Production load adjustable reaction kettle

A production load, adjustable technology, applied in chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of short polymerization operation cycle and achieve the effect of favorable heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

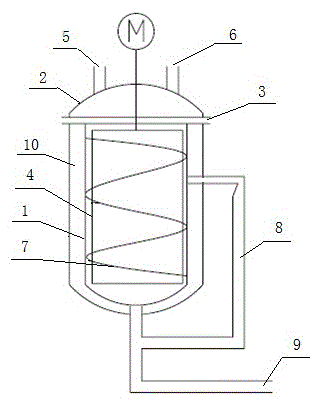

[0014] like figure 1 As shown, a reaction kettle with adjustable production load includes a kettle body 1 and a kettle cover 2. The kettle body 1 and the kettle cover 2 are connected by a flange 3. There is a frame stirrer in the kettle body 1, and the surface of the stirrer 4 A scraper 7 is provided, and the scraper 7 adopts a helical or wavy scraper. There is a liquid inlet 5 and a liquid outlet 6 on the lid 2 of the kettle. The bottom of the kettle body 1 is provided with a lower liquid outlet 9. The frame agitator can operate with a full kettle or a half kettle. Because the frame-type agitator is used, the diameter of the frame type is large, which is conducive to heat transfer. The liquid driven by it can bring the static layer down from the wall of the polymerization tank to solve the problem of gas phase gel, and the conversion rate of the total reaction of the reactor can reach 97.5-98.5%.

[0015] The kettle body 1 has a liquid outlet 6 and a lower liquid outlet 9, ...

Embodiment 2

[0017] Embodiment 2 is the same as Embodiment 1, a kind of production load adjustable reaction kettle, the difference is that: the kettle body 1 is provided with an external circulation pipe 8, and one end of the external circulation pipe 8 is connected to the lower liquid outlet 9, and the external circulation The other end of the pipe 8 is connected to the kettle body 1, and the polymerization liquid in the kettle body 1 is returned to the kettle body 1 through the lower liquid outlet 9 through the external circulation pipe 8, thus forming an external circulation of the kettle body, thereby taking away heat.

Embodiment 4

[0019] Embodiment 4 is the same as Embodiment 1, a kind of production load adjustable reaction kettle, the difference is that: the kettle body 1 is provided with a cooling water jacket 10, and there is cooling water in the cooling water jacket 10, so as to realize the constant temperature jacket And internal temperature-jacket temperature control, improve control accuracy, and prevent accidents caused by temperature out of control or fluctuations in process parameters from affecting the reaction effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com