Sugarcane mill roller

A technology for pressing rollers and sugarcane, which is applied in the direction of extracting juice from sugarcane, etc. It can solve the problems of easy wear and short service life of roller teeth and roller grooves, and achieve the goals of reduced power consumption, good sugarcane holding capacity, and improved crushing recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

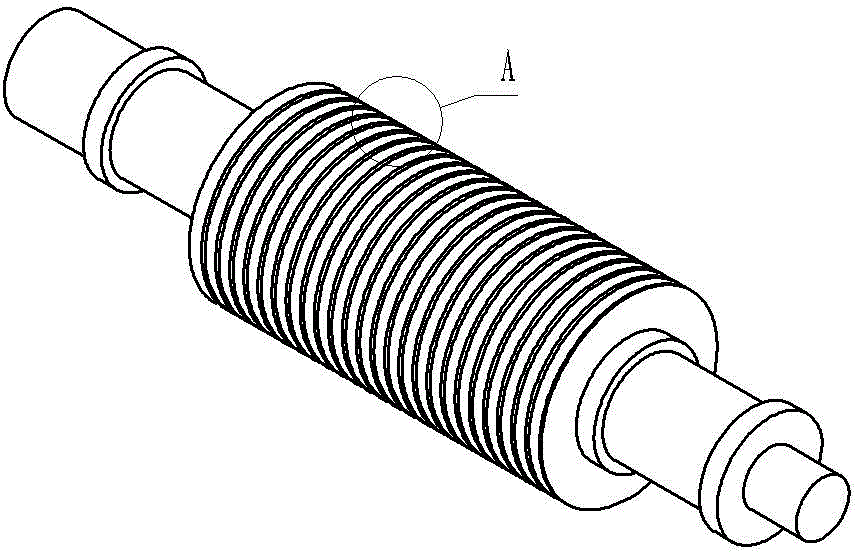

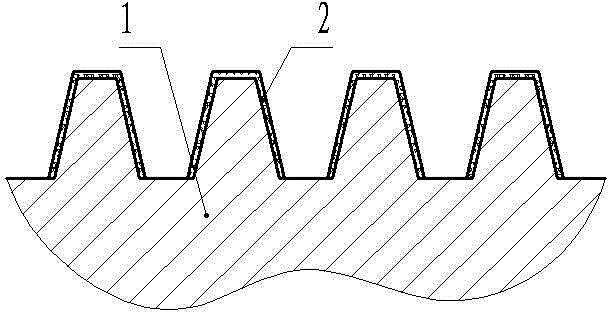

[0012] Such as figure 1 and figure 2 The shown sugarcane pressing roll comprises a roll shaft and a roll body 1 arranged on the roll shaft, the outer surface of the roll body 1 is provided with roll teeth, and the roll teeth have tooth top surfaces and tooth flanks connected to both sides of the tooth top surfaces, A wear-resistant layer 2 is provided on the top surface and the side surface of the tooth. The wear-resistant layer 2 is a chromium carbide surfacing layer formed by surfacing welding of chromium carbide electrodes on the surface of the roller teeth. The thickness of the surfacing layer is 1 mm.

Embodiment 2

[0014] The thickness of the surfacing layer is 2 millimeters, and other features are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com