Foam maker and control method thereof

A foaming machine and template technology, which is applied to the foaming machine and its control field, can solve the problems of large instantaneous starting current, increased instantaneous current, unfavorable operation, etc., and achieves the improvement of the degree of mechanical automation, the improvement of the utilization rate of electric energy, and the improvement of The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

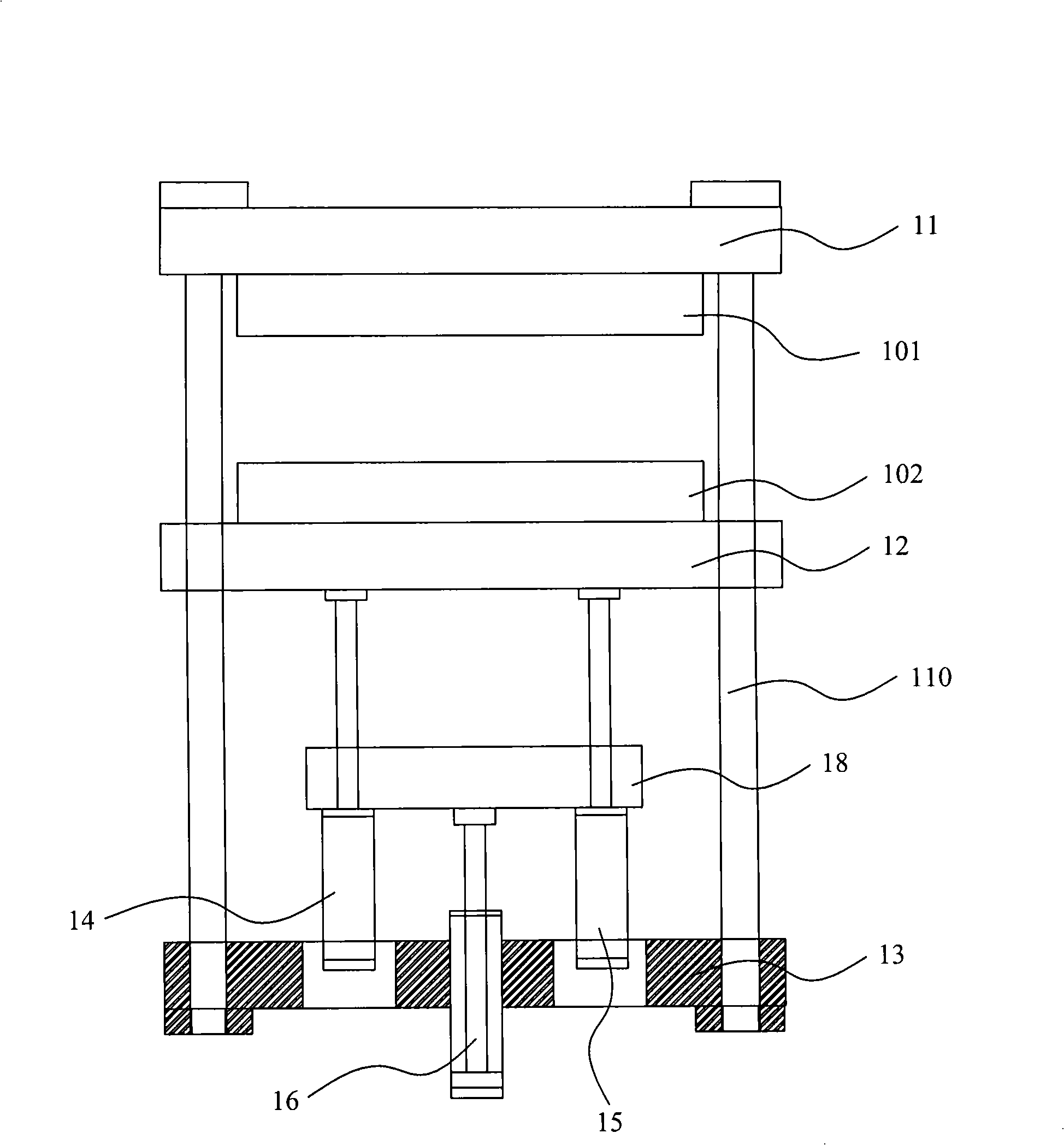

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims. The same components are denoted by the same reference numerals in the drawings.

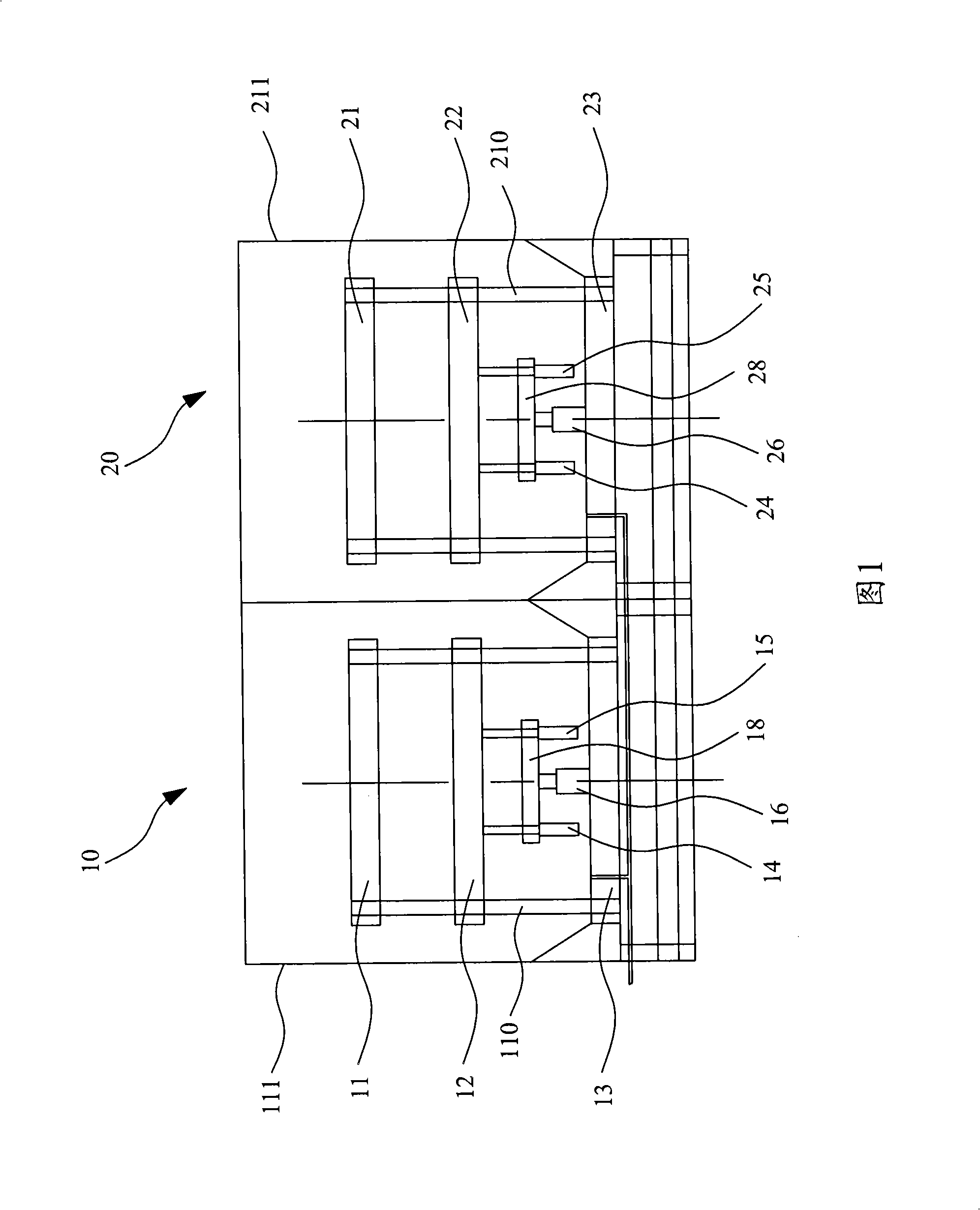

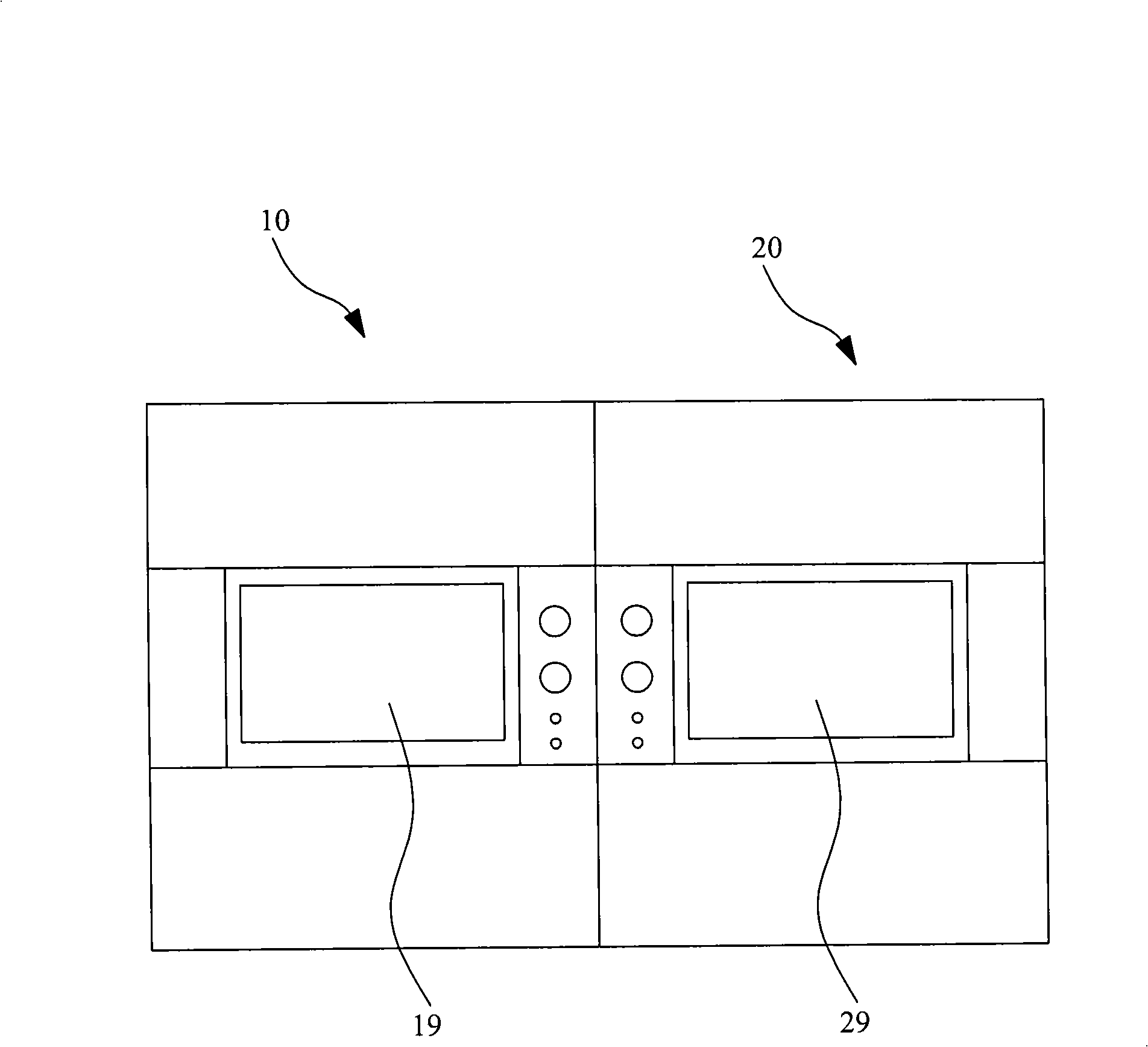

[0038] Below, refer to Figure 1 and figure 2 The foaming machine according to the present invention is described. Foaming machine according to the present invention comprises a plurality of clamping devices, only two clamping devices 10, 20 are shown in Fig. 1, but the present invention is not limited thereto, it can have more than two clamping devices . The main structure of each mold clamping device is basically the same, and the structure of the mold clamping device will be described below by taking the mold clamping device 10 as an example.

[0039] The mold clamping device 10 respectively includes a lower template 13, a middle template 12, an upper template 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com