Integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery

A technology for flue gas desulfurization and coke oven flue, which is applied in steam generation method using heat carrier, chemical instrument and method, dispersed particle filtration, etc. The effect of large evaporation, more waste heat recovery and low exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

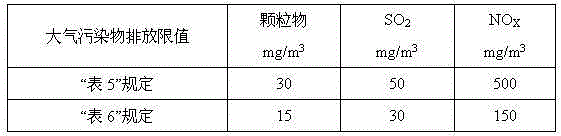

[0058] The present invention adopts coke oven flue gas low-temperature SCR denitrification + dry desulfurization system. The prior art generally adopts coke oven flue gas semi-dry desulfurization + low-temperature SCR denitrification system. See Table 1 for specific comparison:

[0059] Table 1. Comparison between the integrated system of desulfurization, denitrification and waste heat recovery of the present invention and the prior art

[0060]

Embodiment 2

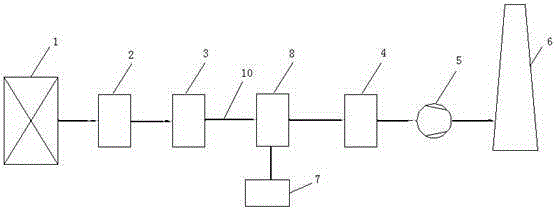

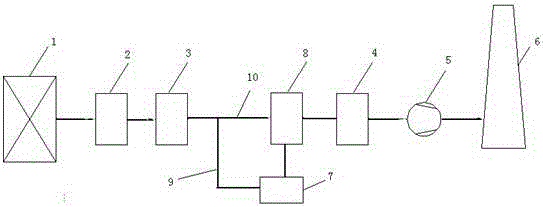

[0062] An integrated system for coke oven flue exhaust gas desulfurization and denitrification and waste heat recovery, including a coke oven 1, a low-temperature SCR denitrification system 2, a waste heat boiler 3, a flue 10, a pulverizer 7, a filter system 4, and a chimney 6; The coke oven 1, the low-temperature SCR denitrification system 2, the waste heat boiler 3, the filter system 4 and the chimney 6 are sequentially connected through a flue 10, and a dry powder absorbent is arranged on the flue 10 between the waste heat boiler 3 and the filter system 4 Inlet, the dry powder absorbent inlet is connected to the outlet of the pulverizer 7 through a pipeline, and the pulverizer 7 is provided with an absorbent inlet.

[0063] The waste heat boiler 3 is a heat pipe natural circulation waste heat boiler, and the existing technology generally adopts a flue-type water pipe natural circulation waste heat boiler, and the specific comparison is shown in Table 2:

[0064] Table 2. Co...

Embodiment 3

[0067] An integrated system for coke oven flue exhaust gas desulfurization and denitrification and waste heat recovery, including a coke oven 1, a low-temperature SCR denitrification system 2, a waste heat boiler 3, a flue 10, a pulverizer 7, a filter system 4, and a chimney 6; The coke oven 1, the low-temperature SCR denitrification system 2, the waste heat boiler 3, the filter system 4 and the chimney 6 are sequentially connected through a flue 10, and a dry powder absorbent is arranged on the flue 10 between the waste heat boiler 3 and the filter system 4 Inlet, the dry powder absorbent inlet is connected to the outlet of the pulverizer 7 through a pipeline, and the pulverizer 7 is provided with an absorbent inlet.

[0068] The low-temperature SCR denitration system 2 is an SCR denitration system with a temperature range of 160°C to 290°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com