X65 hot-rolled steel plate for marine riser and preparation method of steel plate

A hot-rolled steel plate, X65 technology, applied in the field of X65 hot-rolled steel plate for marine risers and its preparation, can solve the problems of acid corrosion resistance, low-temperature toughness, low yield ratio, etc., to achieve fine core grains, low yield Strength ratio, the effect of improving strength and ultra-low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a preparation method of X65 hot-rolled steel plate for marine riser, the steps include:

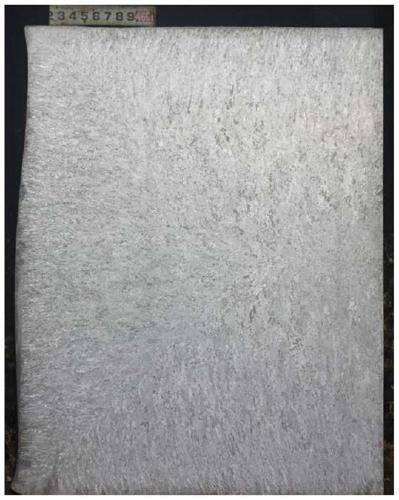

[0042] 1) Continuous casting produces high-clean, extra-thick continuous casting slabs that meet the chemical composition requirements. The central segregation is controlled at Class C 0.5, and the non-metallic inclusions of A / B / C / D are controlled within 1.5. The thickness of the continuous casting slab And the specific chemical composition is shown in Table 1. The central segregation of the continuous casting slab is well controlled, such as figure 1 shown;

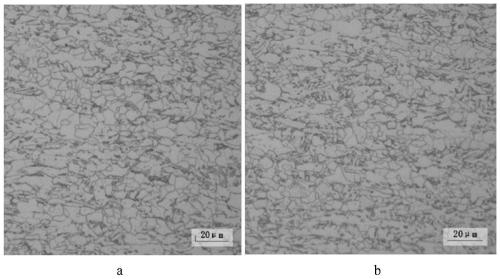

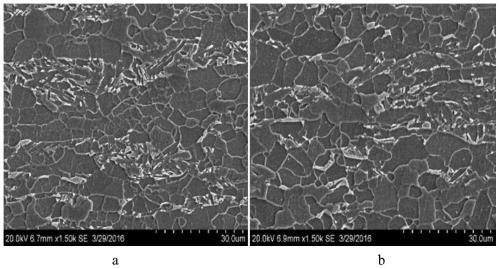

[0043] 2) The differential temperature rolling process is adopted in the rough rolling stage, and the surface of the billet is cooled by spraying high-pressure water to form a temperature gradient in the thickness section of the billet, so that the surface temperature of the billet is lower than that of the core, so that the rolling deformation can fully penetrate into the core of the billet , refine...

Embodiment 2-5

[0051] The present invention further provides embodiments 2-5, and embodiments 2-5 respectively provide a preparation method of X65 hot-rolled steel plates for marine risers, the specific steps of which are basically the same as those in embodiment 1, adopting 400mm continuous casting slab, continuous casting The segregation in the center of the slab is well controlled, and then the continuous casting slab undergoes rough rolling, three-stage finish rolling, cooling and other processes, and the steel plate obtains a fine and uniform structure of ferrite + a small amount of acicular ferrite, and the structure of the surface and core of the steel plate is uniform sex is good. The difference from Example 1 lies in the chemical composition of the steel plate and some process parameters, as shown in Table 1 and Table 2 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com