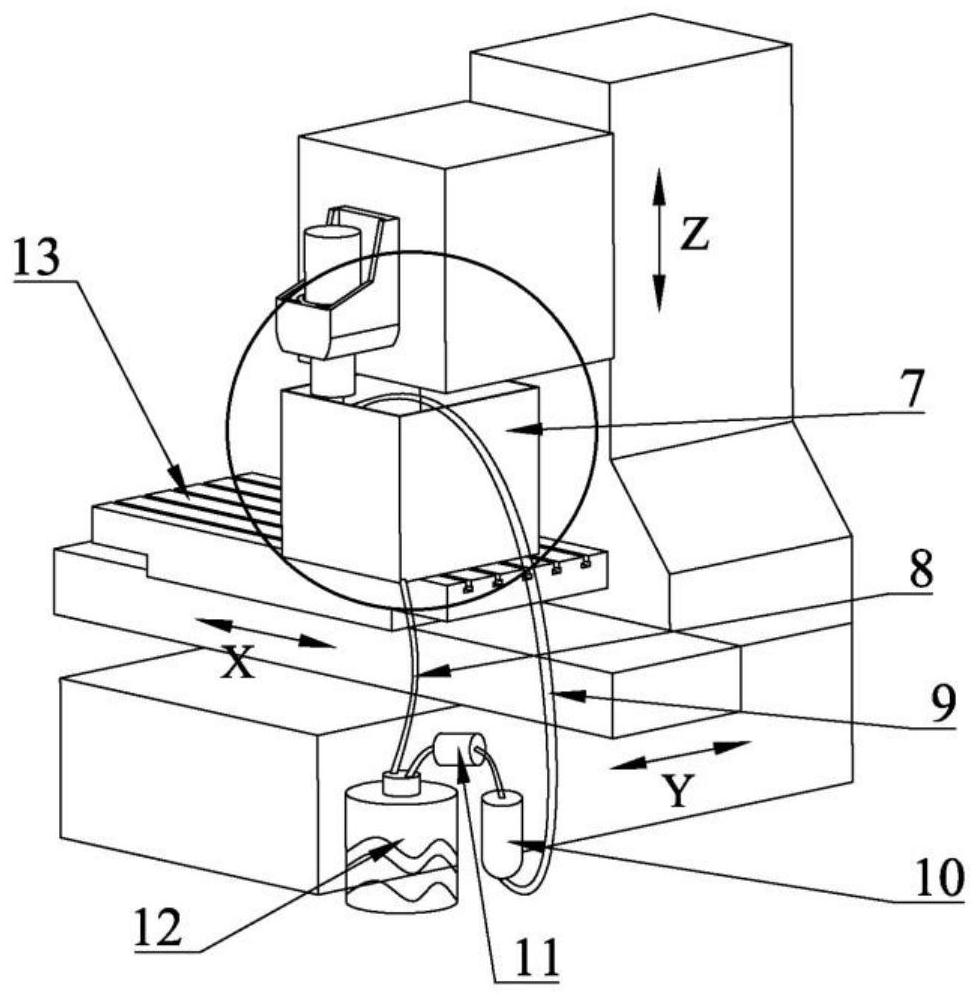

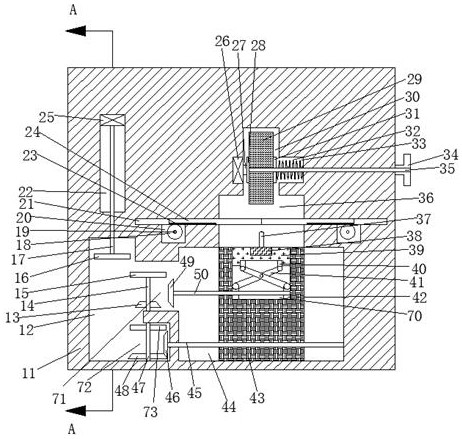

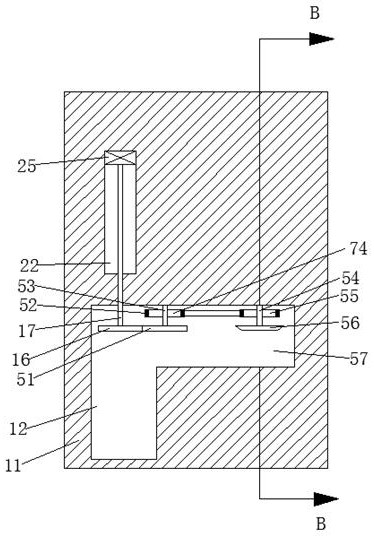

Efficient and precise in-situ dressing method and device for cup-shaped arc grinding wheel

ActiveCN113183032BLarge amount of removalGuaranteed trimming accuracyAbrasive surface conditioning devicesNumerical controlEngineering

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

A grinding wheel wear repairable device

ActiveCN110815049BEfficient trimmingIncrease profitGrinding drivesAbrasive surface conditioning devicesElectric machineryEngineering

A device for repairing grinding wheel wear, including a device main body, a left and right sliding chamber is provided at the lower end of the device main body, a large threaded rod is rotatably provided between the left and right walls of the left and right sliding chamber, and the outer circle of the large threaded rod The surface thread is connected with left and right sliding blocks that can slide left and right relative to the inner walls of the left and right sliding chambers. Small threaded rod, the left and right ends of the small threaded rod are threadedly connected with large sliders that can slide left and right relative to the inner wall of the small threaded rod, the upper ends of the large sliders on both sides are hinged to support rods, and the inner walls of the upper and lower sliding chambers The upper end can slide up and down with up and down sliding blocks. The invention realizes the up and down and left and right movement of the repair pin through three different modes of the orbital motor, so that the worn grinding wheel can be trimmed efficiently, improving the utilization rate of resources, reducing loss.

Owner:嘉兴祥盛汽车配件制造有限公司

Water-based anticorrosion coating composition

ActiveCN108884352BEfficient trimmingImprove corrosion resistanceAnti-corrosive paintsPolymer scienceMeth-

The present invention relates to an aqueous coating composition comprising: - an aqueous latex of a copolymer [copolymer (A)] consisting essentially of repeating units derived from: (i) vinylidene chloride (VDC), (ii) vinyl chloride (VC), (iii) one or more than one alkyl (meth)acrylates [monomer (MA)] having from 1 to 12 carbon atoms in the alkyl group and (iv ) one or more than one aliphatic α-β-unsaturated carboxylic acid [monomer (AA)], relative to the total weight of the copolymer, the proportion of recurring units derived from monomer (AA) is at least 1.0 % by weight, wherein: (A) said copolymer (A) is stabilized to dehydrochlorination in such a way that after heat treatment at about 120° C. for 2 hours, relative to the total weight of the copolymer (A), the The total chloride content of the solid residue of the aqueous latex is less than 1000 ppm; (B) said copolymer (A) does not undergo any significant crystallization when heated in such a way that (j) it The ratio of the crystallinity index (CI) after a heat treatment of 48 hours of heating to (jj) its crystallinity index before such heat treatment (CI 热处理之后 / CI 热处理之前 ) is less than 1.15; and - at least one anticorrosion pigment [pigment (P)] comprising an aluminum salt of (poly)phosphoric acid modified with an alkaline earth metal oxide; - at least one nonionic surfactant [surfactant (NS)]; and - at least one inorganic filler different from the pigment (P) [filler (I)] in an amount such that when measured relative to the dry coating composition, comprises from 20% vol. to 40% Total pigment volume concentration (PVC) of vol. including pigment (P) and filler (I).

Owner:SOLVAY SA

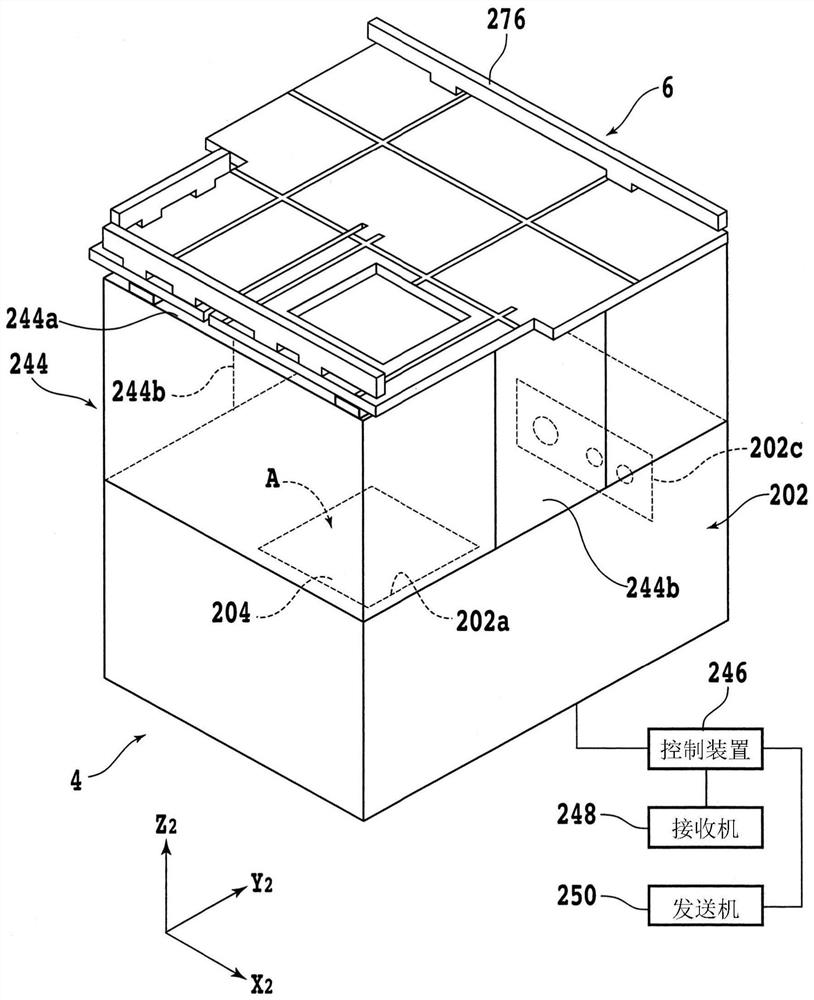

Cutting apparatus, tray, and transport system

PendingCN113492467AEfficient trimmingSemiconductor/solid-state device manufacturingFeeding apparatusTransport systemWorkbench

The invention provides a cutting apparatus, a tray and a transport system. The cutting apparatus can efficiently assemble and disassemble a board relative to a sub-chuck table. A cutting apparatus includes a chuck table having a holding surface used for holding either a workpiece unit that includes a plate-shaped workpiece supported on an annular frame by a tape or a tray shaped similarly to the annular frame, a rest area used for placing a receptacle that houses the workpiece unit or the tray, a transport unit configured to transport the workpiece unit or the tray between the rest area and the chuck table, the transport unit having a holding pad that holds the workpiece unit or the tray, a sub-chuck table that is disposed sideways of the chuck table and has a holding surface used for holding a board for use in adjusting a cutting unit, and a board transport unit configured to transport the board between the tray held on the chuck table and the sub-chuck table.

Owner:DISCO CORP

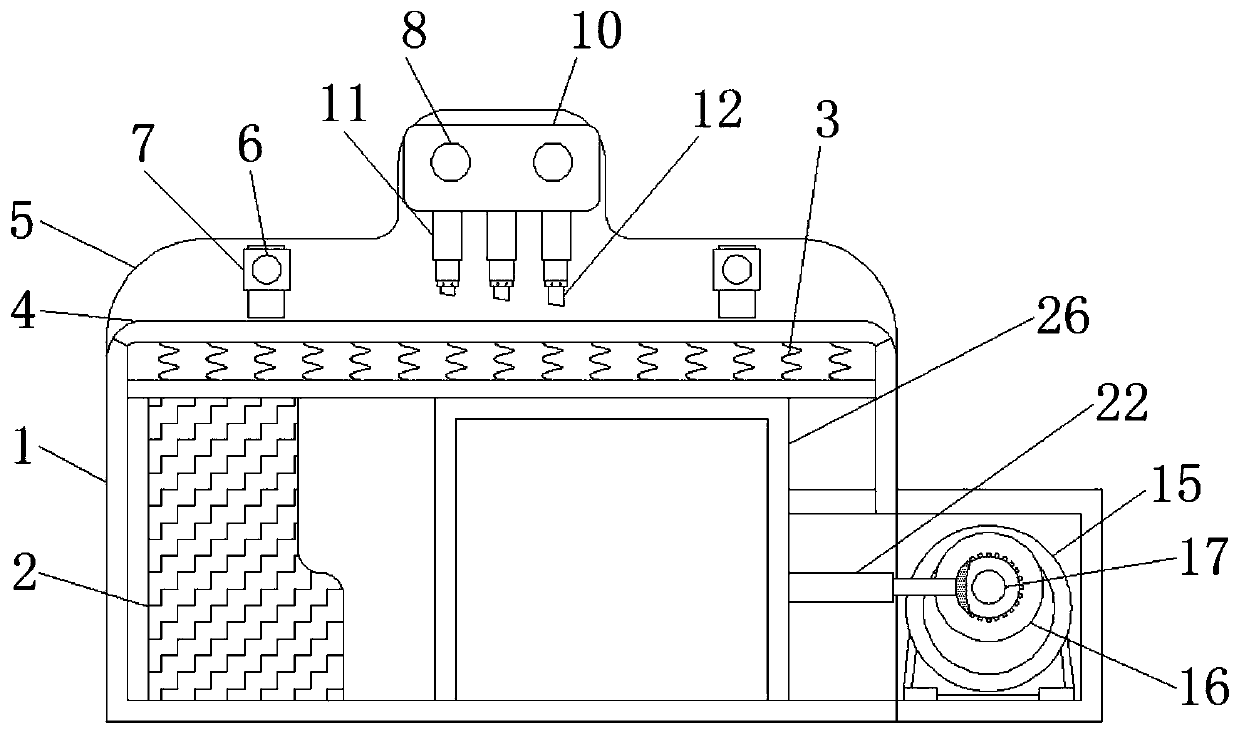

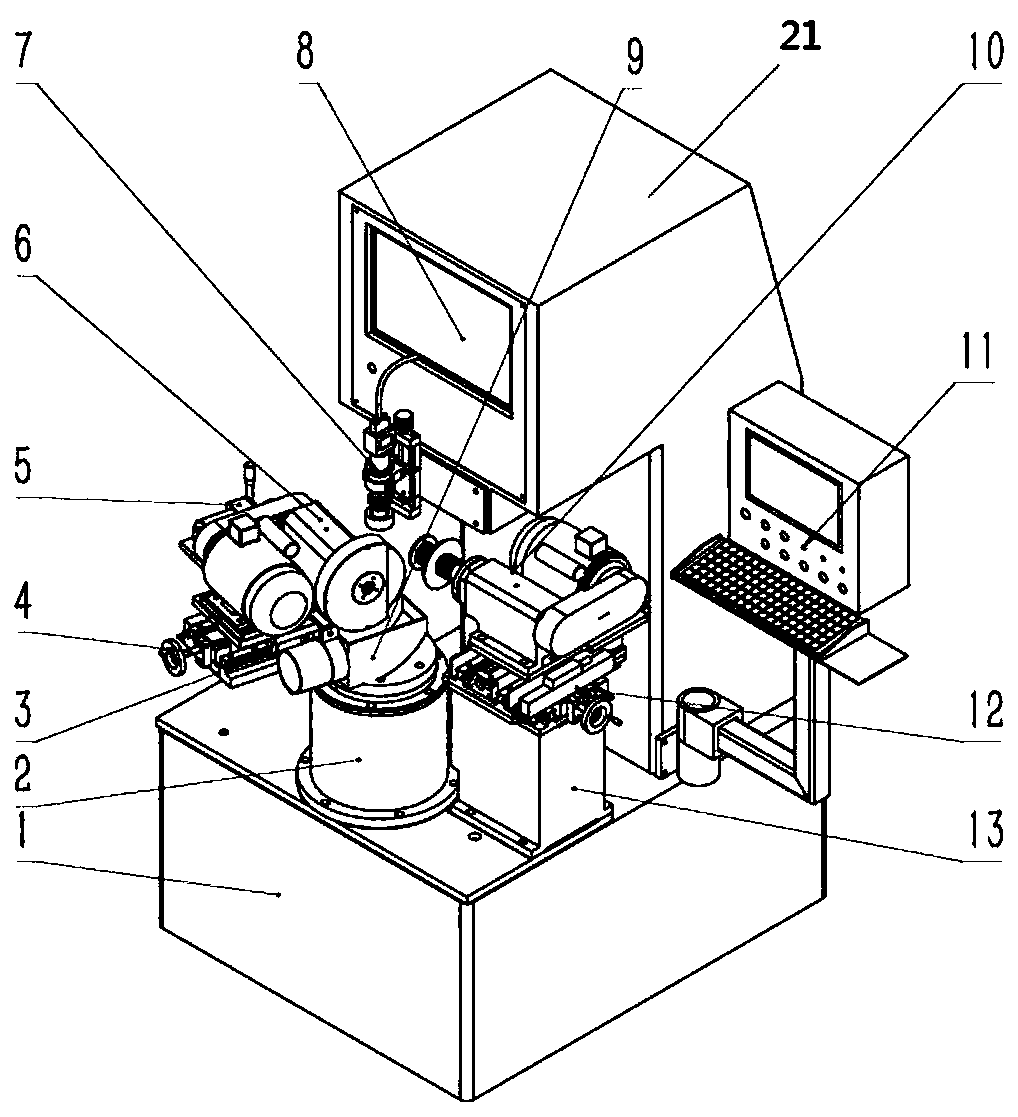

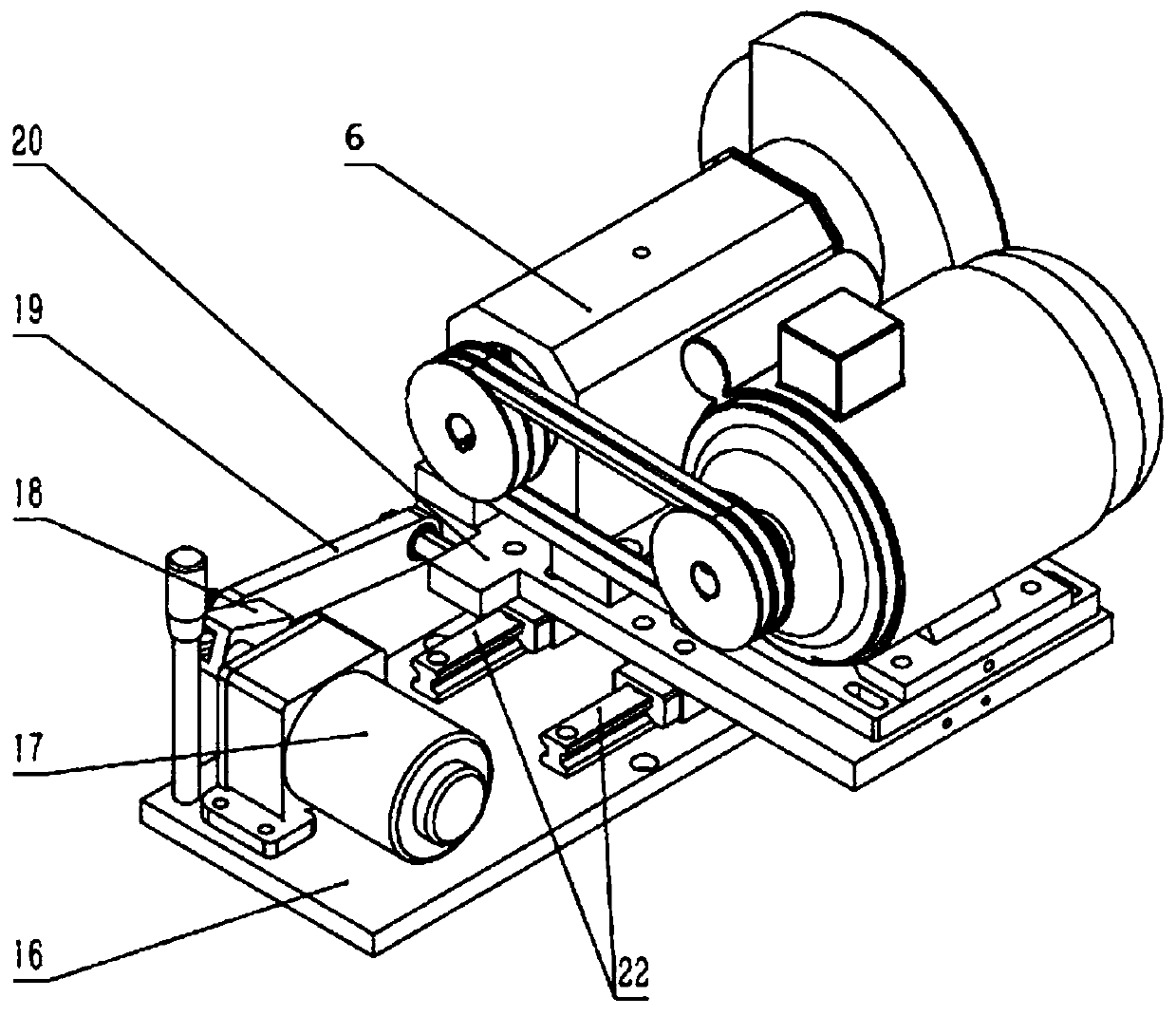

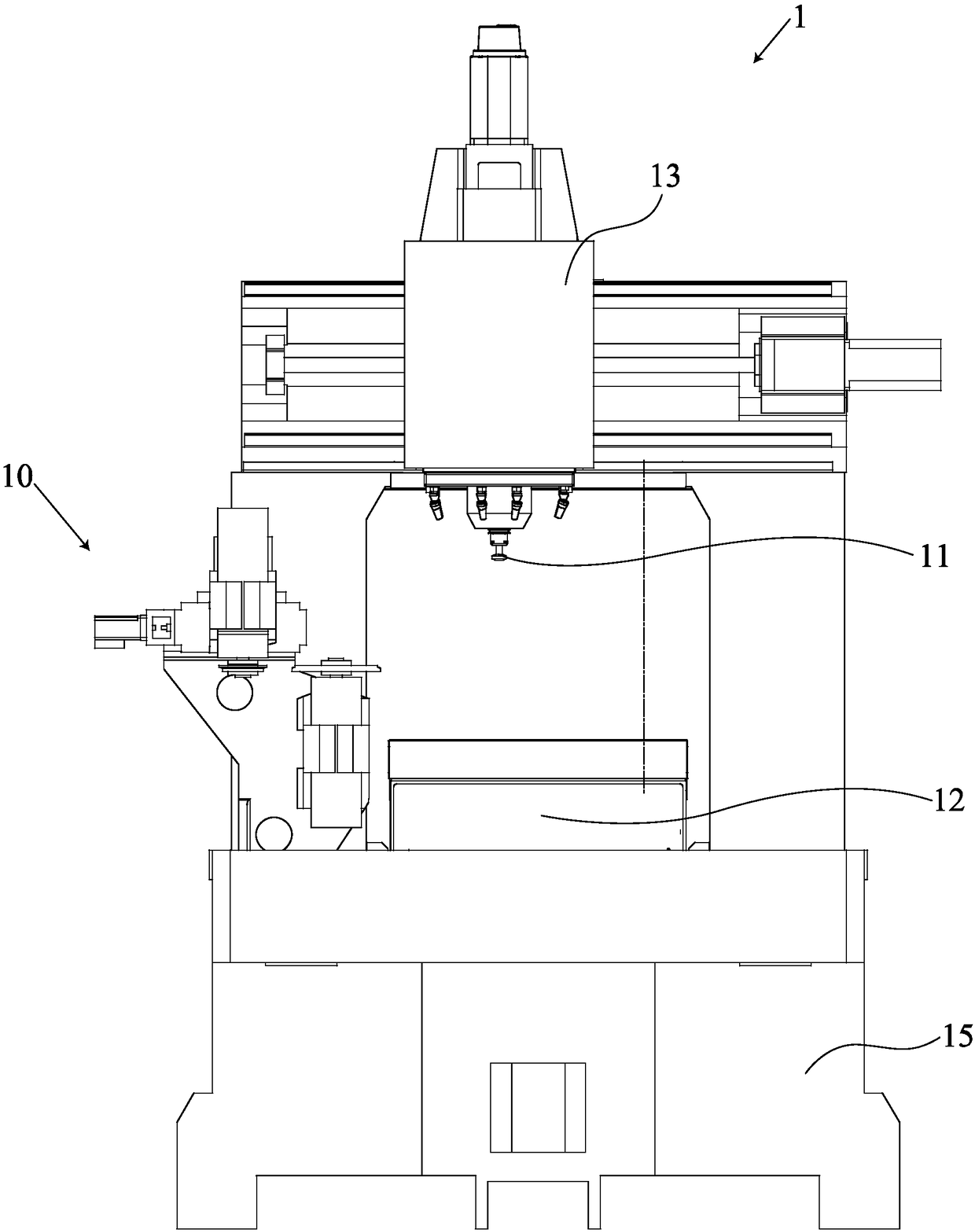

Grinding wheel dressing machine tool and method for dressing grinding wheel

ActiveCN106625252BEfficient trimmingImprove trimming accuracyGrinding drivesAbrasive surface conditioning devicesHardnessSharpening

The invention discloses a grinding wheel dressing machine tool and a grinding wheel dressing method thereof. The grinding wheel dressing machine tool comprises a machine tool body. A dressing grinding wheel assembly, a dressed grinding wheel assembly, an optical measuring frame and a cantilever type console are mounted on the machine tool body. The dressing grinding wheel assembly comprises a rotary fixing seat arranged on the machine tool body, a rotary tray is arranged at the top of the rotary fixing seat, a dressing grinding wheel feeding mechanism is arranged on the rotary tray, and a dressing grinding wheel motor spindle mechanism and a reciprocating mechanism are arranged on the dressing grinding wheel feeding mechanism. The dressed grinding wheel assembly comprises a fixing seat arranged on the machine tool body, and a cross-shaped feeding mechanism and a dressed grinding wheel motor spindle mechanism are arranged at the top of the fixing seat. According to the grinding wheel dressing machine tool and the grinding wheel dressing method thereof, the principle that the rotating speed of a dressed grinding wheel is different from the rotating speed of a dressing grinding wheel, and the grinding wheels are different in particle size and hardness is adopted for achieving shape dressing and sharpening of the dressed grinding wheel, diamond grinding wheels and CBN grinding wheels can be dressed easily and efficiently, and the grinding wheel dressing machine tool has the characteristics of easy operation, high dressing precision, stable structure and the like.

Owner:XINAN TOOLS GUIZHOU PROV

Method for roughly trimming diamond grinding wheel

InactiveCN103042468BReduce the gripQuick removalGrinding feed controlAbrasive surface conditioning devicesMicrometerPulsed laser beam

The invention provides a method for roughly trimming a diamond grinding wheel. The method includes steps of A, scanning the surface of the diamond grinding wheel, acquiring the highest point of the surface of the grinding wheel and determining the position of the highest point in radial, axial and generating line directions; B, emitting a focused pulse laser beam along the inner normal direction of the surface of the grinding wheel and enabling the position of a focal spot of the focused pulse laser beam to be coincided with the position of the highest point of the grinding wheel in the radial, axial and generating line directions; C, erecting a silicon carbide roller at a position opposite to a generating line of the grinding wheel and setting the cutting depth as 0.005mm; and D, repeating the steps once after the grinding wheel is trimmed for 3 to 5 minutes until a circle run-out error of the grinding wheel is not larger than 20 micrometers. The method has the advantages that diamond grains are ablated and directly removed by the focused pulse laser beam, remaining diamond grains are removed by the silicon carbide roller, deteriorative layers of surfaces of the grains which are ablated by laser, grains without holding force and the like are mechanically peeled off, and the method is applicable to efficiently roughly trimming diamond grinding wheels with large grains.

Owner:HUNAN UNIV

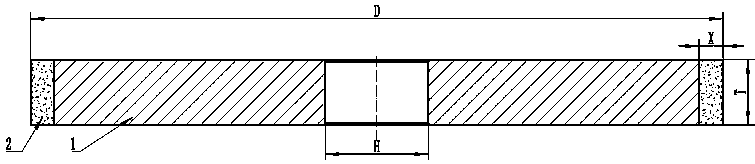

A kind of optical curve grinding wheel and its preparation method

ActiveCN111496699BSimple processing technologySimple and fast operationTransportation and packagingAbrasion apparatusSuperhard materialGrinding wheel

The invention belongs to the technical field of dressing of superhard grinding wheels, and in particular relates to an optical curve grinding wheel for dressing superhard material chamfering grinding wheels of metal bond; it includes a base body and an abrasive layer, and the abrasive layer includes the following raw materials in parts by weight: abrasive 30-40 parts, and 60-70 parts of metal bonding agent; the metal bonding agent is composed of the following raw materials in parts by weight: 30-55 parts of copper powder, 25-50 parts of tin powder, and 5-10 parts of silver powder. The grinding wheel formula and processing technology of the invention are simple, and the operation is simple and convenient; the metal bond superhard material chamfering grinding wheel can be trimmed, the processing effect is good, and the micro groove size of the chamfering grinding wheel can reach the accuracy of plus or minus 0.01mm.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Surface finishing process of stainless steel cleaning utensils used in pharmaceutical workshop

The invention relates to a surface finishing process of stainless steel sanitary appliances for pharmaceutical workshops. The surface finishing process includes following steps: 1), surface coarse grinding; 2), surface accurate grinding; 3), surface polishing; 4), surface coarse drawing; 5), surface accurate drawing; 6), surface finishing. The surface finishing process has the advantages that appearance quality of the stainless steel sanitary appliances is improved remarkably, and the process has quite good effect on finishing welding surfaces of the stainless steel sanitary appliances and finishing surface find sand grains and is worthy of popularization and application.

Owner:扬州江净航空设备科技有限公司

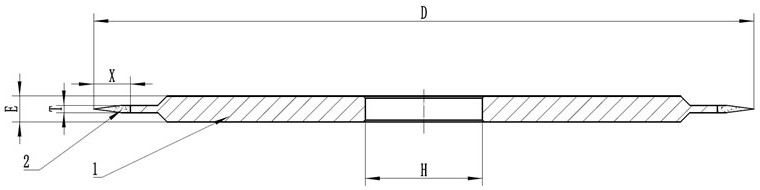

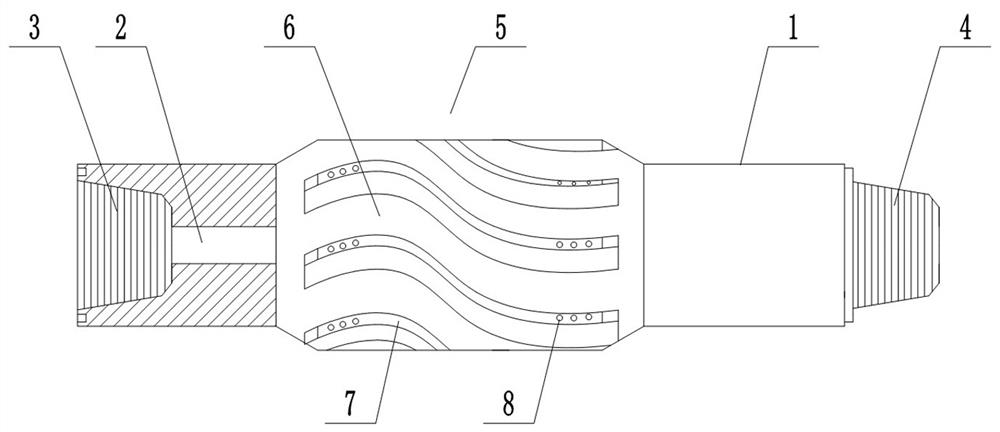

Bidirectional borehole trimmer for well drilling

PendingCN113153198AEfficient trimmingAvoid drill stickingBorehole/well accessoriesWell drillingStructural engineering

The invention provides a bidirectional borehole trimmer for well drilling. The bidirectional borehole trimmer comprises a body, a channel is formed in the body in the axial direction of the body, one end of the body is provided with an internal thread used for being in threaded connection with a drill rod, the other end of the body is provided with an external thread used for being in threaded connection with the drill rod, the middle of the body is a working section, a plurality of spiral grooves are formed in the surface of the working section in the circumferential direction, cutting teeth are arranged on flanges on the two sides of each spiral groove, the cutting teeth are distributed at the two ends of the outer surface of each flange and are made of high-wear-resistance alloy, and the number and the arrangement mode of the cutting teeth are not limited. According to the bidirectional borehole trimmer for well drilling provided by the invention, the cutting teeth arranged on the convex edges of the working section of the bidirectional borehole trimmer can be used for efficiently trimming a borehole during tripping-in and tripping-out, so that the phenomenon of jamming of a drill is avoided, the construction efficiency is effectively improved, and the construction cost is saved.

Owner:河南易发石油工程技术有限公司

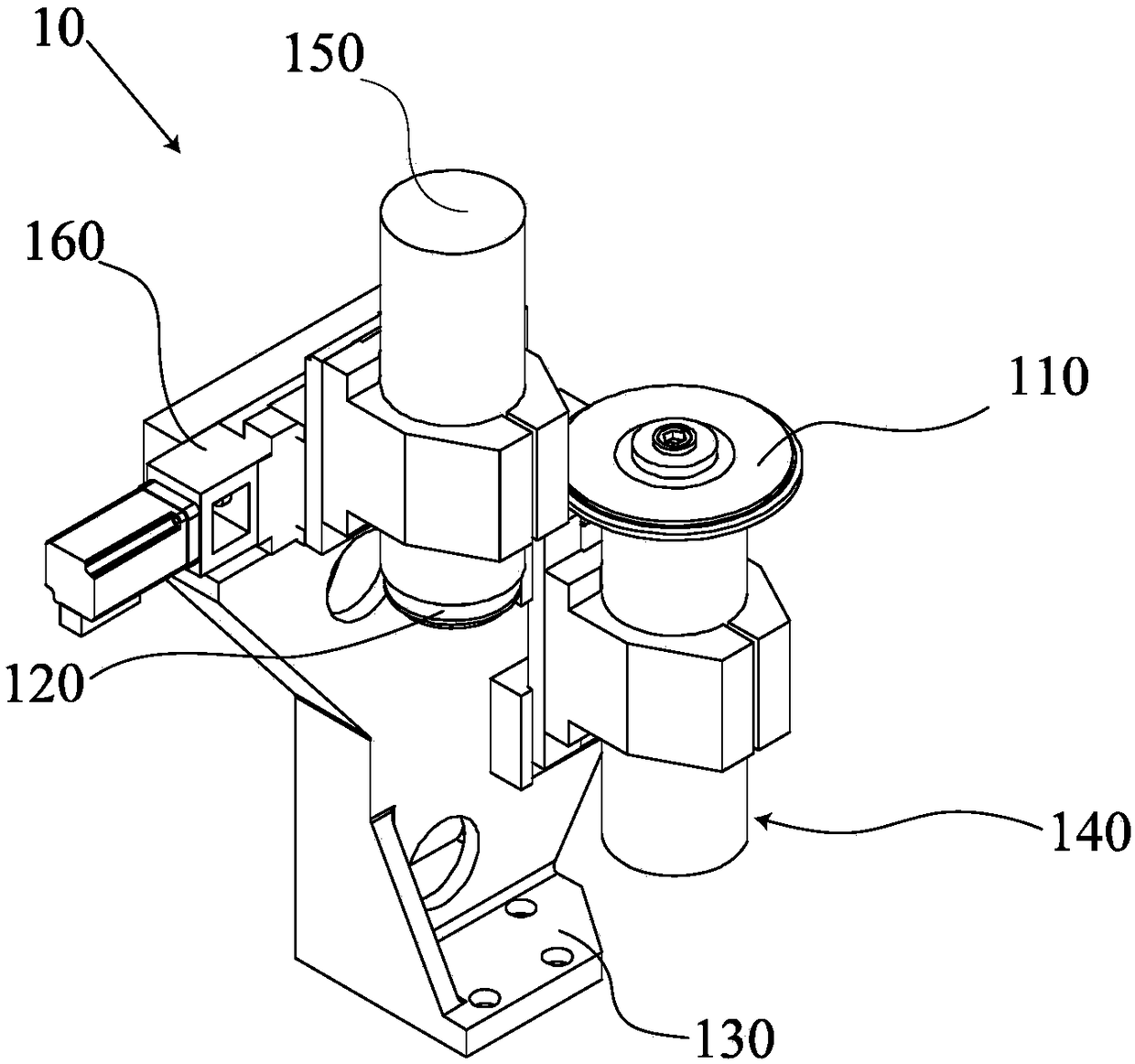

Dressing unit and numerical control processing device

PendingCN109202726AEfficient trimmingIncrease productivityAbrasive surface conditioning devicesNumerical controlEngineering

The invention provides a dressing unit for dressing a grinding wheel which is used for processing a workpiece. The dressing unit comprises a rack, a first driving part and a second driving part, wherein the first driving part is arranged on the rack and comprises a first rotating shaft; a first dressing wheel can be mounted on the first rotating shaft; the first driving part is numerically controlled to drive the first rotating shaft to rotate at a first preset rotating speed in order to dress the grinding wheel while the first dressing wheel is combined with the grinding wheel; the second driving part is arranged on the rack and comprises a second rotating shaft; a second dressing wheel is mounted on the second rotating shaft; and the second driving part is numerically controlled to drivethe second rotating shaft to rotate at a second preset rotating speed in order to dress the first dressing wheel while the second dressing wheel is combined with the first dressing wheel. The invention also provides a numerical control processing device.

Owner:广东科杰技术股份有限公司 +1

A kind of superhard grinding tool dressing tool and preparation method thereof

The invention relates to a superhard abrasive dressing tool, which is made of the following raw materials in mass percentage: 30-55% of ordinary abrasive, 10-35% of PTFE powder, 20-40% of resin powder, and 5-5% of modified filler 34%, reinforced fiber material 5‑10%, coupling agent 1‑6%. The dressing tool of the present invention has a wide range of applications, high efficiency and low cost, and can be applied to dressing of diamond and CBN grinding wheels with a particle size of 45# to 20000# for various hardness binders; the dressing efficiency is lower than 3-10min, and the dressing effect is excellent. Can reach 1cm 2 The sharpness rate of abrasives on the plane is above 98%.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

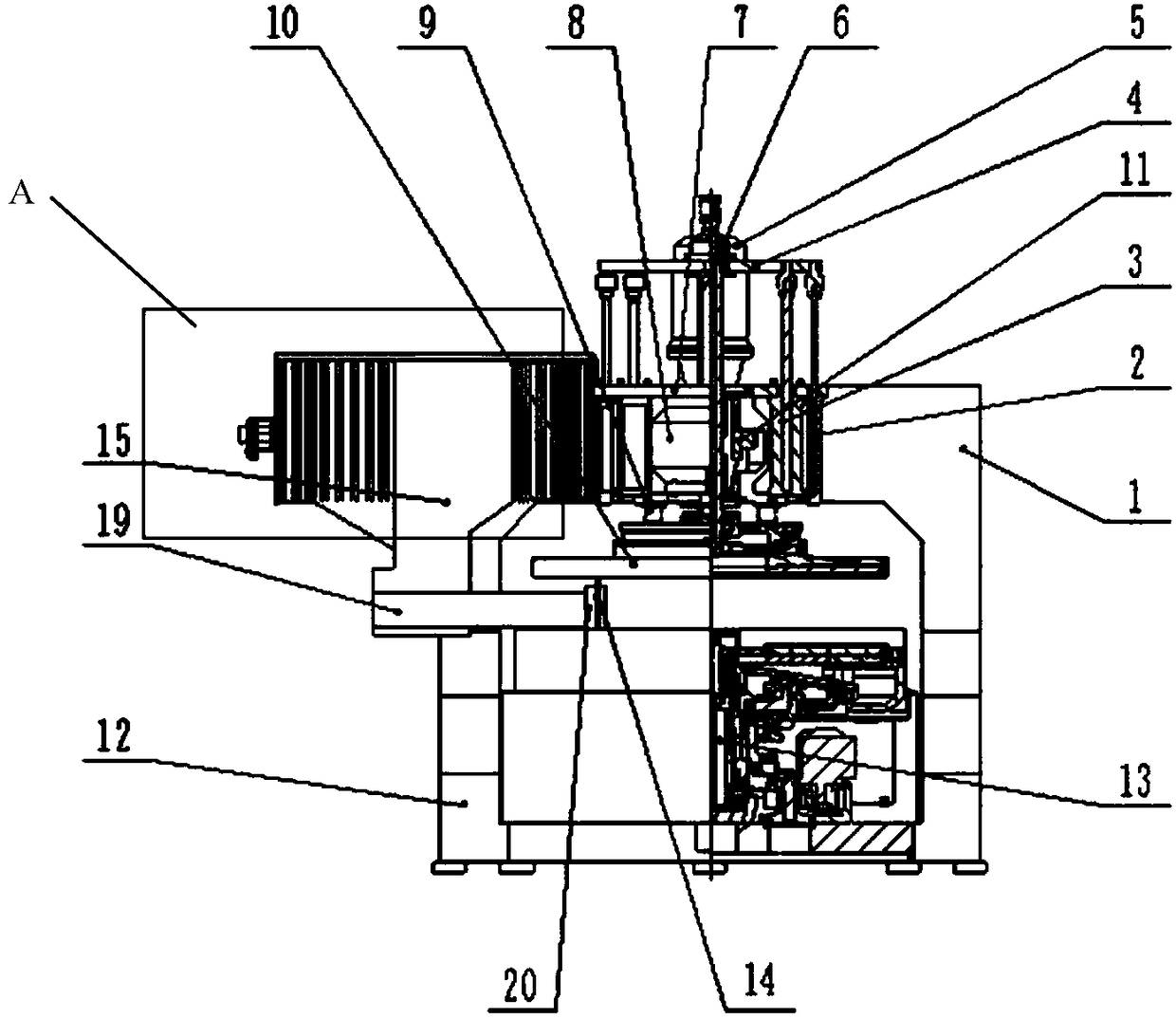

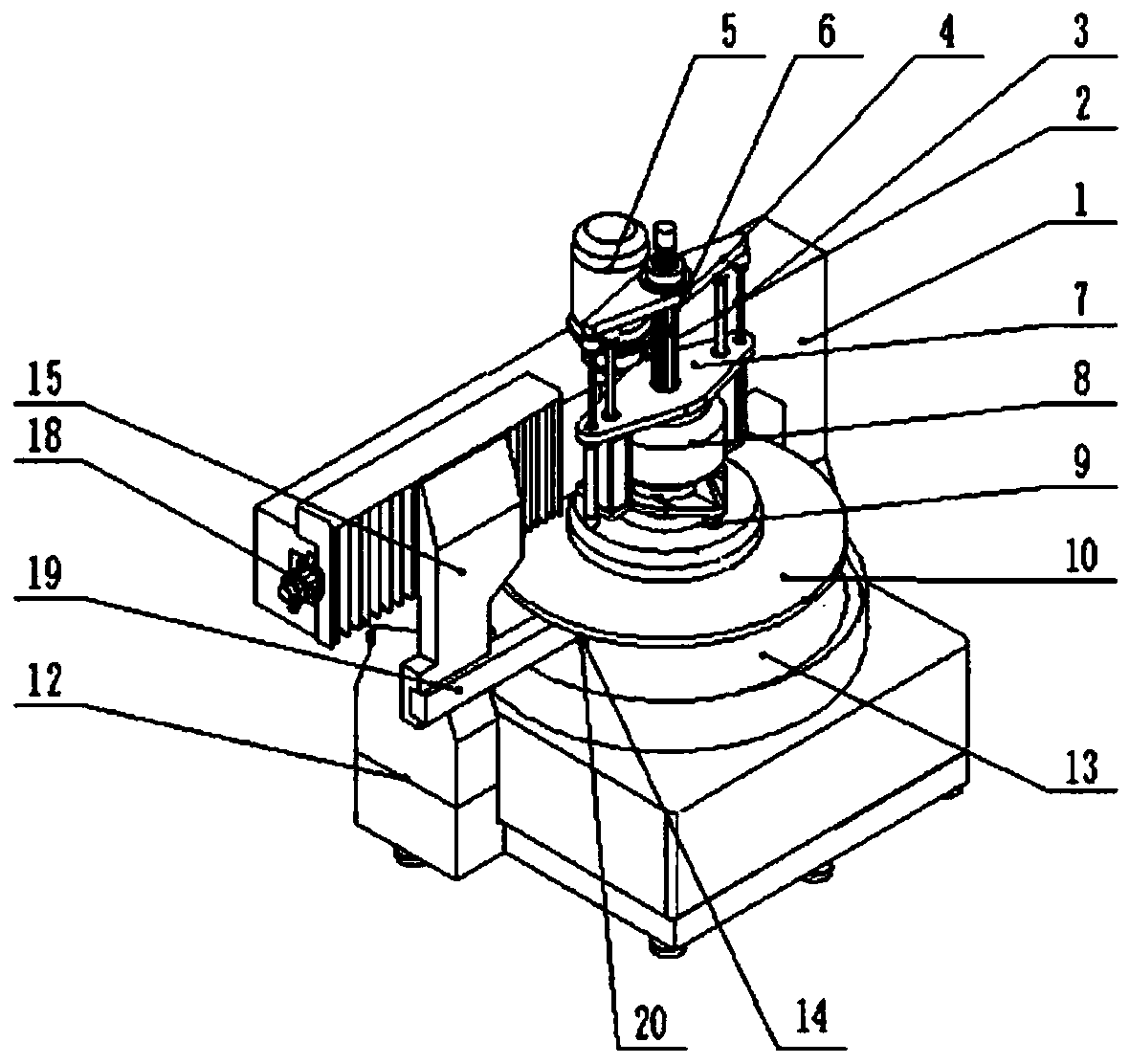

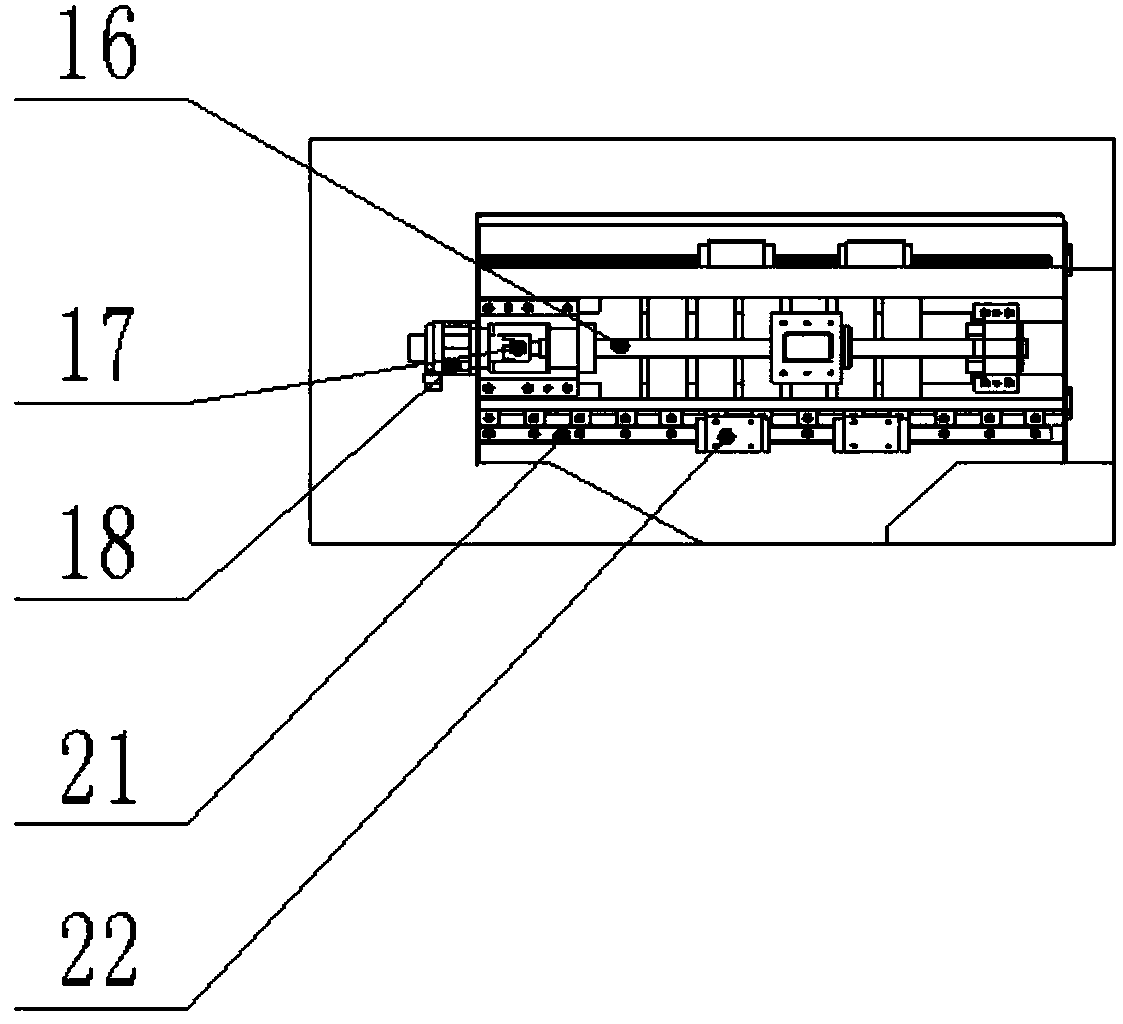

A high-precision balanced sapphire double-sided grinding machine

ActiveCN106737126BImprove balanceEfficient trimmingLapping machinesAbrasive surface conditioning devicesGear wheelEngineering

The invention relates to a high-precision balanced-type sapphire double-surface grinding machine. The machine comprises a bottom frame (12), a gantry column (1), a lower plate system (13) and an upper plate system (10). The upper plate system and the lower plate system are arranged on a spindle shaft (6) in a sleeving mode and capable of rotating coaxially. A balanced-type upper-plate device sleeved on the spindle shaft is arranged above the upper plate system. A planetary gear decelerator (5) downwardly extending along an output shaft is arranged on a crossbeam of the gantry column. A gear of the planetary gear decelerator at the lower end of the output shaft is engaged with a gear (11) arranged at the lower part of the spindle shaft in a sleeving mode. One side of the crossbeam of the gantry column is provided with a transverse lead screw (16) and a pair of linear sliding rails (12). The lead screw is equipped with a nut seat which is firmly connected with a sliding saddle (15) horizontally sliding along a linear sliding rail. The outside of the crossbeam is provided with a servo motor (18). An output shaft of the servo motor is connected with the lead screw. The lower end of the sliding saddle is connected with a transverse knife rod (19). The front end of the transverse knife rod is provided with a knife chuck (20) and upper and lower knives (14). The high-precision balanced-type sapphire double-surface grinding machine is simple in structure, reliable in performance and easy in operation and control.

Owner:昆明台鼎精密机械有限公司 +1

Tooth surface processing device and gear manufacturing method

ActiveCN104507613BImprove surface roughnessAvoid Grinding BurnsGrinding feed controlBonded abrasive wheelsSurface roughnessEngineering

A gear tooth surface processing device and a gear manufacturing method are provided which are capable of adjusting processing pressure for the purpose of improving the surface roughness of high-hardness gears and the like. The gear tooth processing device (10) has: a helical grindstone (2); a position adjusting means (3) which is capable of moving the relative positions of a rotary axis (C) of the helical grindstone (2) and a rotary axis (X) of a gear to be processed (W); and a control means (7). The control means (7) includes: a position control unit (71) which operates the position adjusting means (3) so as to adjust the relative positions of the rotary axis (C) of the helical grindstone (2) and the rotary axis (X) of the gear to be processed (W) to cause only one of the tooth surfaces to be processed (11), from among the gear tooth surfaces that form a single tooth of the gear to be processed (W), to make contact with a grindstone tooth surface (21) of the helical grindstone (2) such that the helical grindstone (2) and the gear to be processed (W) are engaged; a grindstone rotation means control unit (72) for operating a grindstone rotation means (4); and a torque control means control unit (73) for operating a rotation torque control means (5) so as to adjust the rotation torque within a predetermined range.

Owner:AISIN AI CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com