Novel anthracite heating stove

A heating furnace, anthracite technology, applied in lighting and heating equipment, fluid heaters, water heaters and other directions, can solve the problems of inability to centralize heating, prone to accidents, etc., to achieve convenient manufacturing and installation, conducive to heat transfer, convenient The effect of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

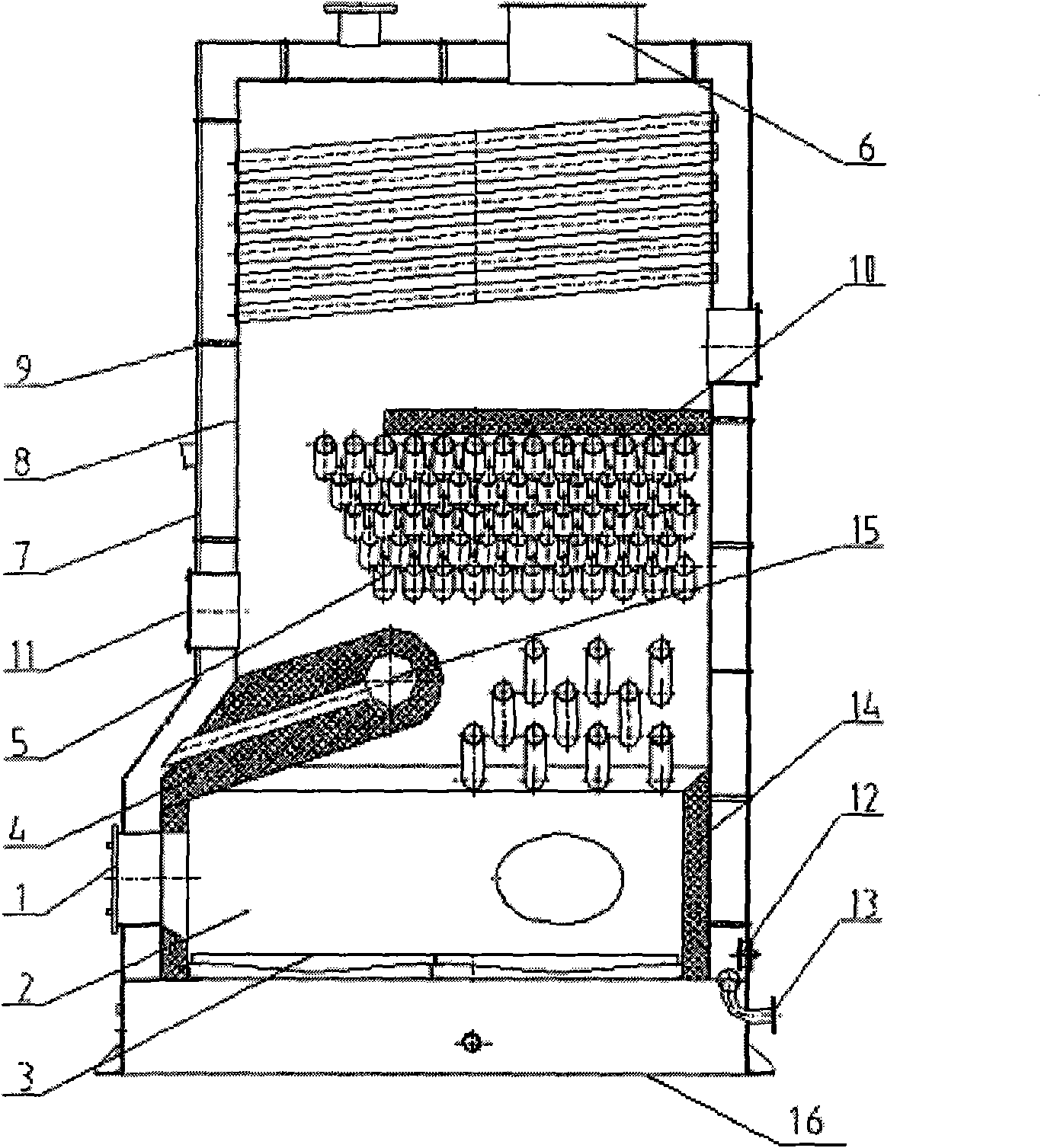

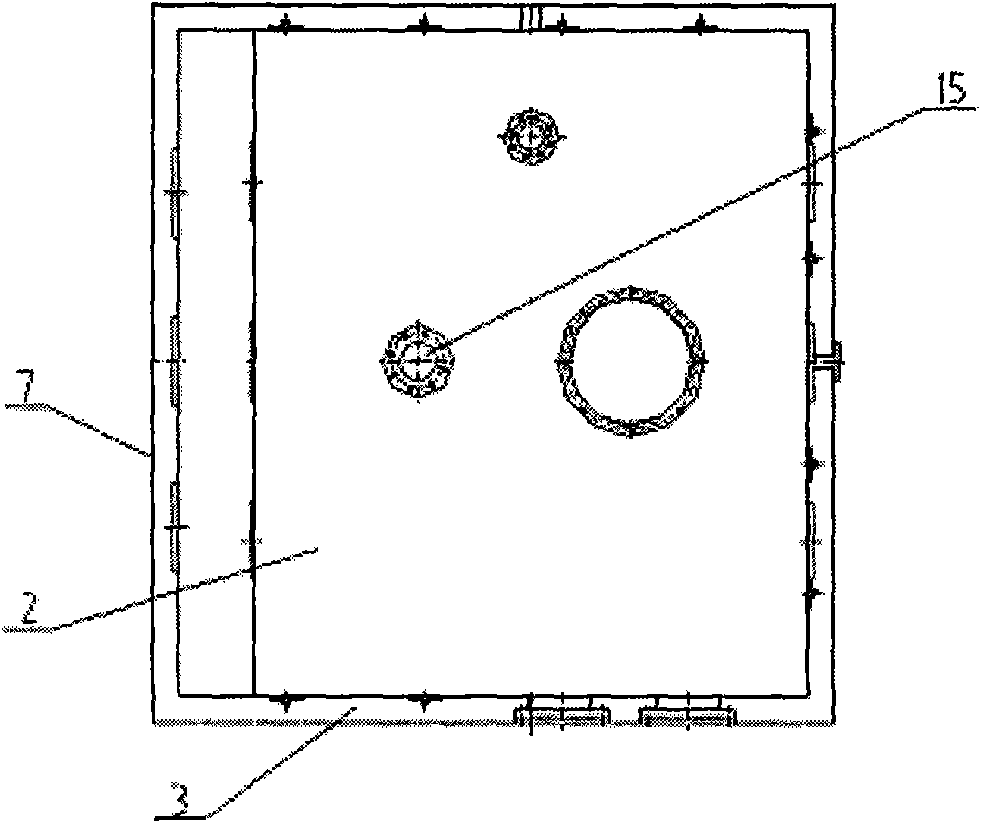

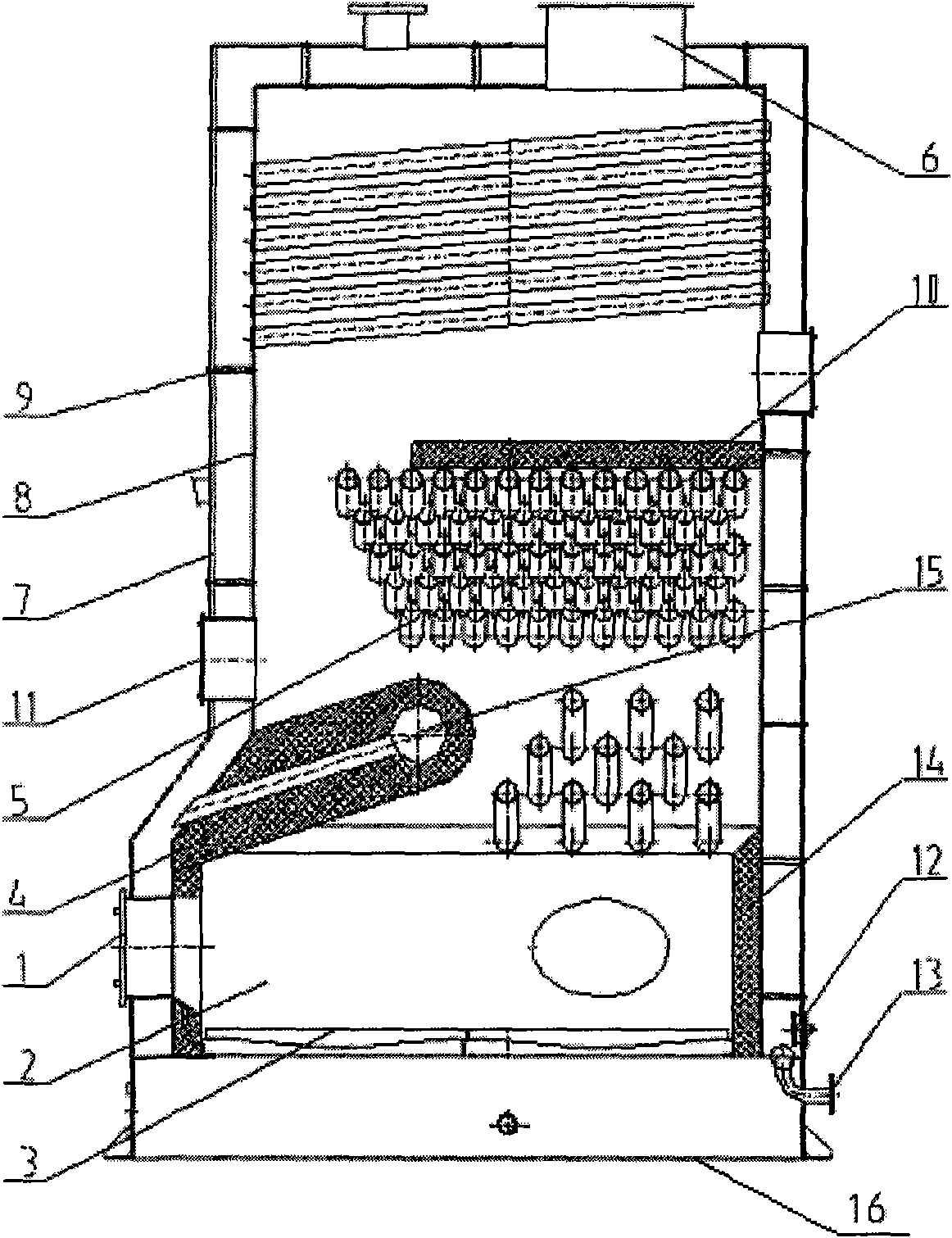

[0010] specific implementation plan

[0011] A fire grate (3) is connected between the coal inlet (1) and the combustion chamber (2). Finally, the generated high-temperature flue gas is discharged from the chimney (6) through the multi-layer horizontal water pipes (5) arranged in a staggered arrangement. There is a water space between the outer shell (7) and the inner shell (8). The inner shell (8) is welded with multi-layered horizontal water pipes (5). The cold water enters the outer shell (7) from the water inlet pipe, and passes through The horizontal water pipe (5) is drawn out by the outlet pipe after circulation. The outer shell (7) adopts a square box structure, and the inner shell (8) is welded with tension struts (9); it is interlaced with the multi-layer horizontal water pipes (5), and the multi-layer horizontal water pipes (5) are connected with concrete partitions The plate (10) has a soot cleaning hole (11) at the position of the multi-layered horizontal water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com