Patents

Literature

89results about How to "Stable oil pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

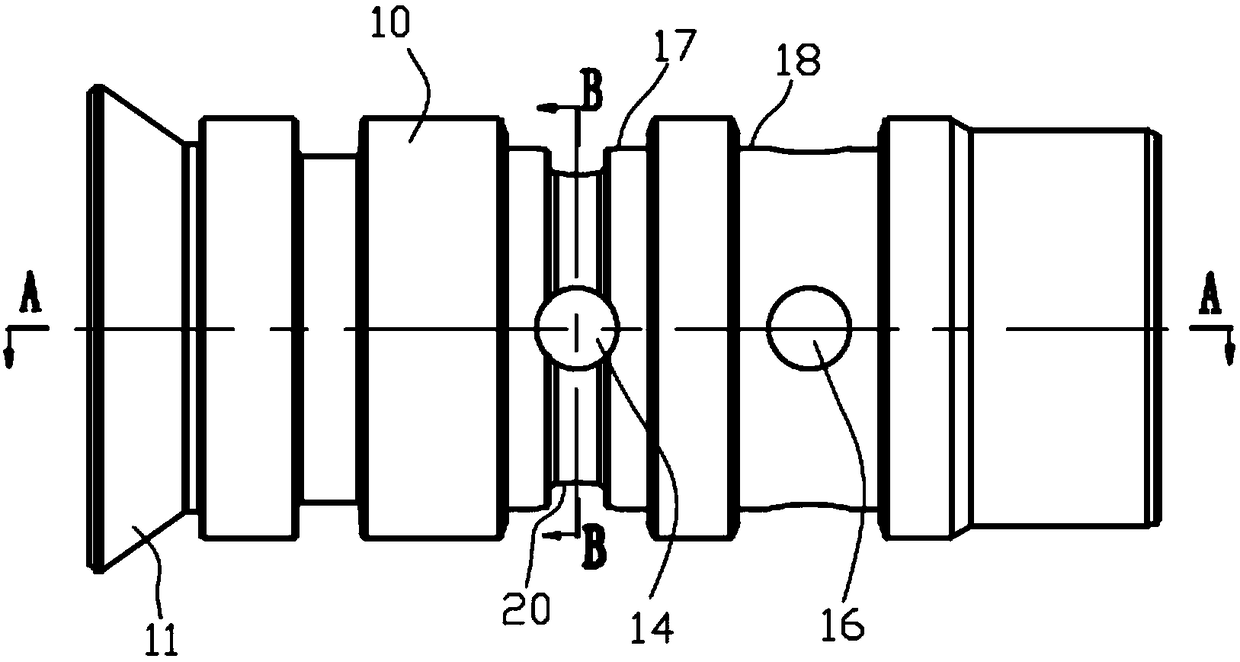

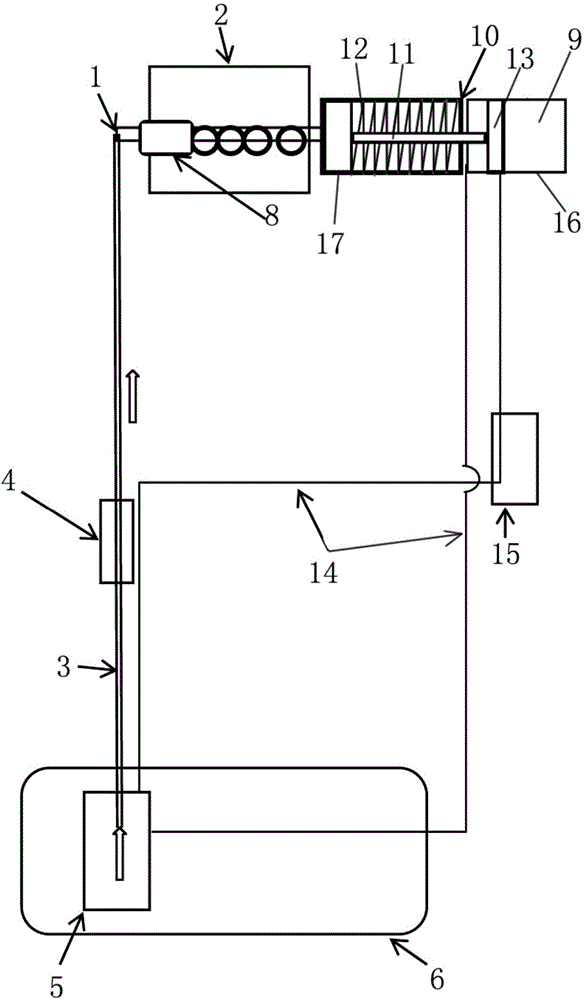

Single-cylinder bolt expansion and contraction control system and construction machine

InactiveCN102619794AReduce the impactExtended service lifeServomotor componentsServomotorsControl systemControl valves

The invention provides a single-cylinder bolt expansion and contraction control system and a construction machine. The single-cylinder bolt expansion and contraction control system comprises a first reversing control valve communicated with an auxiliary oil source; a telescopic oil cylinder comprises a core pipe which is arranged on a cylinder barrel and accommodated in a piston rod; a first oil circuit is connected with the first hydraulic fluid port of the first reversing control valve; a second oil circuit is connected with the second hydraulic fluid port of the first reversing control valve; the oil inlet ends of a first check valve and a second check valve are communicated with the telescopic oil cylinder; one end of a third oil circuit is communicated with the oil outlet ends of the first and the second check valves; and the other end of the third oil circuit is communicated with an electromagnetic ball valve. The core pipe in the telescopic oil cylinder is only used for returning oil during the work process of the single-cylinder bolt expansion and contraction control system. The pressure of return oil is lower, so that the impact on the core pipe is lower, and the service life of the core pipe is prolonged.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

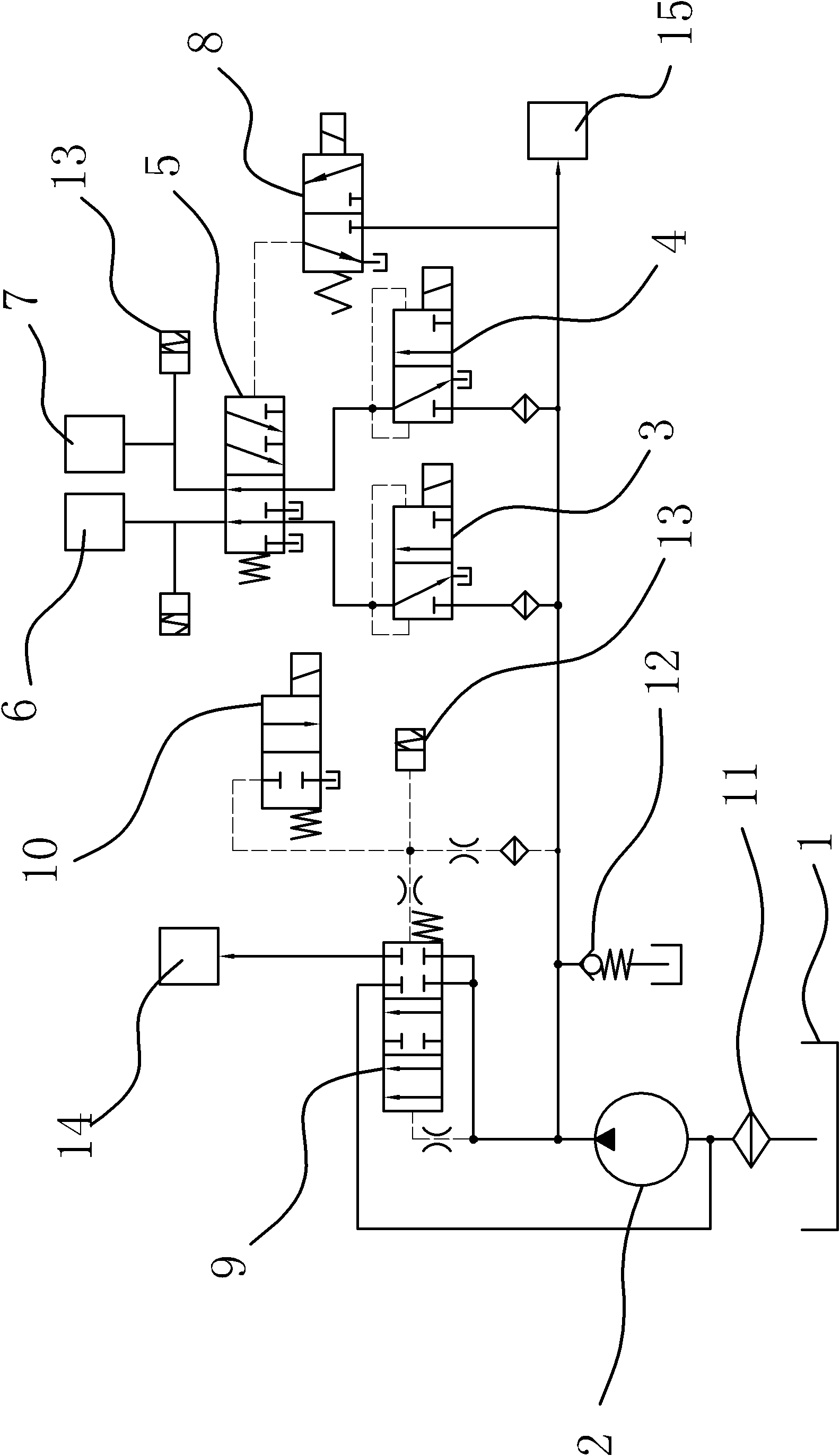

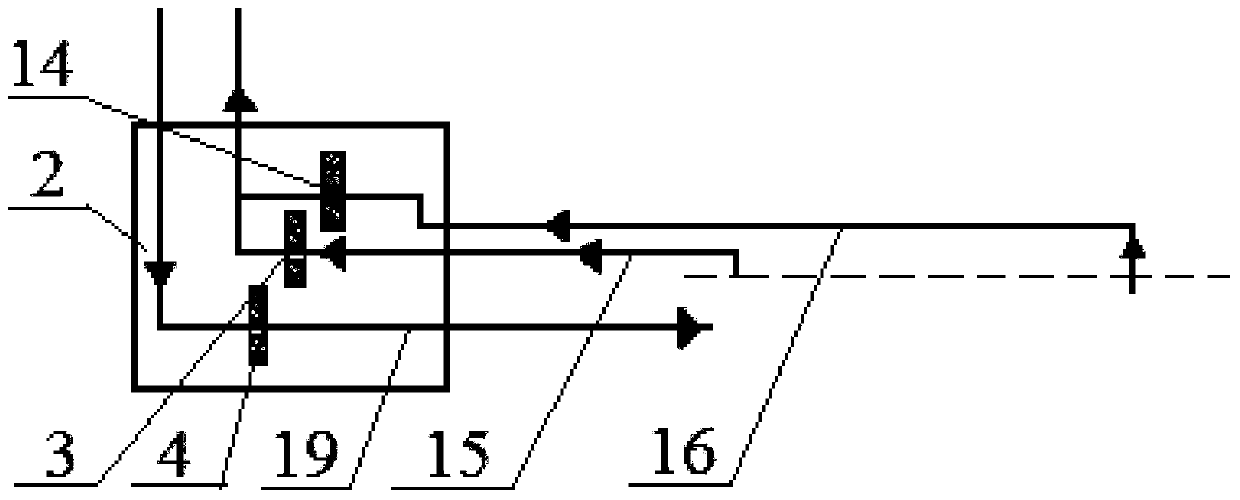

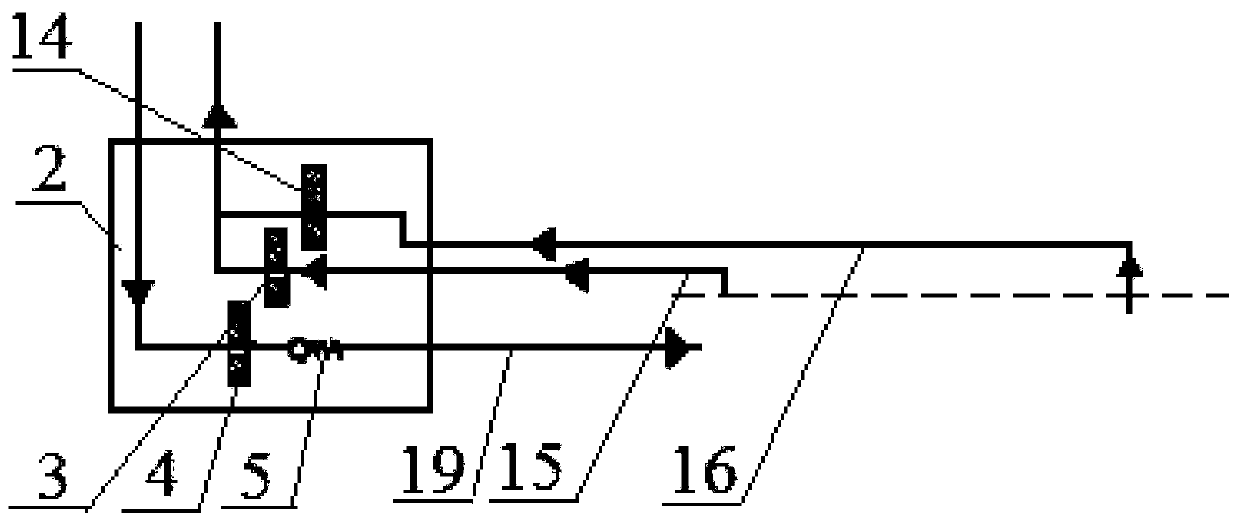

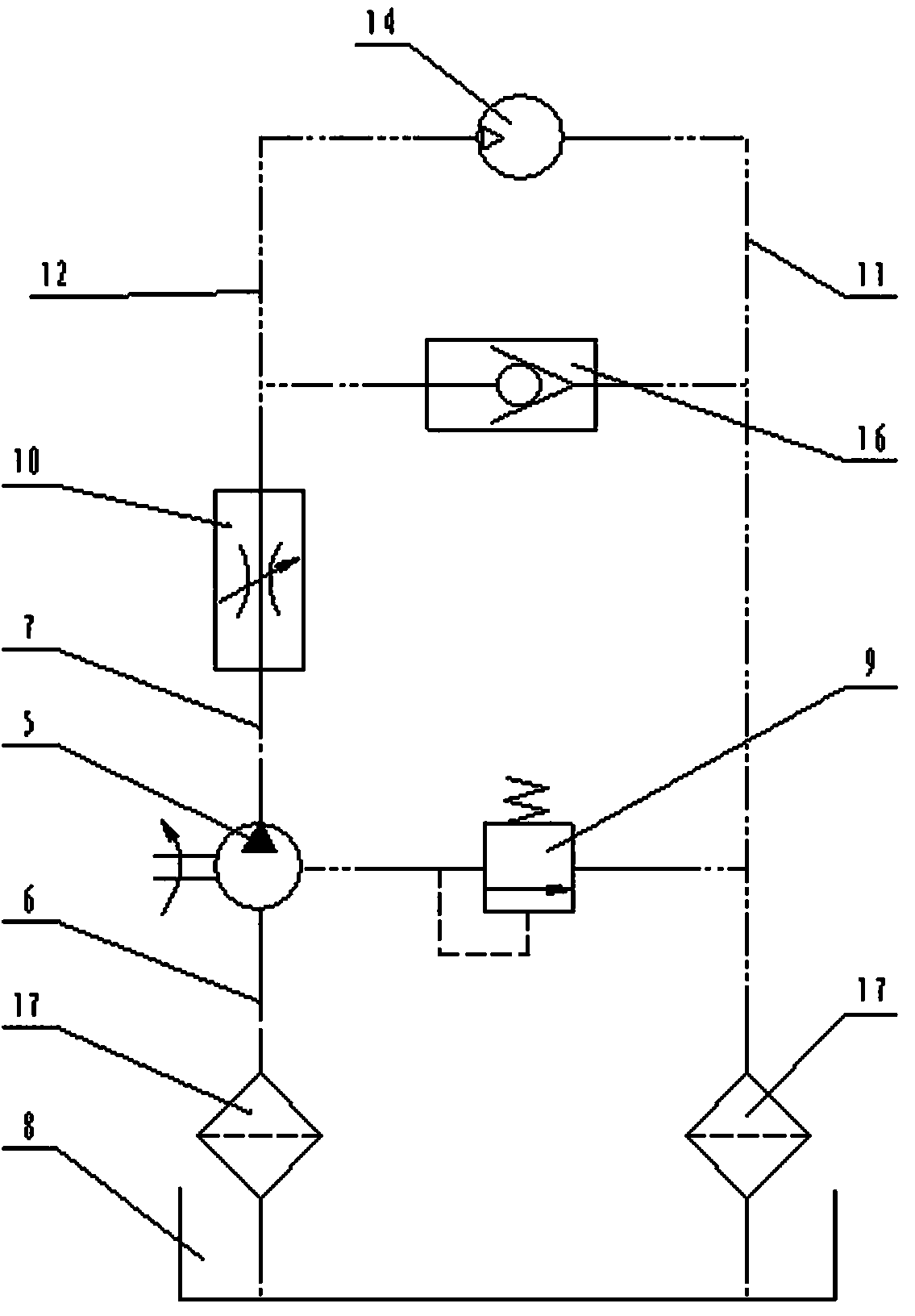

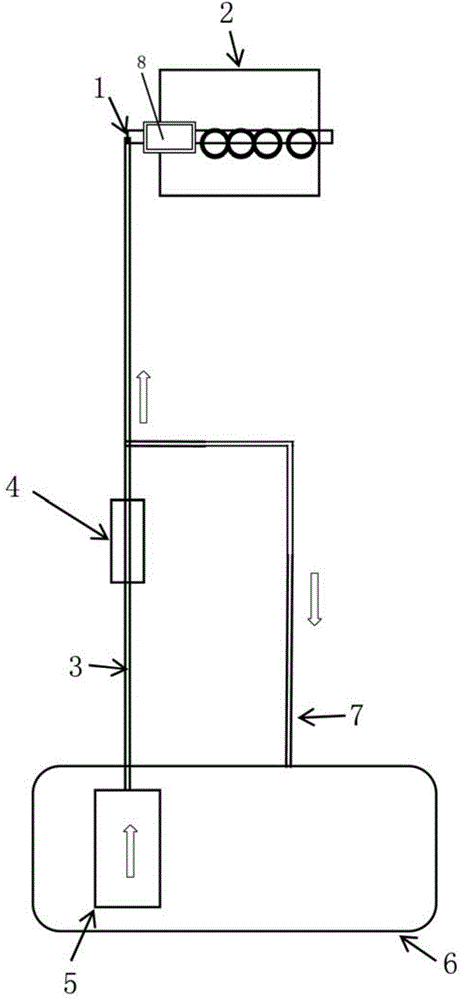

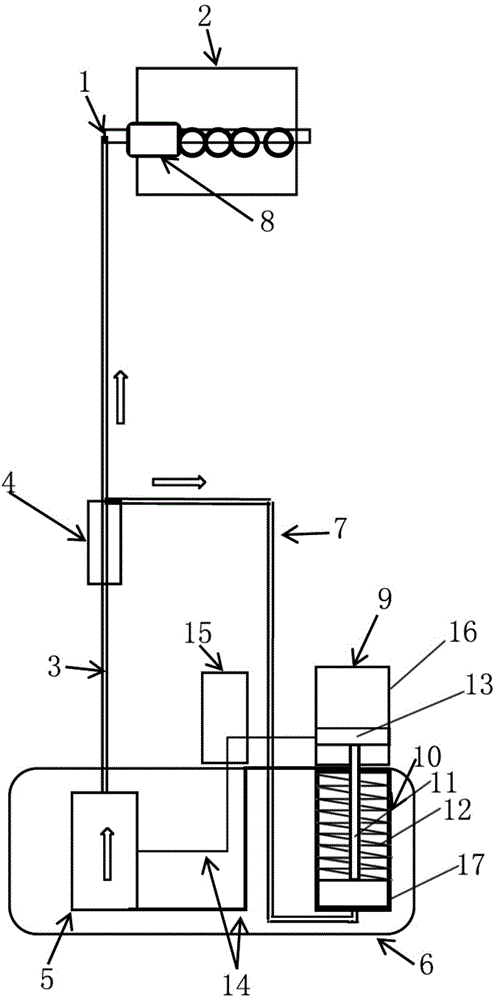

Clutch hydraulic control device of double-clutch automatic transmission

ActiveCN102062204AAvoid destructionGuaranteed normal drivingClutchesGearing controlAutomatic transmissionSolenoid valve

The invention provides a clutch hydraulic control device of a double-clutch automatic transmission, belonging to the technical field of automobile clutches. The clutch hydraulic control device is beneficial to the solution to the technical problem that in the prior art, the pressure-proportion solenoid valve is easy to put into two gears to cause an automobile to be destroyed while the pressure-proportion solenoid value has faults. The clutch hydraulic control device of the double-clutch automatic transmission comprises an oil tank, an oil pump, a pressure-proportion solenoid valve 1, a pressure-proportion solenoid valve 2 and a directional control valve 1, wherein oil outlets of the pressure-proportion solenoid valve 1 and the pressure-proportion solenoid valve 2 are respectively connected with a clutch 1 and a clutch 2 through the directional control valve 1; the directional control valve 1 is provided with an unloading port which is connected with the oil tank; an oil outlet of the oil pump is also connected with a pressure regulating unit which can regulate oil pressure at the oil outlet of the oil pump. The clutch hydraulic control device is beneficial to the prevention of the automobile from being destroyed because two gears are simultaneously put into, thereby ensuring that the safety of a double-clutch system is greatly improved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

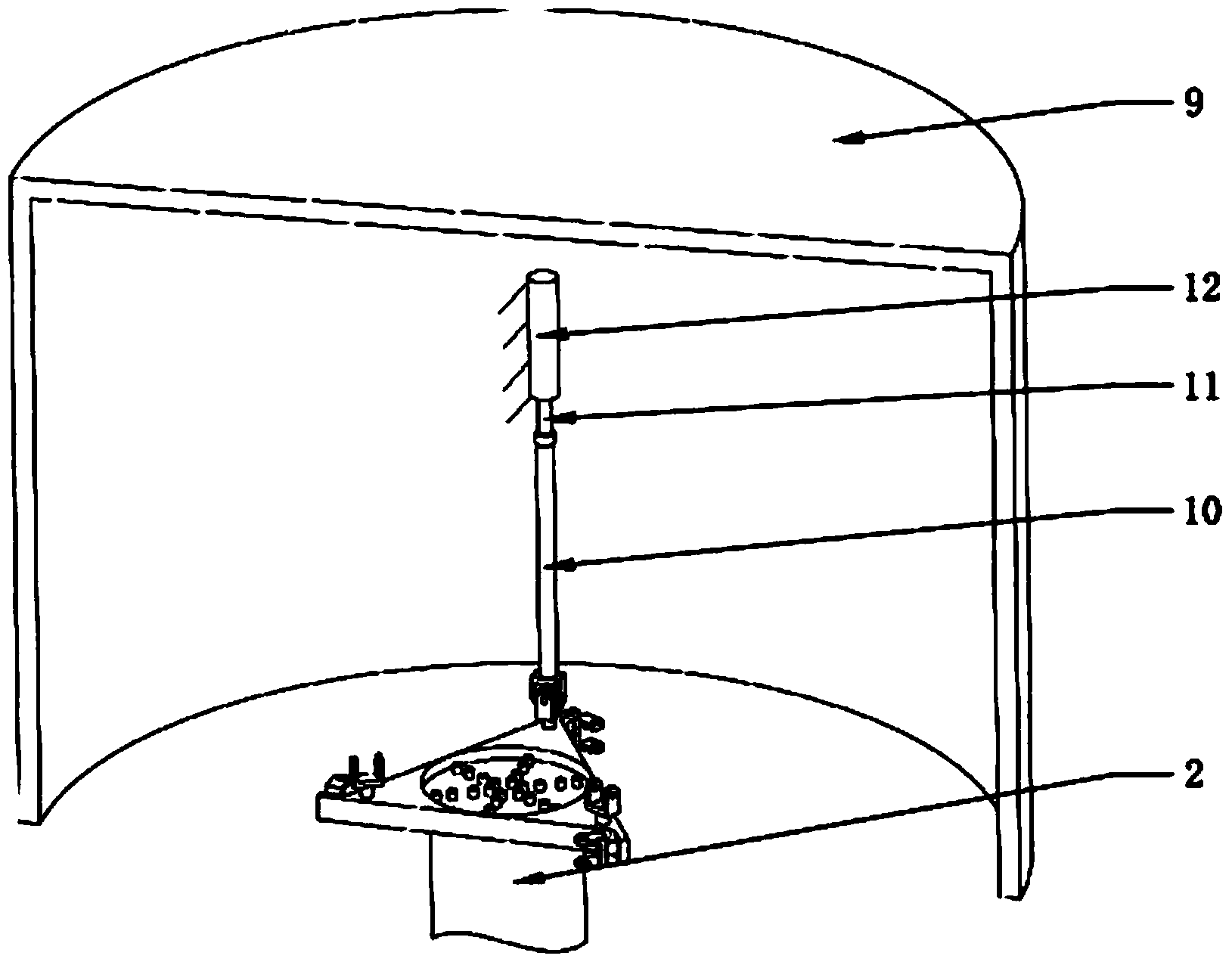

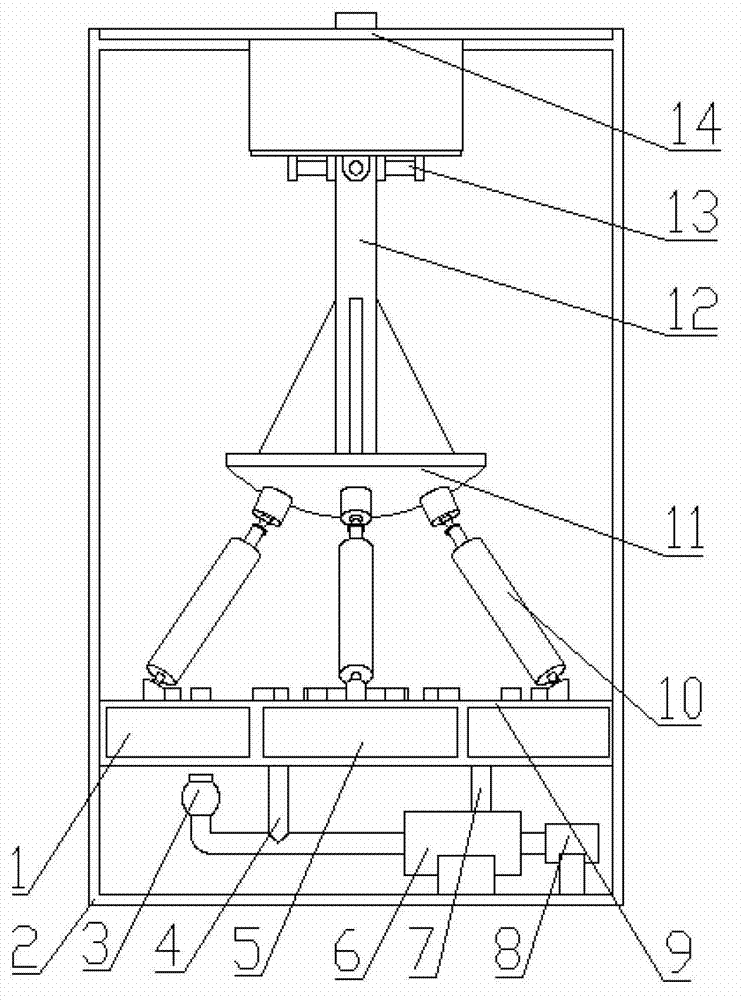

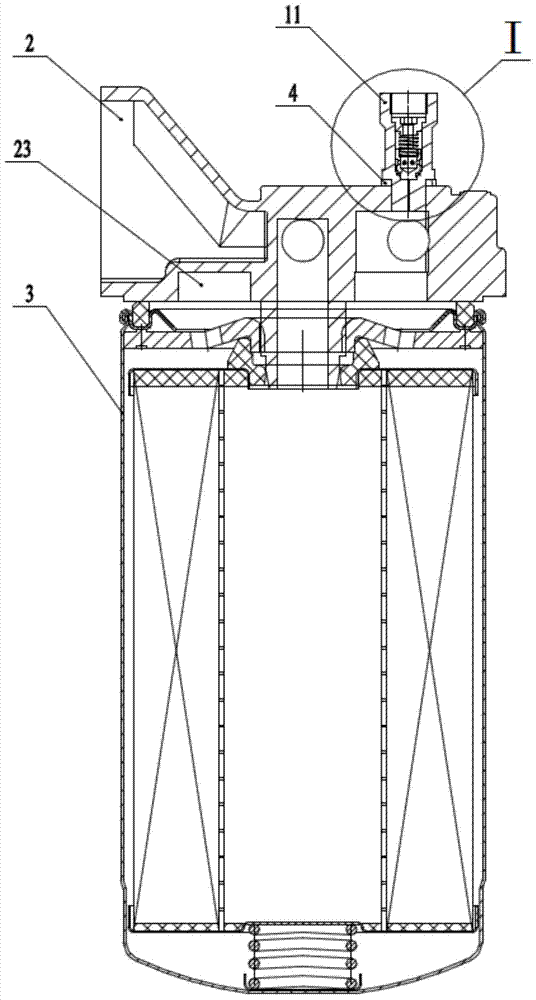

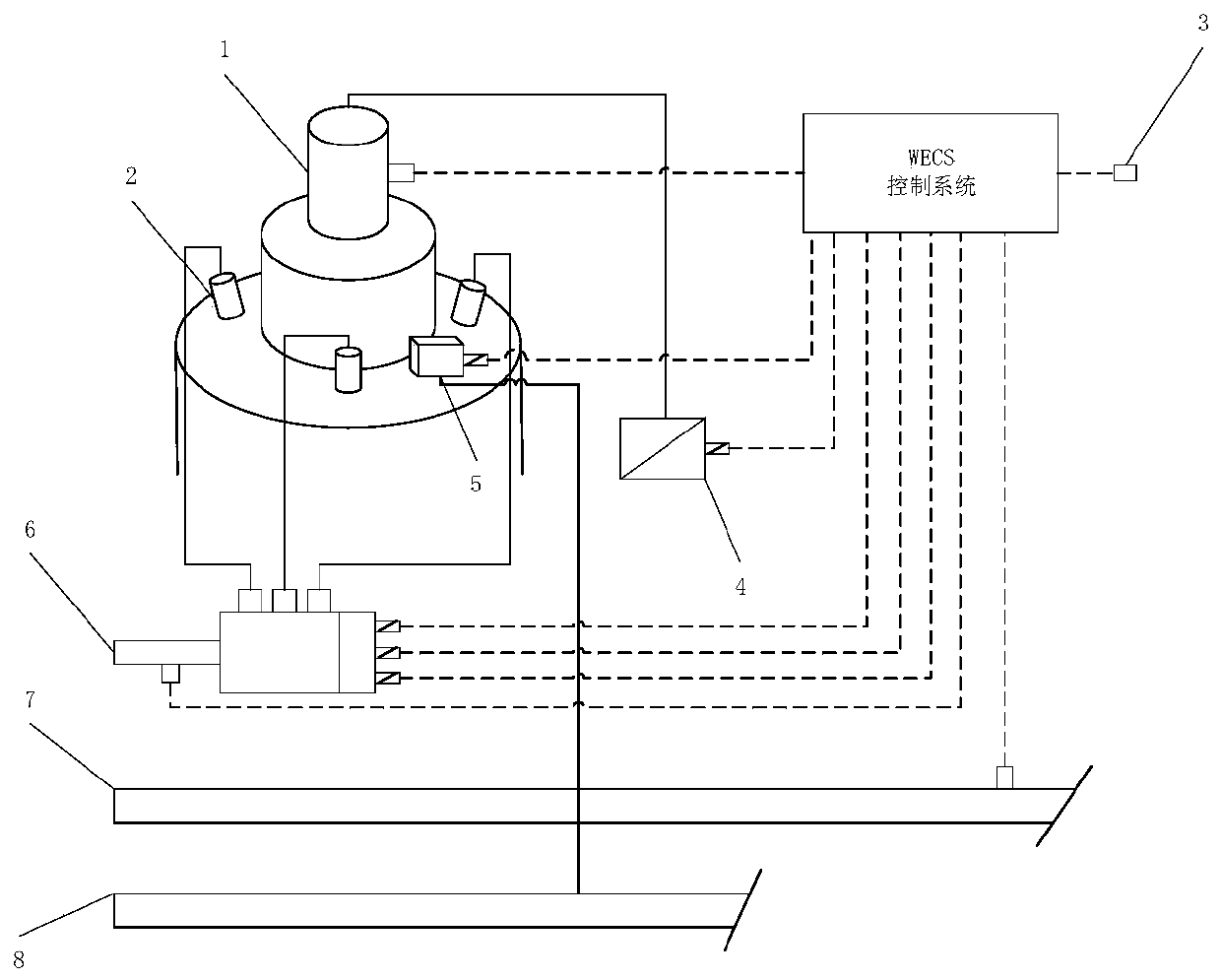

Full-DOF (Degree Of Freedom) wave power generation device

InactiveCN104389720AIncrease power generationCompact structureMachines/enginesEngine componentsWave power generationVertical plane

The invention provides a full-DOF (Degree Of Freedom) wave power generation device. The full-DOF wave power generation device comprises a float, an oil tank platform, hydraulic rod groups, a support tank body and oil transportation pipes, wherein the float is arranged at the lower side of the oil tank platform; one end of each hydraulic rod group is connected with the oil tank platform, the other end of each hydraulic rod group is connected with the inner side of the support tank body, and the oil tank platform is connected with the hydraulic rod groups through the oil transportation pipes; the hydraulic rod groups comprise a transverse hydraulic rod group and a longitudinal hydraulic rod group; the longitudinal hydraulic rod group is arranged on the oil tank platform in the axial direction, and the transverse hydraulic rod group is arranged on the oil tank platform in the circumferential direction. According to the full-DOF wave power generation device provided by the invention, multiple hydraulic rod groups are adopted, one part of the hydraulic rod groups are circularly arrayed in the horizontal plane, the other part of the hydraulic rod groups are equidistantly arranged in the vertical plane in parallel, and since the motion direction of waves is not determined, the motion of piston rods in cylinder bodies can be caused by motion and rotation, which are caused by the waves, of the float in each direction.

Owner:SHANGHAI JIAO TONG UNIV

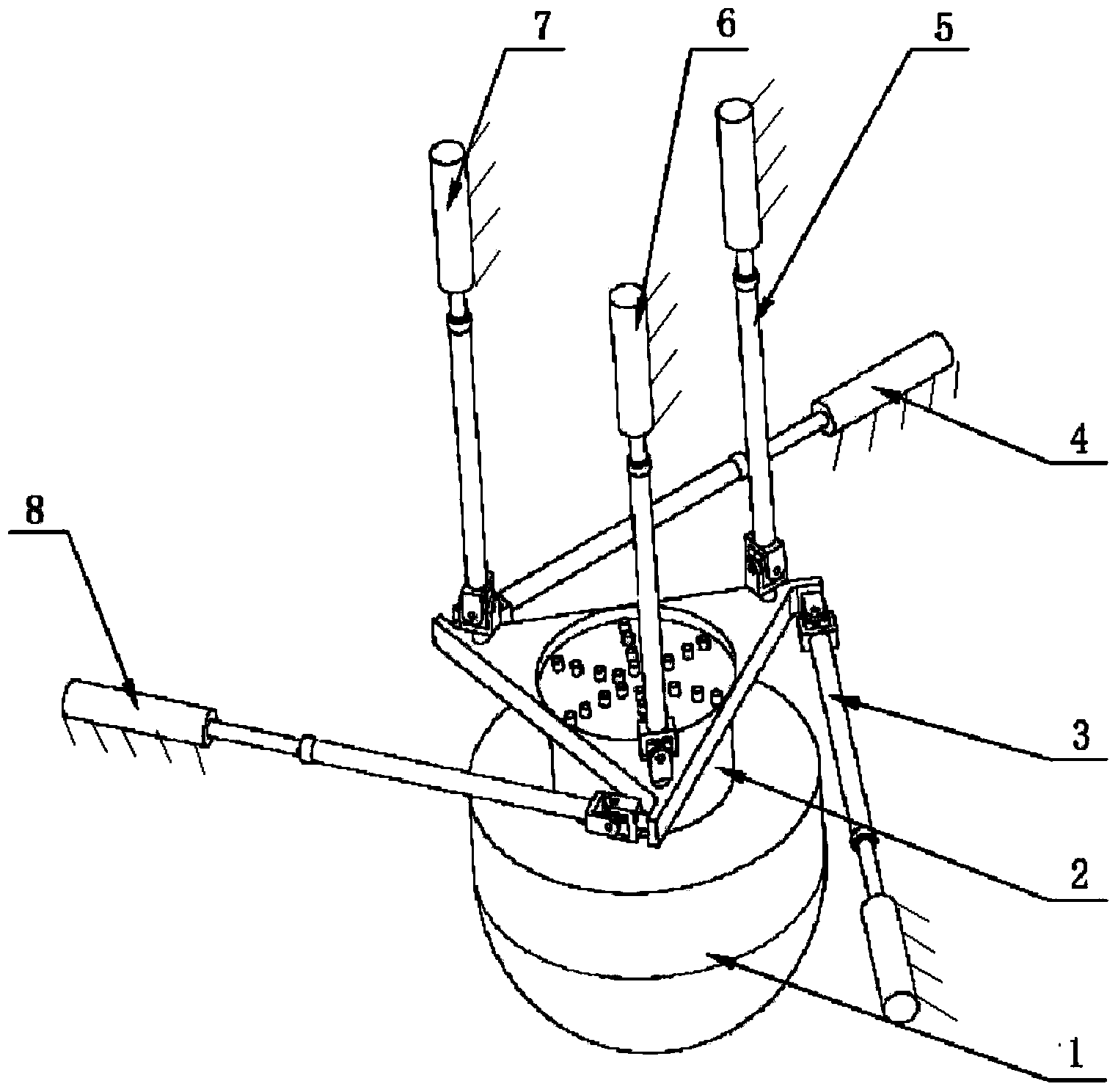

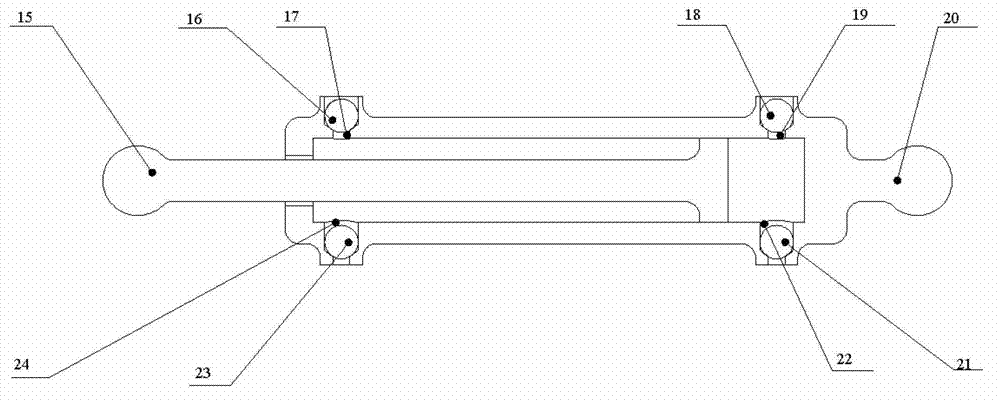

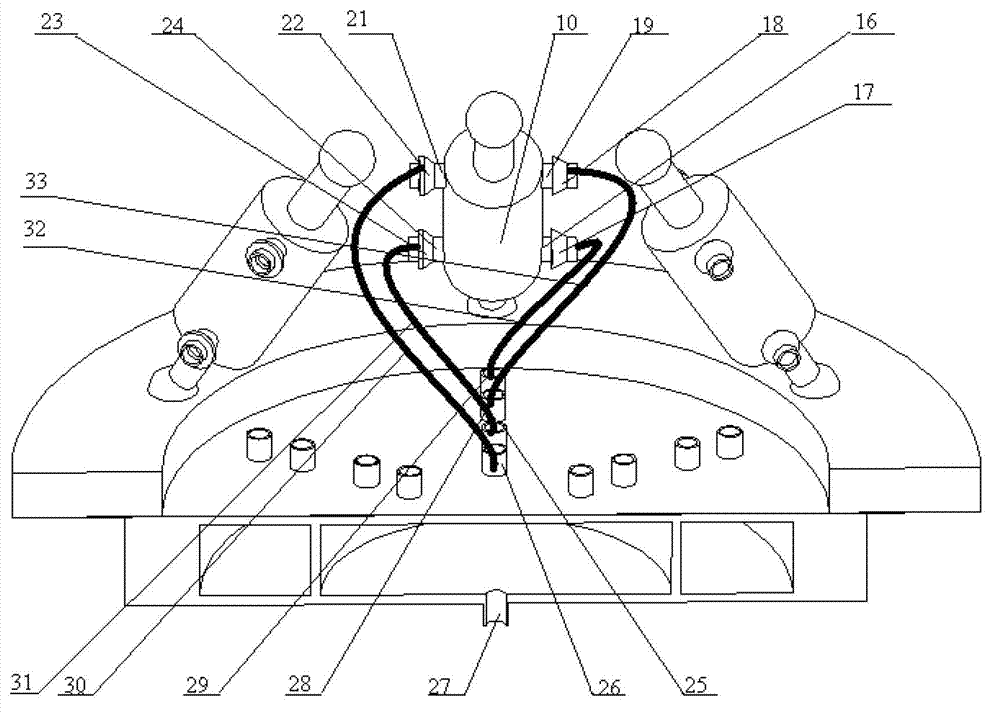

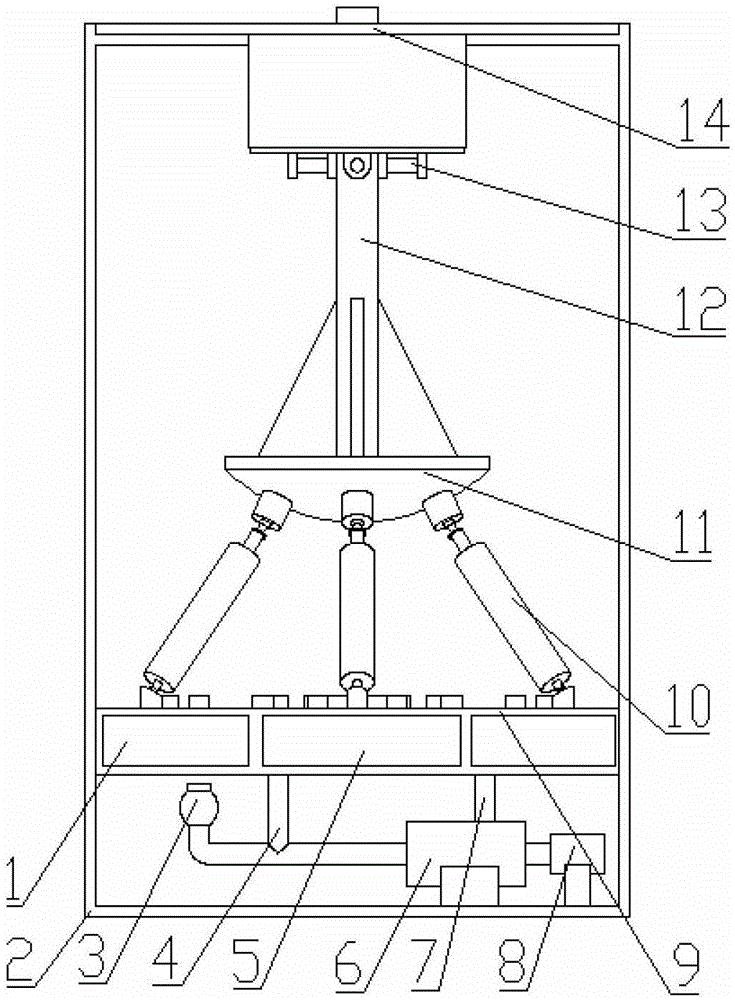

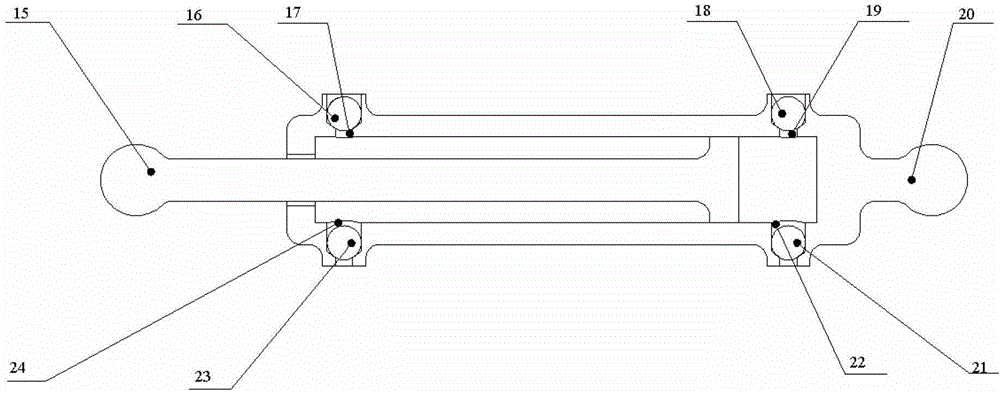

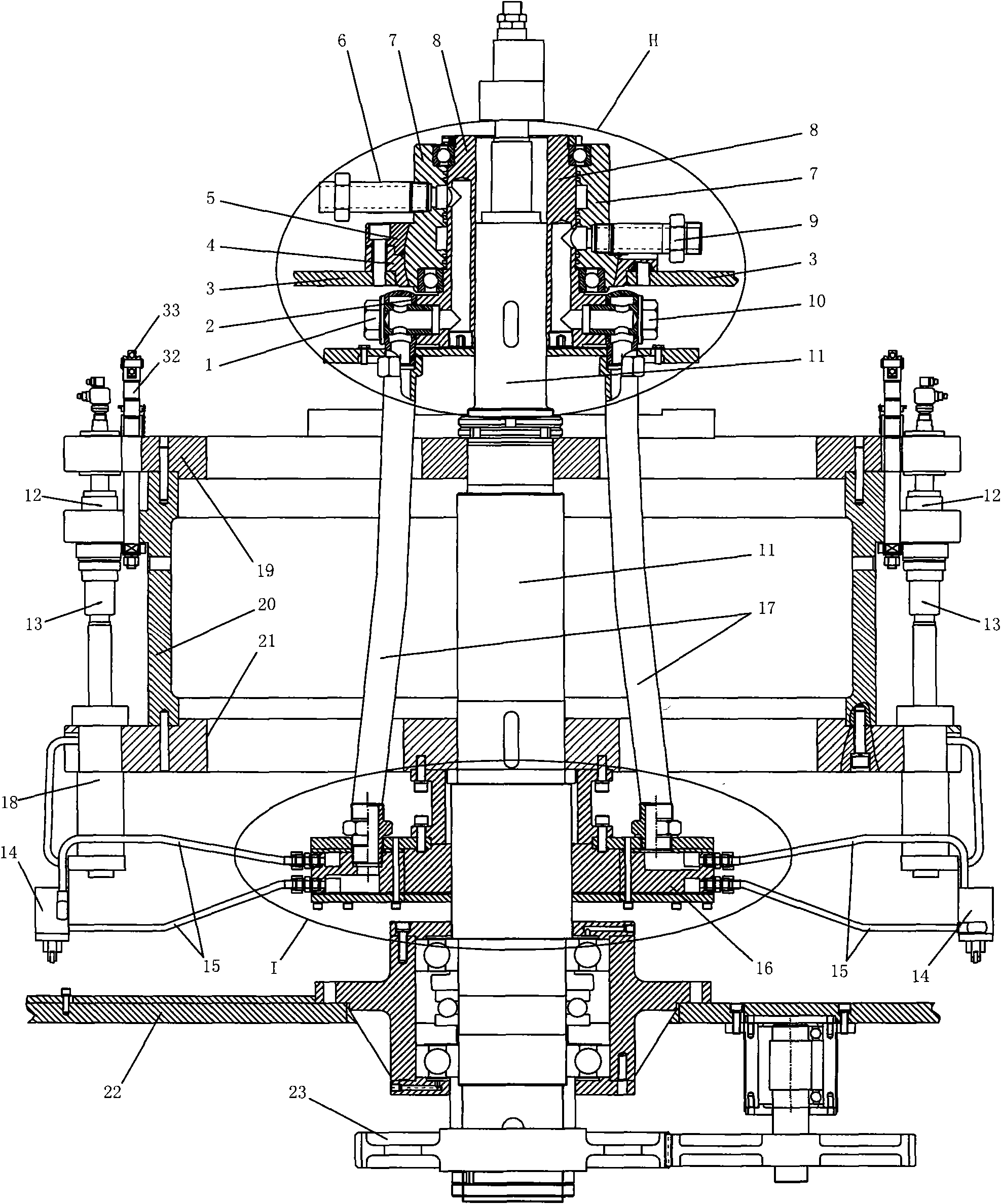

Novel parallel multidimensional oscillating sea wave power generation device

InactiveCN103306882AImprove sealingReduced risk of corrosionMachines/enginesEngine componentsHydraulic motorHydraulic cylinder

The invention discloses a novel parallel multidimensional oscillating sea wave power generation device. The novel parallel multidimensional oscillating sea wave power generation device comprises a floater, and a sealing cover plate, a two-dimensional rotating hinge, an oscillating rod, an oscillating platform, six hydraulic cylinders, an oil tank, a hydraulic motor, a power generator and an energy accumulator which are all arranged in the floater, wherein the sealing cover plate is fixedly connected to a protruding eave of the floater; the oil tank is fixedly connected to the floater; one end of the two-dimensional rotating hinge is fixedly connected to the sealing cover plate and the other end is connected to the oscillating rod; one end of the oscillating rod penetrates through the sealing cover plate to be fixedly connected to an external device and the other end is fixedly connected to the oscillating platform; the six hydraulic cylinders are connected in parallel to work; the two ends of the six hydraulic cylinders are respectively hinged to the oscillating platform and the oil tank through spherical hinges; the oil tank is connected with the hydraulic motor through a flow-dividing pipe and a return pipe; the power generator is connected with the hydraulic motor; the power generator and the hydraulic motor are arranged on the bottom surface of the floater; the energy accumulator is connected with the hydraulic motor. The novel parallel multidimensional oscillating sea wave power generation device has the advantages of long service life, low maintenance cost, low environmental pollution, capability of fully absorbing sea wave energy, high power generation efficiency and the like.

Owner:SHANGHAI JIAO TONG UNIV

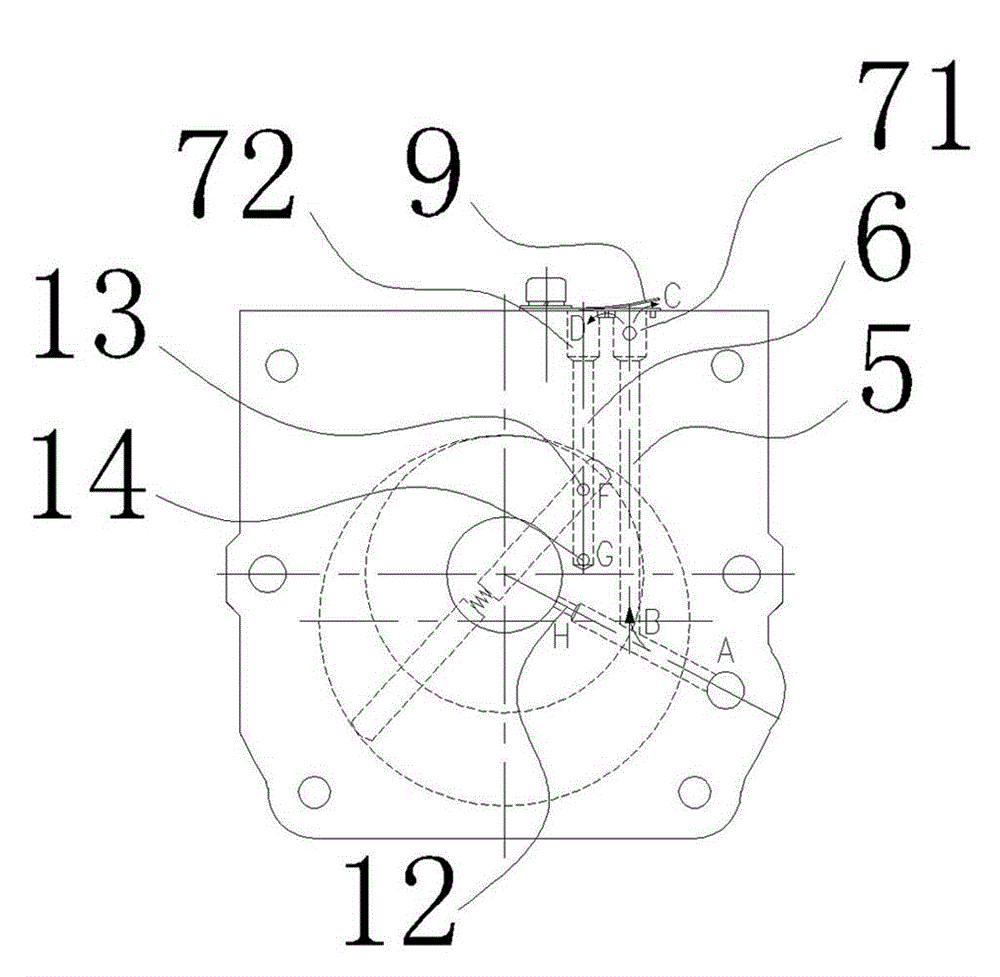

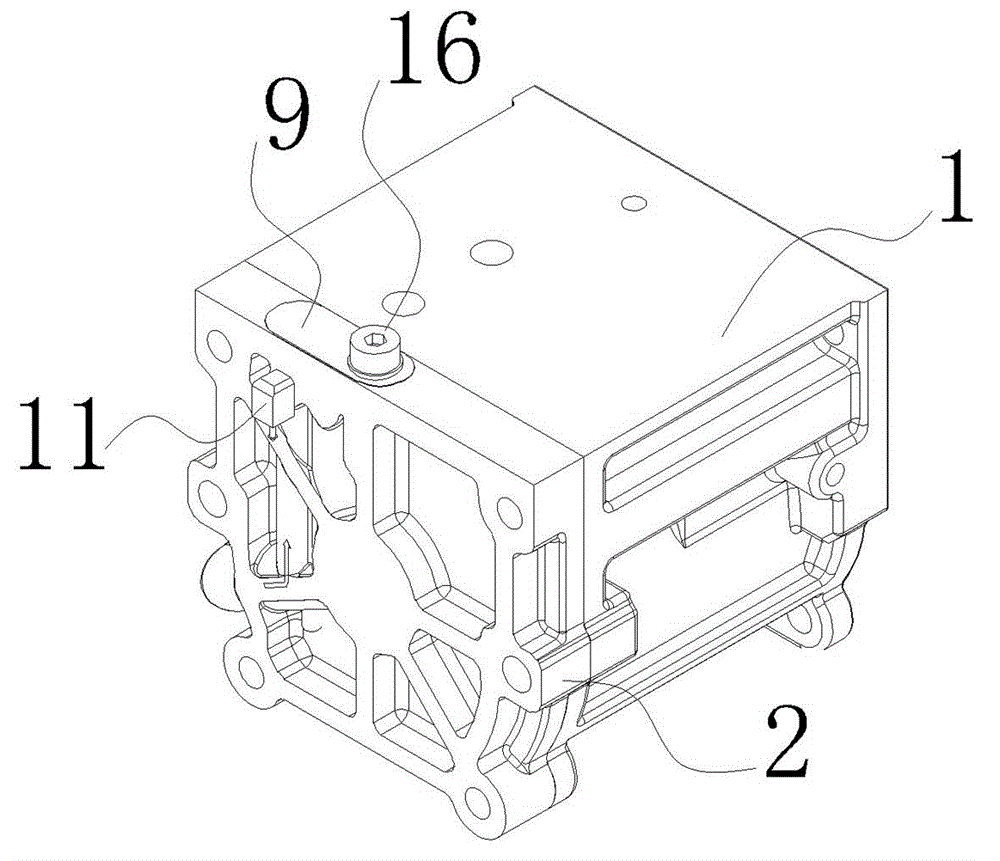

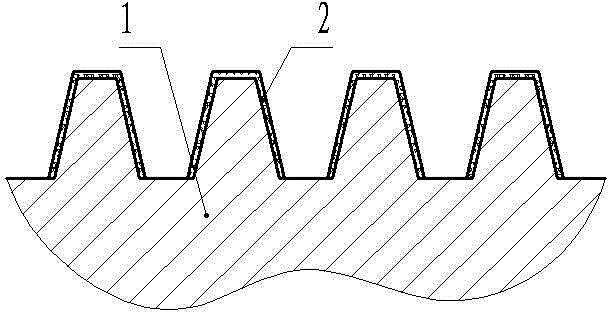

Anti-oil back streaming structure of vacuum pump

ActiveCN102748296AGuaranteed tightnessWill not affect restartingRotary/oscillating piston pump componentsLiquid fuel engine componentsPump chamberEngineering

The invention discloses a rotary-vane vacuum pump and provides an anti-oil back streaming structure of the vacuum pump. The anti-oil back streaming structure is an ingenious idea and avoids pumping oil entering into the pump chamber and vacuum system when the vacuum pump shouts down, thereby solving the technical problems that the pumping oil enters into the pump chamber after the vacuum pump shuts down which leads to difficult start of the vacuum pump and damage of related parts in severe cases, and the pumping oil enters into the vacuum system in cases of failures of the anti-oil back streaming valve, and the like in the prior art. The anti-oil back streaming structure comprises a pump stator and a pump rear cover, wherein a pump rotor is eccentrically arranged in the pump chamber bounded by the pump stator and the pump rear cover, an oil storage tank is arranged on the pump rear cover, the upper shield of the oil storage tank is provided with an elastic valve block, a pumping oil outlet channel and a pumping oil introduction channel are arranged in the pump rear cover, one end of the pumping oil outlet channel is communicated with one end of the pumping oil introduction channel in the oil storage tank, the other end of the pumping oil outlet channel is connected with the oil pump, the other end of the pumping oil introduction channel is communicated with the end surface of the pump rotor corresponding to the pump rear cover, and a vent is arranged on a passage conducting air between the end surface of the pump rotor and the oil pump.

Owner:ZHEJIANG VALUE MECHANICAL & ELECTRICAL PROD CO LTD

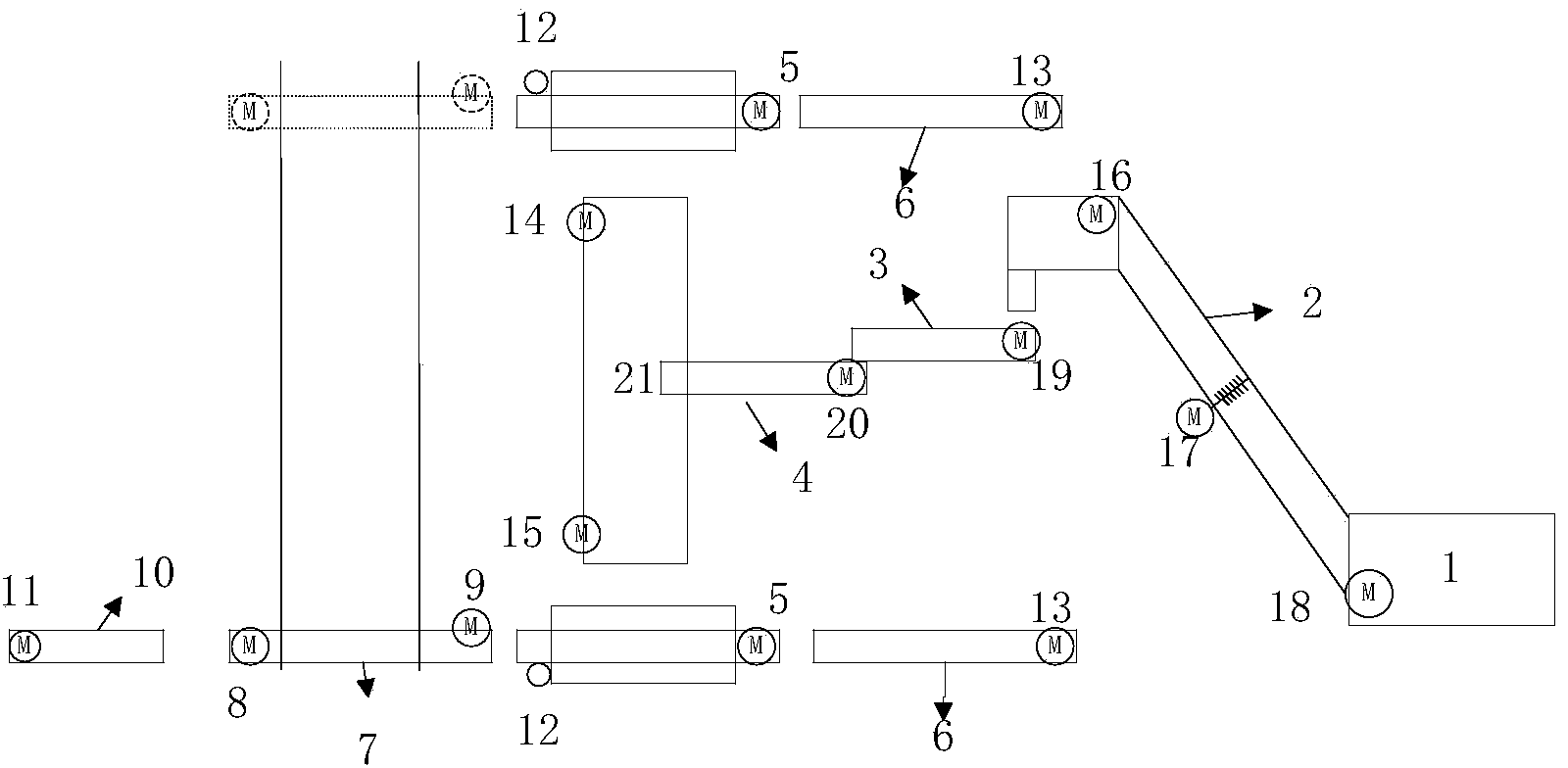

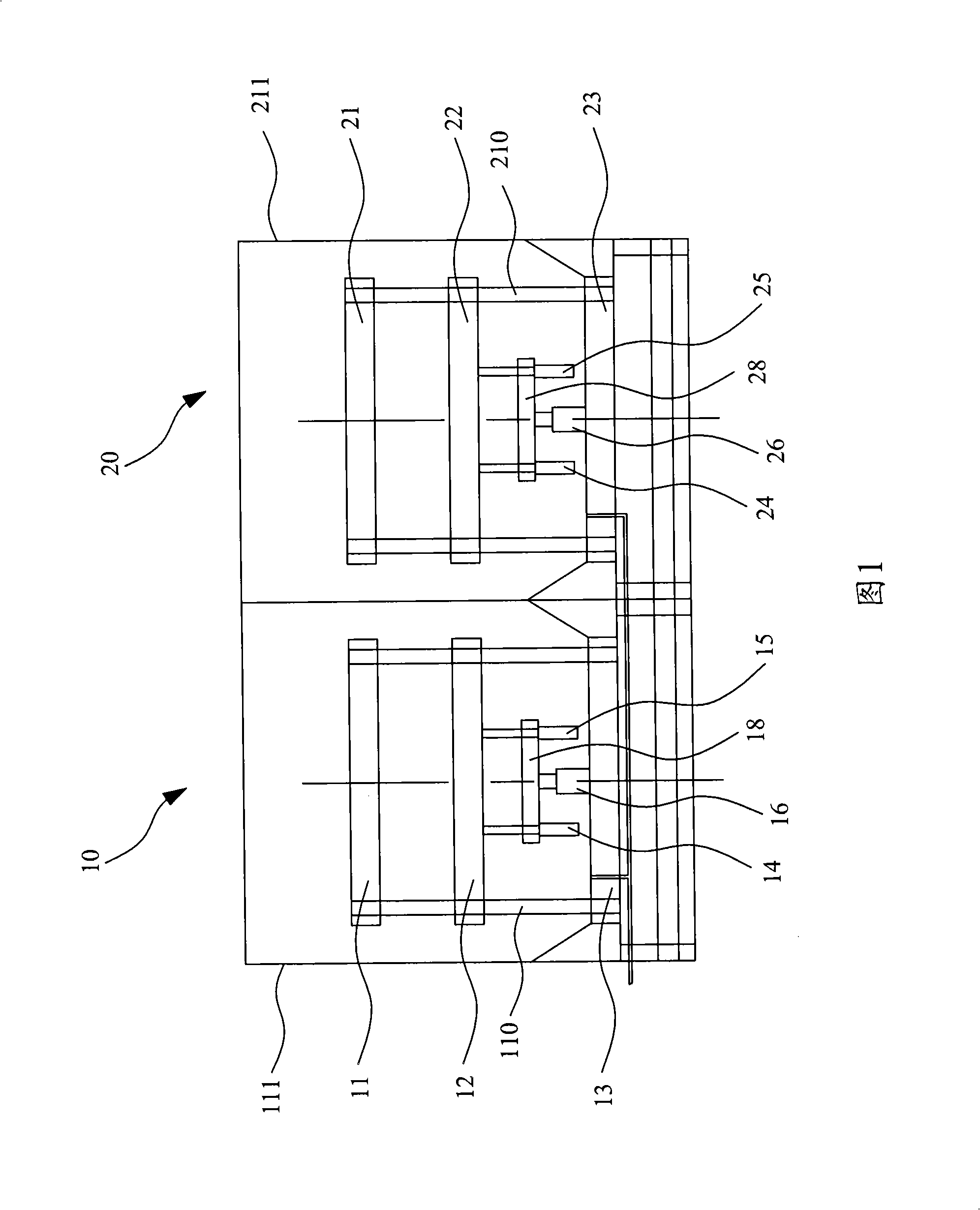

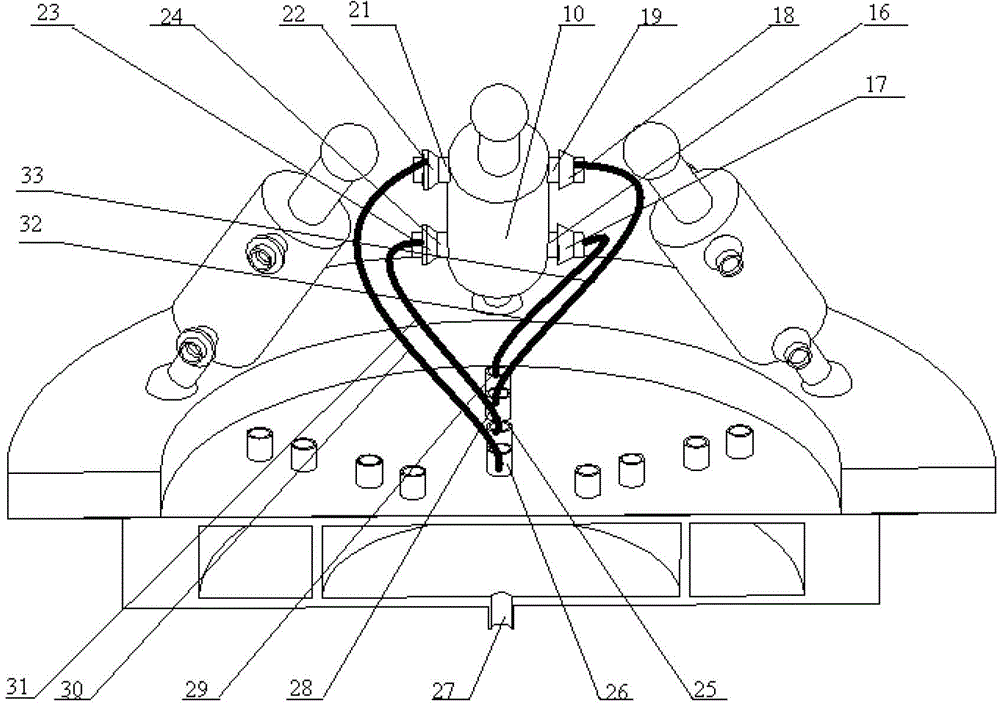

Duplex hydraulic packer of papermaking-method reconstituted tobacco production line and working method thereof

The invention discloses a duplex hydraulic packer of a papermaking-method reconstituted tobacco production line and a working method thereof. The packer comprises a tobacco storage cabinet, a conveying belt, an electronic belt scale, a vibrating groove and a material distribution trolley which are sequentially connected with one another, wherein material boxes and pressing heads are respectively arranged at the two sides of the material distribution trolley; each group of material boxes and pressing heads is provided with a carton conveying belt motor and is in action connection with a box inlet roller way, and each box inlet roller way is provided with a box inlet roller way motor; each group of material boxes and pressing heads is further in action connection with a box conveying trolley, a box conveying trolley motor and a box conveying trolley roller way motor are arranged at the two ends of each box conveying trolley, each box conveying trolley is in action connection with a conveying roller way, and each conveying roller way works through the drive of a conveying roller way motor. The duplex hydraulic packer of the papermaking-method reconstituted tobacco production line and the working method thereof have the beneficial effects that the performance of a servo system is exerted fully and the production efficiency of tobacco packing is increased.

Owner:山东瑞博斯烟草有限公司

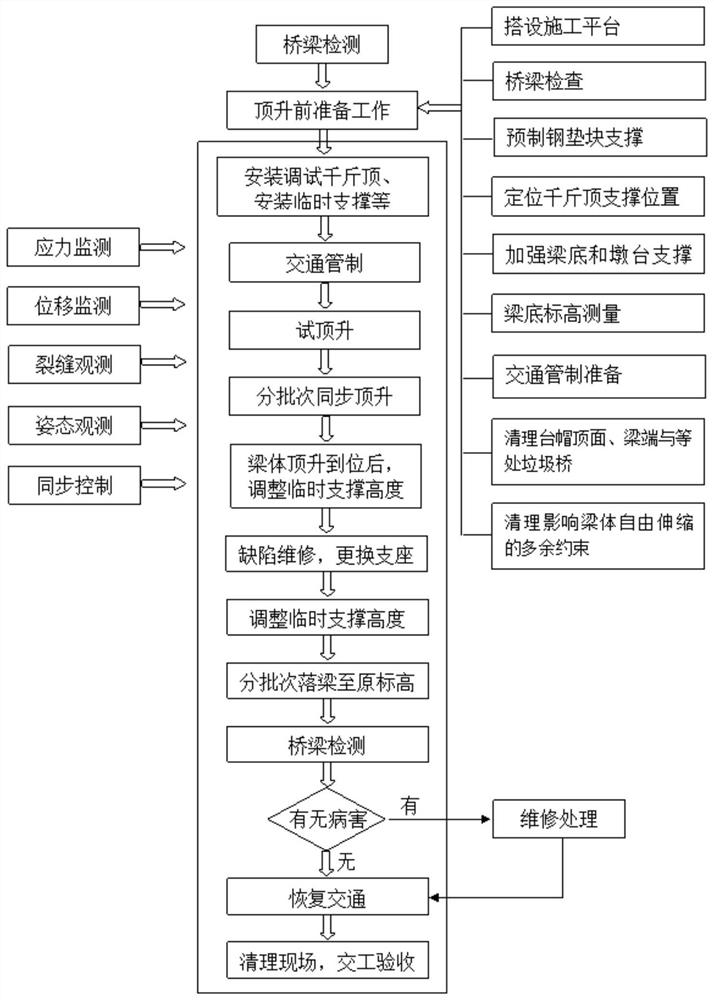

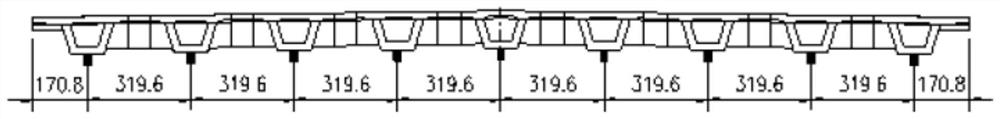

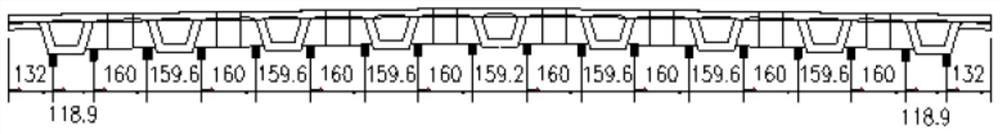

Construction method for synchronously jacking whole bridge to replace support

InactiveCN112144406ANo overturningDo not change the stress conditions of the structureBridge structural detailsBridge erection/assemblyArchitectural engineeringJackscrew

The invention provides a construction method for synchronously jacking the whole bridge to replace a support, and belongs to the field of municipal construction. The construction method comprises thefollowing steps that S1, preparation work is carried out before jacking; S2, jacking preparation is carried out; S3, trial jacking is carried out; S4, a main beam is jacked synchronously; and S5, thesupport is replaced. Temporary supporting is conducted so that the old support is withdrawn, a leveling steel plate is additionally arranged, and the beam is fallen down; after the leveling steel plate and the new support are installed, beam falling and reset operation can be conducted, all jacks are subjected to oil returning and beam falling synchronously, the beam body needs to be kept overallbalanced in the beam falling process, and synchronous overall beam falling is conducted according to the jacking inverse process and in a graded mode till the beam body is completely fallen. Accordingto the construction method, on the premise that the bridge structure is not damaged and the stress condition of the bridge structure is not changed, the limitation that the engineering beam is largein tonnage, small in space and the like is effectively solved by adopting a multi-point whole jacking mode, the support is replaced well, and the bridge operation condition is good.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

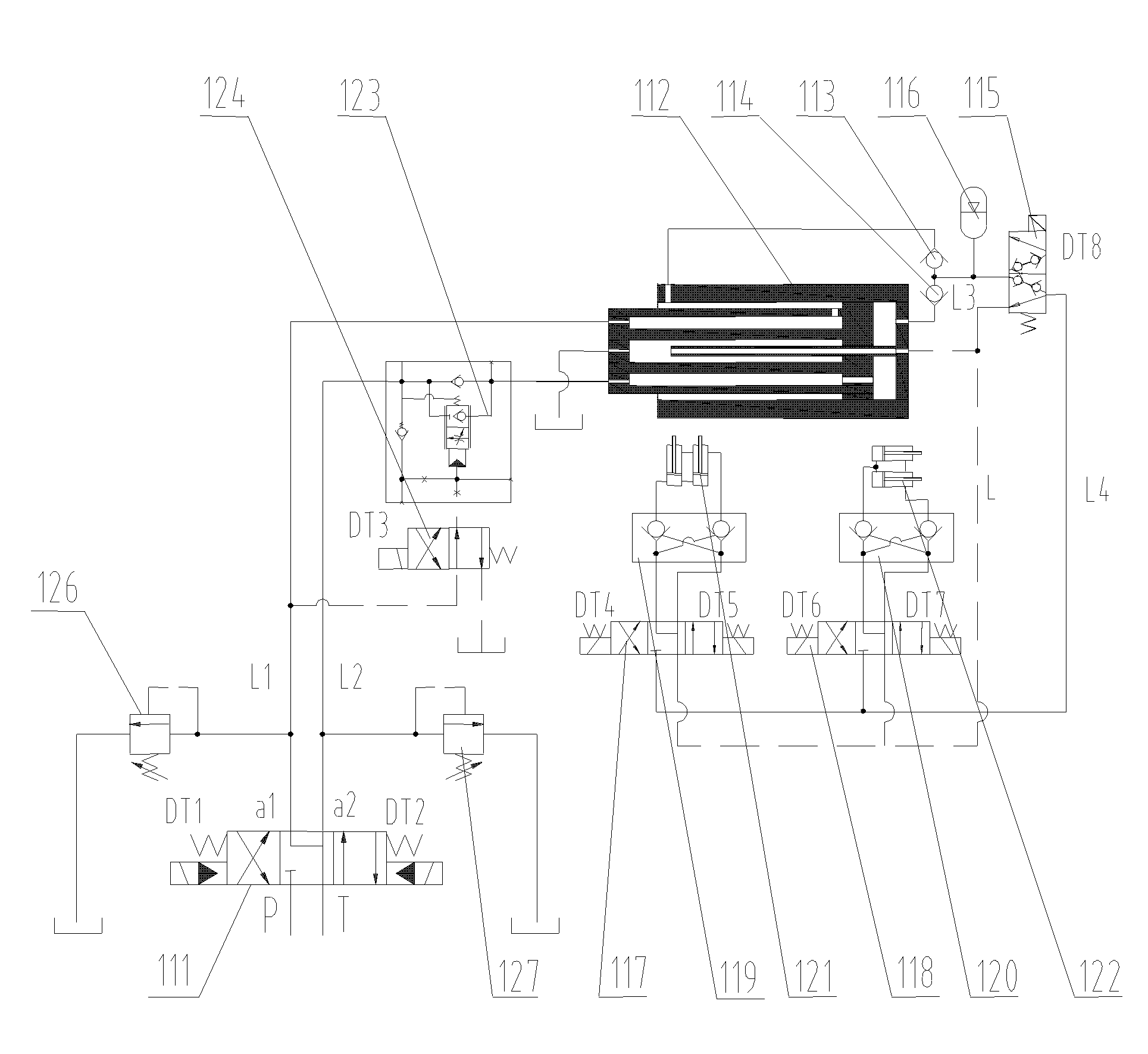

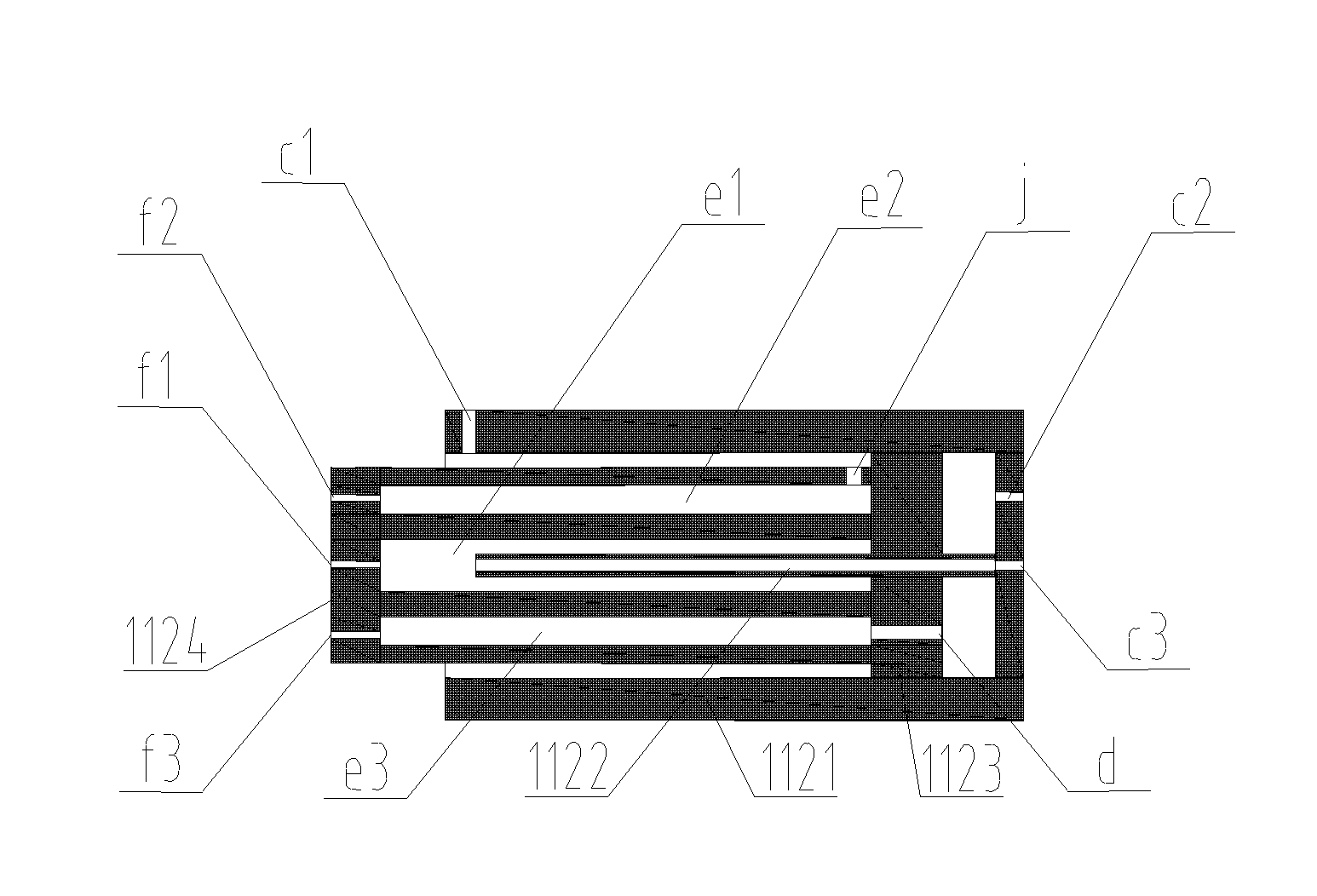

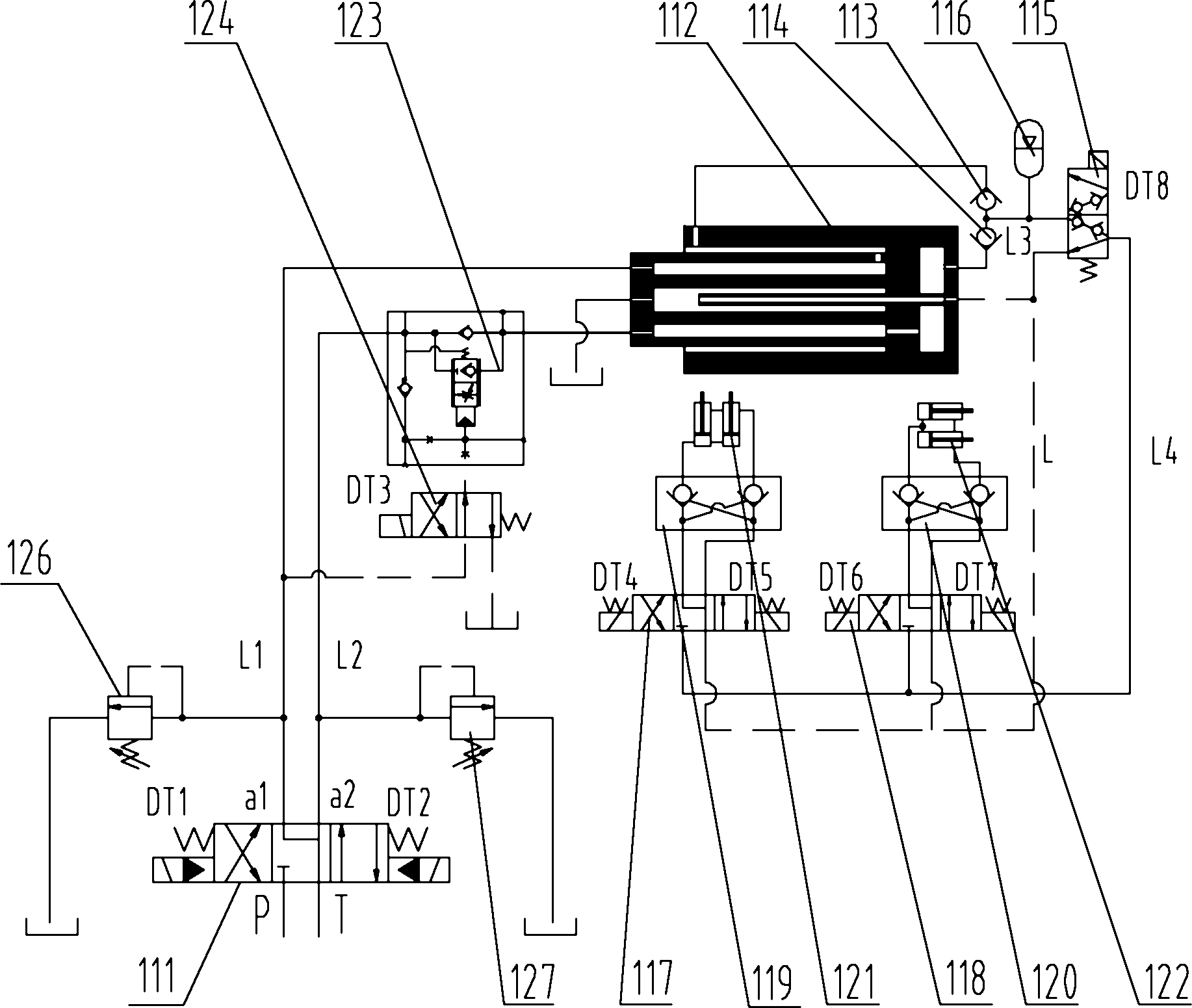

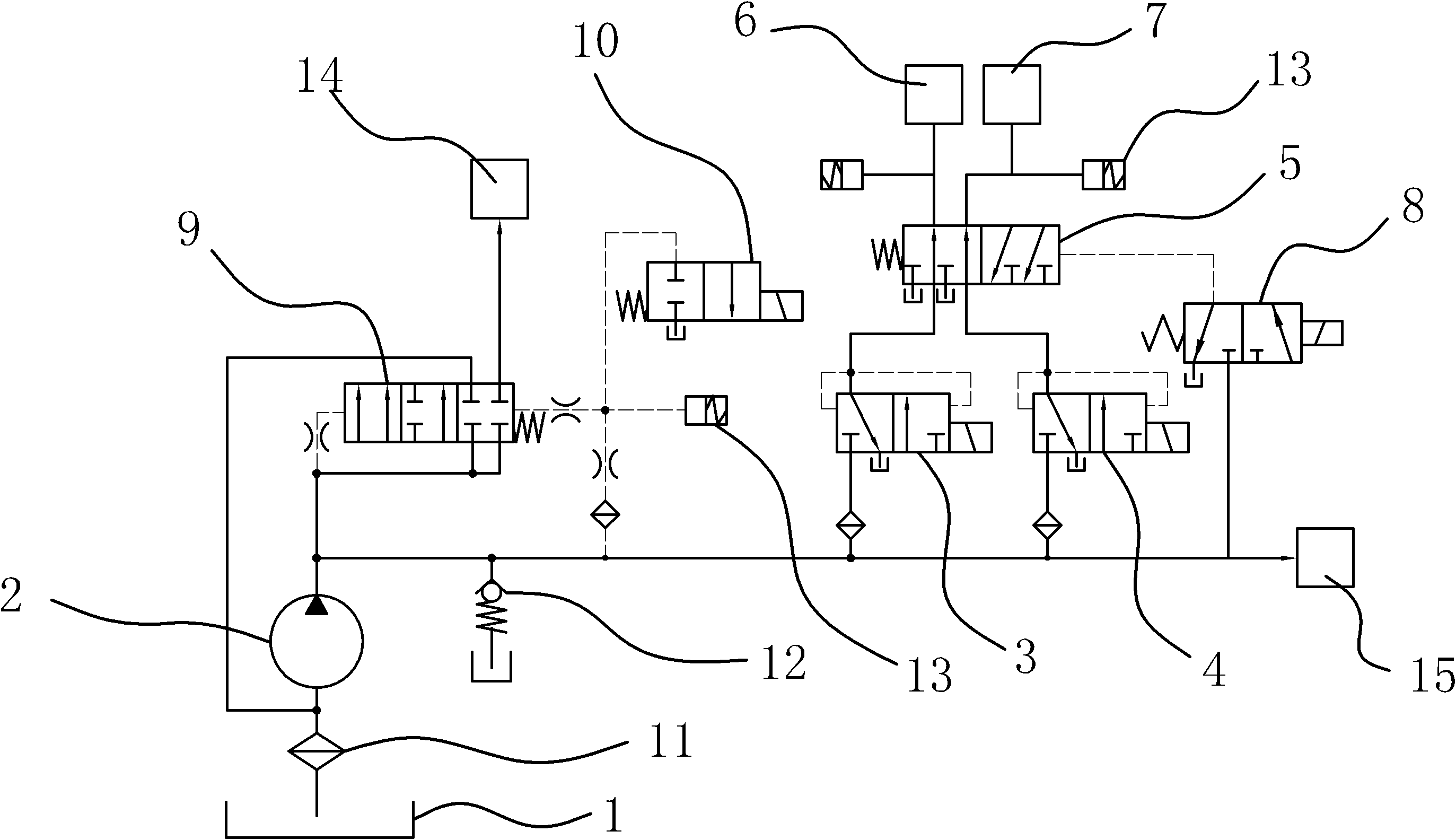

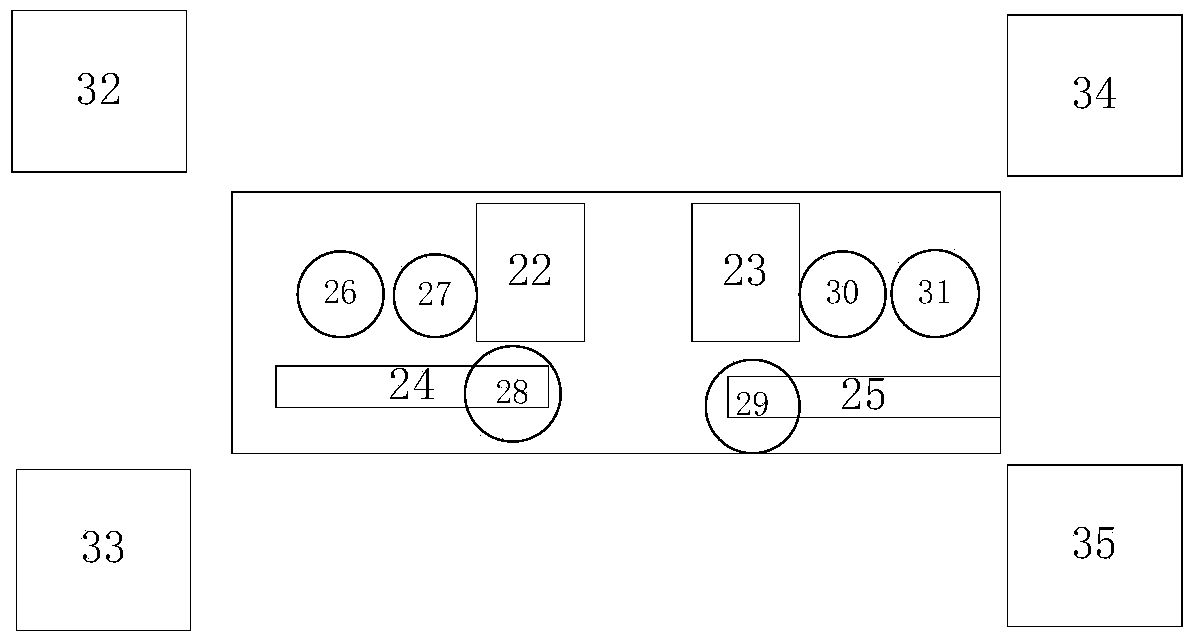

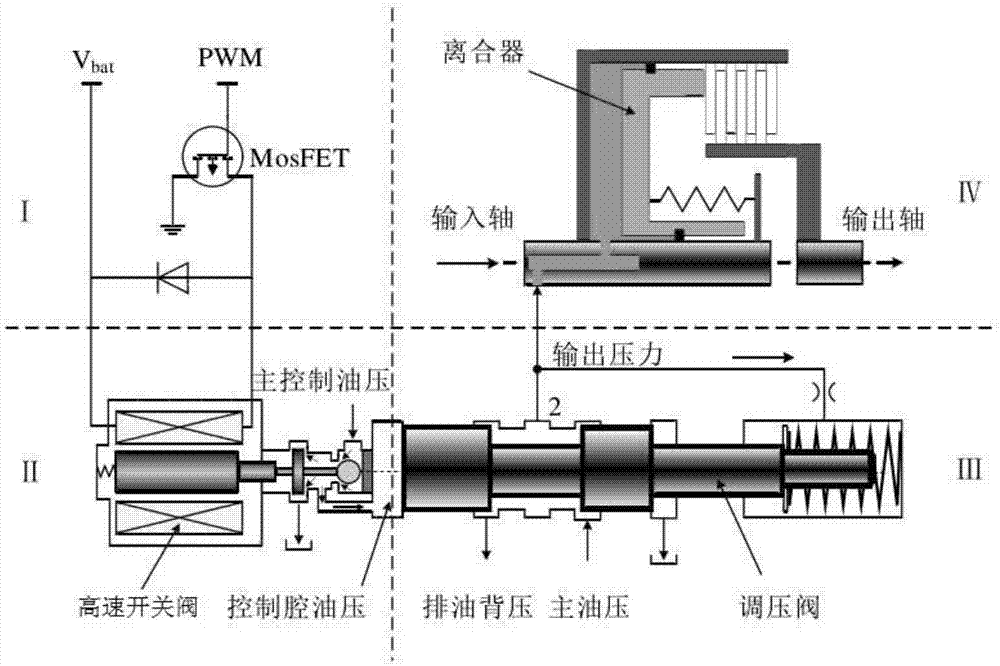

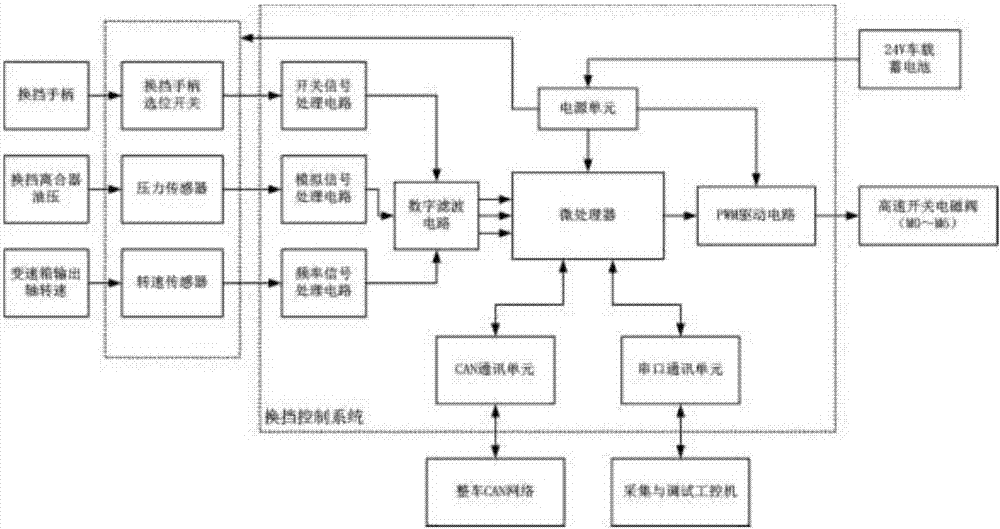

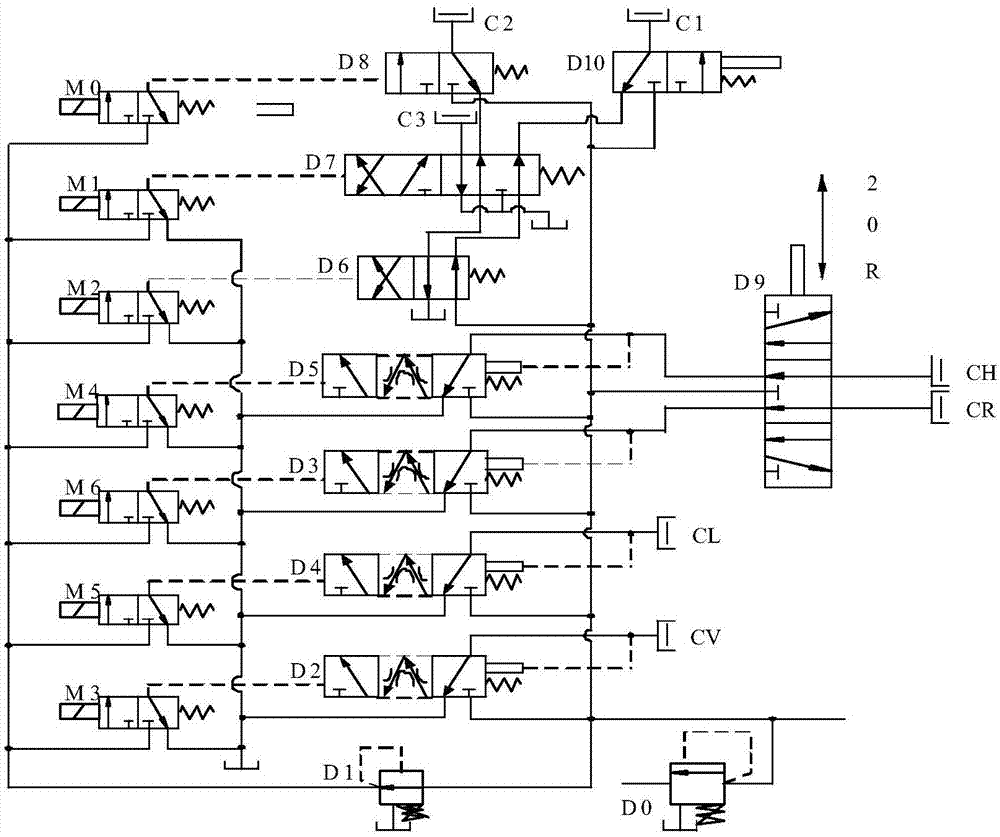

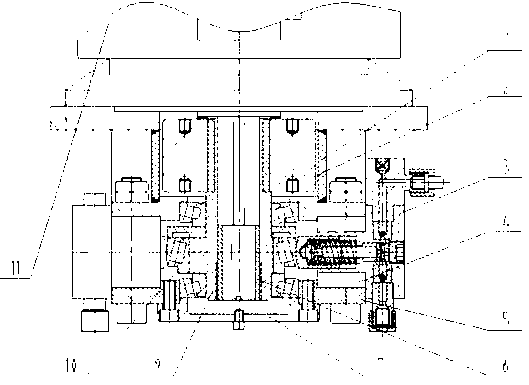

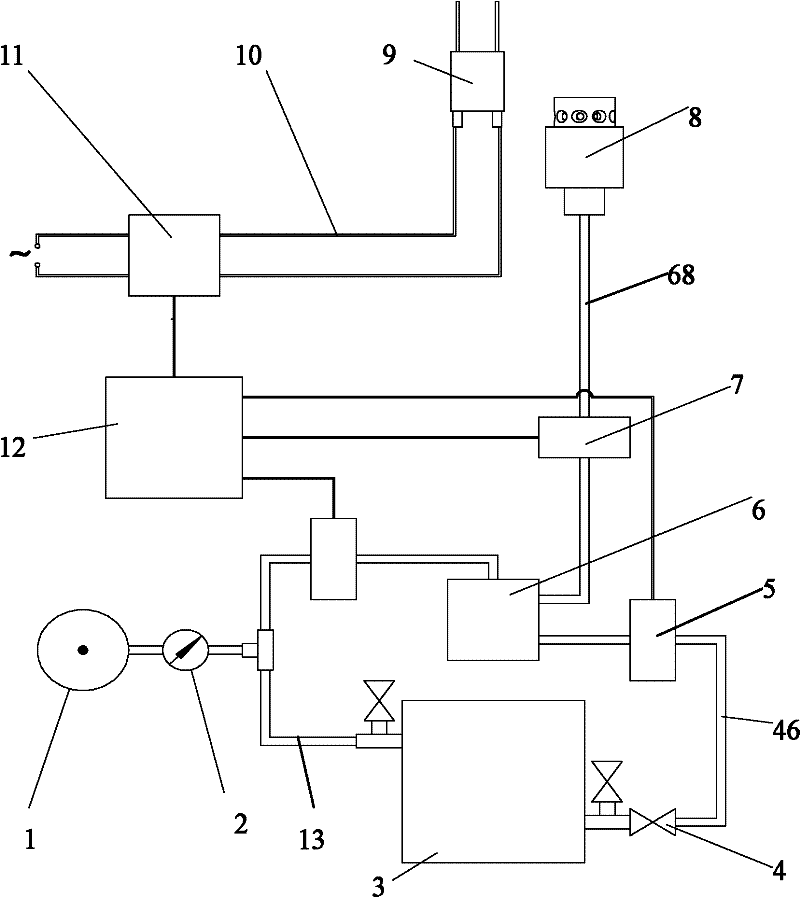

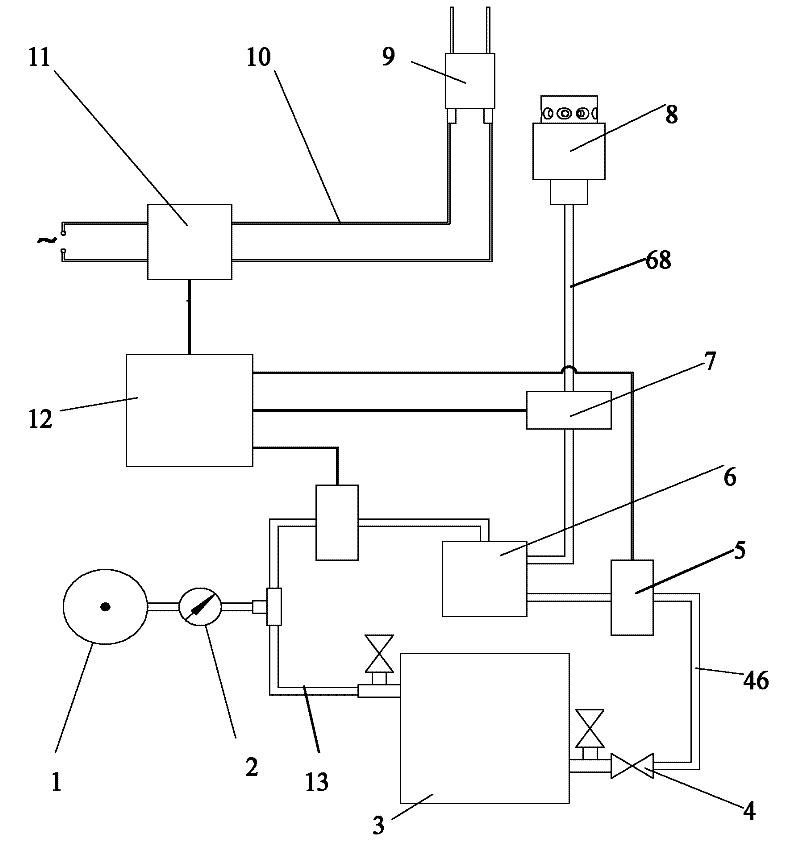

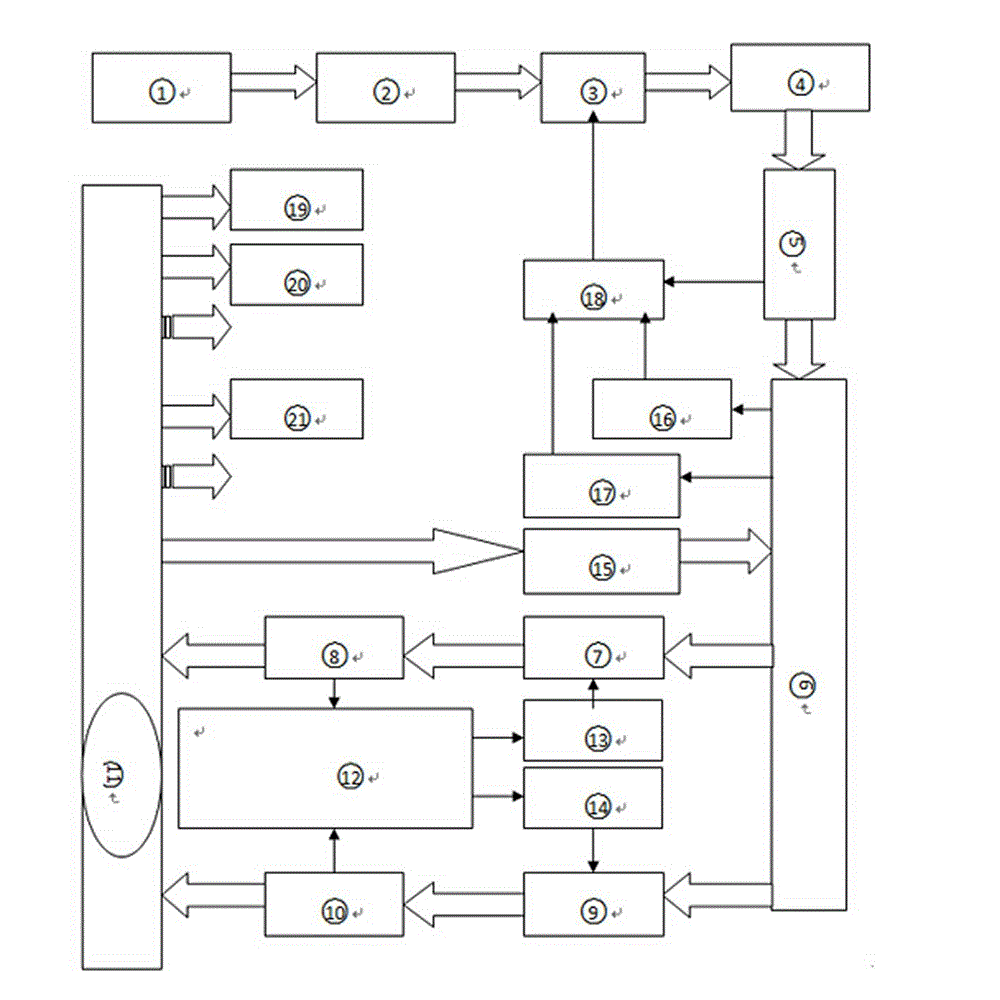

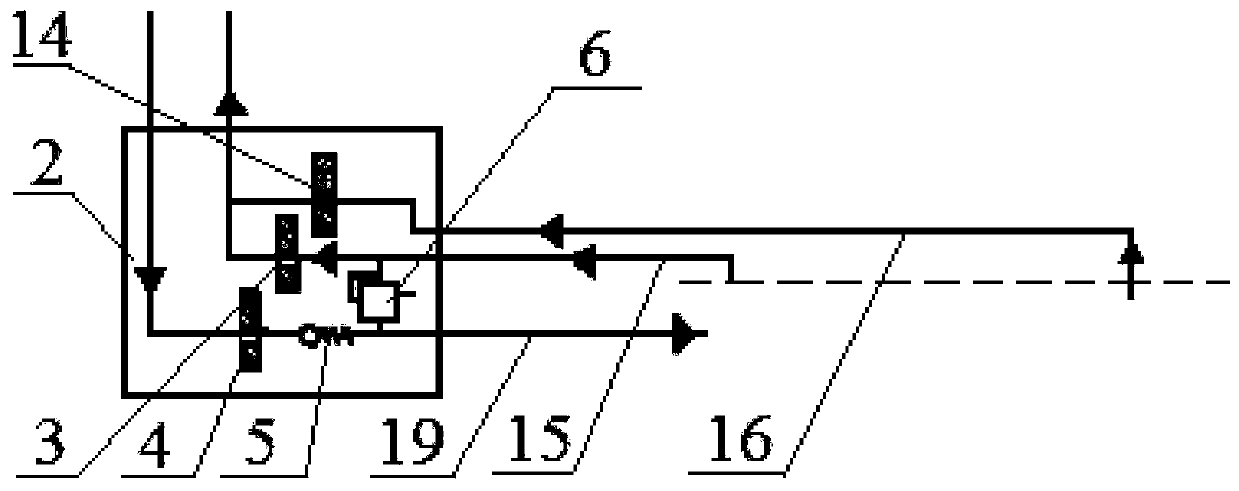

Electro-hydraulic control system of hydrodynamic-mechanic automatic transmission and control method of electro-hydraulic control system

ActiveCN107448595AEnsure safetyStable oil pressureGearing controlFluid gearingsAutomatic transmissionControl system

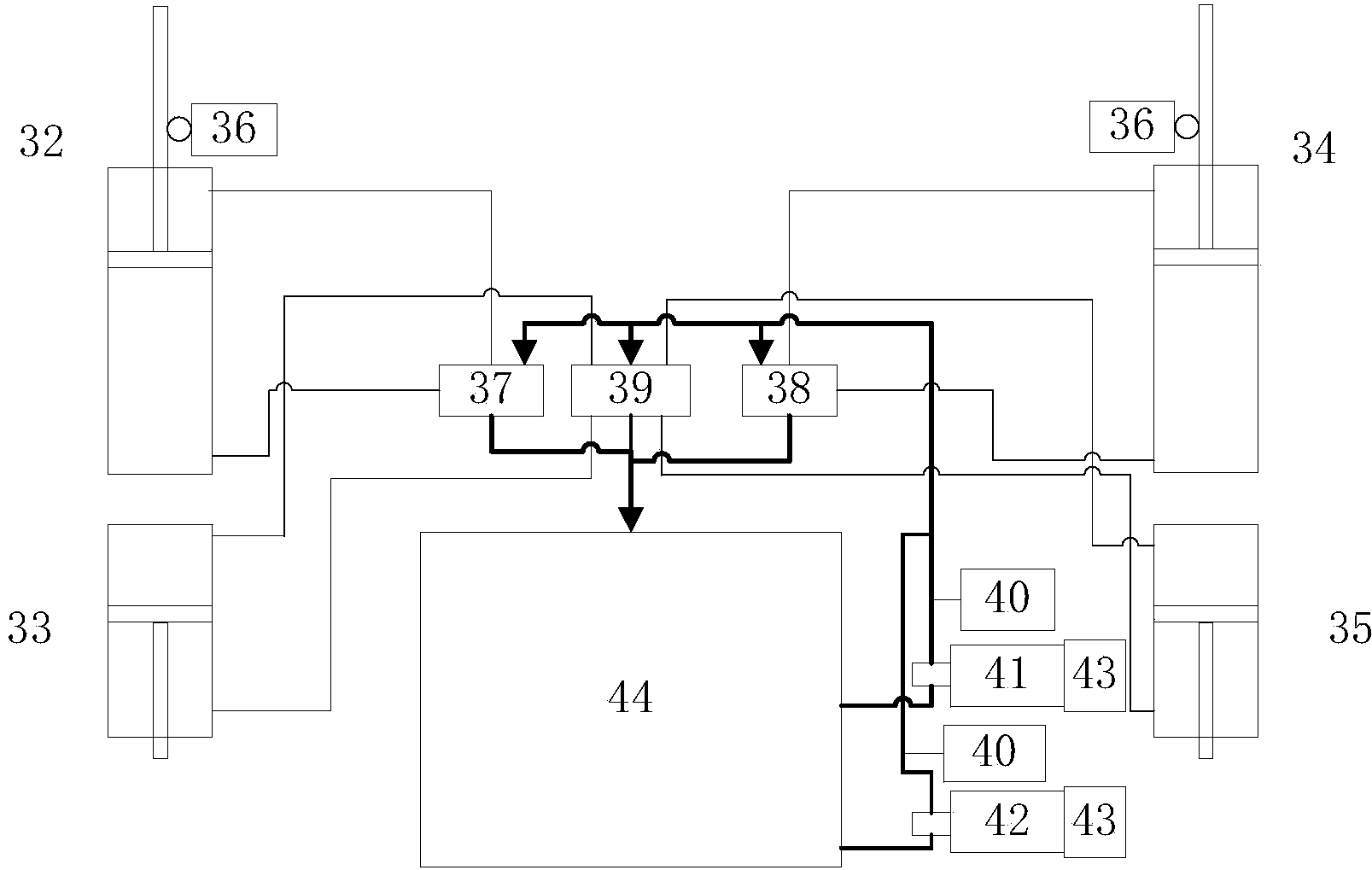

The invention relates to an electro-hydraulic control system of a hydrodynamic-mechanic automatic transmission and a control method of the electro-hydraulic control system. The electro-hydraulic control system comprises a shift control system, a shift lever, electromagnetic valves, a hydraulic shift valve group and a clutch; the shift control system is connected with the shift lever and the electromagnetic valves through wires, and the electromagnetic valves are connected with the hydraulic shift valve group; the hydraulic shift valve group is controlled through the electromagnetic valves, oil charging and discharging of a piston of the clutch is controlled, and connection and disconnection of the clutch is realized; automatic shift operation of the hydraulic mechanical type automatic transmission of tracked vehicles can be realized, system oil pressure is regulated in time through a pressure regulating valve of a hydraulic control system, stable oil pressure in loops is guaranteed, a manual shift mode and an automatic shift mode are switched smoothly, and safety of the system is guaranteed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

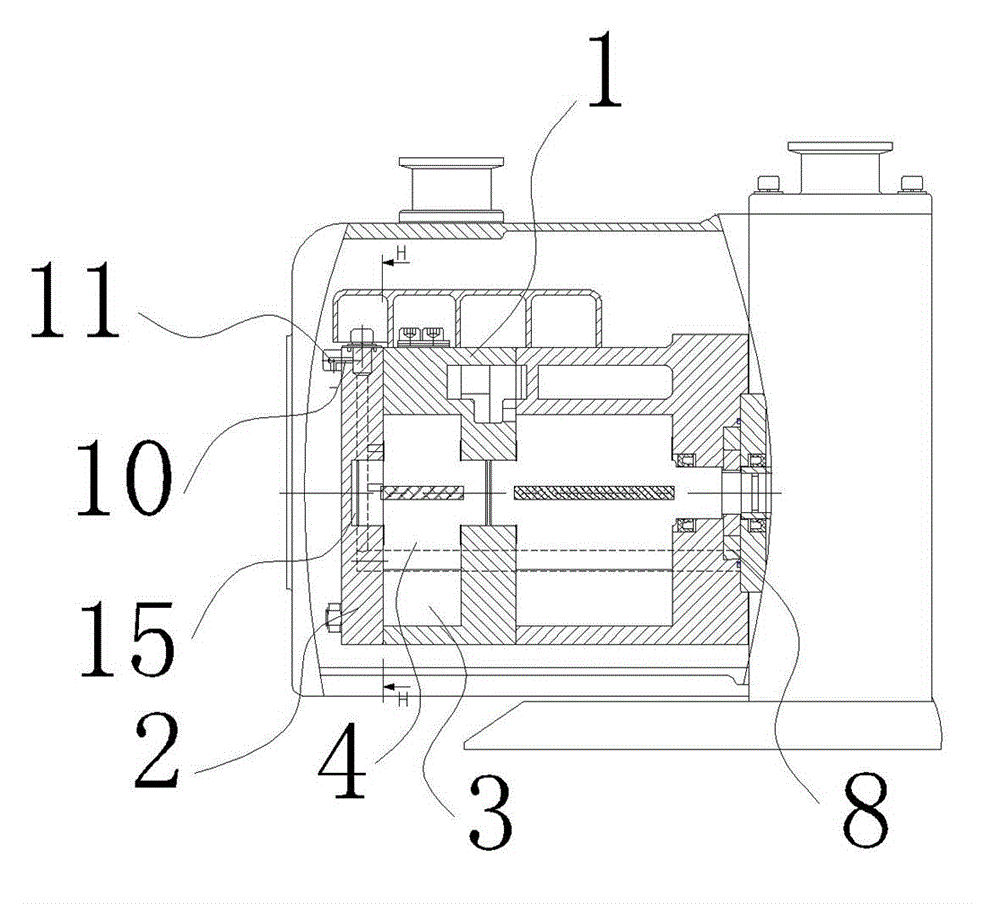

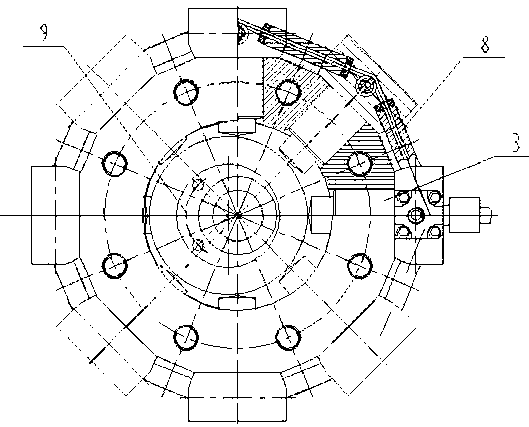

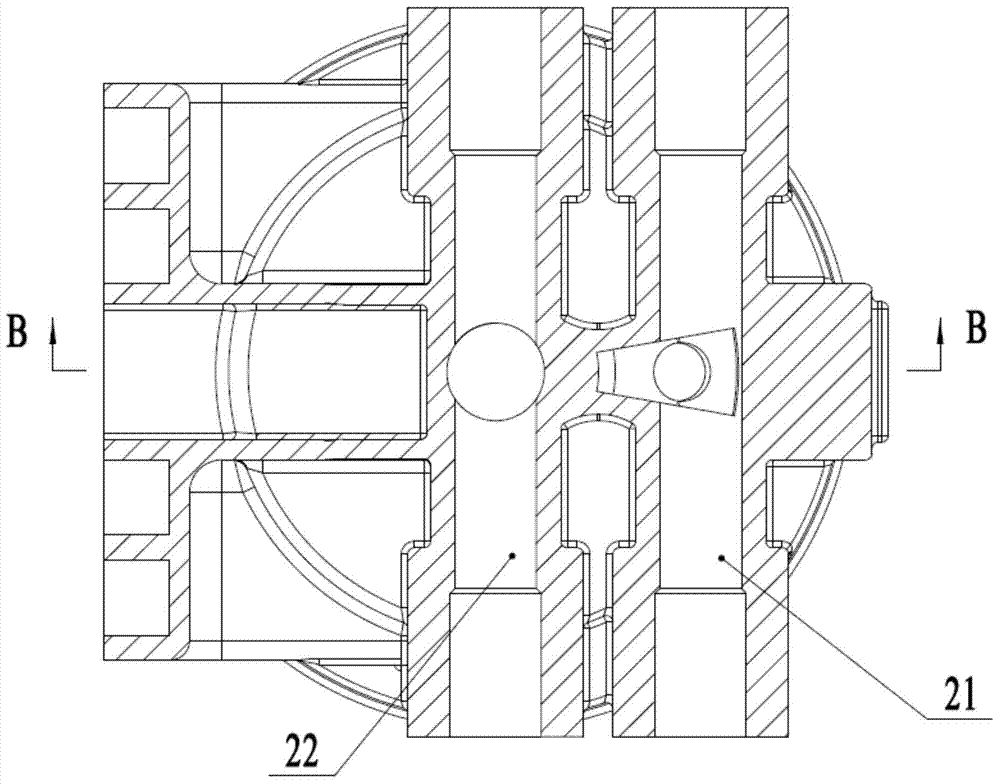

Ultrahigh pressure radial plunger pump

InactiveCN103133291AReduce intermediate linksEnsure adequate lubricationPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringVariable pressure

The invention discloses an ultrahigh pressure radial plunger pump, and belongs to the technical field of hydraulic control. The ultrahigh pressure radial plunger pump comprises a motor which is arranged on a bearing framework, an eccentric shaft is sleeved on an output shaft of the motor, multiple sets of plunger pumps are evenly distributed on the periphery of the eccentric shaft, the multiple sets of plunger pumps with the output shaft of the motor as the center, a conical roller bearing is sleeved on the eccentric shaft, and the outer ring of the conical roller bearing simultaneously contacts with the top ends of the multiple sets of plunger pumps with the output shaft of the motor as the center. The ultrahigh pressure radial plunger pump can achieve variable pressure and variable flow, the multiple plunger pumps can be in parallel connection, oil mass supply of a large-scale hydraulic pressure station is satisfied, sealing performance is good, service life is long, reliability is high, performance cost ratio is high, and the ultrahigh pressure radial plunger pump is suitable for application and popularization.

Owner:SICHUAN SHENGBAO ELECTRICAL TECH

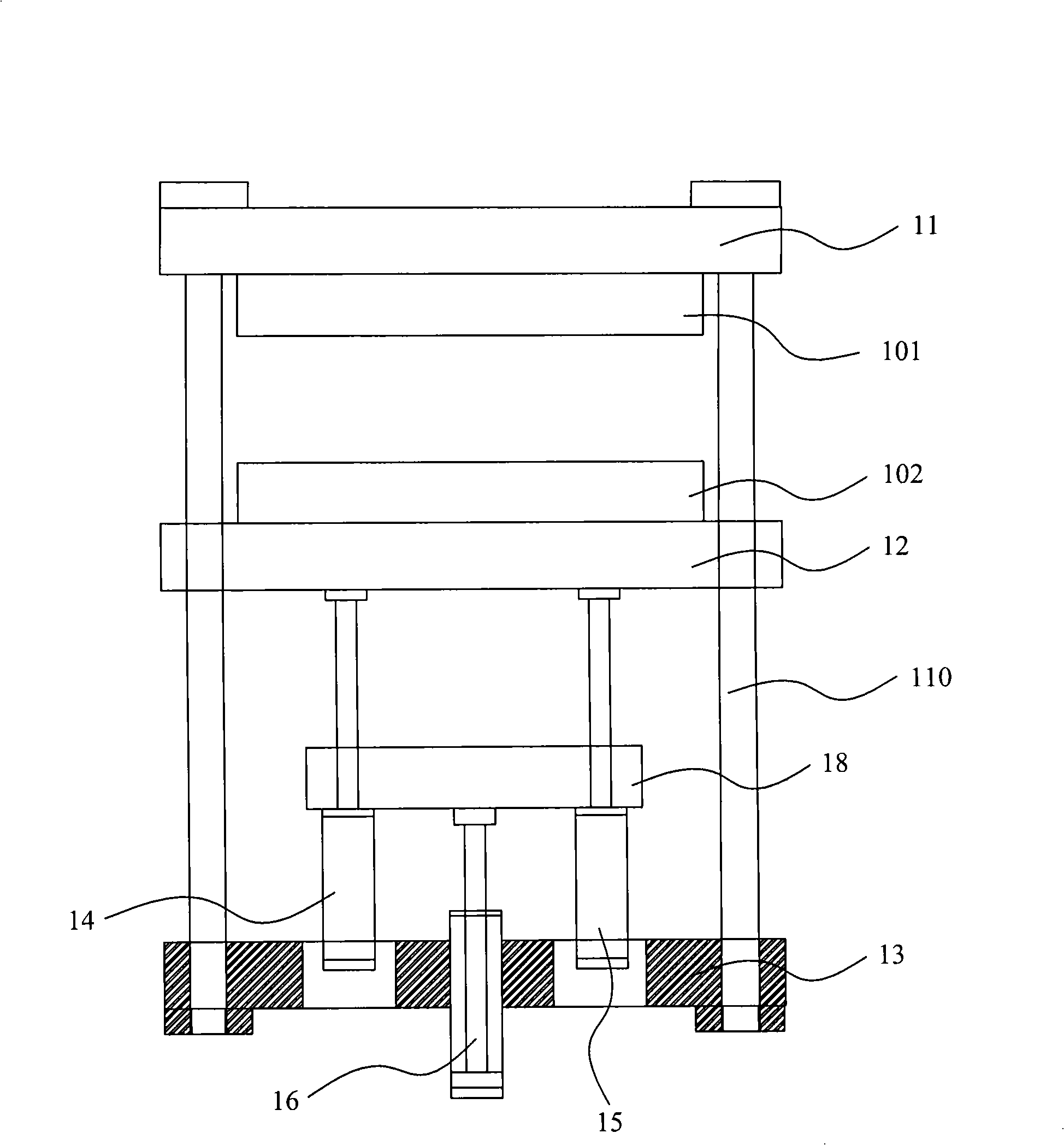

Foam maker and control method thereof

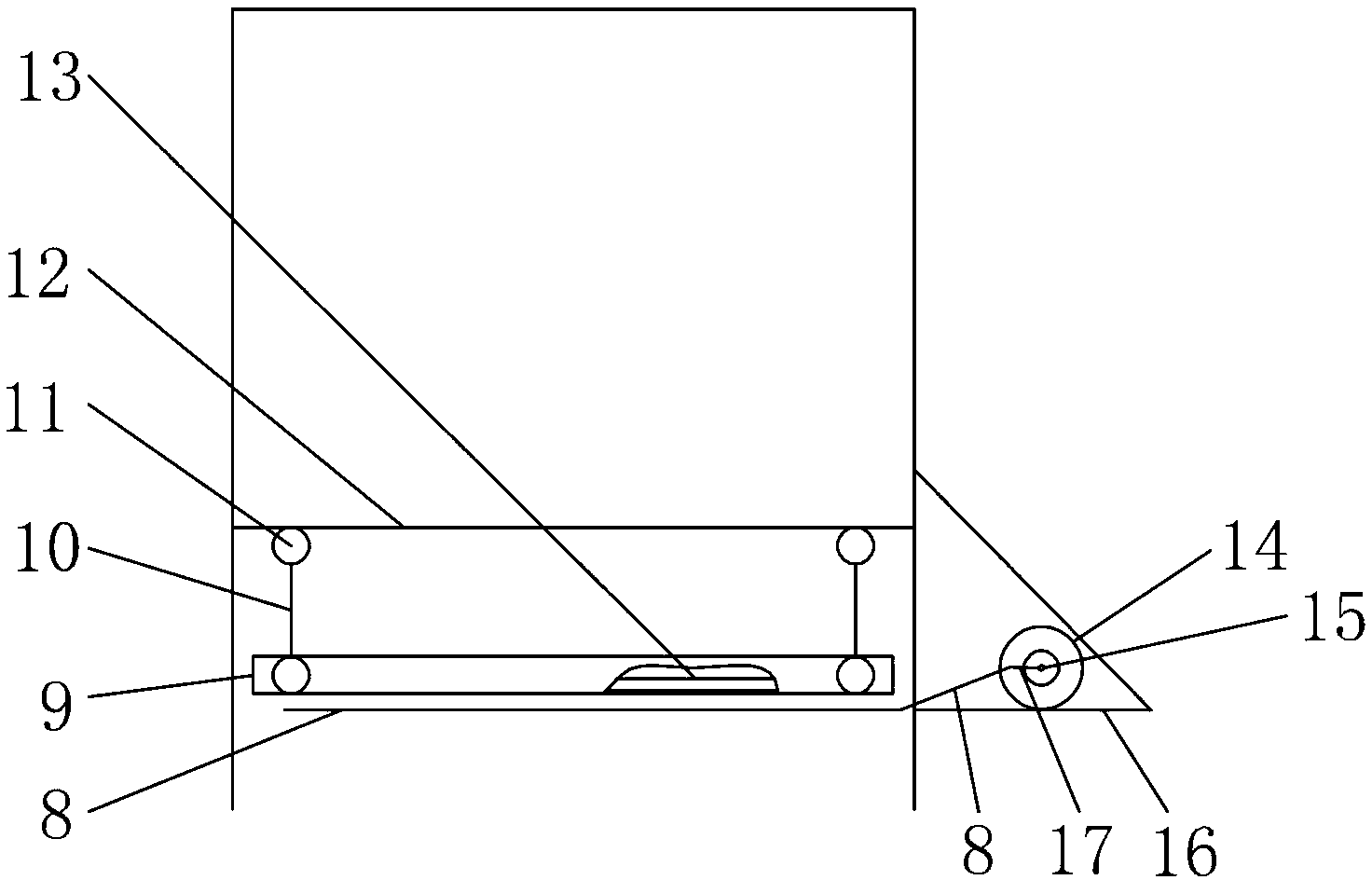

The invention provides a foaming machine which includes a clamping device. The clamping system includes a lower template which is fixed on the base of the foaming machine and is fixedly provided with a guide shaft; a middle template which is provided with a lower die, arranged above the lower template and can move up and down along the guide shaft; an upper template which is provided with an upper die opposite to the lower die and is arranged on the top part of the guide shaft and is above the middle template; an oil cylinder which is arranged between the middle template and the lower template and is characterized in that the oil cylinder is a secondary oil cylinder. The foaming machine according to the invention can reduce the height of the machine, increasing the parallelism of a compression die, improving the utilization efficiency of energies and improving the automatization of the machine.

Owner:蔡祥山

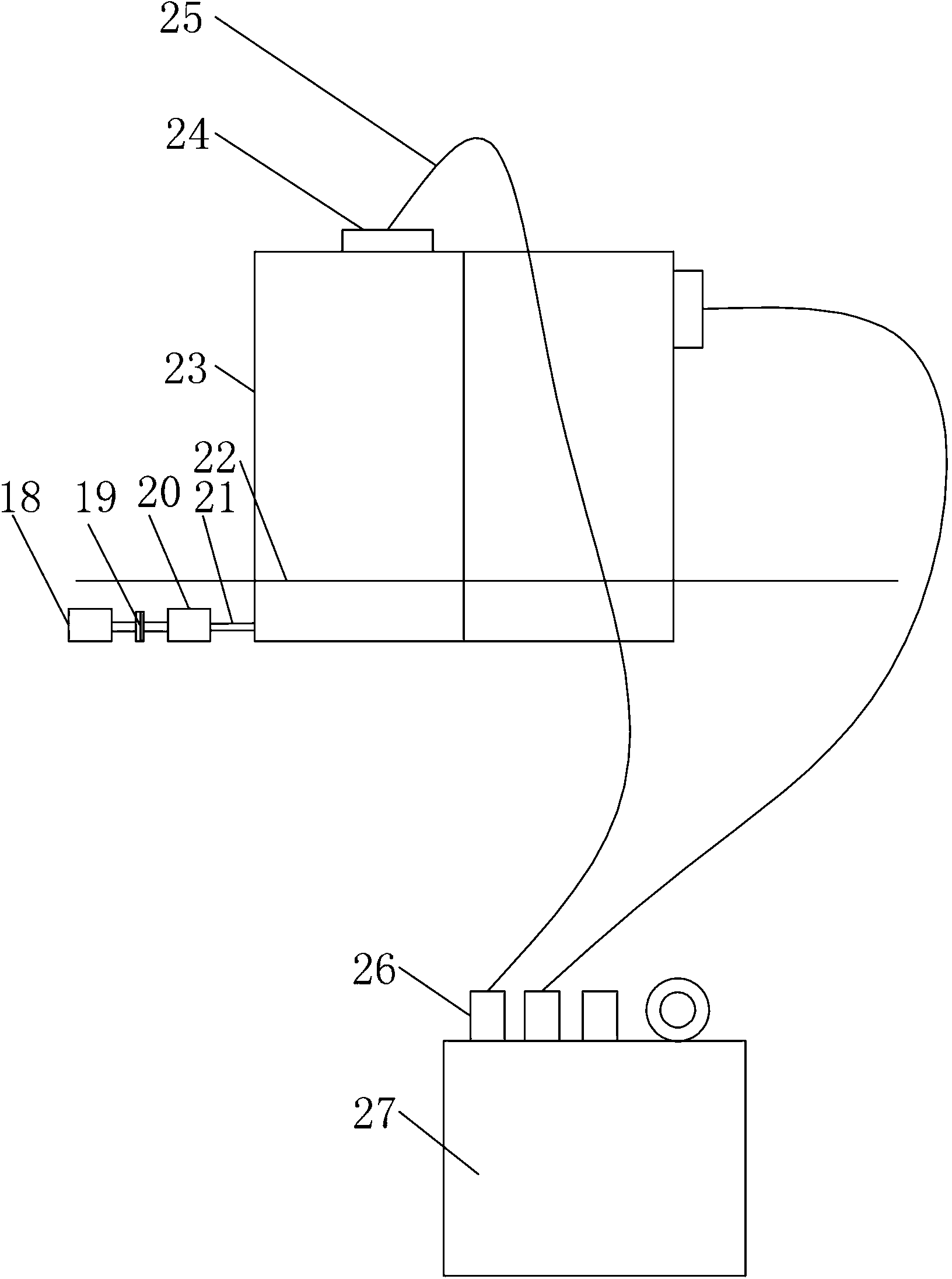

Fuel oil flaming system

The invention relates to a fuel oil flaming system, which comprises an oil storage device for storing fuel oil, a pressurizing device connected with the oil storage device to pressurize the fuel oil so as to form high-pressure fuel oil, an atomizing device connected with the oil storage device through a first pipeline (46) and used for atomizing the high-pressure fuel oil discharged from the oil storage device, and an ignition device for igniting the high-pressure fuel oil atomized by the atomizing device to form flame. By coordination of the pressurizing device, the atomizing device and the ignition device, the fuel oil is pressurized and fully combusted, and the shape of the flame is stable, so that the fuel oil flaming system is more energy-saving and environment-friendly, safe and stable.

Owner:华强方特(深圳)智能技术有限公司

Automatic constant-pressure control device used for centralized supply in process of spraying optical cable grease

InactiveCN104607332ASolve the average speedReduce labor intensityLiquid spraying apparatusFrequency changerProduction line

An automatic constant-pressure control device used for centralized supply in the process of spraying optical cable grease comprises a first-stage filter which is connected with a sprayed grease packaging barrel, the first-stage filter is connected with a grease inlet pump, the grease inlet pump is connected with a second-stage filter connected with a pressure control switch, the second-stage filter is connected with the grease inlet pump which is connected with a grease inlet pump control frequency converter, the second-stage filter is connected with a grease storage tank which is connected with a main pressure pump and an auxiliary pressure pump, the grease storage tank is connected with an electric control system through a weighing sensor and a proximity switch, pressure transmitters are connected with the grease storage tank through the main pressure pump and the auxiliary pressure pump, the main pressure pump and the auxiliary pressure pump are connected with the pressure transmitters through frequency converters, the electric control system is connected with the main pressure pump and the auxiliary pressure pump through the frequency converters, a pressure gauge is connected with the grease storage tank through a grease return detection pressure gauge, and the pressure gauge is connected with spraying guns from the first spraying gun to the twentieth spraying gun. The constant-pressure control technology is firstly introduced into the process of spraying the optical cable grease, and while pressure constancy of the sprayed grease is ensured, constant-pressure centralized supply for a large-scale production line is achieved.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

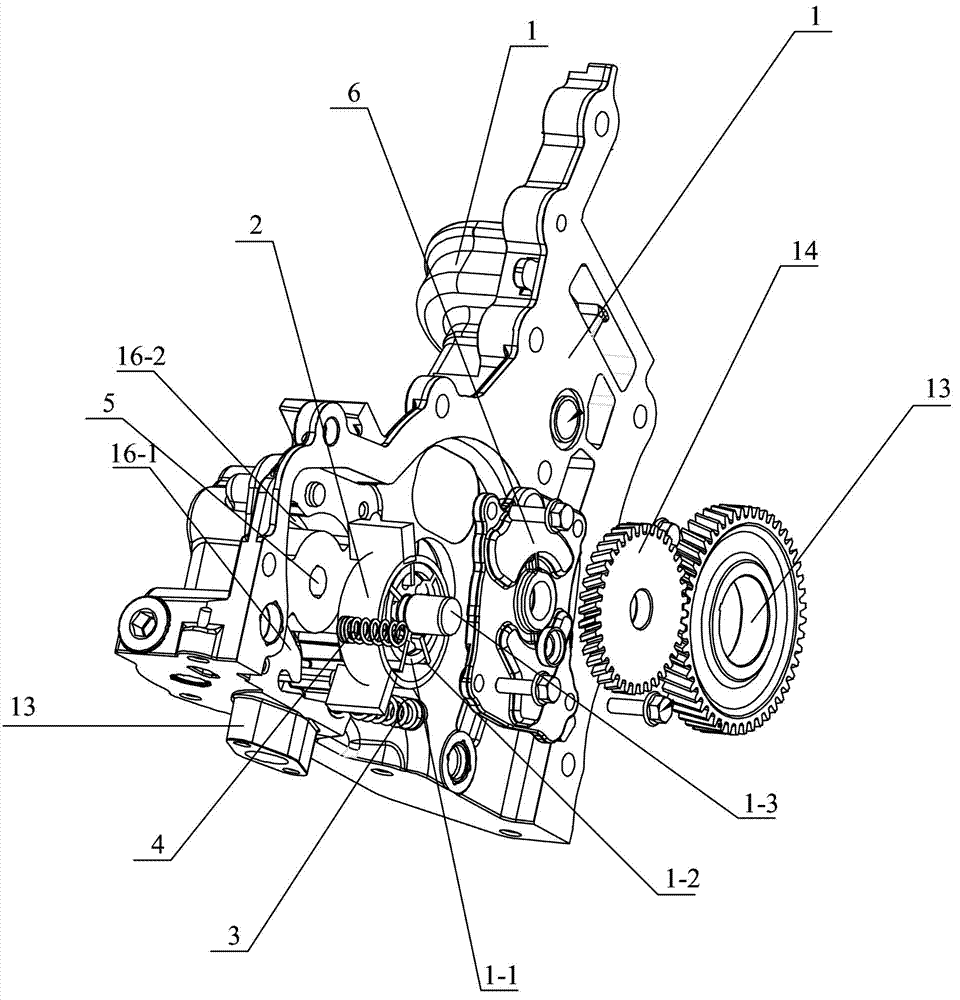

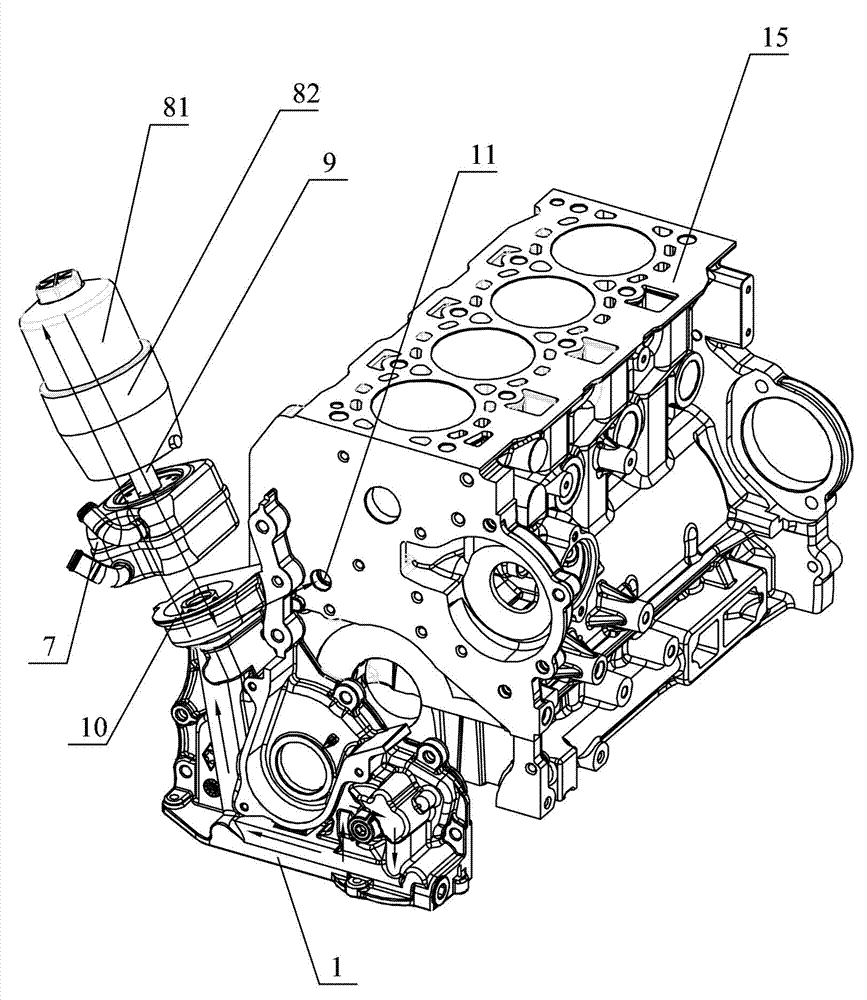

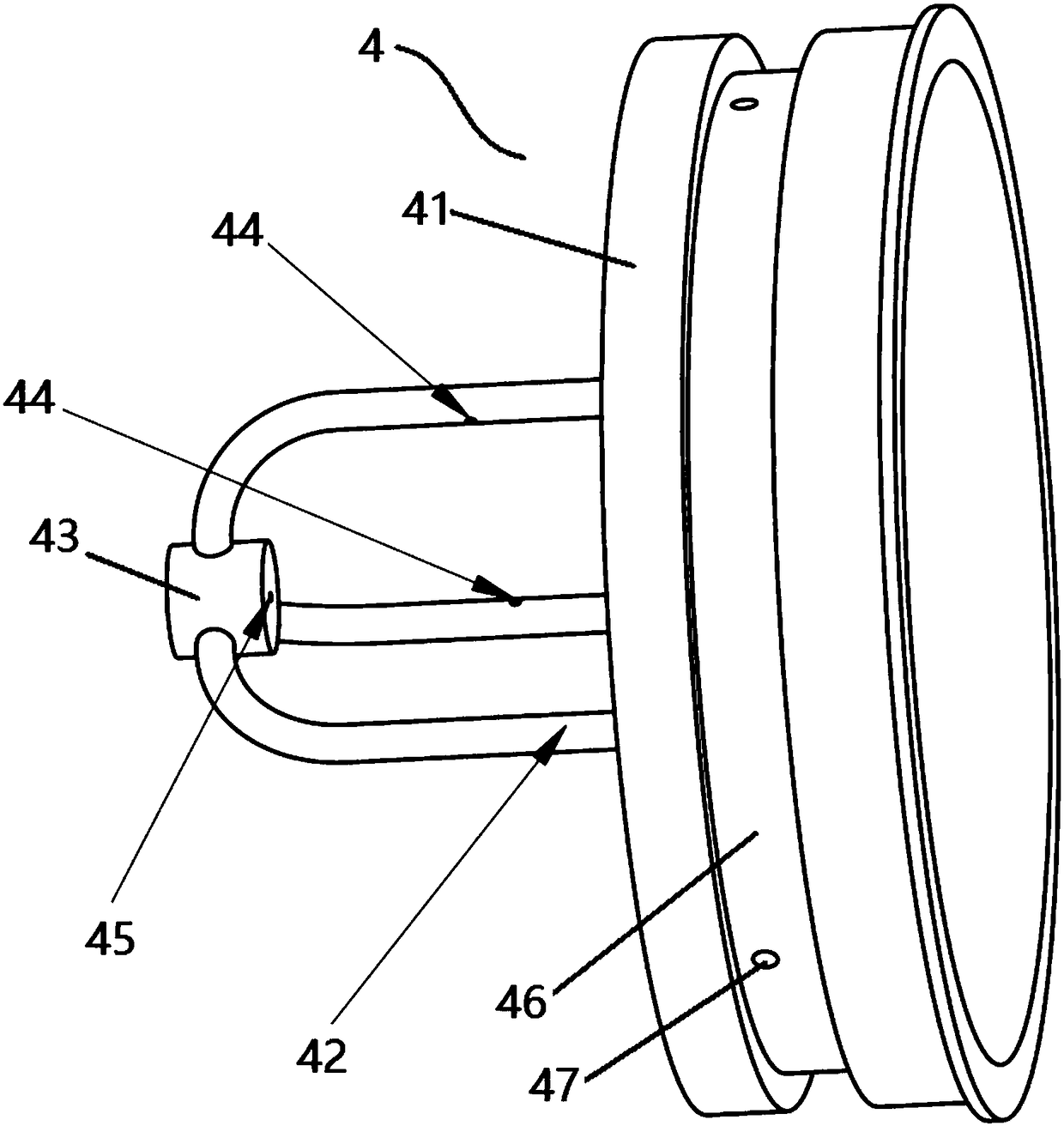

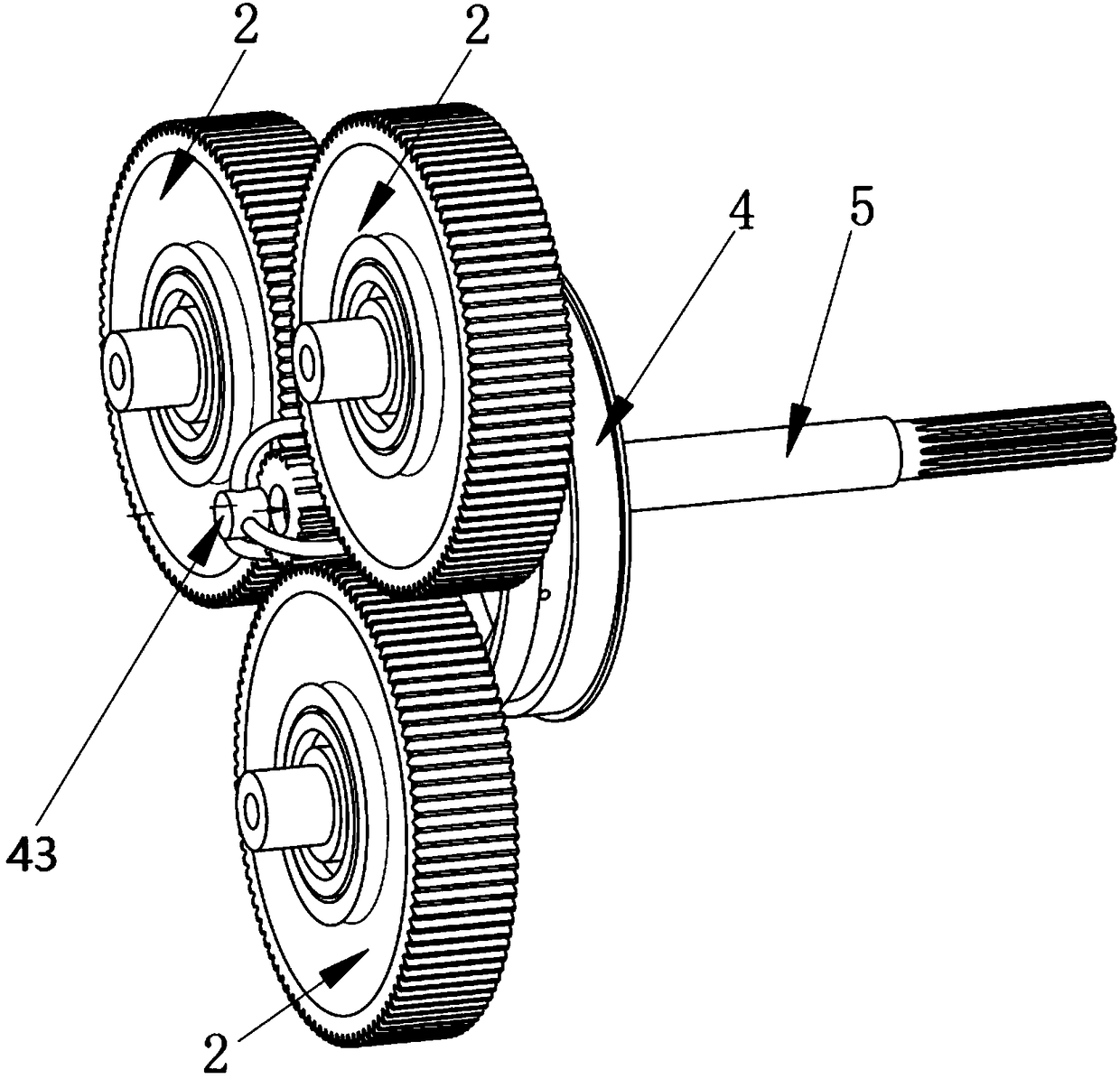

Parallel type rotor pump, liquid taking method and engine dry type oil pan lubricating system

ActiveCN103806977AContinuous and stable oil supplyStable oil pressureLubricating pumpsPressure lubrication with lubrication pumpEngineeringOil supply

The invention relates to a parallel type rotor pump, a liquid taking method and an engine dry type oil pan lubricating system. The parallel type rotor pump can conduct liquid supply and liquid return simultaneously; when the liquid level is horizontal, liquid in a liquid taking box can be pumped through a second liquid taking pipe, and when the liquid level is inclined, the liquid in the liquid taking box can be pumped through a first liquid taking pipe. According to the liquid taking method, by arranging the two liquid taking pipe with different liquid taking heights, it is guaranteed that the liquid can be pumped from the liquid taking box through the second liquid taking pipe when the liquid level is horizontal and the liquid can be pumped from the liquid taking box through the first liquid taking pipe when the liquid level is inclined. The lubricating system can enable an engine to pump engine oil in an oil pan through a first liquid taking passageway of the parallel type rotor pump under the working conditions that power is high, acceleration and deceleration are sudden, a left large dip angle and a right large dip angle are formed during turning, and severe jolt occurs, and therefore continuous and stable oil supply of the engine dry type oil pan lubricating system can be guaranteed.

Owner:HUBEI SANJIANG BOATS SCI & TECH

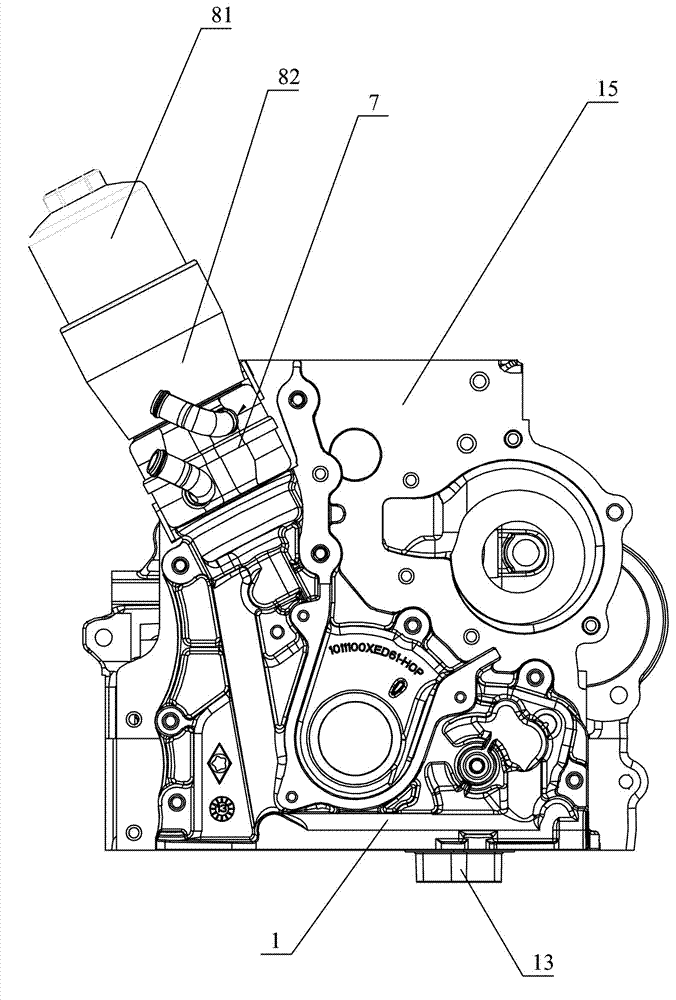

Engine oil pump with variable displacement and engine lubrication system with same

ActiveCN103196024AStable oil pressureImprove performanceMachines/enginesLubricating pumpsLubricationOil pressure

The invention relates to an engine oil pump with variable displacement. The engine oil pump with the variable displacement comprises a blade groove wheel which generates negative pressure through rotation so as to enable engine oil to be absorbed in the engine oil pump from an oil bottom casing. Blades of the blade groove wheel are arranged in a rotation cavity of an engine oil pump casing, and the rotation cavity is arranged on the engine oil pump casing through an eccentric distance adjusting mechanism and a blade central shaft in adjustable eccentric distance mode. The invention further provides an engine lubrication system with the engine oil pump with the variable displacement. The engine oil pump is simple in structure, short in engine oil flow oil path and small in oil path resistance, guarantees main oil path oil pressure, and simultaneously can save energy and reduce emission. The engine oil pump and the lubrication system are suitable for engines of various vehicles.

Owner:长城汽车股份有限公司平湖分公司

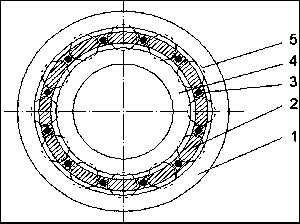

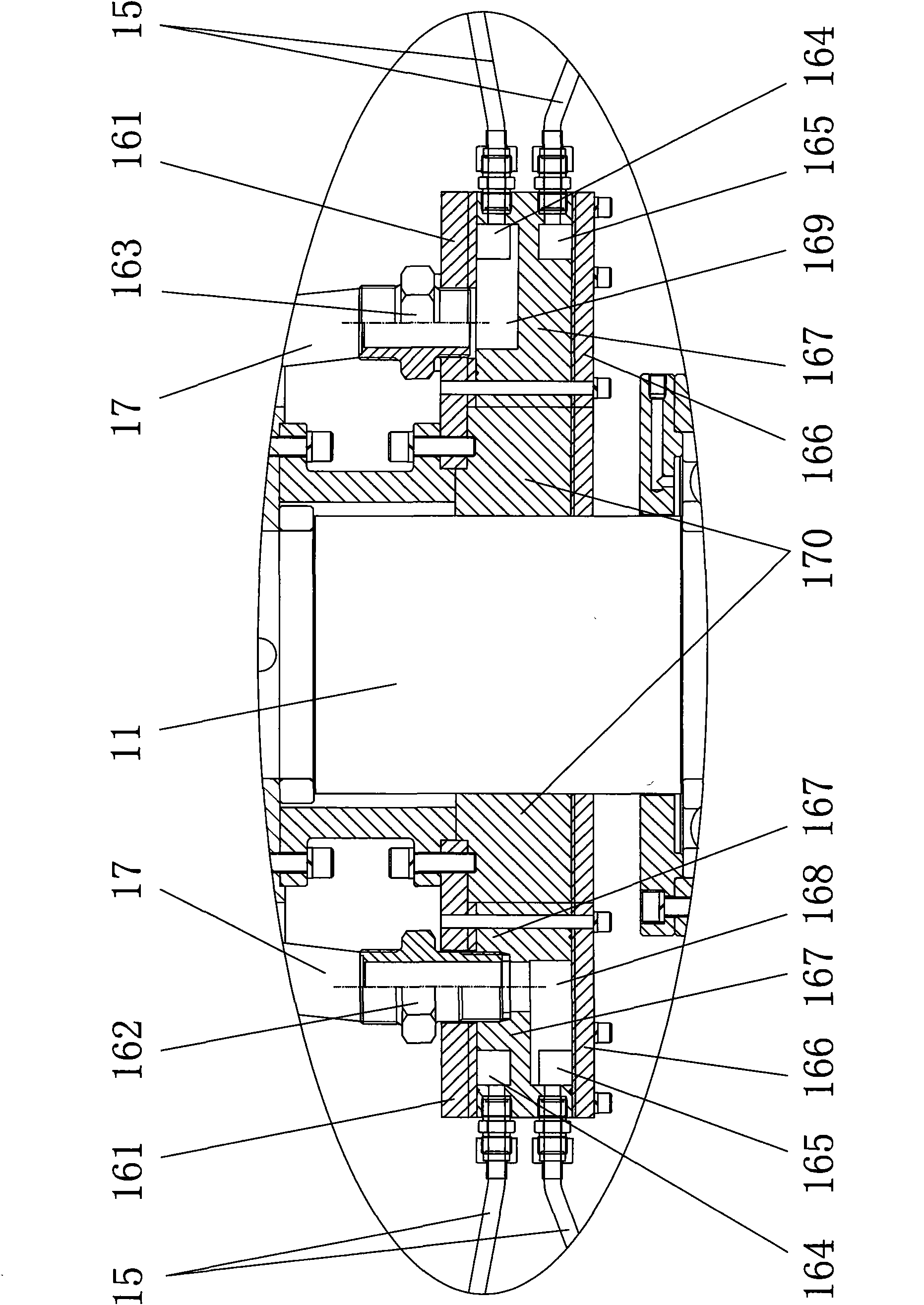

Marine large dismountable and self-lubricating rolling bearing device

InactiveCN108194513AExtended service lifeStable oil pressureBearing componentsEngine lubricationElectricityControl set

A marine large dismountable and self-lubricating rolling bearing device comprises a bearing inner ring, a bearing outer ring, a roller, a dismountable retainer, a pressurization oil tank, an oil tankelectromagnetic valve, a pressurization pump and an external control set, wherein the dismountable retainer is arranged between the bearing inner ring and the bearing outer ring, and roller swim ringtype sealing rings are arranged in pocket holes of the dismountable retainer and disposed on two sides of the bearing; the pressurization oil tank communicates with the swim ring type sealing rings through the oil tank electromagnetic valve and communicates with the pressurization pump; the oil tank electromagnetic valve is arranged on the lower side of a tank body of the pressurization oil tank and electrically connected with the external control set; the pressurization pump communicates with the pressurization oil tank and communicates with the swim ring type sealing rings; and the externalcontrol set is electrically connected with the oil tank electromagnetic valve, the pressurization pump and the swim ring type sealing rings. By the adoption of the dismountable retainer, when a certain part of the rolling bearing is abraded or damaged, the dismountable retainer can be opened, the abraded or damaged part is replaced, and overall replacement is not needed. The sealing rings are provided with a self-lubricating device so that the stable oil pressure in the bearing can be maintained and the service life of the bearing can be prolonged.

Owner:ZHEJIANG OCEAN UNIV

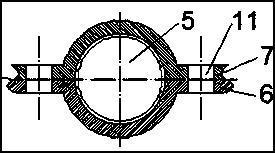

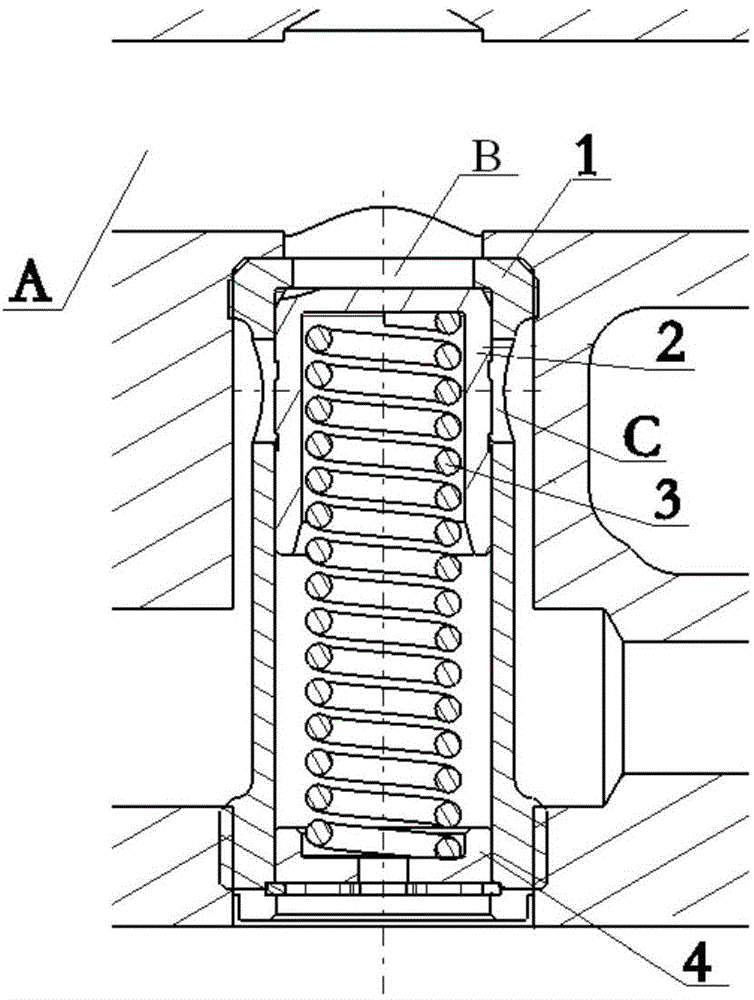

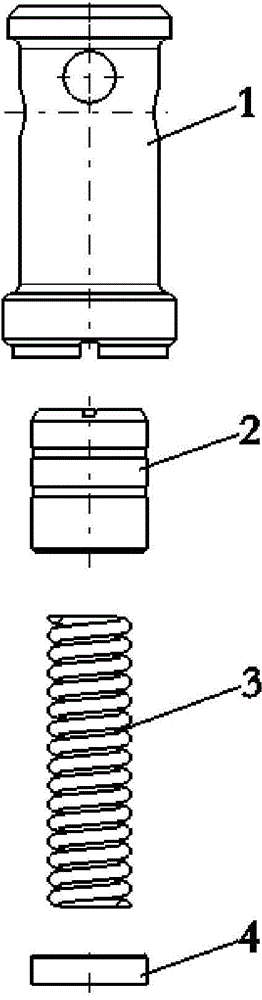

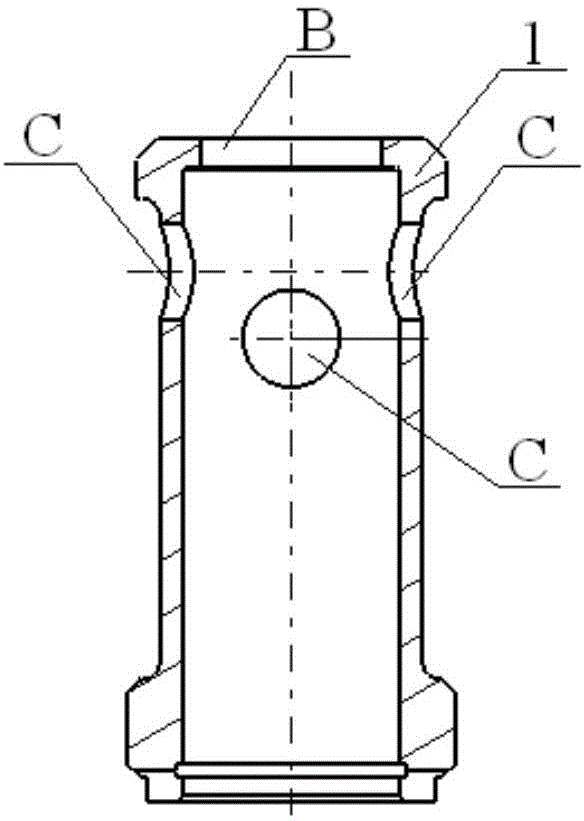

Engine and pressure limiting valve thereof

InactiveCN104153841AHigh working reliabilityAvoid breakingLubrication pressure controlVariable stiffnessHigh stiffness

The invention discloses a pressure limiting valve of an engine. The pressure limiting valve of the engine comprises a valve body, a valve element and a spring, wherein the valve element and the spring are arranged in the valve body; the valve element is in sliding fit with the valve body through the spring; the valve body is provided with an oil discharging hole and an oil feeding hole; the oil feeding hole and the oil discharging hole are connected with each other while the spring is compressed and are disconnected from each other while the spring recovers; the spring is a variable-stiffness spring; and the stiffness of one end, which is close to the valve element, of the variable-stiffness spring is smaller than that of the other end, which is far away from the valve element, of the variable-stiffness spring. Because the spring is the variable-stiffness spring, the stiffness of the side, which is close to the valve element, of the spring is small; when the pressure of a main oil gallery fluctuates, the recovery speed of the valve element is reduced, fluctuation of the valve element due to high stiffness of the inside of the valve body is effectively restrained, and a phenomenon that the spring and the engine naturally vibrate, so that resonance is caused, and the spring is broken is avoided; the service life of the spring is greatly prolonged; and the working reliability of the pressure limiting valve is improved. The invention also provides an engine comprising the pressure limiting valve.

Owner:WEICHAI POWER YANGZHOU DIESEL ENGINE

Brick making system device

InactiveCN103252836ASmall particle sizeIncrease usageCeramic shaping plantsAuxillary shaping apparatusMachining vibrationsBrick

The invention discloses a brick making system device, and belongs to the technical field of brick manufacture. A three-box batching machine vibration device is arranged between a three-box batching machine and a weighing device, a brick making pipeline is changed, and an automatic board feeding machine matched with a brick making machine is additionally arranged. A discharging port of the weighing device is connected with a feeding port of a stirrer through a conveying belt, and a discharging port of the stirrer is connected with a feeding box of the brick making machine through a conveying belt. After the vibration part is added, the size of material particles can be effectively reduced, a metal object is screened and removed, product quality is guaranteed, a using ratio of a die is improved, and a damaged rate of the brick making machine is reduced. The pipeline of the brick making machine is shortened, maintenance is convenient, oil pressure is stable, energy consumption is low, and maintaining cost is effectively reduced. After the matched automatic board feeding machine is additionally arranged, labor intensity is reduced, four to six boards can be pushed at a time, and working efficiency is improved accordingly.

Owner:DEZHOU TIANYUAN GRP

Parallel multi-dimensional swing wave power generation device

InactiveCN103306882BImprove sealingReduced risk of corrosionMachines/enginesEngine componentsHydraulic cylinderHydraulic motor

The invention discloses a novel parallel multidimensional oscillating sea wave power generation device. The novel parallel multidimensional oscillating sea wave power generation device comprises a floater, and a sealing cover plate, a two-dimensional rotating hinge, an oscillating rod, an oscillating platform, six hydraulic cylinders, an oil tank, a hydraulic motor, a power generator and an energy accumulator which are all arranged in the floater, wherein the sealing cover plate is fixedly connected to a protruding eave of the floater; the oil tank is fixedly connected to the floater; one end of the two-dimensional rotating hinge is fixedly connected to the sealing cover plate and the other end is connected to the oscillating rod; one end of the oscillating rod penetrates through the sealing cover plate to be fixedly connected to an external device and the other end is fixedly connected to the oscillating platform; the six hydraulic cylinders are connected in parallel to work; the two ends of the six hydraulic cylinders are respectively hinged to the oscillating platform and the oil tank through spherical hinges; the oil tank is connected with the hydraulic motor through a flow-dividing pipe and a return pipe; the power generator is connected with the hydraulic motor; the power generator and the hydraulic motor are arranged on the bottom surface of the floater; the energy accumulator is connected with the hydraulic motor. The novel parallel multidimensional oscillating sea wave power generation device has the advantages of long service life, low maintenance cost, low environmental pollution, capability of fully absorbing sea wave energy, high power generation efficiency and the like.

Owner:SHANGHAI JIAOTONG UNIV

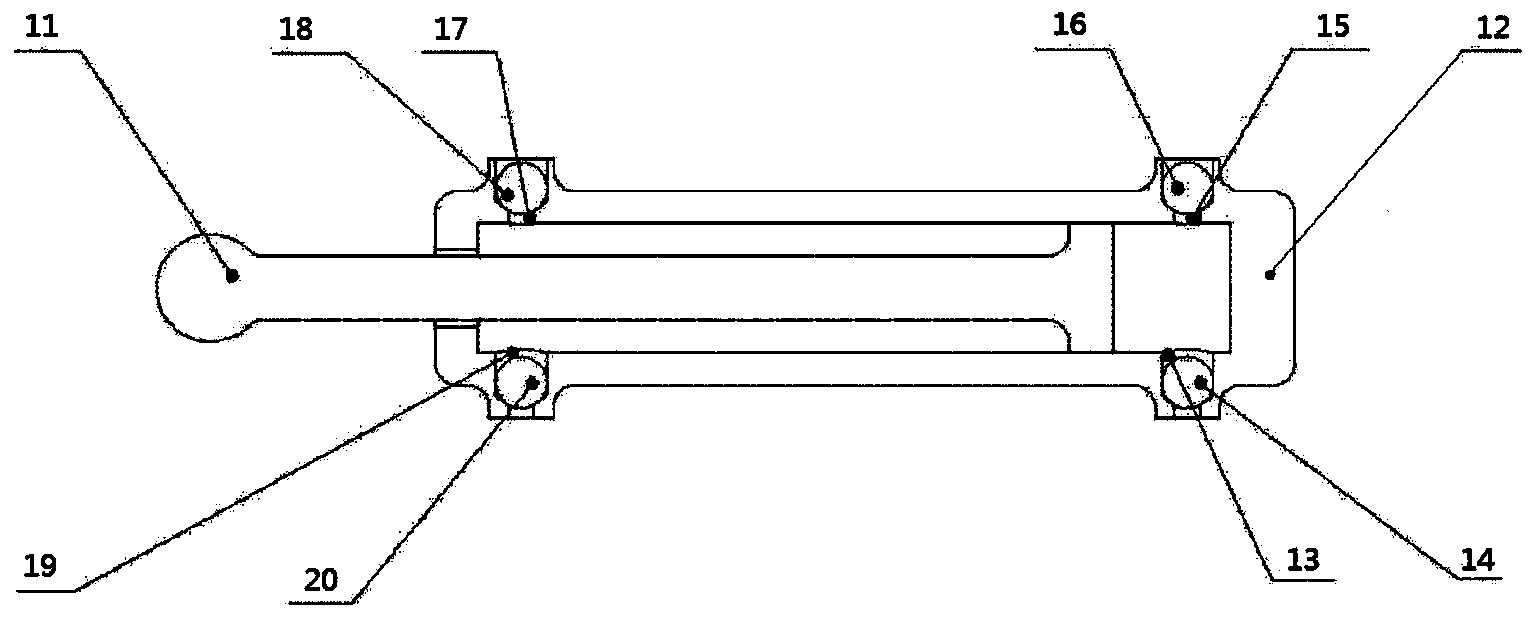

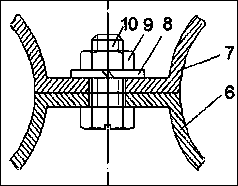

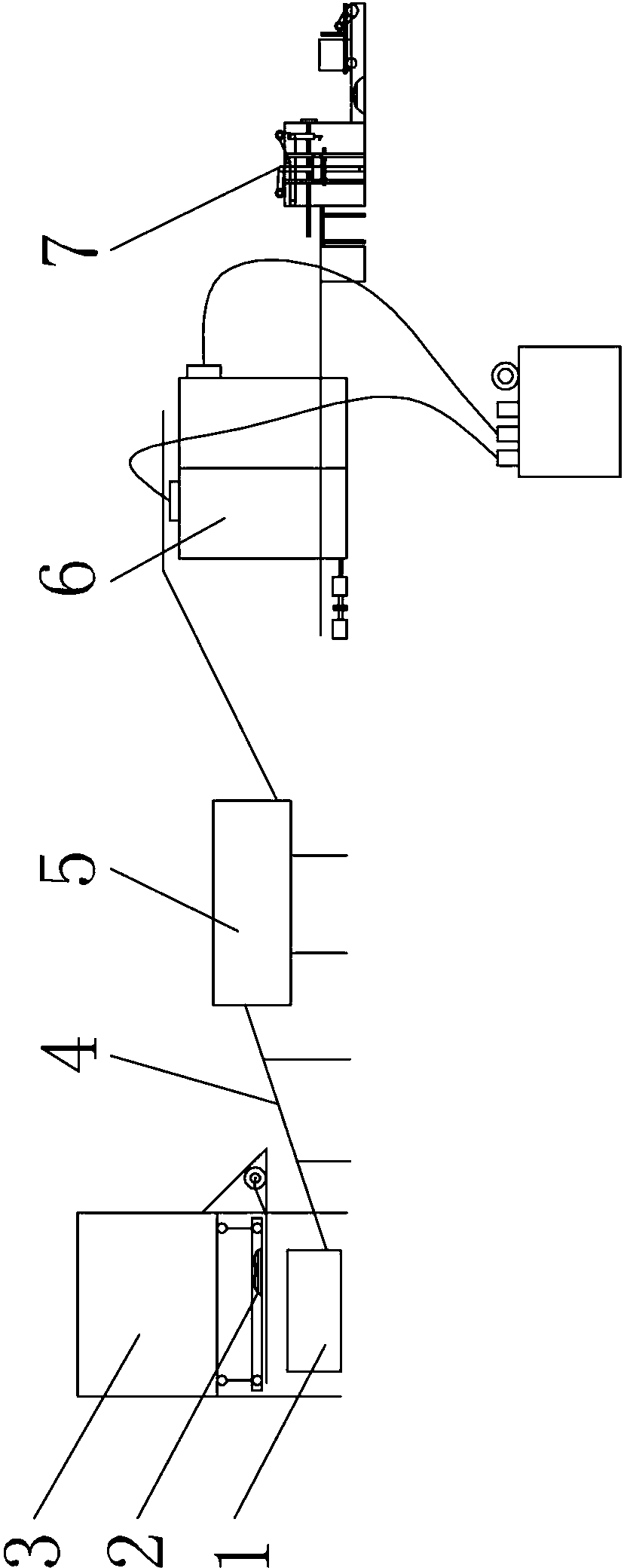

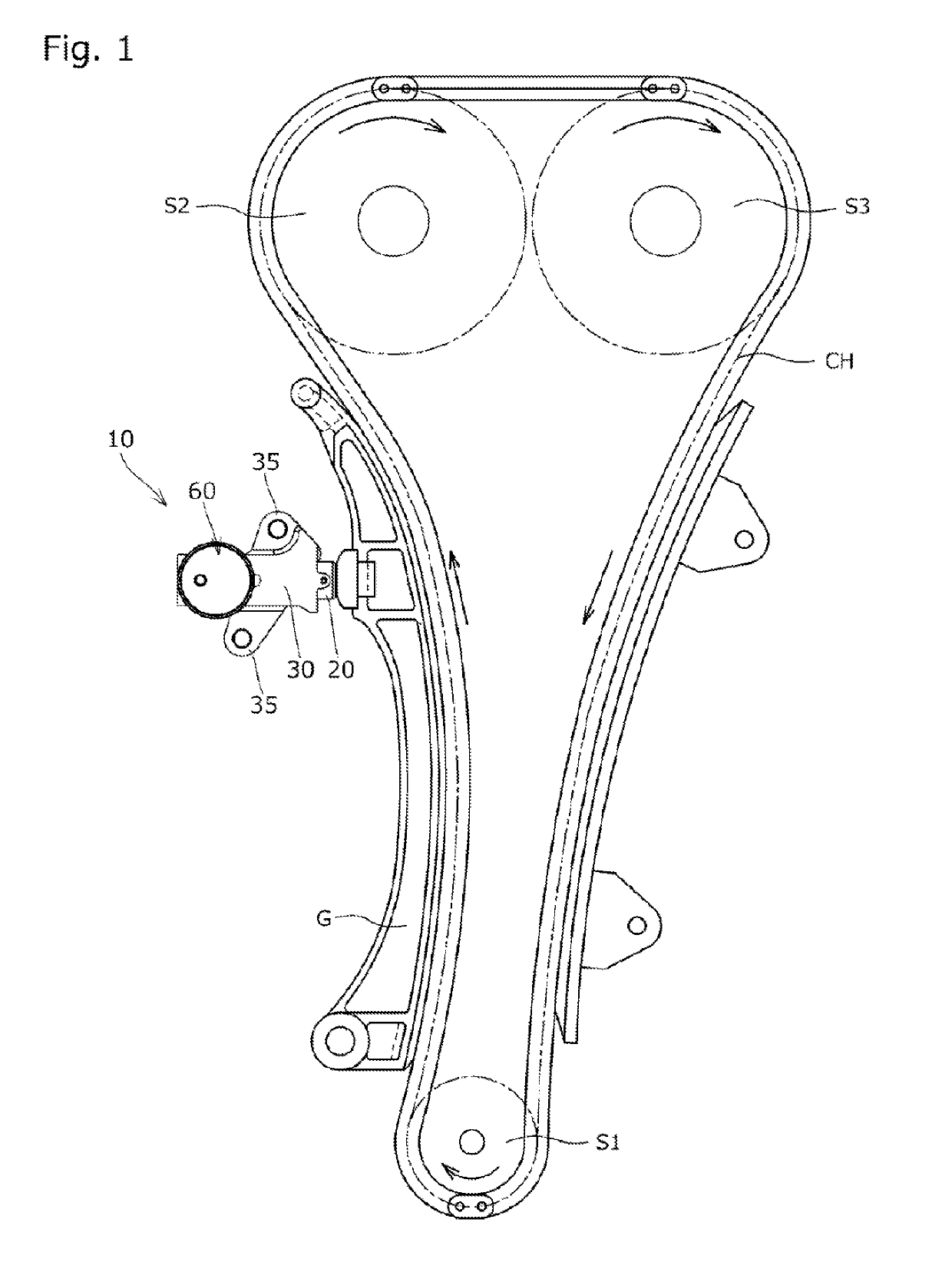

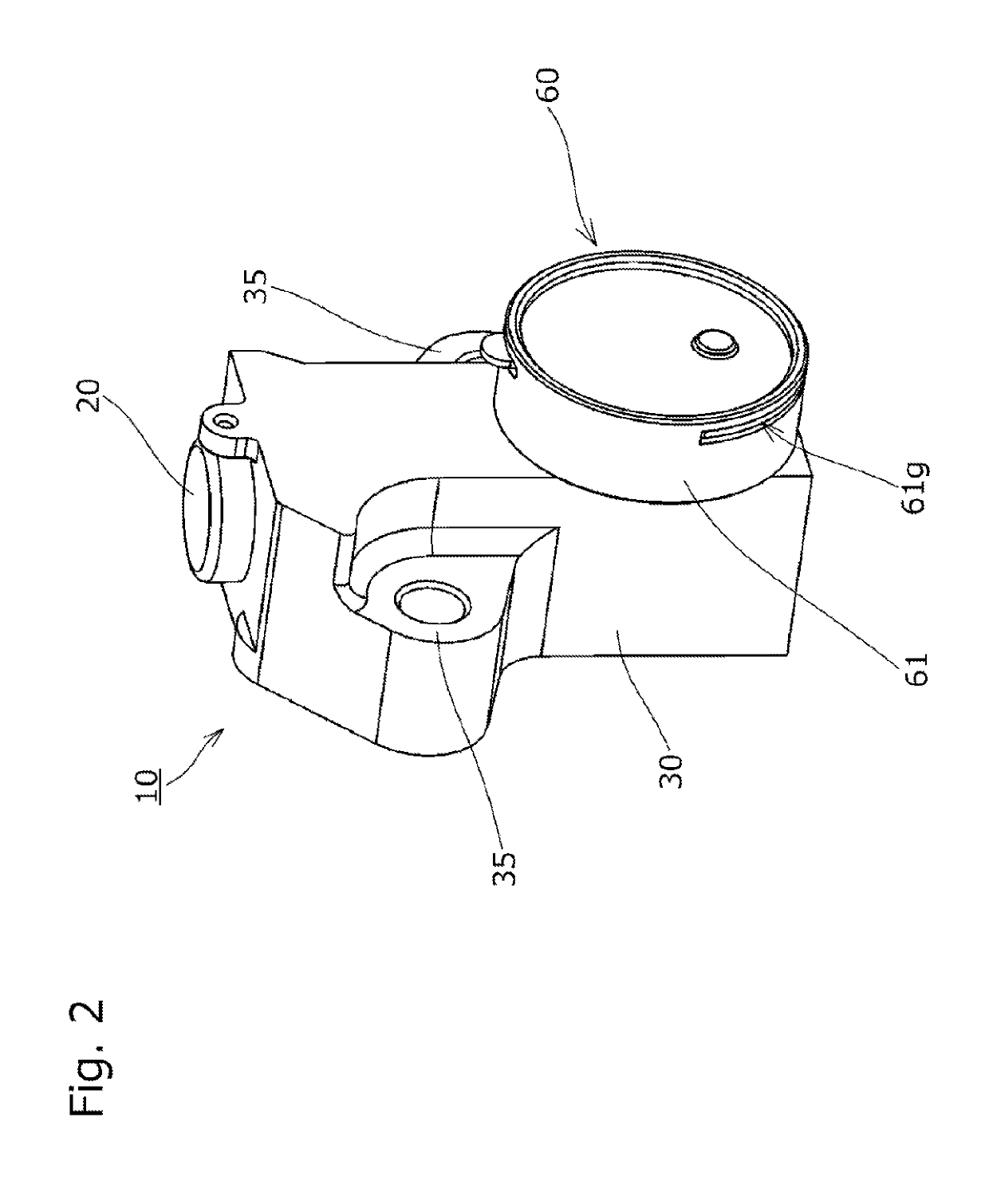

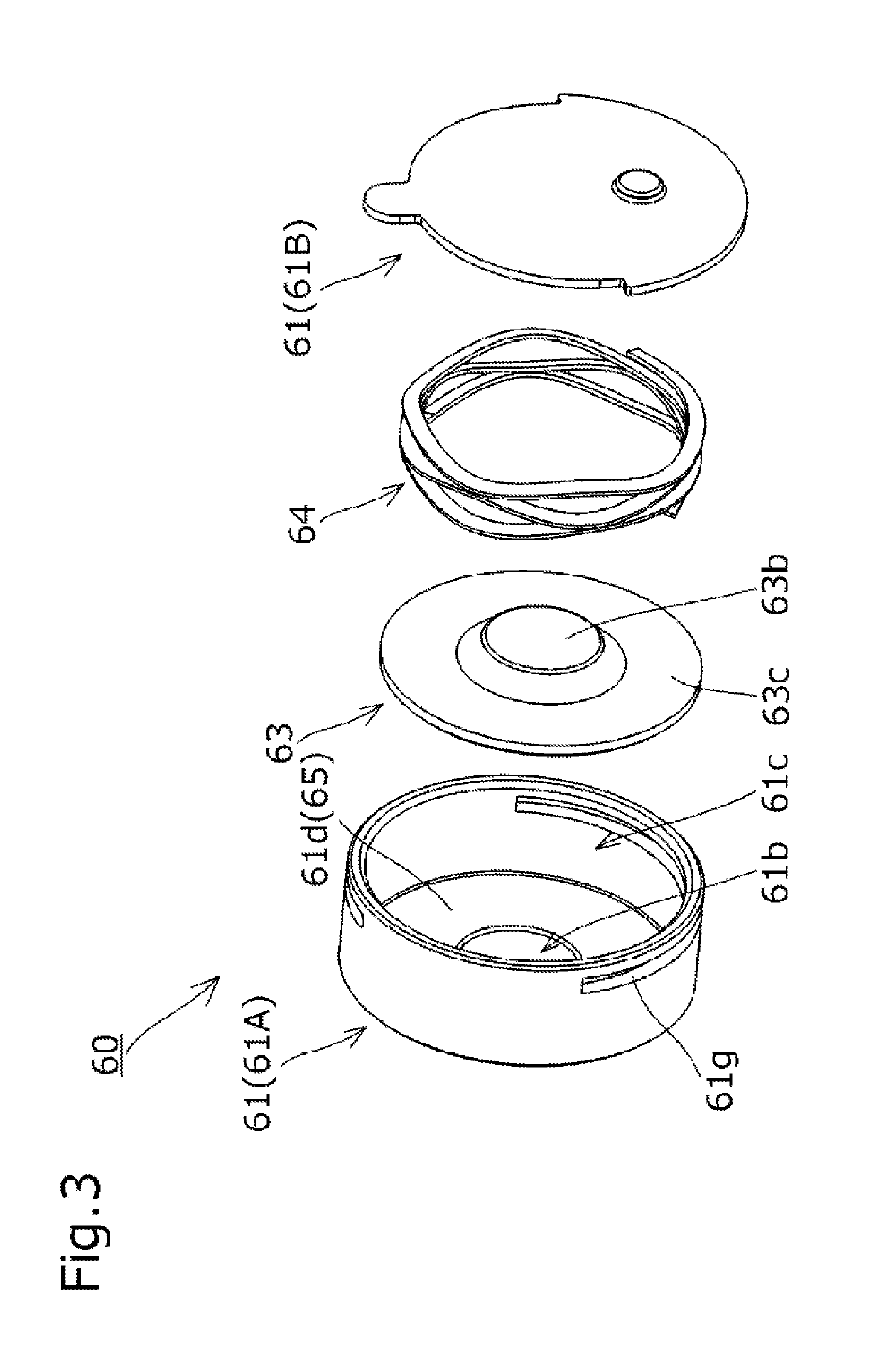

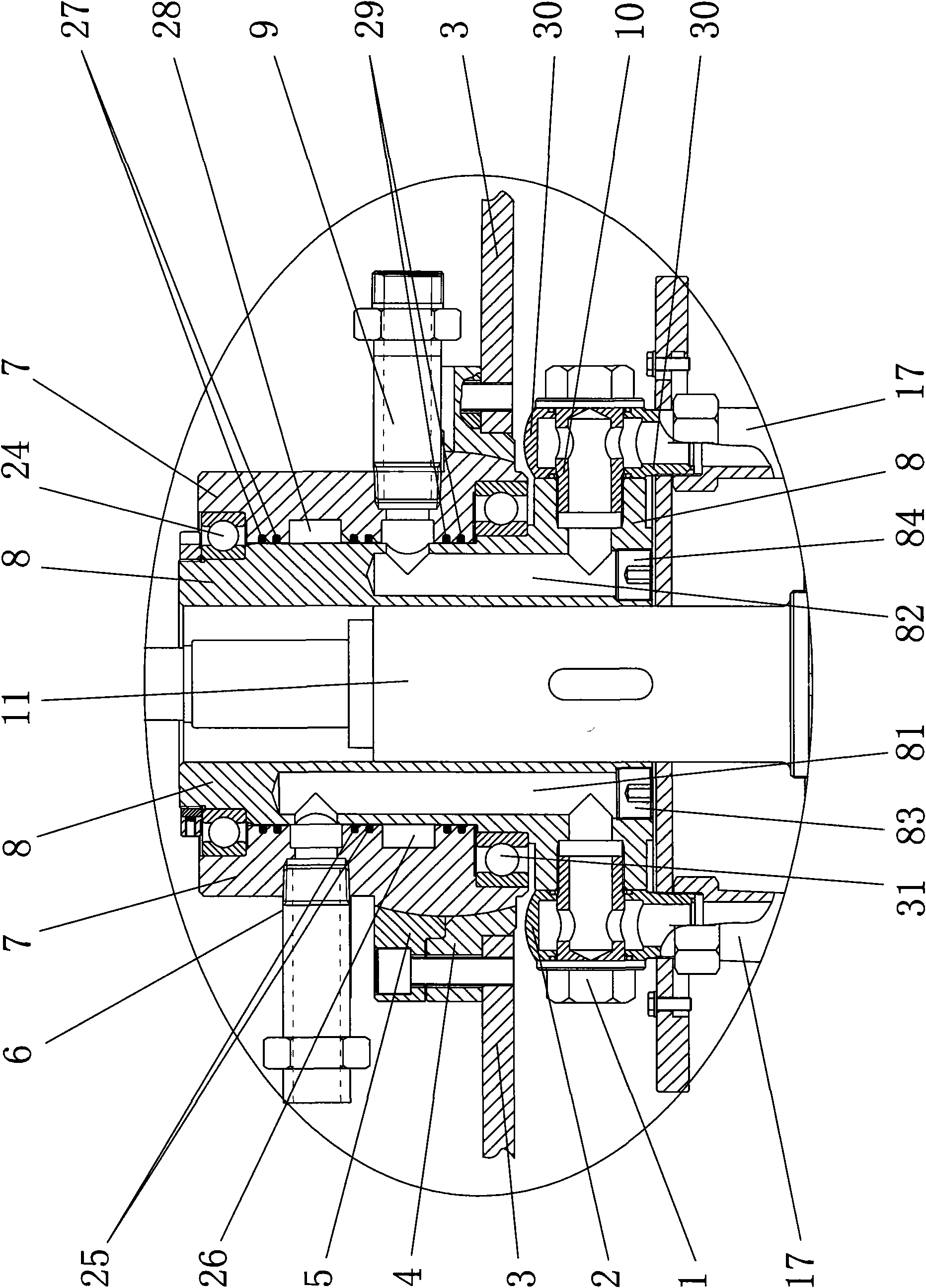

Tensioner

ActiveUS20190257392A1Reduce fuel consumptionReduce power levelGearingEngineeringMechanical engineering

Provided is a tensioner capable of stabilizing an oil pressure in an oil pressurizing chamber. The tensioner includes a pressure adjustment unit. The pressure adjustment unit includes a unit case attached to the housing or the plunger, a moving member disposed in the case inner space to be capable of moving closer to and farther away from the oil pressurizing chamber, and a pressure adjustment biasing unit which biases the moving member toward the oil pressurizing chamber. A gap between an inner wall of the case inner space and the moving member is configured to be held in a liquid tight state at any position between a position where the moving member is closest to the oil pressurizing chamber as a result of moving and a position where the moving member is most distant from the oil pressurizing chamber.

Owner:TSUBAKIMOTO CHAIN CO

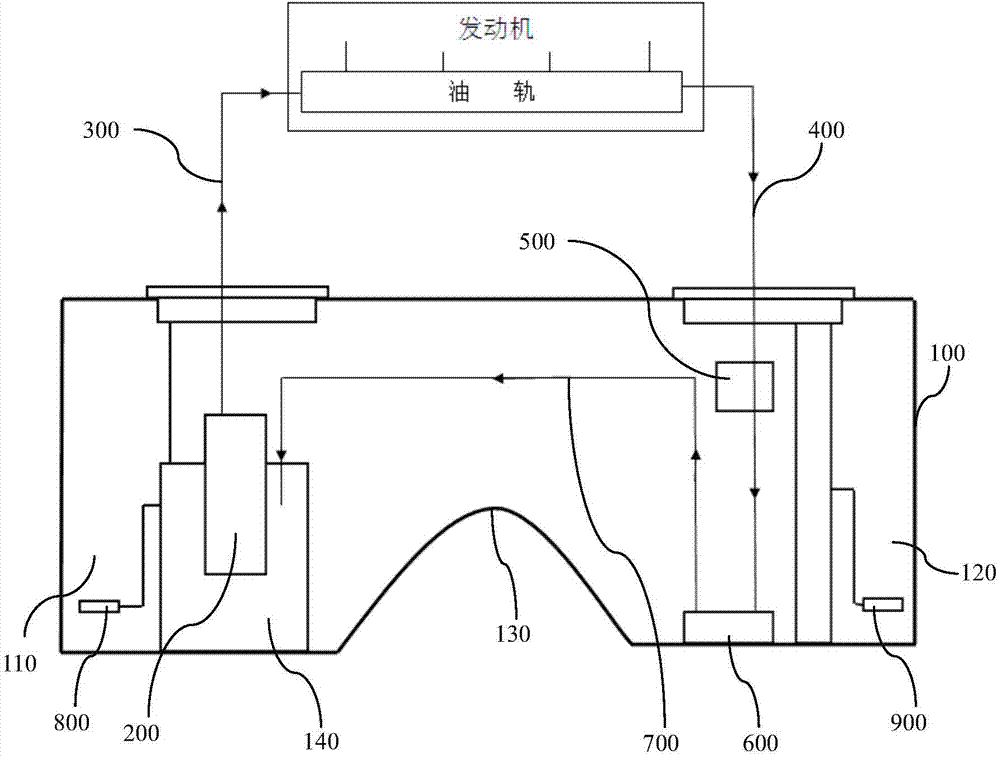

Oil supply system of saddle-shaped gasoline tank

InactiveCN103498742ASimple structureAct as a power sourceMachines/enginesLiquid fuel feedersSiphonFuel tank

The invention provides an oil supply system of a saddle-shaped gasoline tank. The oil supply system comprises the saddle-shaped gasoline tank, a fuel pump, a siphoning mechanism and a siphon. A main gasoline tank body is arranged on one side of the gasoline tank, and an auxiliary gasoline tank body is arranged on other side of the gasoline tank. The fuel pump is arranged in the main gasoline tank body and conveys gasoline in the main gasoline tank body to an engine. The siphoning mechanism is arranged in the auxiliary gasoline tank body. One end of the siphon is communicated with the siphoning mechanism, the other end of the siphon is communicated with the main gasoline tank body, and therefore gasoline in the auxiliary gasoline tank body can be conveyed to the main gasoline tank body. The oil supply system further comprises an oil return pipe. One end of the oil return pipe is communicated with a high-pressure oil rail of the engine, and the other end of the oil return pipe is communicated with the siphoning mechanism. The oil supply system of the saddle-shaped gasoline tank is simple in structure, low in cost and high in stability.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

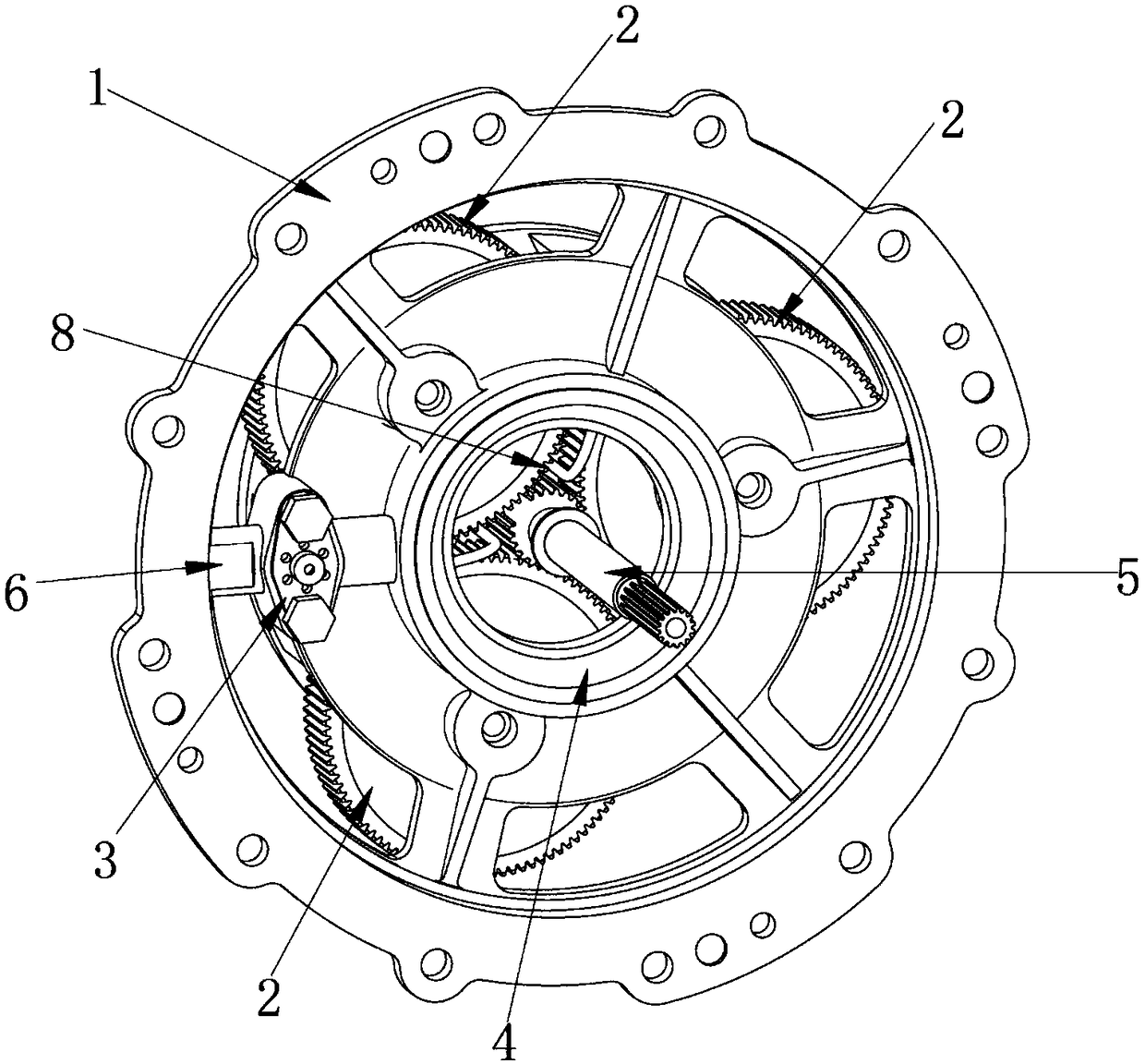

Lubricating structure of speed reduction transmission device for gas turbine

InactiveCN108061152AGuaranteed uptimeExtended service lifeGear lubrication/coolingGear wheelCooling effect

The invention discloses a lubricating structure of a speed reduction transmission device for a gas turbine. The speed reduction transmission device comprises a sun gear shaft, a gear holder and a plurality of transmission gears, wherein the transmission gears are uniformly distributed on the gear holder in the circumferential direction; a lubricating oil distributing ring is arranged at the oil outlet end of a lubricating oil channel in the gear holder; an annular oil supply base of the lubricating oil distributing ring is embedded into a center hole of the gear holder and forms a closed oil way ring cavity; a radial oil spraying hole in each radial oil spraying pipeline guides lubricating oil to be sprayed to meshing points of the sun gear shaft and the transmission gears in the radial direction; and a tail end oil spraying hole in an axial nozzle is right opposite to a front end oil inlet of a central lubricating oil passage, guides the lubricating oil to flow to the rear end of thesun gear shaft and further distributes the lubricating oil distribution. The lubricating structure has the advantages that the overall structure is ingenious, the oil pressure is stable, the lubricating and cooling effects on friction pairs such as the sun gear shaft and the transmission gears are good, and guarantees can be provided for weight reduction, stable and reliable operation and prolongation of the service life of the gas turbine.

Owner:CAS HEFEI MICRO GAS TURBINE RES INST CO LTD

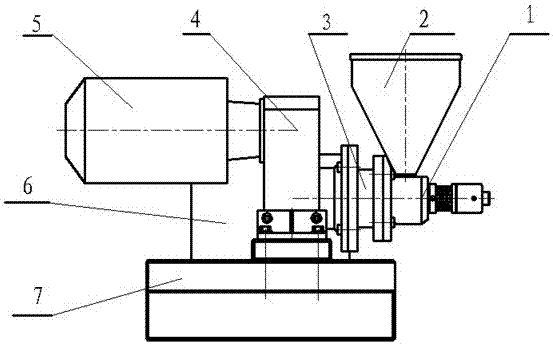

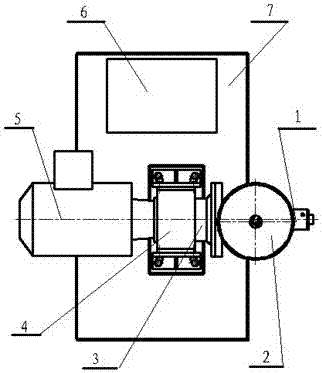

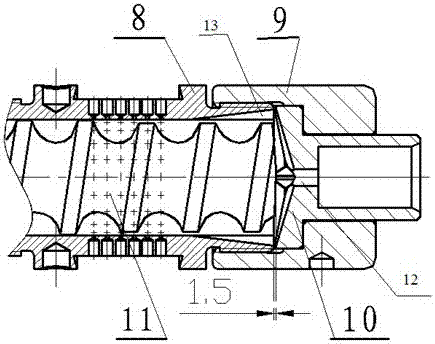

A low-temperature screw oil press

ActiveCN104786537BHigh power transmission efficiencyImprove oil yieldPressesHead pressingElectric machinery

The invention discloses a low-temperature screw oil press, which comprises a press, and the press includes a press cage and a press head fixed at one end of the press cage, and the cake outlet head and the press head are arranged in a space formed by There is a screw press shaft, and the end of the screw press shaft close to the press head communicates with the outside world through the cake outlet of the cake outlet on the press head; the press cage communicates with the feeding funnel; the press cage communicates with the The feed funnel is connected, and also includes a frequency conversion motor and a frequency converter to control the speed of the frequency conversion motor. The frequency conversion motor drives the screw press shaft to rotate through a reducer; the diameter of the end of the screw press shaft close to the cake outlet It is smaller than the diameter of the end of the screw press shaft away from the cake outlet head. The invention has simple manufacturing process and small volume, improves the transmission efficiency of the oil press, improves the oil yield, and reduces the pressing temperature.

Owner:HUNAN ACAD OF FORESTRY

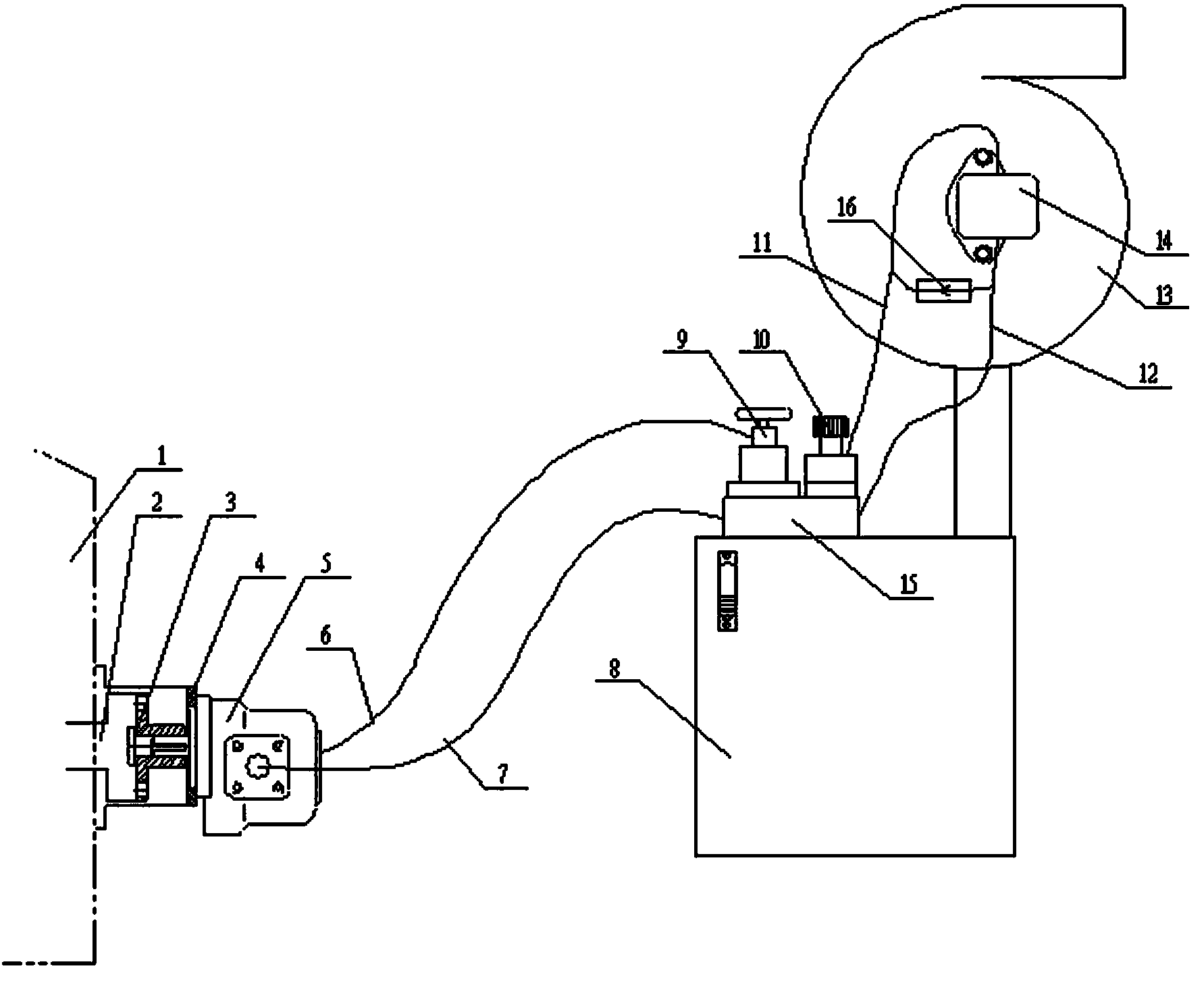

Hydraulic driving device for draught fan of pneumatic type seeding machine

InactiveCN104106331AStable speedFix stability issuesPump installationsSingle grain seedersHydraulic motorFuel tank

The invention provides a hydraulic driving device for a draught fan of a pneumatic type seeding machine, relating to the technical field of pneumatic type seeding machines. The hydraulic driving device is characterized in that a power output shaft of a tractor is connected with an oil pump and drives the oil pump to rotate, power oil supplied by the oil pump is conveyed to a hydraulic motor by an oil pump outlet pipe and a hydraulic motor inlet pipe, the hydraulic motor drives the draught fan for seeding to rotate, and is communicated with an oil tank by a hydraulic motor outlet pipe, a hydraulic control element is arranged in a hydraulic system, and the running speed of the draught fan for seeding is controlled by the hydraulic control element. The hydraulic driving device has the beneficial effects of being matched with the tractor conveniently, ensuring the stable rotation of the hydraulic motor for driving the draught fan for seeding without limitation of the size of an oil valve of the tractor to finally achieve ideal seeding, and overcoming the phenomena of unstable wind power, seedling shortage and seedlingless ridges caused by turning, stopping, machine tool lifting and the like of the existing domestic pneumatic type seeding; besides, the hydraulic driving device has the characteristics of simple and compact structure, small occupied area, convenience in adjustment and reliability in working.

Owner:HEBEI NONGHAHA MASCH GRP CO LTD

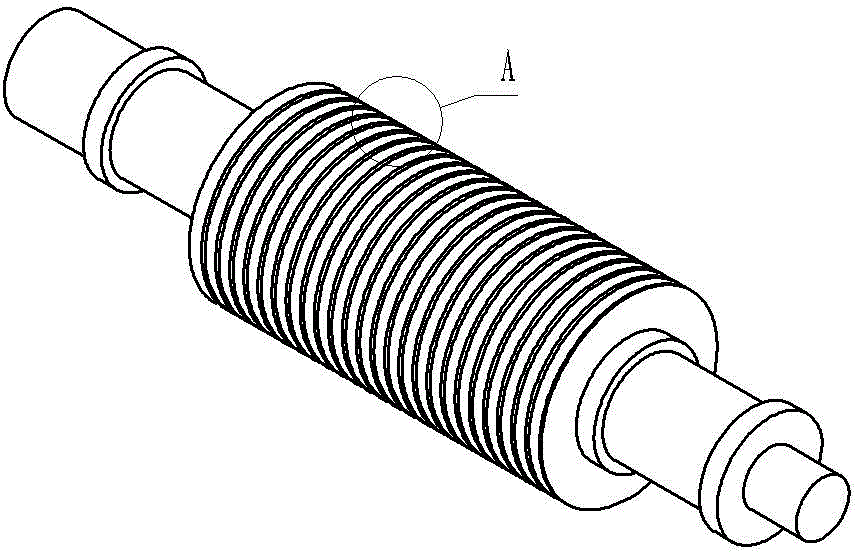

Sugarcane mill roller

InactiveCN104004861AHigh surface hardnessExtended service lifeJuice extraction from sugarcaneChromium carbideWear resistant

The present invention discloses a sugarcane mill roller, which belongs to the technical field of sugarcane sugar-pressing equipment manufacturing. The sugarcane mill roller includes a roll shaft and a roller body installed on the roll shaft, roll teeth are installed on the outer surface of the roller body, each roll tooth has a tooth top surface and tooth side surfaces connected to both sides of the tooth top surface, a wear-resistant layer is provided on the tooth top surfaces and the tooth side surfaces; and the wear resistant layer is a chromium carbide surfacing welding layer with a thickness of 1 to 2 mm. Compared to the prior art, the surface hardness of the roller teeth is improved in the present invention, and the roller teeth only require replacement after being used for two milling campaigns, so that the service life of the sugarcane mill roller is prolonged.

Owner:LIUZHOU YUELIU SUGAR MACHINE MFG CO LTD

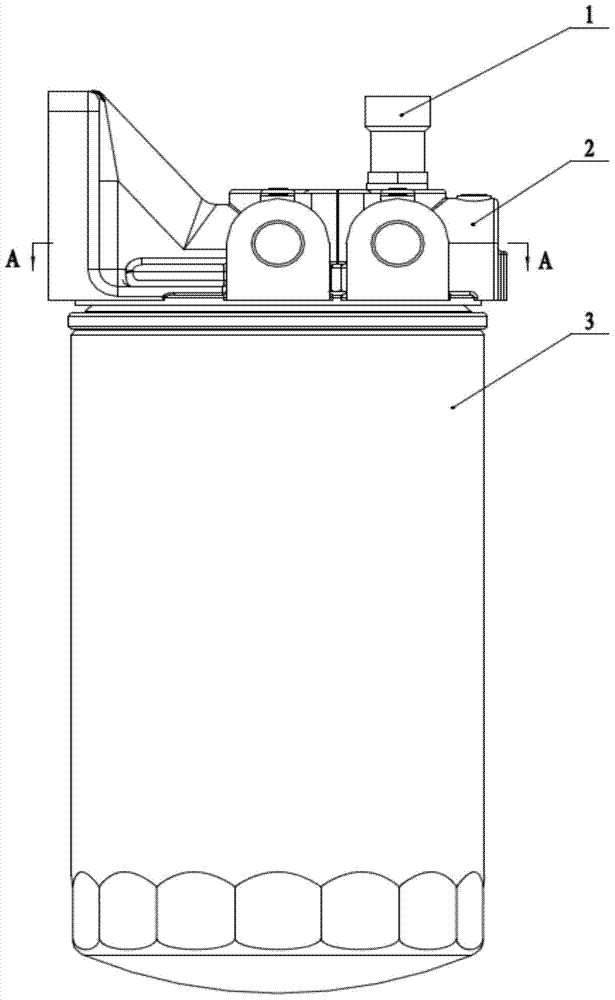

Automatic air-exhausting fuel oil filtering system

InactiveCN104727999AGuaranteed uptimeAvoid stalled conditionsMachines/enginesLiquid fuel feedersInlet channelFlameout

The invention discloses an automatic air-exhausting fuel oil filtering system. The automatic air-exhausting fuel oil filtering system comprises a filter base and a filter tank arranged on the filter base. The filter base is provided with an oil inlet cavity and an oil outlet cavity, and the oil inlet cavity is communicated with an inner cavity of the filter tank through an oil inlet channel. An automatic air exhausting device is arranged above the oil inlet cavity or the oil inlet channel and comprises a one-way valve seat. The one-way valve seat comprises a valve seat body, an outer installation head, an inner installation head, installation outer threads arranged on the outer installation head and matched with threads, first installation inner threads, second installation inner threads, a valve cavity arranged in the valve seat body, a one-way valve body, a sealing ring, a one-way valve spring and an in-through-hole hexagonal nut, wherein the valve seat body, the outer installation head and the inner installation head are integrated, the first installation inner threads and the second installation inner threads are arranged on the inner installation head and matched with threads, and the one-way valve body, the sealing ring, the one-way valve spring and the in-through-hole hexagonal nut are installed in the valve cavity. By means of the automatic air-exhausting fuel oil filtering system, air in an oil way can be effectively and automatically removed, fuel oil can be saved, it can be guaranteed that an engine stably runs, flameout conditions can be avoided in the running process, and the service life of movement parts in a high-pressure oil pump is prolonged.

Owner:广西华原过滤系统股份有限公司

Hydraulic oil pipe system for plastic bottle cap molding press

InactiveCN101570043BSufficient oil supplyStable oil pressureDomestic articlesOil pressurePetroleum engineering

The invention discloses a hydraulic oil pipe system for plastic bottle cap molding press, comprising a machine bracket and a spindle; the upper end of the spindle is sheathed with a rotary internal connector and a connector sleeve; the rotary internal connector is fixed with the circumference of the spindle; the connector sleeve is connected with the machine bracket; the lower end of the spindle is provided with an oil separating disc; an oil inlet and an oil outlet are arranged on the connector sleeve; a plurality of annular oil grooves are arranged between the connector sleeve and the rotaryinternal connector; the upper and the lower ends of the ring oil grooves are both sealed by sealing rings; a plurality of oil transporting channels which are corresponding to the annular oil groovesone by one and are communicated individually are arranged within the rotary internal connector; the oil transporting channels are in communication with the oil supplying space and the oil reflowing space by independent oil transporting pipelines; the oil supplying space and the oil reflowing space in the oil separating disc are both sealed and separated from each other without communication; and the oil supplying space and the oil reflowing space are connected with the reversing valve of each molding press unit by independent oil pipes. This technical scheme has the characteristics of sufficient oil supply, stable oil pressure, rational structure, convenient maintenance, etc.

Owner:SHAOXING HUANGGUAN MACHINERY

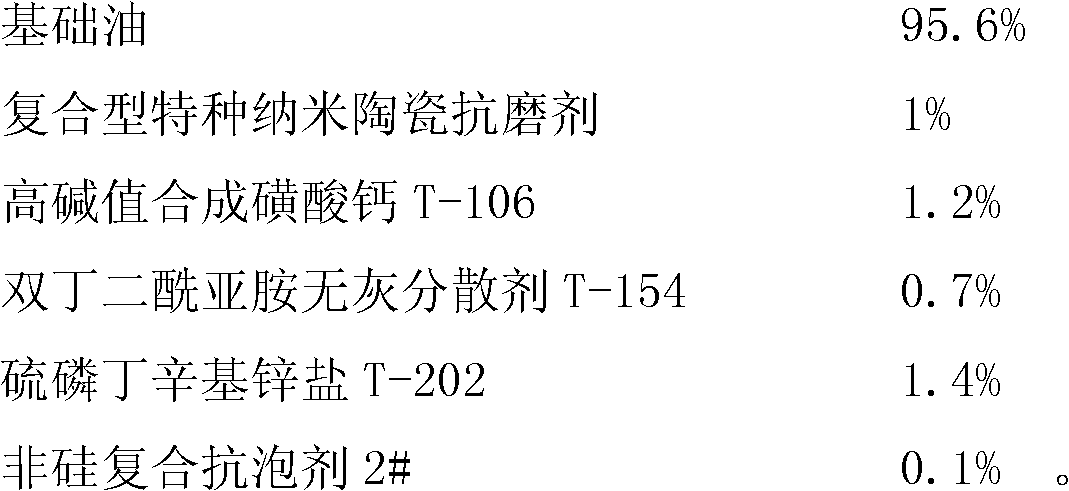

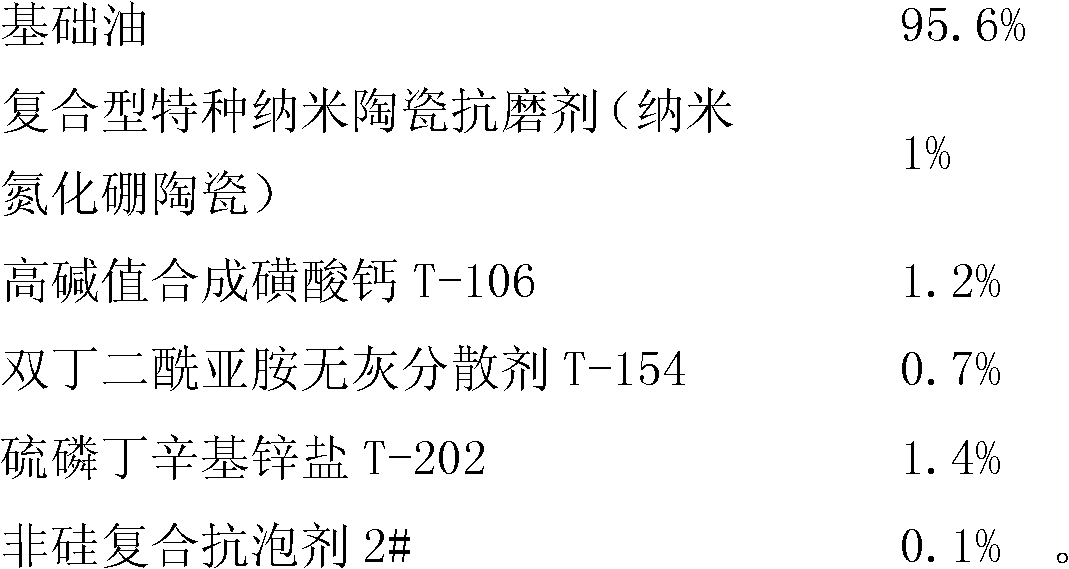

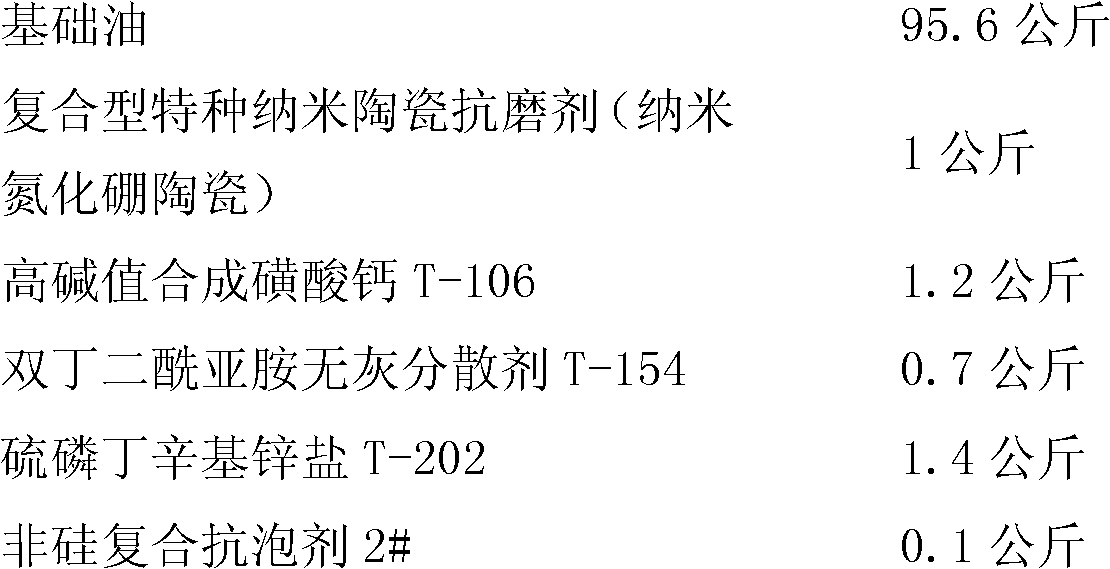

Nanometer dual-fuel lubricating oil and preparation method thereof

InactiveCN103173269AReduce wearExtended service lifeLubricant compositionFuel efficiencySuccinchlorimide

The invention relates to nanometer dual-fuel lubricating oil comprising the following mixed components in percentage by weight: 95.6% of base oil, 1% of composite special nanometer ceramic anti-wear agent, 1.2% of high-base number synthetic calcium sulfonate T-106, 0.7% of dual succinimide ashless dispersant T-154, 1.4% of sulfur phosphorous butyloctyl zinc salt T-202 and 0.1% of non-silicon composite anti-foaming agent 2#. The nanometer dual-fuel lubricating oil disclosed by the invention has the advantages of effectively reducing the abrasion of a motor, prolonging the service life of the motor, remarkably improving the fuel efficiency, reducing the fuel consumption, obviously reducing the exhaust gas emission, reducing the air pollution, protecting the environment, effectively improving the working environment of the motor, improving the acceleration performance, increasing the power, obviously reducing the temperature of the motor, reducing the equilibrium temperature of parts and the lubricating oil to about 75 DEG and eliminating the mechanical thermal expansion phenomenon, having excellent cleaning dispersing performance and effectively controlling the generation of oil sludge carbon deposit to ensure that the oil products are not easy to age.

Owner:圣保路石油化工(天津)股份有限公司

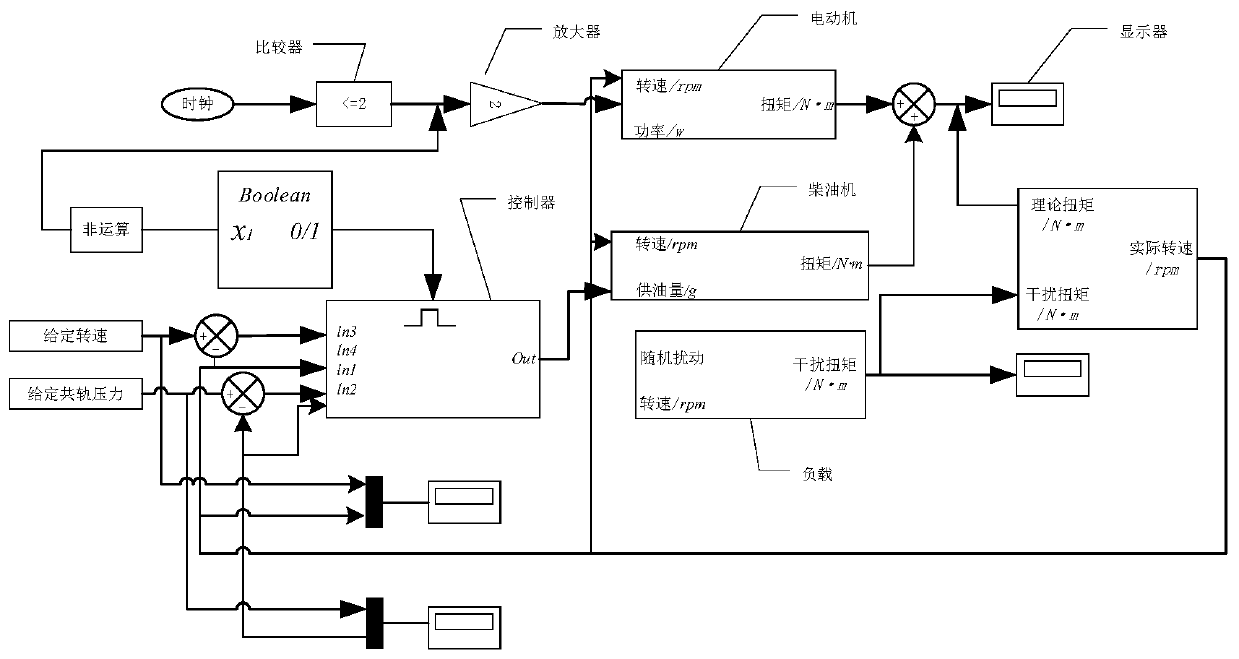

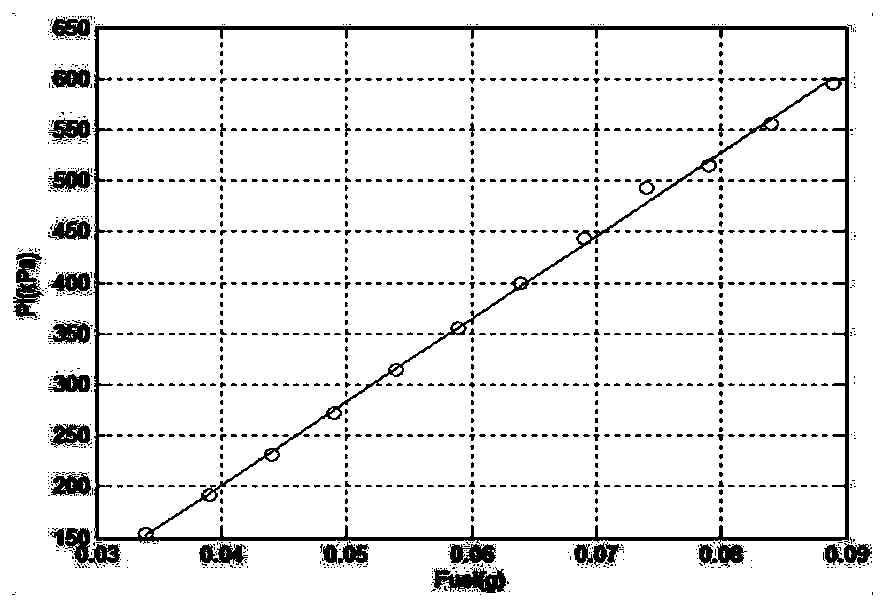

Diesel common rail pressure and rotation speed coupling control system based on sliding mode variable structure

InactiveCN110131064AStable oil pressureUniform atomizationElectrical controlSpeed sensing governorsLinear relationshipLoad following power plant

The invention discloses a diesel common rail pressure and rotation speed coupling control system based on a sliding mode variable structure. The diesel common rail pressure and rotation speed couplingcontrol system based on the sliding mode variable structure comprises a fuel injector, a fuel injector control unit, a high pressure common rail tube, a rotation speed sensor and a control valve, wherein common rail pressure in the high pressure common rail tube is set and controlled by an engine control system, and adjusted along with changes of engine load, the control valve comprises an electromagnetic valve located on a fuel inlet pipeline of the high pressure common rail tube and used for changing the capacity of a hydraulic cavity, a counterbalance valve located on a fuel return pipeline of the high pressure common rail tube, a pilot-operated type overpressure regulating valve located on the upper stream of the high pressure common rail tube and used for overpressure protection, anda pilot valve which controls fuel injection quantity by changing pressure of front and rear cavities of a piston in a piston type flow switch, a non-linear relationship between the rotation speed andthe fuel injection quantity of a diesel is represented through a non-linear speed regulating system model based on the sliding mode variable structure, and stability of fuel injection is guaranteed by using the non-linear speed regulating system model and controlling the control valve. The diesel common rail pressure and rotation speed coupling control system based on the sliding mode variable structure guarantees stability of the fuel injection, and is good in reliability, stability and robustness.

Owner:WUHAN UNIV OF TECH

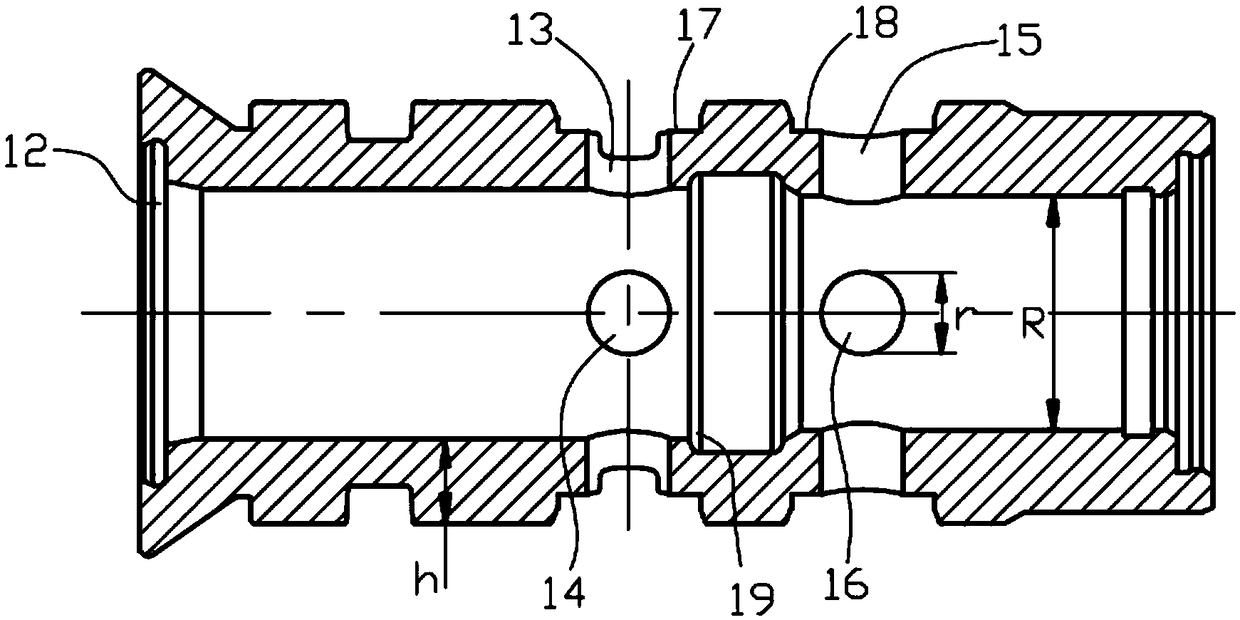

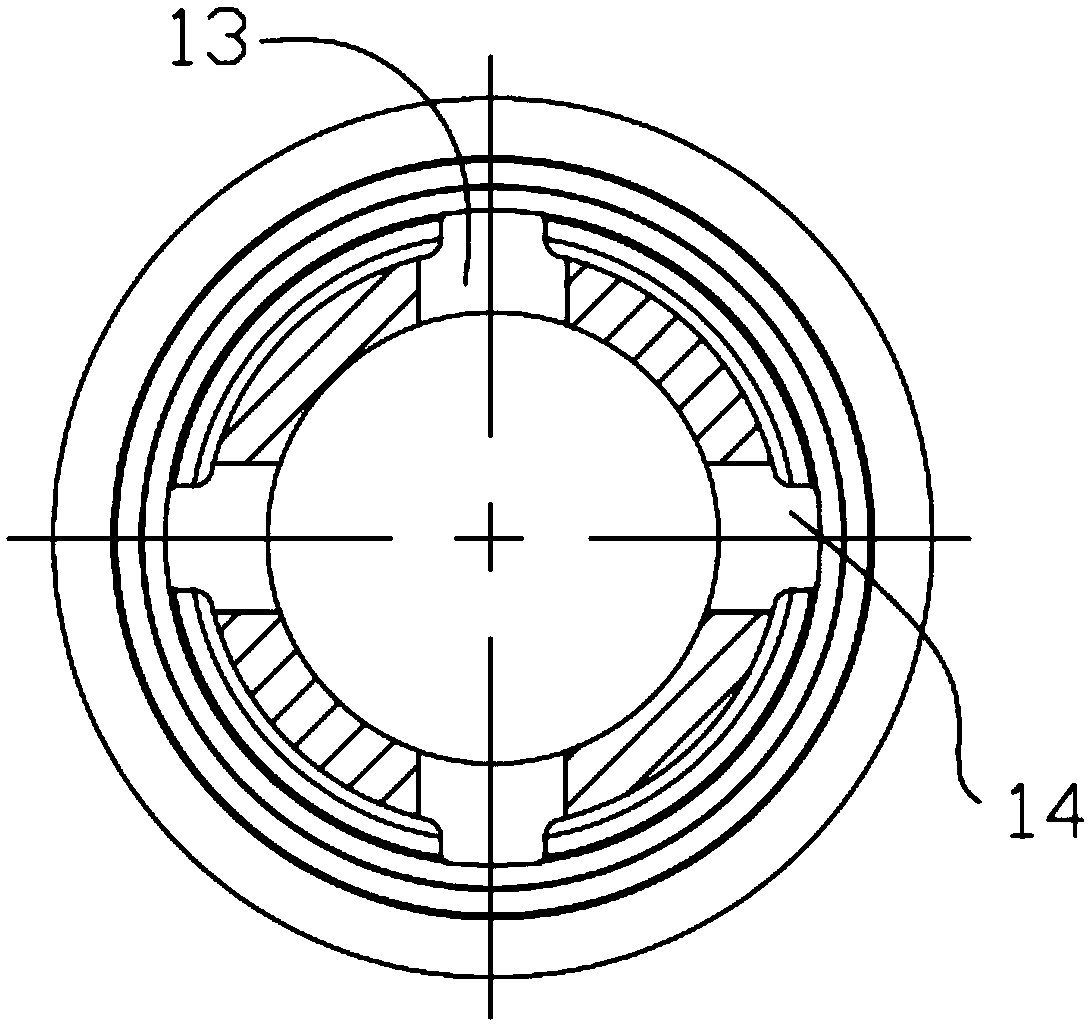

Valve body of automobile hydraulic brake valve and production process thereof

PendingCN109109843ASimple structureReduce weightFluid braking transmissionHydraulic brakeOil pressure

The invention particularly relates to a valve body of an automobile hydraulic brake valve and a production process thereof, belonging to the technical field of automobile spare parts, the valve body includes two communicating ports, a conical end face is arranged at one of the ports of the valve body, four sets of radial through holes are arranged in the middle of the valve body, which are a radial through hole I, a radial through hole II, a radial through hole III and a radial through hole IV, the radial through hole I and the radial through hole II are perpendicular to and intersect with each other, the radial through hole III and the radial through hole IV are perpendicular to and intersect with each other, the wall thickness of the valve body is h, the inner diameter of the valve bodyis R, the radial through hole I, the radial through hole II, the radial through hole III and the radial through hole IV have the same aperture r, and r<h<2r<R<3r. The valve body has the advantages ofsimple structure, light weight, high structural strength, long service life, and can provide stable oil pressure, so that the braking is faster and more sensitive.

Owner:大昌汽车部件(苏州)有限公司

Vehicle fuel supply system

InactiveCN106150799ALow powerReduce fuel consumptionMachines/enginesLiquid fuel feedersElectricityFuel tank

The invention discloses a vehicle fuel supply system which comprises an engine, a pressure regulator, an electric fuel pump and a fuel tank; the electric fuel pump is positioned in the fuel tank; the engine communicates with the pressure regulator; the pressure regulator communicates with the electric fuel pump through a fuel inlet tube; an energy accumulator and a rheostat are connected between the engine and the electric fuel pump; the energy accumulator is connected to the rheostat; one end of the energy accumulator communicates with the engine; and other end of the rheostat is electrically connected to the electric fuel pump to form a loop. The vehicle fuel supply system is simple in structure and is low in cost, can control fuel pump capacity of the electric fuel pump according to needs of the engine, is high in control flexibility, is good in reliability, effectively saves energy, and solves the problem that energy of the fuel supply system is wasted.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com