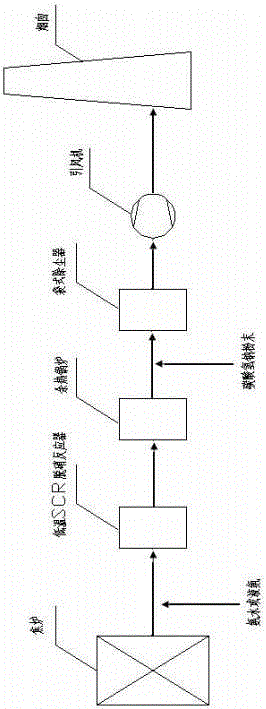

Coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process

A coke oven flue and waste gas desulfurization technology, which is applied in air quality improvement, chemical instruments and methods, and dispersed particle filtration, can solve problems such as high operating costs, high energy consumption, and secondary pollution, and achieve recovery of waste heat, Low energy consumption and low exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

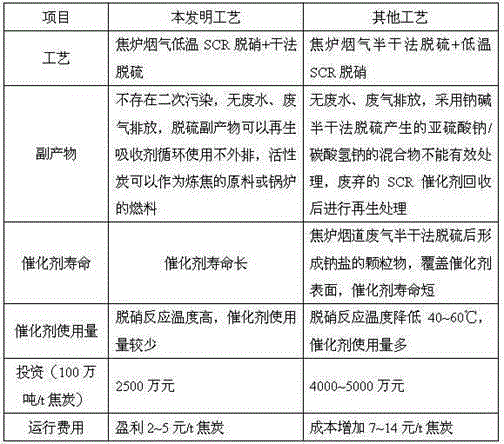

[0050] The present invention adopts coke oven flue gas low-temperature SCR denitrification + dry desulfurization process. The prior art generally adopts coke oven flue gas semi-dry desulfurization + low-temperature SCR denitrification process. See Table 1 for specific comparison:

[0051] Table 1. Comparison between the integrated process of desulfurization, denitrification and waste heat recovery of the present invention and the prior art

[0052]

Embodiment 2

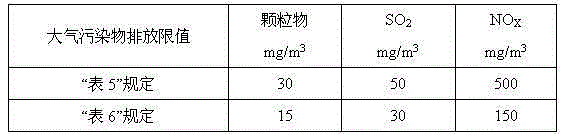

[0054] An integrated process of coke oven flue gas desulfurization and denitrification and waste heat recovery. Under the action of low-temperature SCR denitrification catalyst, coke oven flue gas removes nitrogen oxides in flue gas through SCR reaction, and reduces coke through waste heat boiler. After the furnace flue gas temperature, spray sodium-based dry powder absorbent to the flue gas for desulfurization, desulfurization for secondary use, and then filter to remove particulate matter in the coke oven flue gas, and finally discharge up to the standard. The exhaust gas can meet the highest standard required by GB16171-2012. The desulfurized products collected by the filter are sent to the power plant for desulfurization for secondary use.

[0055] The waste heat boiler described is a heat pipe natural circulation waste heat boiler. The existing technology generally adopts a flue-type water pipe natural circulation waste heat boiler. The specific comparison is shown in Tab...

Embodiment 3

[0059] An integrated process of coke oven flue gas desulfurization and denitrification and waste heat recovery. Under the action of low-temperature SCR denitrification catalyst, coke oven flue gas undergoes SCR reaction to remove nitrogen oxides in flue gas, and waste heat is recovered through waste heat boiler Finally, the flue gas is desulfurized by spraying sodium-based dry powder absorbent to the flue gas, and the desulfurized flue gas is dedusted by a filter before being discharged up to standard.

[0060] The temperature range of the low-temperature SCR denitration catalyst is 160°C to 290°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com