Wheel front burr removing device

A cleaning device and burr technology, applied in the field of wheel grinding, can solve the problems of difficulty in ensuring the roundness of the cap mouth and the rim roundness, the burr is not easy to be cleaned, the removal efficiency is low, etc. short beat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

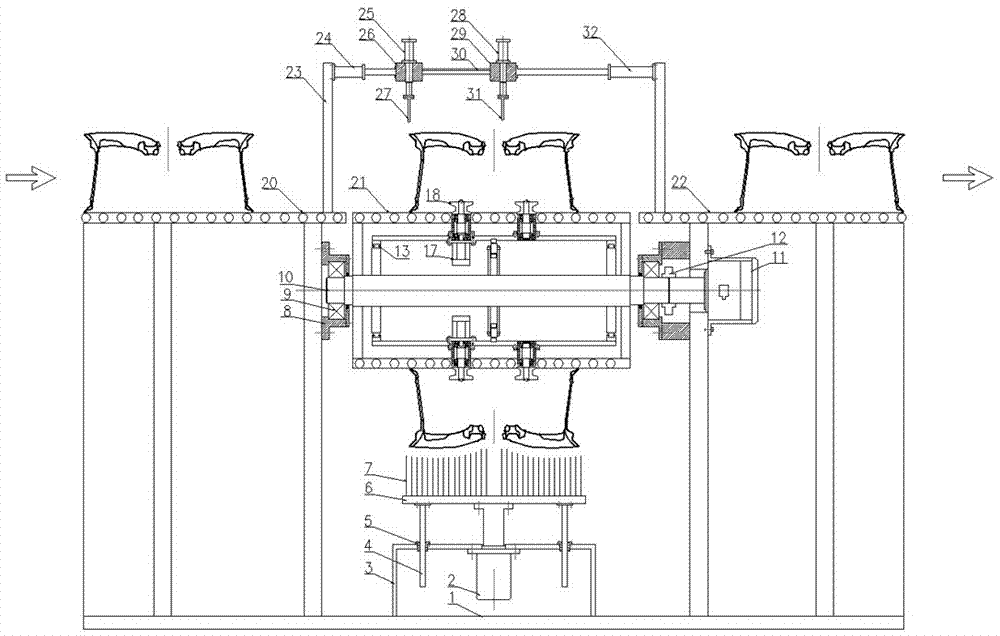

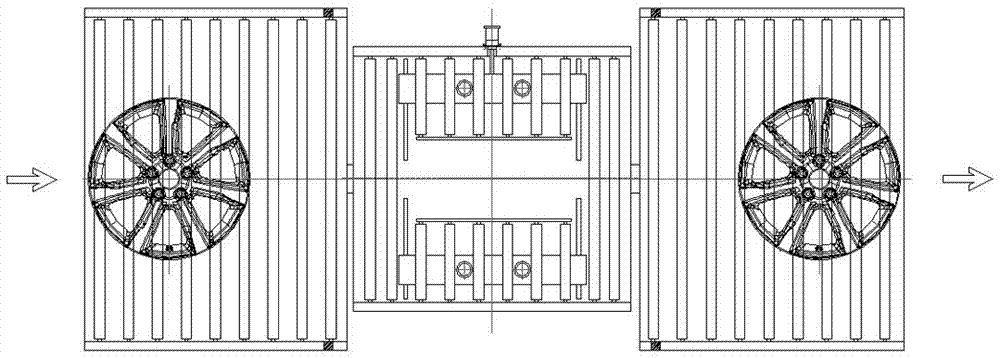

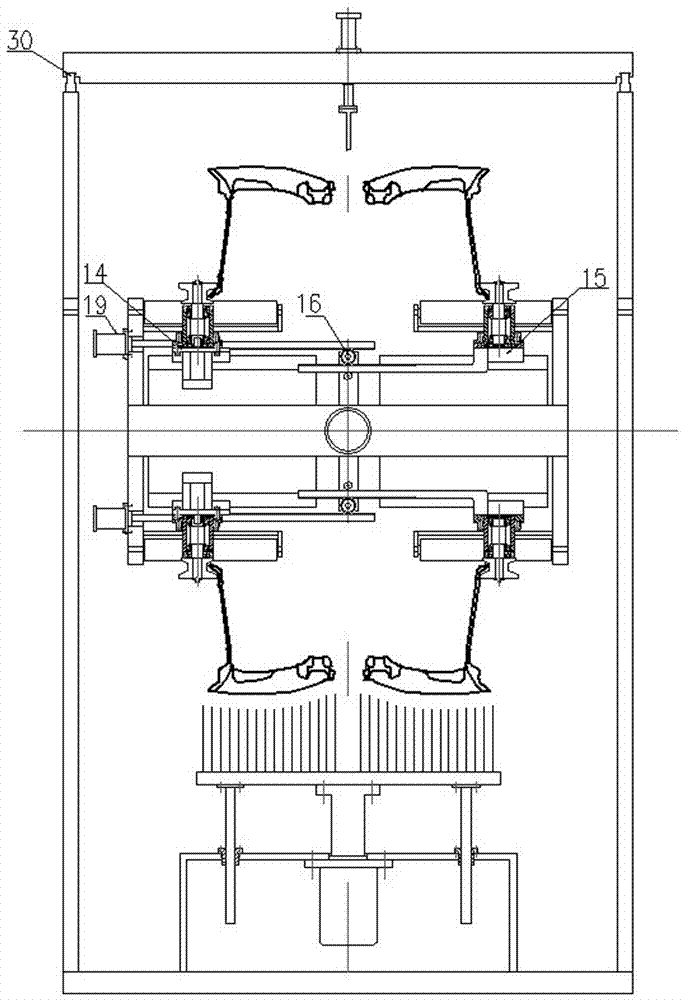

[0019] The details and working conditions of the specific device proposed by the present invention will be given below in conjunction with the description of the accompanying drawings.

[0020] A wheel front burr cleaning device, which consists of a frame 1, a lifting cylinder 2, a support frame 3, a guide column 4, a guide sleeve 5, a lifting table 6, a brush 7, a bearing seat 8, a bearing 9, a turning platform 10, and a servo motor Ⅰ11, coupling 12, guide rail 13, left slide 14, right slide 15, rack and pinion structure 16, servo motor Ⅱ17, clamping wheel 18, clamping cylinder 19, feeding roller table 20, working roller table 21, outlet Material roller table 22, tool system support frame 23, wheel rim bayonet adjustment cylinder 24, rim burr bayonet feed cylinder 25, left slide table 26, wheel rim burr bayonet 27, cap opening burr bayonet feed cylinder 28, right slide Platform 29, adjustment guide rail 30, hat mouth burr knife 31 and hat mouth burr knife adjustment cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com