Energy-saving oil pump

A technology for energy-saving machines and oil pumps, applied to pump components, mechanical equipment, machines/engines, etc., can solve problems that cannot be overcome at the same time, large defects, etc., and achieve the effect of simple structure, low production cost, and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

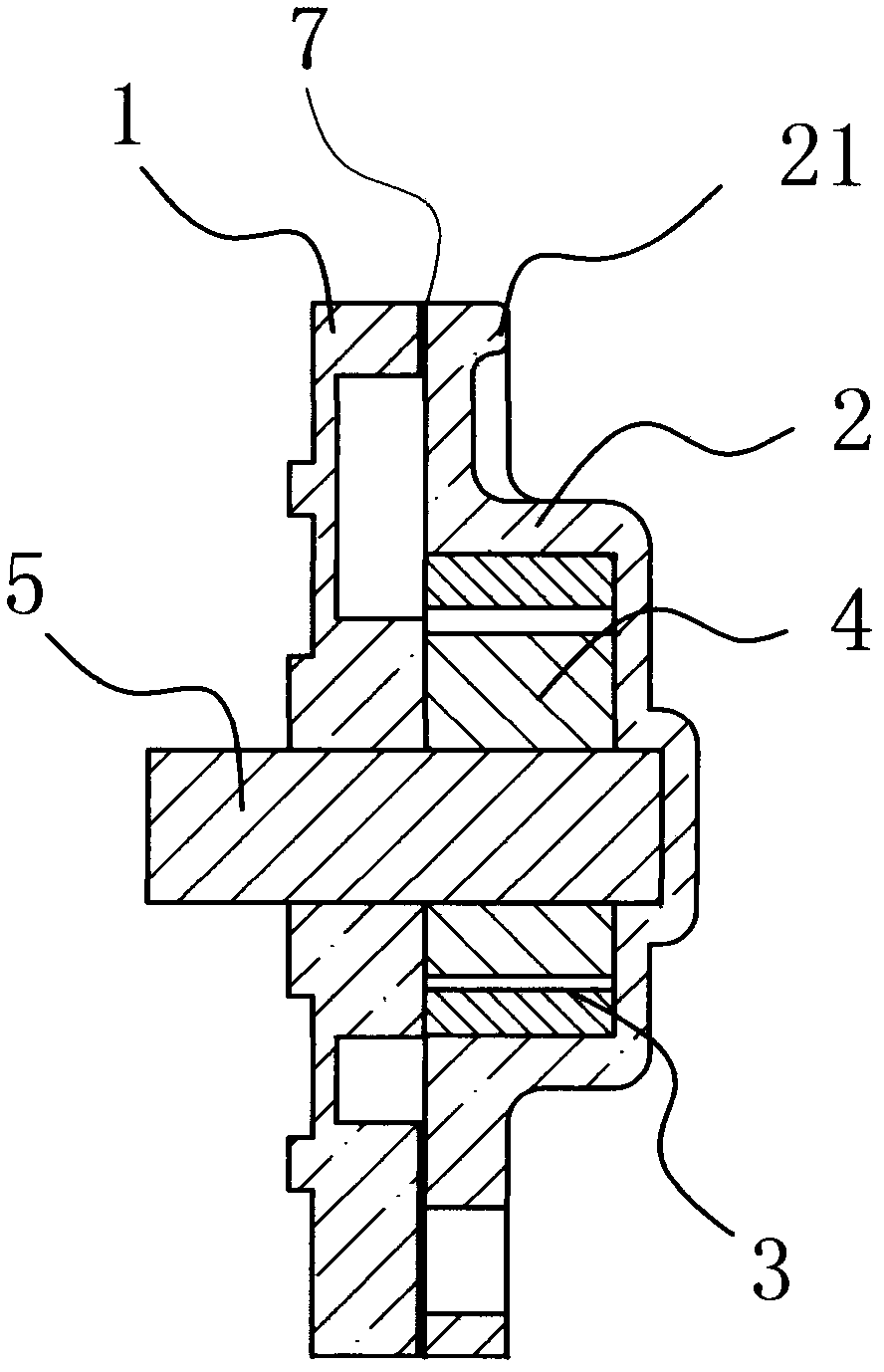

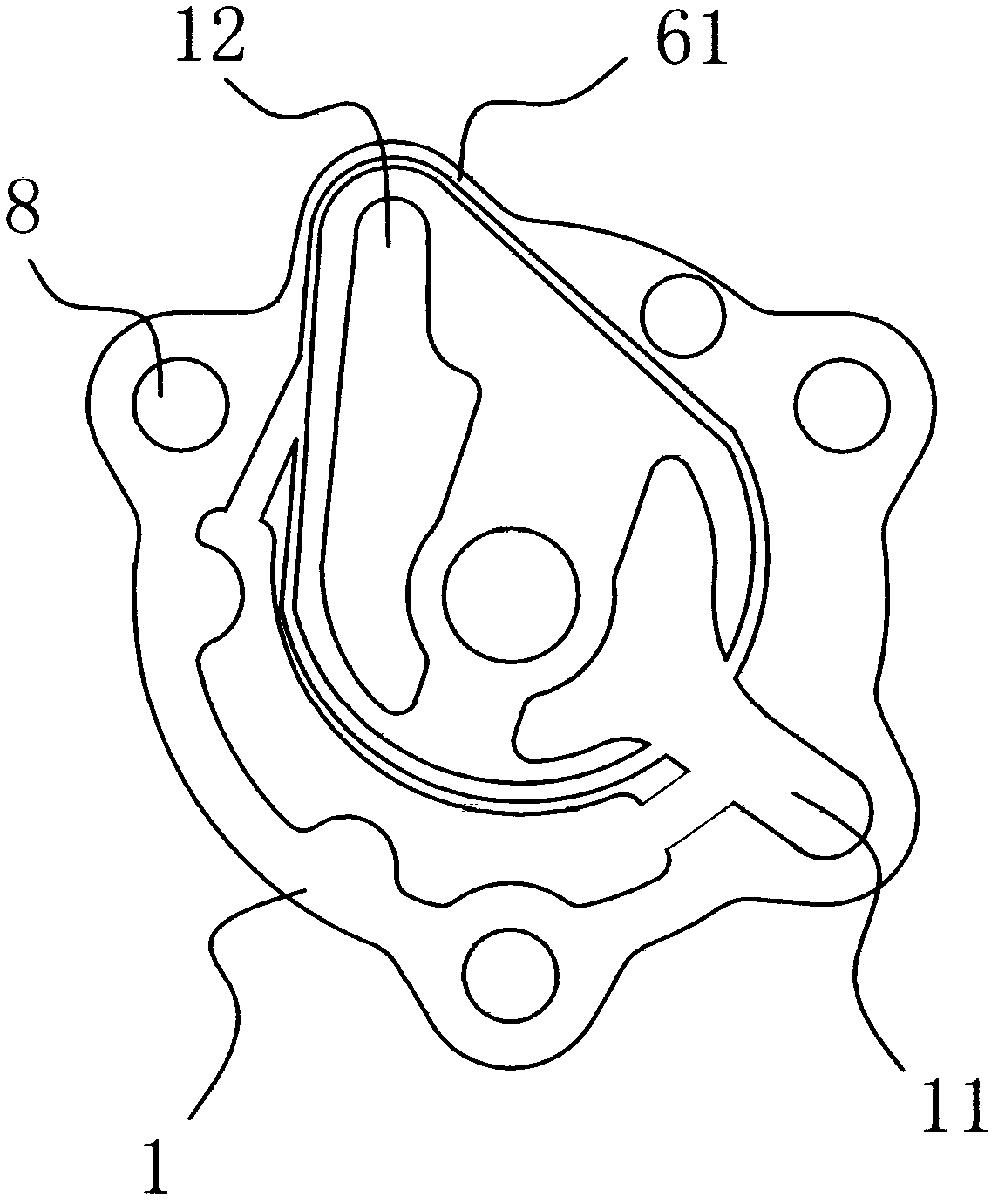

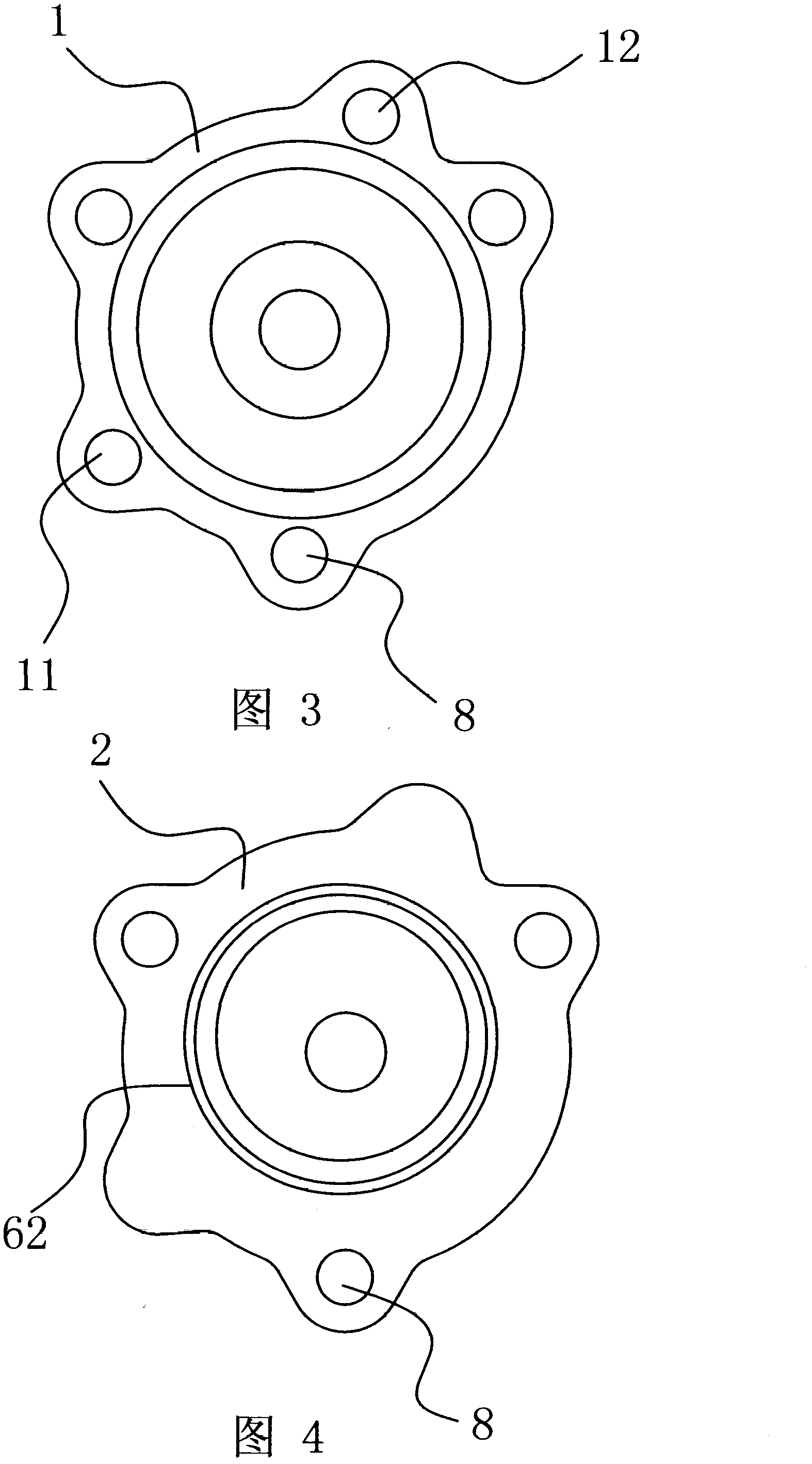

[0019] like figure 1 As shown, the energy-saving oil pump includes a pump body 1 and a pump cover 2 that are interlocked with each other. A cylindrical stator 3 is fixed on the inner wall of the pump cover 2, and a rotor 4 is arranged inside the stator 3. The rotor 4 is sleeved on the rotor On the shaft 5 , one end of the rotor shaft 5 is rotationally connected with the pump cover 2 , and the other end passes through the pump body 1 and extends out of the pump body 1 . The pump body 1 is provided with an oil inlet hole 11 and an oil outlet hole 12 , and an oil passage around the periphery of the rotor 4 is provided between the joint surface of the pump body 1 and the pump cover 2 . The shape of the state-owned channel here is similar to the peripheral shape of the pulley drive structure.

[0020] like Figure 5 As shown, the outer end of the pump cover 2 is provided with reinforcing ribs 21 arranged along the edge, and the reinforcing ribs 21 are connected with the pump cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com