A kind of superhard grinding tool dressing tool and preparation method thereof

A technology for dressing tools and superhard abrasives, which is applied in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc. Iron materials have problems such as low dressing efficiency, which is beneficial to mass production and preparation, wide applicability, and high brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation particle size is 120#, length × width × height is 100mm × 50mm × 5mm dressing tool (dressing plate), it is made of raw material common abrasive, PTFE powder, resin powder, modified filler, reinforcing fiber material and coupling agent , see Table 2 for the weight percentage and type and model of each raw material.

[0034] Table 2 The weight percentage and type model of each raw material

[0035] materials Particle Size / Particle Size mass percentage Manufacturer / Model Green silicon carbide 120# 30 Baige Abrasives Co., Ltd. PTFE powder 60-80μm 15 Shenyang Wuliang Technology Co., Ltd. Phenolic resin powder 60-80μm 25 Jinan Shengquan Group / PF-2827 silica 240# 20 Shanghai Chaowei Nano Technology Co., Ltd. glass fiber 10μm 5 China Jushi Co., Ltd. coupling agent / 5 KH550

[0036] The preparation method of the above-mentioned superhard abrasive dressing tool specifically includes the ...

Embodiment 2

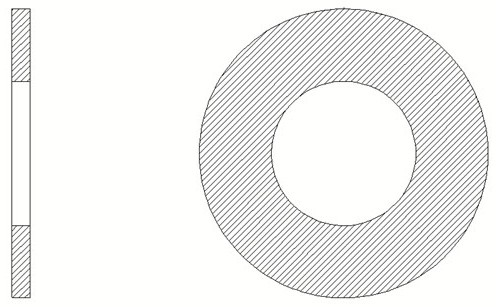

[0045] Preparation particle size is 400#, and outer diameter * inner diameter * height is the trimming tool (dressing ring, see figure 1 ), which is made from raw material common abrasive, PTFE powder, resin powder, modified filler, reinforcing fiber material and coupling agent, and the weight percentage and type model of each raw material are shown in Table 4.

[0046] Table 4. The weight percentage and type and model of each raw material

[0047] materials Particle Size / Particle Size mass percentage Model / manufacturer White corundum 400# 35 Baige Abrasives Co., Ltd. PTFE powder 30-50μm 10 Shenyang Wuliang Technology Co., Ltd. Polyimide Resin Powder 30-50μm 30 Jinan Shengquan Group calcium carbonate 600# 11 Shanghai Chaowei Nano Technology Co., Ltd. glass fiber 10μm 10 China Jushi Co., Ltd. coupling agent / 4 KH550

[0048] The preparation method of the above-mentioned superhard abrasive dressing too...

Embodiment 3

[0057] The preparation particle size is 800#, outer diameter × inner diameter × height is the trimming tool (dressing ring) of 100mm × 80mm × 10mm, it is made of raw material common abrasive, PTFE powder, resin powder, modified filler, reinforcing fiber material and coupling agent See Table 6 for the weight percentage and type and model of each raw material.

[0058] Table 6 The weight percentage and type model of each raw material

[0059] materials Particle Size / Particle Size mass percentage Model / manufacturer boron carbide 800# 30 Shanghai Chaowei Nano Technology Co., Ltd. PTFE powder 10-18μm 20 Shenyang Wuliang Technology Co., Ltd. Polyimide Resin Powder 10-20μm 25 Jinan Shengquan Group Titanium dioxide 1000# 15 Shanghai Chaowei Nano Technology Co., Ltd. Asbestos silk 10μm 9 China Jushi Co., Ltd. coupling agent / 1 KH792

[0060] The preparation method of the above-mentioned superhard abrasive dre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com