Screen type evaporation blade, and humidifier evaporation assembly applied to screen type evaporation blade

A technology of evaporation components and humidifiers, which is applied in the field of parts structure, can solve the problems of complicated humidifier structure, high energy consumption, noise and radiation, etc., and achieve the effect of improving humidification efficiency, wide application range and increasing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings.

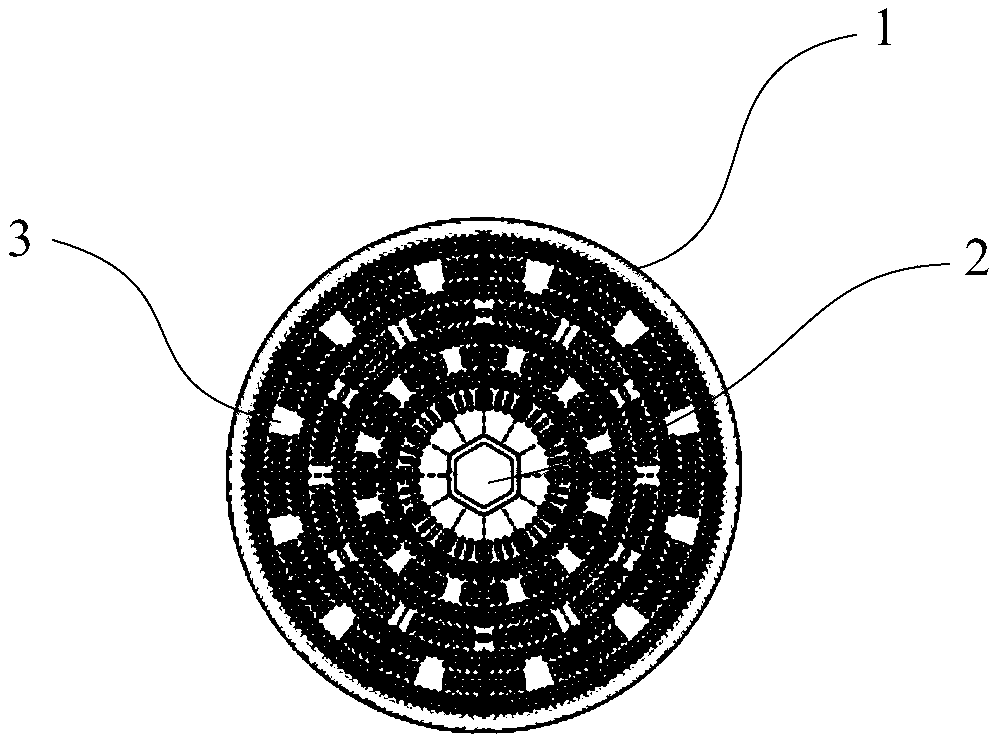

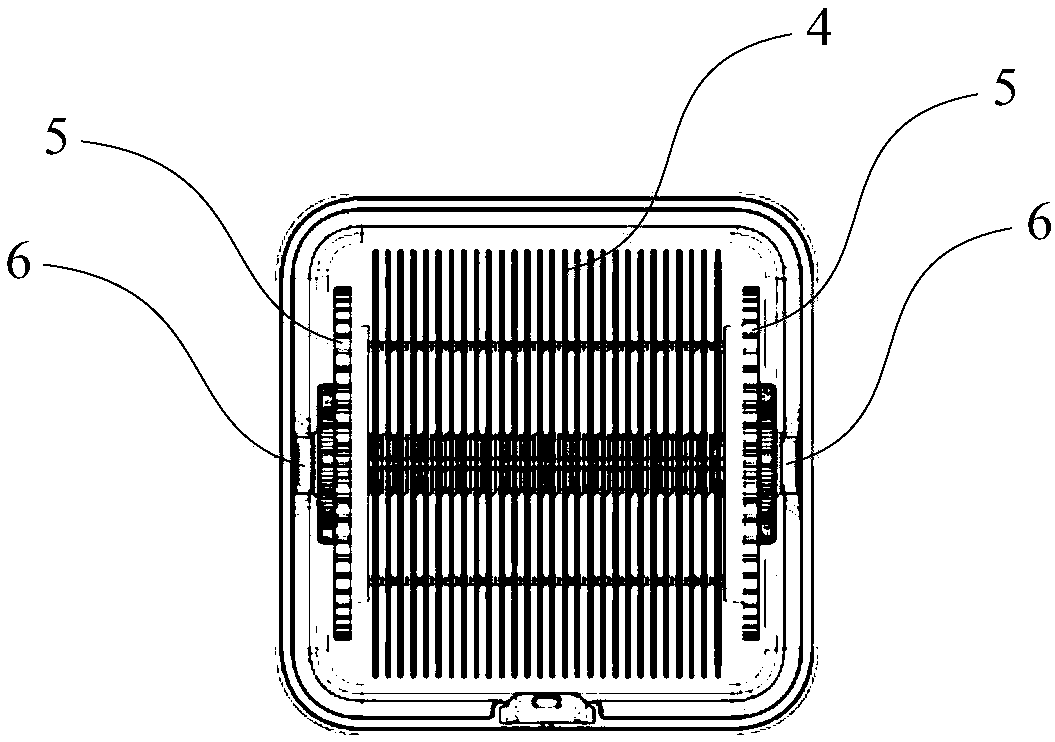

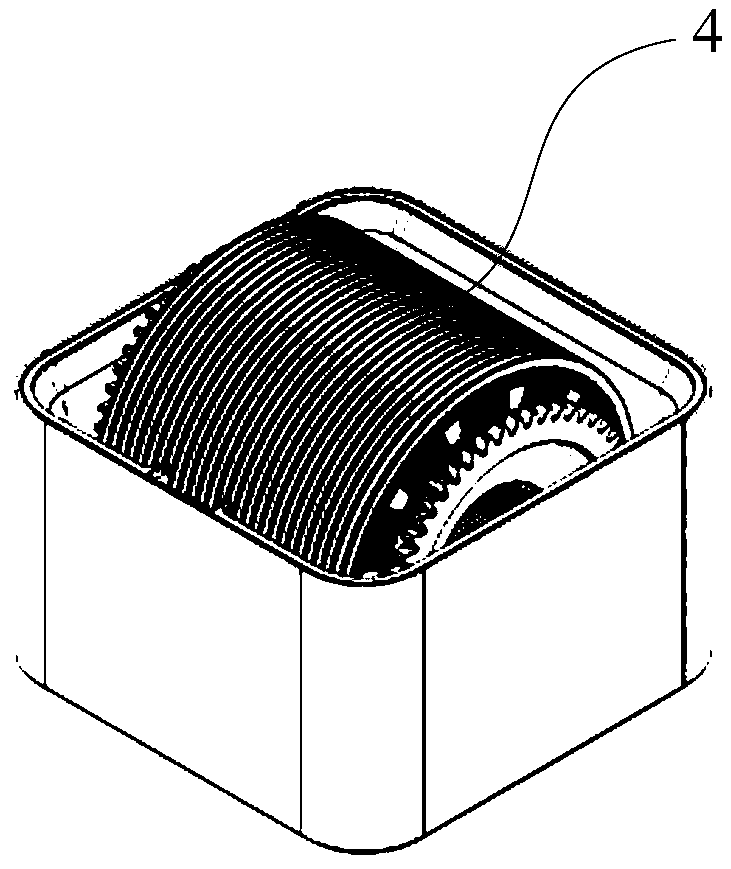

[0019] refer to figure 1 As shown, one embodiment of the present invention is a sieve-type evaporating blade, which includes a blade body 1, which should generally be designed as a circle to save the internal space of the humidifier shell. The blade body 1 can also be designed in other shapes as a whole; and the middle part of the blade body 1 is provided with a shaft hole 2, and the shaft hole 2 can be designed as a straight-sided shape, such as a triangle, a rectangle, and a polygon with more than four sides, etc. , to prevent the rotating shaft 6 from slipping when the blade body 1 rotates in the shaft hole 2; more importantly, as the final improvement of the present invention, a plurality of small through holes or blind holes need to be set on the blade body 1. Holes, in small through holes or blind holes evenly distributed around the shaft hole 2, such as figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com