Multilayer turntable round tower type bran steaming machine

A technology of round tower and bran steamer, which is applied in the field of wine making, can solve the problems of uneven heat transfer, poor steaming effect, and low operating efficiency, and achieve the effect of improving site use efficiency, improving operating efficiency, and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

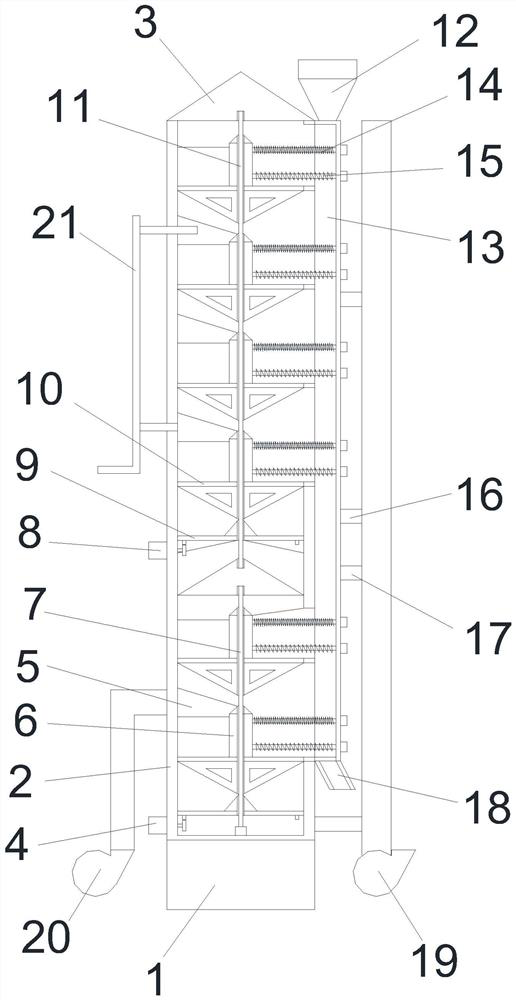

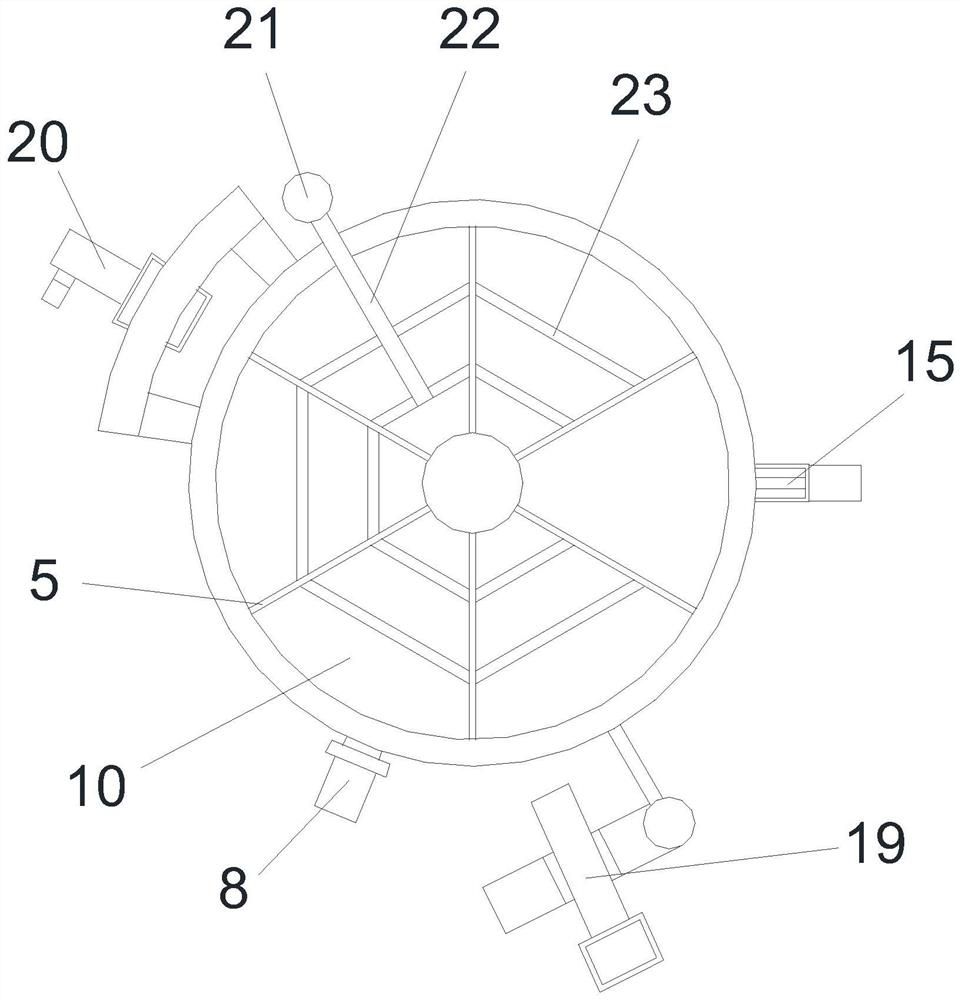

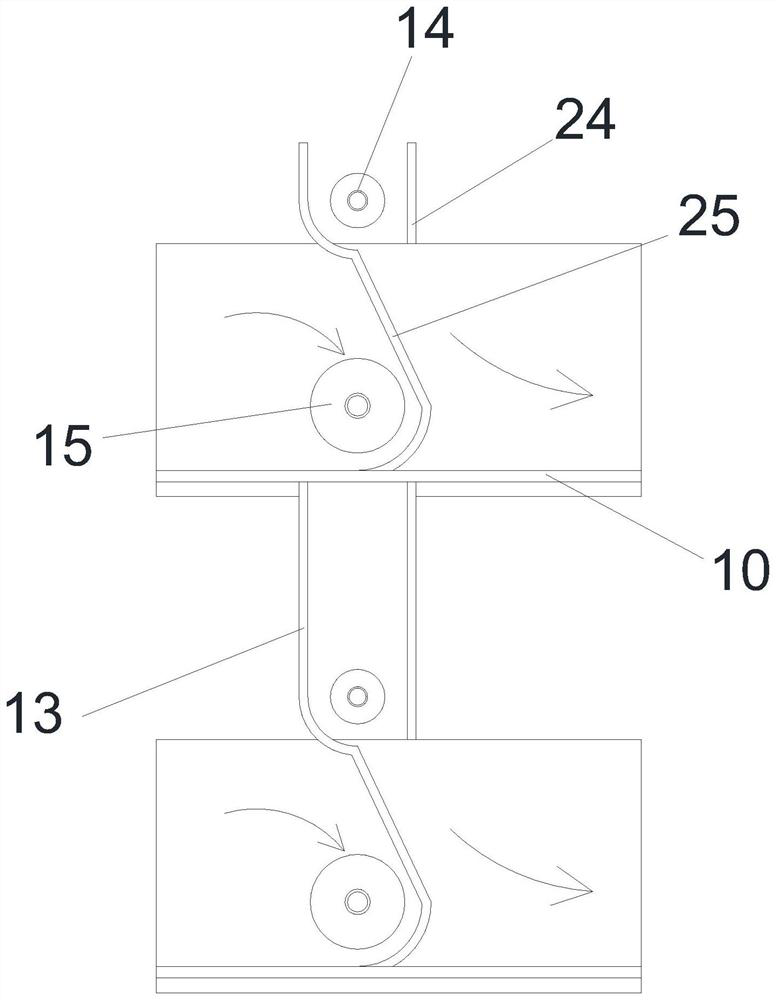

[0029] Embodiment: multi-layer turntable round tower steamer, as Figure 1-Figure 4 As shown, a base 1 is included, a box 2 is arranged above the base 1, and a tower cap 3 is installed on the top of the box 2. The inside of the box 2 includes a evaporation section and a cooling section, and the evaporation section is arranged in the cooling section. At the upper position, the material is evaporated through the evaporation section, and the evaporated material is cooled through the cooling section. The right side of the box body 2 is provided with a slide pipe 13, and the internal material of the box body 2 is removed through the slide pipe 13. import and export jobs;

[0030] Both the evaporation section and the cooling section are provided with a drive turntable 9, and the corresponding position of the drive turntable 9 inside the evaporation section is provided with an evaporation section turntable drive motor 8, which can drive the drive turntable 9 to rotate through the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com