Optical curve grinding wheel and preparing method thereof

An optical curve grinding and grinding wheel technology, which is used in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of inability to carry out mass production of chamfered grinding wheels, inability to process chamfered grinding wheels, and changes in grinding performance. It is not easy to lose accuracy, facilitates heat transfer, and reduces the effect of grinding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

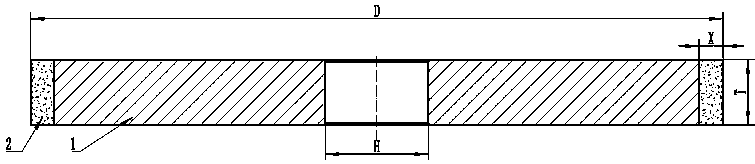

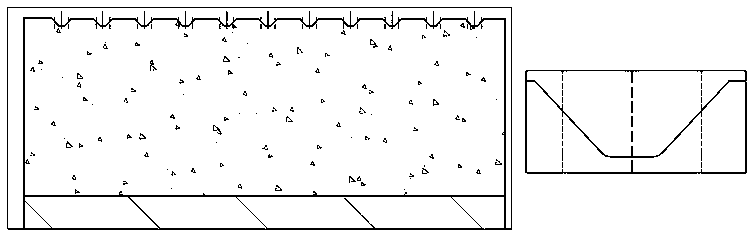

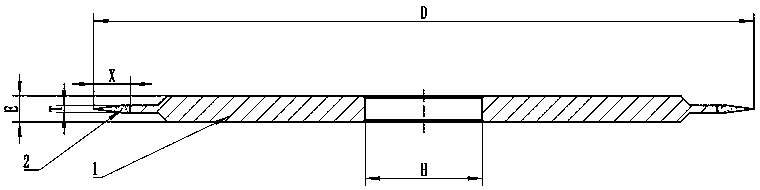

[0033] Such as image 3 As shown, an optical curve grinding wheel includes a stainless steel substrate 1 and an abrasive layer 2, wherein the abrasive layer 2 includes abrasive materials and a metal bond, and is specifically composed of the following raw materials in parts by weight: 35 parts of copper powder, tin powder 25 parts, silver powder 10 parts, cubic boron nitride 30 parts (400 mesh).

[0034] The thickness of the abrasive layer 2 is lower than that of the substrate 1, and the edge of the abrasive layer 2 is designed with sharp corners, which is more convenient for dressing the chamfering grinding wheel. In the present invention, the emery wheel model that adopts is 14E1 , where: D represents the diameter of the grinding wheel, T represents the thickness of the abrasive layer, H represents the diameter of the inner hole of the grinding wheel, E represents the total thickness of the grinding wheel substrate, and X represents the width of the abrasive layer.

[0035...

Embodiment 2

[0044] For the optical curve grinding wheel provided in this embodiment, compared with Embodiment 1, the formulation of the abrasive layer is adjusted as follows:

[0045] The abrasive layer is composed of the following raw materials in parts by weight: 30 parts of copper, 25 parts of tin, 5 parts of silver powder, and 40 parts of cubic boron nitride; the mesh size of the cubic boron nitride is 280 mesh.

[0046]Compared with the preparation method of the optical curve grinding wheel in Example 1, adjust some preparation parameters as follows:

[0047] Step 1) Take 5 parts of copper powder, 5 parts of silver powder, 40 parts of abrasive, and the mixing time of the abrasive layer in the three-dimensional mixer is 20 hours;

[0048] Step 4) In a heat-resistant steel mold at 2500kg / cm 2 pressure to suppress;

[0049] Step 5) In a double-body hot-pressing sintering furnace, the temperature is raised to 500° C. at a rate of 100° C. / h and kept for 2 hours for molding and sintering...

Embodiment 3

[0051] For the optical curve grinding wheel provided in this embodiment, compared with Embodiment 1, the formulation of the abrasive layer is adjusted as follows:

[0052] The abrasive layer is made of the following raw materials in parts by weight: 33 parts of copper, 26 parts of tin, 6 parts of silver powder, and 35 parts of cubic boron nitride; the mesh size of the cubic boron nitride is 400 mesh.

[0053] Compared with the preparation method of the optical curve grinding wheel in Example 1, adjust some preparation parameters as follows:

[0054] Step 1) Take 3 parts of copper powder, 6 parts of silver powder, 35 parts of abrasive, and the mixing time of the abrasive layer in the three-dimensional mixer is 10 hours;

[0055] Step 4) In a heat-resistant steel mold at 2000kg / cm 2 pressure to suppress;

[0056] Step 5) Raise the temperature to 450° C. at a rate of 100° C. / h in a double-body hot-pressing sintering furnace and keep it for 1.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com