Automatic constant-pressure control device used for centralized supply in process of spraying optical cable grease

An automatic control device and ointment technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems that the uniformity of spraying amount cannot be guaranteed, the oil circuit system is mixed with air, and the ointment has no filter device, etc., so as to eliminate the product Unqualified phenomenon, stable oil pressure, and the effect of reducing labor intensity of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

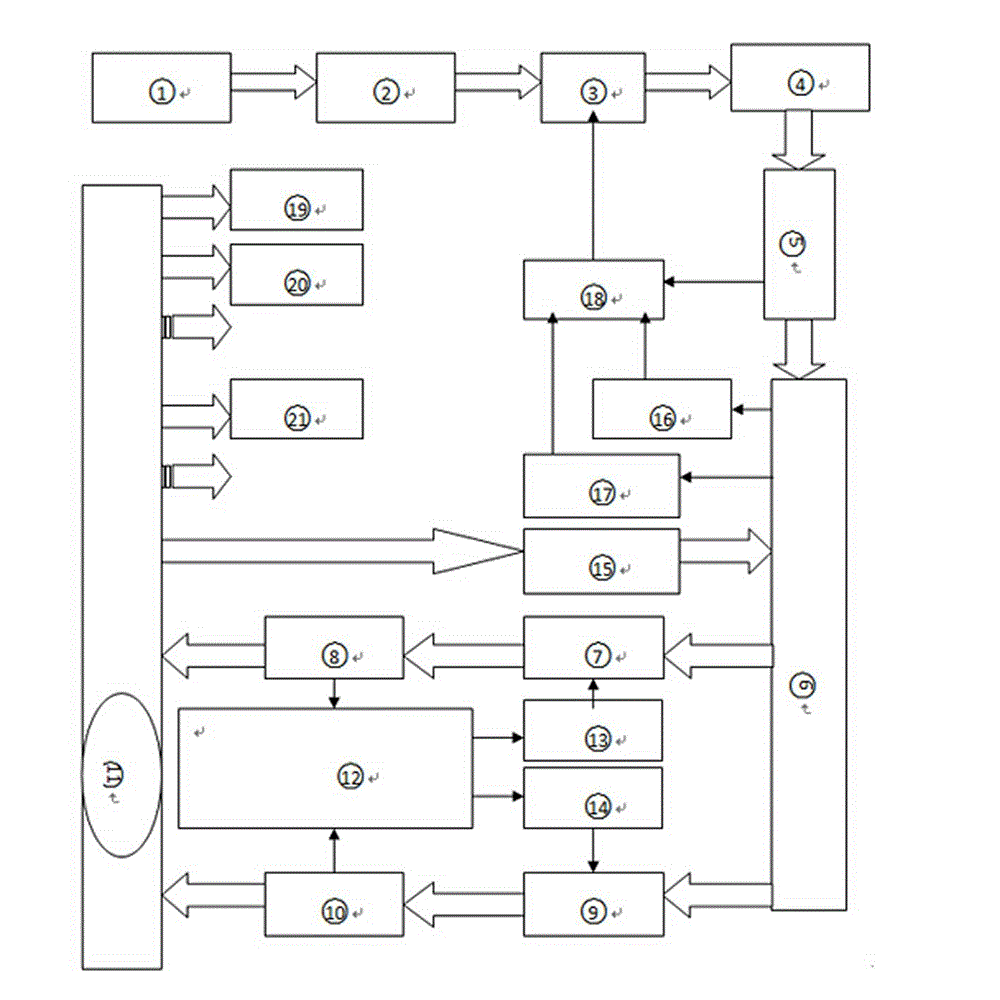

[0010] Such as figure 1 As shown, a constant pressure automatic control device for centralized supply of optical cable ointment spraying includes a primary filter 2 connected to a spray ointment packaging barrel 1, the primary filter is connected to an oil inlet pump 3, and the The oil inlet pump is connected with the secondary filter 5 connected with the pressure control switch 4, the secondary filter is connected with the oil inlet pump connected with the oil inlet pump control frequency converter 18, and the secondary filter is connected with the main pressure pump 7 It is connected to the oil storage tank 6 of the auxiliary pressure pump 9, the oil storage tank is connected to the electric control system 12 through the load cell 16 and the proximity switch 17, and the pressure transmitter I8 and the pressure transmitter II10 are connected through the main pressure pump 7 is connected with the auxiliary pressure pump 9 and the oil storage tank, the main pressure pump and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com