A low-temperature screw oil press

A technology of oil press and screw, which is applied in the field of low-temperature oil output device, can solve the problems such as the reduction of the reusable value of the cake, the lack of stepless variable speed motor, and the complicated manufacturing process of the cold press, so as to destroy the effect of cold pressing and improve Power transmission efficiency, the effect of extending the pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

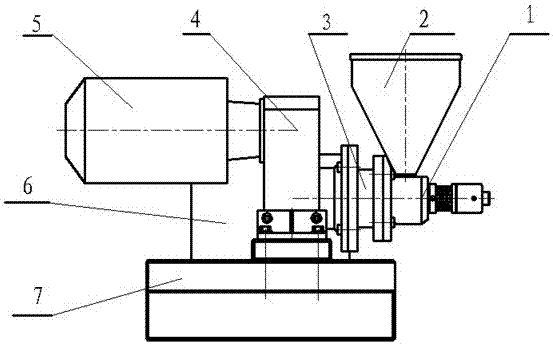

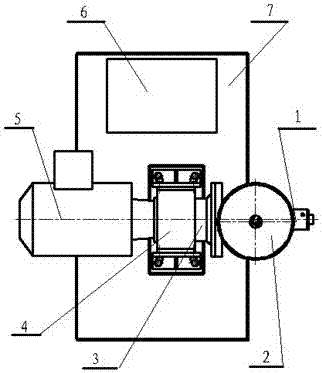

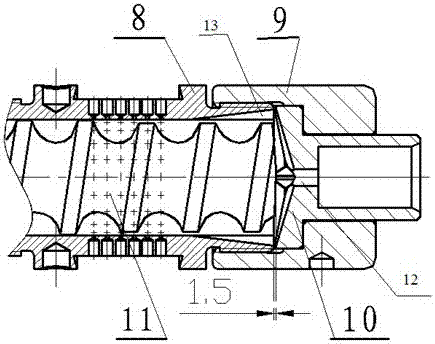

[0016] Such as Figure 1-Figure 3 As shown, an embodiment of the present invention includes a squeeze machine 1, and the squeeze machine 1 includes a squeeze cage 8, a squeeze head 9 fixed at one end of the squeeze cage 8, and the cake outlet head 10 and the squeeze head 9 are formed. A screw press shaft 11 is arranged in the space, and one end of the screw press shaft 11 close to the press head 9 communicates with the outside world through the cake outlet 12 of the cake output head 10 on the press head 9; The feeding funnel 2 is connected, and also includes a frequency conversion motor 5 and a frequency converter 6 for controlling the rotation speed of the frequency conversion motor 5 , and the frequency conversion motor 5 drives the screw press shaft 11 to rotate through a reducer 4 .

[0017] The press machine 1 and the reducer 4 are connected through the connecting flange 3 , and the frequency converter 6 and the reducer 4 are all installed on the frame 7 .

[0018] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com