A kind of diamond grinding wheel dressing method

A diamond grinding wheel and diamond technology, used in metal processing equipment, abrasive surface adjustment devices, manufacturing tools, etc., can solve the problems of poor dressing effect, low dressing accuracy, low hardness, etc., and achieve the effect of avoiding excessive consumption and cutting edge. good effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The diamond grinding wheel dressing method of the present embodiment comprises the steps:

[0034] 1) Take the whole diamond grinding wheel to be dressed. The diamond grinding wheel to be repaired is a resin bonded diamond micropowder grinding wheel, and the particle size of diamond in the diamond grinding wheel to be repaired is 400 mesh, and the concentration is 75%. The diamond grinding wheel to be conditioned includes a base body of the grinding wheel to be conditioned, the base body of the grinding wheel to be conditioned is an annular disc, and a diamond abrasive layer is arranged on the outer peripheral surface of the annular disc. The angle α between the cutting surface of the outer peripheral surface of the diamond abrasive layer and the side surface of the diamond grinding wheel is 90°. The diameter of the grinding wheel to be trimmed is 10 mm, and the thickness is 10 mm.

[0035] Take the electroplated diamond grinding wheel. The particle size of the diamo...

Embodiment 2

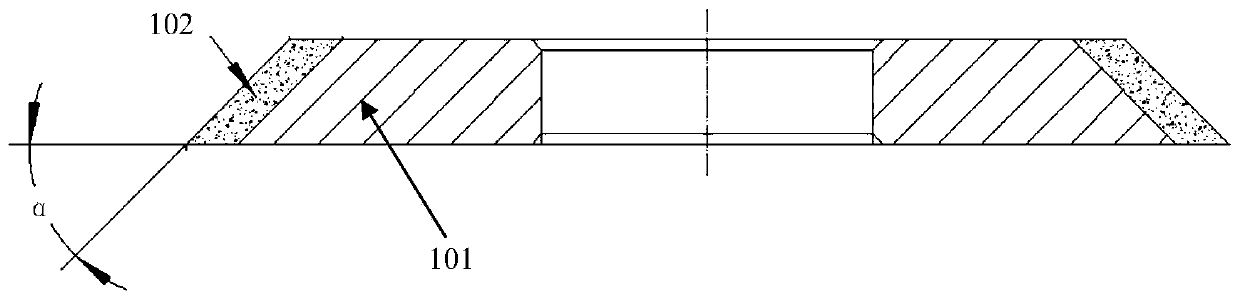

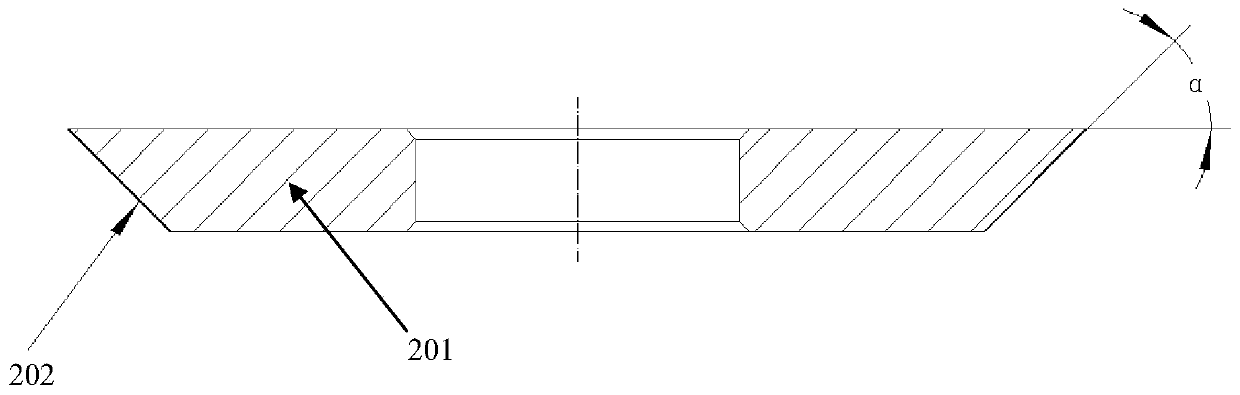

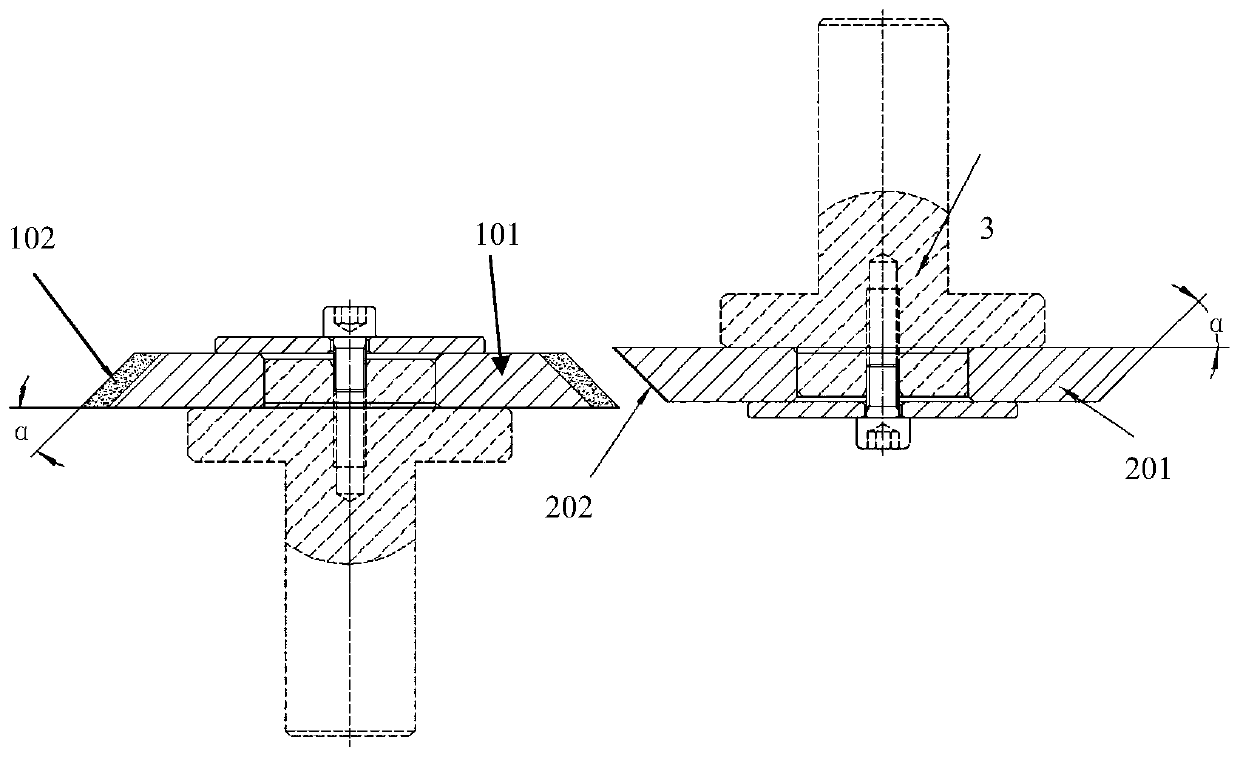

[0043] The diamond grinding wheel dressing method of the present embodiment, as Figure 1-Figure 3 shown, including the following steps:

[0044] 1) Take the whole diamond grinding wheel to be dressed. The diamond grinding wheel to be repaired is a resin bond diamond micropowder grinding wheel, and the particle size of diamond in the diamond grinding wheel to be repaired is 600 mesh, and the concentration is 75%. The diamond grinding wheel to be conditioned includes a grinding wheel base 101 to be conditioned, which is an annular disk, and a diamond abrasive layer 102 is arranged on the outer peripheral surface of the annular disk. The angle α between the cut surface of the outer peripheral surface of the diamond abrasive layer and the side surface of the diamond grinding wheel is 75°. The diameter of the grinding wheel to be trimmed is 15mm and the thickness is 8mm.

[0045] Take the electroplated diamond grinding wheel. The particle size of the diamond abrasive in the el...

Embodiment 3

[0053] The diamond grinding wheel dressing method of the present embodiment comprises the steps:

[0054] 1) Take the whole diamond grinding wheel to be dressed. The diamond grinding wheel to be repaired is a resin bond diamond micropowder grinding wheel, and the particle size of diamond in the diamond grinding wheel to be repaired is 1000 mesh, and the concentration is 125%. The diamond grinding wheel to be conditioned includes a base body of the grinding wheel to be conditioned, the base body of the grinding wheel to be conditioned is an annular disc, and a diamond abrasive layer is arranged on the outer peripheral surface of the annular disc. The angle α between the cutting surface of the outer peripheral surface of the diamond abrasive layer and the side surface of the diamond grinding wheel is 45°. The diameter of the grinding wheel to be trimmed is 25mm, and the thickness is 25mm.

[0055] Take the electroplated diamond grinding wheel. The particle size of the diamond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com