Automatic rod changing device for drill carriage and rod feeding and collecting method thereof

A rod device and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of drill pipe slipping, drilling angle uncertainty, etc., and achieve the effect of convenient rod changing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

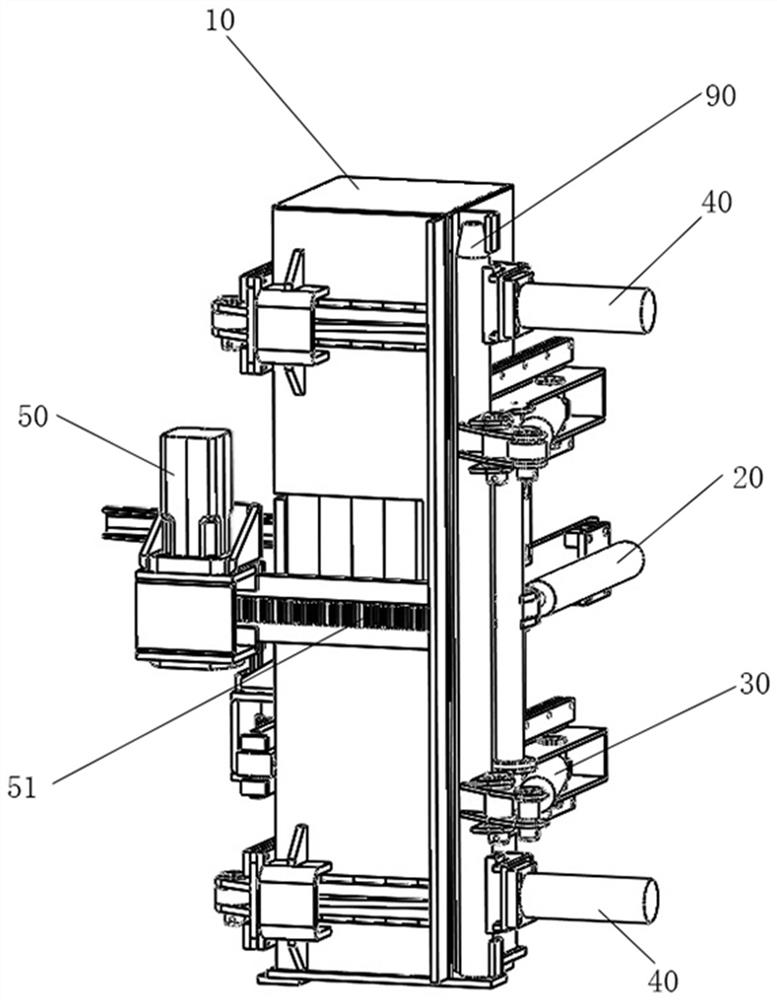

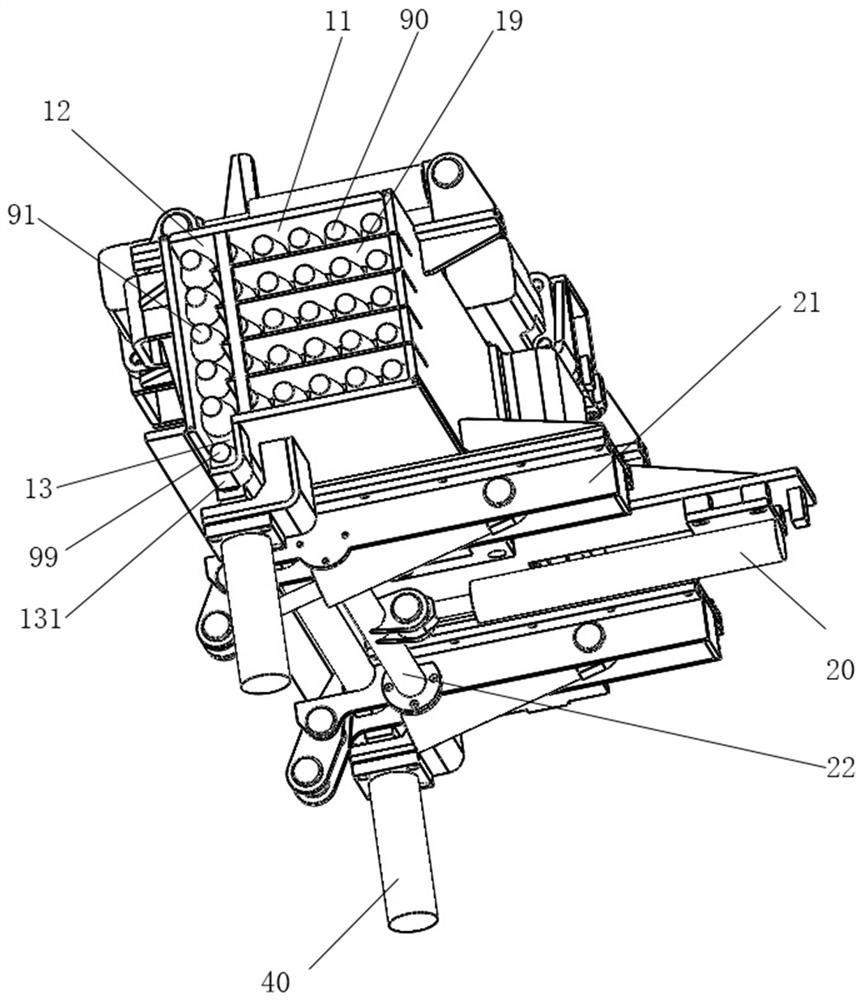

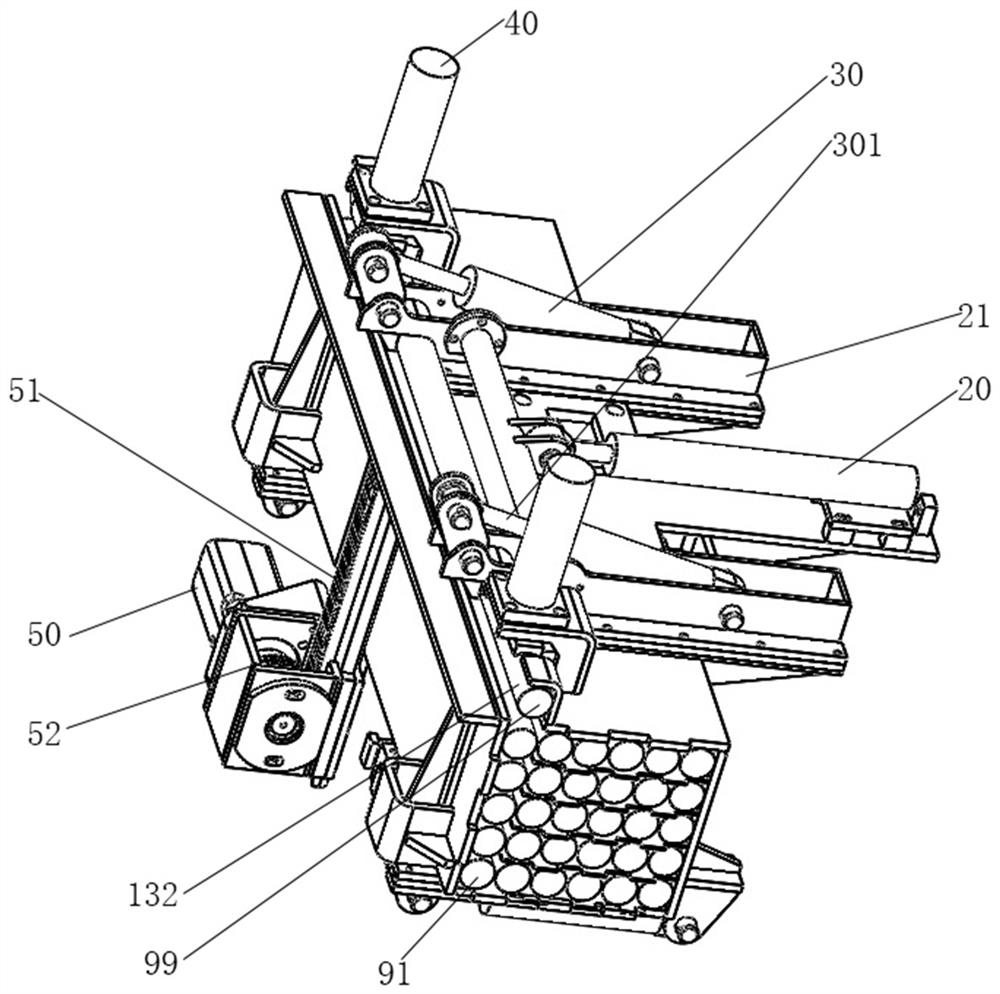

[0045] Such as figure 1 , 3 , 5, an automatic rod changing device for a drilling rig, comprising a drill rod box 10, the wall of the drill rod box 10 is provided with a rod sending motor A50, a rod sending motor B60, a delivery cylinder 20, a rod receiving cylinder A40, a rod receiving Cylinder B70.

[0046] Such as figure 2 , the interior of the drill rod box 10 is divided into a normal warehouse 11 and a turnover warehouse 12 that are connected to each other. A discharge bracket 131 is fixed on the wall of the drill rod box 10. The space wrapped by the discharge bracket 131 is the delivery warehouse 13, the turnover warehouse 12 communicates with the delivery bin 13. The meaning of the connection is "the drill pipe can be moved from one bin to another bin". The normal bin 11 is provided with multiple rows of drill pipes 90 parallel to the turnover bin 12, and each row of drill pipes 90 includes There are a plurality of drill pipes 90 , the turnover bin 12 is a single row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com