Fuel oil flaming system

A fuel, high-pressure fuel technology, applied in the direction of flame launcher, flame launcher, weapon type, etc., can solve the problems of easy to burn to the audience, reduce viewing, pollute the environment, etc., and achieve the diversification and enhancement of fire performances. The effect of ornamental and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

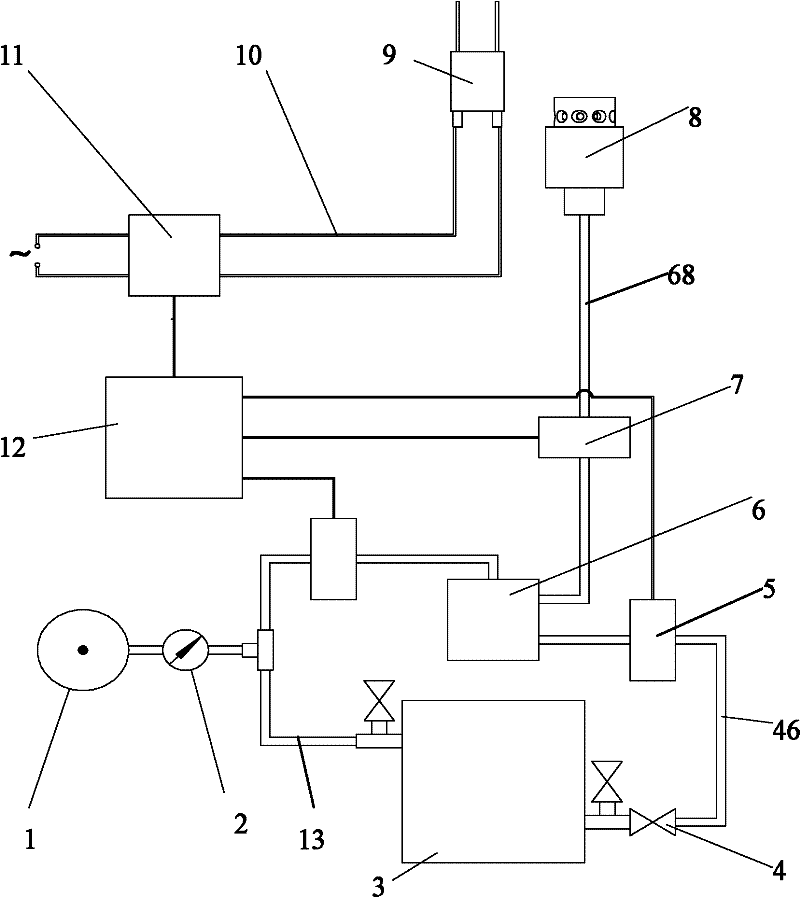

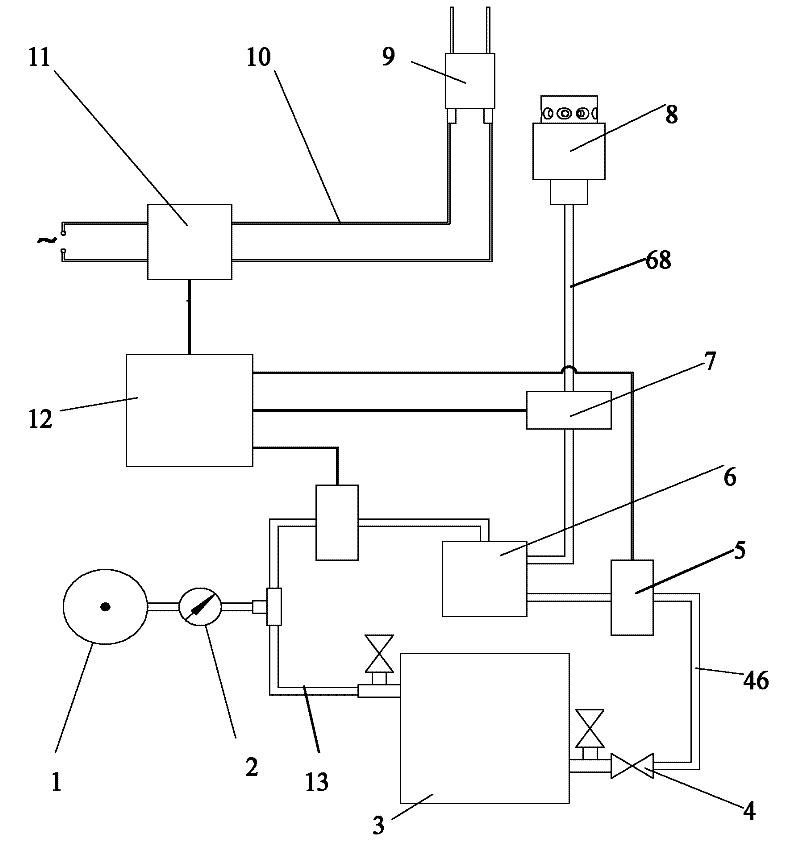

[0020] The invention relates to a fuel injection fire system, in particular to a fire injection system for burning petroleum fuel. Such as figure 1 As shown, in the preferred embodiment of the present invention, the fuel injection system of the present invention includes a fuel storage device, a pressurizing device, an atomizing device, an ignition device and a control module 12 .

[0021] Wherein, in this embodiment, the oil storage device is preferably a high-pressure fuel storage tank 3 . Both ends of the high-pressure fuel storage tank 3 are respectively connected with a first pipeline 46 and a second pipeline 13, the first pipeline 46 is connected with the atomizing device, and the second pipeline 13 is connected with the pressurizing device.

[0022] Wherein, the pressurizing device includes a high-pressure inert gas source 1 , a pressure regulator 2 and a high-pressure cut-off valve 4 . Wherein, the high-pressure inert gas source 1 enters the tank from the input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com