Oil supply system of saddle-shaped gasoline tank

An oil supply system, saddle-shaped technology, applied in the direction of the charging system, engine components, liquid fuel feeder, etc., can solve the problems of high cost, complex structure, etc., to ensure oil, ensure liquid level, oil-free The effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

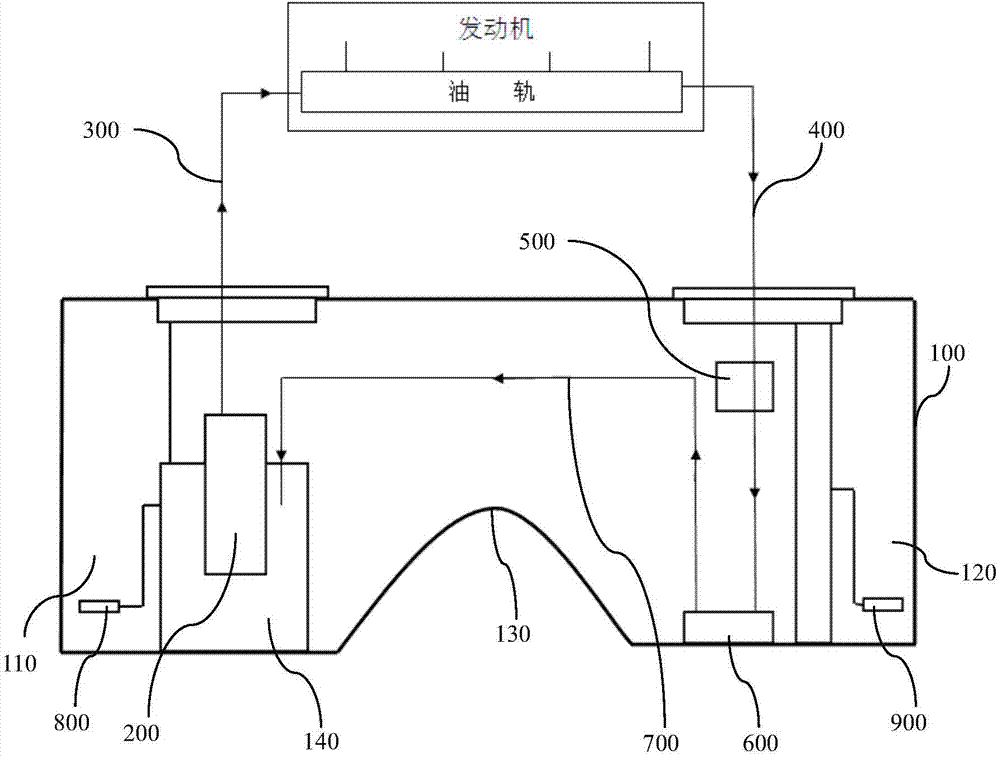

[0021] refer to figure 1 , The saddle-shaped gasoline fuel tank fuel supply system of the present invention mainly includes a gasoline fuel tank 100, a fuel pump 200, an engine, an oil return pipe 400, a siphon mechanism 600 and a siphon pipe 700. Wherein, one side of the gasoline tank 100 is the main tank 110, the other side is the auxiliary tank 120, and the middle is the bulge 130, so that the entire gasoline tank 100 is in the shape of a saddle. In order to improve the fuel utilization rate, the gasoline in the auxiliary fuel tank 120 needs to be supplemented into the main fuel tank 110 to participate in the fuel supply of the engine. Preferably, the fuel pump 200 is arranged in the main fuel cup 140 in the main fuel tank 110, wherein the function of the main fuel cup 140 is to ensure the liquid level of the fuel pump 200, and preferably the main fuel cup 140 has a filter screen or filter cotton (not shown). ) and other filtering structures to ensure that the oil flowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com