Ultrahard abrasive grinding wheel compounded efficient and precise finishing method

A superabrasive, composite technology, applied in the direction of abrasive surface adjustment devices, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as high-temperature carbonization, expensive dressing devices, and abrasive wear on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

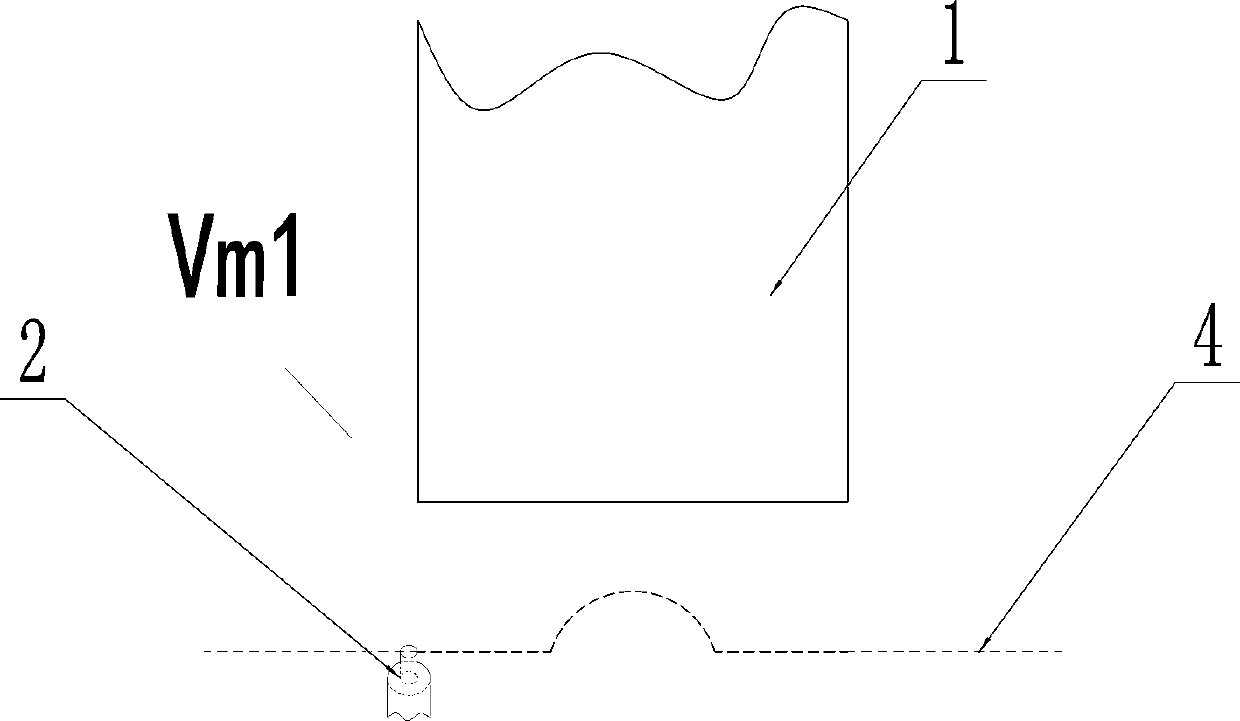

[0039] like Figure 1-Figure 6 As shown, a superabrasive grinding wheel composite efficient precision dressing method comprises the following steps:

[0040] Step 1. Abrasive Waterjet Rough Repair:

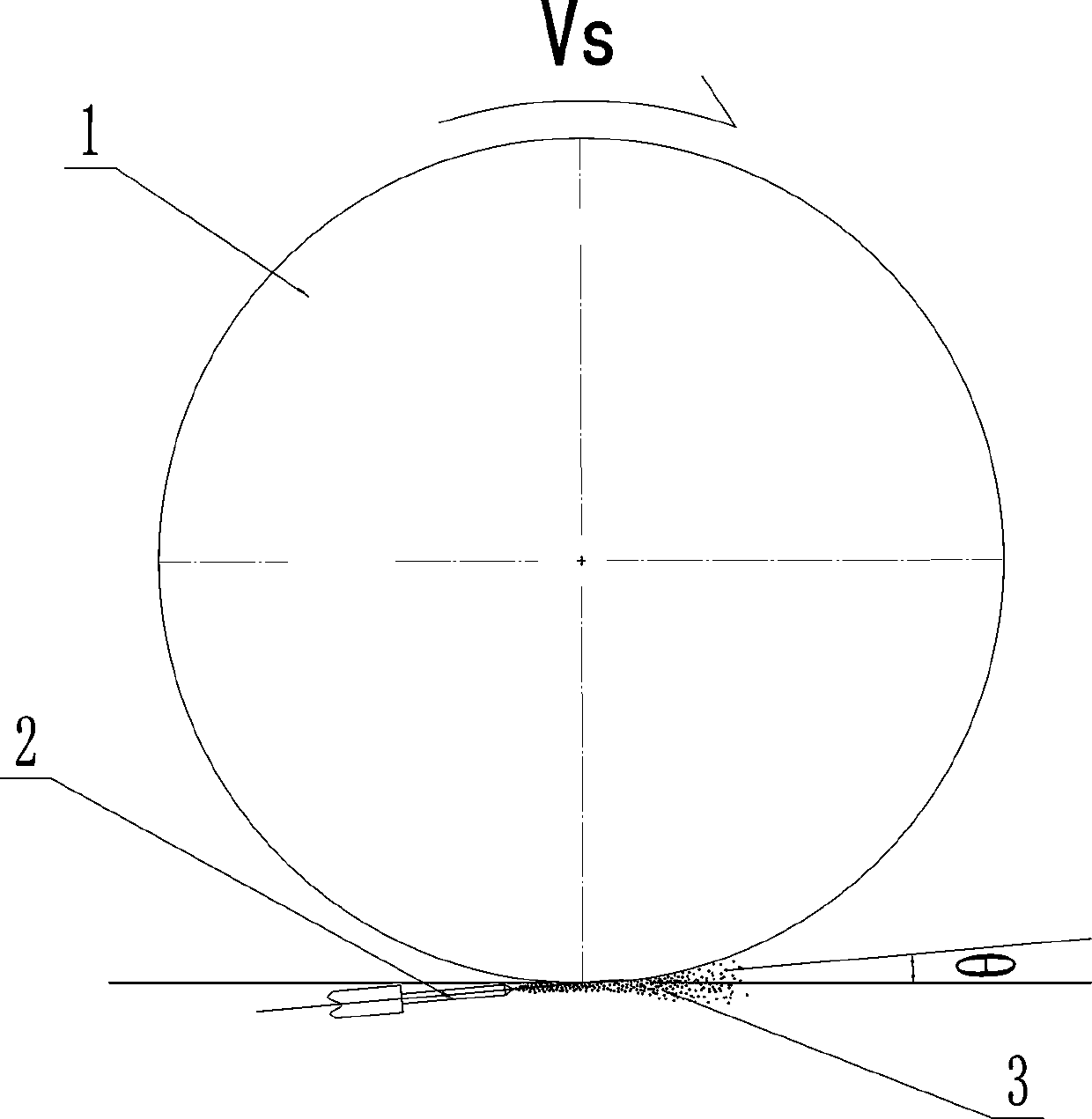

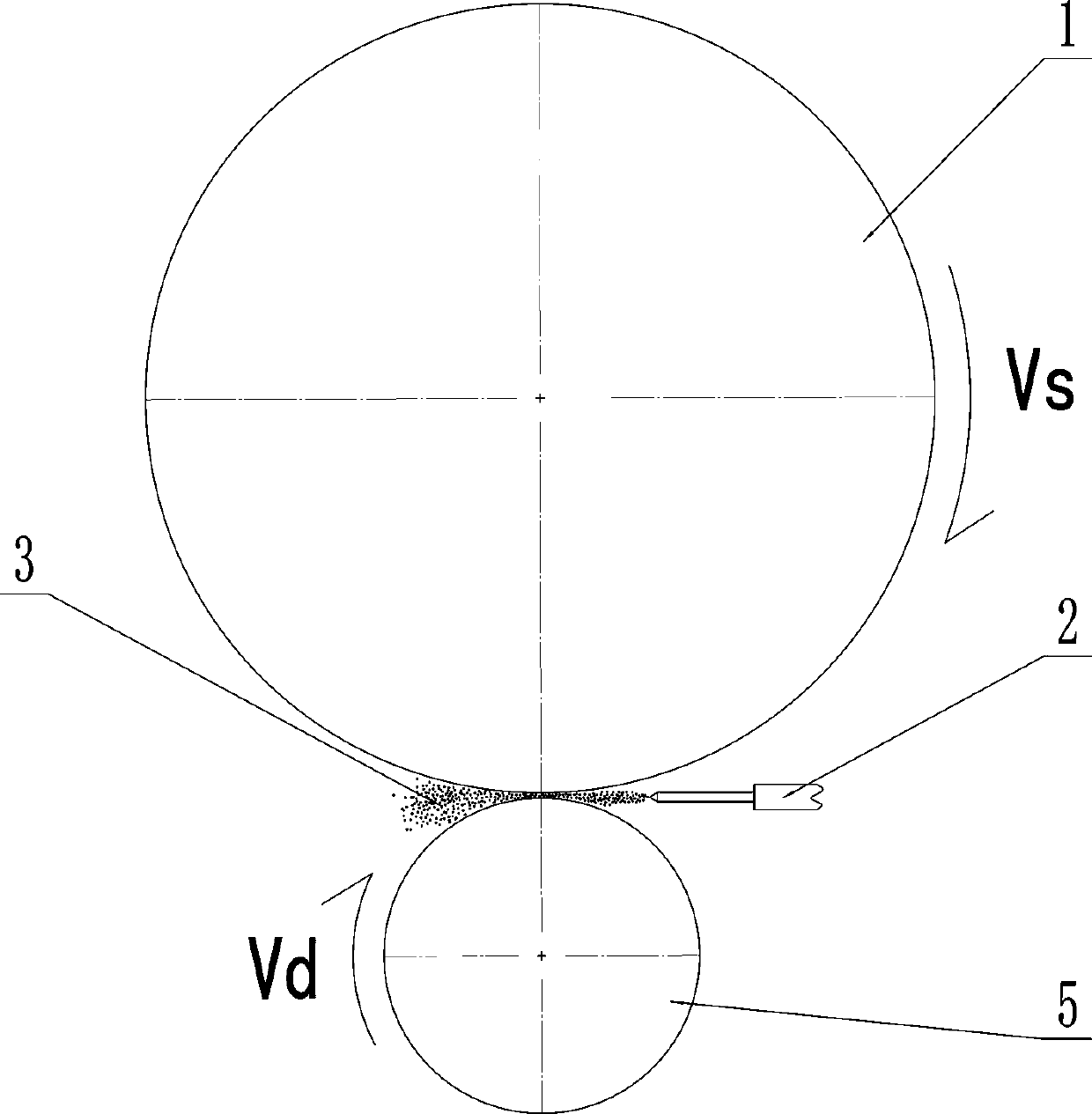

[0041] The superabrasive grinding wheel rotates at a certain speed, and the injection direction of the abrasive water jet 3 is perpendicular to the axis of the superabrasive grinding wheel 1, and forms a certain angle with the tangent line of the outer circle of the superabrasive grinding wheel 1. The tangent line of the outer circle is consistent, and the spraying effect is small. If the angle is too large, it is easy to remove too much bonding agent and abrasive particles. Therefore, the angle should be controlled within a reasonable small angle range;

[0042] At the same time, the abrasive water jet nozzle 2 reciprocates along the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com