Patents

Literature

331results about How to "Reduced risk of corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

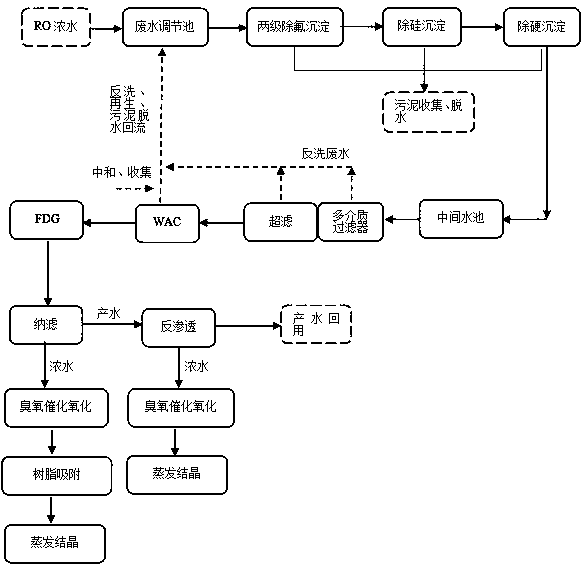

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

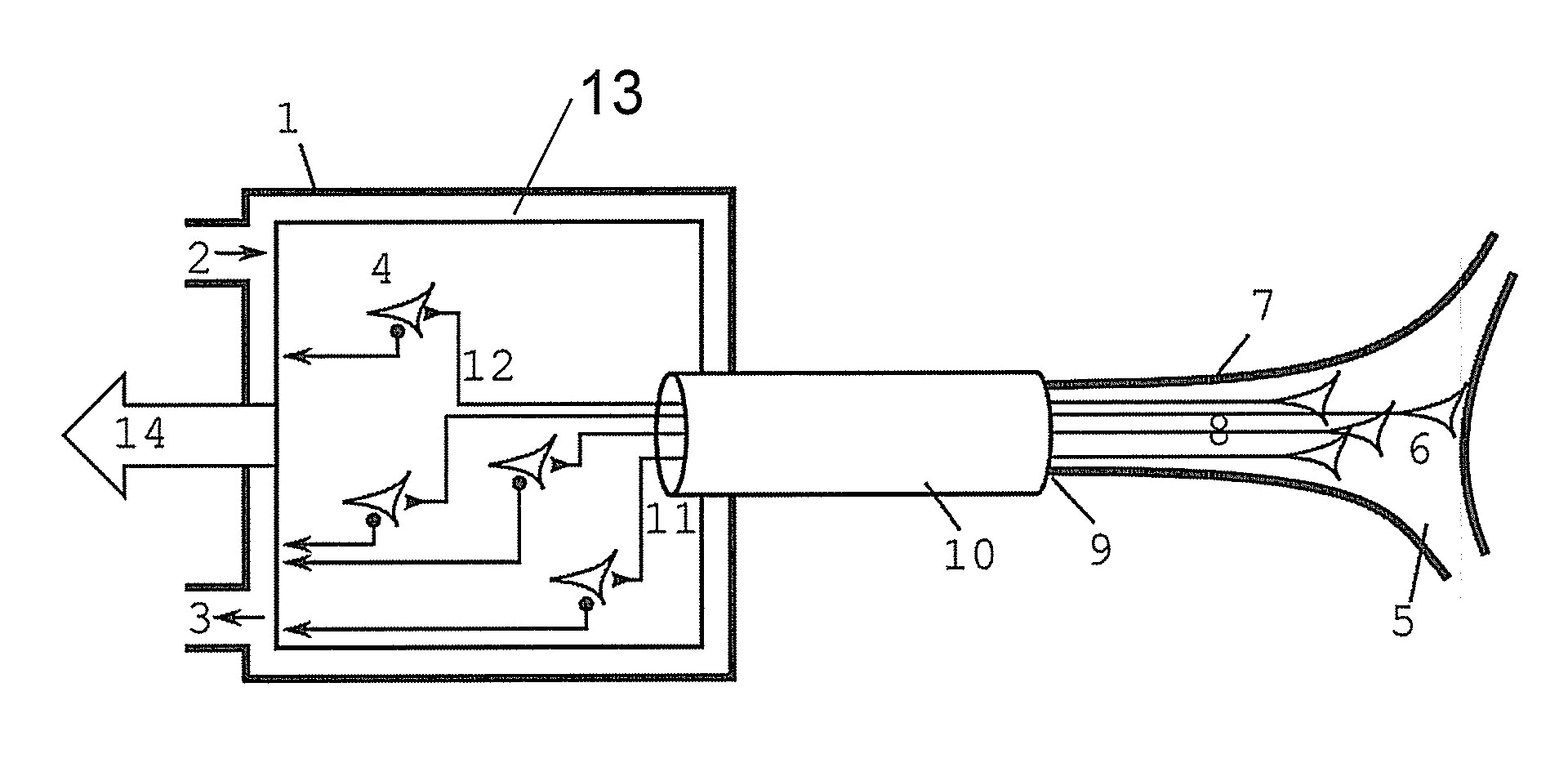

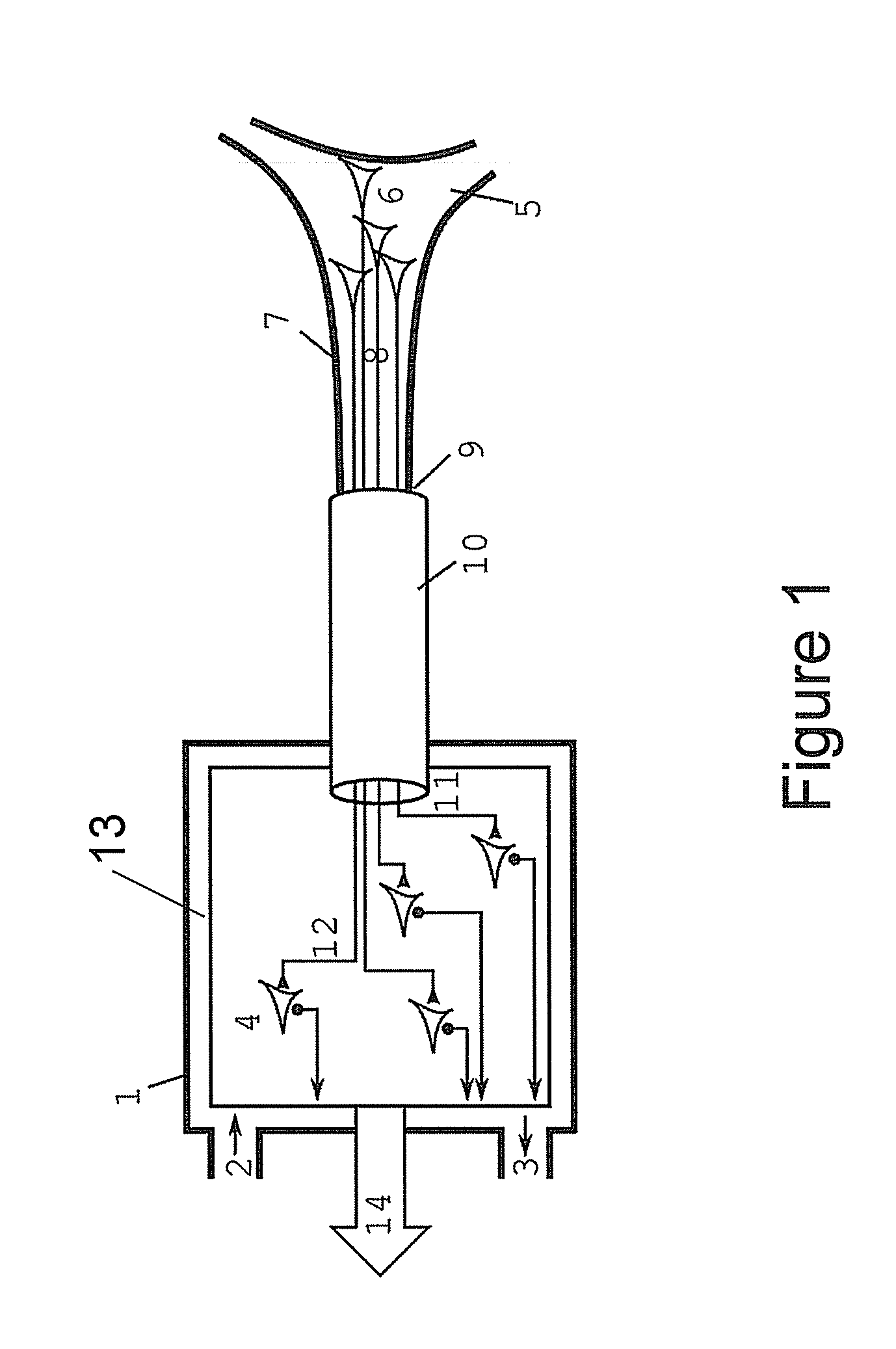

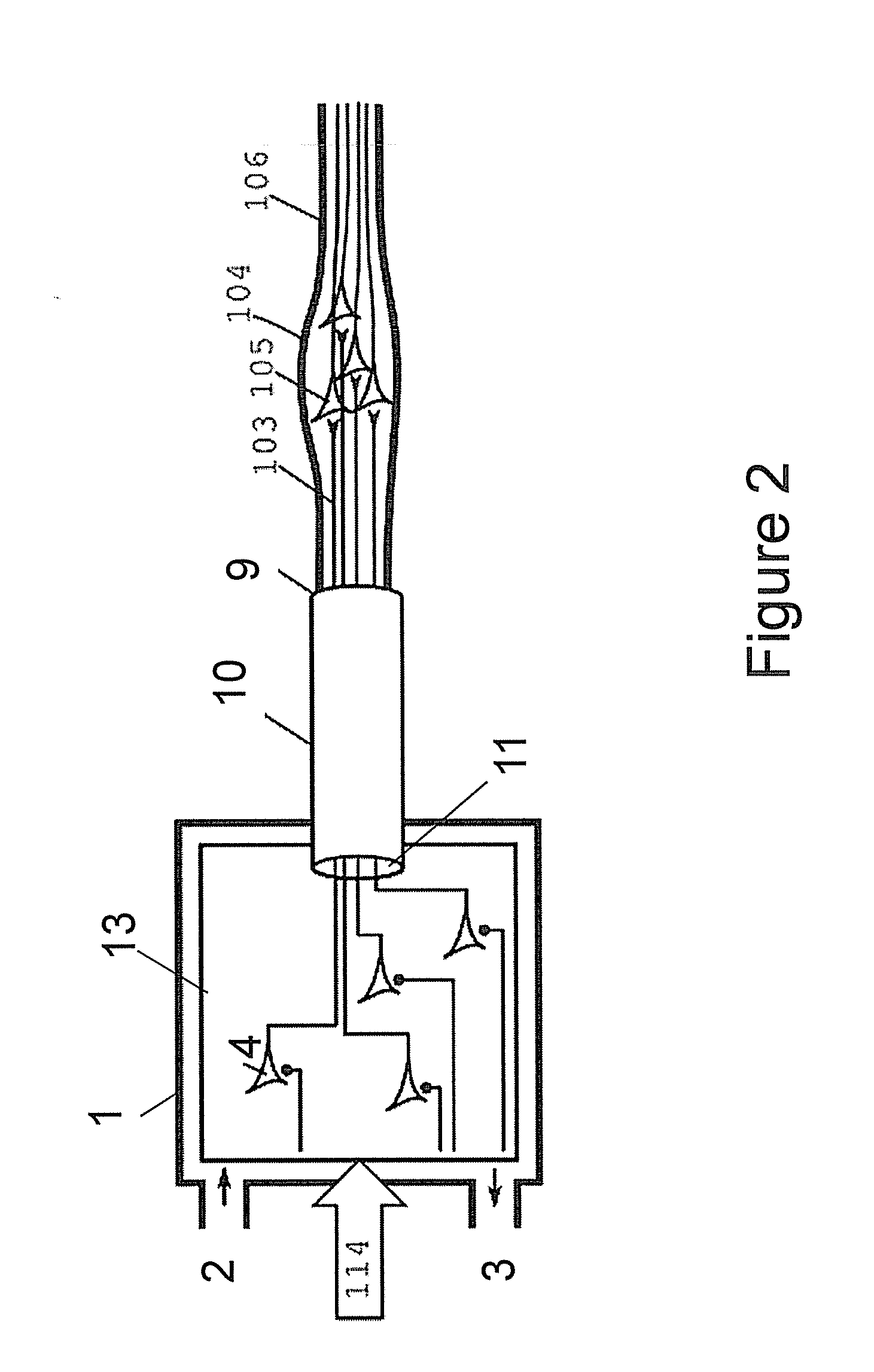

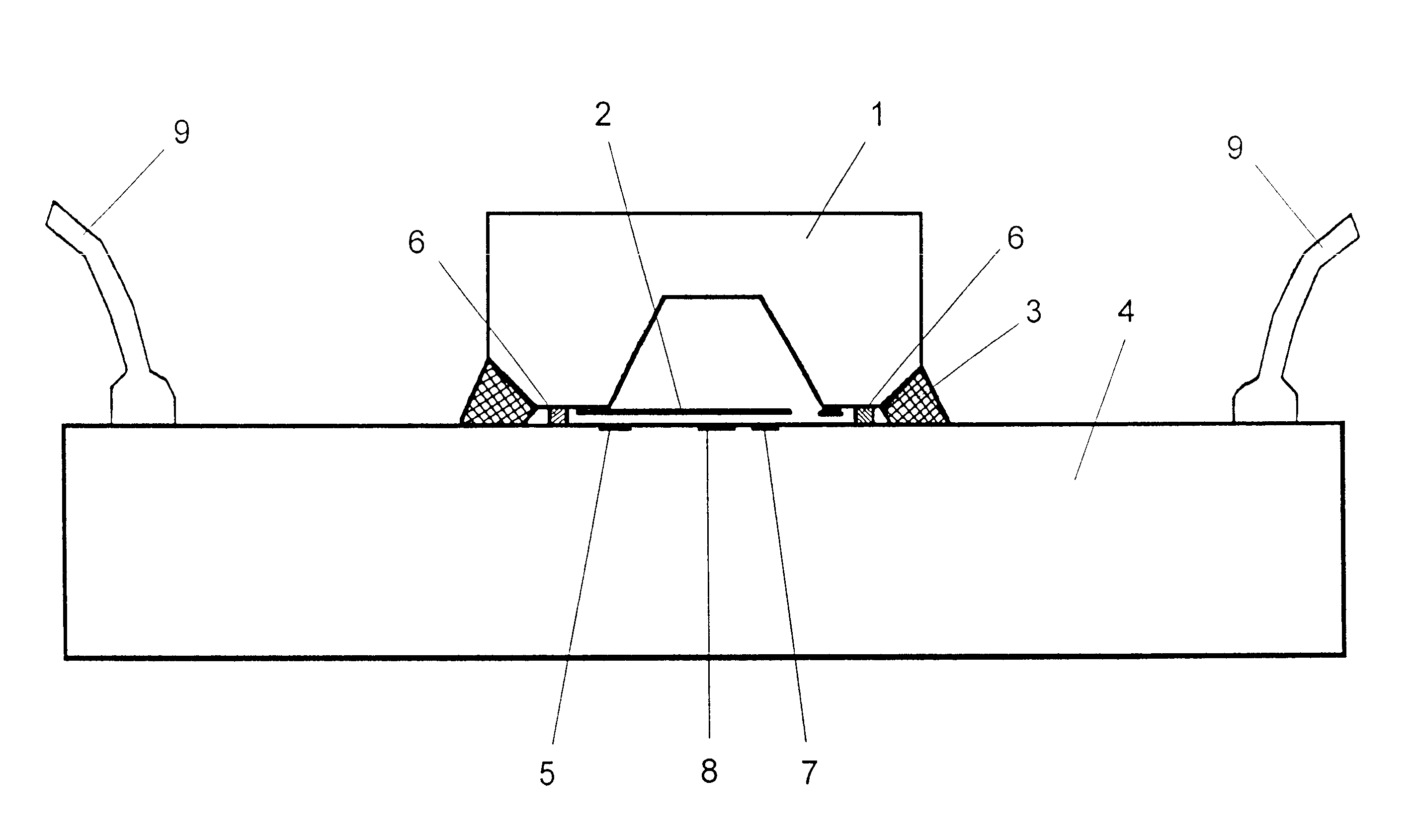

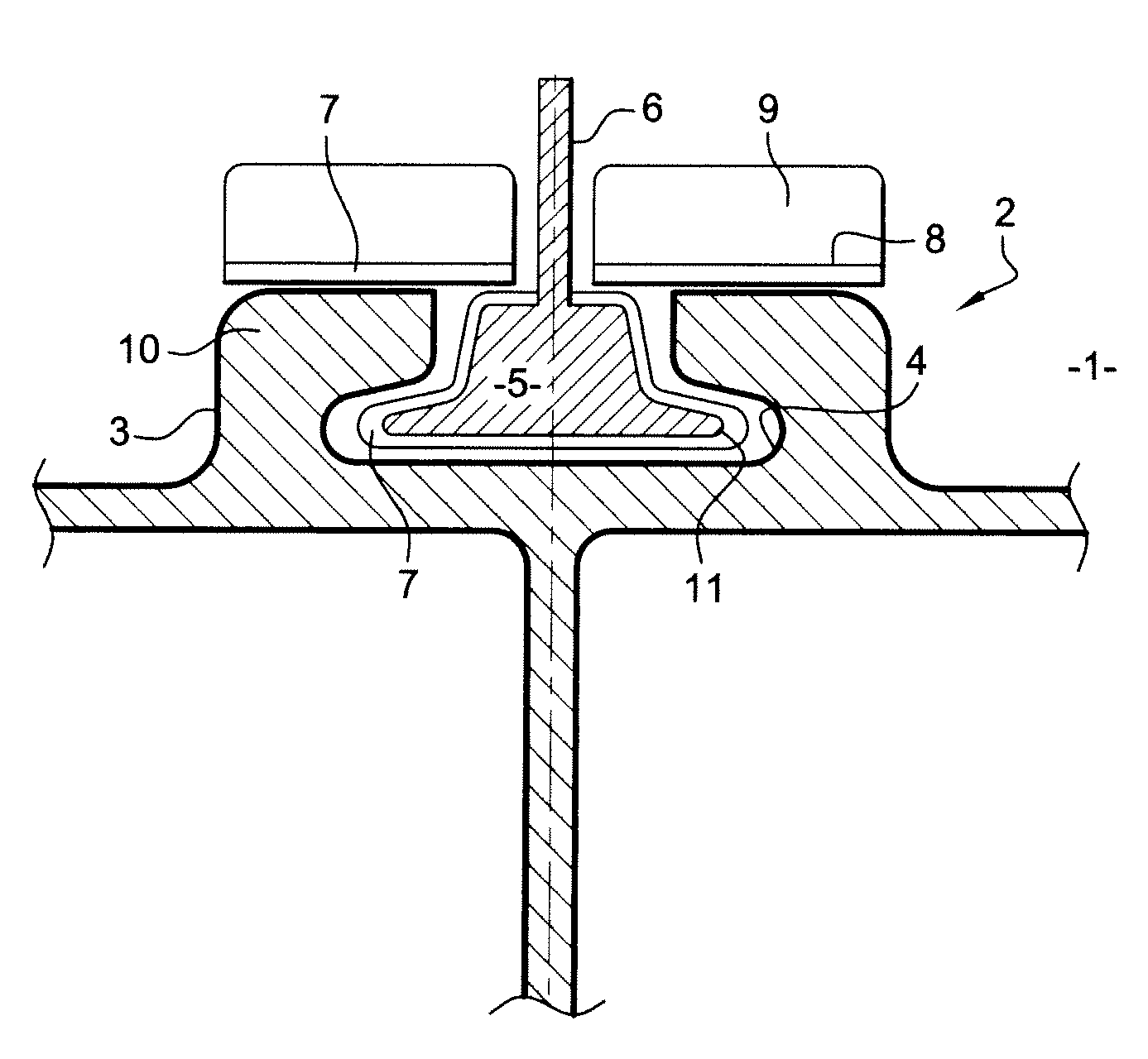

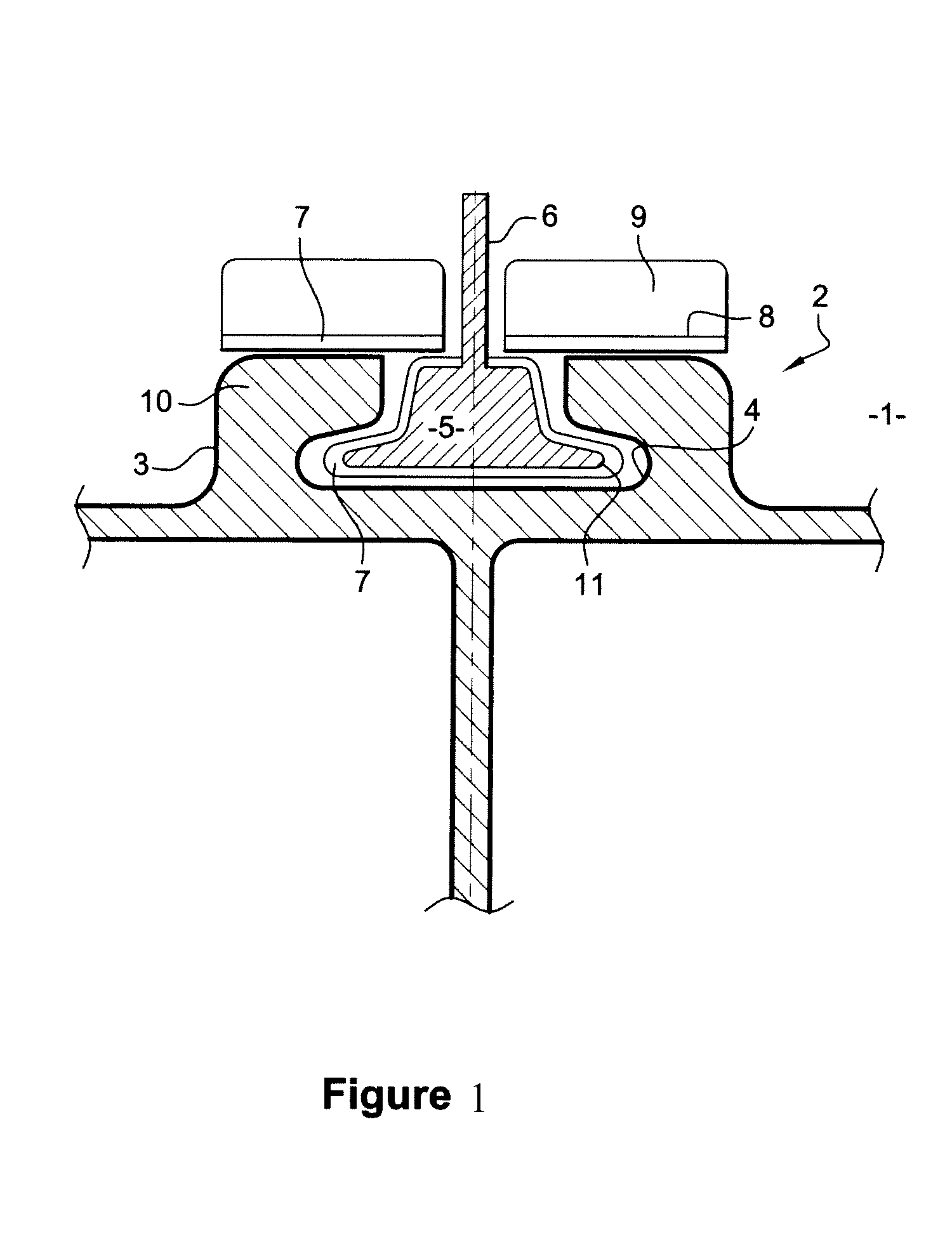

Bio-Hybrid Implant for Connecting a Neural Interface With a Host Nervous System

InactiveUS20110257501A1Manufacture useReduce the risk of contaminationSpinal electrodesSensorsElectronic circuitNeuron

A bio-hybrid implant suitable for recording and / or stimulating cells, the implant comprising (a) at least one closed insulated chamber (1) containing a substrate (502) with a neural interface (13) for connecting neurons to an electronic circuit, (b) at least one flexible guiding channel (10) having a first interface (11) to connect to at least one of the closed insulated chambers (1) and a second interface (9) to connect to a hosts' nerve system (7) or to another insulated chamber.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

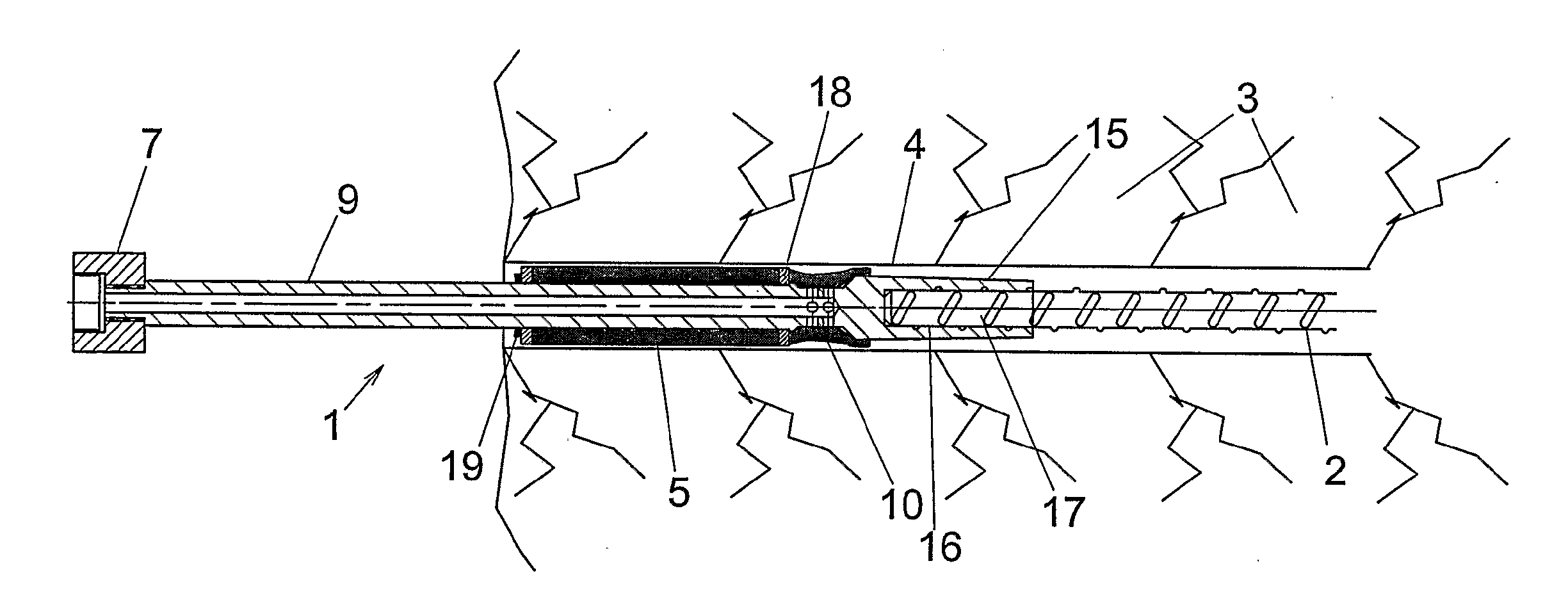

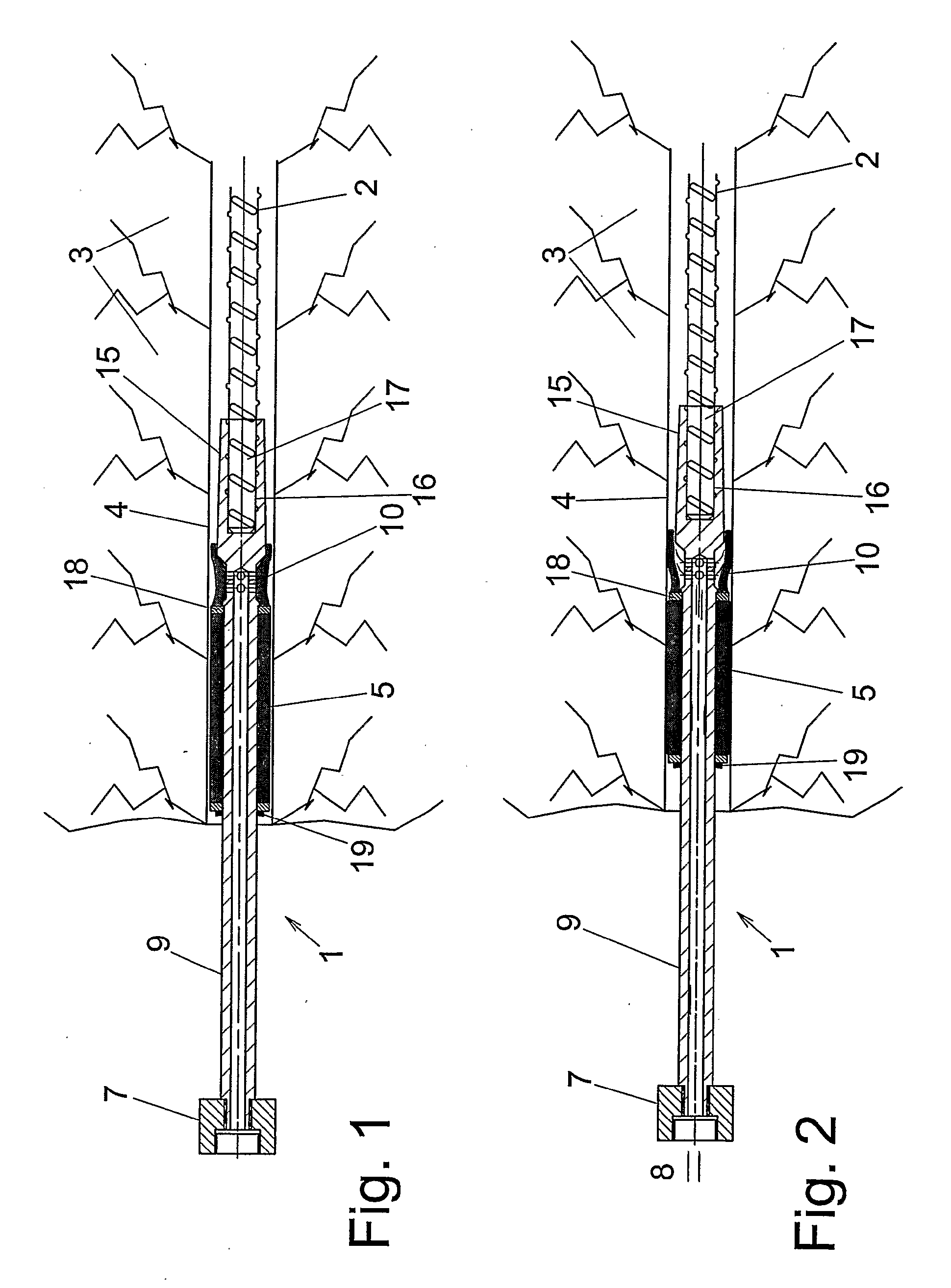

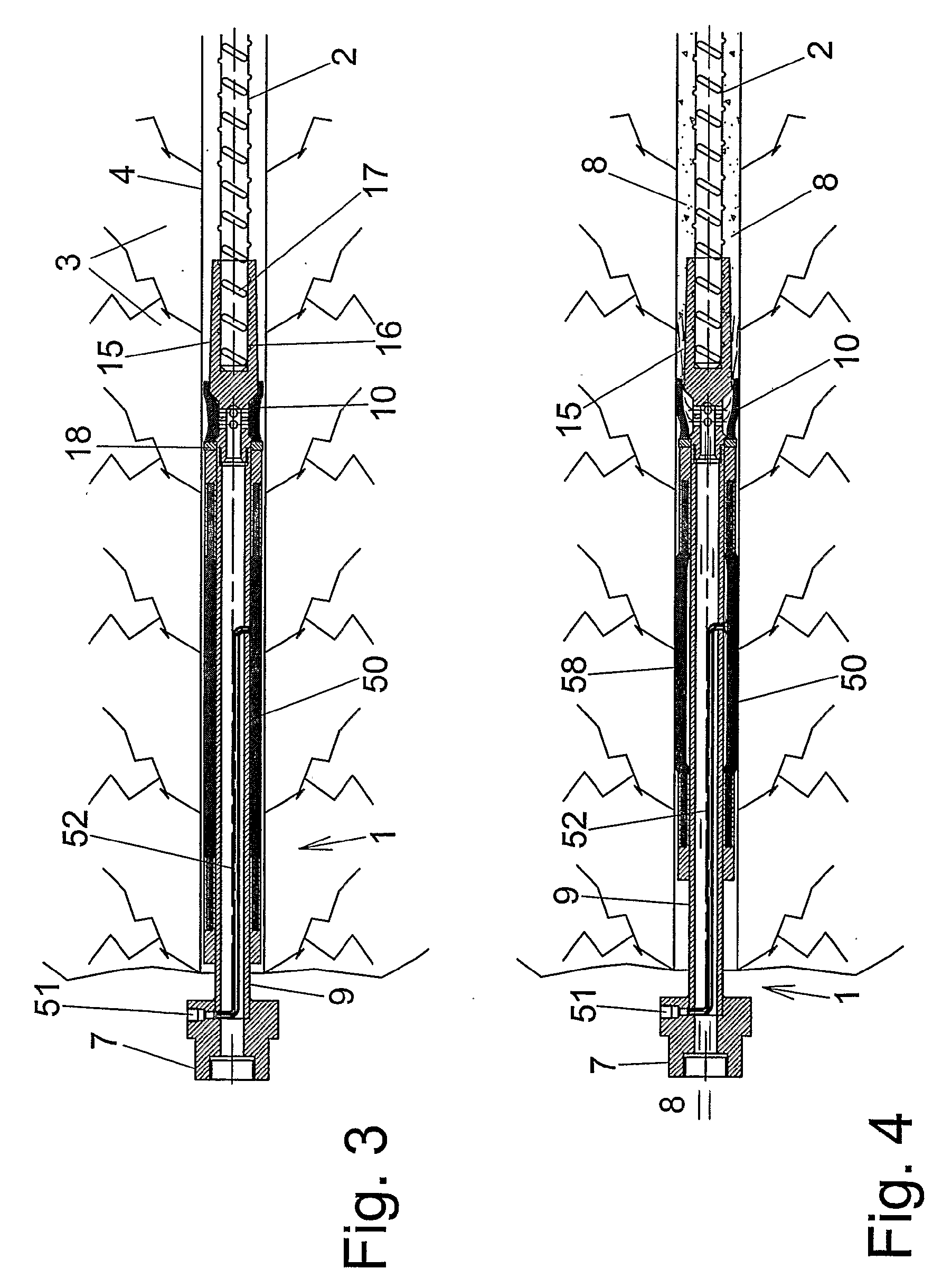

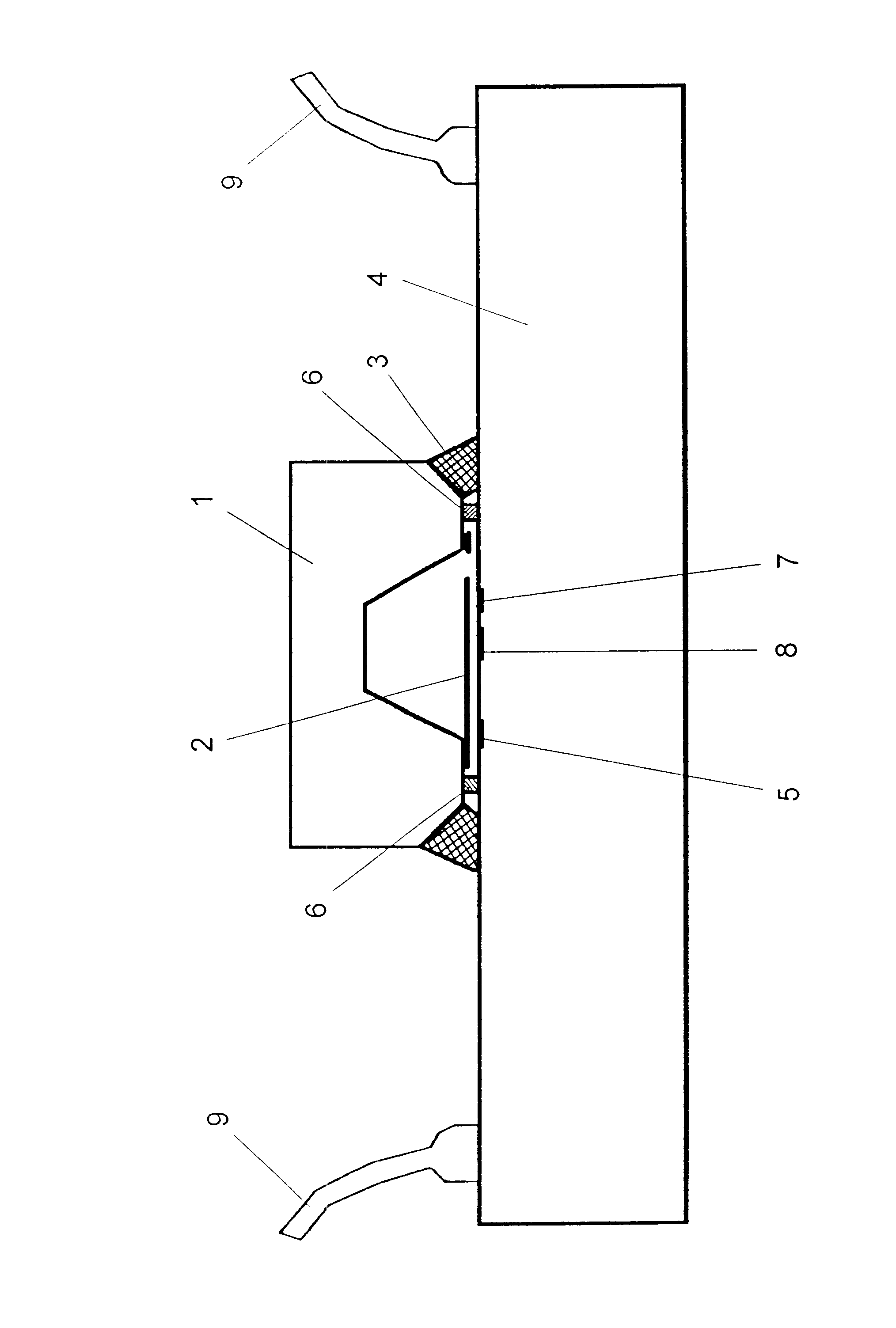

Arrangement for injecting and affixing a reinforcing or anchoring element in a rock wall

InactiveUS20090052995A1Simpler to seal-offReduced risk of corrosionConstructionsAnchoring boltsCouplingEngineering

The present invention relates to an arrangement and to a method for injecting and affixing a reinforcing and / or anchoring element in a rock wall. The arrangement includes means (15; 65) for connection to a reinforcing and / or anchoring element (2; 62), an injection pipe (9) which is connected to the coupling means at a front end facing inwardly in the hole and which includes means (7) for connection to means for supplying injection medium (8). The arrangement also includes a check valve (10) for co-action with the injection medium, and an expandable seal (10; 50; 60). The arrangement is designed as a separate unit that can be loosened from the reinforcing and / or anchoring element upon completion of the injection phase. The method comprises corresponding process steps.

Owner:ATLAS COPCO CRAELIUS

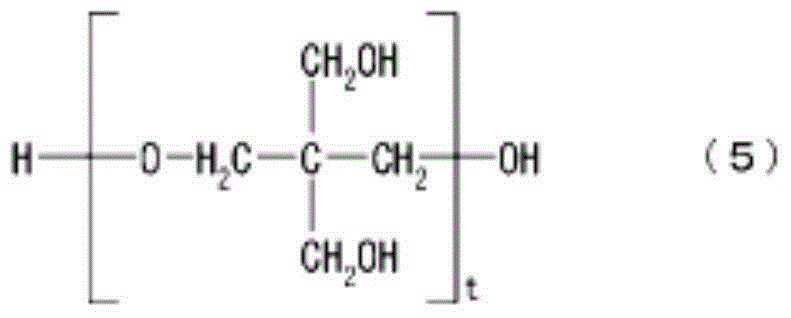

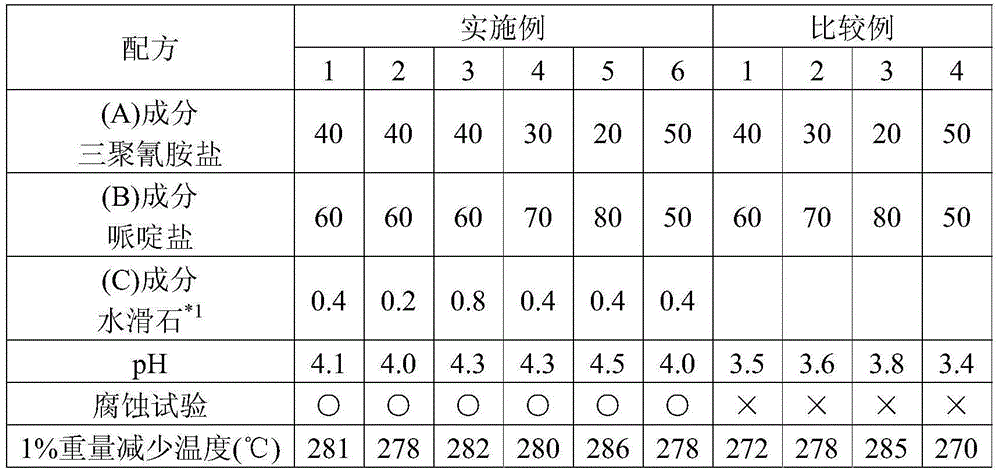

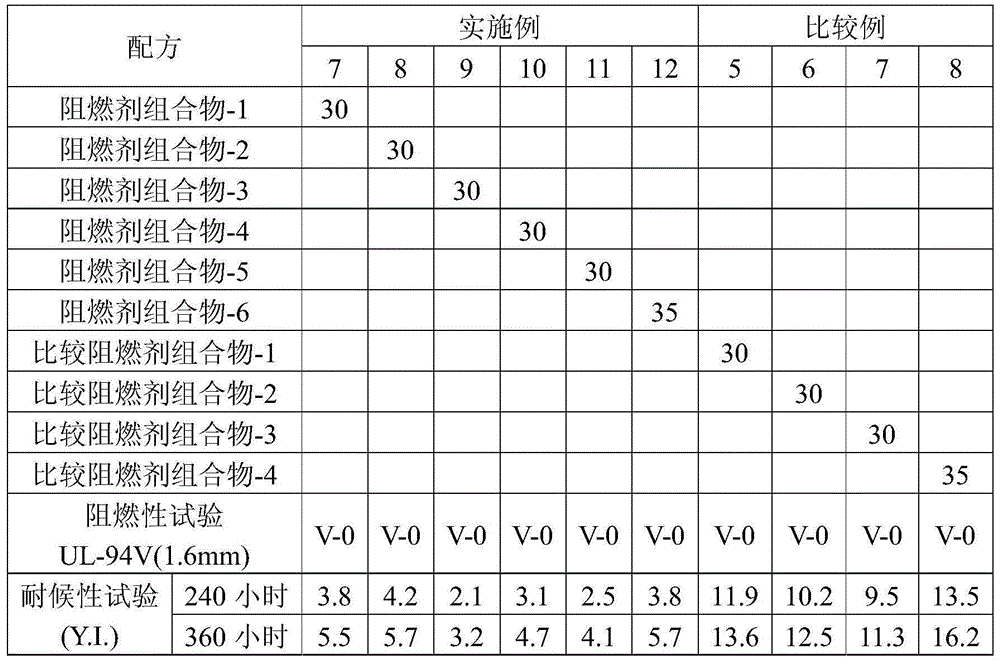

Flame-retardant composition and flame-retardant synthetic resin composition

InactiveCN105209576AImprove heat resistanceImprove flame retardant performanceFireproof paintsMelamine phosphateHeat resistance

The present invention provides a flame-retardant composition having excellent heat resistance and reduced risk of corroding processing equipment during resin compounding, specifically a flame-retardant composition containing 20-50 parts by mass of component (A), 50-80 parts by mass of component (B) (where the total of component (A) and component (B) is 100 parts by mass), and 0.01-5 parts by mass of component (C). Component (A): one or more melamine salts selected from melamine orthophosphate, melamine pyrophosphate, melamine polyphosphate, and mixtures containing two or more of these melamine salts. Component (B): one or more piperazine salts selected from piperazine orthophosphate, piperazine pyrophosphate, piperazine polyphosphate, and mixtures containing two or more of these piperazine salts. Component (C): hydrotalcite compound.

Owner:ADEKA CORP

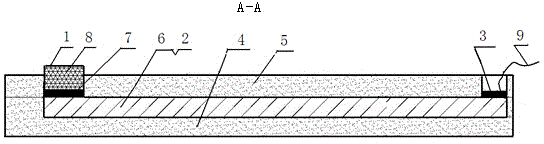

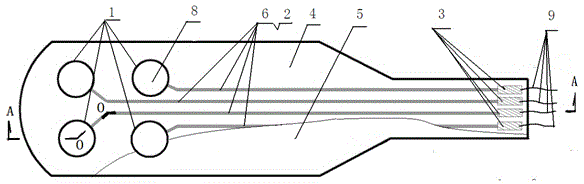

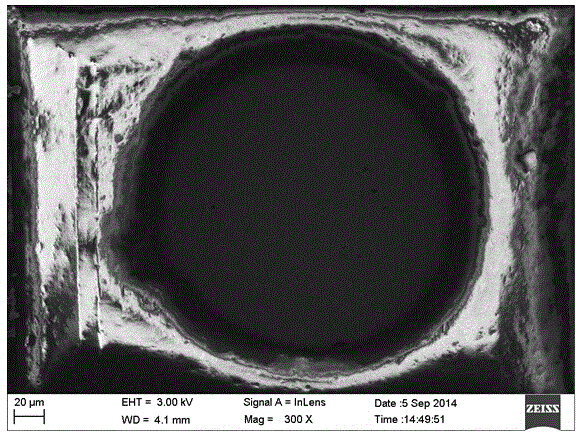

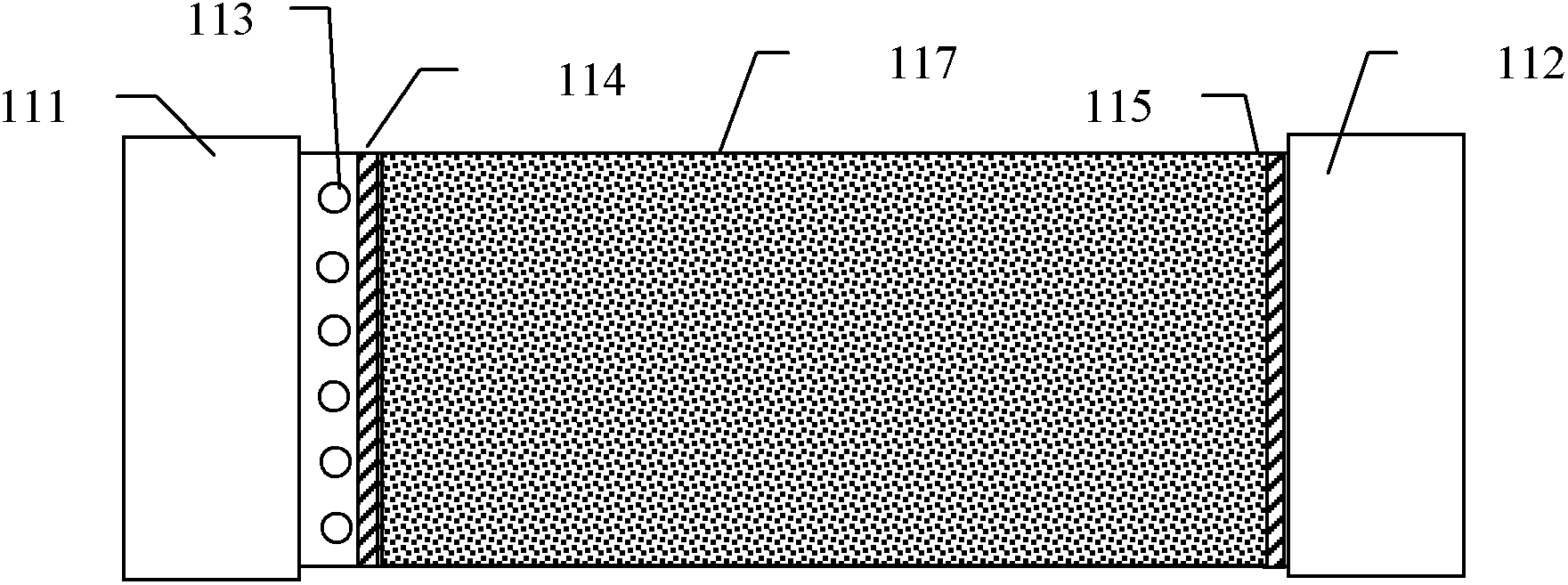

Implantable flexible array electrode used for organism and preparation method of implantable flexible array electrode

InactiveCN104548335AImprove charging capacityFacilitate transmissionInternal electrodesExternal electrodesBiological bodyElectric capacity

The invention relates to an implantable flexible array electrode used for an organism and a preparation method of the implantable flexible array electrode. The implantable flexible array electrode comprises a substrate, wherein the substrate is provided with copper foil layers, one end of each copper foil layer is a copper foil layer of each electrode point, the other end of each copper foil layer is a copper foil layer of each bonding pad, and a wire is arranged at the middle part of each copper foil layer; the copper foil layer of each electrode point and the copper foil layer of each bonding pad are further plated with gold plating layers; the gold plating layer of each electrode point is covered with a high-capacity film layer. The preparation method comprises steps as follows: manufacturing of copper foil layers of the electrode points, the wires and the bonding pads, hot-pressing package and gold plating and electrochemical modification of the electrode points. The implantable flexible array electrode and the preparation method have the advantages that the charge transmission performance of the array electrode is good, bidirectional functions of electrical nerve stimulation and nerve electrical recording are realized, and the array electrode can be easily accepted by a receptor, and is easy to machine and low in cost.

Owner:WUHAN GREENTEK

Microsensor having a sensor device connected to an integrated circuit by a solder joint

InactiveUS6520014B1Accurate measurementReduced risk of corrosionAcceleration measurement using interia forcesSemiconductor/solid-state device detailsElectricityIntegrated circuit

In a microsensor with a micro-electromechanical sensor element and an integrated circuit for measuring, calibration and compensation electronics, whereby the sensor is connected electrically to the integrated circuit (IC), the micro-electromechanical sensor element is arranged directly on the integrated circuit with accurate positioning, and is connected with electric conductivity via a circulating soldered joint.

Owner:AUSTRIA MIKRO SYST INT

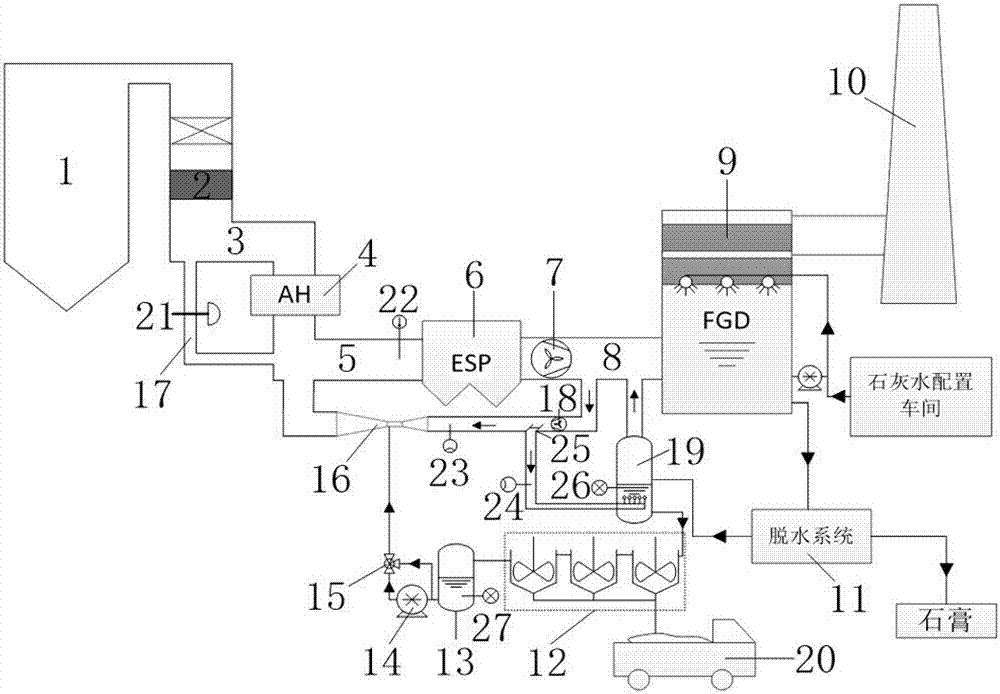

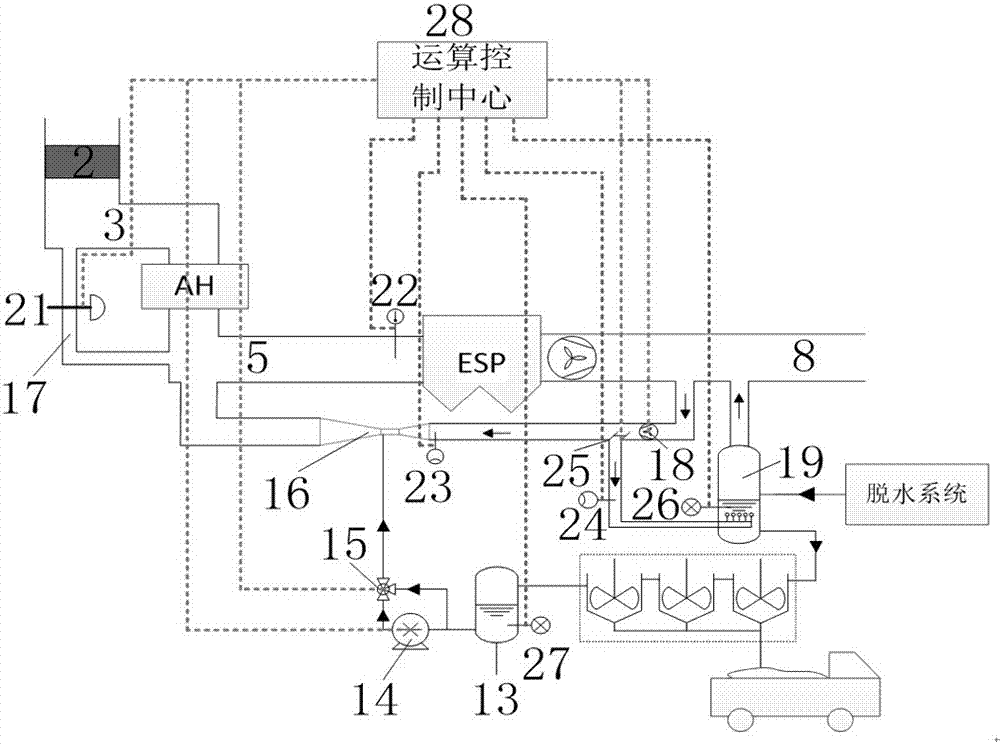

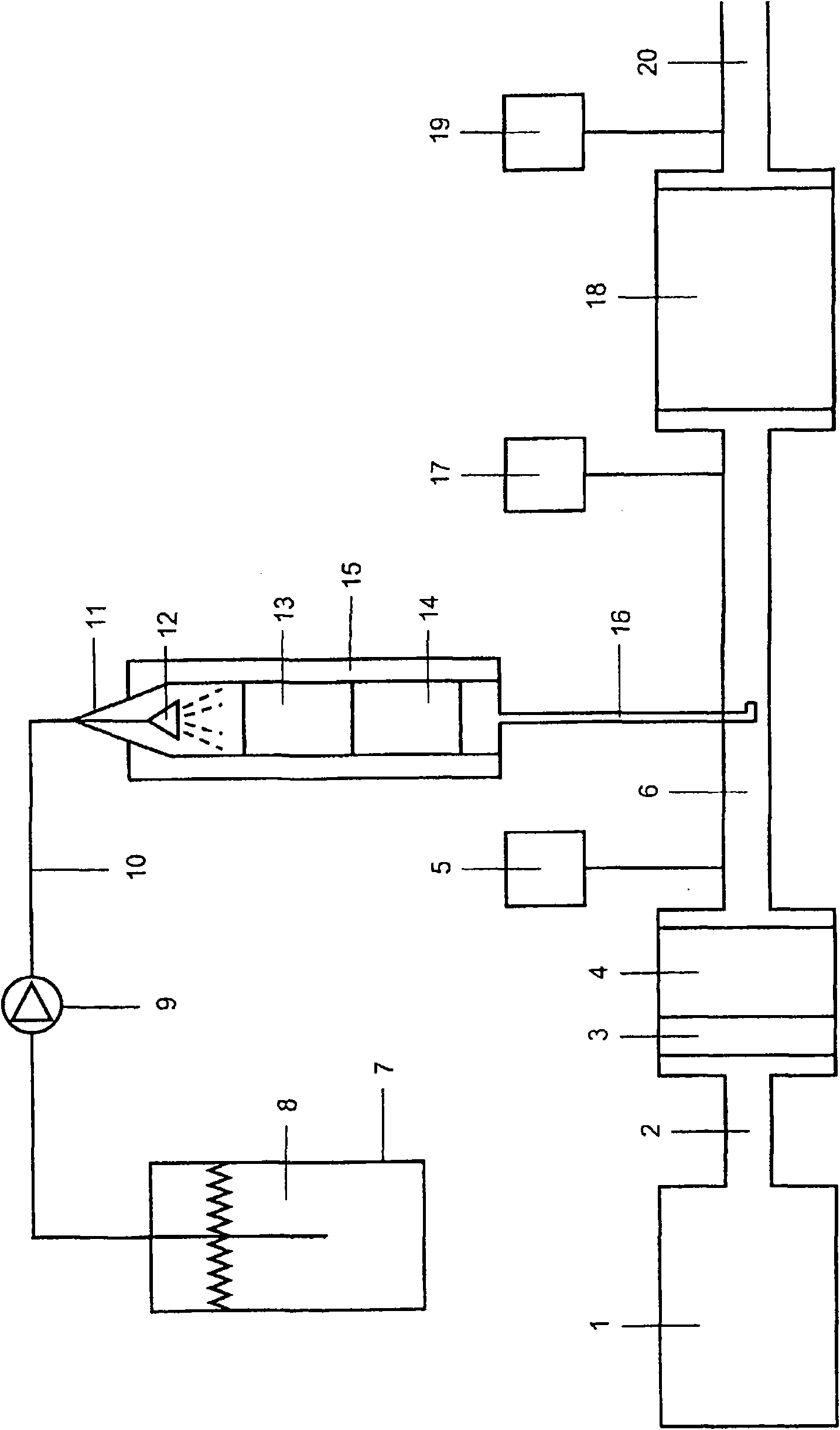

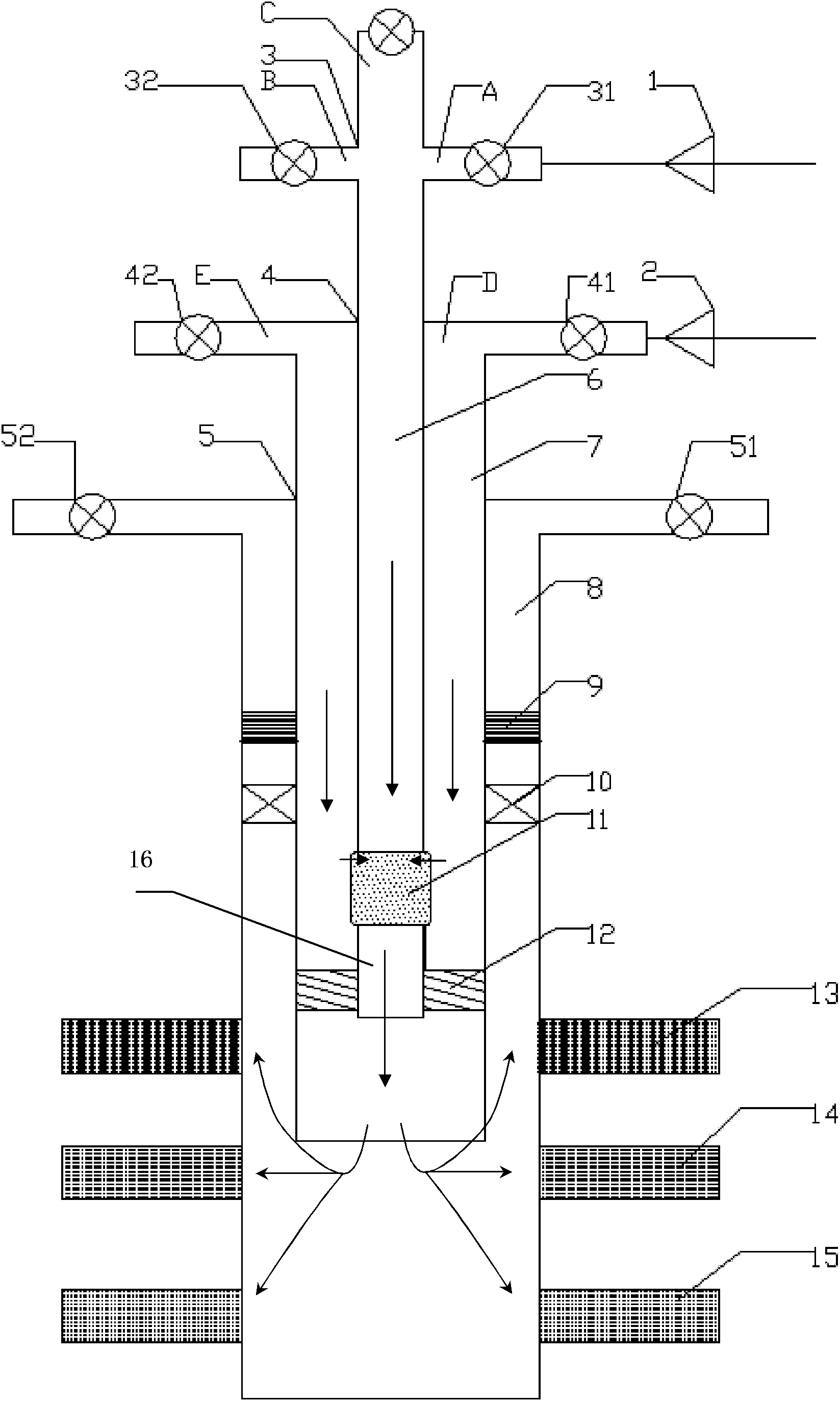

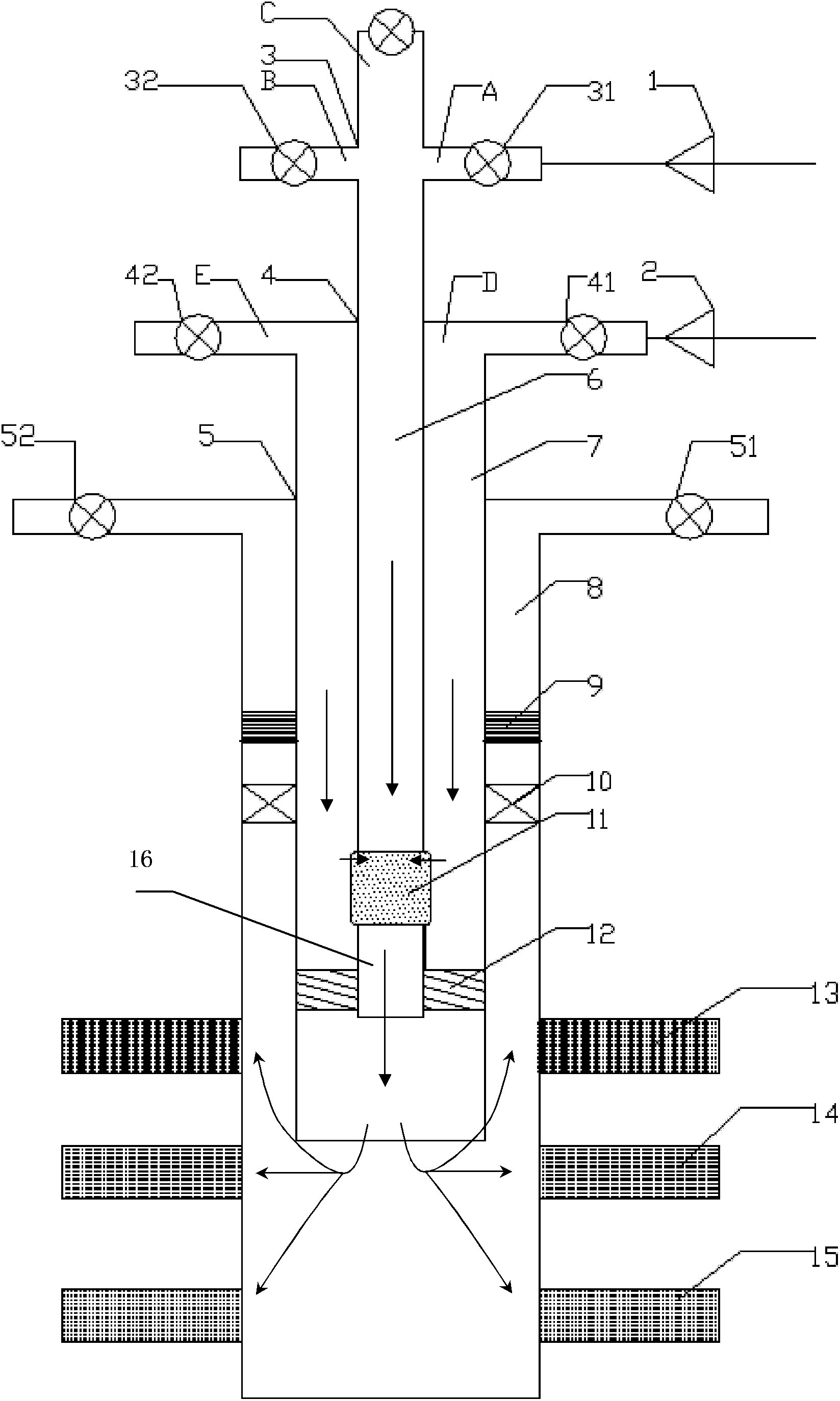

Method and device for achieving desulfurization wastewater zero discharging with full flue gas

PendingCN108006683ATo achieve the effect of reduction treatmentAvoid problems with temperatures below the acid dew pointGas treatmentEmission preventionEvaporationSlurry

The invention discloses a method and device for achieving desulfurization wastewater zero discharging with full flue gas. The method includes the steps that desulfurization wastewater discharged froma coal-fired power plant slurry dewatering system is directly fed into a bypass bubble tower in front of a desulfurizing tower, and then is subjected to reducing concentration with hot flue gas in front of the desulfurizing tower; desulfurization wastewater concentrated water is fed into three connection tanks for charging treatment; settled supernatant liquid is fed into a wastewater tank to be buffered and stored; part of waste heat flue gas is led out behind an electrostatic dust collector and is further pressurized through a high-pressure fan to be fed into an inlet of a Venturi atomizingtube; the desulfurization wastewater stored in the wastewater tank is led into the Venturi tube through negative pressure at a pipe opening of the Venturi tube, high-speed airflow at the throat position of the Venturi tube can impact and atomize the led-in desulfurization wastewater, and meanwhile the waste heat flue gas and liquid drops are subjected to forceful heat transfer so that the pre-evaporation effect on the liquid drops can be achieved; and solid evaporated products are captured by the follow-up electrostatic dust collector or a bag-type dust remover, and therefore low-cost zero discharging of the desulfurization wastewater can be realized.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

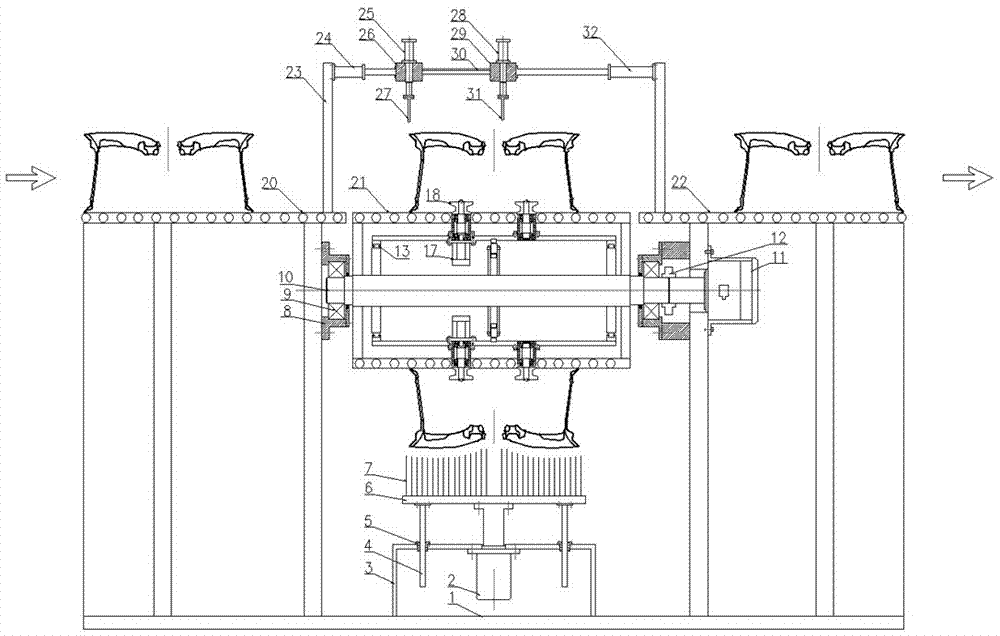

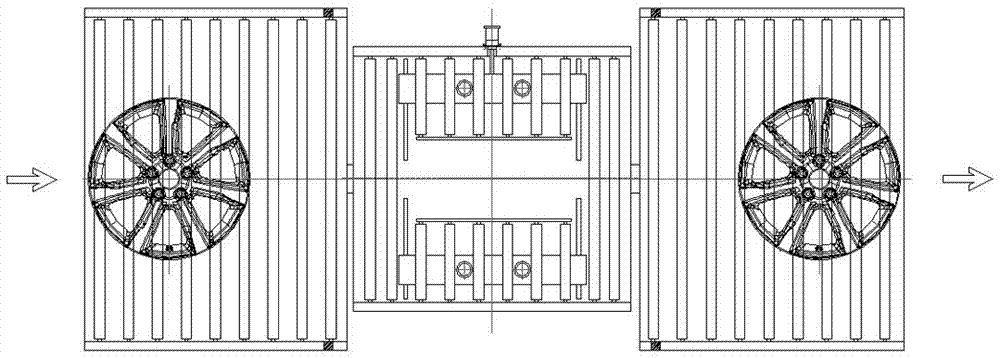

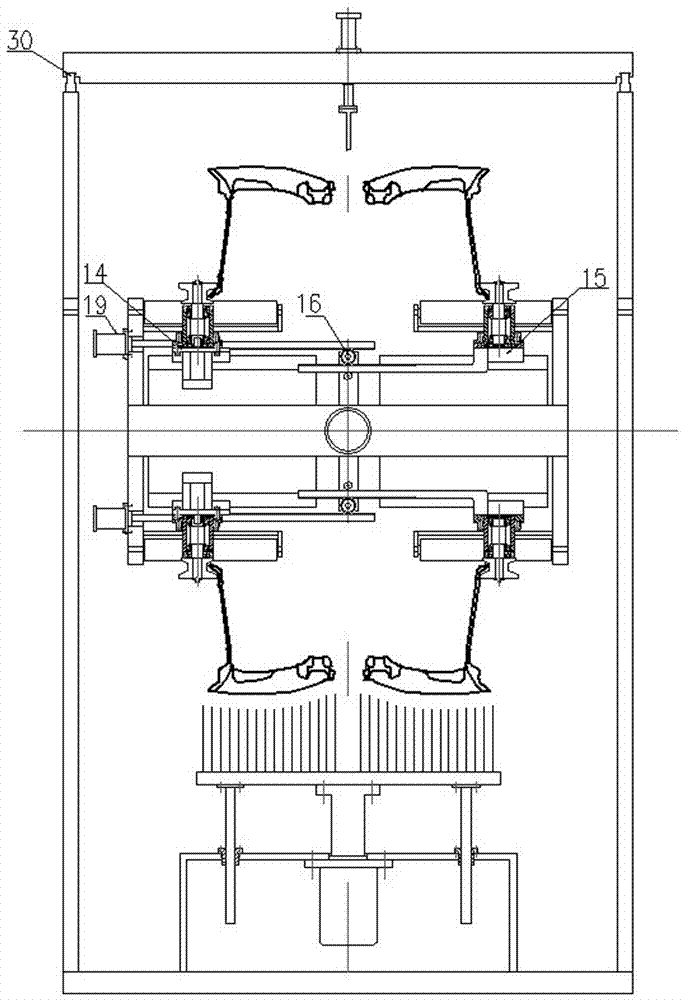

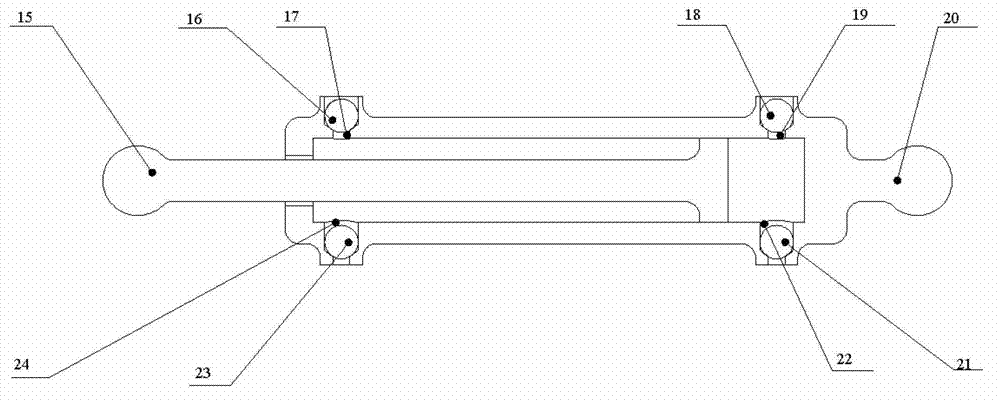

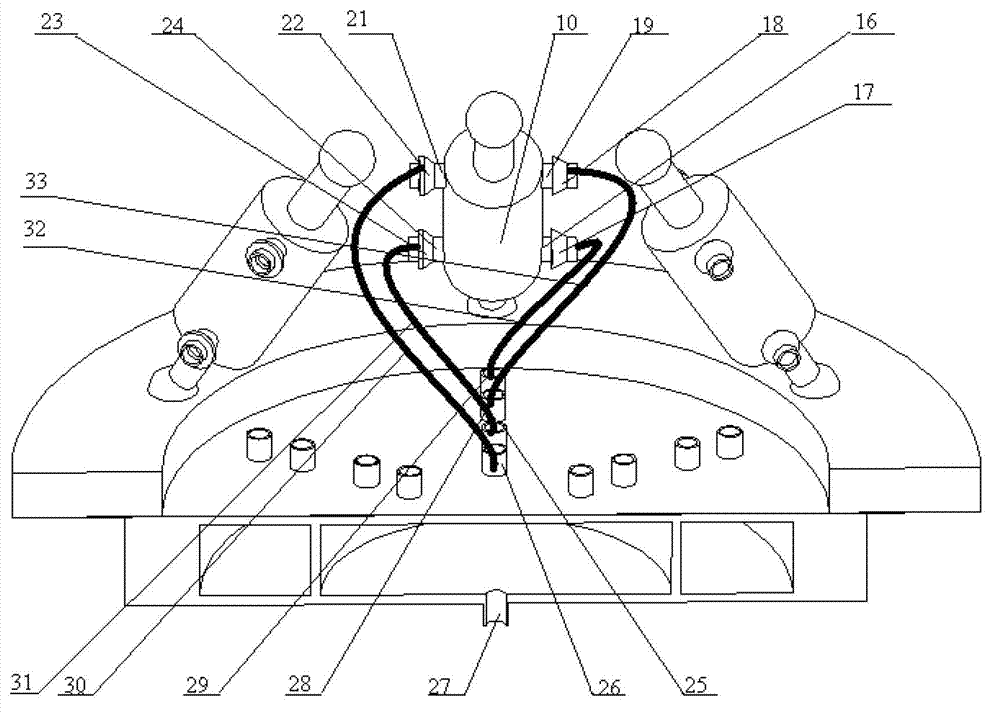

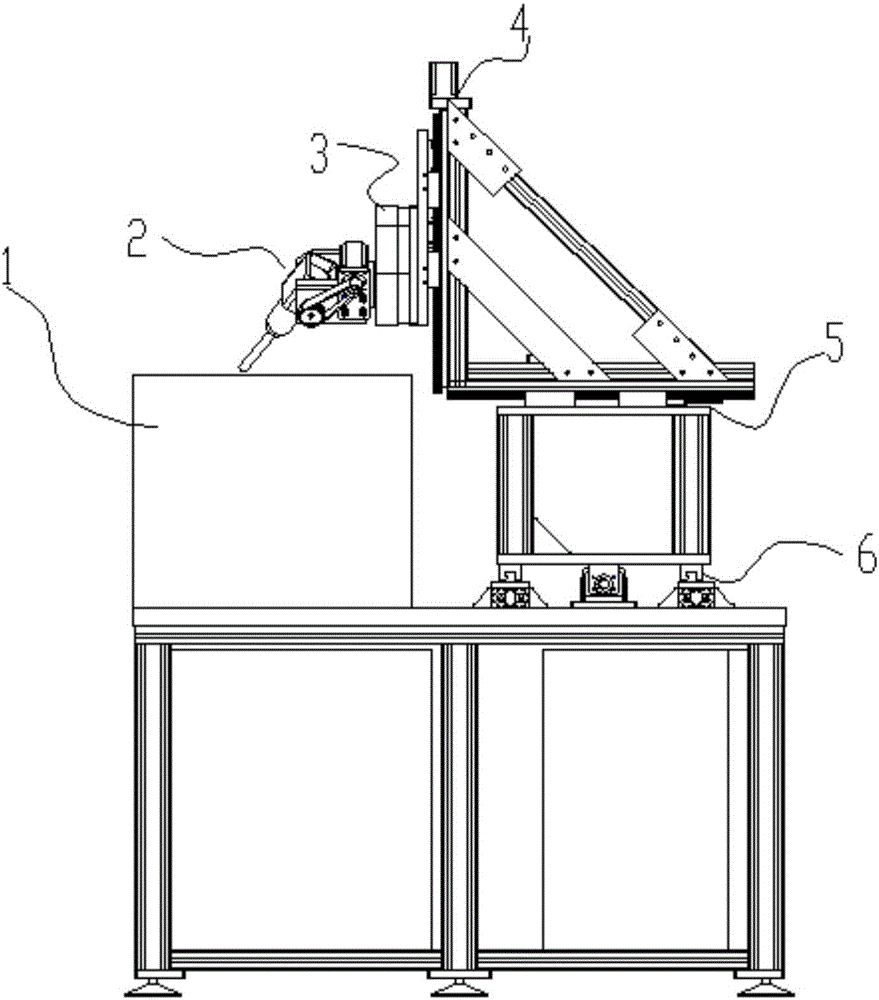

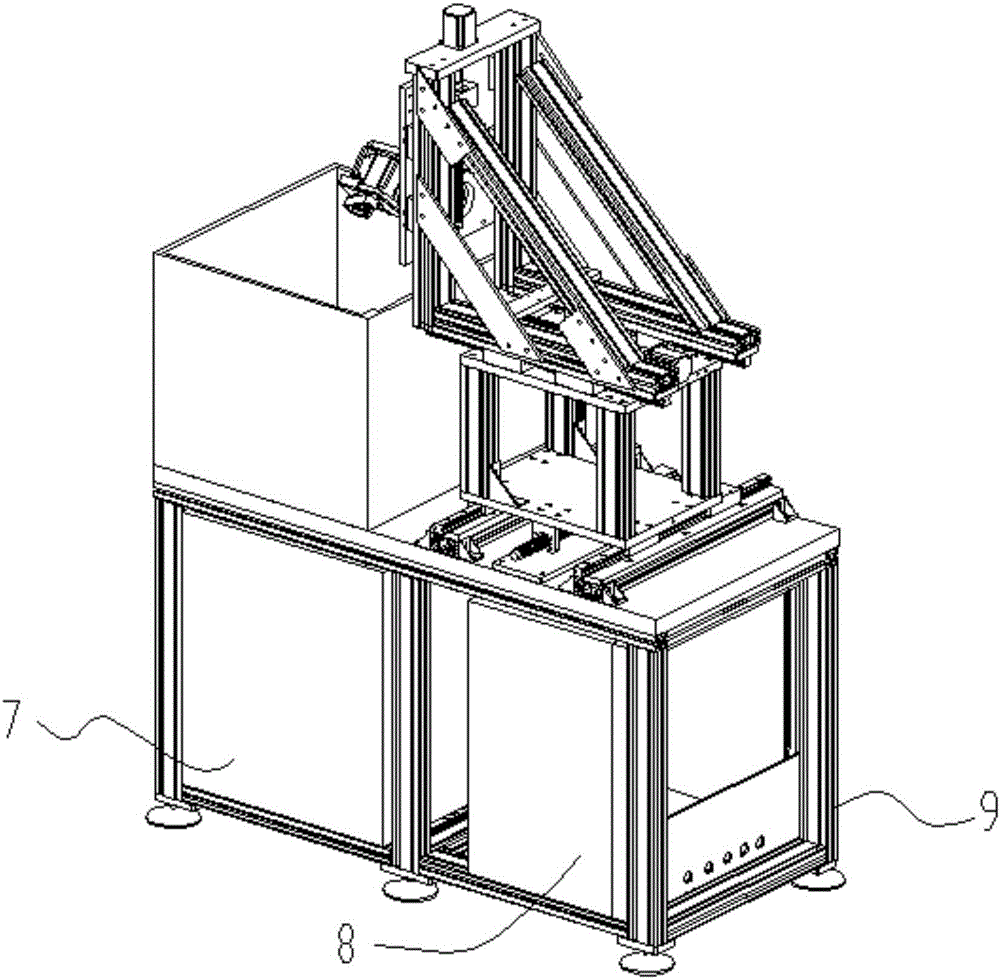

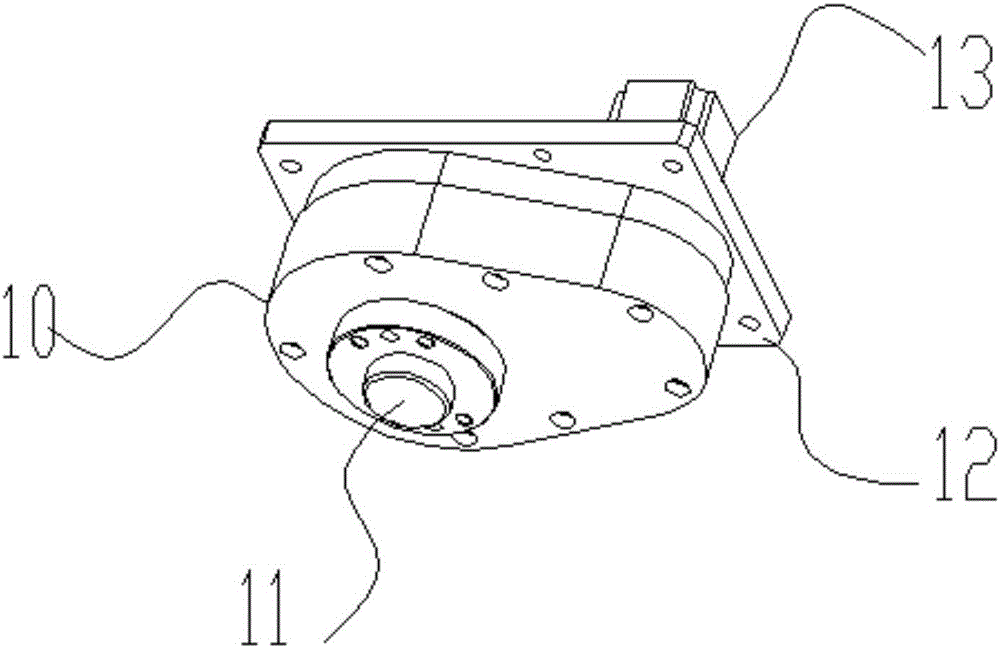

Wheel front burr removing device

InactiveCN107363669AImprove painting yieldImprove efficiencyEdge grinding machinesPolishing machinesCouplingRotation system

Provided is a wheel front burr removing device. The wheel front burr removing device is composed of a rack (1), a lifting cylinder (2), a supporting frame (3), a guiding column (4), a guide sleeve (5), a lifting platform (6), a brush (7), a bearing seat (8) and the like. A servo motor I (11) is fixed to the side of the rack (1), the output end of a motor is connected with an overturning platform (10) through a coupling (12), the middle part of the overturning platform (10) is a cuboid, the left side and the right side of the overturning platform are circular shafts, and the shafts are matched with bearings (9); the lower part and the upper part of the overturning platform (10) are exactly the same, and wheel positioning and clamping rotation systems are symmetrically distributed; and the overturning platform (10) is controlled by the servo motor I (11) to rotate 180 degrees at a time, and cyclic switching of the positioning and clamping rotation system at the upper part of the overturning platform (10) and the positioning and clamping rotation system at the lower part of the overturning platform (10) is realized. According to the wheel front burr removing device, burrs at the front faces of wheels can be thoroughly removed, and the wheel front burr removing device has the characteristics of being short in beat, high in efficiency, novel in layout, advanced in technology, high efficient and practical.

Owner:CITIC DICASTAL

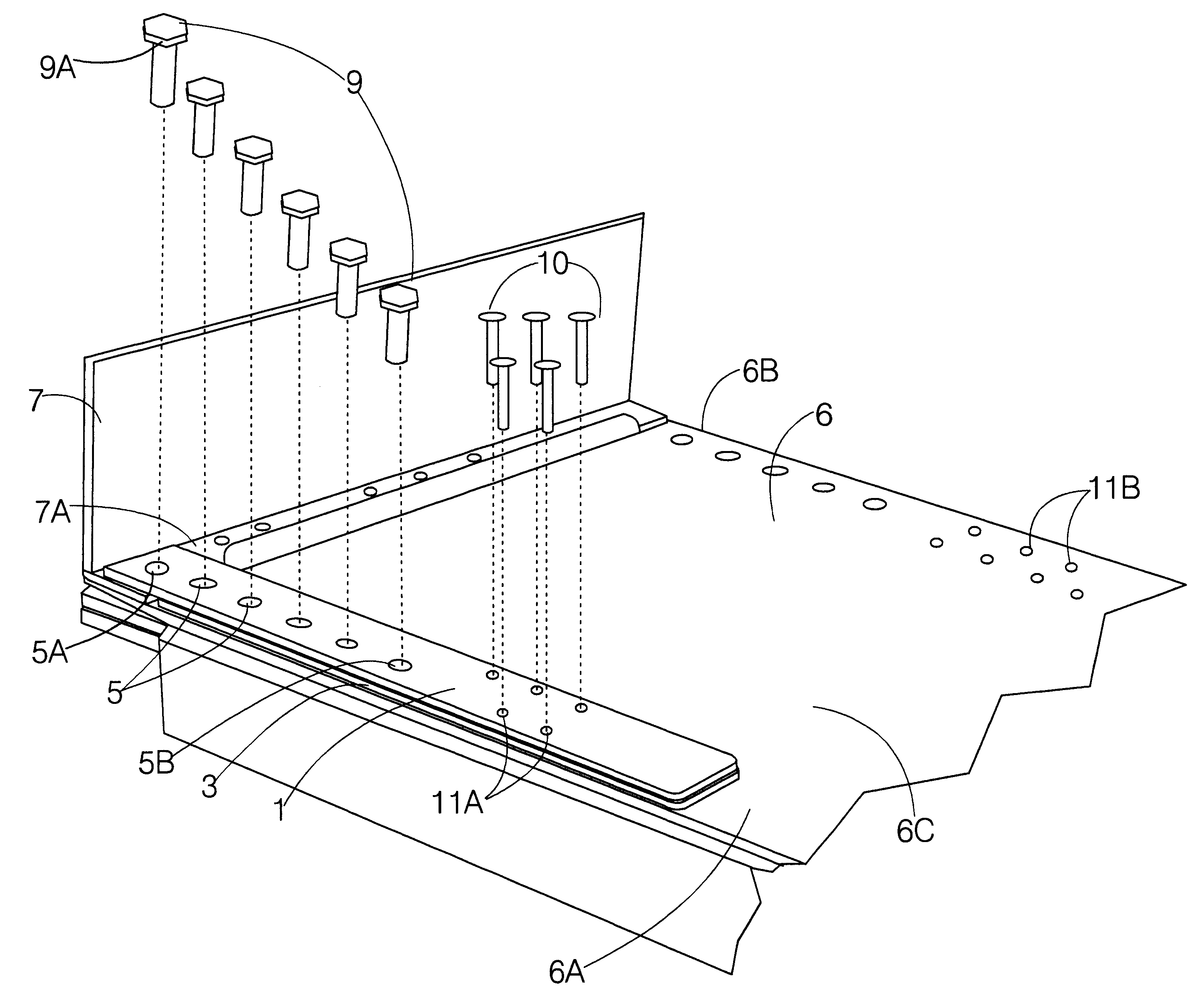

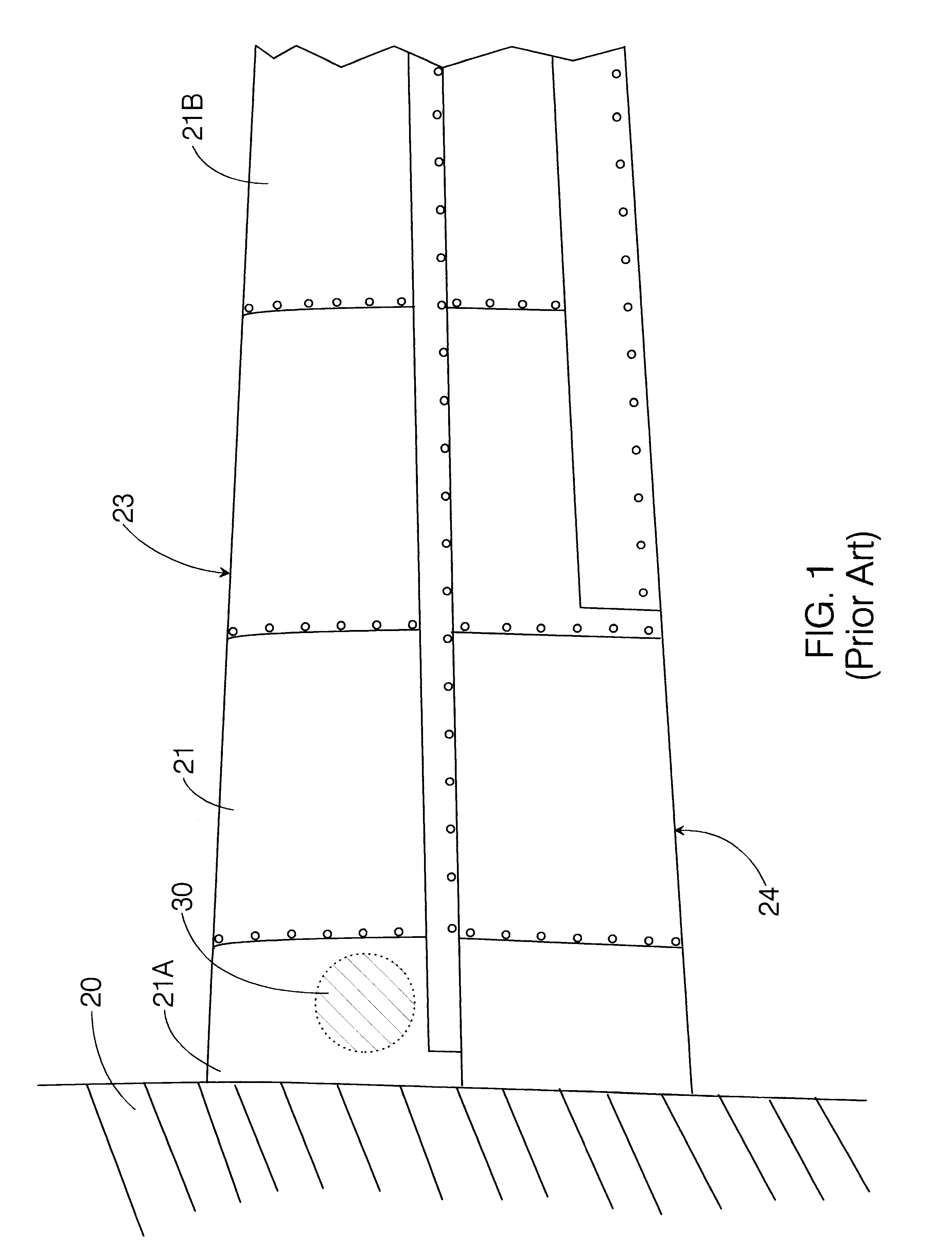

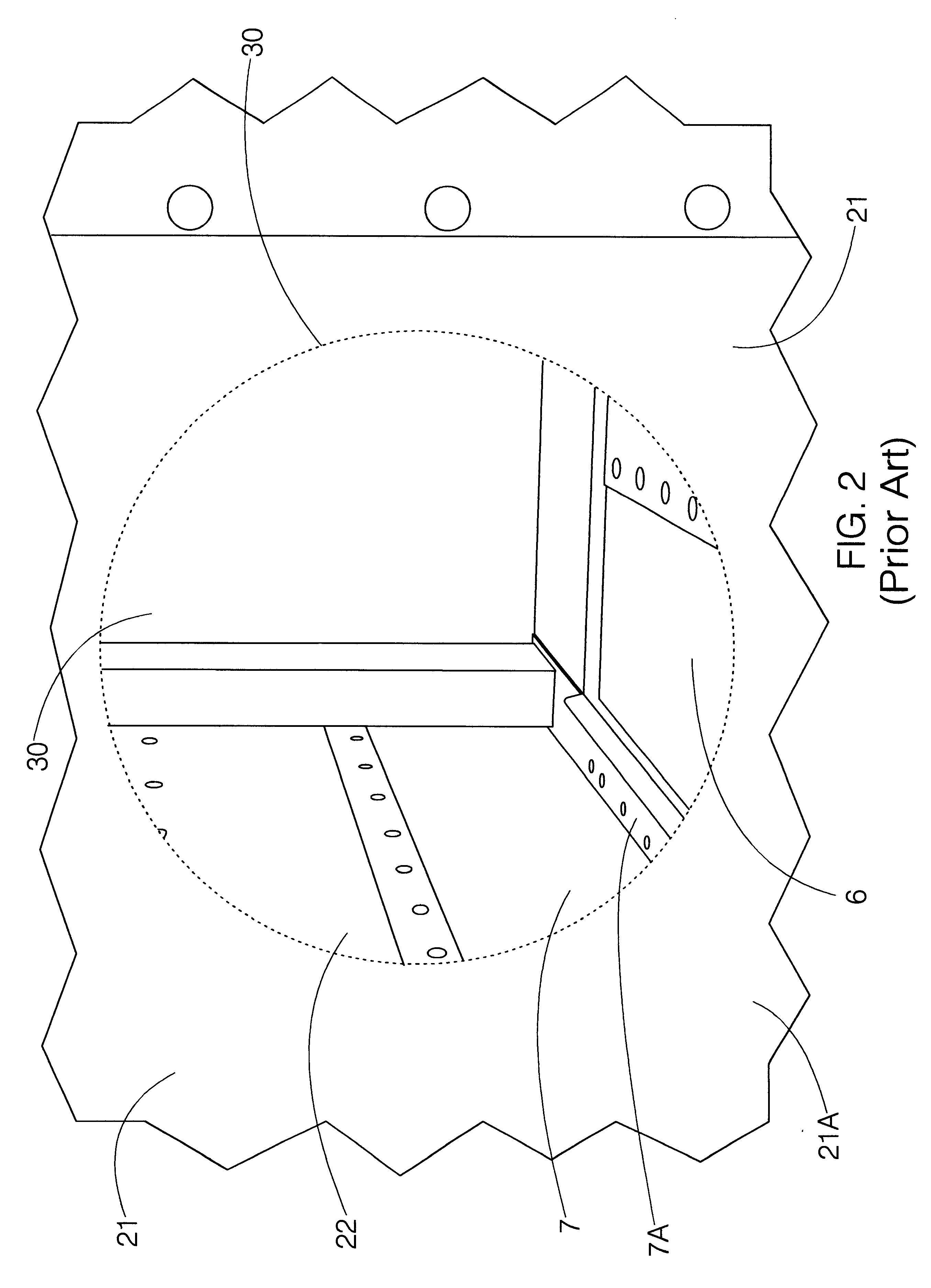

Wing spar modification kit

InactiveUS6328260B1Eliminate dangerReduced risk of corrosionFuselage framesAircraft stabilisationVertical planeAirplane

A kit for reinforcing the wing spar attachment of Lake models of amphibious airplanes. The kit includes two filler-straps and two doubler-straps for each wing spar, and the necessary bolts, rivets, washers and nuts to attach the straps to the wing spar web. The doubler-straps are constructed to fit all models of Lake amphibious airplanes; the thickness of the filler-straps is, however, specific to the model of airplane or the model of wing in which they are to be installed. The doubler-straps and the filler-straps are pre-treated to protect them against corrosion and are marked so as to preclude incorrect inspection. The inboard end of the doubler-strap is angled to correspond to the angle of the wing spar relative to a vertical plane of the airplane.

Owner:ENPAT

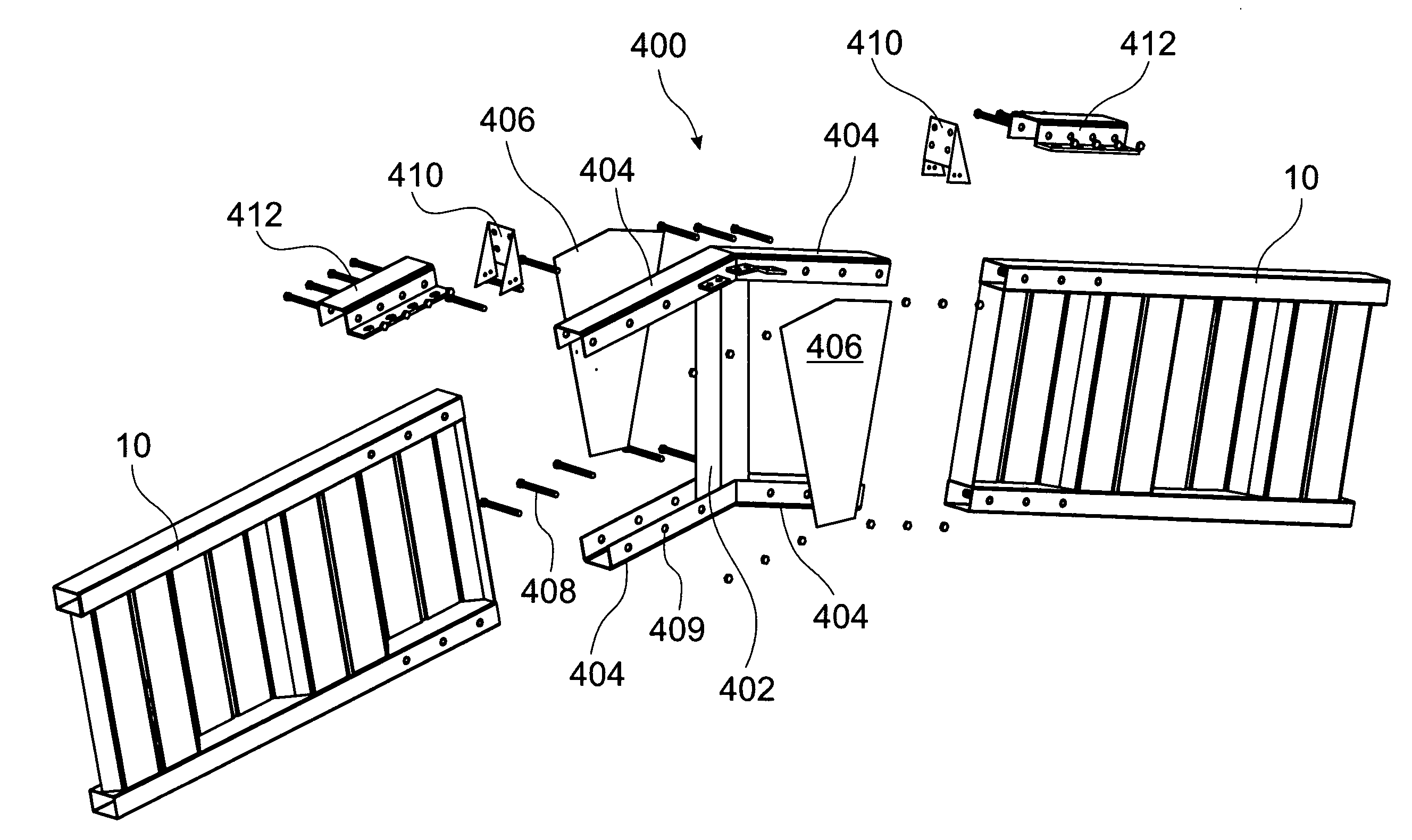

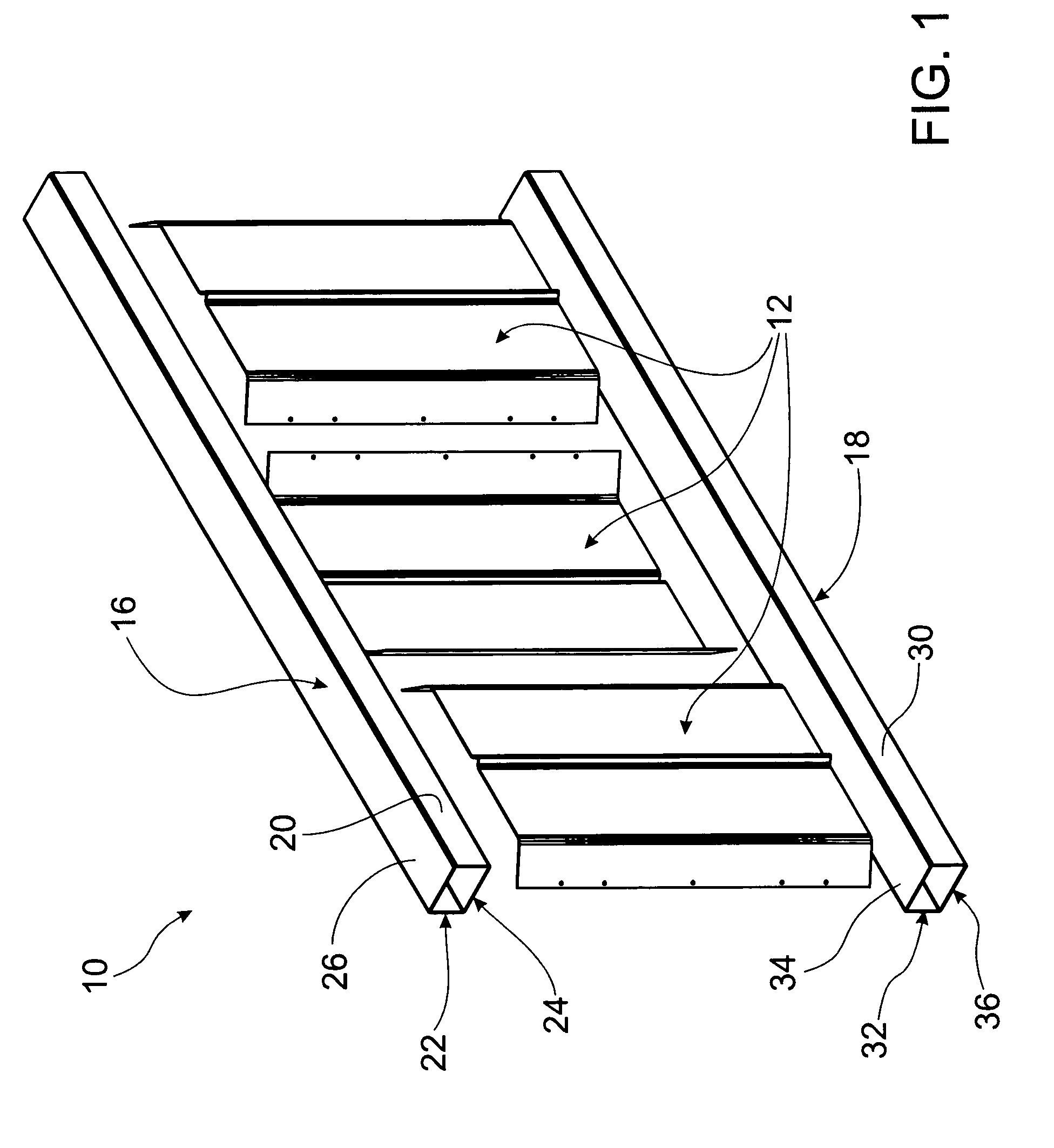

Structural building components and method of constructing same

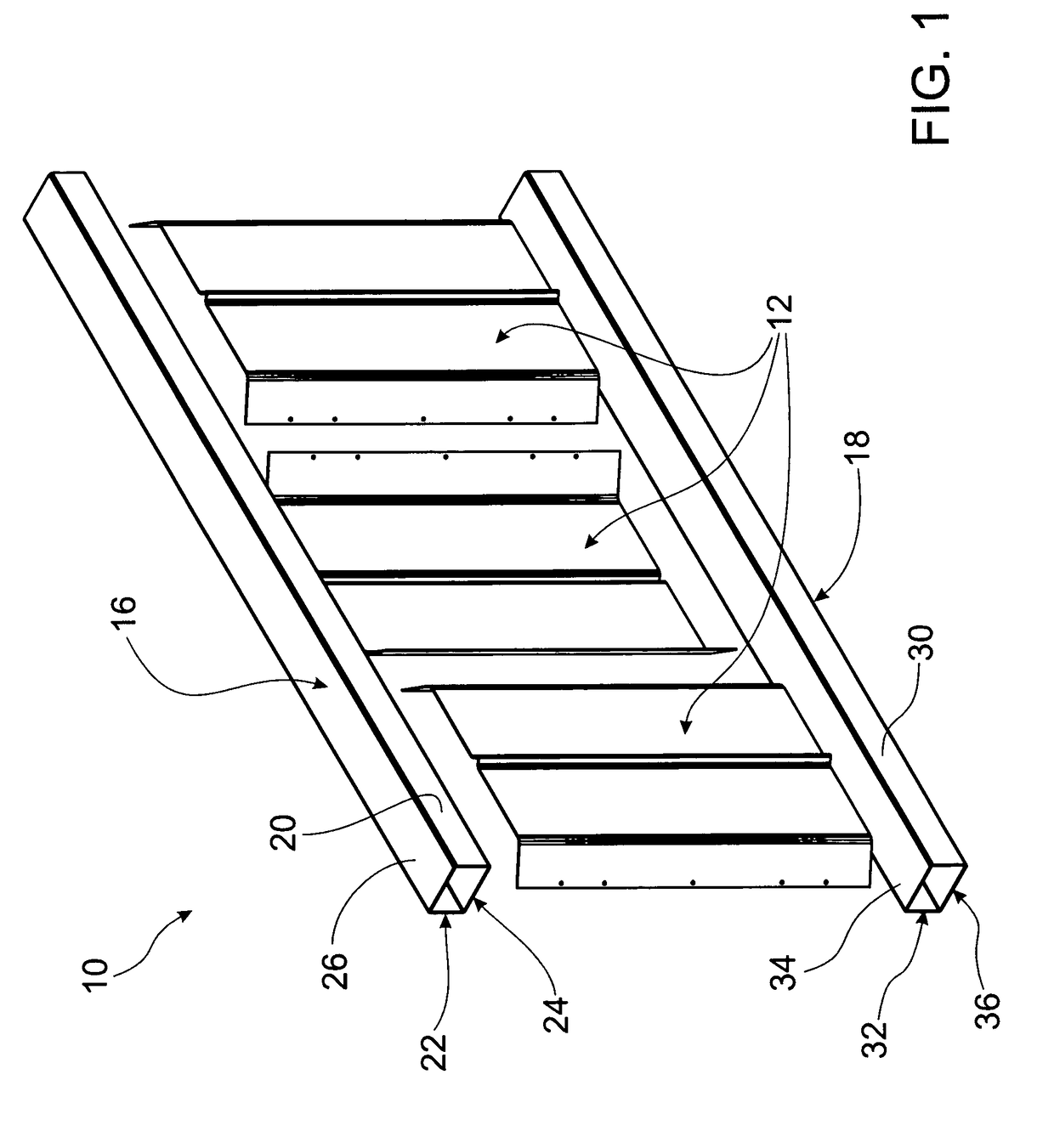

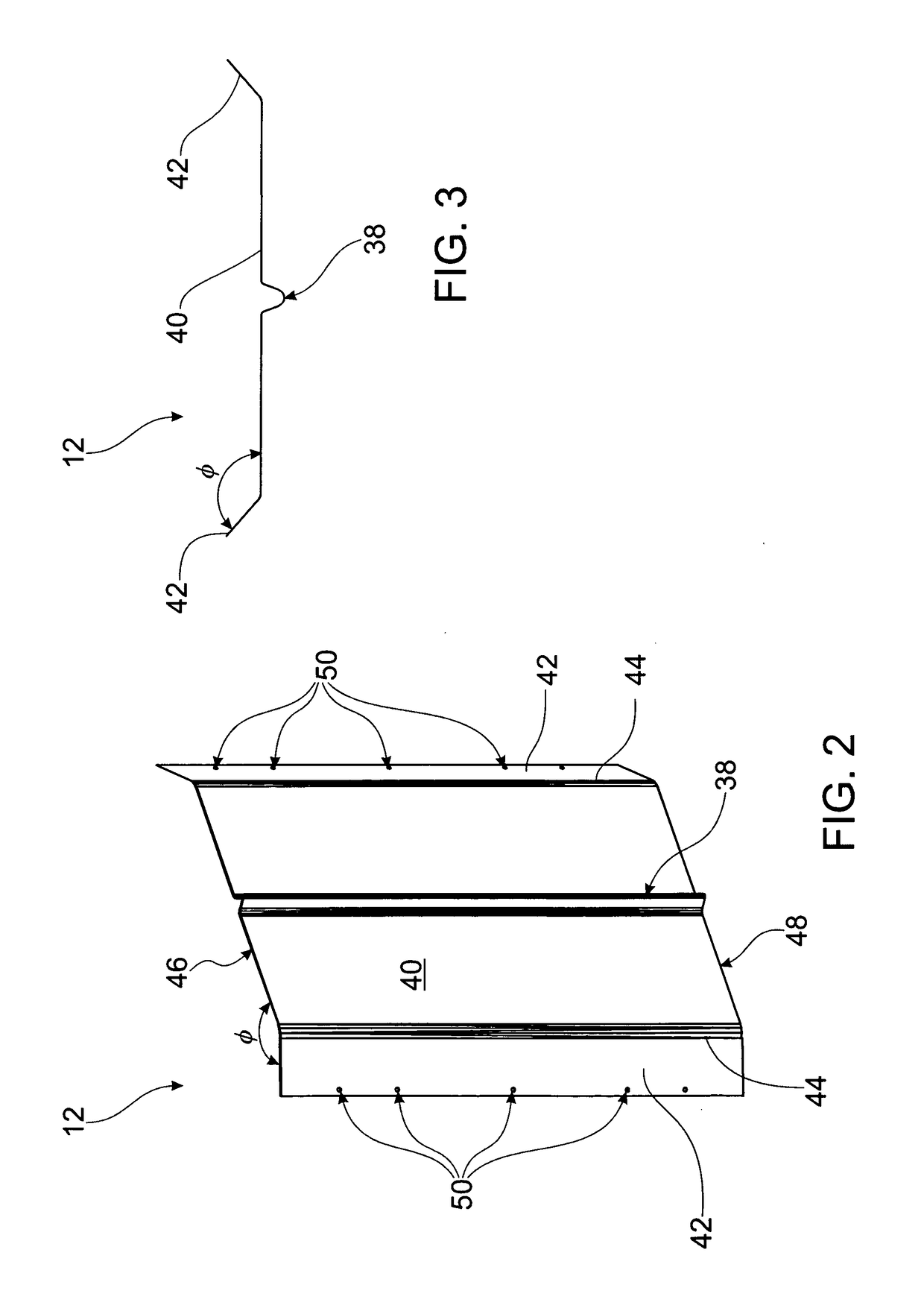

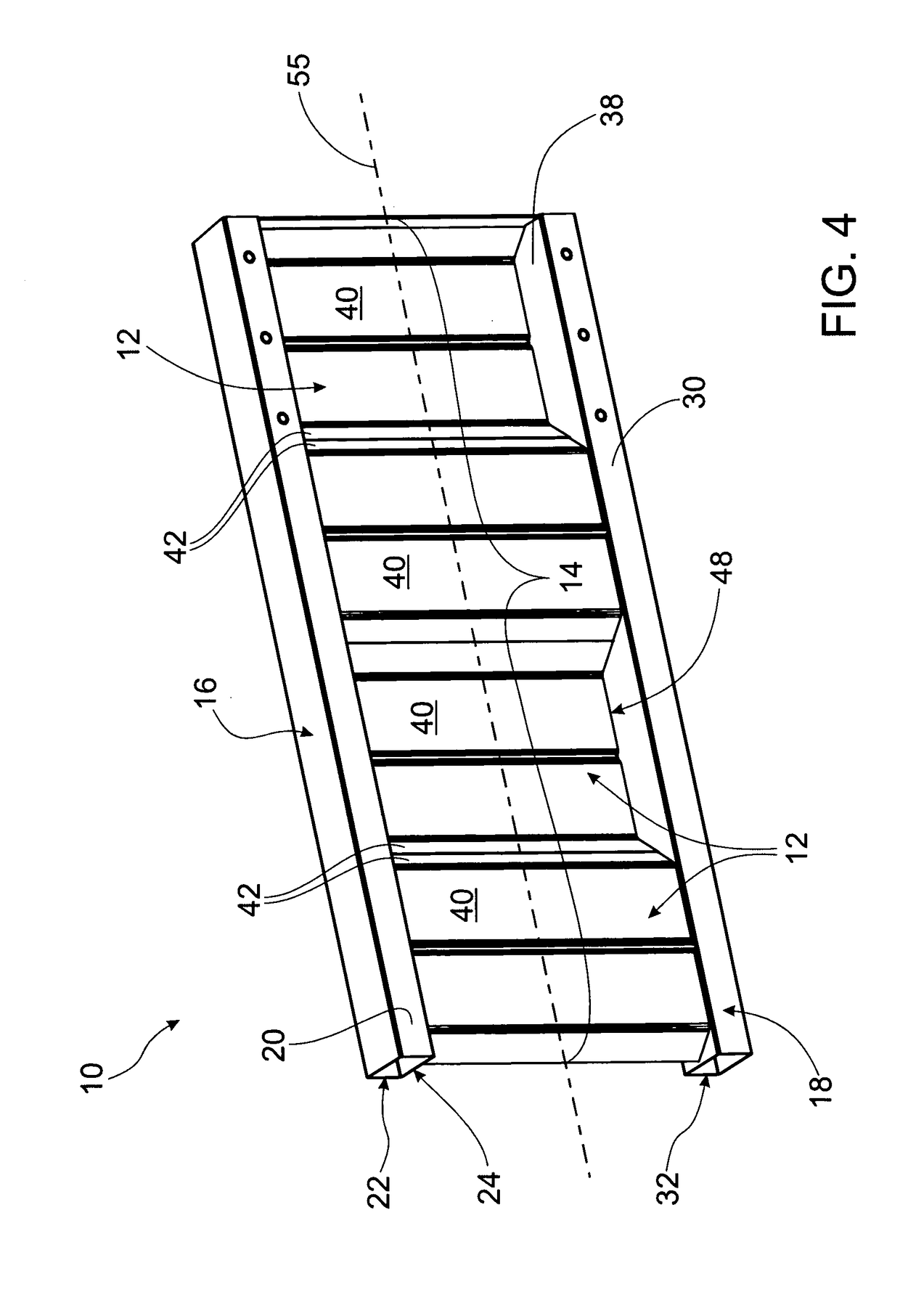

ActiveUS20110113725A1Increased torsional strengthEasy to manufactureMetal-working apparatusLoad-supporting pillarsEngineeringStructure building

Structural building components and a method of constructing the same enable improved beams that can be constructed at a place of use. The method includes providing a first flange (16) and a second flange (18) defining a central beam axis (55). A number of separately formed web sections (12) are provided, each having two convergent side walls (42) and a central wall (40) extending between converging ends of the side walls (42). The web sections (12) are arranged side by side in an alternating arrangement wherein the central walls (40) of adjacent web sections (12) are spaced substantially parallel to each other and are transversely staggered relative to the central beam axis (55). The side walls of adjacent web sections (12) are connected to one another, and the web sections (12) are connected to both the first flange (16) and second flange (18).

Owner:OVERFLOW LTD

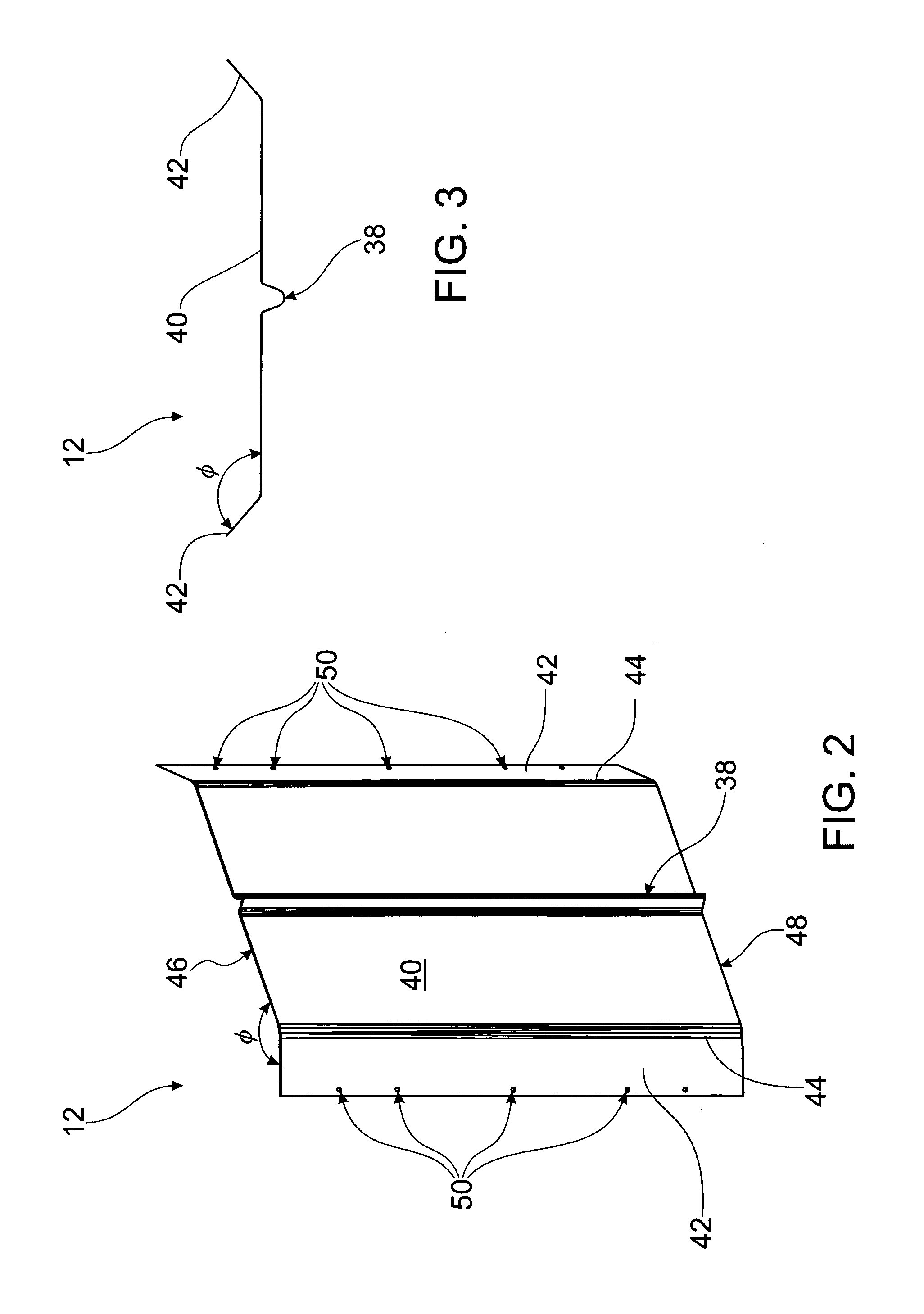

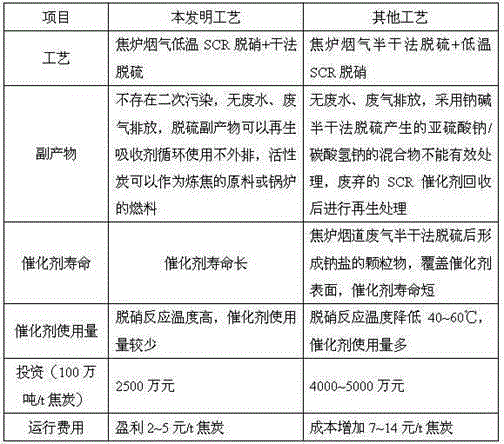

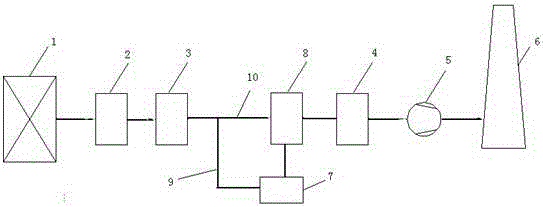

Coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process

InactiveCN105214478AMuch waste heat recoveryIncrease evaporationDispersed particle filtrationAir quality improvementFlueFlue-gas desulfurization

The invention provides a coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process. Coke oven flue waste gas is subjected to an SCR reaction under the effect of a low-temperature SCR denitrification catalyst to remove nitric oxides in flue waste gas, a sodium-based dry powder absorbent is sprayed to flue waste gas for desulfurization after waste heat is recovered through a waste heat boiler, and desulfurized flue waste gas is discharged up to standard after dust removal is conducted through a filter. The process is free of waste water, waste gas emission and heating, denitrification can be directly conducted, the absorbent can be recycled, investment is reduced, and energy is saved.

Owner:CHENGDU HUAXITANG INVESTMENT

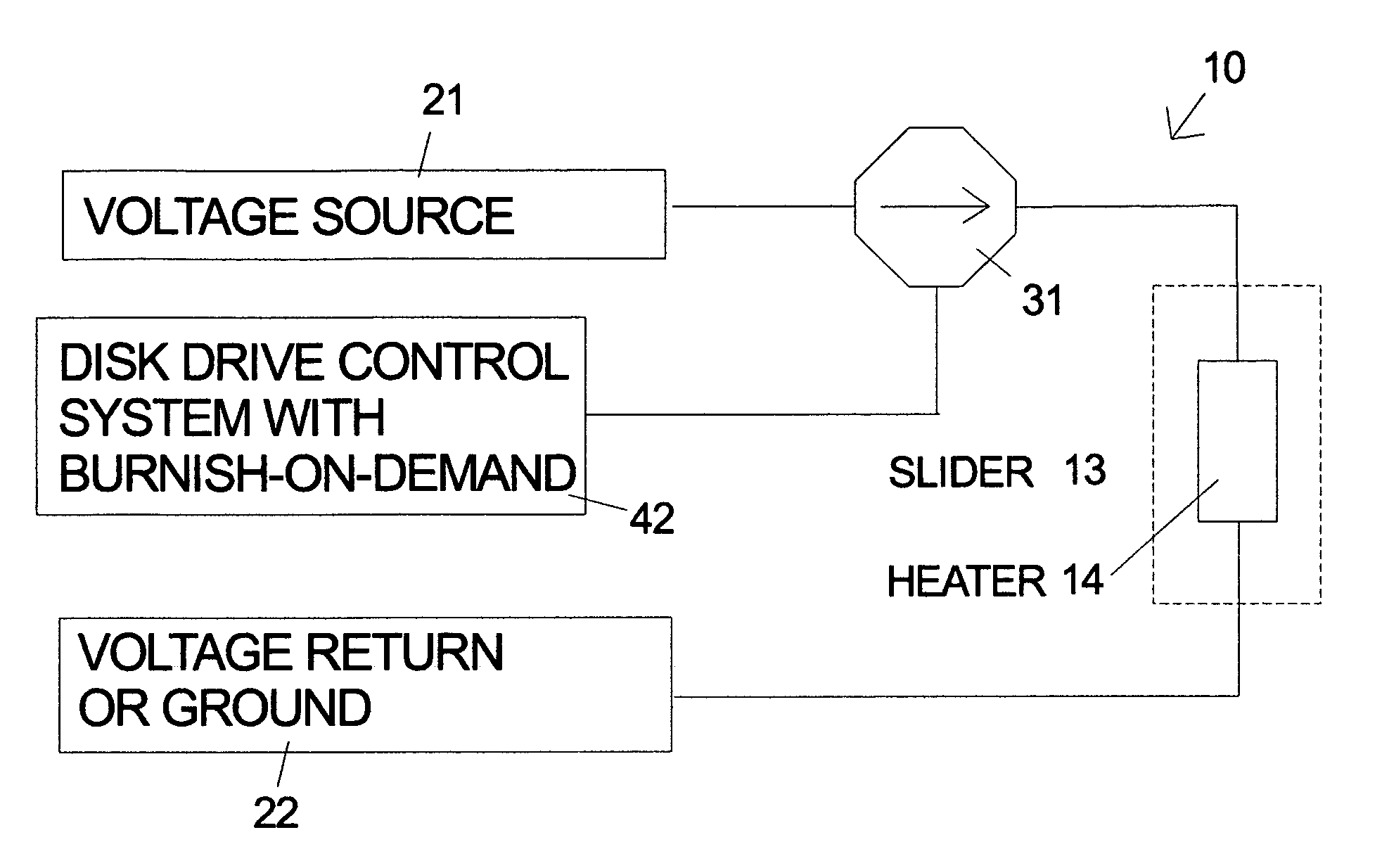

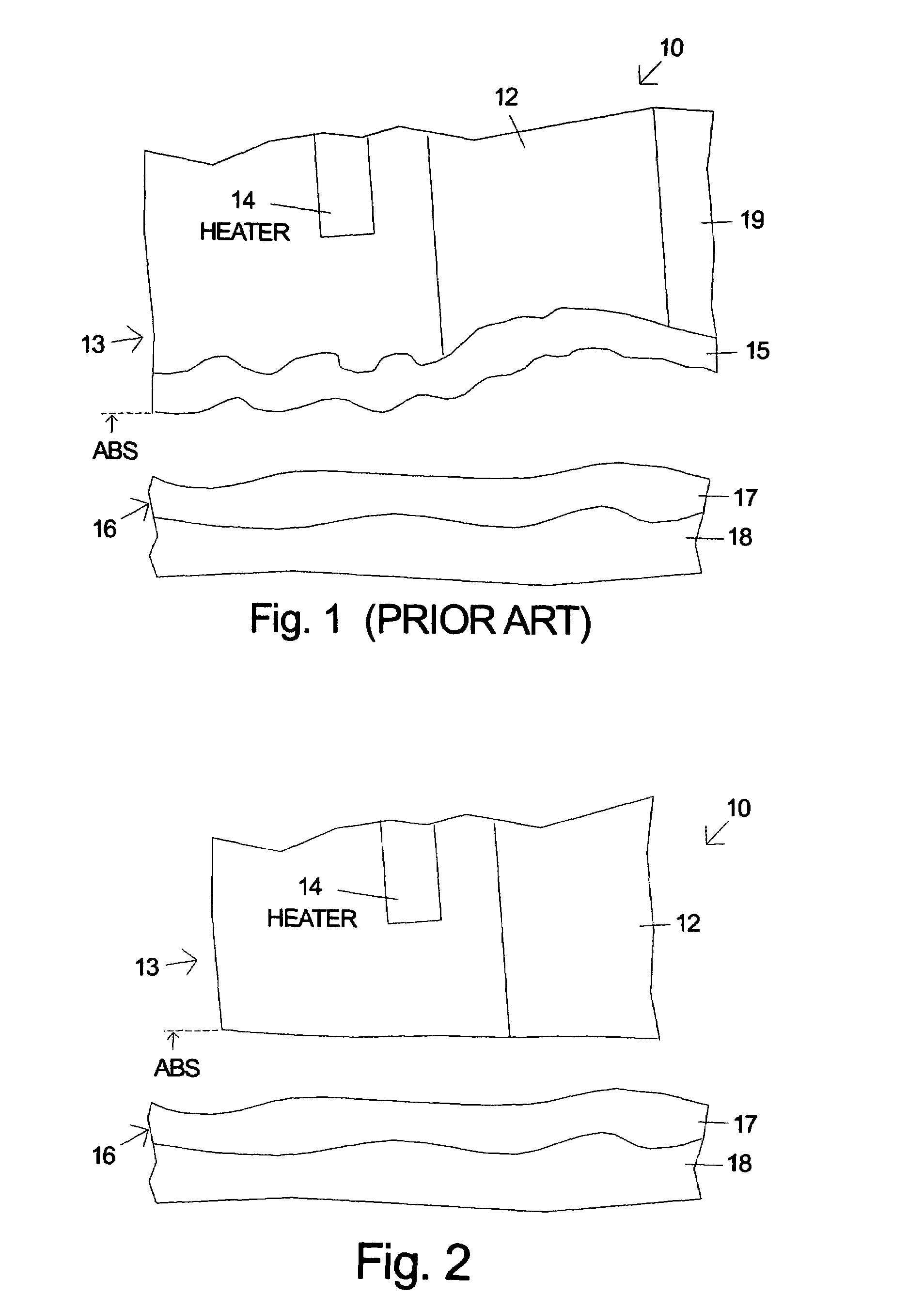

Disk drive slider design for thermal fly-height control and burnishing-on-demand

InactiveUS7495856B2Small liftLow experience requirementElectrical transducersDriving/moving recording headsEngineeringFlying height

Owner:WESTERN DIGITAL TECH INC

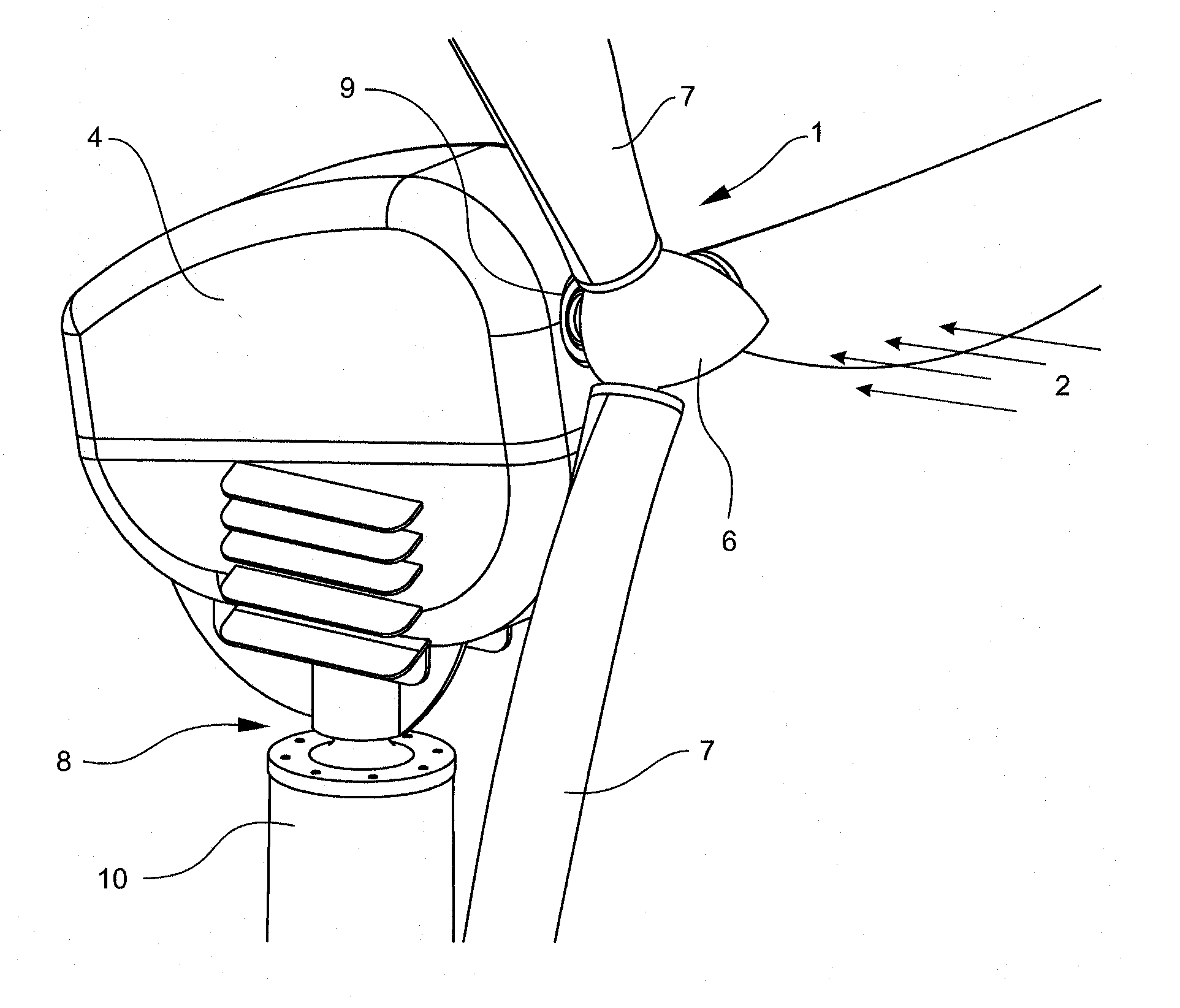

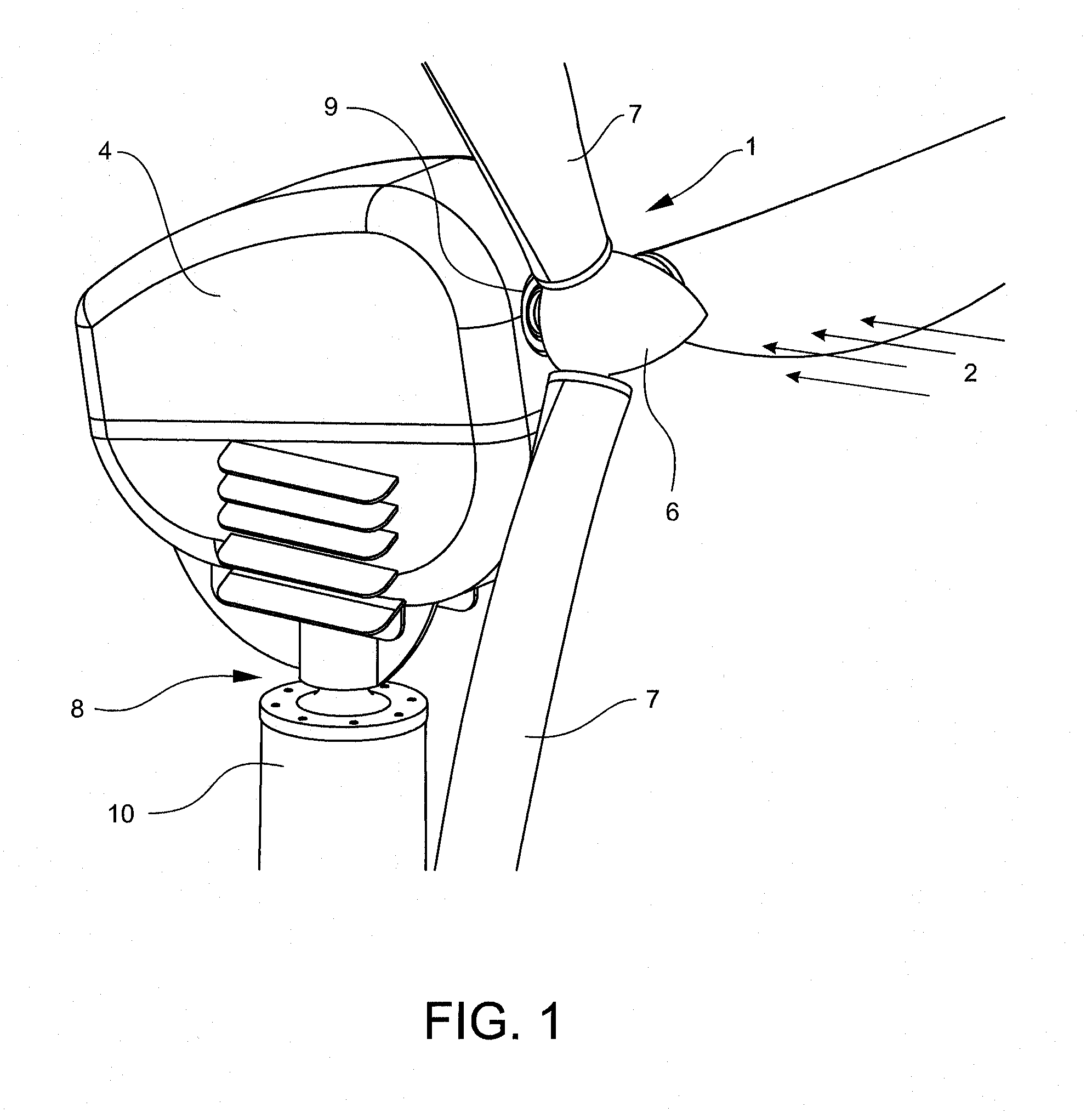

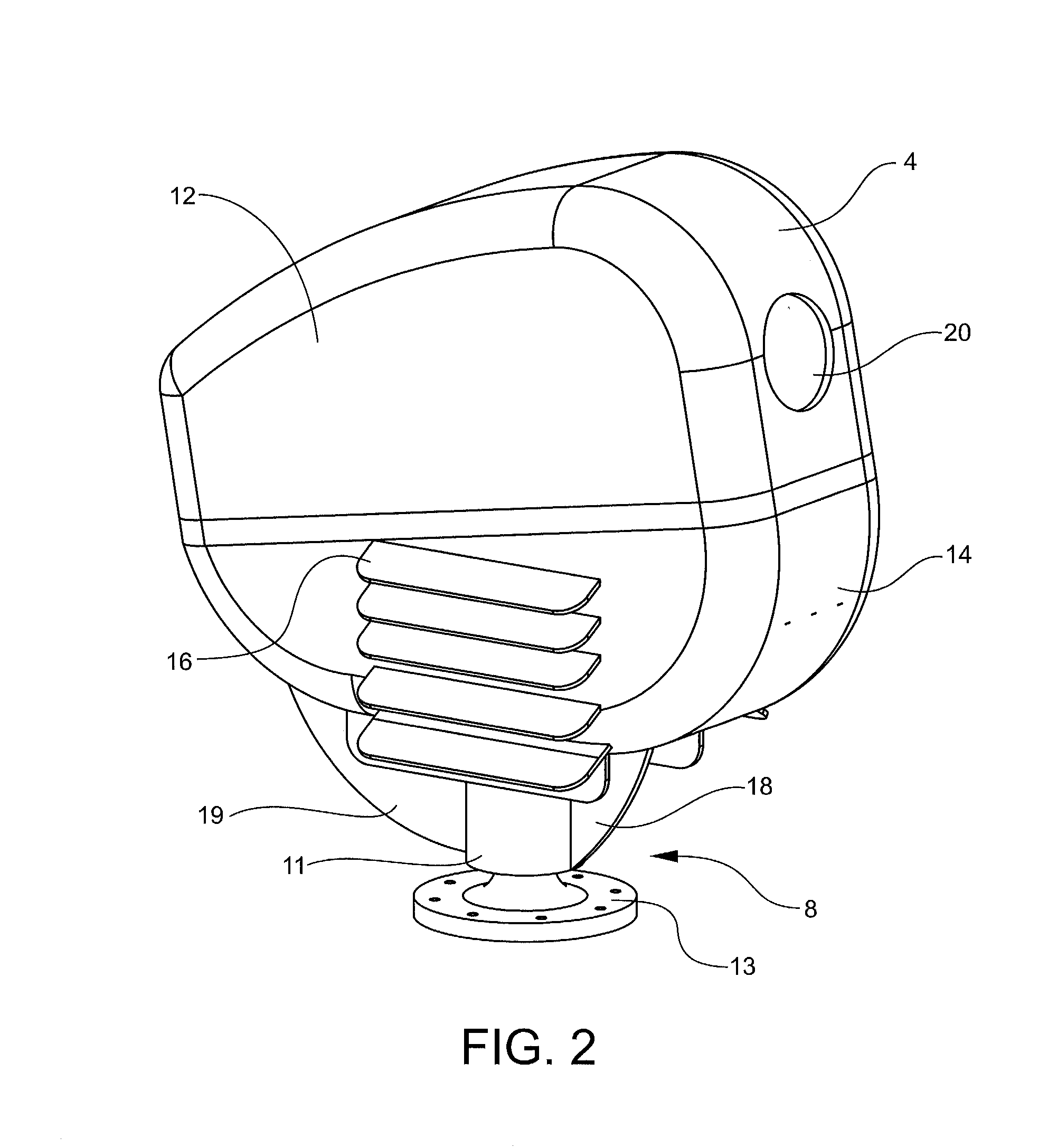

Wind Turbine With Improved Cooling

InactiveUS20110140444A1Improve cooling effectIncrease wind turbine coolingWind motor controlPump componentsNacelleEngineering

A wind turbine with improved cooling, which provides liquid cooling for a wind turbine with a completely closed or at least partially closed cooling circuit, with which the heat to be dissipated from the cooling circuit is dissipated by a nacelle of the wind turbine. The wind turbine with improved cooling dissipates energy losses from heat and applied for the conversion of kinetic energy of wind into mechanical and electrical energy of the wind turbine.

Owner:WINTER CURT B

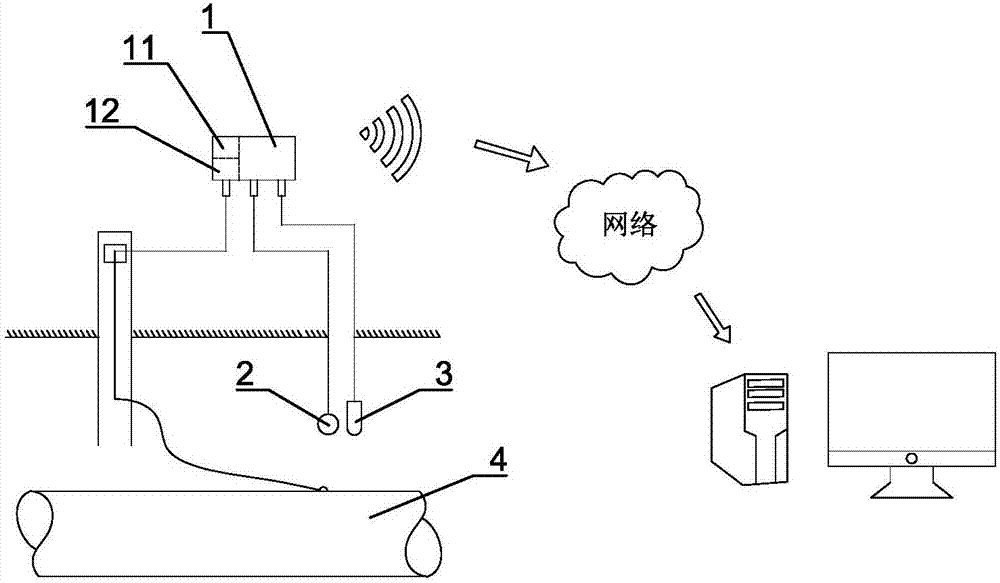

System for monitoring dynamic direct-current interference of pipeline based on Beidou and risk assessment method

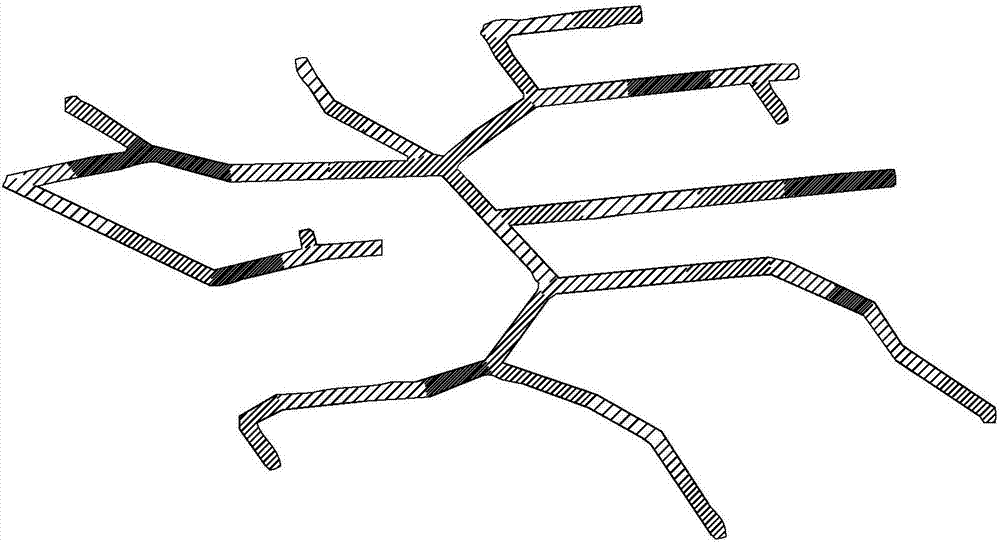

ActiveCN107145685ASimple structureEasy to implementData processing applicationsDesign optimisation/simulationMonitoring systemEngineering

The invention relates to a system for monitoring dynamic direct-current interference of a pipeline based on Beidou and a risk assessment method. The monitoring system comprises multiple monitoring units dispersedly arranged and corresponding to test piles in a gas pipe network and server units in communicating connection with the monitoring units, wherein each monitoring unit comprises a potential recorder, a checking piece and a reference electrode, wherein the checking piece and the reference electrode are buried in one side of the gas pipeline and are respectively connected with the potential recorder through cables, and the potential recorder is connected with the gas pipeline through a cathode testing line in the corresponding test pile. The monitoring system has the advantages of being simple in structure, easy to implement, high in accuracy and good in real-timeliness, intelligentization and visual management of the gas pipe network can be achieved, the corrosion risk of the gas pipeline is reduced, and the reliability of safe operation is improved. The risk assessment method has the advantages of being simple in process, convenient to achieve, scientific and reasonable.

Owner:BEIJING GAS GRP +2

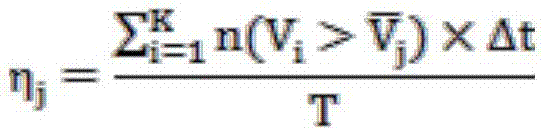

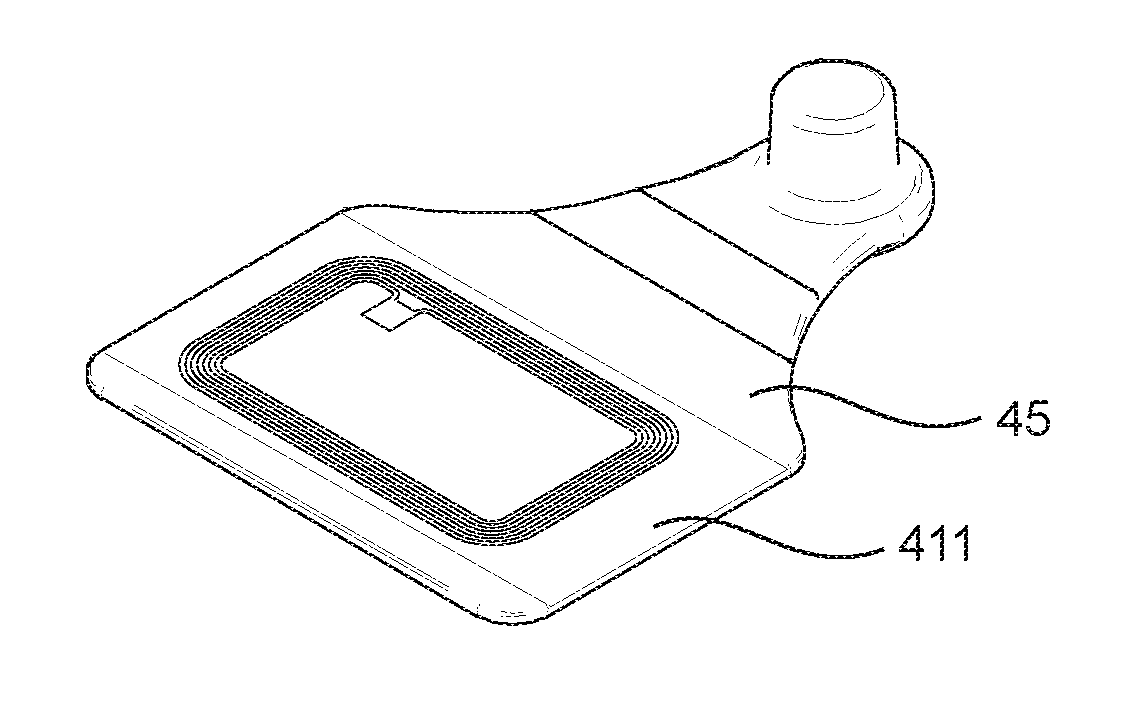

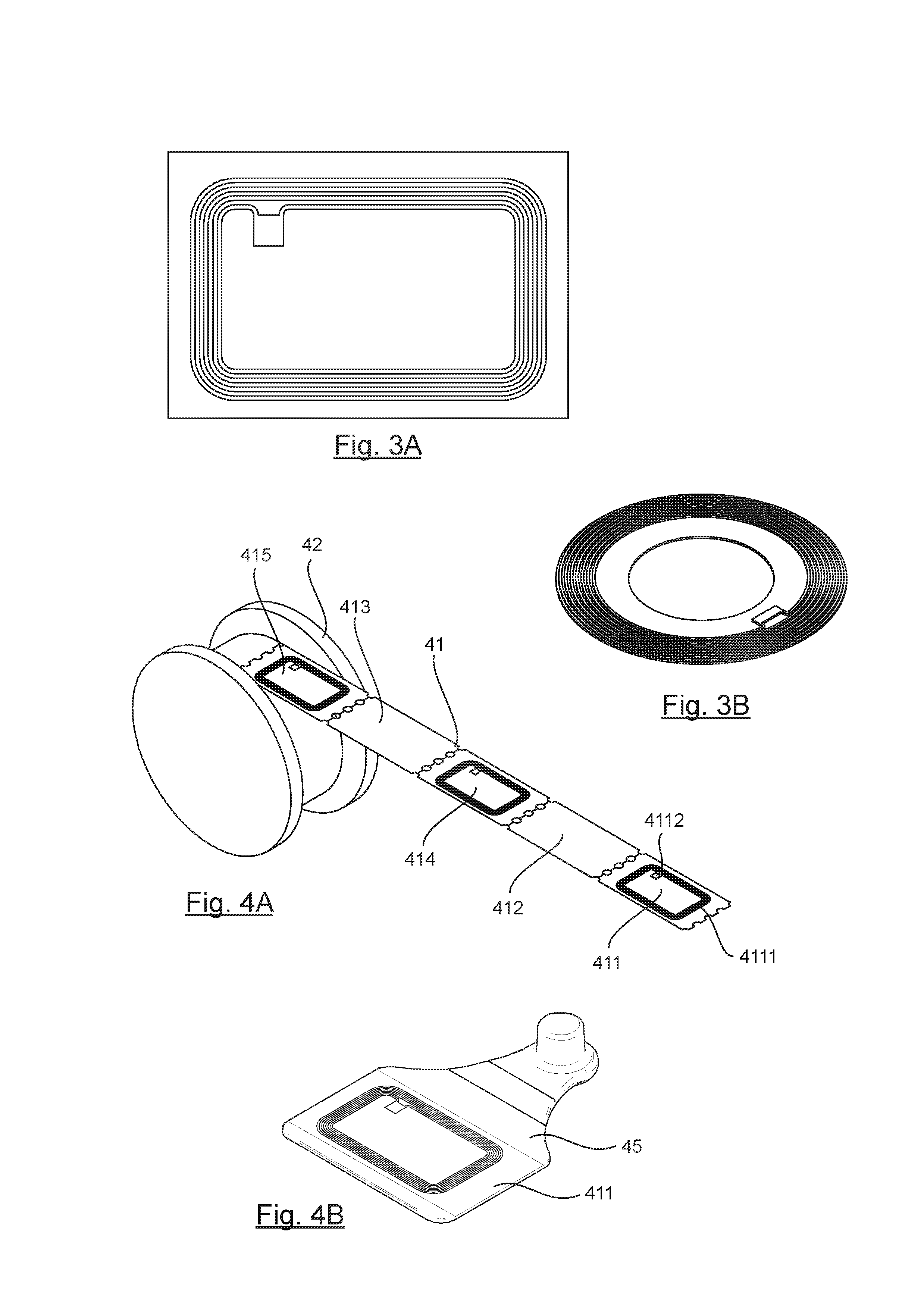

Device for identifying an animal and corresponding manufacturing device

InactiveUS20130175347A1Reduced risk of corrosionOptimize volumeConfectioneryAnimal feeding stuffElectronic componentBiomedical engineering

The invention relates to a device for identifying an animal bearing at least one identifier of said animal. According to the invention, such a device comprises at least one planar UHF antenna (141) and at least one planar electronic component (142) that extends in one and the same plane corresponding to a surface of a flexible film (14) secured to a planar element of said device.

Owner:ALLFLEX EURO SAS

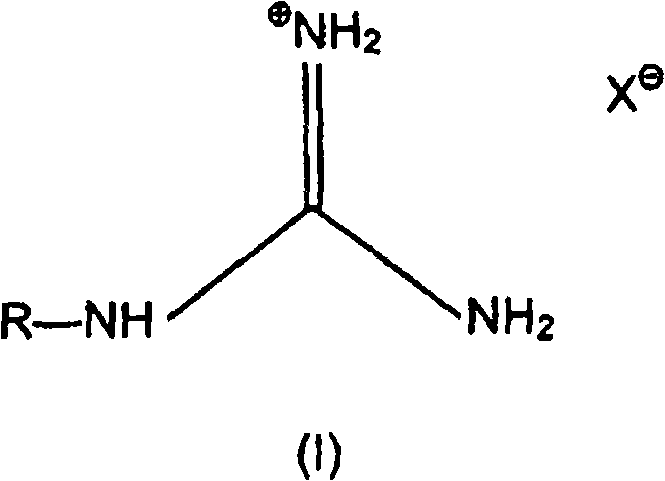

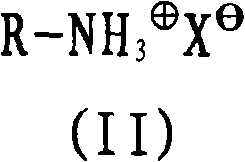

Method for the selective catalytic reduction of nitrogen oxides in exhaust gases of vehicles

InactiveCN101568371AReduced risk of corrosionGas treatmentInternal combustion piston enginesSilicon dioxideCorrosion

The invention relates to the use of aqueous guanidinium formiate solutions, optionally combined with urea and / or ammonia and / or ammonium salts, for the selective catalytic reduction of nitrogen oxides using ammonia in exhaust gases of vehicles. The inventive guanidinium formiate solutions enable a reduction of the nitrogen oxides by appoximately 90 %. Furthermore, said guanidinium formiate solutions can enable an increase in the ammonia forming potential from 0.2 kg, corresponding to prior art, up to 0.4 kg ammonia per litre of guanidinium formiate, along with freezing resistance (freezing point below -25 DEG C). The risk of corrosion of the inventive guanidinium formiate solutions is also significantly reduced compared to that of solutions containing ammonium formiate.

Owner:ALZCHEM AG

Structural building components and method of constructing same

ActiveUS8468774B2Increased torsional strengthEasy to manufactureMetal-working apparatusLoad-supporting pillarsEngineeringStructure building

Structural building components and a method of constructing the same enable improved beams that can be constructed at a place of use. The method includes providing a first flange (16) and a second flange (18) defining a central beam axis (55). A number of separately formed web sections (12) are provided, each having two convergent side walls (42) and a central wall (40) extending between converging ends of the side walls (42). The web sections (12) are arranged side by side in an alternating arrangement wherein the central walls (40) of adjacent web sections (12) are spaced substantially parallel to each other and are transversely staggered relative to the central beam axis (55). The side walls of adjacent web sections (12) are connected to one another, and the web sections (12) are connected to both the first flange (16) and second flange (18).

Owner:OVERFLOW LTD

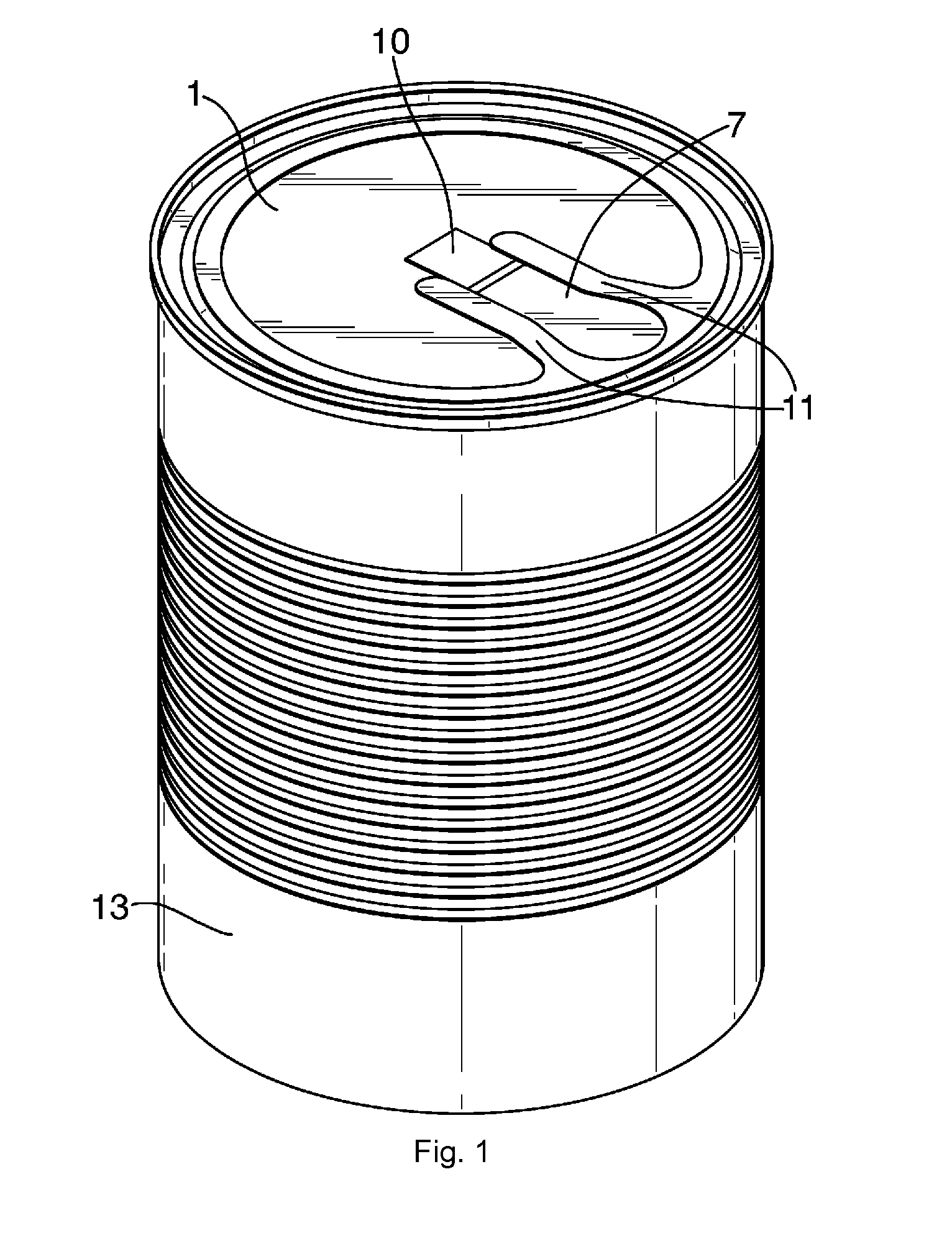

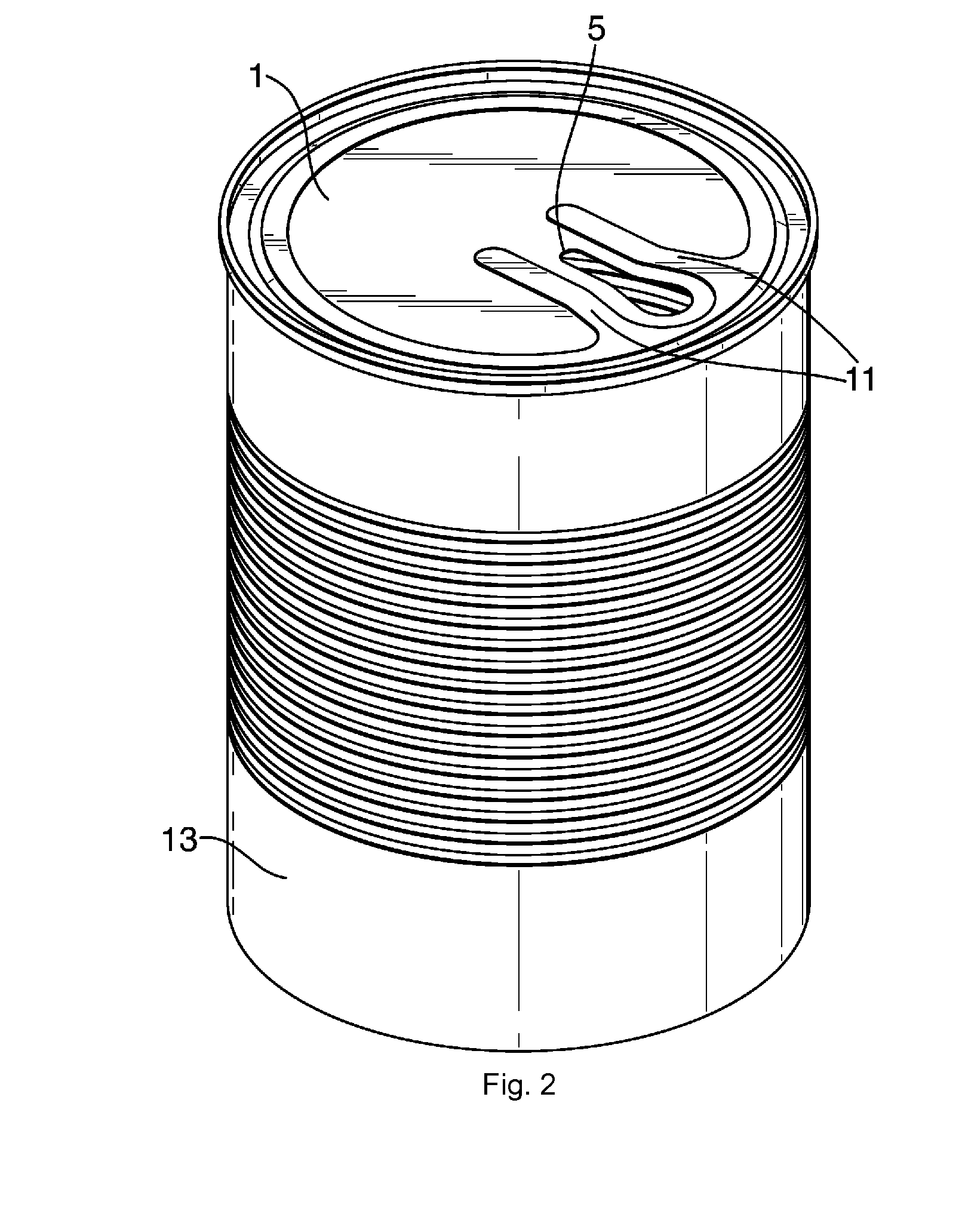

Metal containers

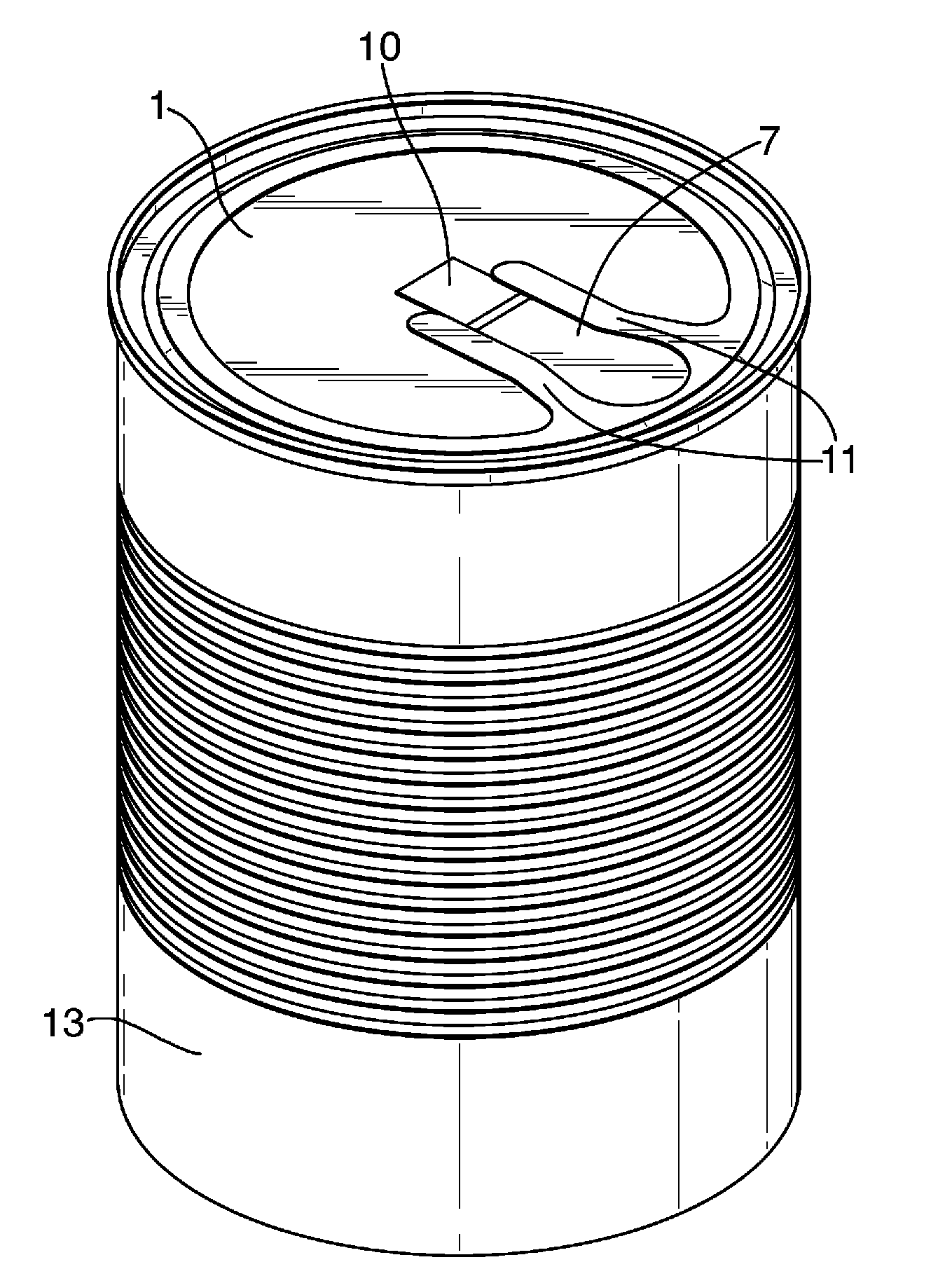

InactiveUS20100089924A1Avoid corrosionReduce riskCapsLiquid surface applicatorsLacquerMechanical engineering

A metal container or component part of a metal container (e.g. a can end or sidewall of a can body) has an aperture defined by a cut edge about the periphery of the aperture, with a cover element sealed to the outward-facing surface of the can end so as to extend over and cover the aperture. A film of lacquer is directly applied (without the presence of an intermediate primer layer) to the inward-facing of the container / component part so as to coat the entirety of the cut edge and all or part of the inward-facing surfaces of both the can end and that part of the cover element located radially inward of the cut edge, thereby inhibiting corrosion of the cut edge. The invention is particularly suitable for can ends. The invention also relates to a method of making a can end to the invention.

Owner:CROWN PACKAGING TECH

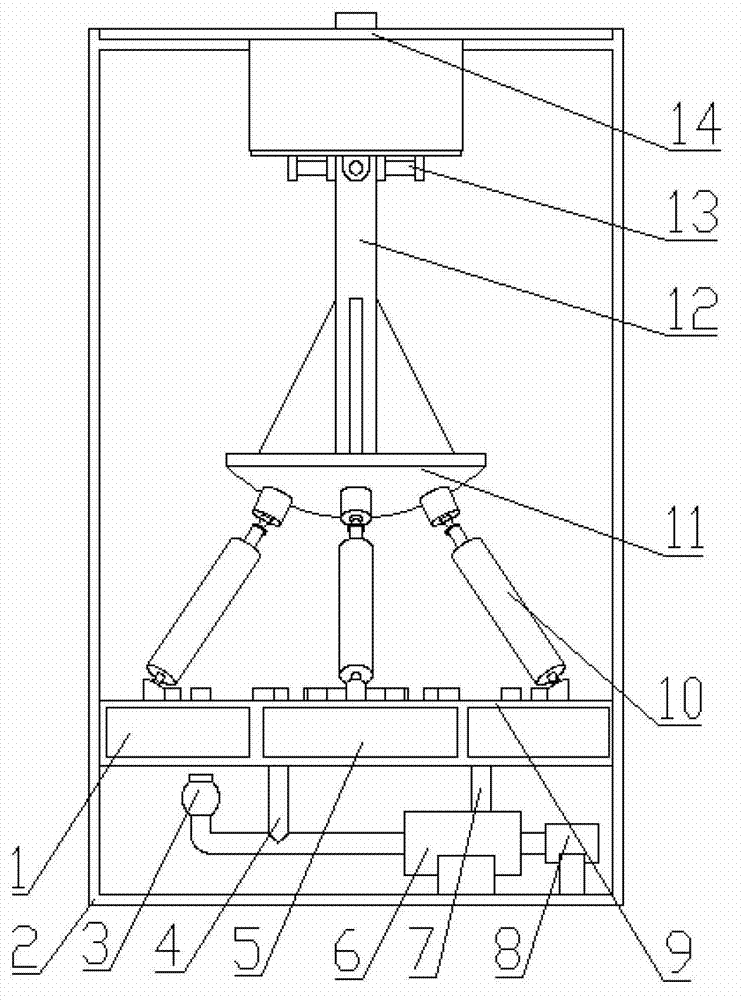

Novel parallel multidimensional oscillating sea wave power generation device

InactiveCN103306882AImprove sealingReduced risk of corrosionMachines/enginesEngine componentsHydraulic motorHydraulic cylinder

The invention discloses a novel parallel multidimensional oscillating sea wave power generation device. The novel parallel multidimensional oscillating sea wave power generation device comprises a floater, and a sealing cover plate, a two-dimensional rotating hinge, an oscillating rod, an oscillating platform, six hydraulic cylinders, an oil tank, a hydraulic motor, a power generator and an energy accumulator which are all arranged in the floater, wherein the sealing cover plate is fixedly connected to a protruding eave of the floater; the oil tank is fixedly connected to the floater; one end of the two-dimensional rotating hinge is fixedly connected to the sealing cover plate and the other end is connected to the oscillating rod; one end of the oscillating rod penetrates through the sealing cover plate to be fixedly connected to an external device and the other end is fixedly connected to the oscillating platform; the six hydraulic cylinders are connected in parallel to work; the two ends of the six hydraulic cylinders are respectively hinged to the oscillating platform and the oil tank through spherical hinges; the oil tank is connected with the hydraulic motor through a flow-dividing pipe and a return pipe; the power generator is connected with the hydraulic motor; the power generator and the hydraulic motor are arranged on the bottom surface of the floater; the energy accumulator is connected with the hydraulic motor. The novel parallel multidimensional oscillating sea wave power generation device has the advantages of long service life, low maintenance cost, low environmental pollution, capability of fully absorbing sea wave energy, high power generation efficiency and the like.

Owner:SHANGHAI JIAO TONG UNIV

Air foam flooding shaft bottom foaming process pipe column

ActiveCN102305055AReduced risk of corrosionImprove leak-proof effectFluid removalWell/borehole valve arrangementsCorrosionEngineering

The invention discloses an air foam flooding shaft bottom foaming process pipe column, which at least comprises an inner pipe and an outer pipe arranged outside the inner pipe. The air foam flooding shaft bottom foaming process pipe column also adopts a ground-matched check valve to simplify ground valve switching operation and reduce the risk of damaging a topping-up pump and an air compressor; because double-pipe injection is adopted, the air and liquid pass through an independent passage respectively to reduce the risk of pipe column corrosion; and a foam generator is arranged at the bottom of a well to generate foams near the well bottom so that the performance of injected foams is guaranteed and the foams better play a role in the displacement of reservoir oil and profile control.

Owner:PETROCHINA CO LTD

Fastener assembly for transport vehicle

ActiveUS20100067999A1Improve the immunityReduce contact wearFlexible elementsMovable seatsPolymerFastener

This invention relates to a fastener assembly that has a rail (1) and a fastener device (6) that can be installed in a transport vehicle, characterized in that a rail head (2) is coated with a layer (3) of alumina with polytetrafluoroethylene seal and that at least a portion (5) of the fastener device in contact with the rail head is made of metal coated with a layer of polymers (7).

Owner:AIRBUS OPERATIONS (SAS)

Five-axle linkage electrolytic and mechanical combination polishing machine for curved surfaces

InactiveCN106239341AImprove polishing efficiencyImprove polishing qualityGrinding carriagesElectrolysis componentsSurface finishSurface layer

The invention relates to a five-axle linkage electrolytic and mechanical combination polishing machine for curved surfaces. The polishing machine comprises a polishing main shaft, a working table, a working water tank and an electrolysis power supply, wherein the polishing main shaft is mounted on a five-axle linkage main rack, the working table is horizontally arranged in the working water tank, a polishing head is mounted on the polishing main shaft, the polishing head comprises a conductive metal core and a non-conductive abrasive surface layer, a positive electrode of the electrolysis power supply is electrically connected with the working table, a negative electrode of the electrolysis power supply is electrically connected with the conductive metal core of the polishing head, the working table is insulated from the polishing head, the five axles comprise an X axle, a Y axle, a Z axle, an A axle and a B axle which are sequentially connected in series, the X axle, the Y axle and the Z axle are moving axles, the directions of every two of the three axles are perpendicular with each other, the A axle is a rotating axle, the rotating central axis is parallel with the Y axle, the B axle is a swinging axle, and the swinging central axis is parallel with the X axle. The polishing efficiency is high, and the surface finish and corrosion resistance of polished products are obviously improved.

Owner:杭州向冉科技有限公司

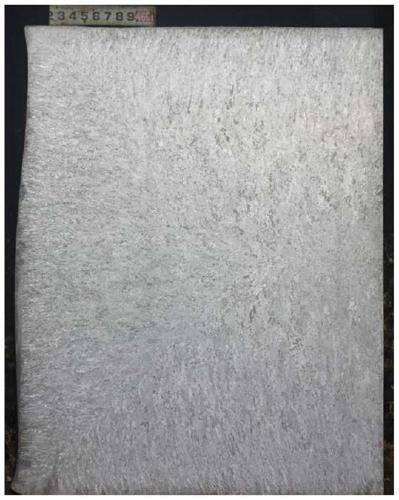

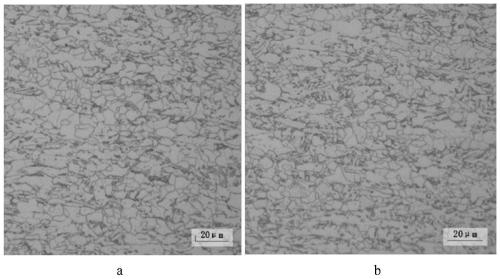

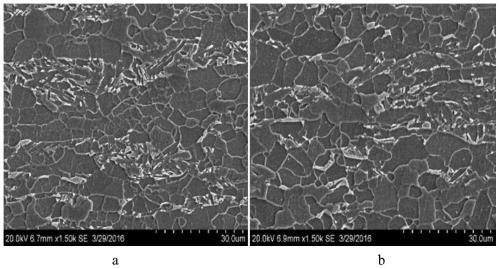

X65 hot-rolled steel plate for marine riser and preparation method of steel plate

The invention provides an X65 hot-rolled steel plate for a marine riser and a preparation method. The X65 hot-rolled steel plate is prepared from, by weight, 0.03%-0.05% of C, 0.10%-0.30% of Si, 1.10%-1.35% of Mn, smaller than or equal to 0.007% of P, smaller than or equal to 0.0008% of S, 0.01%-0.05% of Alt, 0.04%-0.06% of Nb, 0.008%-0.018% of Ti, 0.20%-0.40% of Ni, 0.15%-0.30% of Cr, 0.10%-0.20%of Mo, smaller than or equal to 0.004% of N and the balance Fe and unavoidable impurity elements. The preparation method comprises the steps that continuous casting blanks with the thickness rangingfrom 300 mm to 500 mm are adopted, differential temperature rolling is adopted for steel blank rough rolling, three-stage rolling is adopted for finish rolling, and then fine and squashed hardened austenite grains are obtained; steel plates are cooled after being rolled, and then fine ferrites and a small amount of acicular ferrite structure are obtained, wherein the initial cooling temperature ranges from 760 DEG C to 780 DEG C, and the final cooling temperature ranges from 200 DEG C to 300 DEG C. The X65 hot-rolled steel plate has the advantages of being large in wall thickness, high in strength, low in yield ratio, excellent in low-temperature toughness, fracture resistance and acid resistance and capable of reducing the fracture and corrosion risks of marine risers.

Owner:SHOUGANG CORPORATION

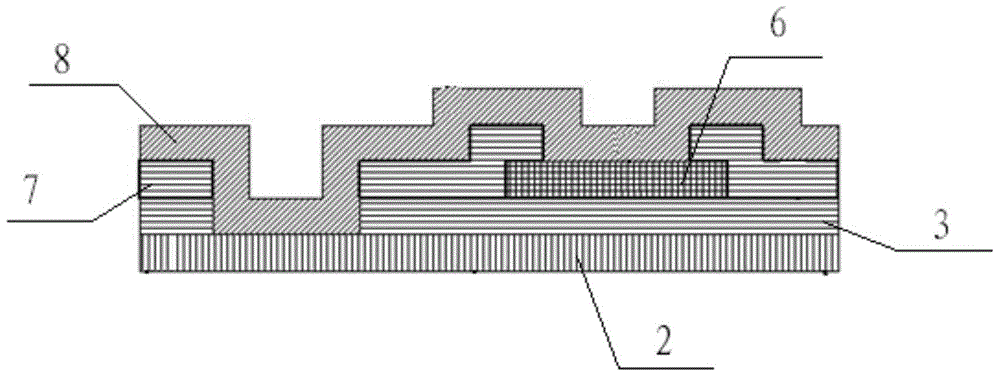

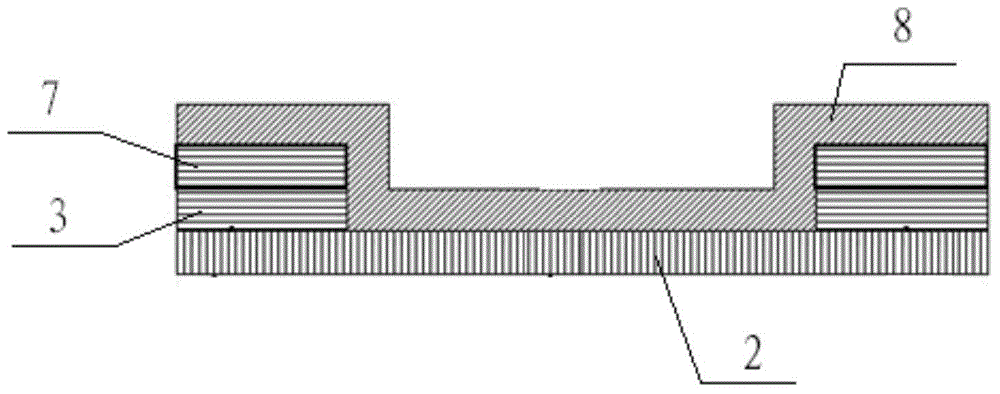

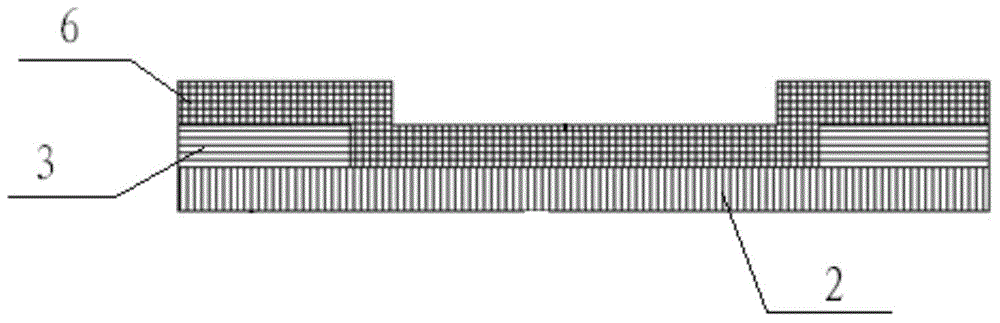

Thin film transistor array substrate and preparation method thereof, display device

ActiveCN104701315AFirmly connectedReduce manufacturing costTransistorSolid-state devicesDisplay deviceOptoelectronics

The invention provides a thin film transistor array substrate and a preparation method thereof, and a display device, belongs to the technical field of display, and aims at solving the problems of high production cost due to more mask plates in preparation, corrosion of a grid electrode, and electrostatic discharge in adapting of a grid electrode of the existing thin film transistor array substrate and the preparation method, and the display device. According to the existing thin film transistor array substrate and the preparation method, and the display device, the same mask plate is adopted while preparing a second insulating layer and an etching resisting layer, so that one mask plate can be saved, and as a result, the production cost can be reduced; meanwhile, the second insulating layer has the same graph as the etching resisting layer in a display area, and therefore, a pixel electrode is connected with a drain electrode through a through hole; a source electrode and the drain electrode in the side frame area directly cover the grid electrode; when the source electrode and the drain electrode are manufactured from anticorrosion metal, the risk of corrosion of the grid electrode can be reduced, and the risk of electrostatic discharge in adapting of the grid electrode can be also reduced.

Owner:BOE TECH GRP CO LTD +1

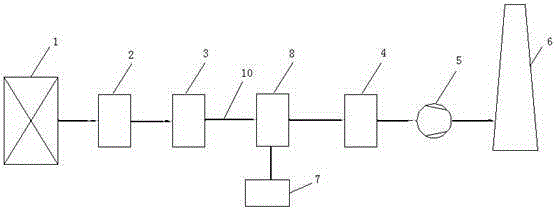

Integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery

InactiveCN105169943AMuch waste heat recoveryIncrease evaporationDispersed particle filtrationSteam generation using hot heat carriersPulverizerFlue-gas desulfurization

The invention provides an integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery. The integrated system comprises a coke oven, a low-temperature SCR denitrification system, a waste heat boiler, a flue, a pulverizer, a filtering system and a chimney. The coke oven, the low-temperature SCR denitrification system, the waste heat boiler, the filtering system and the chimney are sequentially connected through the flue, a dry powder absorbent inlet is formed in the portion, between the waste heat boiler and the filtering system, of the flue and is connected with an outlet of the pulverizer through a pipeline, and an absorbent inlet is formed in the pulverizer. The system is free from waste water and gas emission and capable of directly carrying out denitrification without heating, absorbent can be used circularly, investment can be reduced, and energy can be saved.

Owner:CHENGDU HUAXITANG INVESTMENT

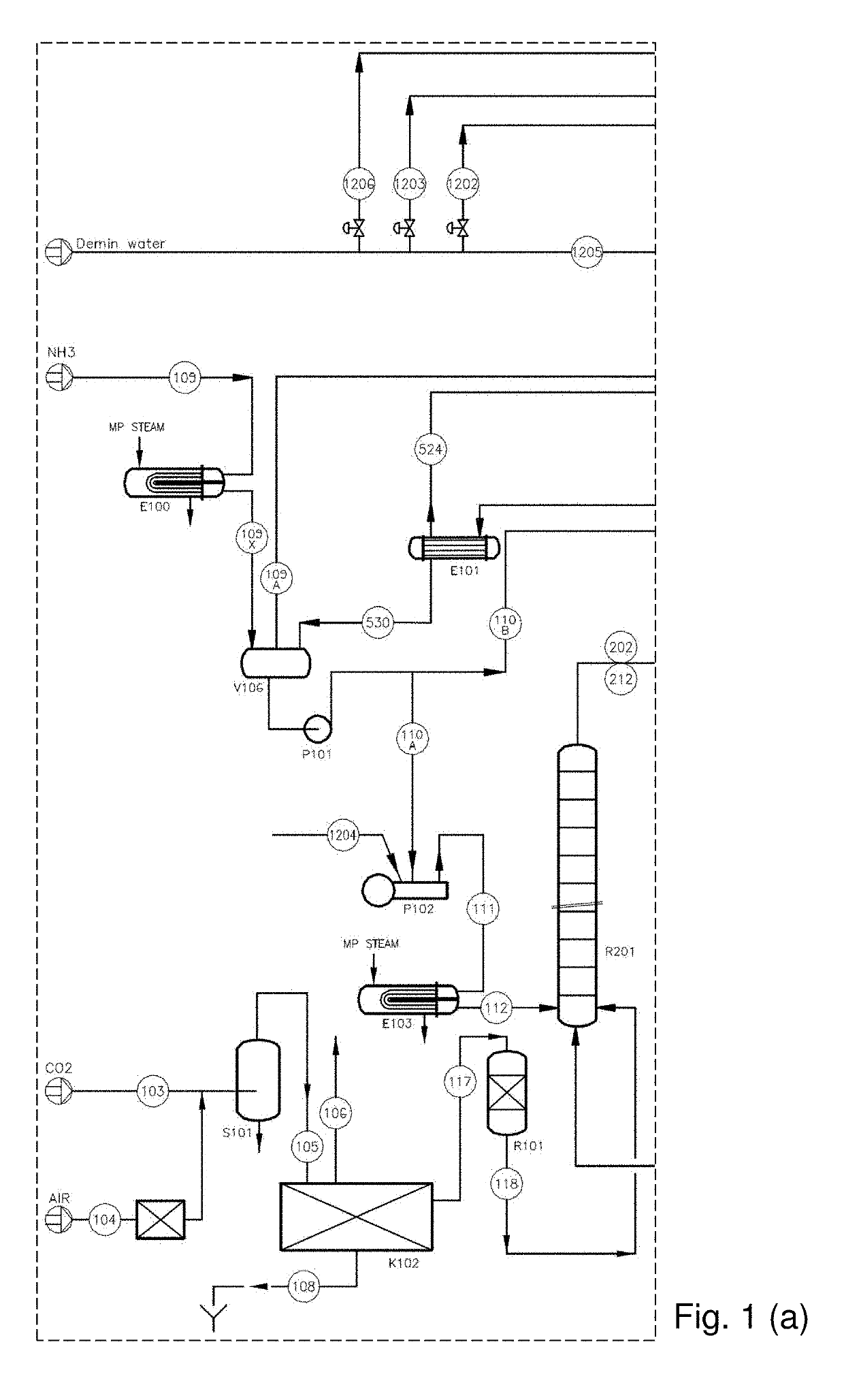

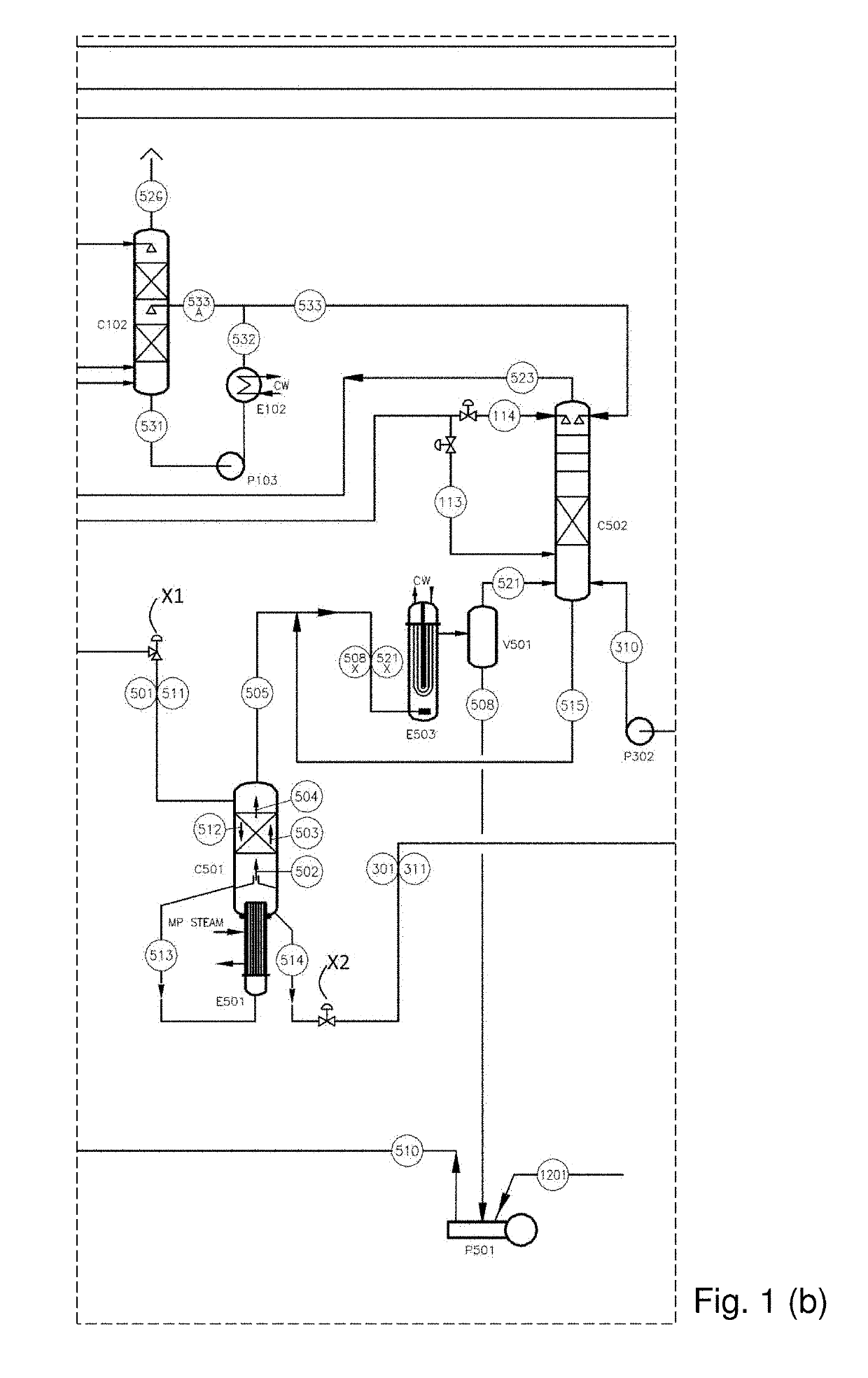

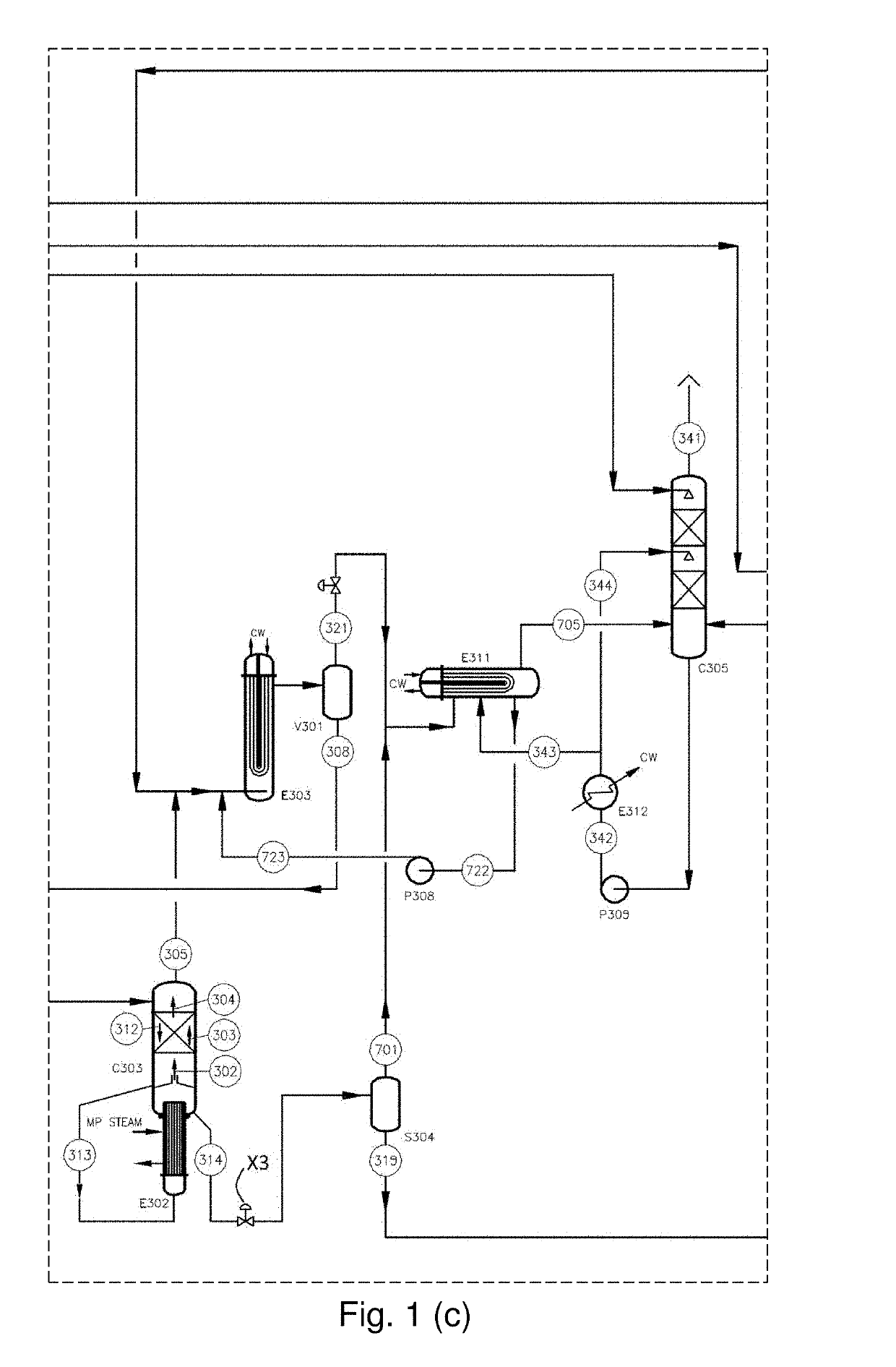

Urea production process and plant

ActiveUS20190185422A1Reduced risk of corrosionReduced life-timeUrea derivatives preparationGas treatmentHigh pressureChemistry

Processes and plants for the production of purified urea solution are described. In a described urea production process, urea is produced in a synthesis section without a high pressure stripper and the urea solution is subjected to purification after the recovery section, to give purified urea solution and off-gas. The purification comprises e.g. steam stripping.

Owner:STAMICARBON BV

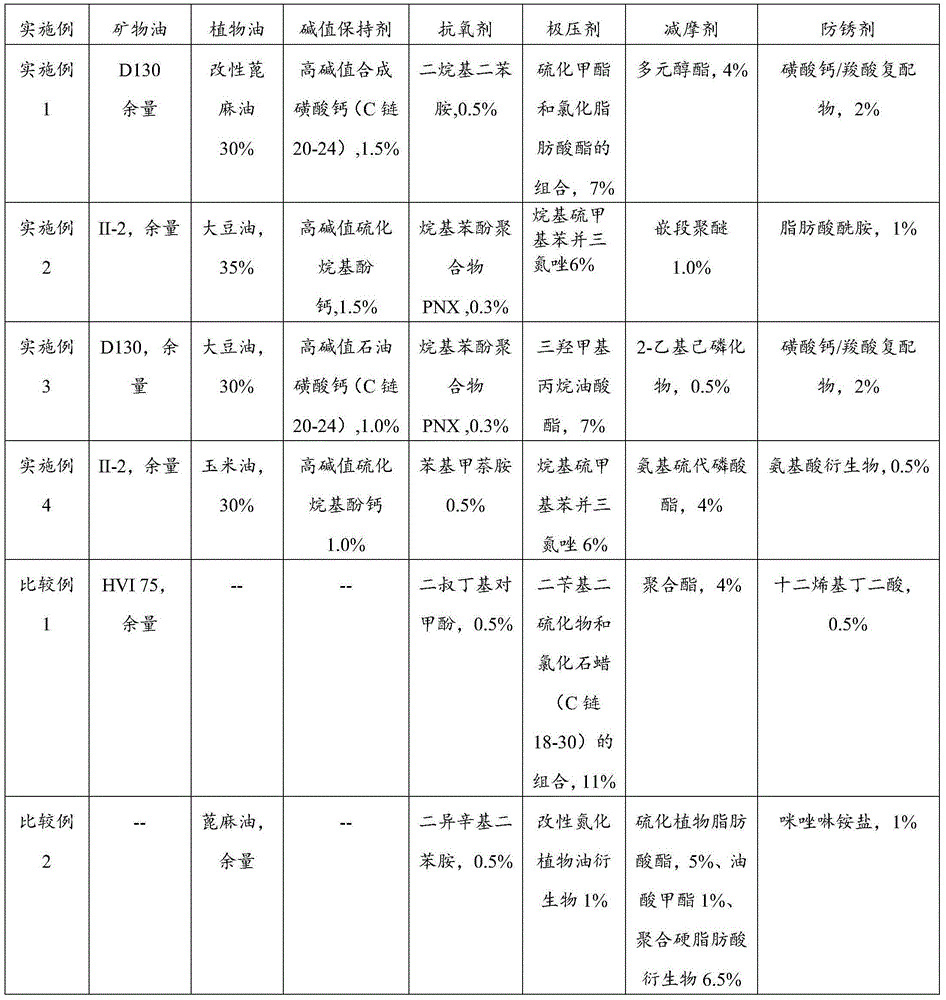

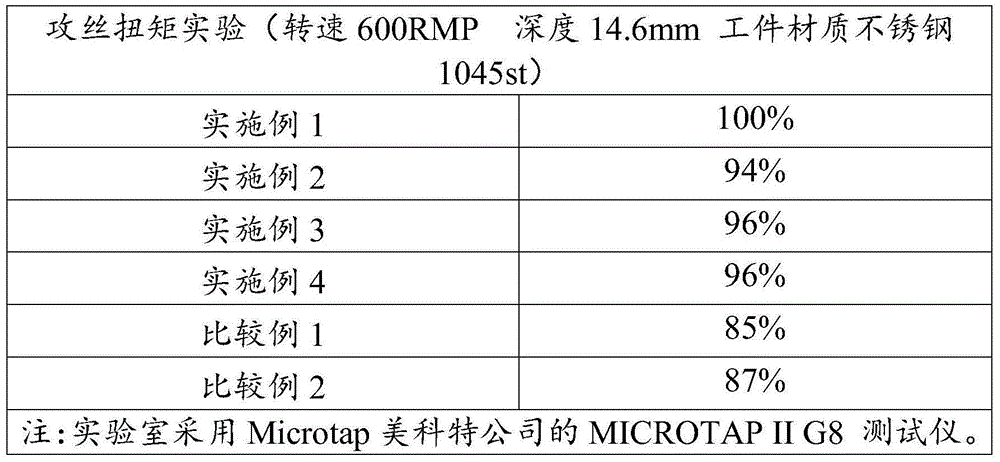

Half-plant type pure-oil-based cutting oil and application thereof

The invention relates to half-plant type pure-oil-based cutting oil and application thereof. The half-plant type pure-oil-based cutting oil mainly solves the problems that in the prior art, oxidation is prone to occurring, high-temperature oil mist is heavy, and low-temperature storage application is inconvenient. The half-plant type pure-oil-based cutting oil is prepared from, by weight, 45-60 parts of mineral oil, 30-45 parts of vegetable oil, 1-2 parts of base number retention agents, 0.2-0.5 part of antioxidants, 3-10 parts of extreme-pressure agents, 1-10 parts of anti-friction agents and 1-3 parts of antirust agents. According to the half-plant type pure-oil-based cutting oil and the application thereof, the problems are better solved, the higher tapping efficiency is achieved, and the half-plant type pure-oil-based cutting oil can be applied to a titanium alloy and stainless steel metal processing technology.

Owner:CHINA PETROLEUM & CHEM CORP

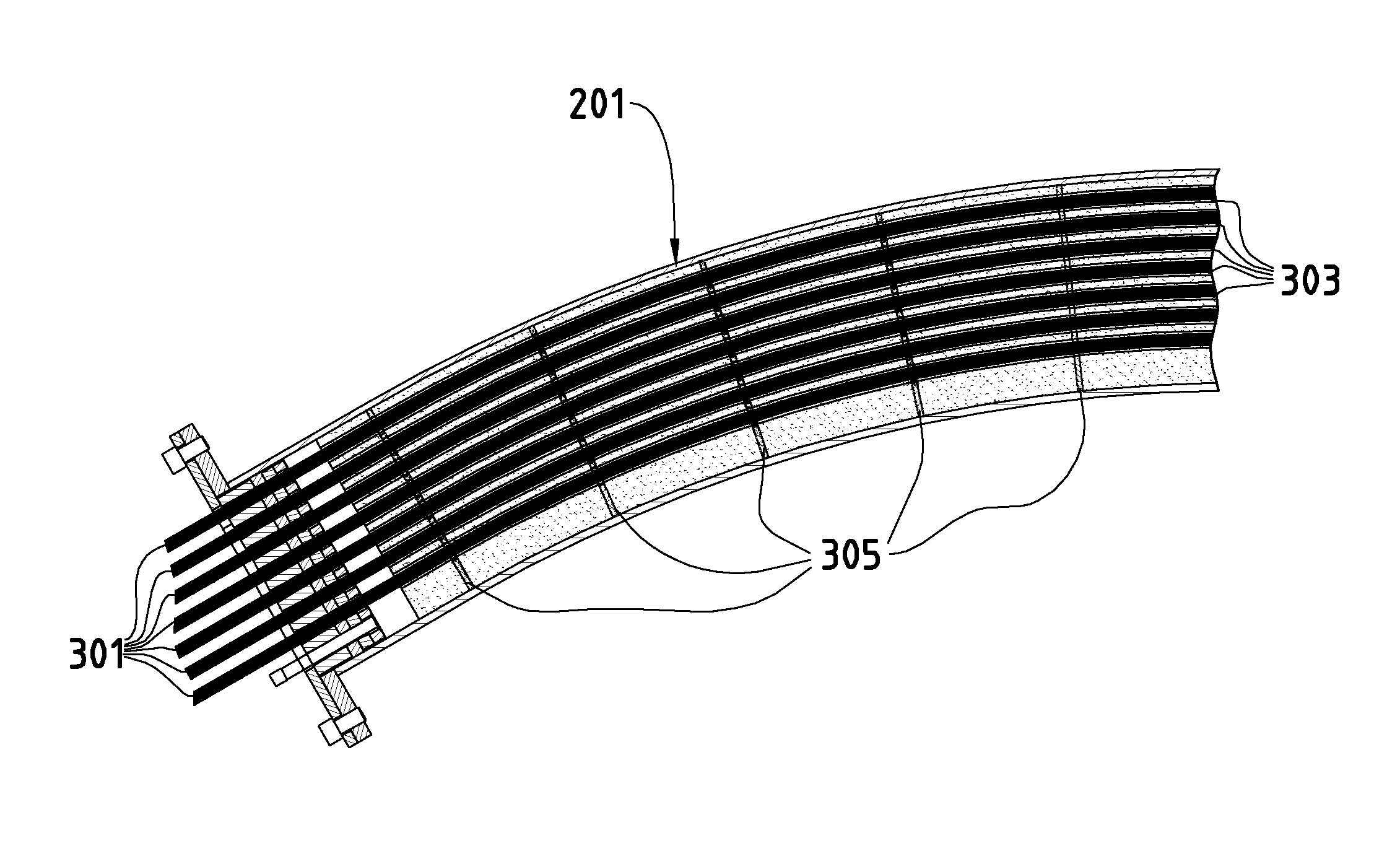

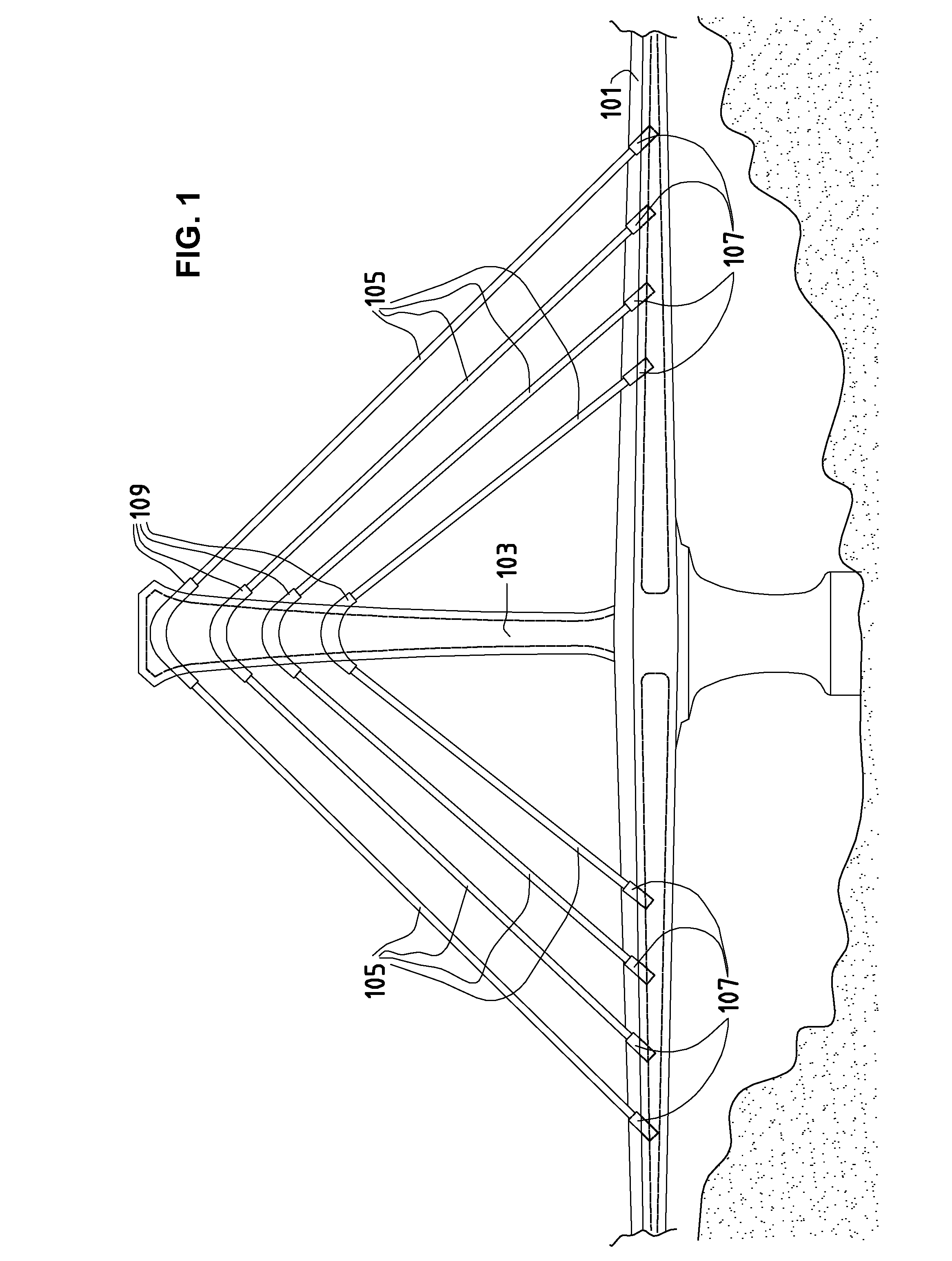

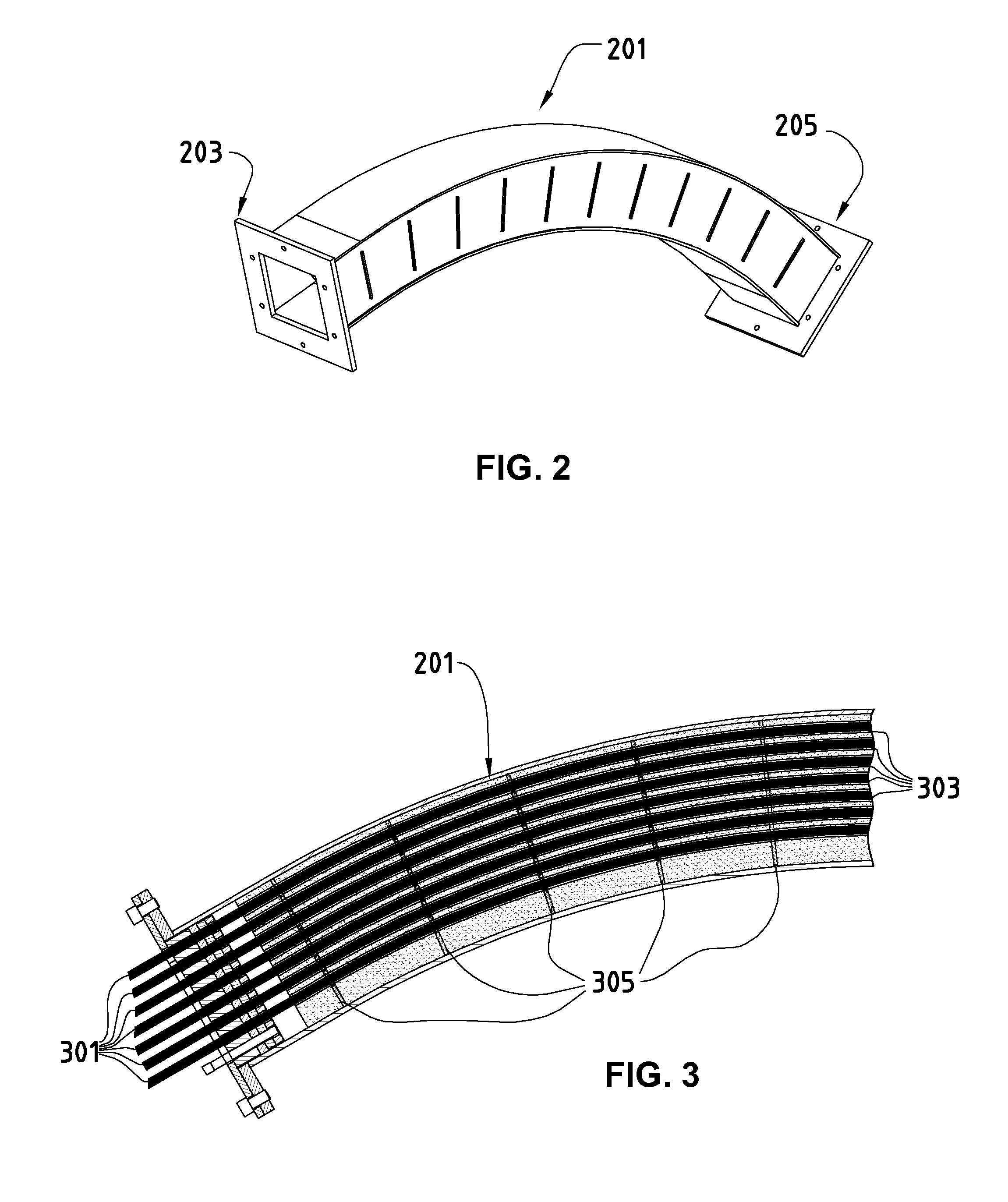

Strand guiding device

ActiveUS8650691B2Reduced risk of corrosionEasy to replaceFluid pressure sealed jointsBridge structural detailsEngineeringCorrosion

The present invention relates to a strand guiding device that comprises a curved body having a first end and a second end. The strand guiding device further comprises at least one channel extending from the first end to the second end inside the strand guiding device, the channel being arranged to be traversed longitudinally by a strand of a cable, and further arranged to hold the strand in place when under tension. The body of the guiding device is filled with a protective material for protecting the strand from corrosion and allowing later removal of the strand.

Owner:VSL INT AG

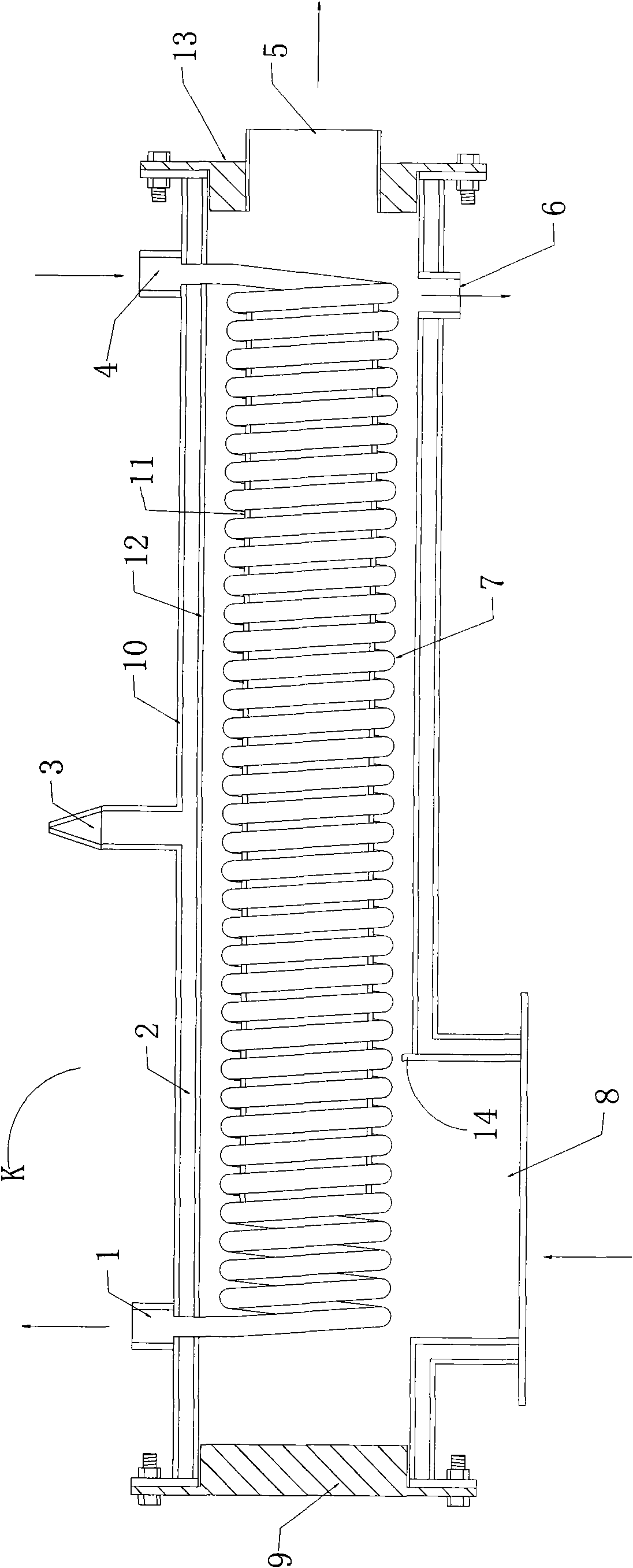

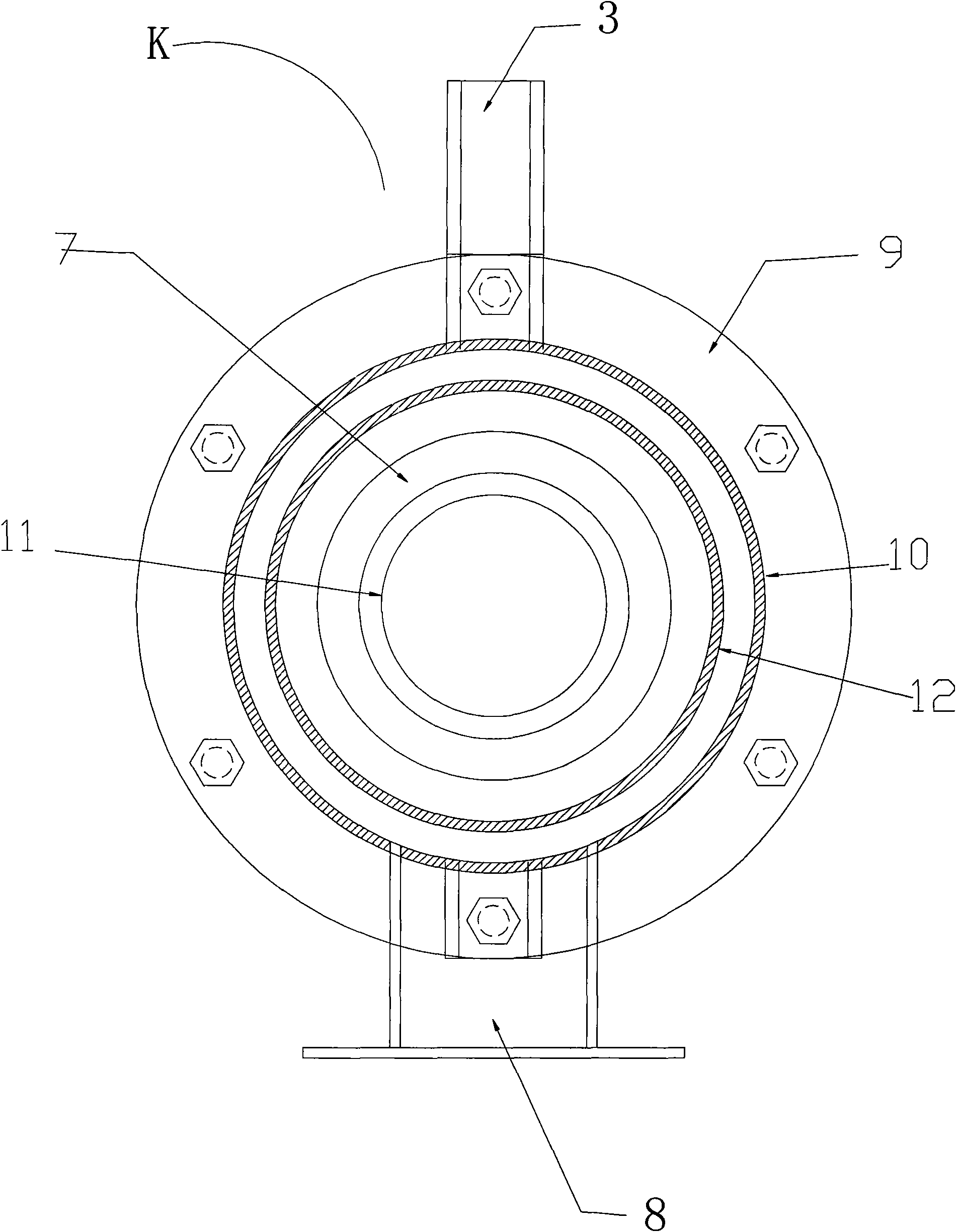

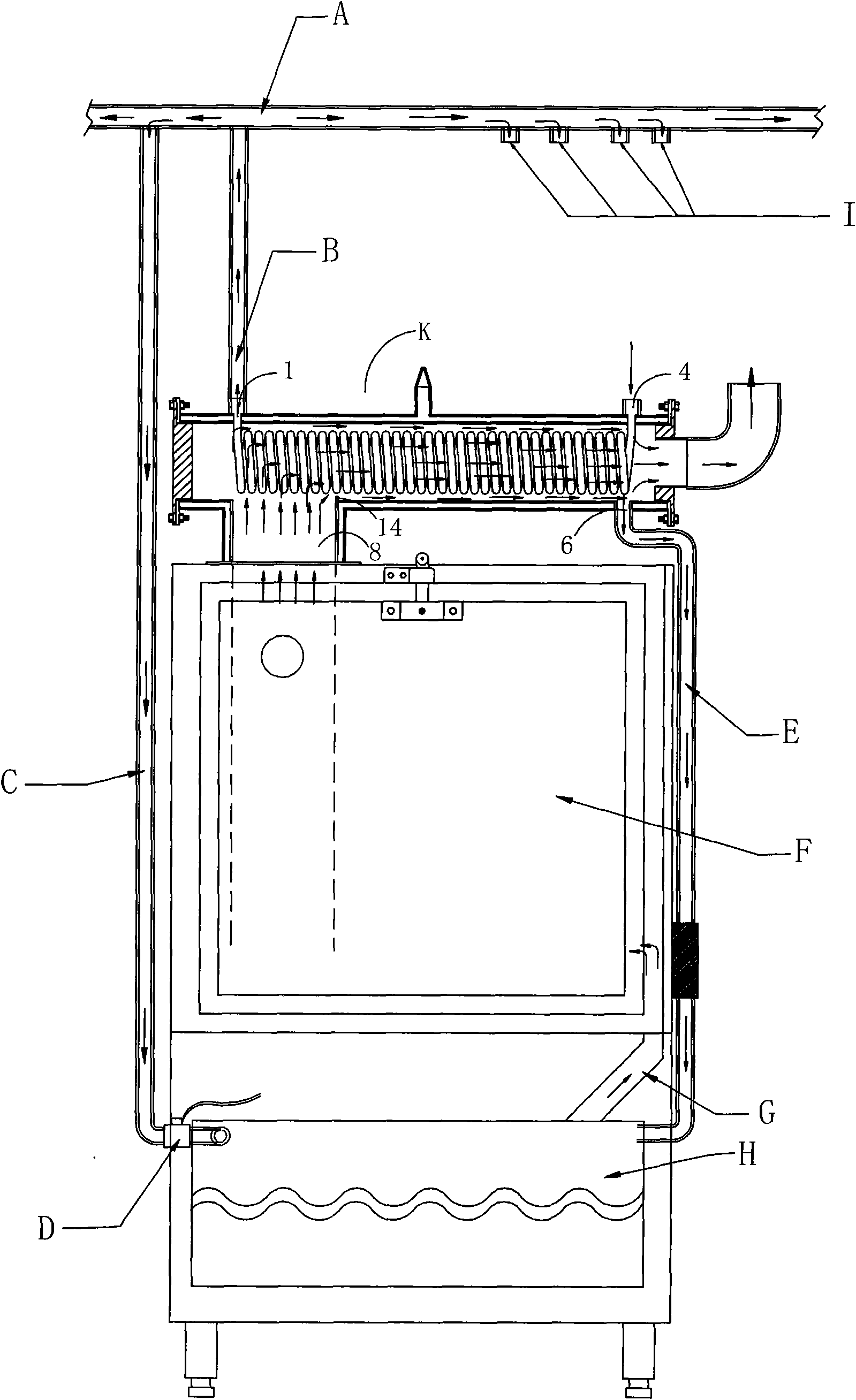

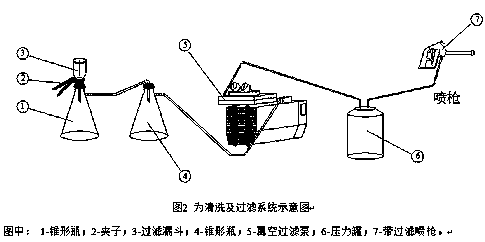

Heat exchange water recoverer for waste steam of steaming cabinet and external connection structure thereof

InactiveCN101603785AAvoid generatingSolve wasteSteam cooking vesselsHeat exchanger casingsDistilled waterWater resources

The invention discloses a heat exchange water recoverer for waste steam of steaming cabinet and external connection structure thereof. The recoverer comprises housing, a recovered hot water outlet disposed on the housing, which communicates with a water tank of the steaming cabinet and each of hot water supply pipelines for supplying hot water, a water inlet for injecting cold water, an air inlet for introducing waste steam discharged from the steaming cabinet, an air outlet for discharging waste steam, a distilled water outlet communicating with water tank of the steaming cabinet, and a water pipe installed in the housing, with a water inlet end communicating with the water inlet, and a water outlet end communicating with the recovered hot water outlet. The invention effectively solves the problems of the steaming cabinet in the prior art such as energy water resource waste.

Owner:杜嘉辉

Coating layer-carried aero-engine part cleanness checking method and device thereof

InactiveCN109701932AReduced risk of corrosionShort stayDrying gas arrangementsMaterial analysis by optical meansSolventFilter paper

The invention relates to a coating layer-carried aero-engine part cleanness checking method. The method mainly comprises such contents as precleaning, drying, cleaning, cleaning solvent collection andcleanness checking; cleaning solvent uses petroleum ether; the petroleum ether is sprayed to clean parts by using a pressure cleaning gun; after three times of spray cleaning, all cleaning liquid iscollected for cleanness checking; a filter paper of 0.8 micron is adopted to filter the collected cleaning liquid; then, the particle size of hard impurity particles remained on the filter paper is checked; and when the number of hard particles of larger than 30 microns and smaller than 100 microns is not more than 5, related technical requirements are met. The method has the characteristics of high cleaning efficiency, high cleaning quality and convenience to operate, and meanwhile, cannot damage basal bodies of the cleaned parts.

Owner:SHENYANG LIMING INT POWER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com