Patents

Literature

35results about How to "New layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

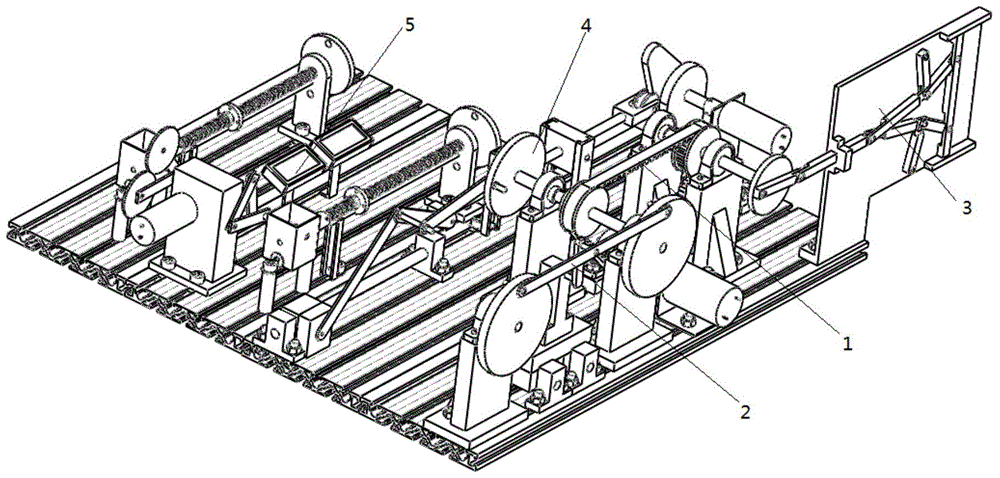

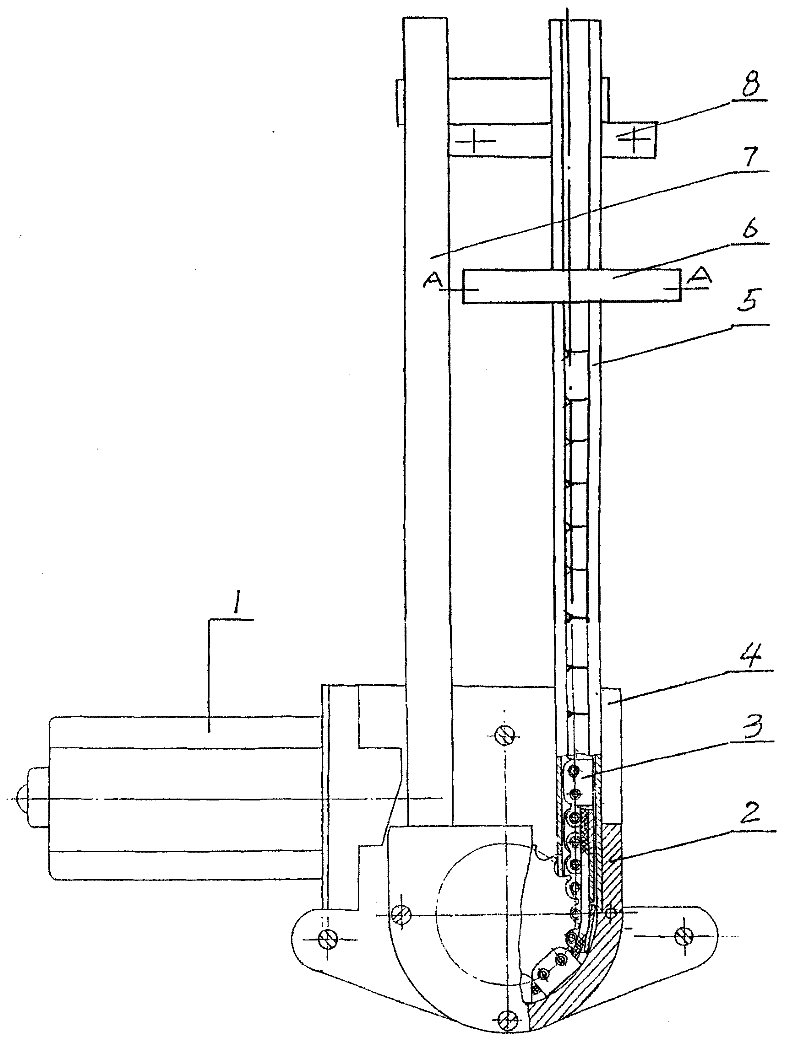

Wheel front burr removing device

InactiveCN107363669AImprove painting yieldImprove efficiencyEdge grinding machinesPolishing machinesCouplingRotation system

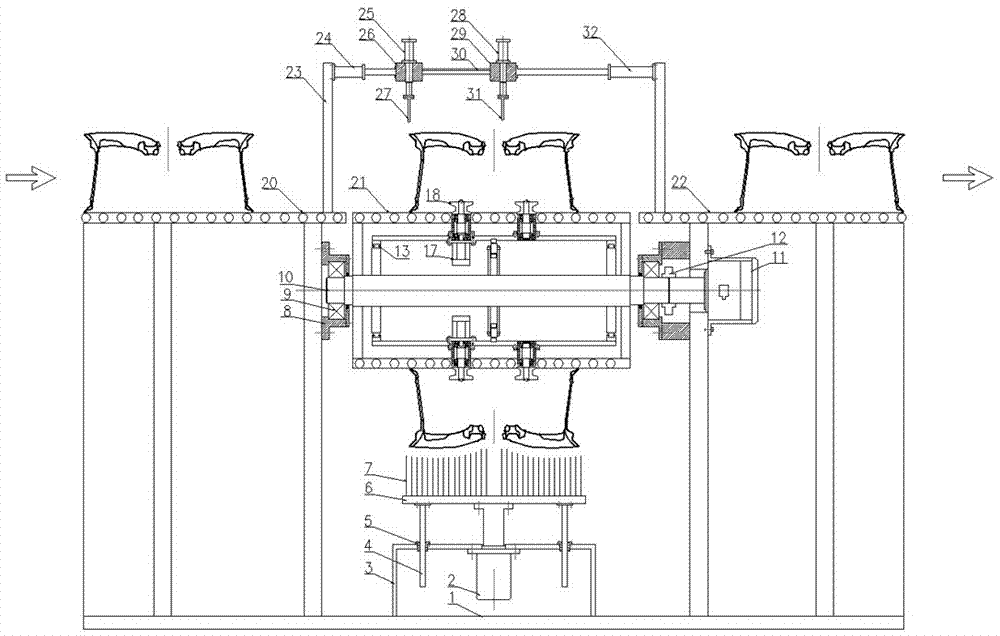

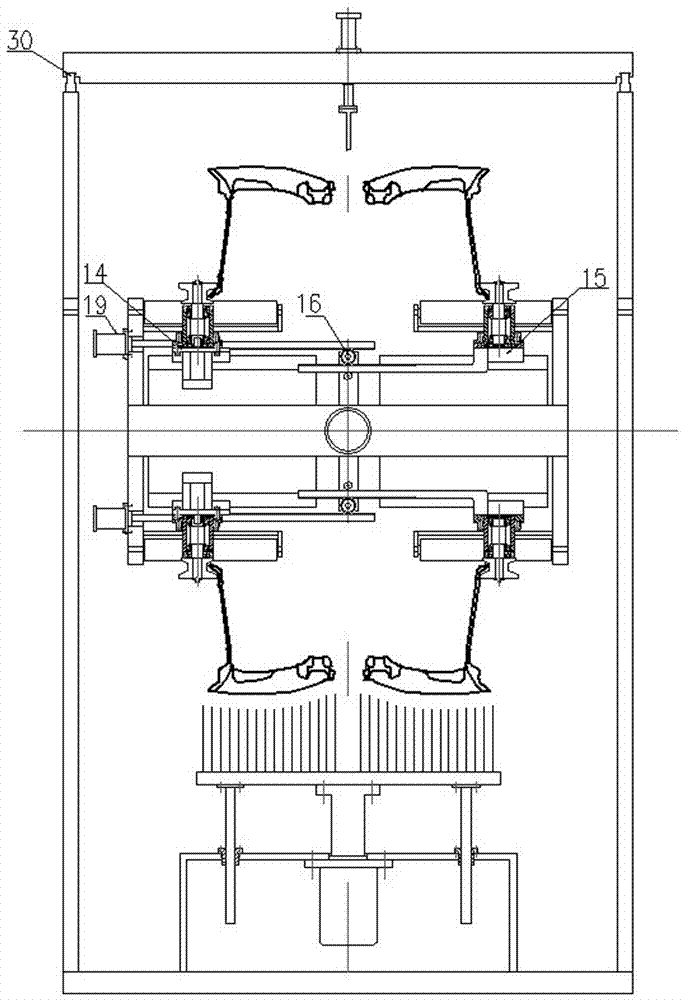

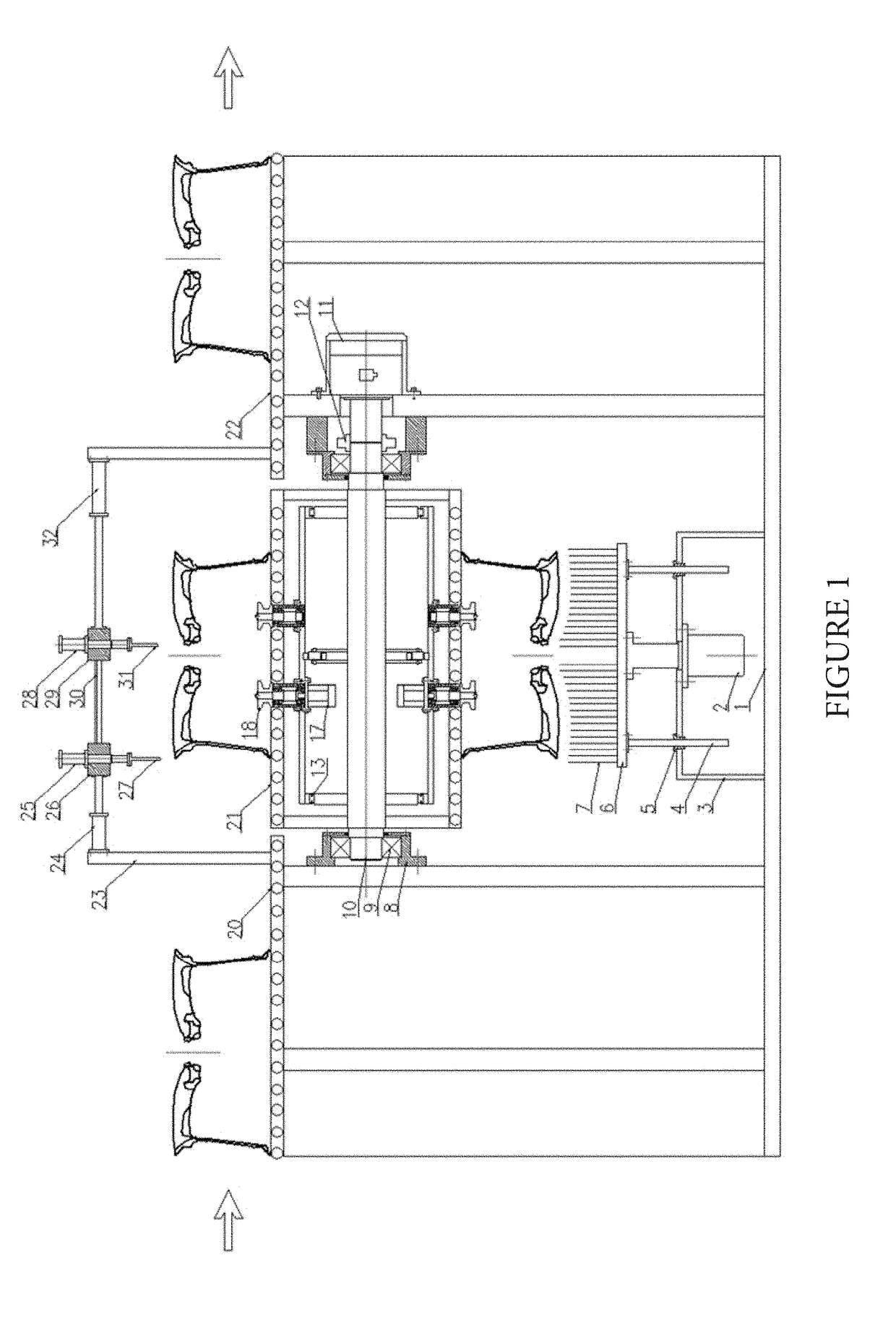

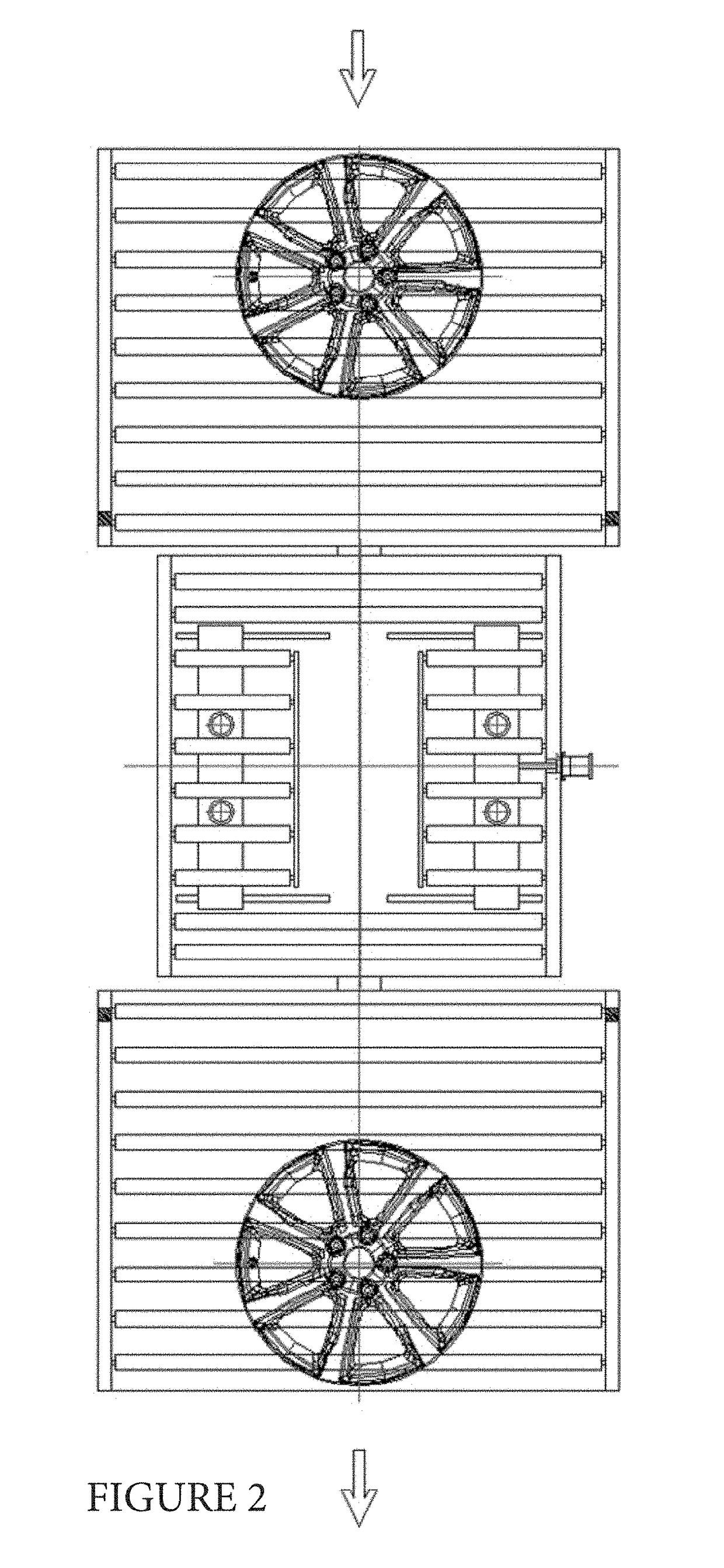

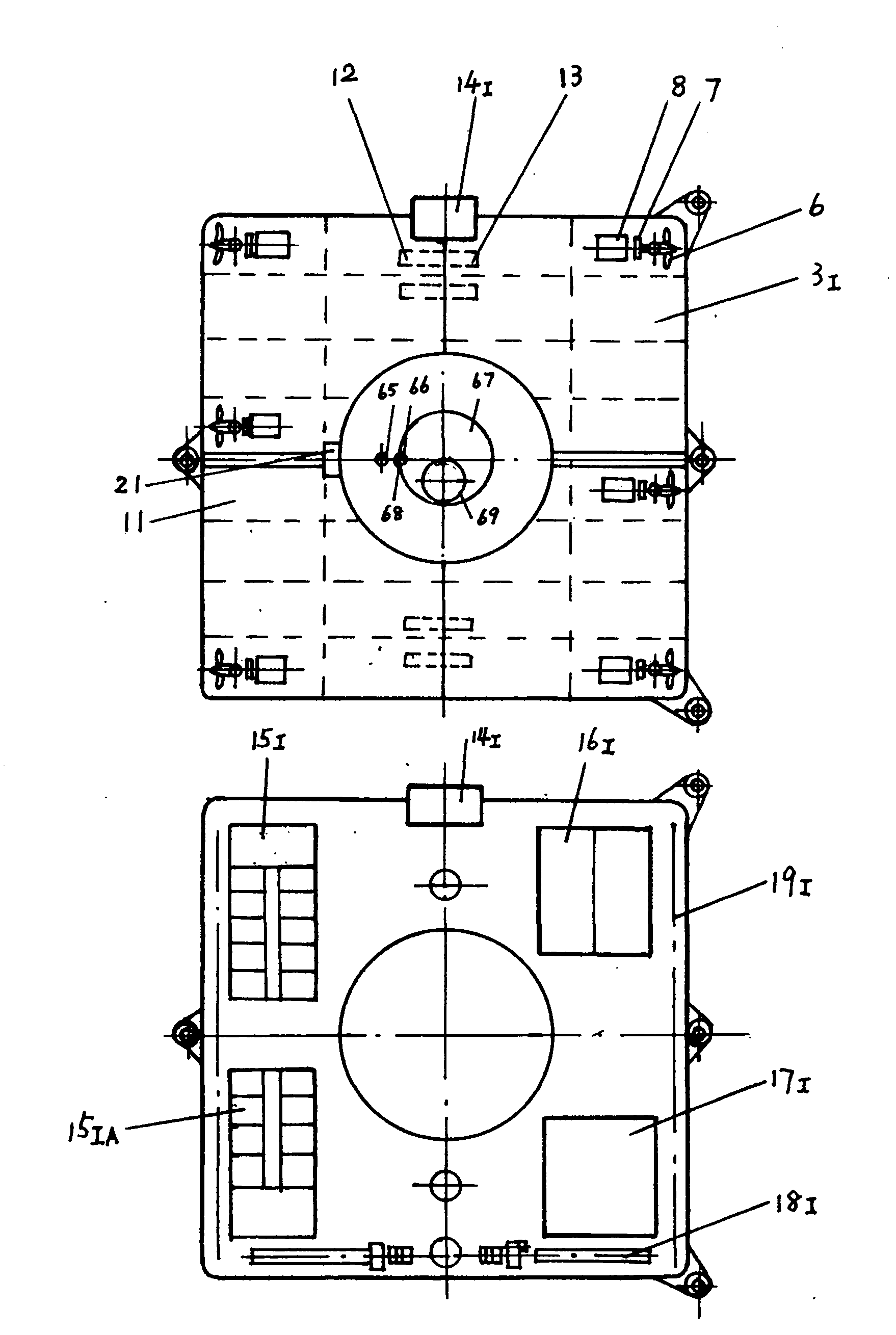

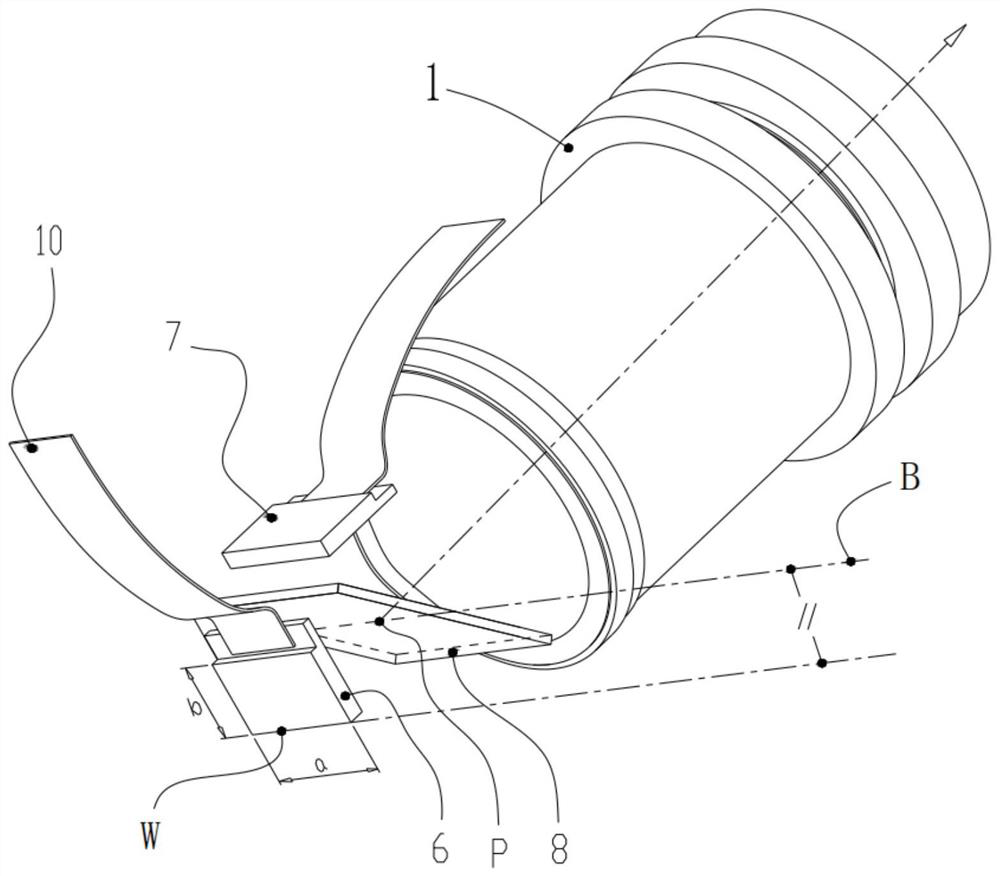

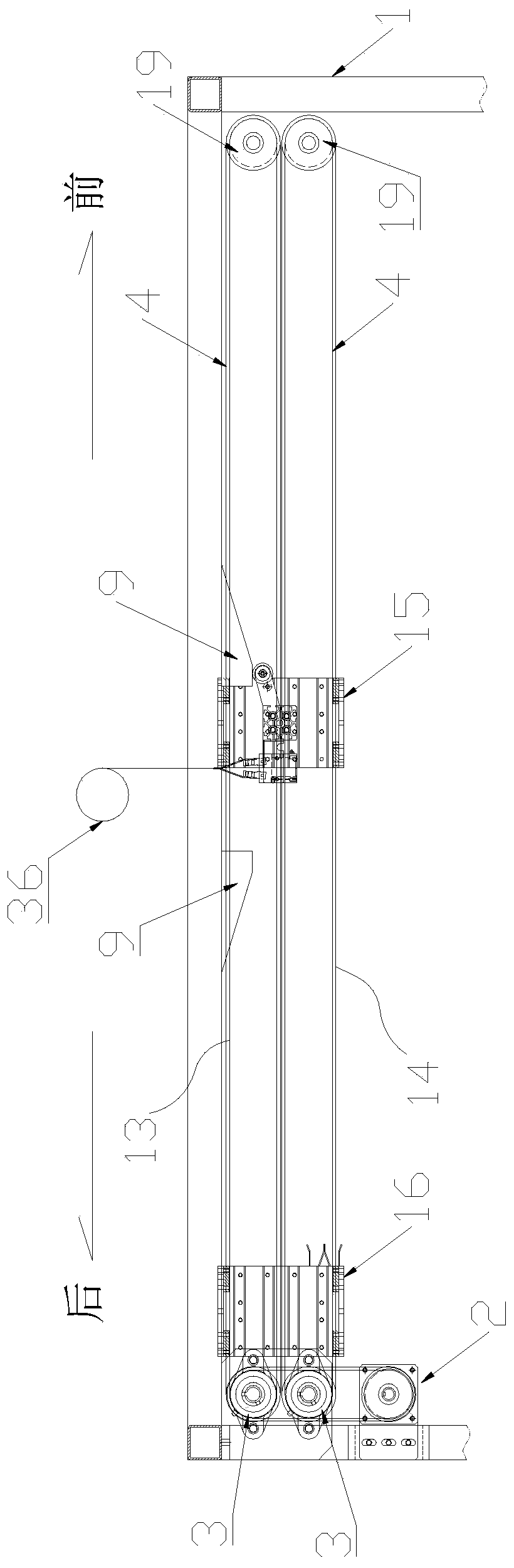

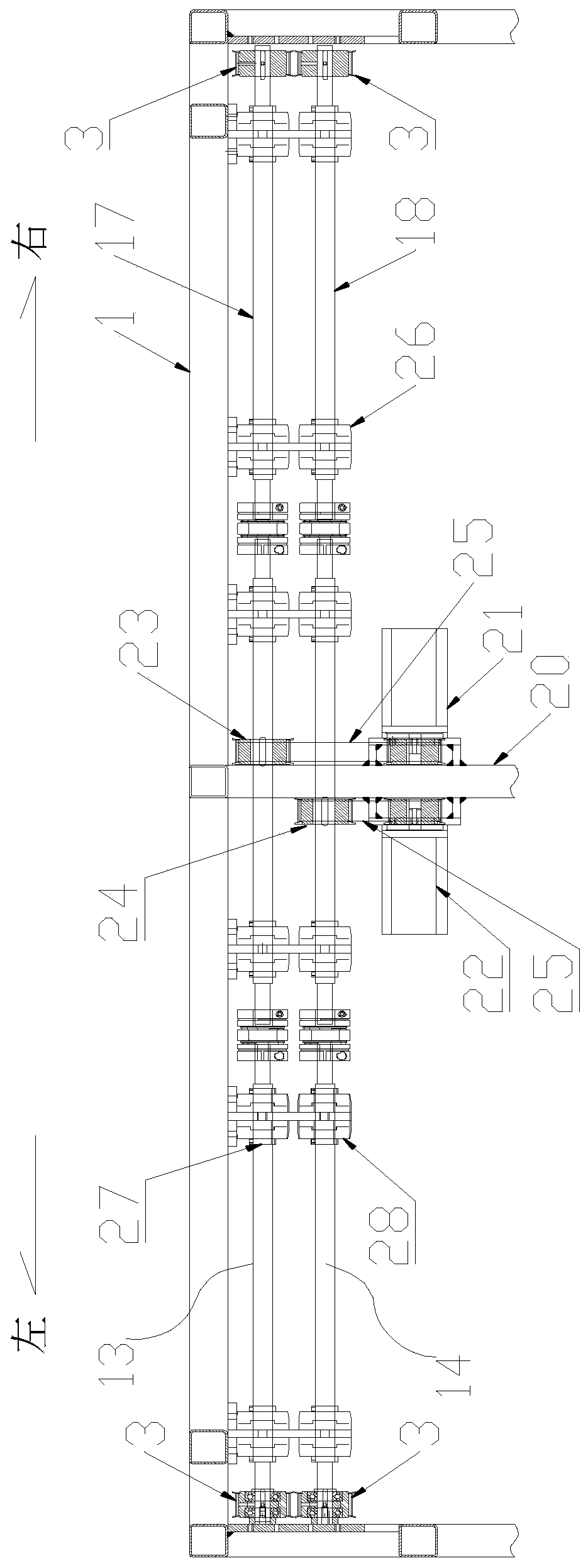

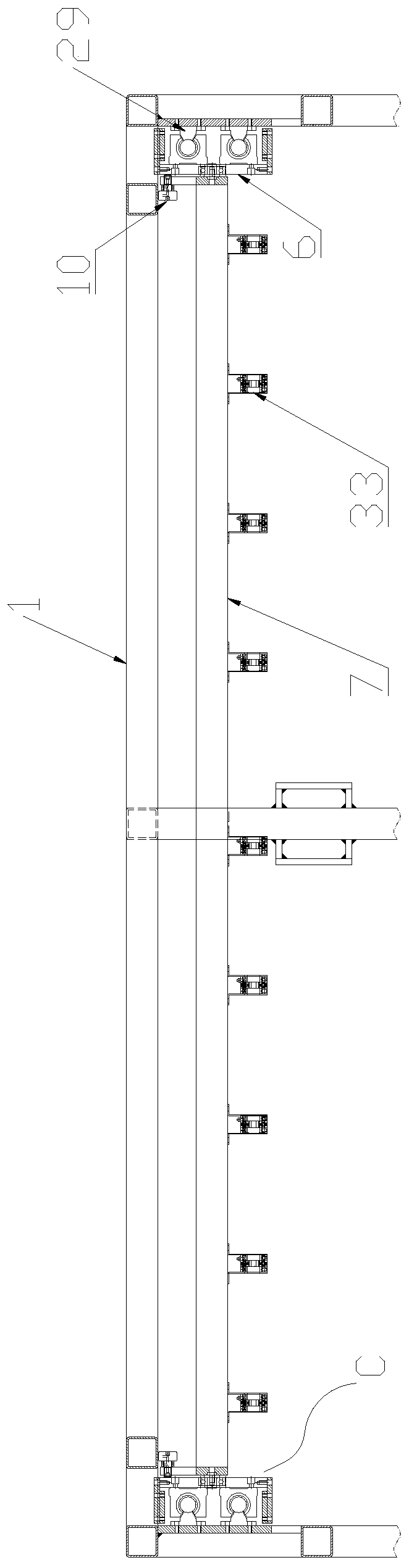

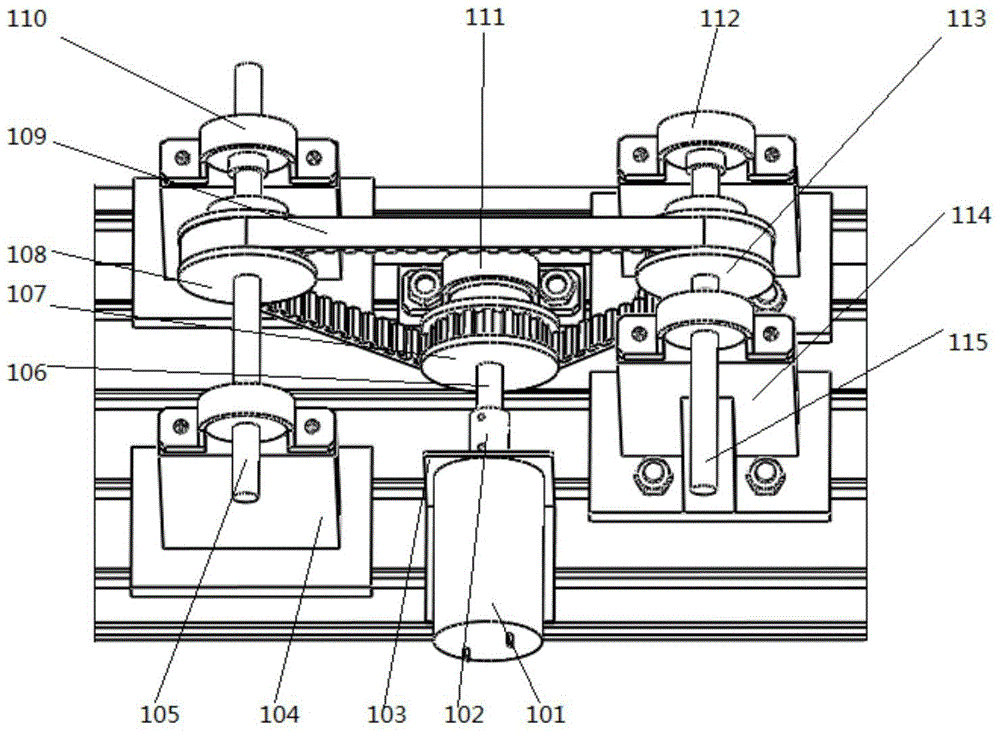

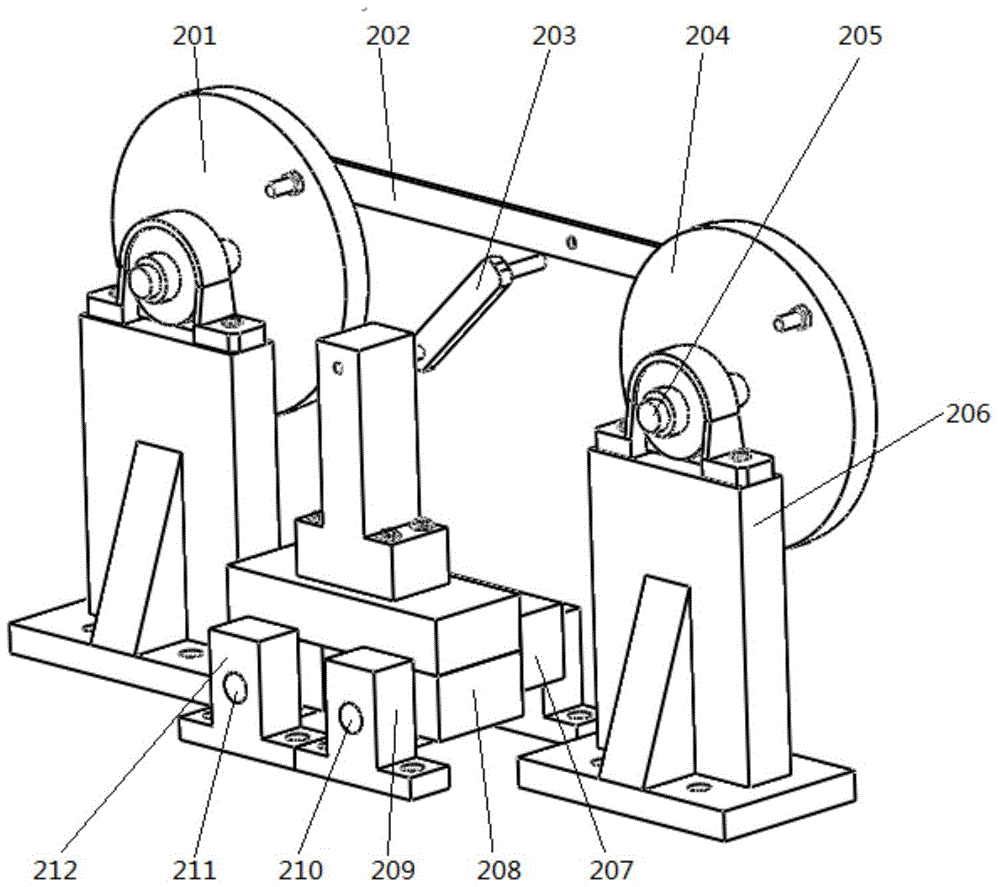

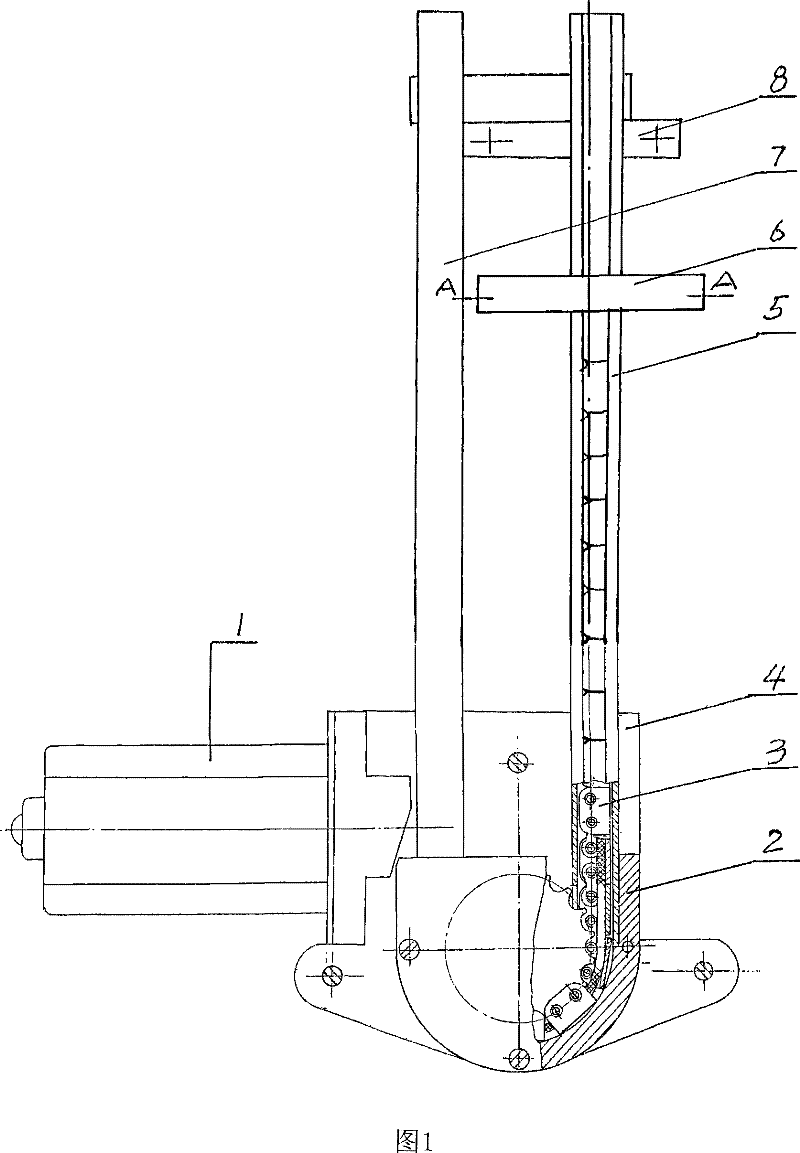

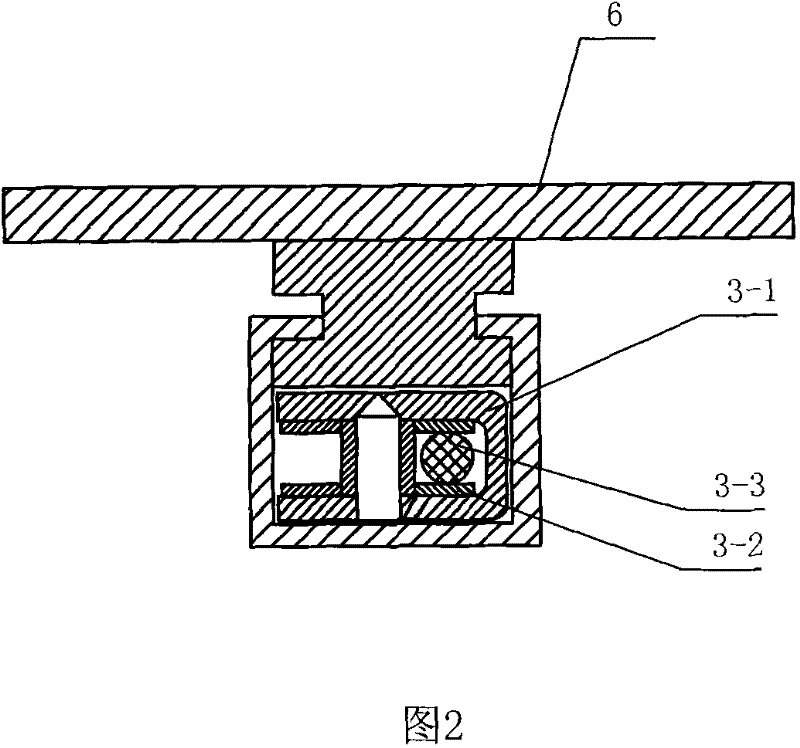

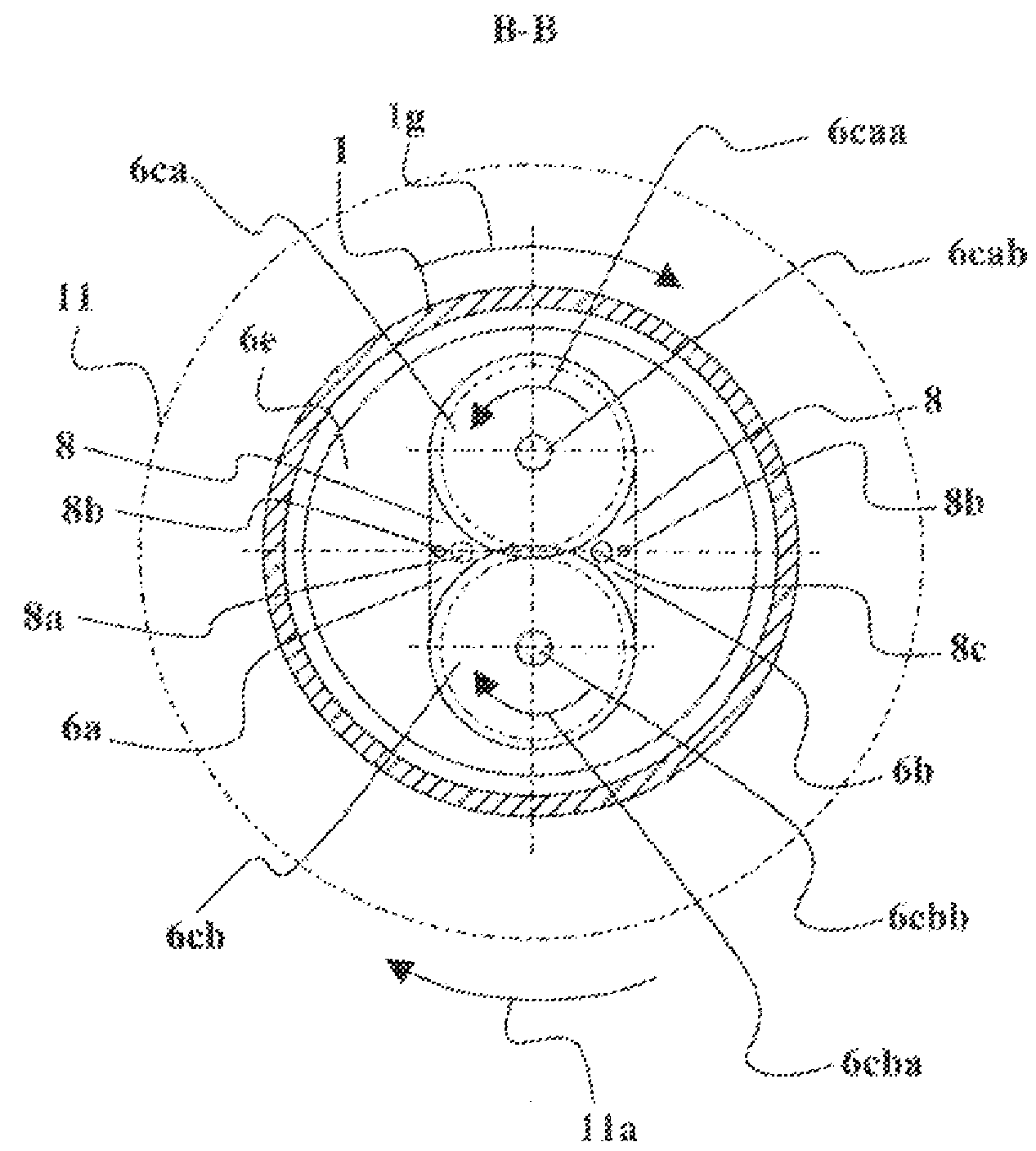

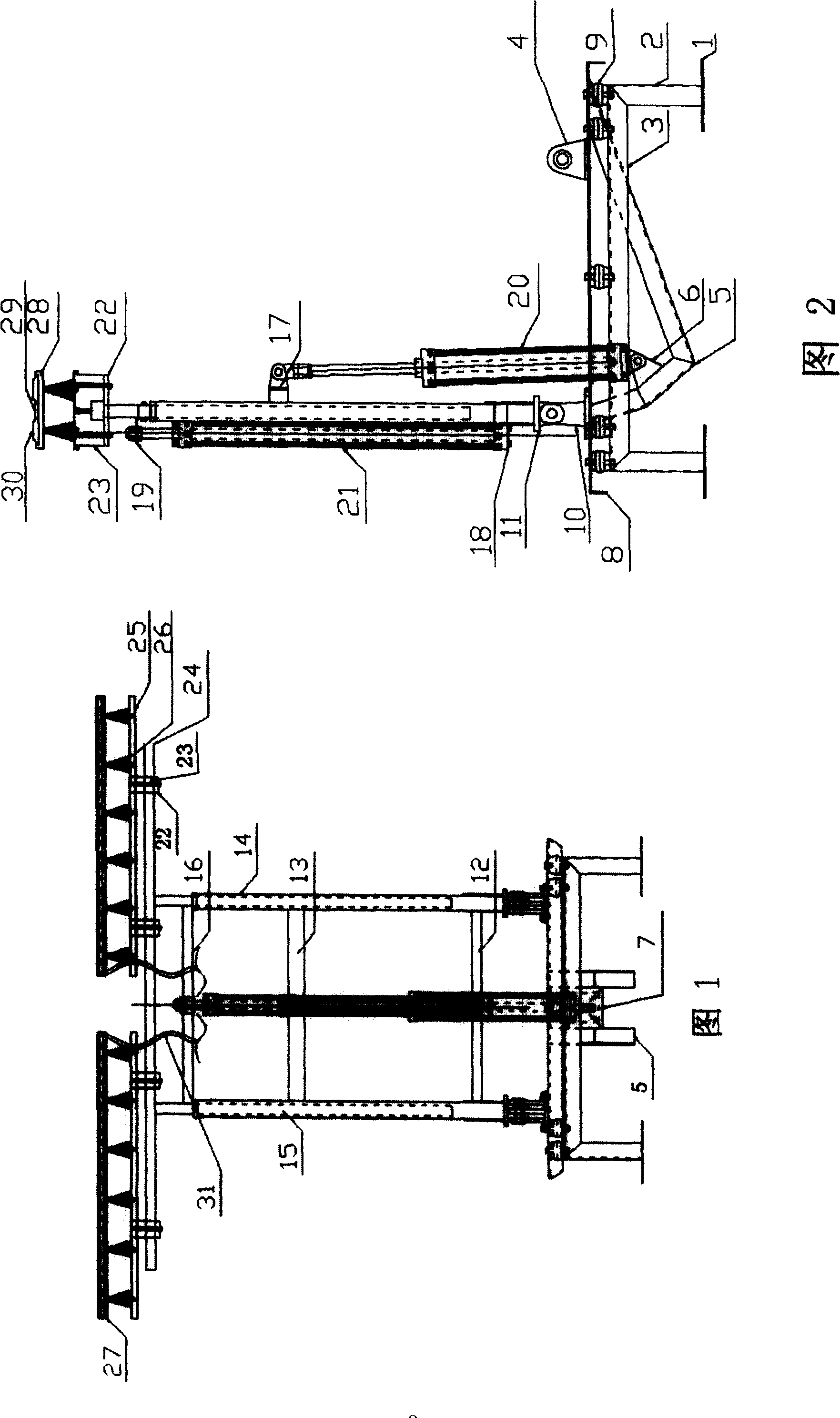

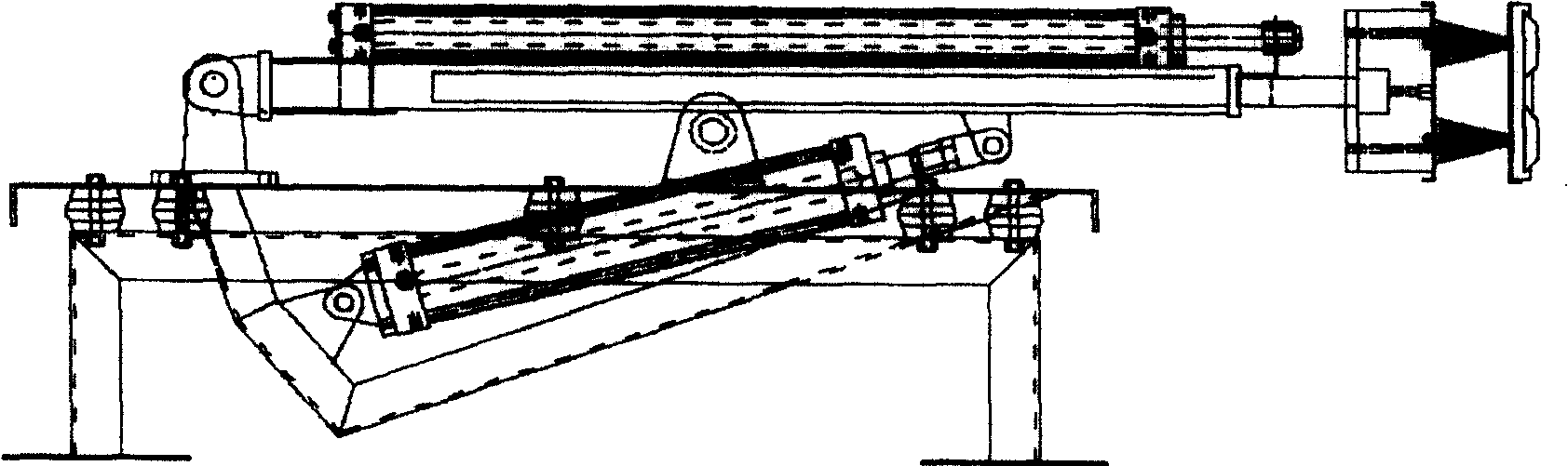

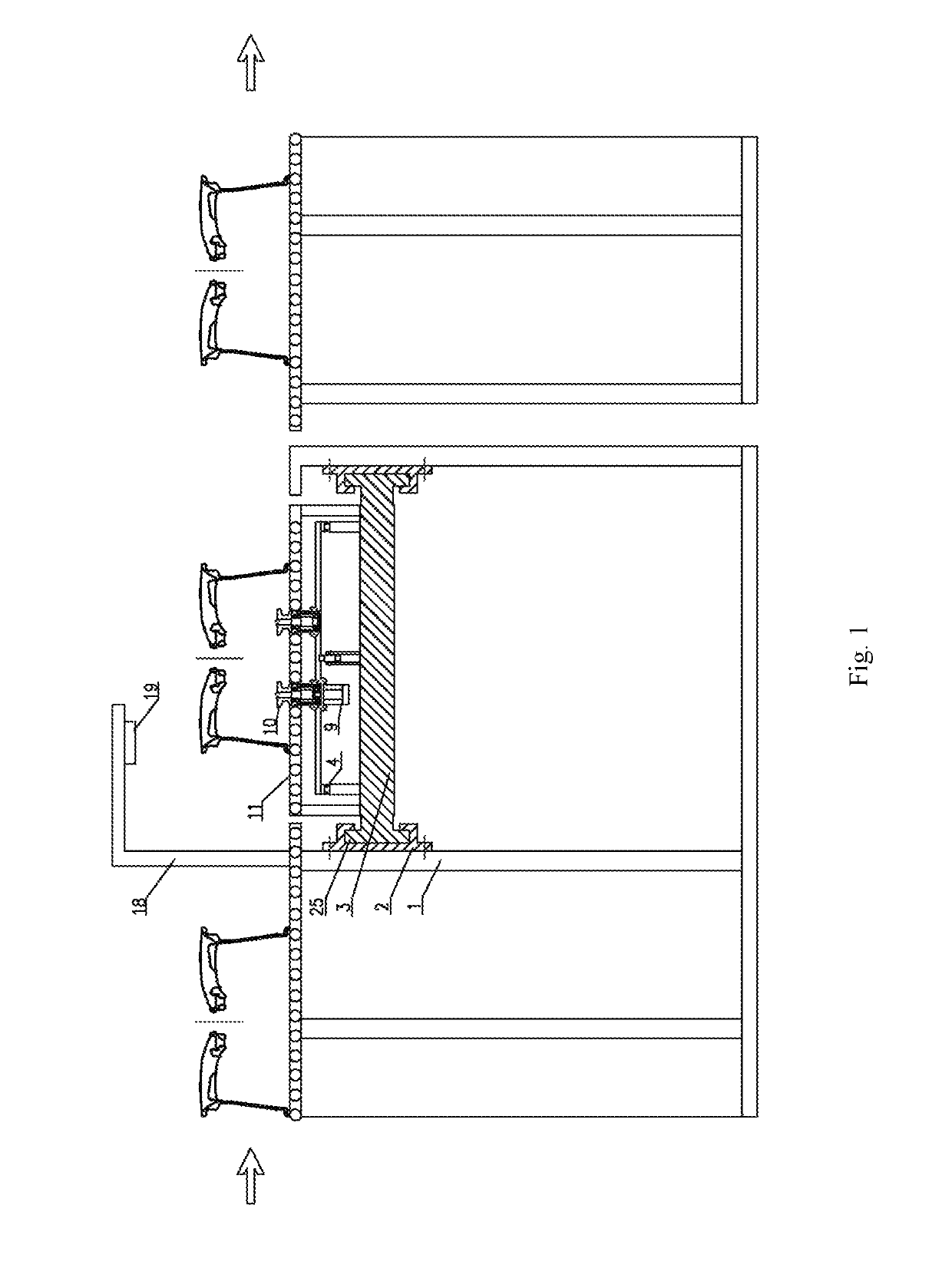

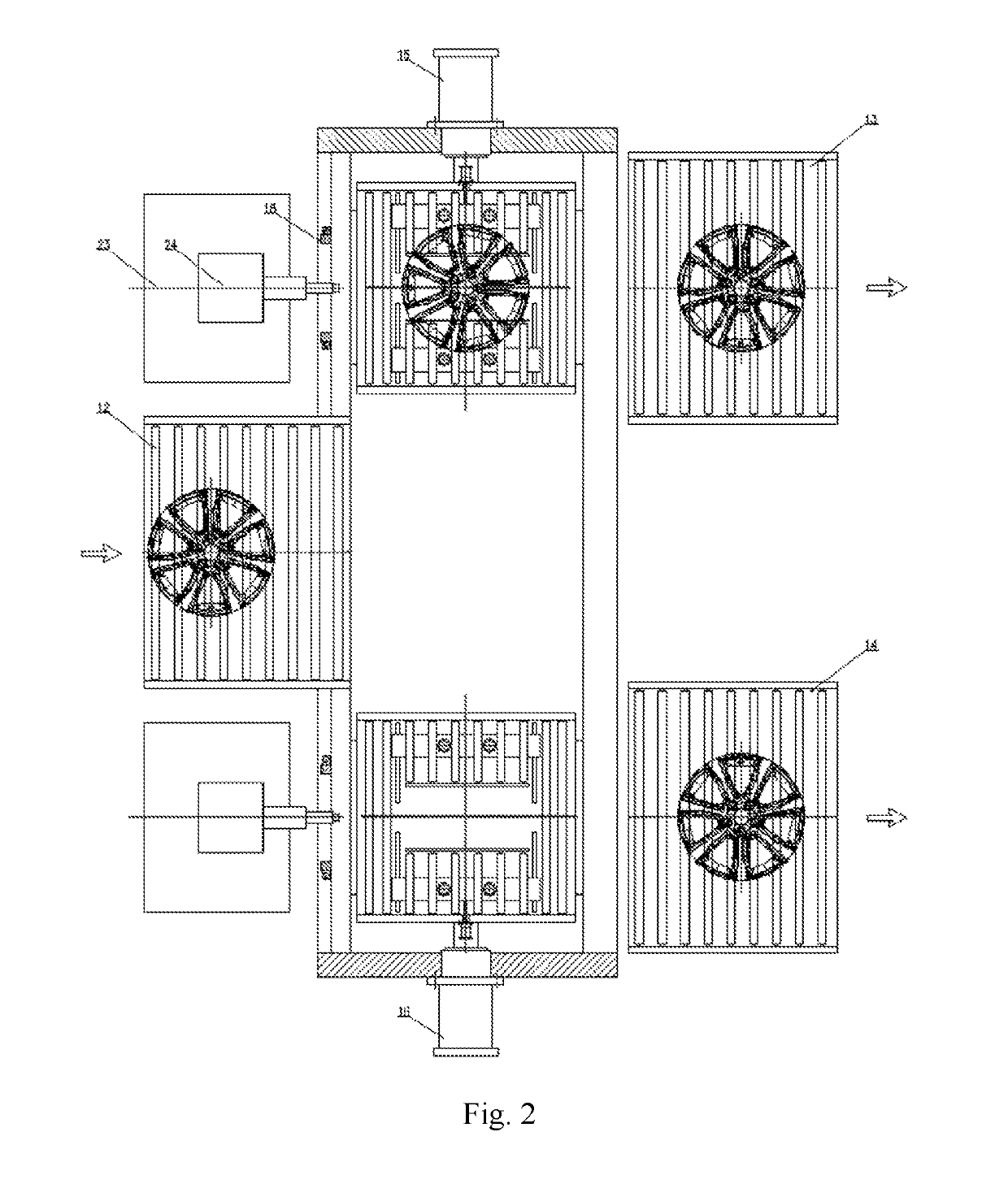

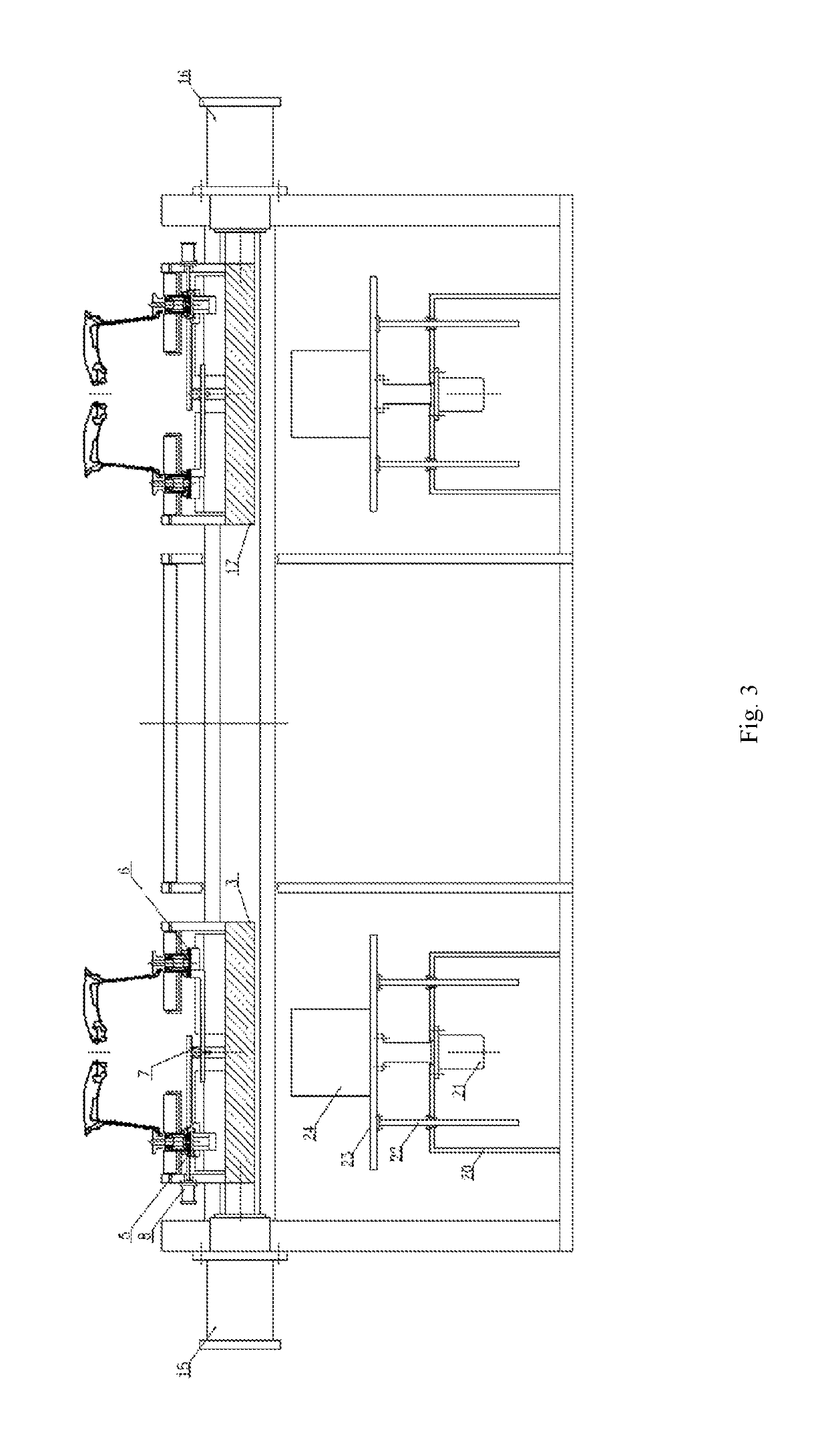

Provided is a wheel front burr removing device. The wheel front burr removing device is composed of a rack (1), a lifting cylinder (2), a supporting frame (3), a guiding column (4), a guide sleeve (5), a lifting platform (6), a brush (7), a bearing seat (8) and the like. A servo motor I (11) is fixed to the side of the rack (1), the output end of a motor is connected with an overturning platform (10) through a coupling (12), the middle part of the overturning platform (10) is a cuboid, the left side and the right side of the overturning platform are circular shafts, and the shafts are matched with bearings (9); the lower part and the upper part of the overturning platform (10) are exactly the same, and wheel positioning and clamping rotation systems are symmetrically distributed; and the overturning platform (10) is controlled by the servo motor I (11) to rotate 180 degrees at a time, and cyclic switching of the positioning and clamping rotation system at the upper part of the overturning platform (10) and the positioning and clamping rotation system at the lower part of the overturning platform (10) is realized. According to the wheel front burr removing device, burrs at the front faces of wheels can be thoroughly removed, and the wheel front burr removing device has the characteristics of being short in beat, high in efficiency, novel in layout, advanced in technology, high efficient and practical.

Owner:CITIC DICASTAL

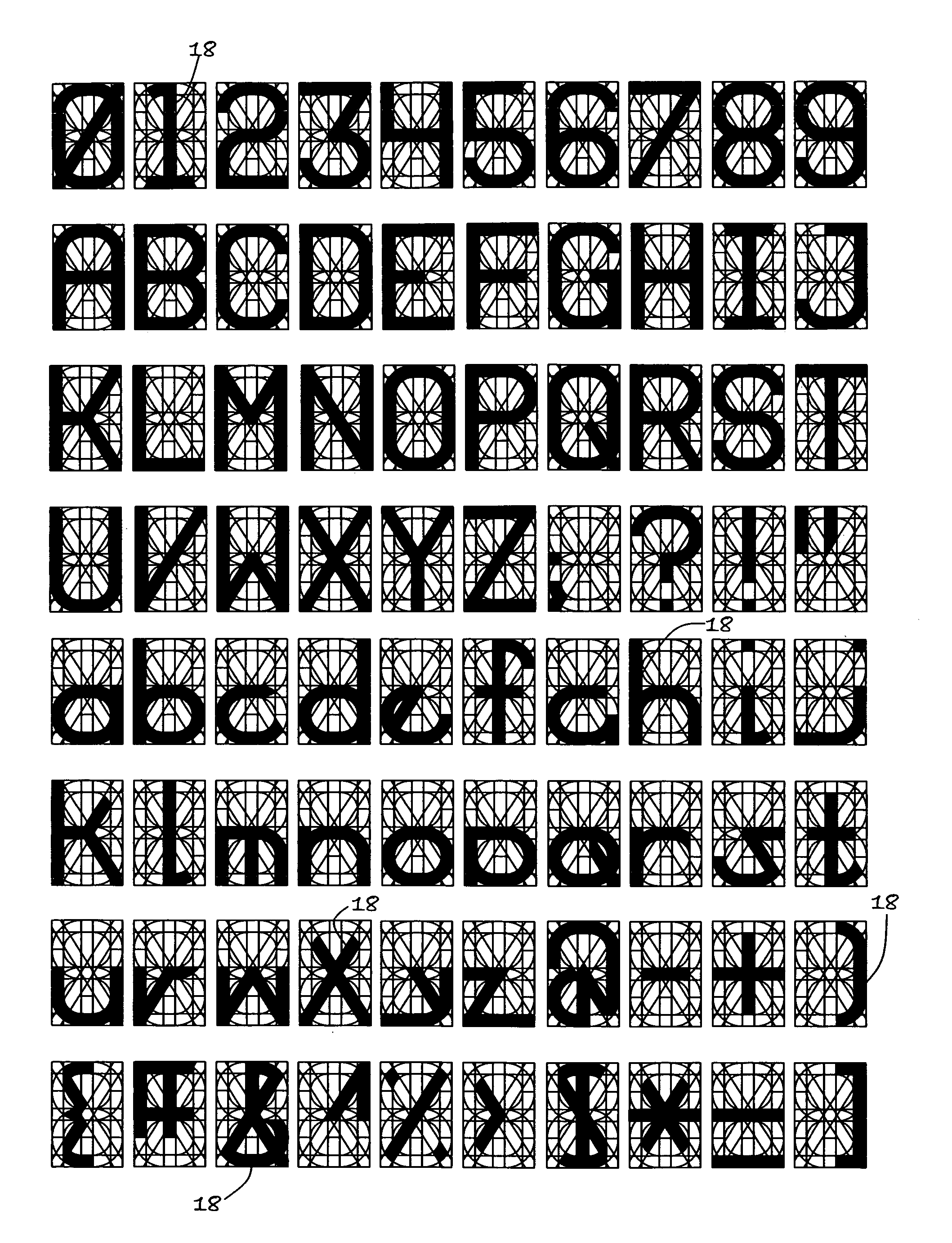

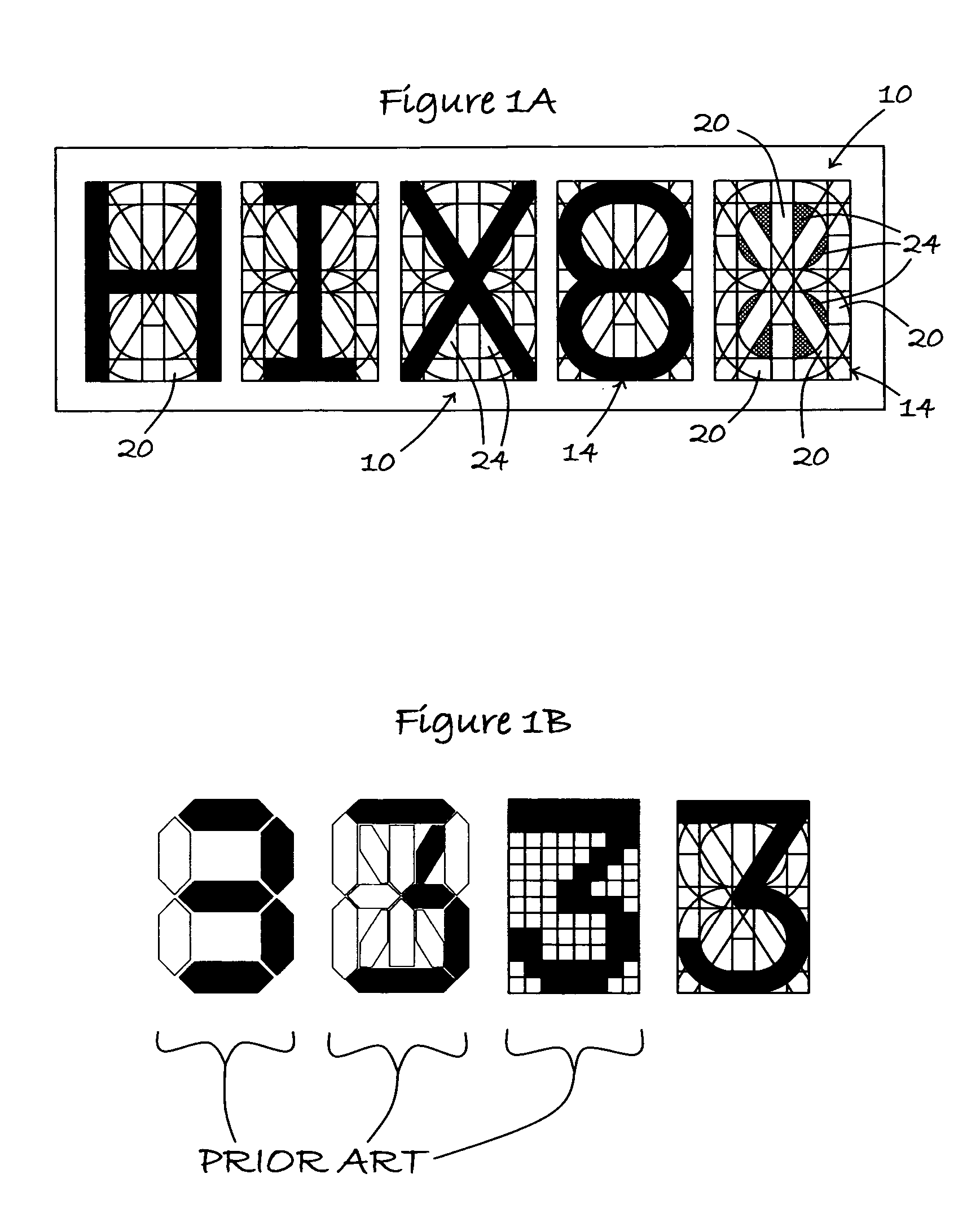

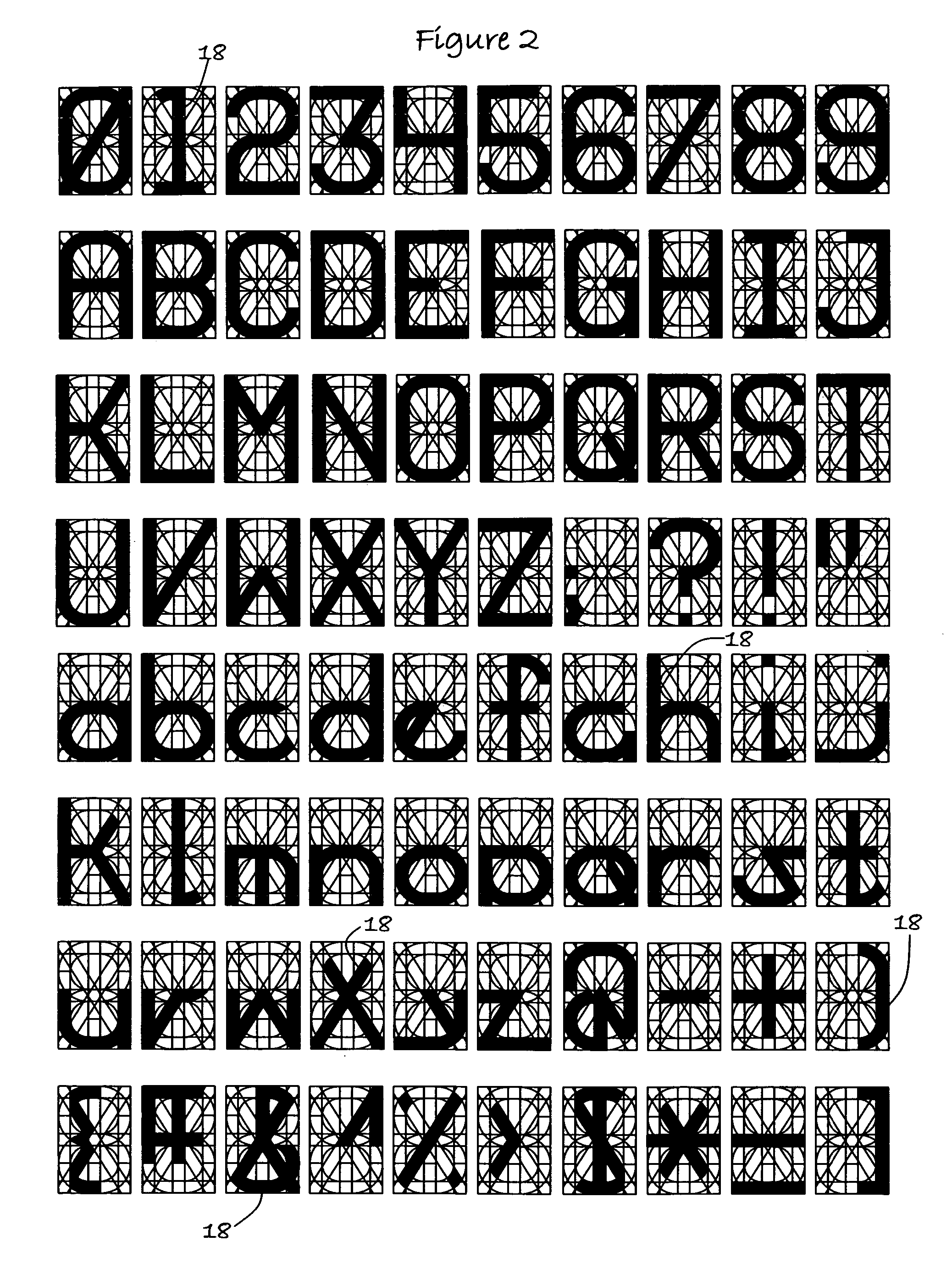

High resolution, low segmentation alphanumeric display for electronic devices

InactiveUS20050104803A1Improve efficiencyNew layoutStatic indicating devicesIdentification meansComputer graphics (images)Display device

A high resolution alphanumeric character display unit is disclosed which has a multi-segmented display screen. The display screen is a mosaic pattern of activatable display segments and dead spaces. The combined dead space accounts for less than 25% of the screen pattern. The activatable display segments have various non-uniform and curvilinear shapes and provide a high resolution alphanumeric character display.

Owner:TUASON CHRISTOPHER

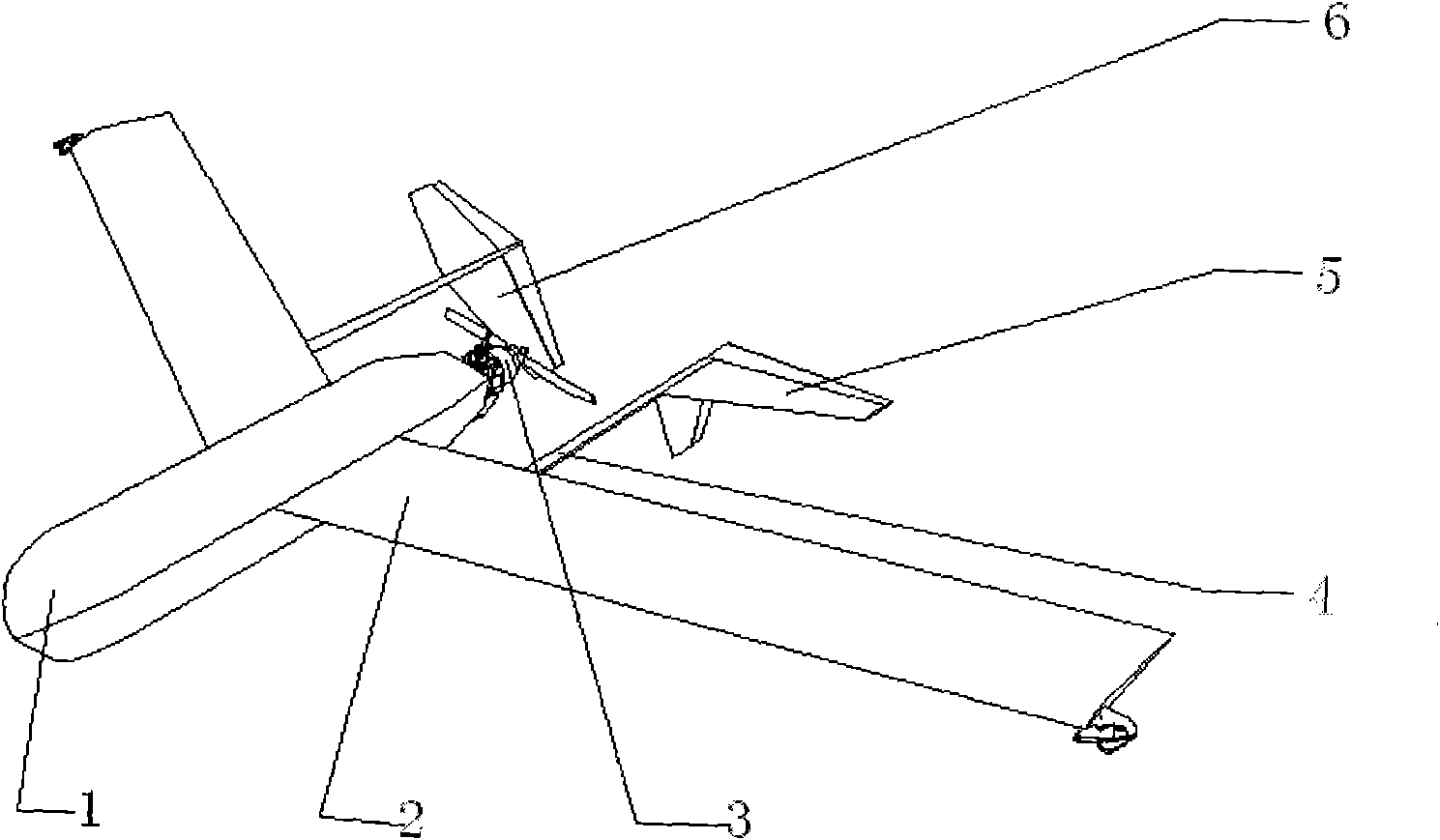

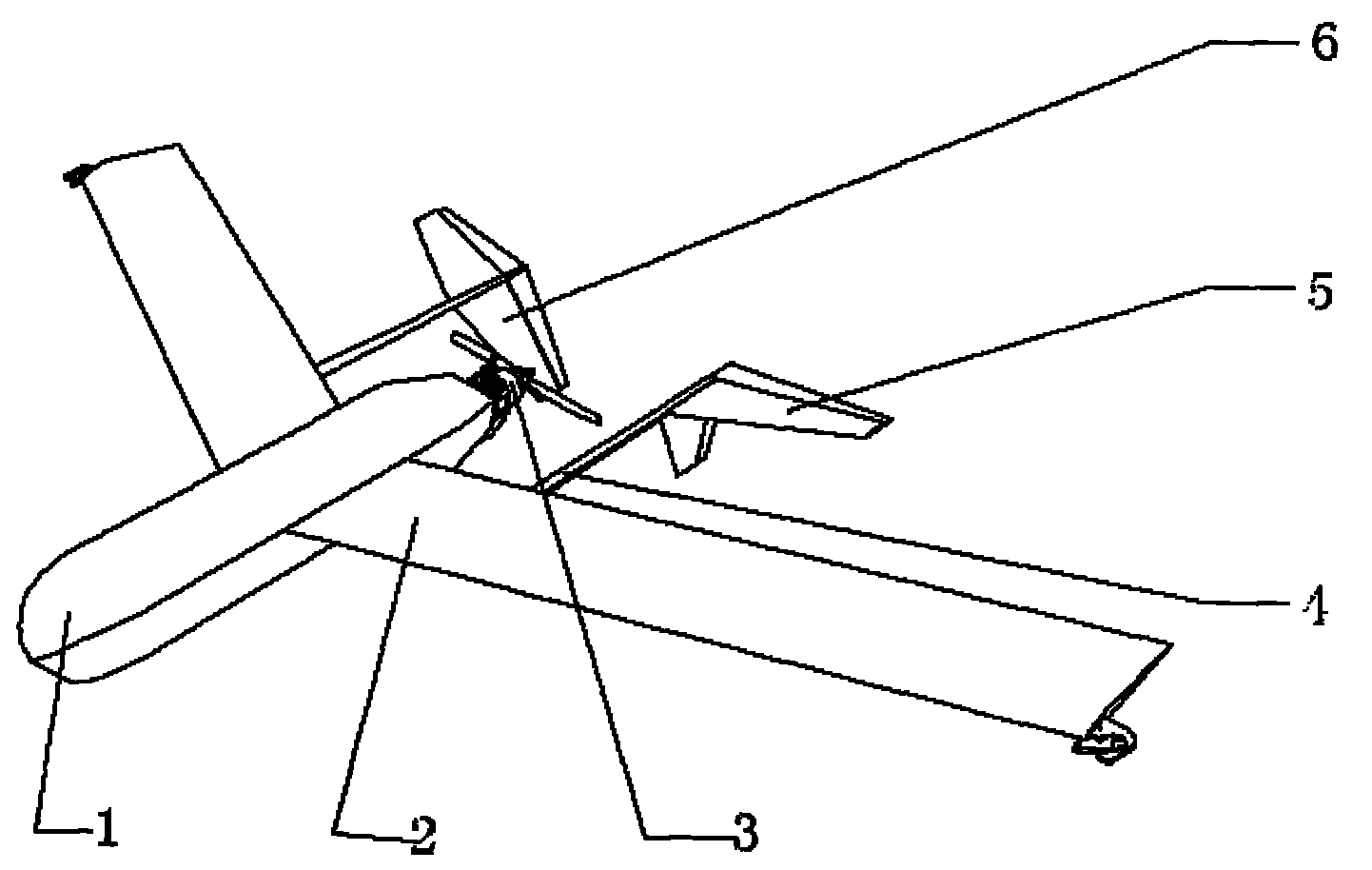

Small UAV aerodynamic layout for vertical rope-type recovery

InactiveCN101774429ANew layoutStrong wind resistanceActuated automaticallyWing adjustmentsJet aeroplaneLoad capacity

The invention relates to a small UAV aerodynamic layout for vertical rope-type recovery on a moving base within a small spatial scope, which comprises a UAV body, wings and an engine tail wing; the wings are upper single wings, and the installation angle is 3 degrees; an engine is arranged at the tail of the UAV body; the layout is characterized in that the aspect ratio of the wings is 9, a sweepback method is adopted, and a sweepback angle is 23 degrees; the lower surface of the middle part of the left wing or the right wing is provided with a horizontal strut for installing the tail wing; the rear end of the horizontal strut is provided with a horizontal tail wing and a vertical tail which is arranged in an inverted way, and the vertical tail is inclined inwards for 15 degrees. Compared with the prior art, the small UAV aerodynamic layout for vertical rope-type recovery has the advantages of reducing the number of operators, and improving the effective load capacity and the wind resistant capability of an airplane.

Owner:AVIC CHENGDU AIRCRAFT DESIGN & RES INST

Bi slide cylinder horizontal bipolar current collector of electrially-propelled vehicle

ActiveCN100999186AReduce volumeReduce weightNon-rotary current collectorPower current collectorsElectricityEngineering

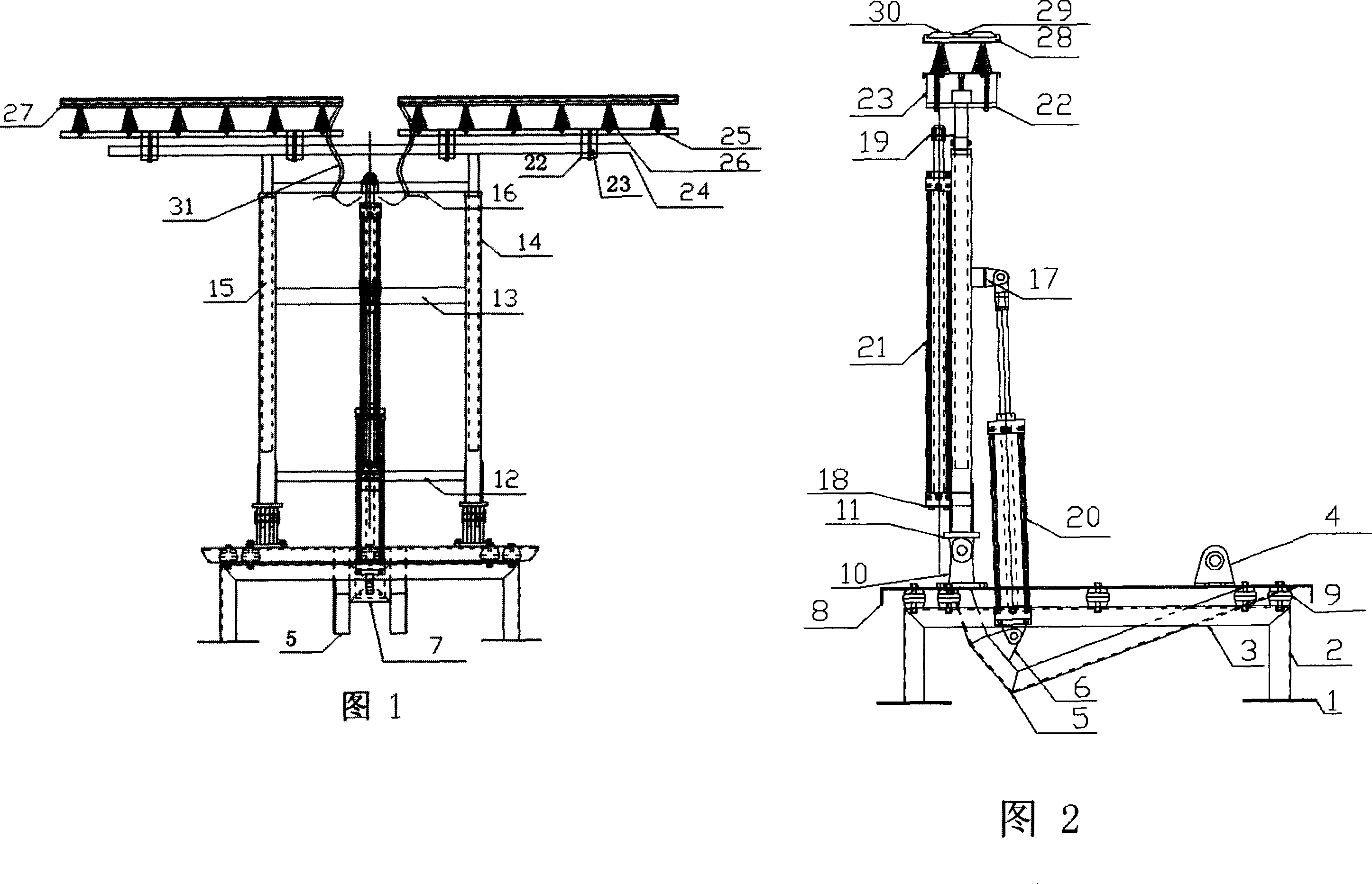

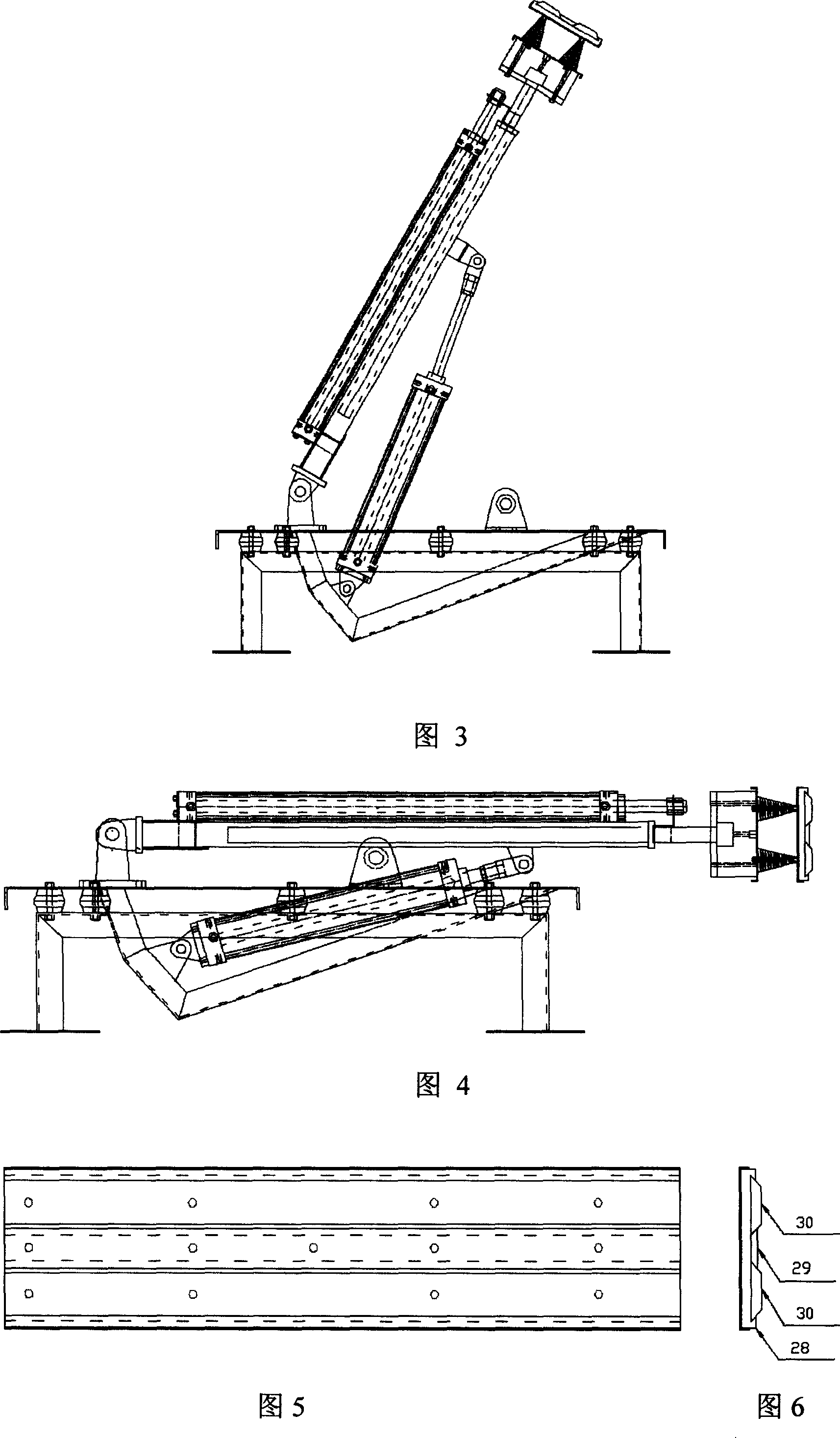

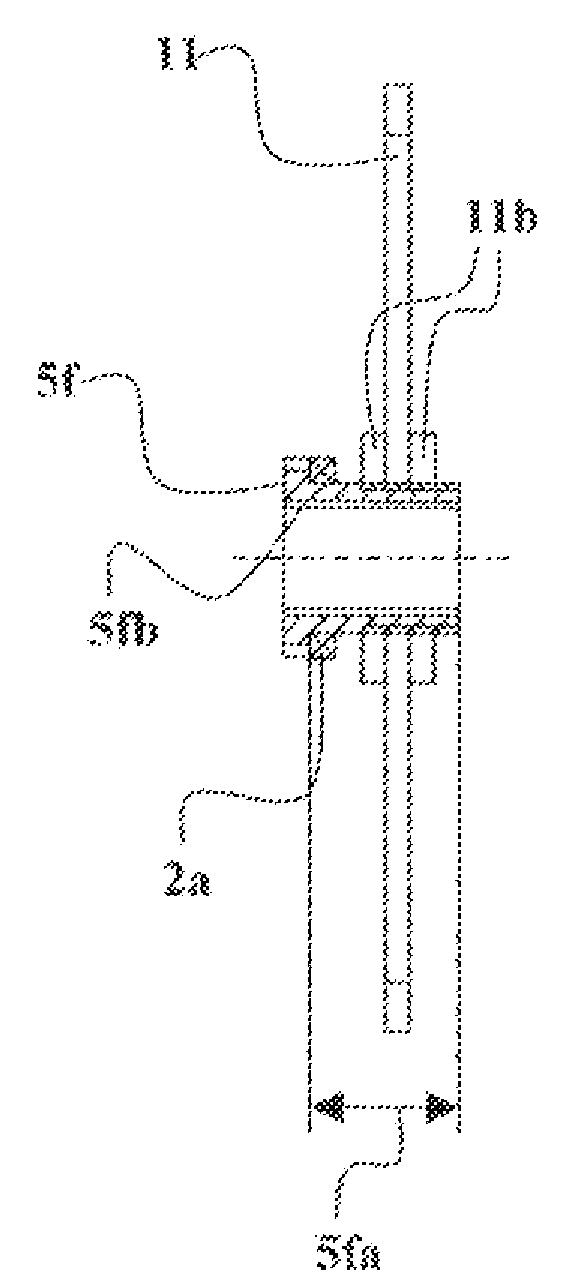

The present invention relates to a double-sleeve horizontal bipolar receiving device for charging trolley car. It is characterized by that it includes base support assembly positioned on the top portion of trolley car body, on the base support assembly a slide sleeve and a two-stage cylinder are movably and fixedly connected, said slide sleeve is formed from external sleeve and internal sleeve, said two-stage cylinder is connected with said slide sleeve and can be used for driving said slide sleeve and making it be upwards and downward moved. Said slide sleeve also is movably connected with one-stage cylinder, said one-stage cylinder is movably connected with said slide sleeve and can be used for supporting said slide sleeve and making it be rotated in a certain angle range, the top portion of said slide sleeve is fixedly connected with the receiver.

Owner:上海中上汽车科技有限公司

Smart socket

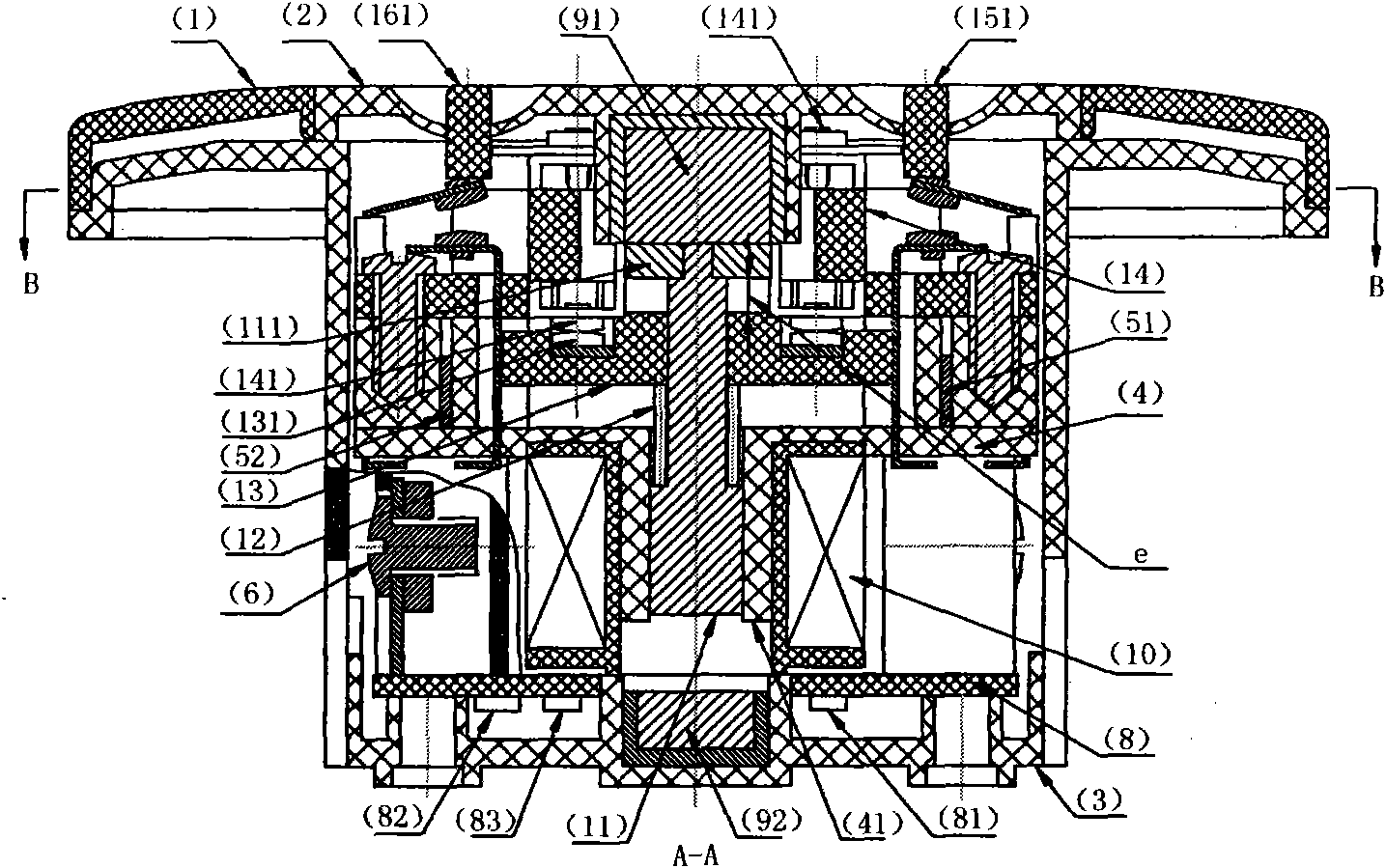

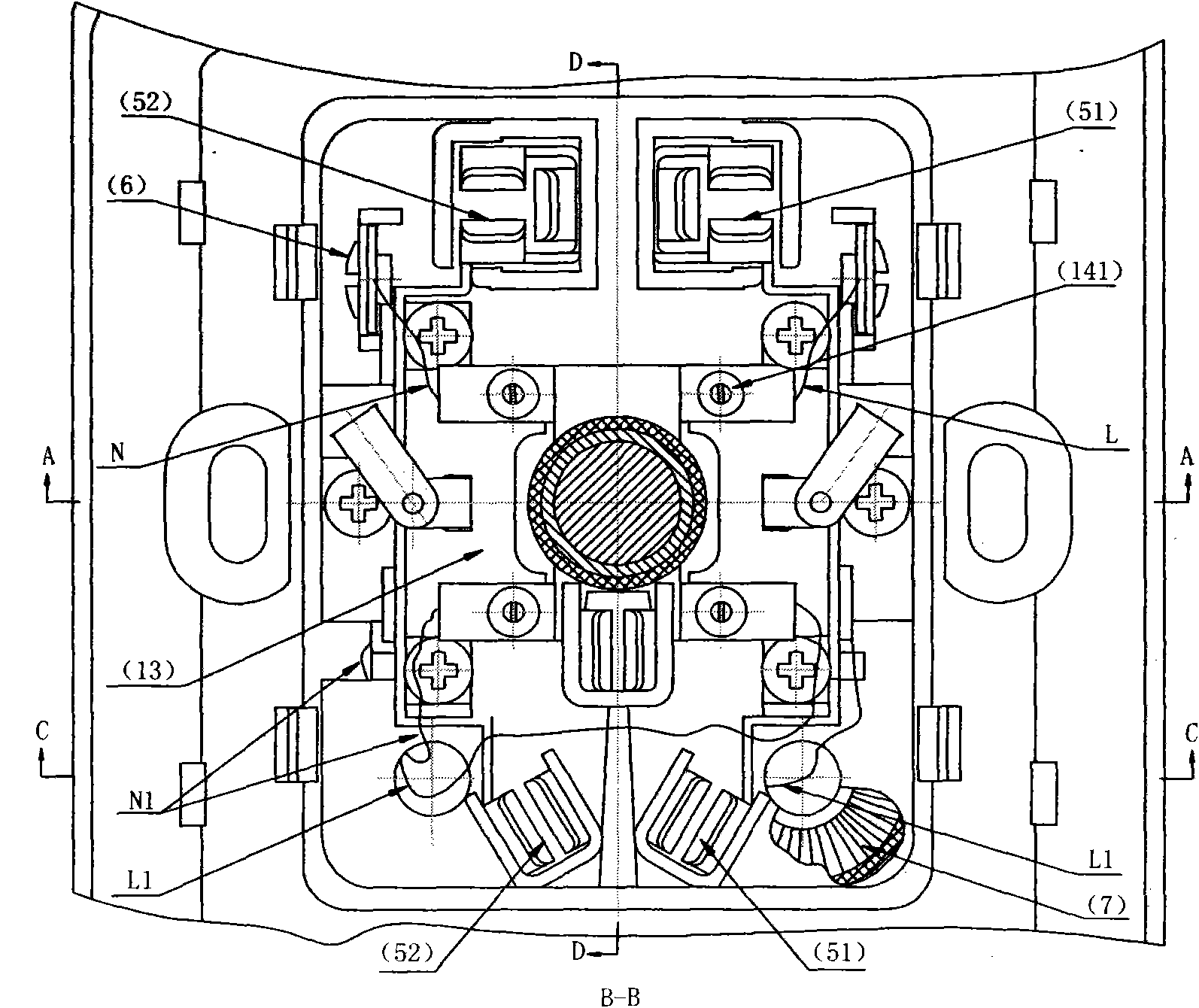

InactiveCN102148452AManagement scienceEasy to manageProgramme controlComputer controlContact pressurePower grid

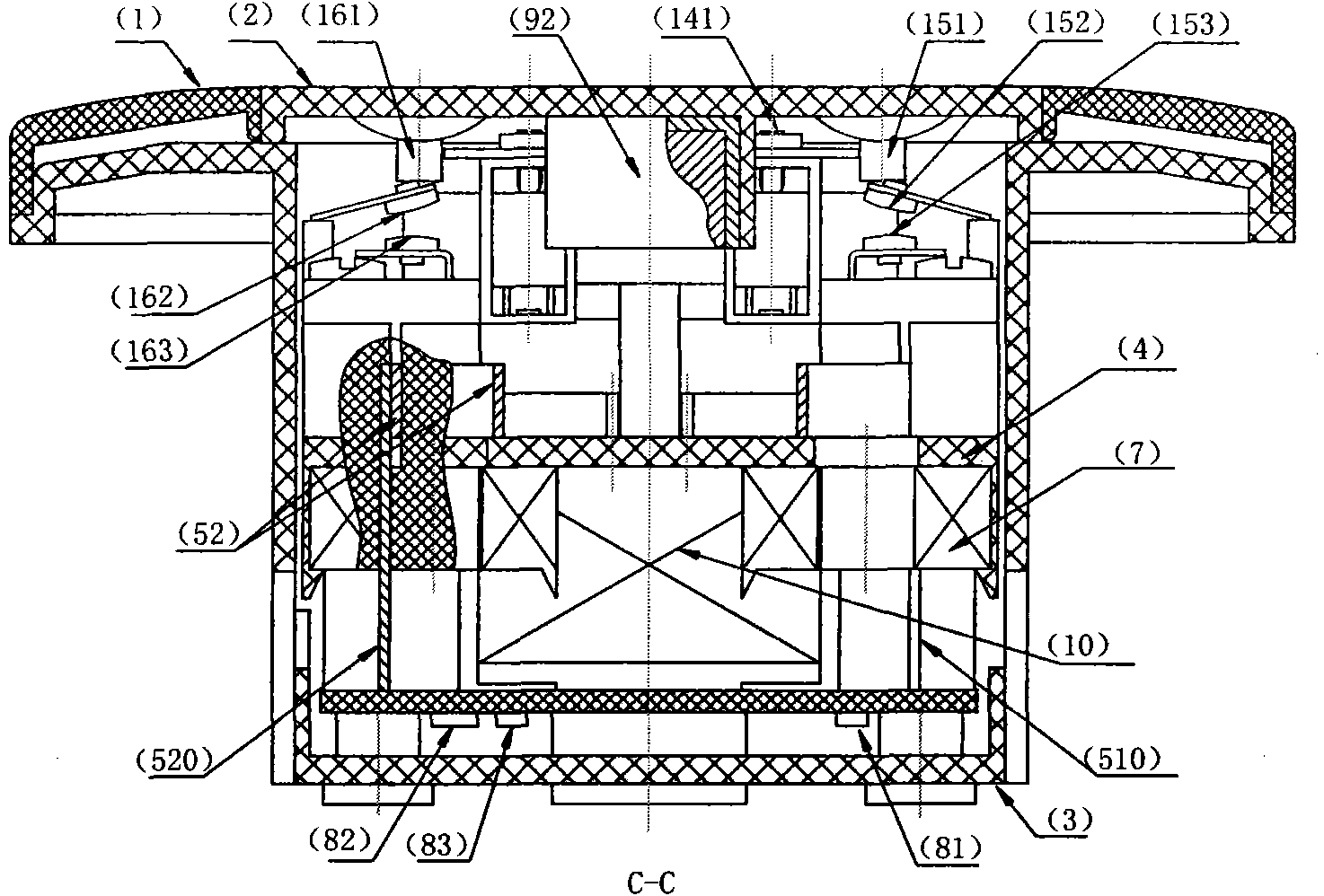

The invention provides a smart socket, which comprises a large panel (1), a small panel (2), a bottom box (3), a bearing plate (4), a right plug bush (51), a left plug bush (52), a connecting terminal (6), a real-time detection device (7), a circuit board (8), an upper permanent magnet (91), a lower permanent magnet (92), a coil (10), a movable core (11), a contact pressure regulation spring (12), a moving contact part (13), a fixed contact part (14), a testing device with a testing button (151), and a resetting device with a resetting button (161), wherein the circuit board (8) is provided with electronic components; the back of the bearing plate (4) is provided with a cylindrical pipe (41) vertically connected with the bearing plate; and the inner chamber of the cylindrical pipe (41) runs through the front of the bearing plate (4). The smart socket provided by the invention is a digital, intelligent, integrated and networked terminal device with control, protection and monitoring functions, solves the problem of inadaptability of conventional packaged extensive management of a power grid requirement side to the development of a power grid, and makes the power grid requirement side enter the new stage of delicacy integrated management.

Owner:郑美华

Wheel front burr cleaning device

InactiveUS20180361527A1Improving paint spraying yieldReduced risk of corrosionEdge grinding machinesPolishing machinesCouplingEngineering

Disclosed is a wheel front burr cleaning device. The device is composed of a rack (1), a lifting cylinder (2), a support frame (3), guide posts (4), guide sleeves (5), a lifting table (6), a brush (7), bearing seats (8) and the like, wherein a servo motor I (11) is fixed on the side of the rack (1), the output end of the motor is connected with a turnover platform (10) via a coupling (12), the middle part of the turnover platform (10) is a cuboid, circular shafts are arranged on the left side and right side of the turnover platform (10), and the shafts are matched with bearings (9); and the structures above and below the turnover platform (10) are completely consistent, wheel positioning clamping rotating systems are distributed symmetrically, and the servo motor I (11) controls the turnover platform (10) to rotate 180 degrees every time, thereby realizing cyclic switching of the positioning clamping systems above and below the turnover platform (10).

Owner:CITIC DICASTAL

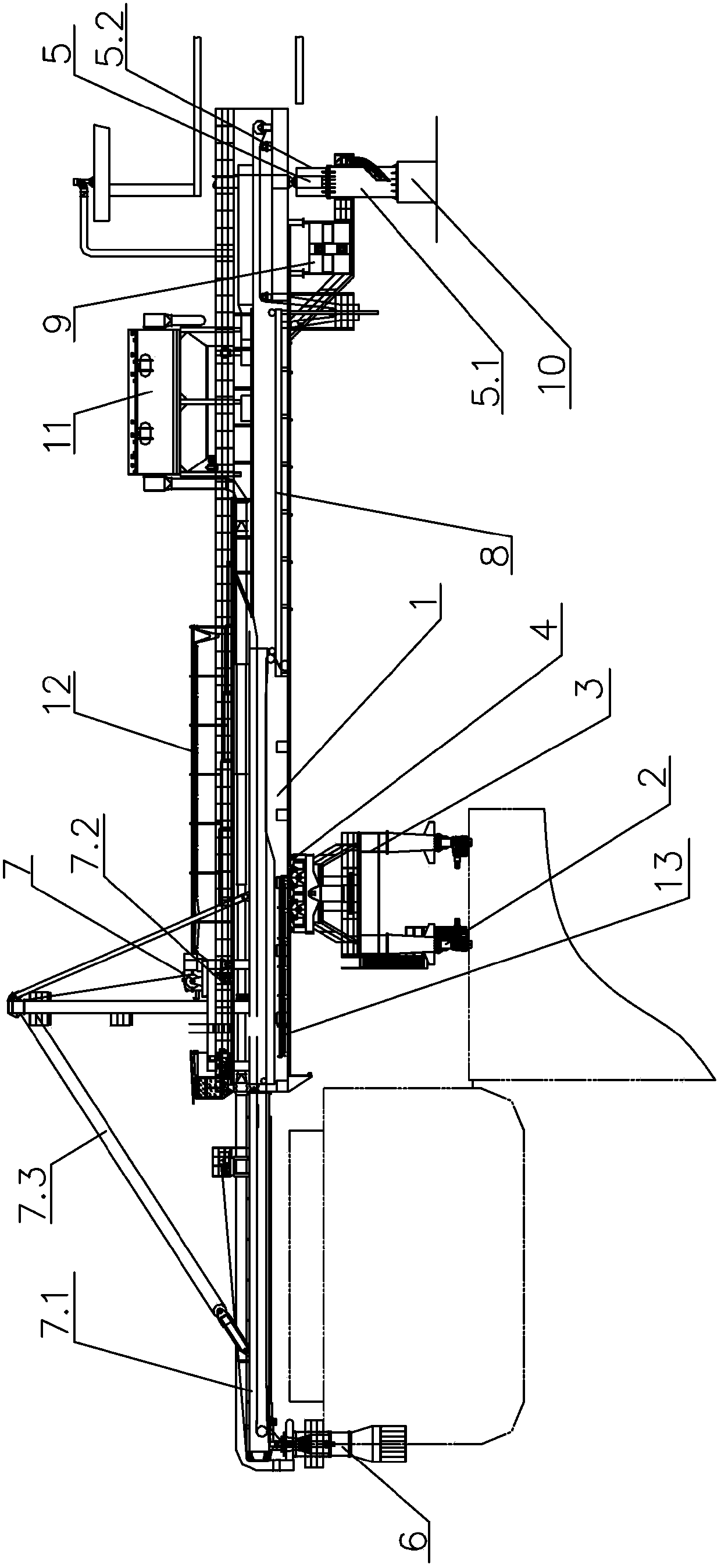

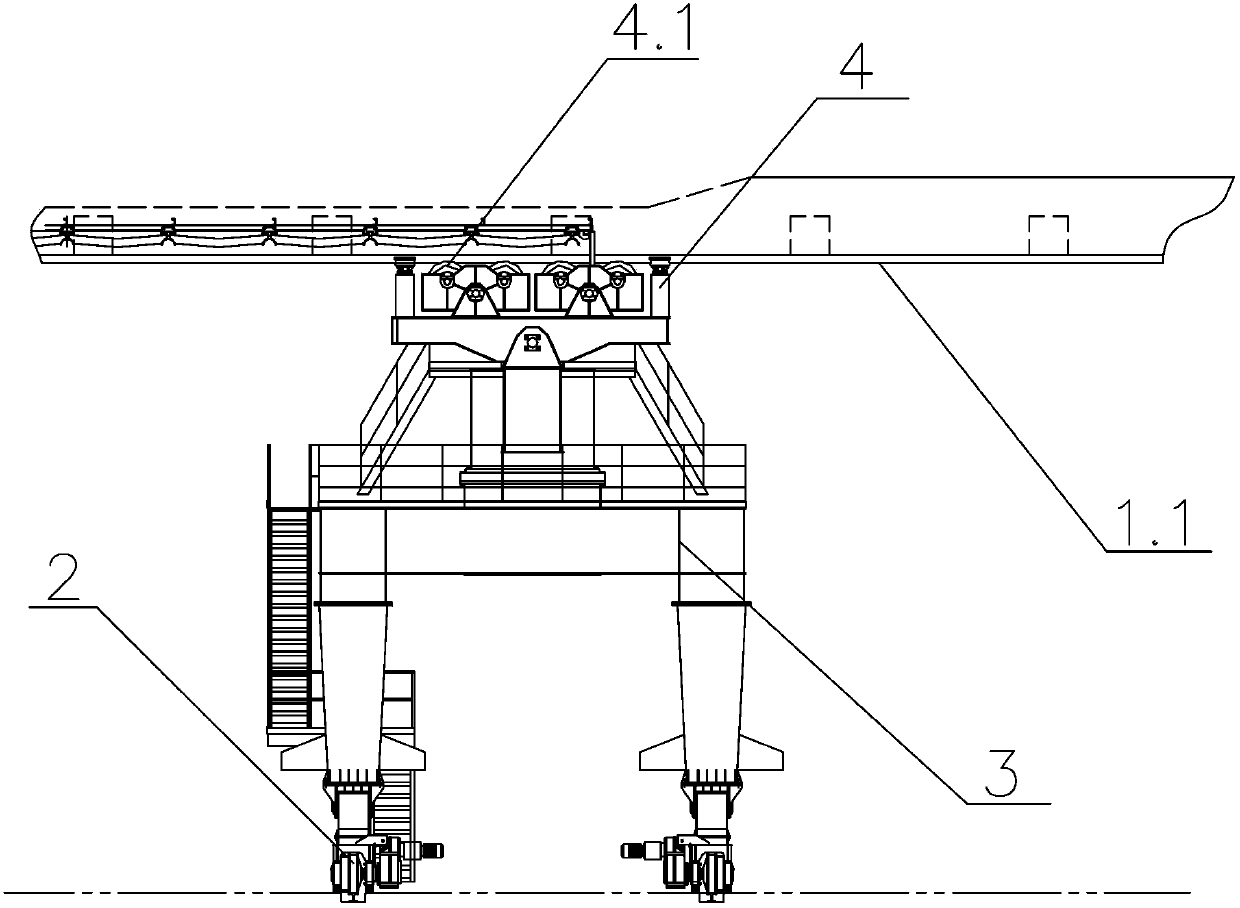

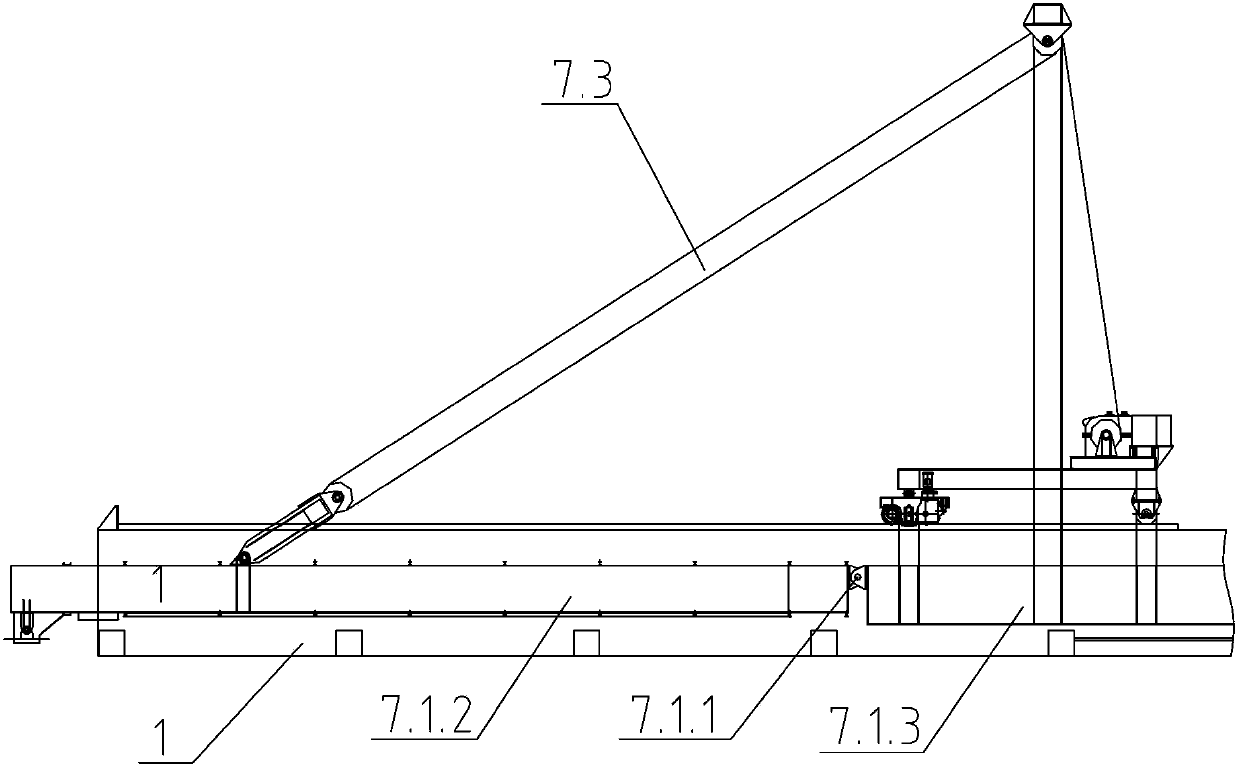

Environment-friendly linear forward swing type bulk cement ship loader

The invention discloses an environment-friendly linear forward swing type bulk cement ship loader. The environment-friendly linear forward swing type bulk cement ship loader comprises a swing arm, a girder travelling mechanism, a gantry frame, a front support system, a rear support system, a telescopic sliding tube system, a cantilever system, a belt conveyer system and an electric transmission system. The cantilever of the cantilever system is perpendicular to the travelling rail of the girder travelling mechanism; the rear support system comprises a fixed support and a rotating support which are connected through a rotating bearing, wherein the fixed support is fixedly connected with a poured rear foundation platform, and the rotating support is connected with the swing arm; the swing arm is driven by the girder travelling mechanism to swing around the rear support system; the front support system is connected with the gantry frame through the rotating bearing; the support pulley set of the front support system moves along the linear rail arranged on the lower flange plate of the swing arm. Due to the fact that the tail portion and other taking points are all fixed, the environment-friendly linear forward swing type bulk cement ship loader can be completely sealed in structure, facilitates efficient dust absorption of a dedusting system, thereby fully achieving the aim of environment-friendly and energy-saving ship loading.

Owner:长江航运科学研究所有限公司

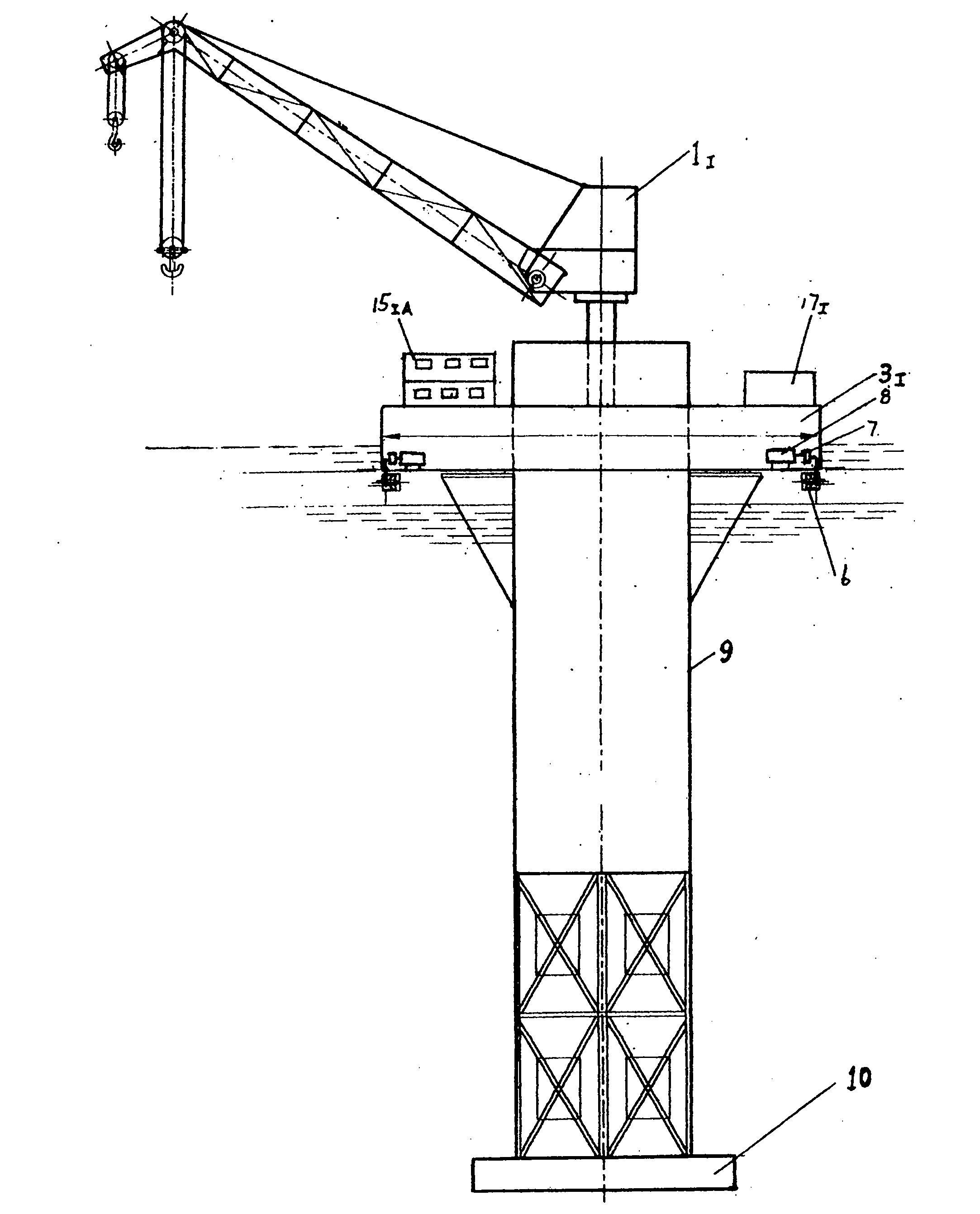

Novel Spar deep sea oil-exploration and oil-extraction engineering platform

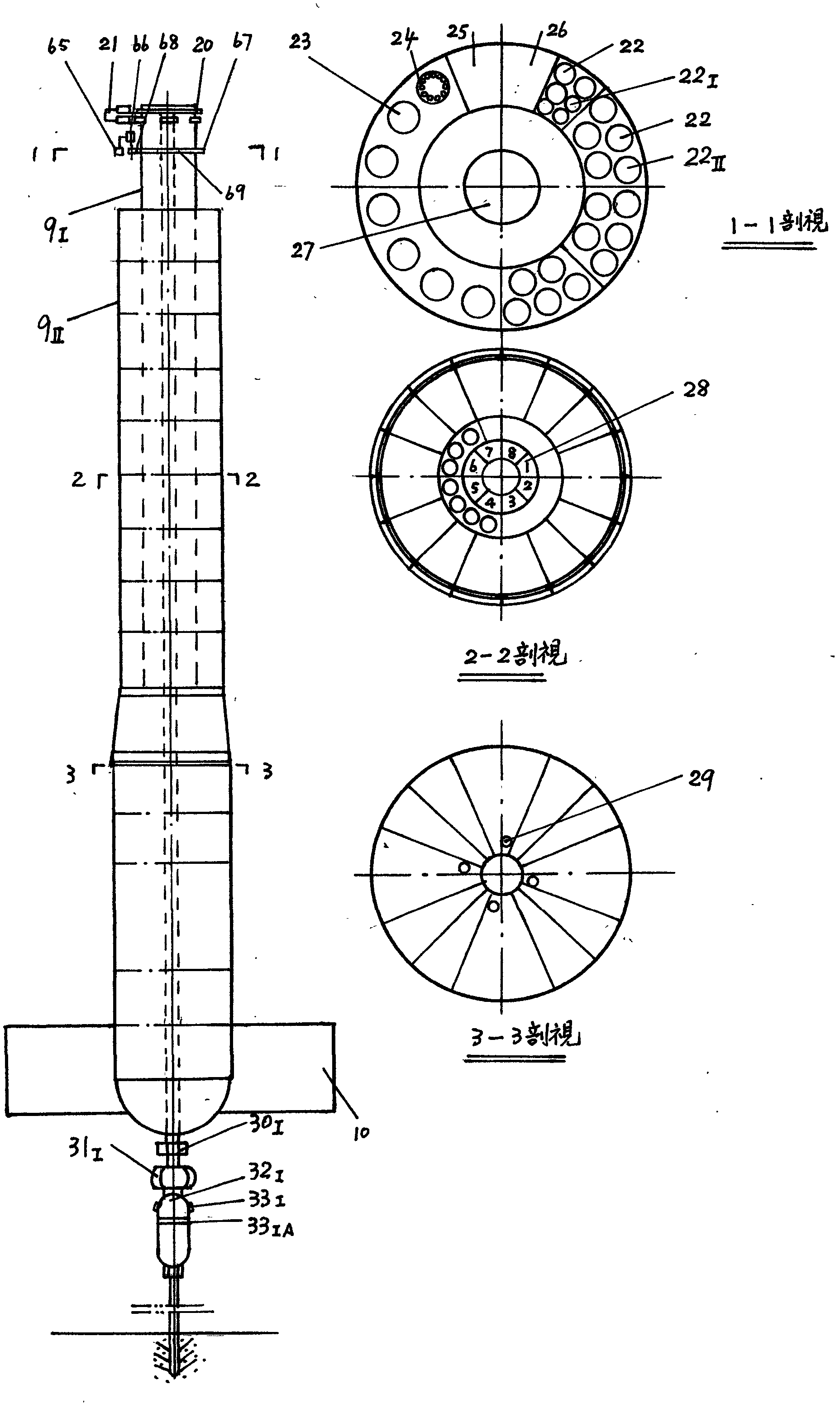

InactiveCN102644453AIncrease flexibilityFrequent movementDerricks/mastsFluid removalAutomatic controlGravity center

The invention provides a novel Spar deep sea oil-exploration and oil-extraction engineering platform which respectively has oil-exploration and oil-extraction functions, wherein an exploration platform adopts a 360-degree full-rotation contra-rotating propeller (or serial propeller) power positioning and propelling device and an oil-extraction platform is provided with a mooring rope, so that an efficient, energy-saving and flexible Spar scheme is provided. The gravity center of a Spar platform is designed to be far lower than a floating center and is unconditionally stable so that a hundred-year mega storm can be resisted and impacted. The arrangement of a drilling rod and a marine riser is compact and novel so as to conveniently operate a mechanical hand of a hydraulic crane; the drilling rod and the marine riser are conveyed into the center of a wellhead through an eccentric wheel of a hydraulic rotary mechanism to be put down and be connected in a butted joint manner, and are automatically controlled by a central control room. The Spar platform is controlled by double wellheads and double valves; and a sea floor wellhead and a seabed marine riser are tightly sealed so as to effectively prevent seawater from entering and preventing oil from being leaked. The oil is convenient to extract and the cost is reduced. A cylindrical structure has double layers so that the strength is high and the work of a central well is effectively protected to be safe and reliable. The total level of the novel Spar deep sea platform is higher than traditional platforms at home and abroad.

Owner:SHANGHAI HONGKOU DISTRICT HAILE APPL TECH RES INST

Rapid response electric heat exchanger

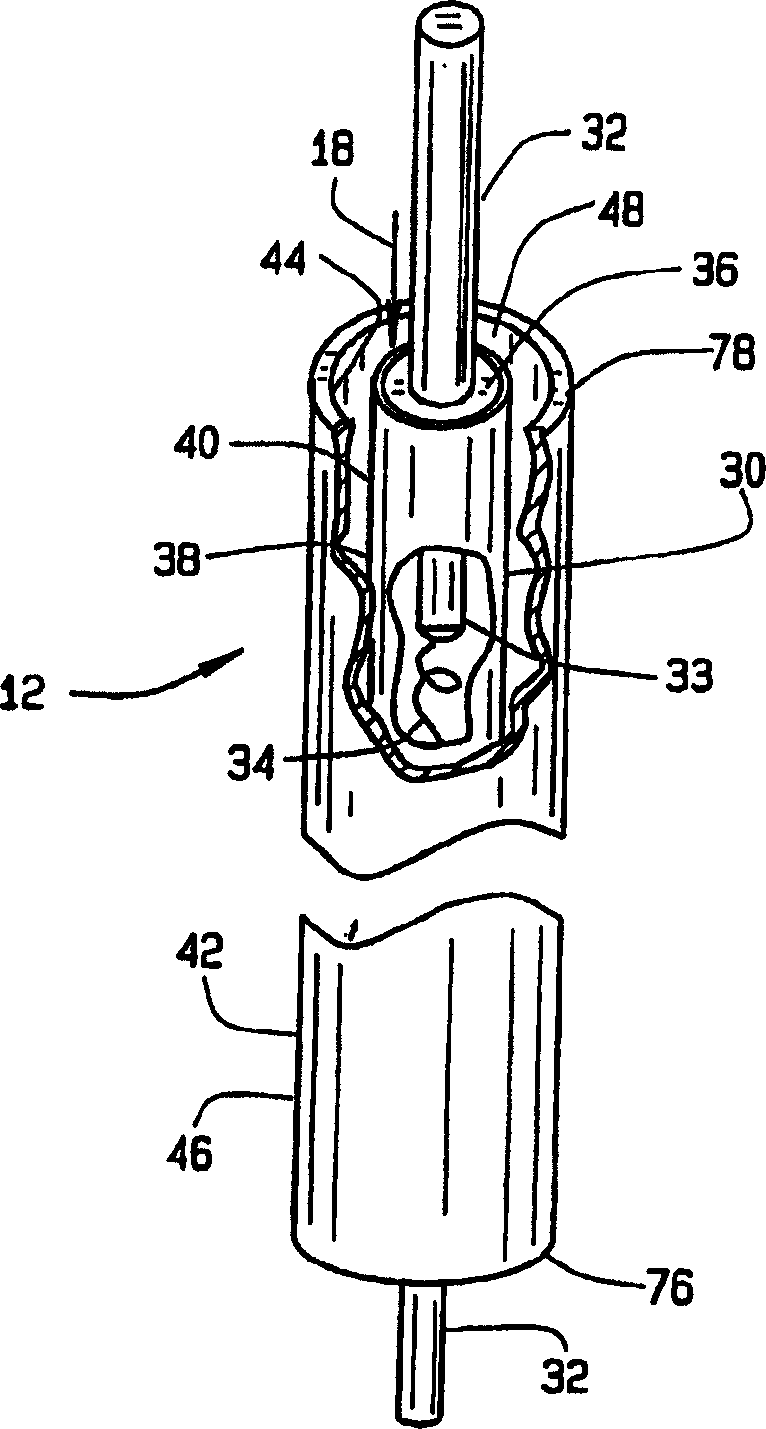

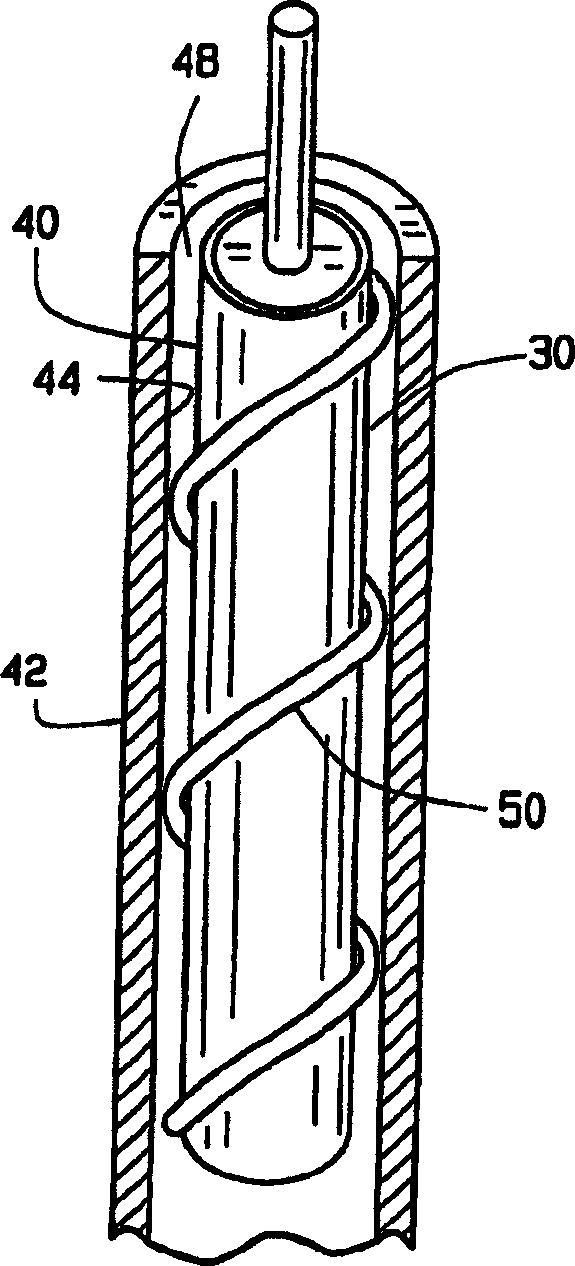

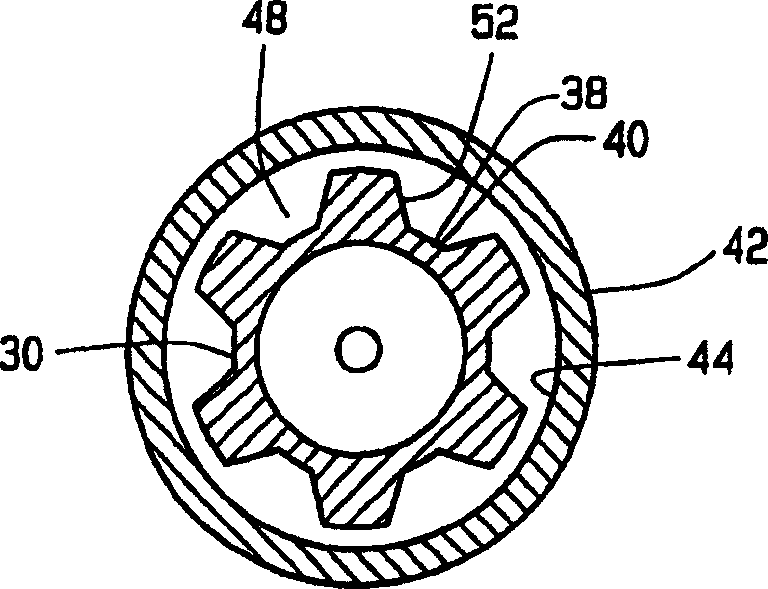

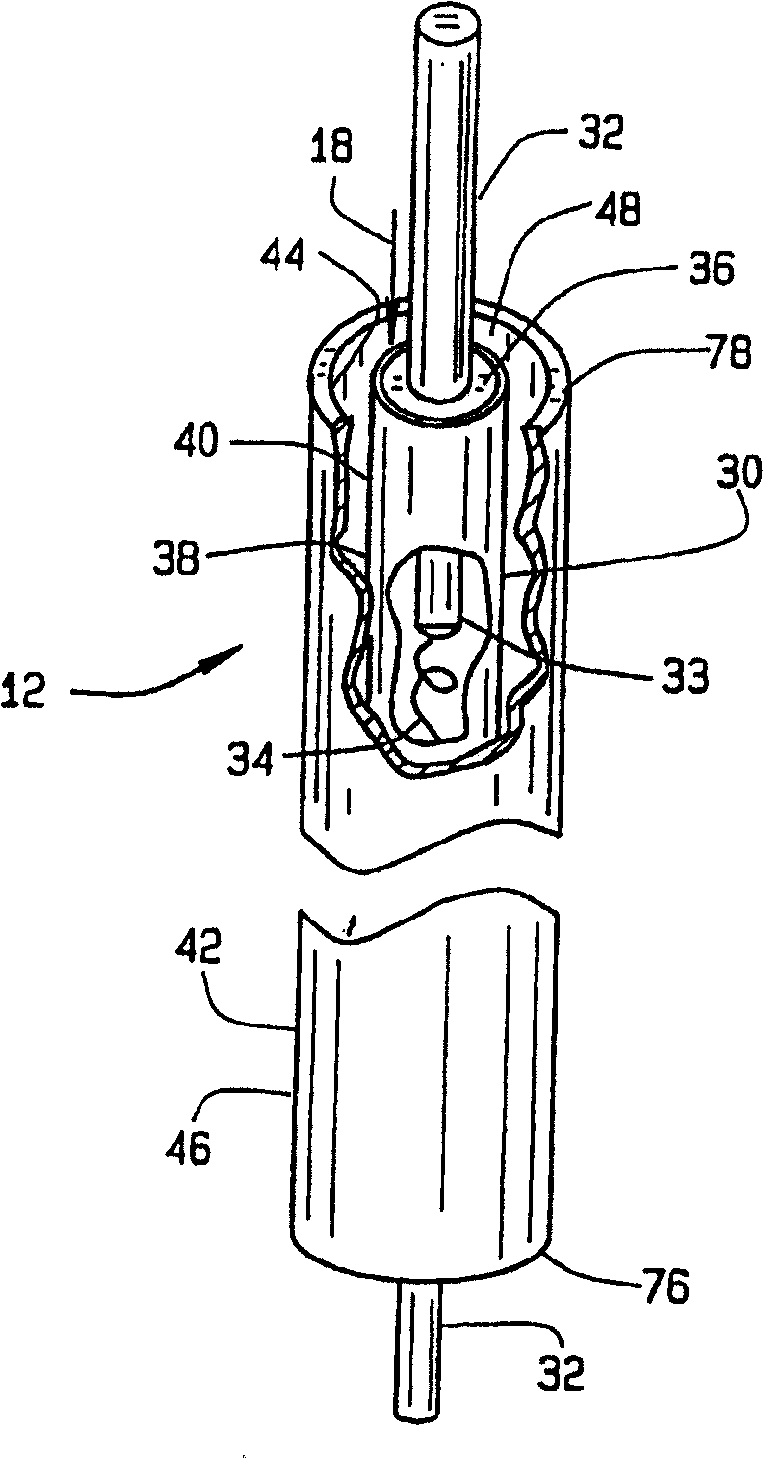

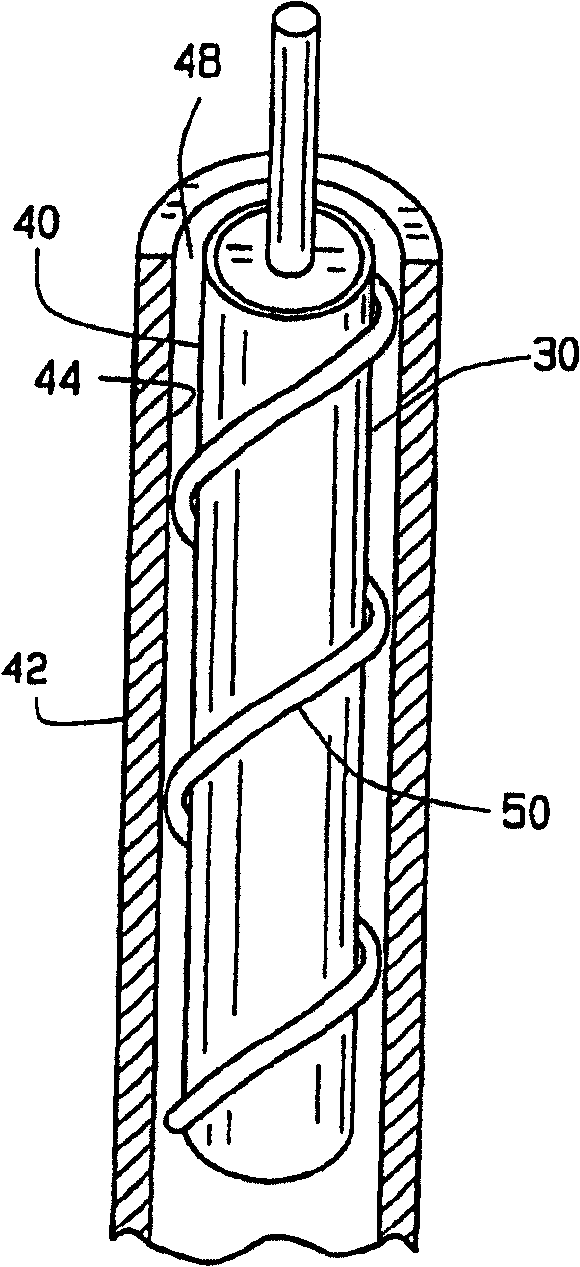

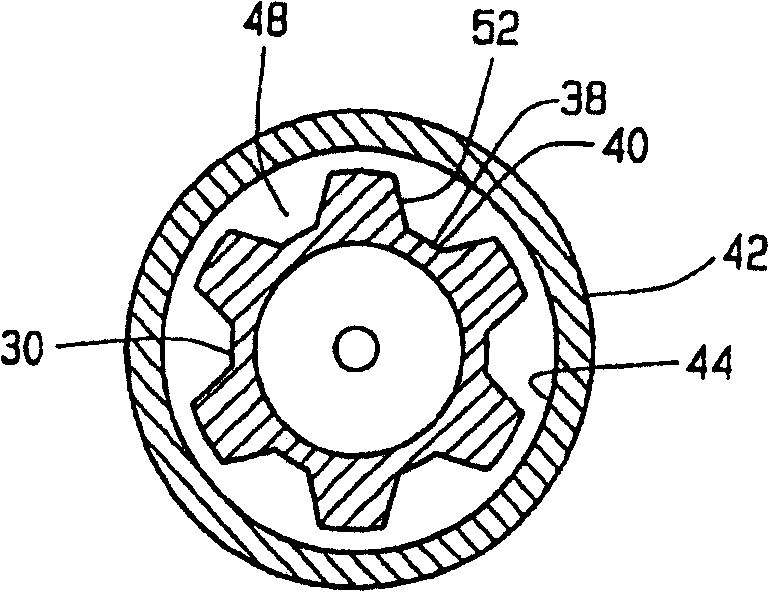

A fluid heat exchanger (12) for use in a fluid heating system (10) is disclosed comprising a rapidly heatable inner tube (30) surrounded by a hollow outer tube (42) for heating fluid flowing through the fluid (18) between the inner tube (30) and the outer tube (42), and circulates the fluid within the fluid heating system (10). When the inner tube (30) is rapidly heated, the circulating fluid (18) is rapidly heated to the predetermined temperature used in the fluid heating system (10).

Owner:WATLOW ELECTRIC MFG

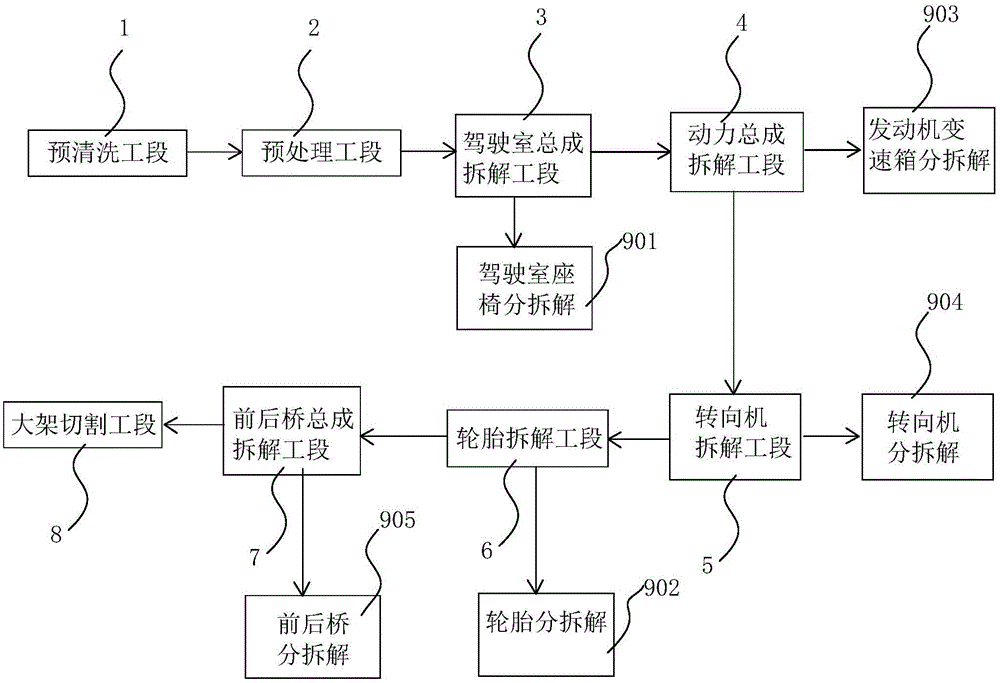

Scrapped autotruck and heavy passenger car disassembling technology

InactiveCN105015650AEasy to sort and recycleImprove protectionVehicle dissasembly recoverySolid waste disposalResource recoveryTruck

The invention relates to a scrapped autotruck and heavy passenger car disassembling technology. According to the technology, the following working sections including precleaning, preprocessing, driving cab assembly disassembling, power assembly disassembling, steering engine disassembling, tire disassembling, front and rear axle assembly disassembling, large frame cutting and split disassembling are included. The scrapped autotruck and heavy passenger car disassembling technology is high in disassembling efficiency, control and operation are automatic, part recycling and classification are convenient, resource recycling and environmental protection are facilitated, and labor conditions are greatly improved; the modernization production line layout is adopted, and the scale is conveniently expanded; environmental pollution can be effectively avoided when disassembling is performed through the scrapped autotruck and heavy passenger car disassembling technology. According to the precleaning working section, a storage battery trailer is adopted for transporting a vehicle to be disassembled to an area to be disassembled, and the environmental protection purpose is achieved better compared with a diesel fork lift truck. According to the large frame cutting working section, the purposes of safety and environmental protection are better achieved compared with gas welding cutting.

Owner:XINGUANG RECYCLING SHANGHAI

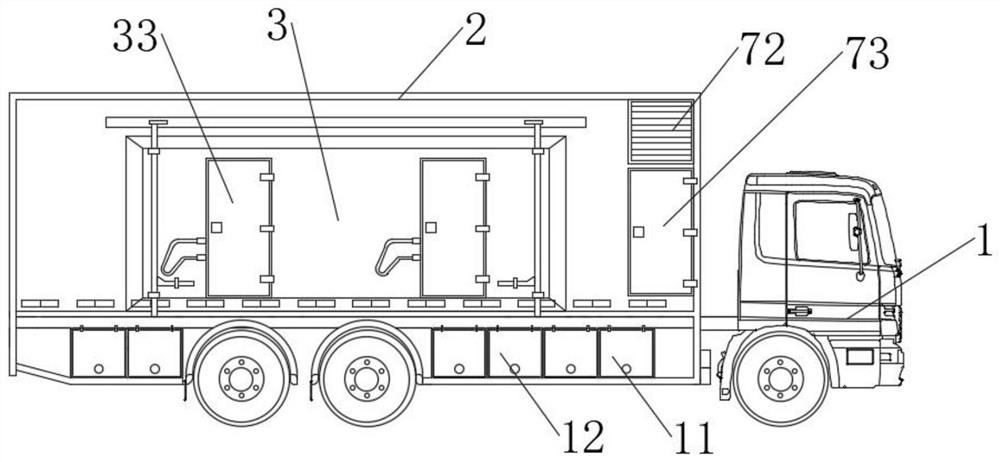

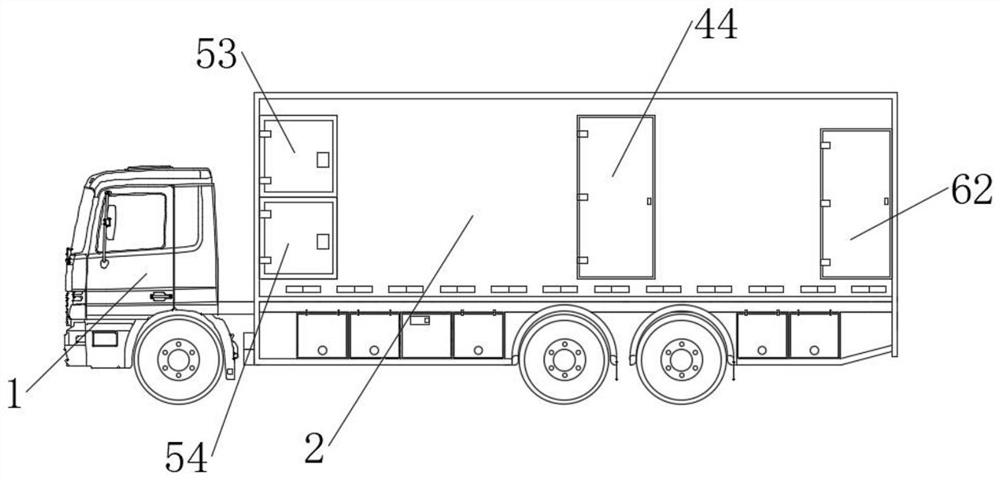

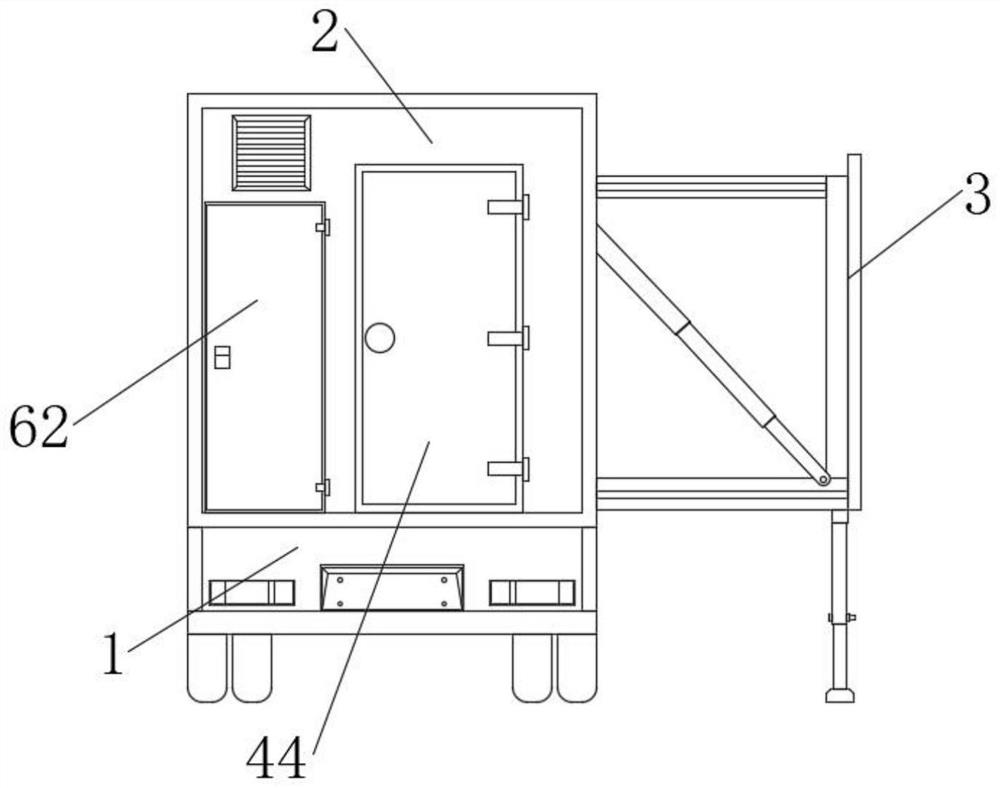

Vehicle-mounted extensible mobile biological safety laboratory

PendingCN113246833AImprove applicabilityLight weightEnclosures/chambersItem transportation vehiclesExperimental laboratoryIn vehicle

The invention relates to the technical field of biological safety protection technologies and equipment, in particular to a vehicle-mounted extensible mobile biological safety laboratory which comprises a loading vehicle, a fixed compartment is connected to the upper portion of the loading vehicle, an extensible compartment is arranged on the right side of the fixed compartment, and the interior of the fixed compartment comprises a laboratory working area. The laboratory working area comprises a reagent storage and preparation area, a specimen preparation area is arranged on one side of the reagent storage and preparation area, an amplification area is arranged on the other side of the specimen preparation area, maintenance access doors are formed in the left side and the rear wall of the reagent storage and preparation area, and an exhaust equipment room is arranged behind the laboratory working area. The laboratory is novel in layout and reasonable in partition, the equipment modules with different functions are relatively independent, the space of the compartment is fully utilized, the unfolding operation area is large, the applicability of the laboratory is improved, and the operation efficiency of operators is improved.

Owner:KF MOBILE SYST

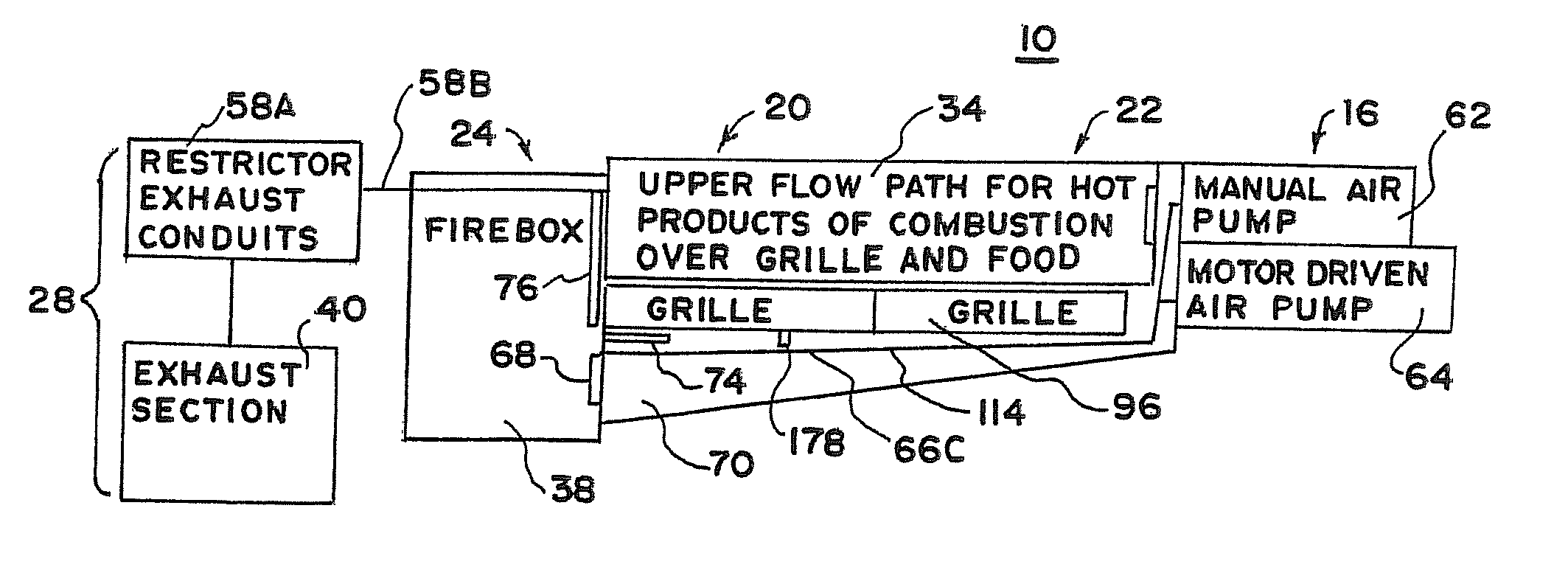

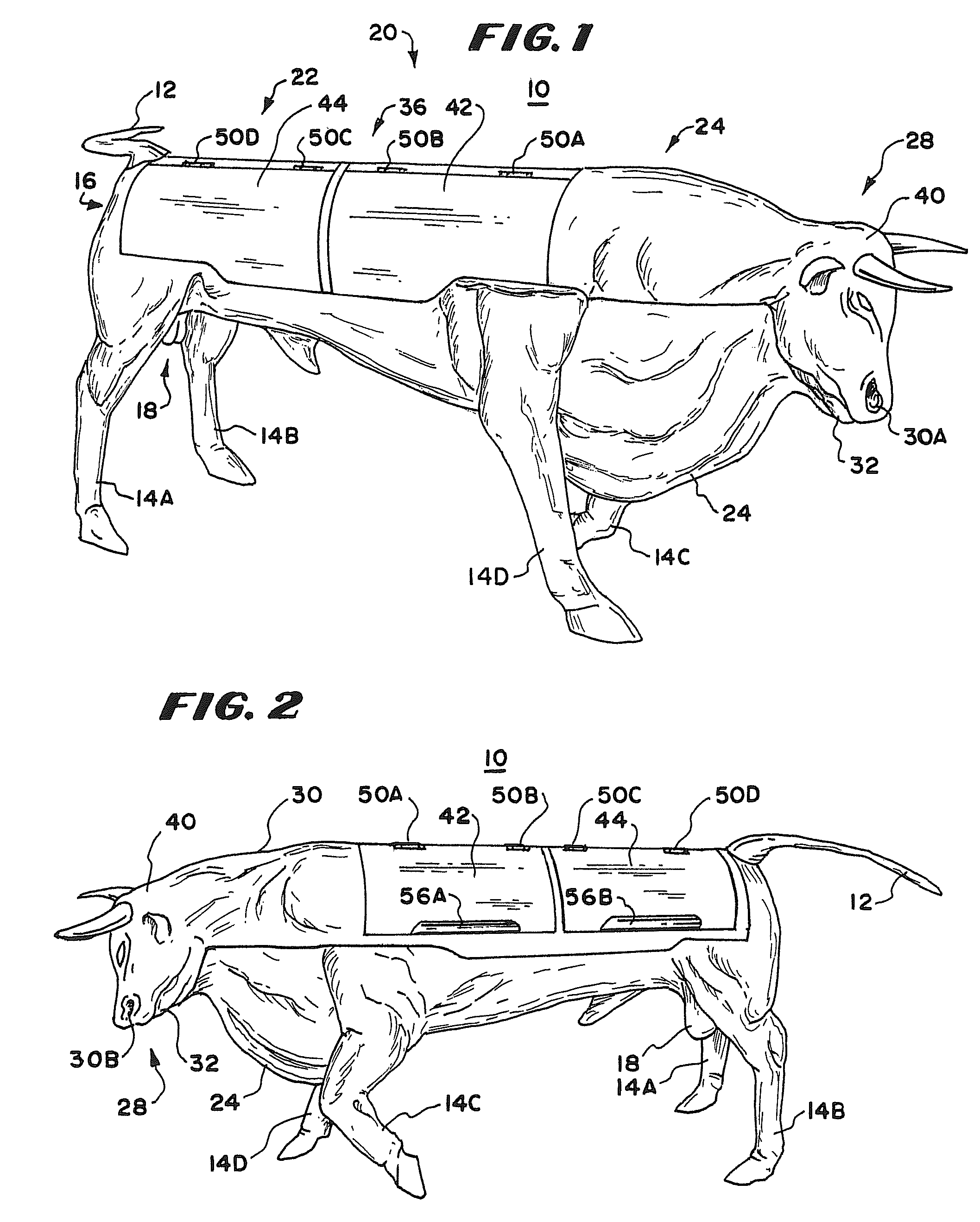

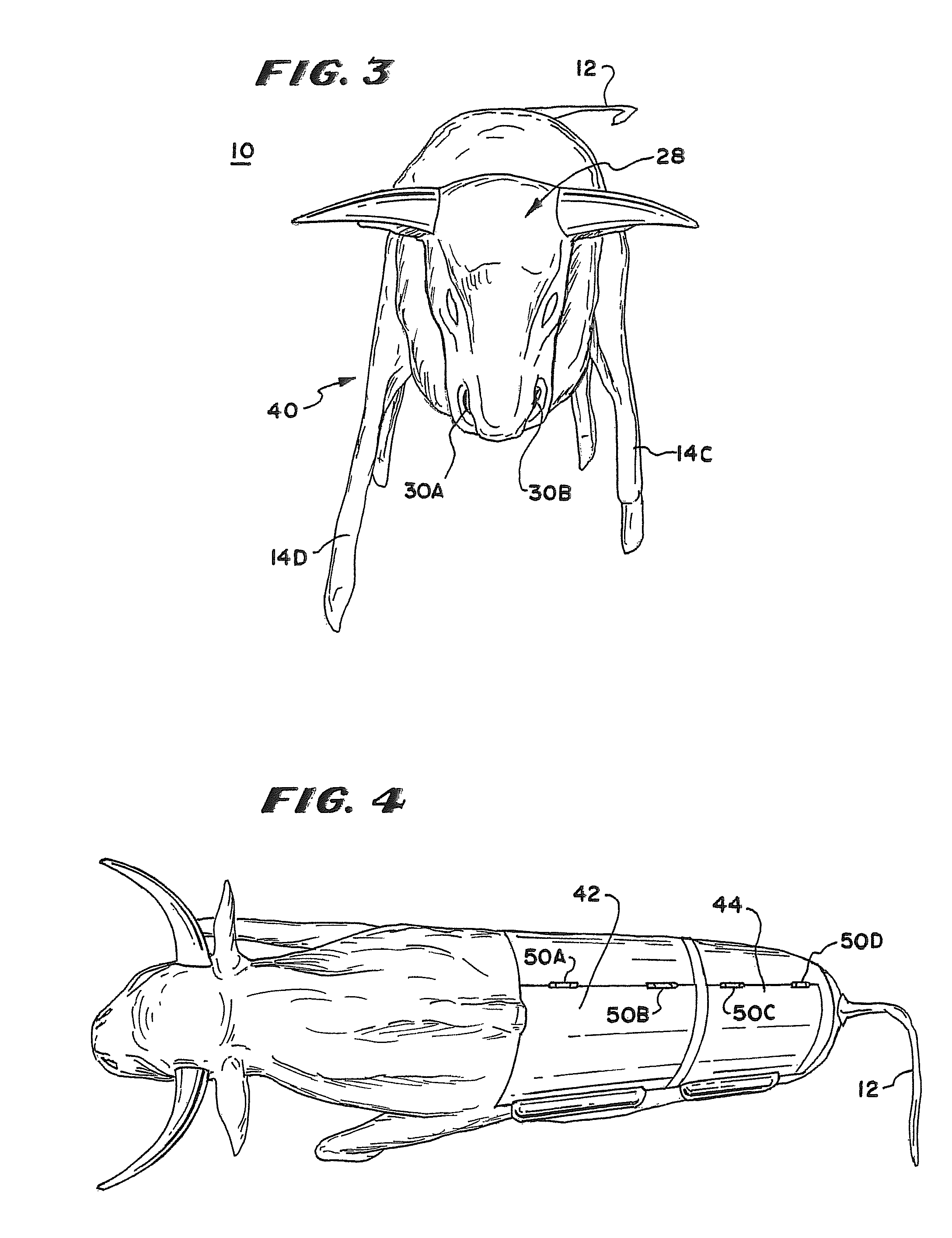

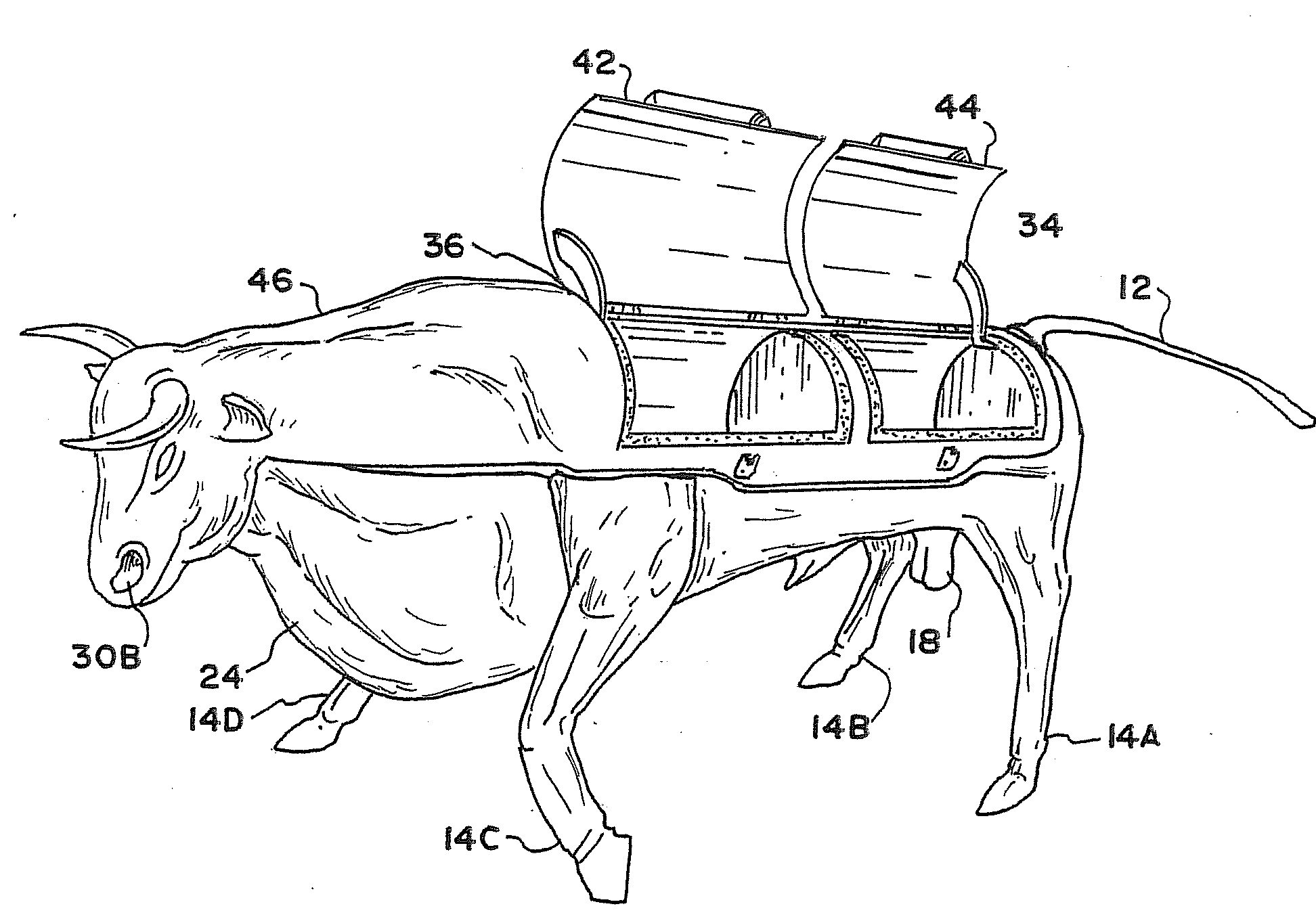

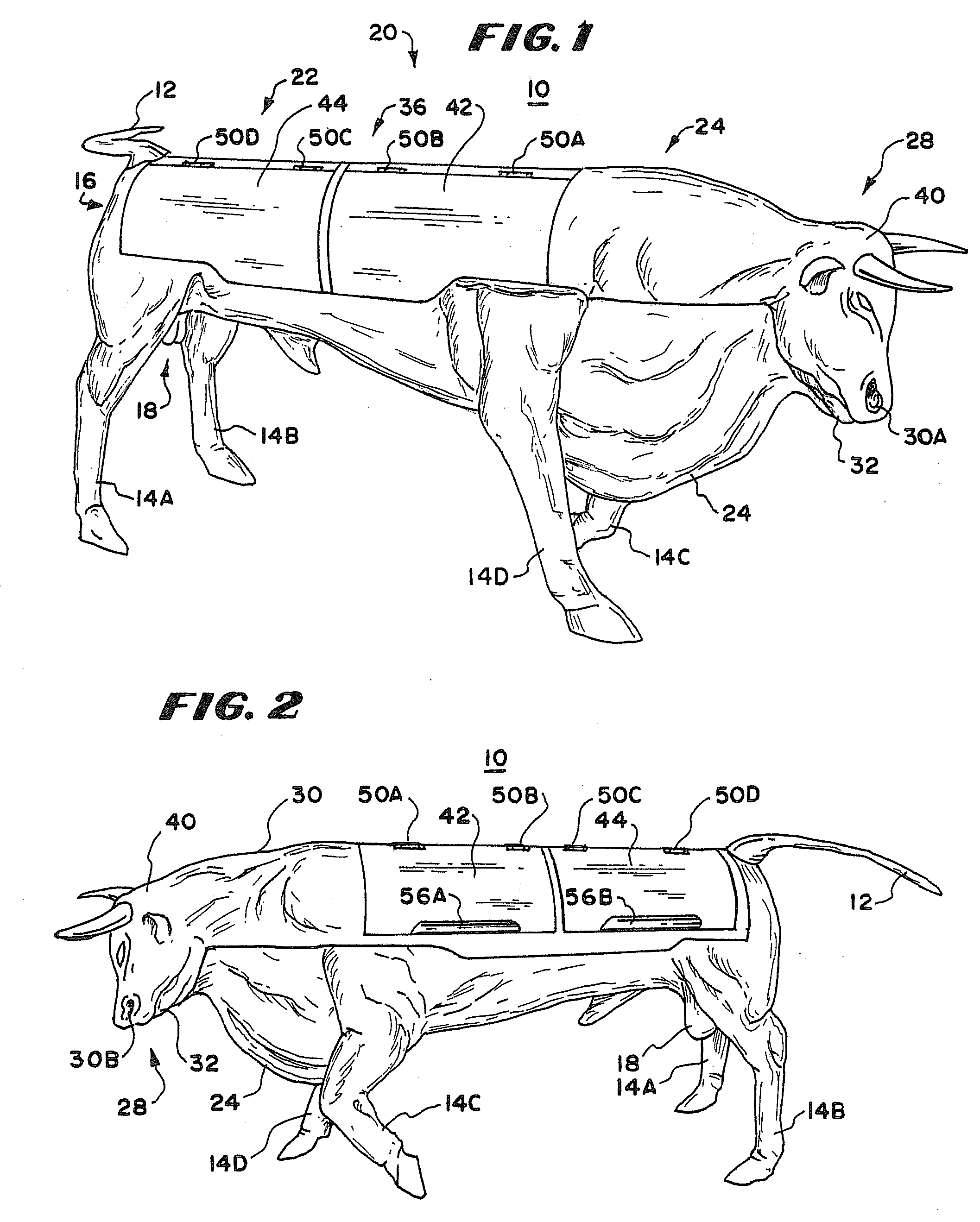

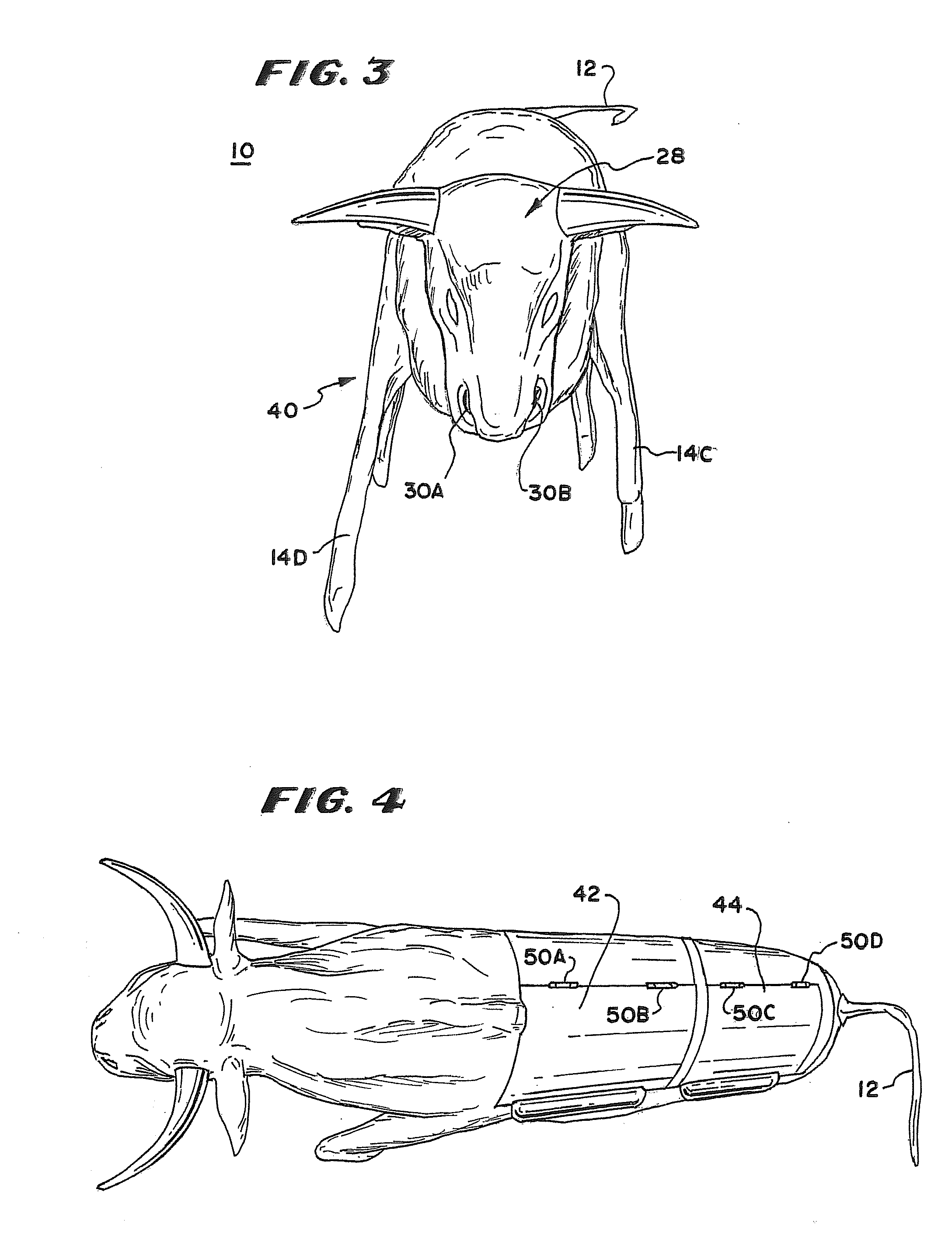

Meat treatment apparatus and method

ActiveUS8092850B2New layoutRealistic representationAir-treating devicesMilk preservationCombustion chamberCounter flow

An offset barbeque smoker grille has an openable cover shaped as the elongated back portion of a quadruped and the products of combustion are applied to meat on said grille with the cover closed and at least one restrictor is included in said fourth flow path to hold smoke in contact with said meat wherein a meat treatment apparatus is used as a smoker. The cooking and smoking uses counter flow from the firebox near the head of the quadruped under the cooking and smoking chambers toward the rump of the quadruped and back over the top of the cooking chambers to provide even cooking.

Owner:MARR RUSSELL A

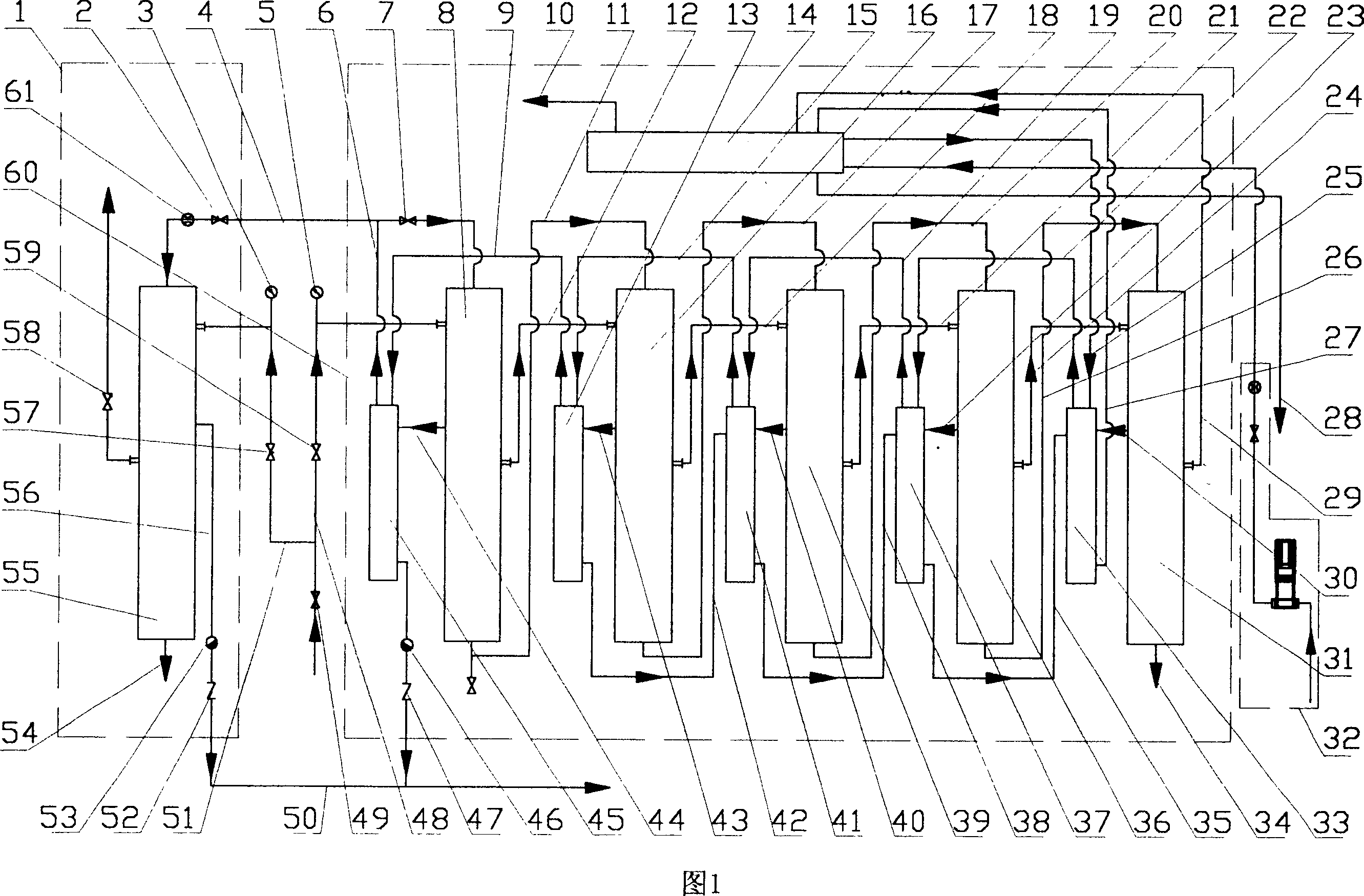

Multifunction multi-effect distilled water machine

InactiveCN1648060AIndependentCompact structureWater/sewage treatment by heatingMultiple-effect evaporationDistilled waterEngineering

The multifunctional multi-effect distilled water machine as one apparatus for preparing distilled water and pure steam consists of water inlet metering unit, connected multi-effect distilled water machine and pure steam generator. The present invention has the advantages of compact structure, novel layout, small size, light weight, high efficiency, etc. The multifunctional multi-effect distilled water machine may be used in sterilizing and producing distilled water, and may be used widely in pharmaceutical factory, food producer, beverage producer, hospital, etc.

Owner:曲景春

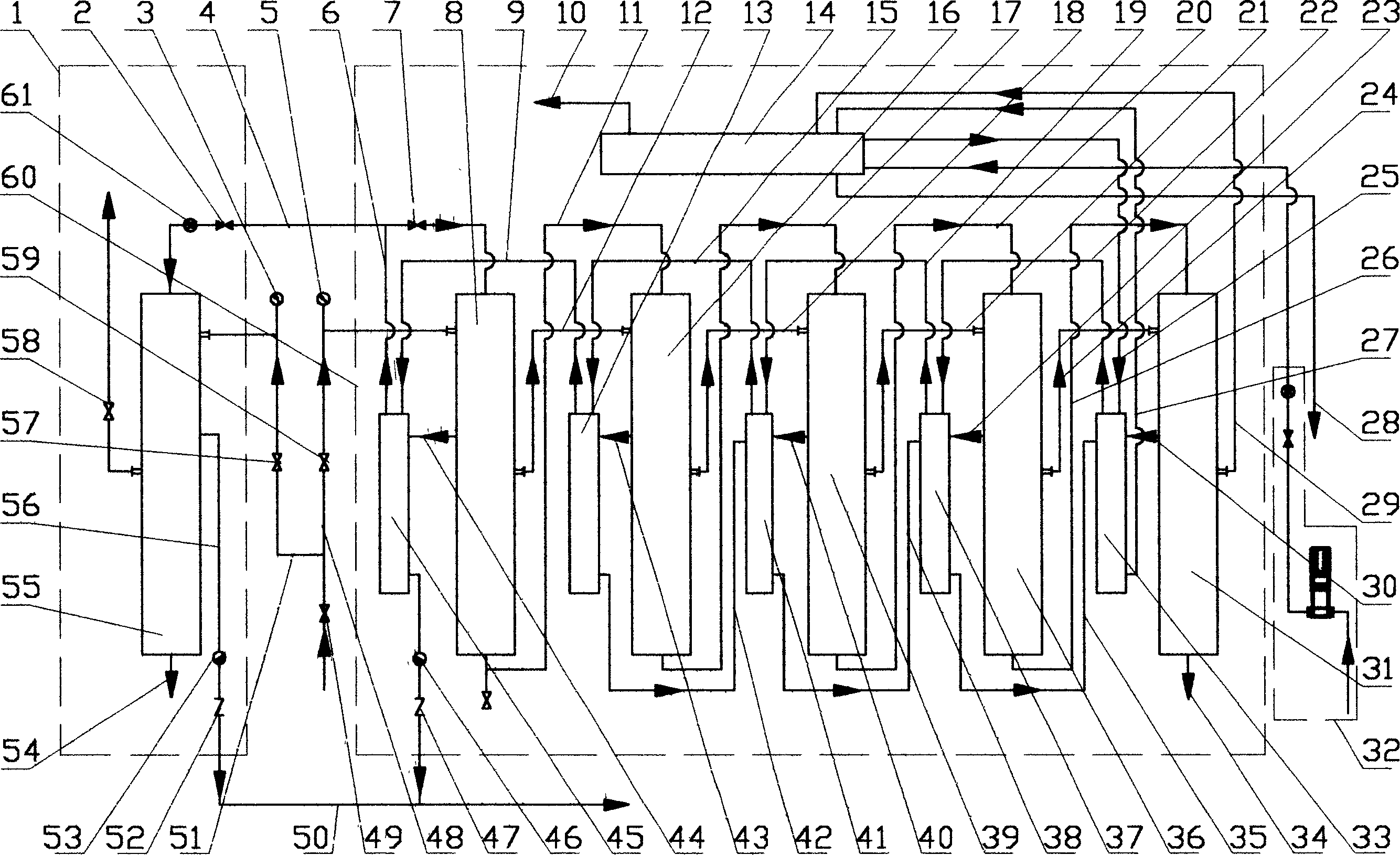

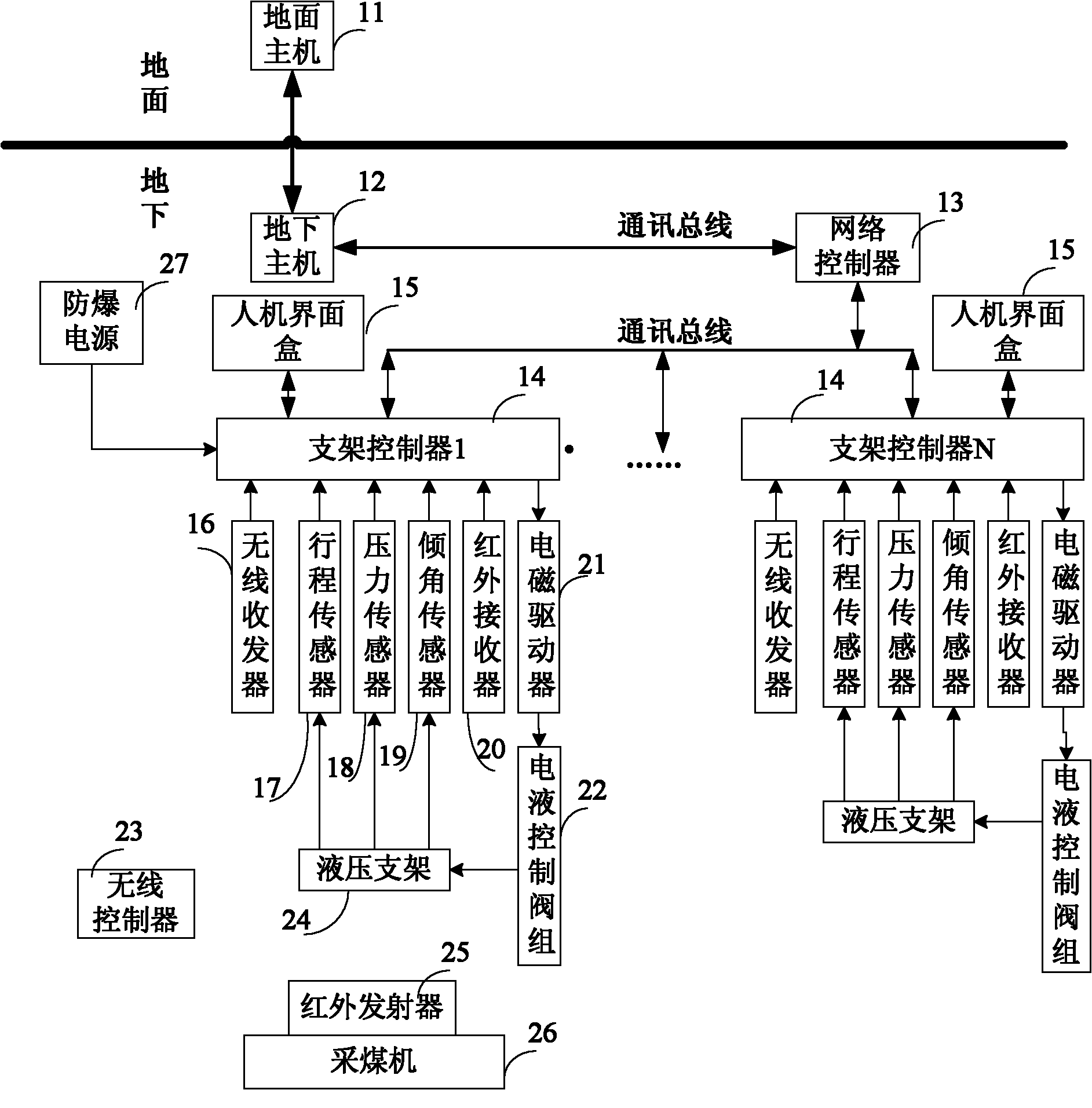

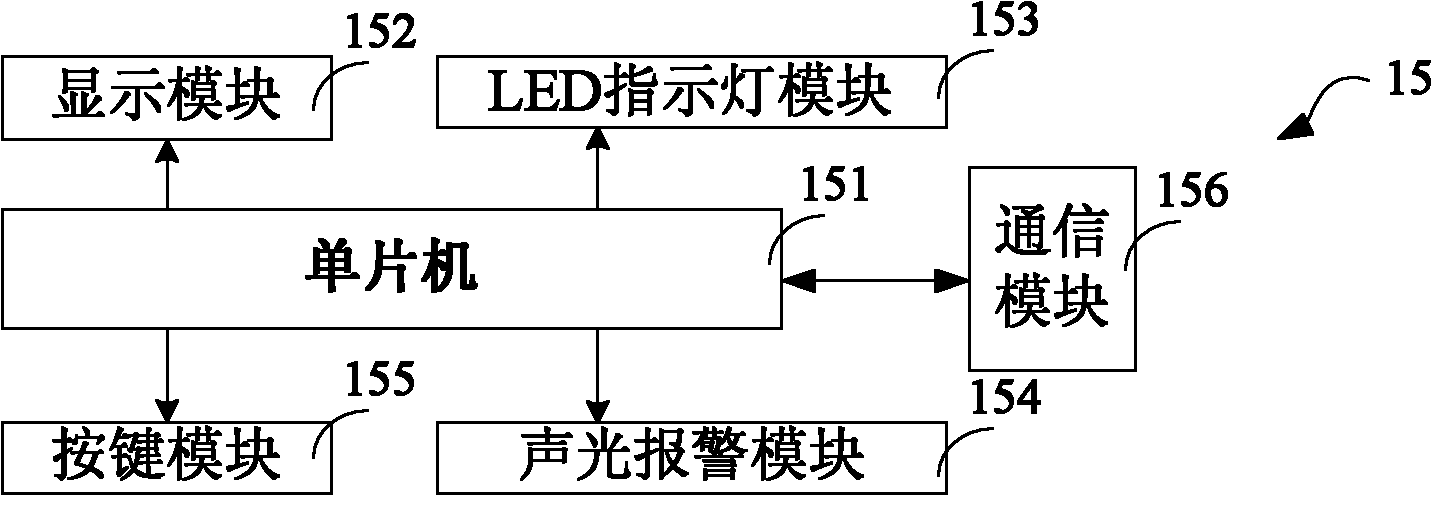

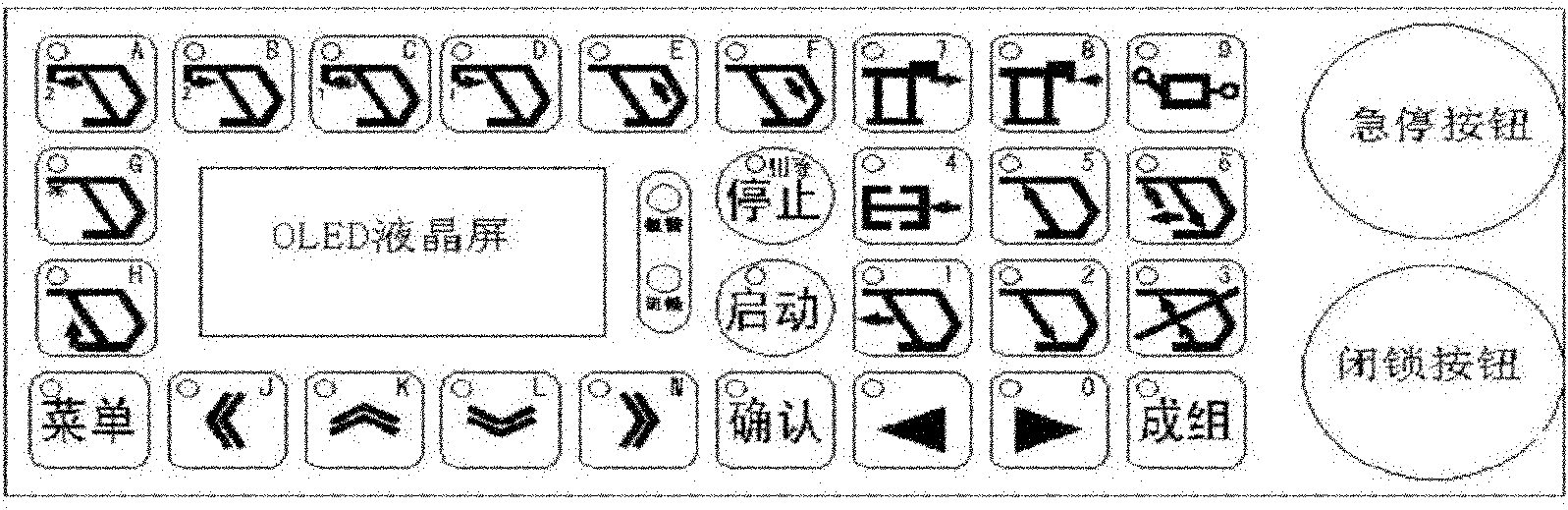

Electro-hydraulic control system for working surface hydraulic support

InactiveCN102071956BImprove the automation level of fully mechanized miningRich in compositionMine roof supportsData informationControl system

The invention relates to an electro-hydraulic control system for a working surface hydraulic support. The electro-hydraulic control system comprises a support controller (14), and a control terminal, an information acquisition device and an electromagnetic driver (21) which are connected with the support controller (14), wherein the control terminal is used for inputting an order and displaying received data information, the information acquisition device is used for acquiring the operating parameter data of the hydraulic support, and the electromagnetic driver (21) is used for driving an electro-hydraulic control valve group (22). The electro-hydraulic control valve group (22) connected with the electromagnetic driver (21) is used for controlling the closing and opening of a tube liquid pathway of the hydraulic support. The support controller (14) is used for transmitting the order from the control terminal and supplying the operating parameter data of the hydraulic support acquired by the information acquisition device to the control terminal. The electro-hydraulic control system is applied to the working surface hydraulic support.

Owner:BEIJING ZHONGKE LINZHONG TECH

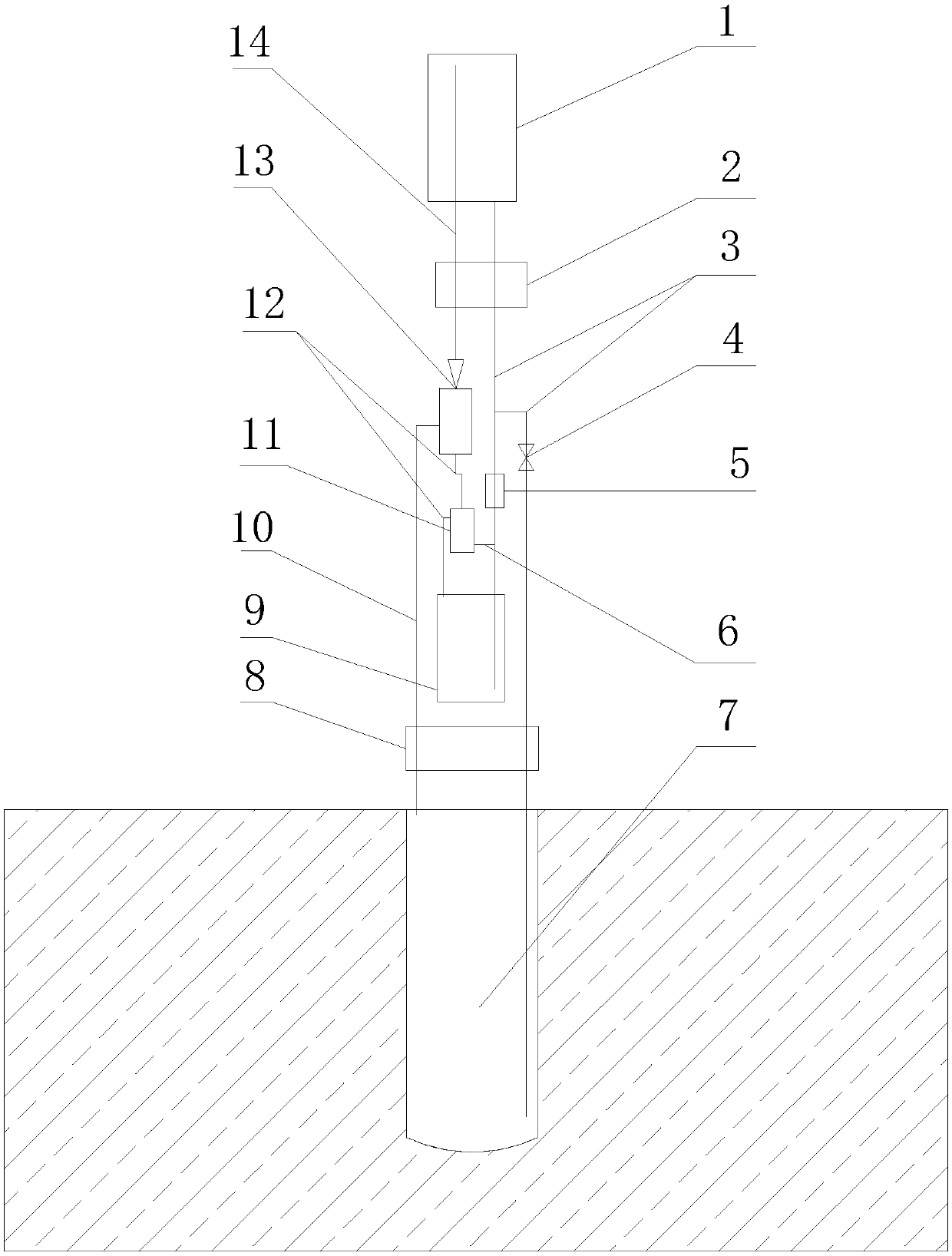

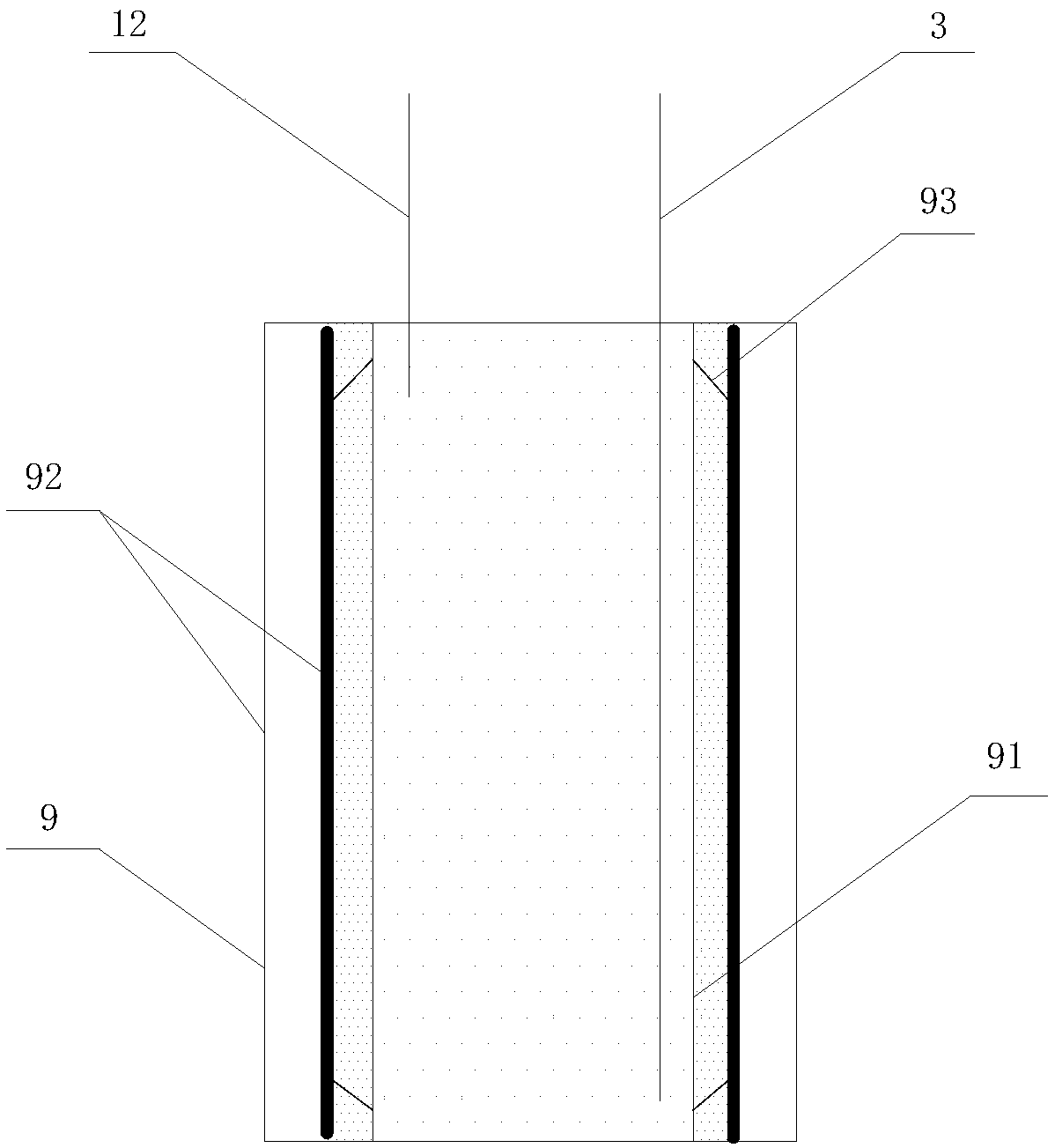

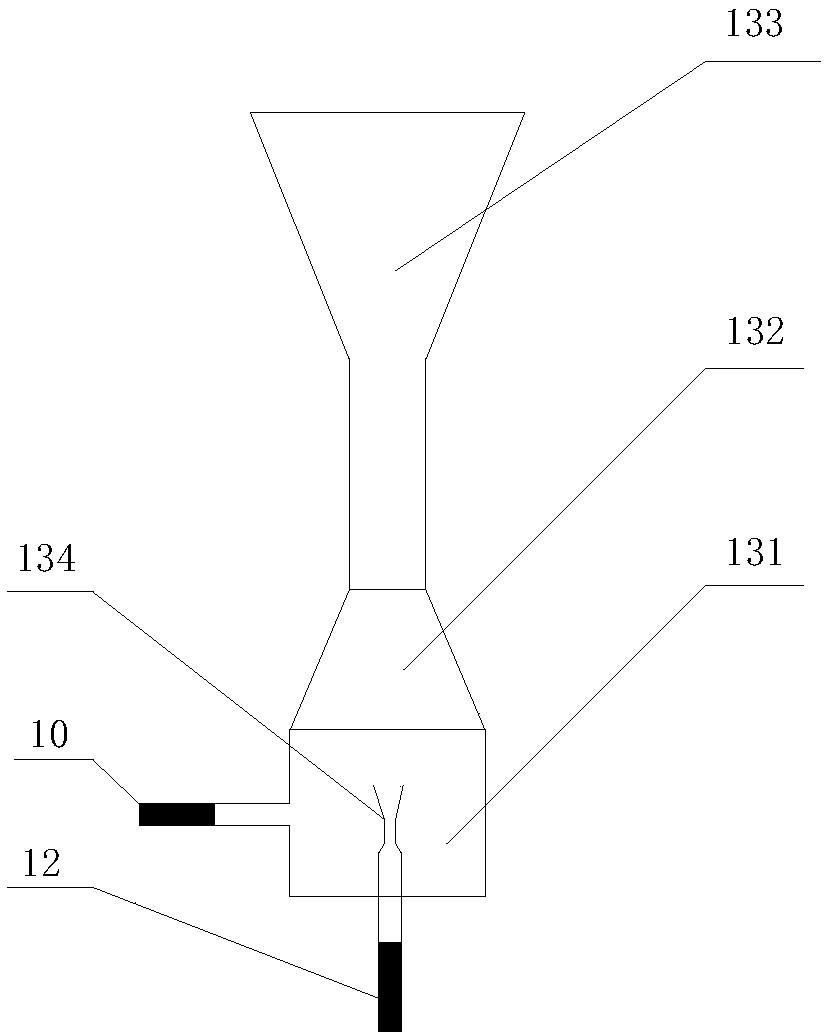

Solar refrigerating device used for manual freezing of water-rich loose and soft ground layer

InactiveCN109520148AImprove heat collection efficiencyImprove heat transfer efficiencySolar heating energyMechanical apparatusThermal energyDisease

The invention relates to a solar refrigerating device used for manual freezing of a water-rich loose and soft foundation. A heat collecting system and a steam injecting refrigerating system are included. The heat collecting system comprises a full-glass vacuum heat collecting pipe and a generator; the cylindrical generator is embedded in the tubular heat collecting pipe, and closed heating mediummedia are arranged between the two; and a gravity circulating manner is adopted for the steam injecting refrigerating system which comprises an evaporator embedded in a water-rich loose and soft ground layer, a condenser, a throttling valve, a steam injector, a one-way valve and the like, and the condenser, the throttling valve, the steam injector and the one-way valve are arranged on the ground surface. The device is vertical type refrigerating integrated machine, solar thermal energy and gravitational potential energy are combined for driving a refrigerating agent to circulate, no movement parts exist, consumption of electric energy and mechanical energy is avoided, running is reliable, and the service life is long. The device can be used for reinforcing weak cementation, large hole gapand water-rich unstable ground layers in engineering of excavating, traversing, filling and the like, and is especially suitable for preventing and controlling the hot melting disease of ice-rich foundations in linear engineering of long-distance railways, highways and power transmission lines in permafrost regions.

Owner:SHIJIAZHUANG TIEDAO UNIV

Multifunction multi-effect distilled water machine

InactiveCN1319866CIndependentCompact structureWater/sewage treatment by heatingMultiple-effect evaporationDistilled waterPulp and paper industry

The multifunctional multi-effect distilled water machine as one apparatus for preparing distilled water and pure steam consists of water inlet metering unit, connected multi-effect distilled water machine and pure steam generator. The present invention has the advantages of compact structure, novel layout, small size, light weight, high efficiency, etc. The multifunctional multi-effect distilled water machine may be used in sterilizing and producing distilled water, and may be used widely in pharmaceutical factory, food producer, beverage producer, hospital, etc.

Owner:曲景春

Meat treatment apparatus and method

ActiveUS20100009053A1New layoutRealistic representationAir-treating devicesMilk preservationCounter flowCombustion chamber

An offset barbeque smoker grille has an openable cover shaped as the elongated back portion of a quadruped and the products of combustion are applied to meat on said grille with the cover closed and at least one restrictor is included in said fourth flow path to hold smoke in contact with said meat wherein a meat treatment apparatus is used as a smoker. The cooking and smoking uses counter flow from the firebox near the head of the quadruped under the cooking and smoking chambers toward the rump of the quadruped and back over the top of the cooking chambers to provide even cooking.

Owner:MARR RUSSELL A

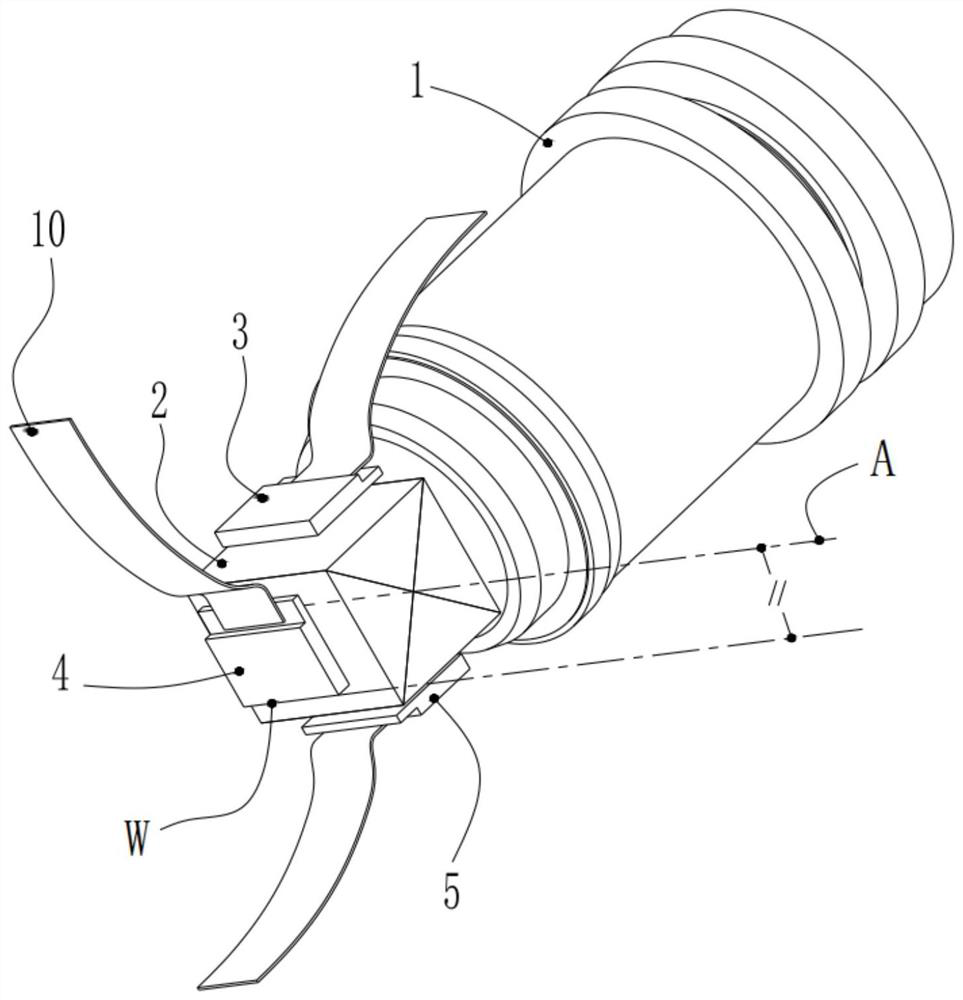

Projection module and projector

PendingCN113238438AIncrease production difficultyProduction difficulty does not affectProjectorsColor photographyEngineeringPrism

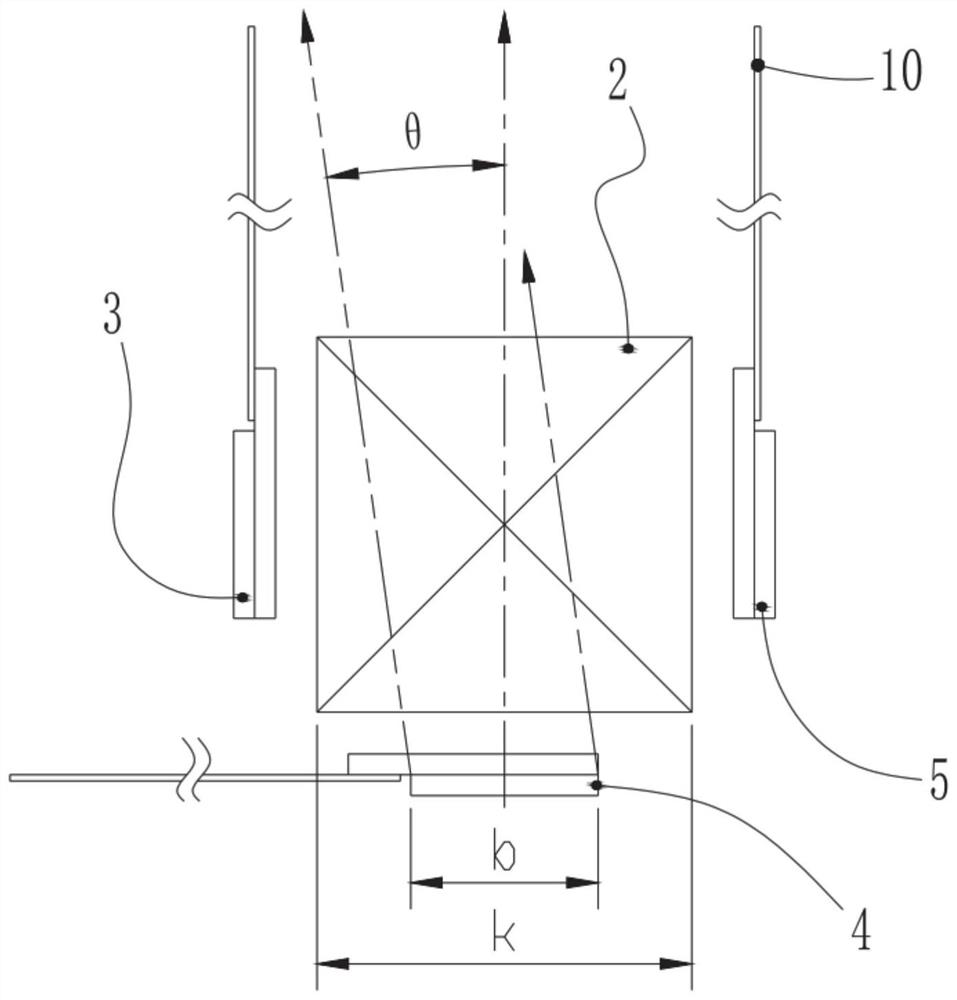

The invention discloses a projection module, which comprises two or three transmission-type LCD light valves, a light combining device and a projection lens. When the number of the LCD light valves is three, the light combining device is an X prism, and the long side W of the display window of any LCD light valve is parallel to the central intersecting line A of the X prism; and when the number of the LCD light valves is two, light emitted by the first LCD light valve penetrates through the light combining device, and light emitted by the second LCD light valve is reflected by the light combining device. The invention further discloses a projector which comprises the projection module. The manufacturing difficulty of the light combining device can be obviously improved, the relatively low manufacturing cost can be realized, the size of the whole machine can be reduced, the appearance stacking of the whole machine can be changed, the manufacturing cost of the projection lens can be reduced, and the product competitiveness can be improved.

Owner:NANHUA INTELLIGENT PRECISION MACHNE (SHENZHEN) CO LTD

Movable grabbing mechanism for towel cloth

PendingCN111573392ANew layoutCompact structureArticle deliveryWebs handlingDrive wheelElectric machinery

The invention provides a movable grabbing mechanism for towel cloth. The movable grabbing mechanism comprises a rack, a driving assembly and a grabbing assembly; the driving assembly is used for moving the grabbing assembly, a synchronous belt of the driving assembly is tensioned on a synchronous wheel and a driven wheel in the front-back direction of the rack, and a driving motor can drive the synchronous belt to operate; and the grabbing assembly is used for grabbing and horizontally pulling the towel cloth and comprises a connecting plate, a cross beam, a clamping jaw, a follow-up boss anda follower, the connecting plate is fixed to the synchronous belt, the cross beam is rotationally connected with the connecting plate in the left-right direction of the rack, the follower and the clamping jaw are fixed to the upper side and the lower side of the cross beam, the follow-up boss is fixed to the rack in the front-back direction of the rack and comprises a wedge-shaped reversing wall,and the follow-up device can be pressed by the reversing wall to rotate the cross beam when passing through the reversing wall so as to change the direction of the clamping jaw. According to the movable grabbing mechanism, the clamping jaw can be overturned without an external driving device, the towel cloth can be reliably grabbed and horizontally moved, the overall layout is compact, the actionis stable, and the synchronism is good.

Owner:常熟寿胜自动化机械有限公司

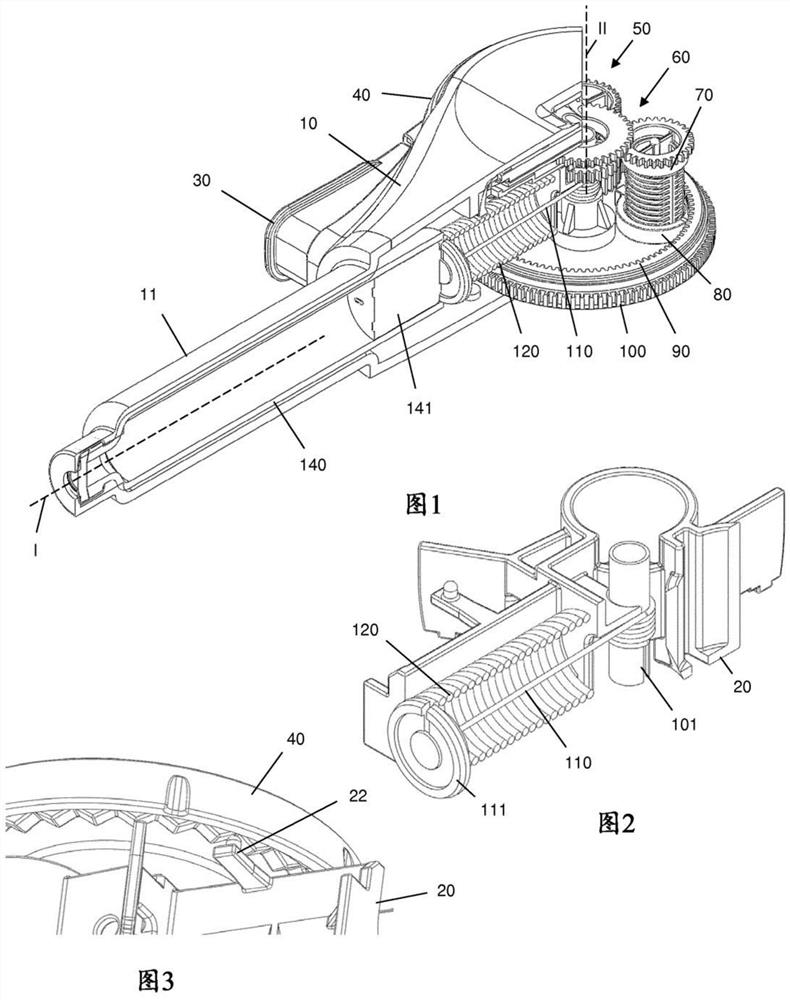

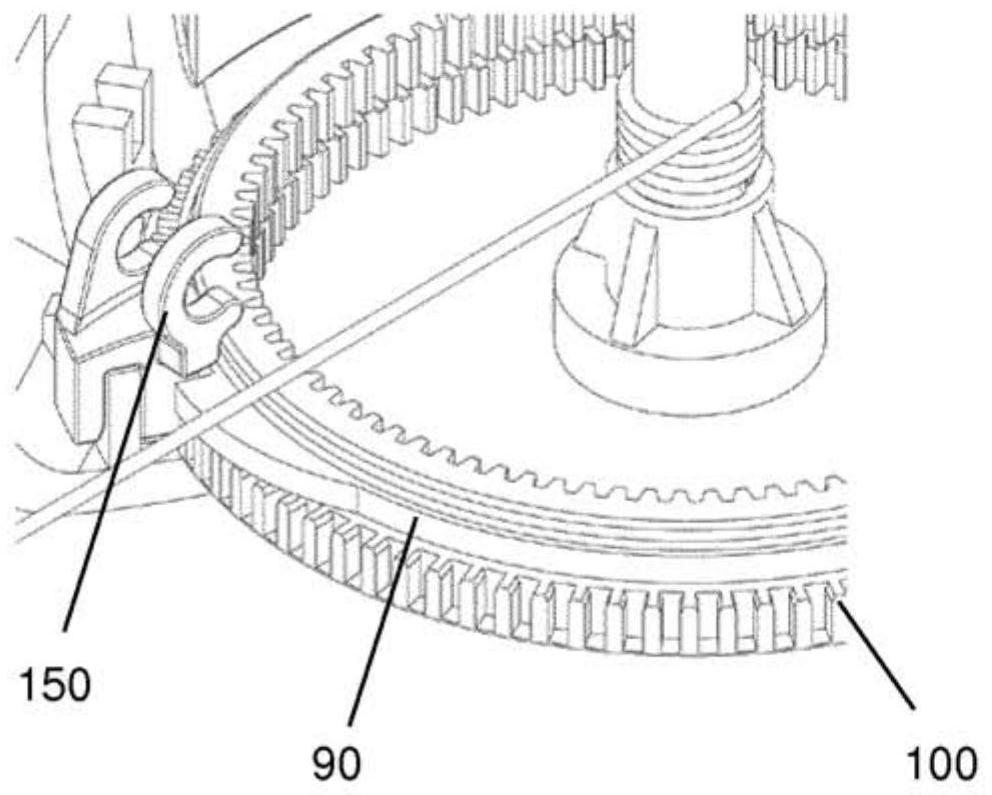

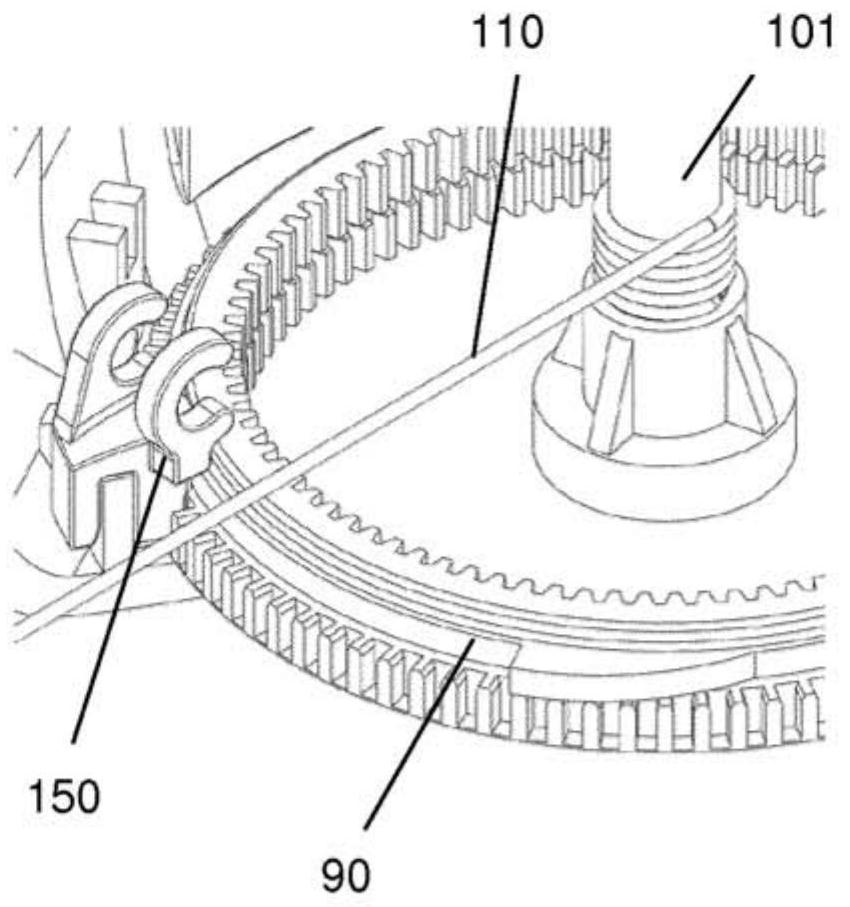

drug delivery device

InactiveCN106999670BNew layoutComfortable to holdIntravenous devicesDose selectionPharmaceutical drug

A drug delivery device for selecting and dispensing a number of user variable doses of a medicament includes a housing having an opening, a dose selector operable to set a dose by rotation relative to the housing, a release member controlling movement of a piston in a dispensing direction, and a display comprising a units number wheel and a tens number wheel which are coupled to each other such that a continuous rotation of the units number wheel is translated into an intermittent rotary motion of the tens number wheel. The release member rotates, during dose dispensing, an angle corresponding to the dose set by the dose selector, thereby allowing a piston to move in a dispensing direction.

Owner:SANOFI SA

A dismantling process for scrapped motor vehicles

ActiveCN105159246BEasy to sort and recycleImprove protectionTotal factory controlProgramme total factory controlControl systemElectrical control

The invention relates to a scrap motor vehicle dismantling process comprising the following sections: an online vehicle buffer assembly line section, a pre-processing assembly line section, an interior and exterior decoration dismantling assembly line section, a chassis dismantling assembly line section, a powertrain fine-dismantling assembly line section, and an assembly fine-dismantling assembly line section. A scrap motor vehicle is dismantled sequentially through the online vehicle buffer assembly line section, the pre-processing assembly line section, the interior and exterior decoration dismantling assembly line section and the chassis dismantling assembly line section; and then, the dismantled assemblies are further dismantled finely though the powertrain fine-dismantling assembly line section and the assembly fine-dismantling assembly line section, wherein the sections of the whole dismantling process are managed and controlled full-automatically by a PLC electrical control system. By adopting the scrap motor vehicle dismantling process, the dismantling efficiency is high, control and running are automated, parts recycling and classifying is convenient, resource recycling and environmental protection are facilitated, and the working condition is improved greatly. Modernized production line layout is adopted, which facilitates scale expanding. Through dismantling by the process of the invention, environmental pollution can be effectively prevented.

Owner:XINGUANG RECYCLING SHANGHAI

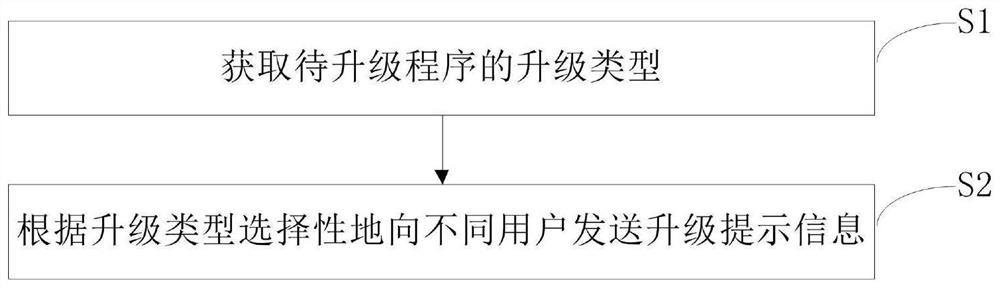

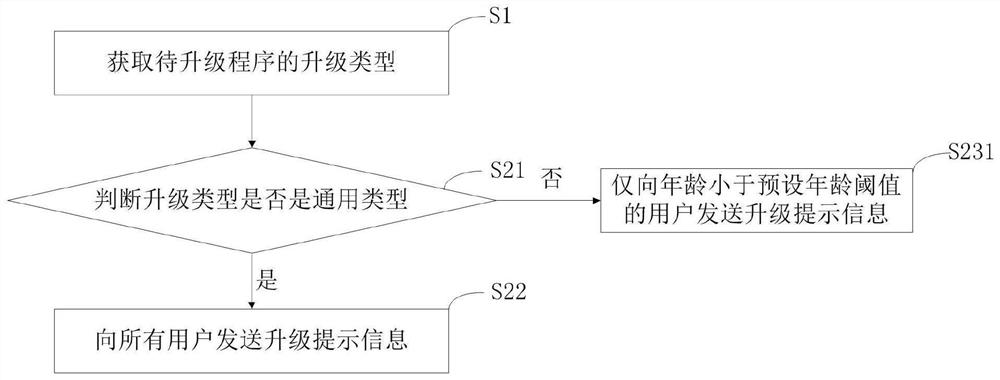

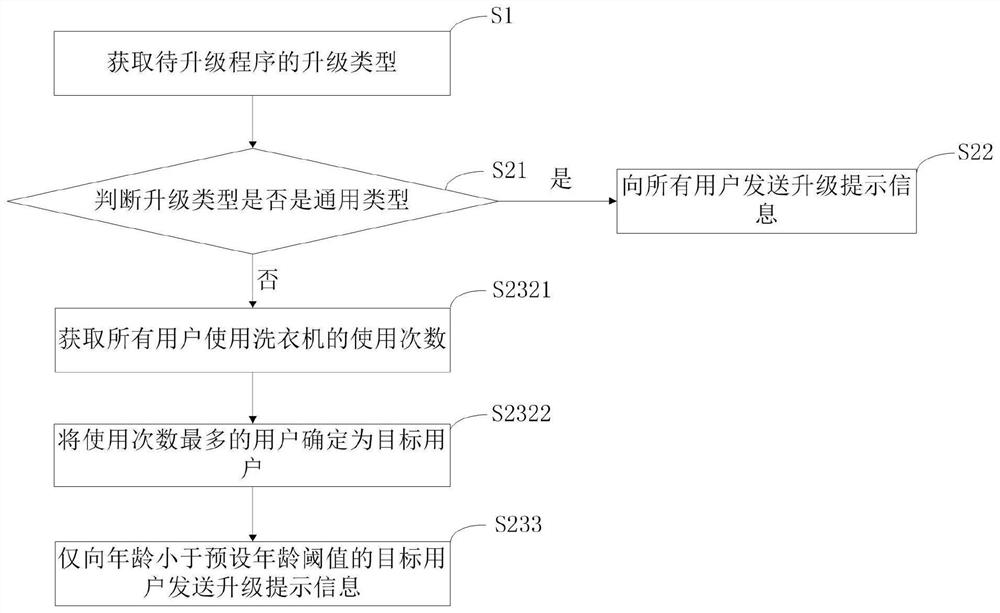

Program upgrade control method for clothes treatment equipment

PendingCN112626792AImprove user experienceNew layoutControl devices for washing apparatusTextiles and paperOperating systemComputer engineering

The invention relates to the technical field of household appliances, particularly provides a program upgrade control method for clothes treatment equipment, and aims to solve the problem of poor user experience due to the fact that upgrade prompt information is sent to a user as long as a program of existing clothes treatment equipment needs to be upgraded. In order to achieve the purpose, the program upgrade control method comprises the following steps: obtaining the upgrade type of a program to be upgraded; and selectively sending the upgrade prompt information to different users according to the upgrade type. By using the method, the most reasonable upgrade prompt information sending mode is provided for the clothes treatment equipment, the upgrade prompt information is sent to the user only when the upgrade type of the program to be upgraded meets the use requirement of the user, and the situation that the upgrade prompt information is sent to the user as long as the program needs to be upgraded is avoided, so that frequent sending of upgrade prompt information to the user and frequent program upgrading are avoided, and thus the uses experience is improved.

Owner:HAIER SMART HOME CO LTD +1

Planar Mechanism Structure Teaching Analyzer

ActiveCN104616581BSolve the problem of simple and monotonous knowledgeA single point of knowledgeEducational modelsKinematicsStructure analysis

The invention relates to a plane mechanism structure teaching analyzer and belongs to the technical field of teaching instruments. The analyzer aims at solving the problems that experiment modes in the mechanical subject experiment teaching are single and outdated, be understood through physical model static displaying, and teaching aid assisted matched structures are complicated, large in size and cannot perform in-class explanation through dynamic displaying and the like. The analyzer comprises five portions: a virtual restraint mechanism unit, a one-freedom mechanism unit, a two-freedom mechanism unit and a low-pair replacing high-pair unit of a plane mechanism and a power shunting unit. The five units are fixed on a bottom plate. By means of the analyzer, sports demonstration and exercise exploration are integrated, the analyzer can be brought into classes to performing teaching of plane mechanism composition, plane mechanism moving condition, mechanism freedom degree calculation methods, mechanism kinematic sketch drawing, mechanism structure analysis and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

car window regulator

InactiveCN101215946BOvercoming the Disadvantages of ForkingFork will notWindowsWindscreensMaterial consumptionEngineering

The invention relates to a utility car window glass elevator, which comprises a sprocket wheel component, a repeater, a chain axis, a chassis, a guide path, a glass holder slide block component, a protecting tube and an upper chassis, wherein the glass holder is installed on the slide block, the slide block is connected with the chain axis through a shaft pin, the chassis and the upper chassis are fixedly connected with car door screws, the guide path, the protecting tube and an endless screw box are connected with the chassis, the repeater is fixed on the chassis through the screws, and the chain axis is connected in a matching mode with a sprocket wheel in the sprocket wheel component. The chain axis is composed of a chain, a rope and an epibolic clip, and the beneficial effect of the invention is that since the invention has novel arrangement, simple and compact structure, little energy consumption, little material consumption, strong and stable elevating force, stable and reliable operation and longer service life compared with various existing products, thereby the invention can be used for controlling electric elevation of window glass of car doors.

Owner:李世良

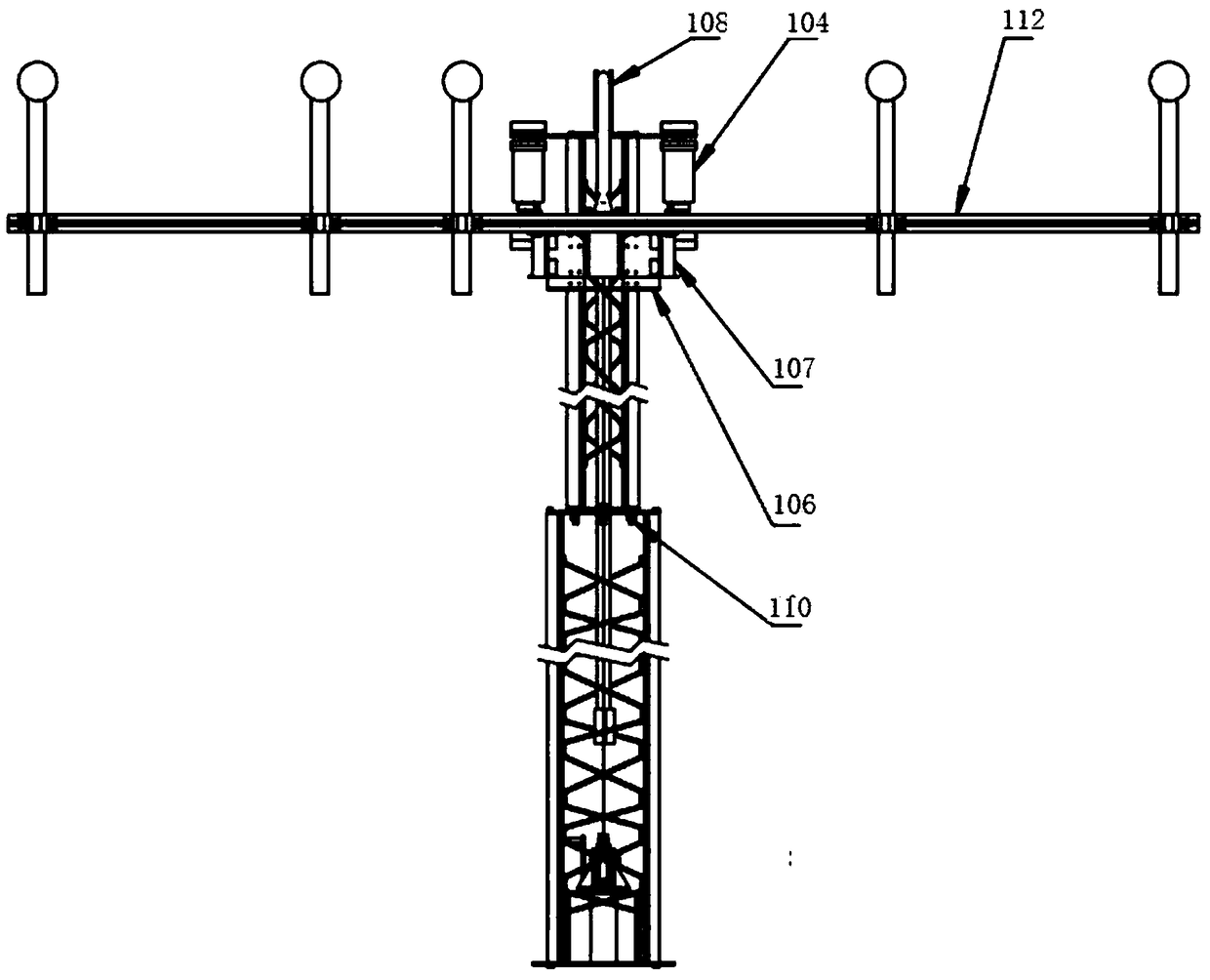

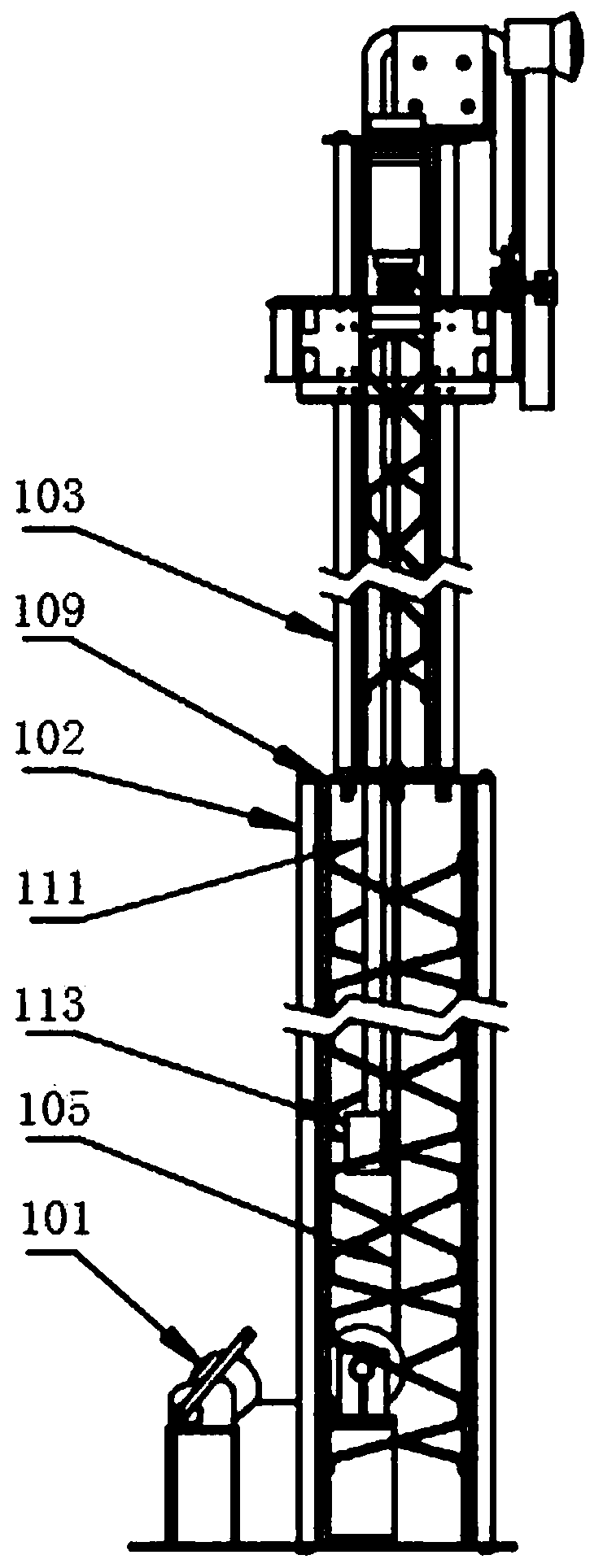

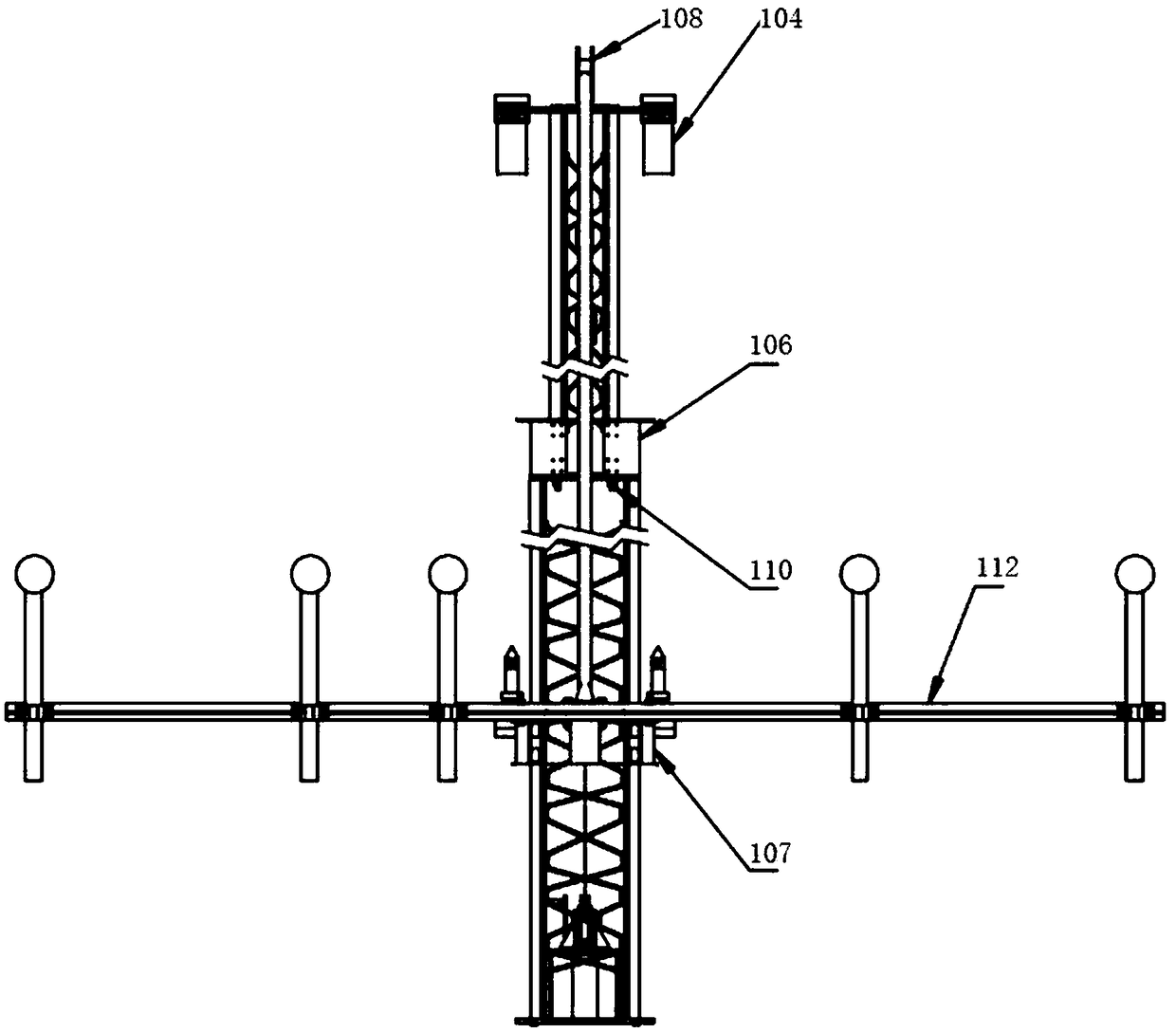

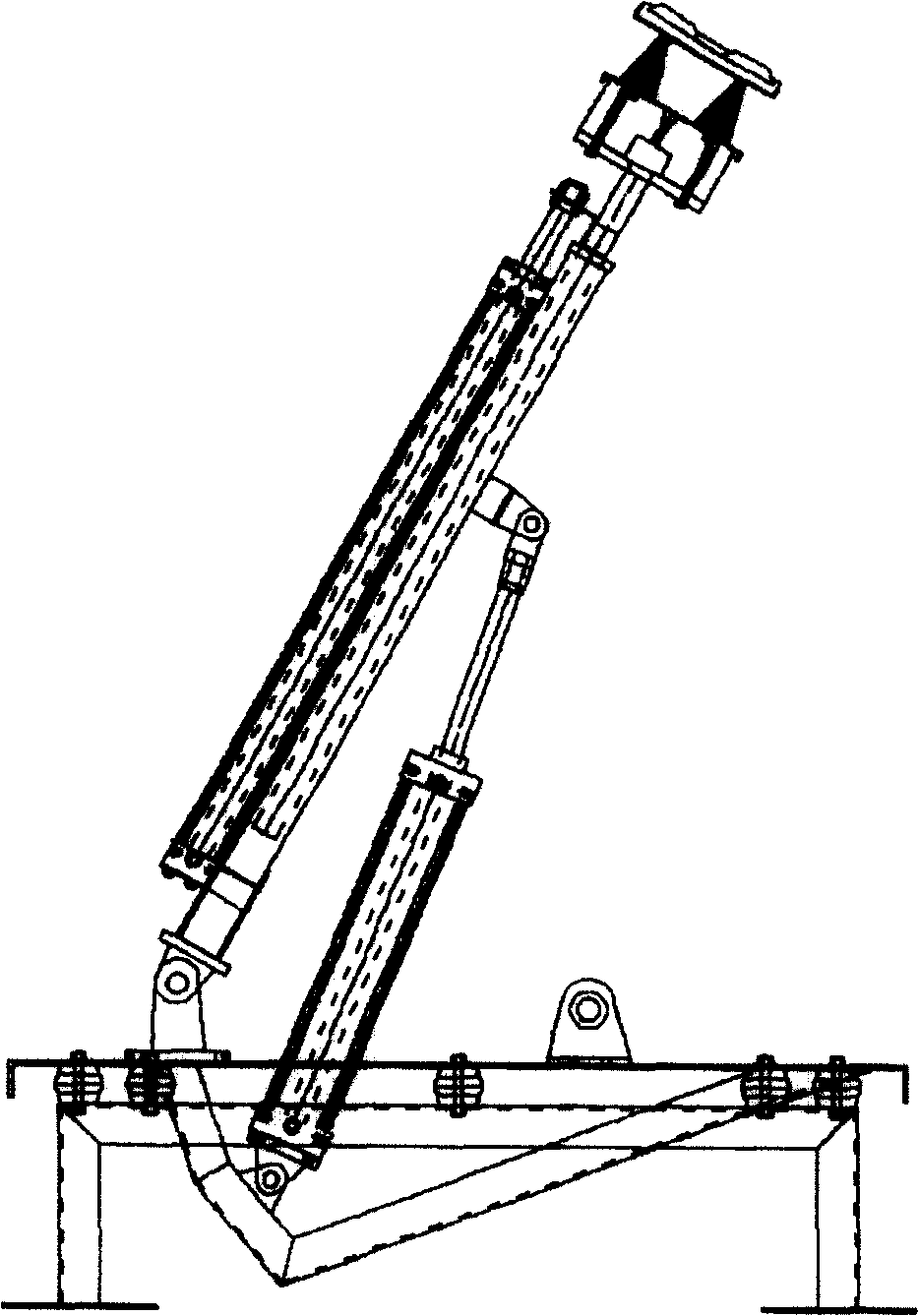

A lifting type easy-folding rod

ActiveCN106764294BShort maintenance timeSmall footprintStands/trestlesLocking mechanismPower equipment

Owner:成都辟思航空科技有限公司

Rapid response electric heat exchanger

Owner:WATLOW ELECTRIC MFG

Speed regulator

InactiveCN103748004ANo maintenanceReduce wearTelemotorsRotary piston pumpsHydraulic motorHydraulic pump

Owner:卡勒·坦斯卡伦

Double-slide cylinder horizontal bipolar current collector of trolley

The present invention relates to a double-sleeve horizontal bipolar receiving device for charging trolley car. It is characterized by that it includes base support assembly positioned on the top portion of trolley car body, on the base support assembly a slide sleeve and a two-stage cylinder are movably and fixedly connected, said slide sleeve is formed from external sleeve and internal sleeve, said two-stage cylinder is connected with said slide sleeve and can be used for driving said slide sleeve and making it be upwards and downward moved. Said slide sleeve also is movably connected with one-stage cylinder, said one-stage cylinder is movably connected with said slide sleeve and can be used for supporting said slide sleeve and making it be rotated in a certain angle range, the top portion of said slide sleeve is fixedly connected with the receiver.

Owner:上海中上汽车科技有限公司

Wide-angle scanning phased-array antenna and communication equipment

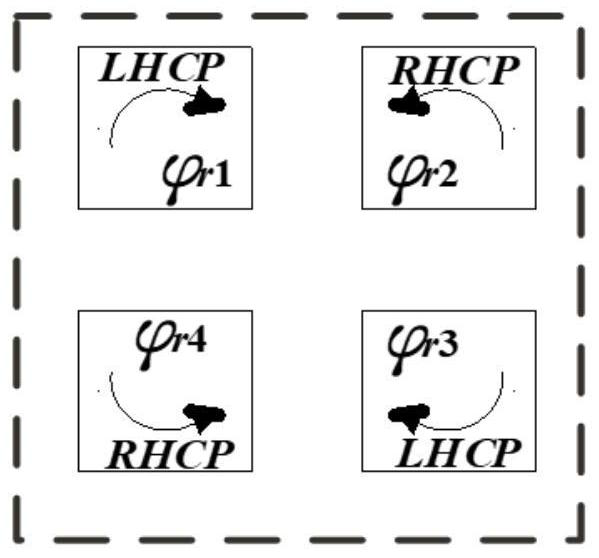

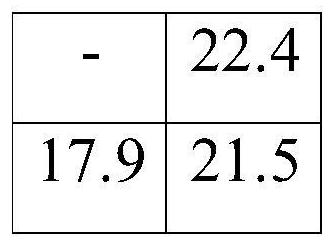

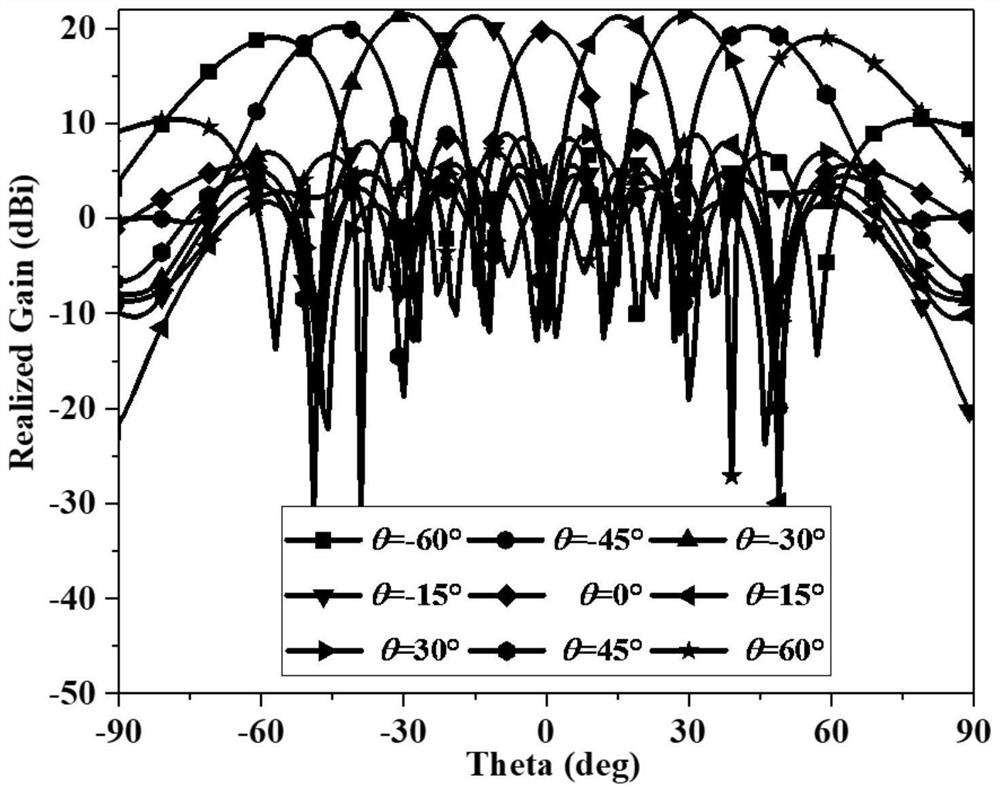

PendingCN114050424ADifferent polarizationLow Gain Ripple CharacteristicsAntenna supports/mountingsPolarised antenna unit combinationsTelecommunicationsMechanical engineering

The invention discloses a wide-angle scanning phased-array antenna and communication equipment. The wide-angle scanning phased-array antenna comprises N antenna sub-arrays, wherein each antenna sub-array comprises at least one left-hand polarized first antenna unit and at least one right-hand polarized second antenna unit which are arranged in a rectangular grid shape, and the first antenna unit and the second antenna unit are arranged adjacently. According to the invention, by adjusting the polarization characteristics and the layout positions of the antenna units, the polarization modes of the adjacent antenna units are different, so that the low-gain fluctuation characteristic of wide-angle scanning is realized.

Owner:YANGTZE DELTA REGION INST OF UNIV OF ELECTRONICS SCI & TECH OF CHINE HUZHOU

Wheel conveyance device or stations, wheel positioning and clamping system for a printing device

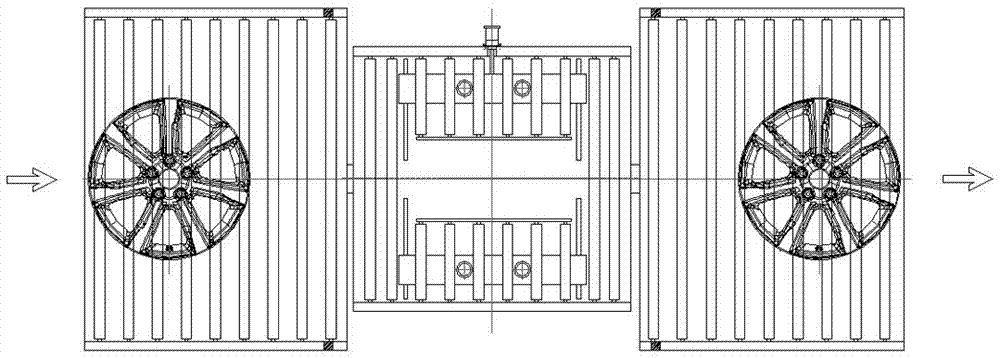

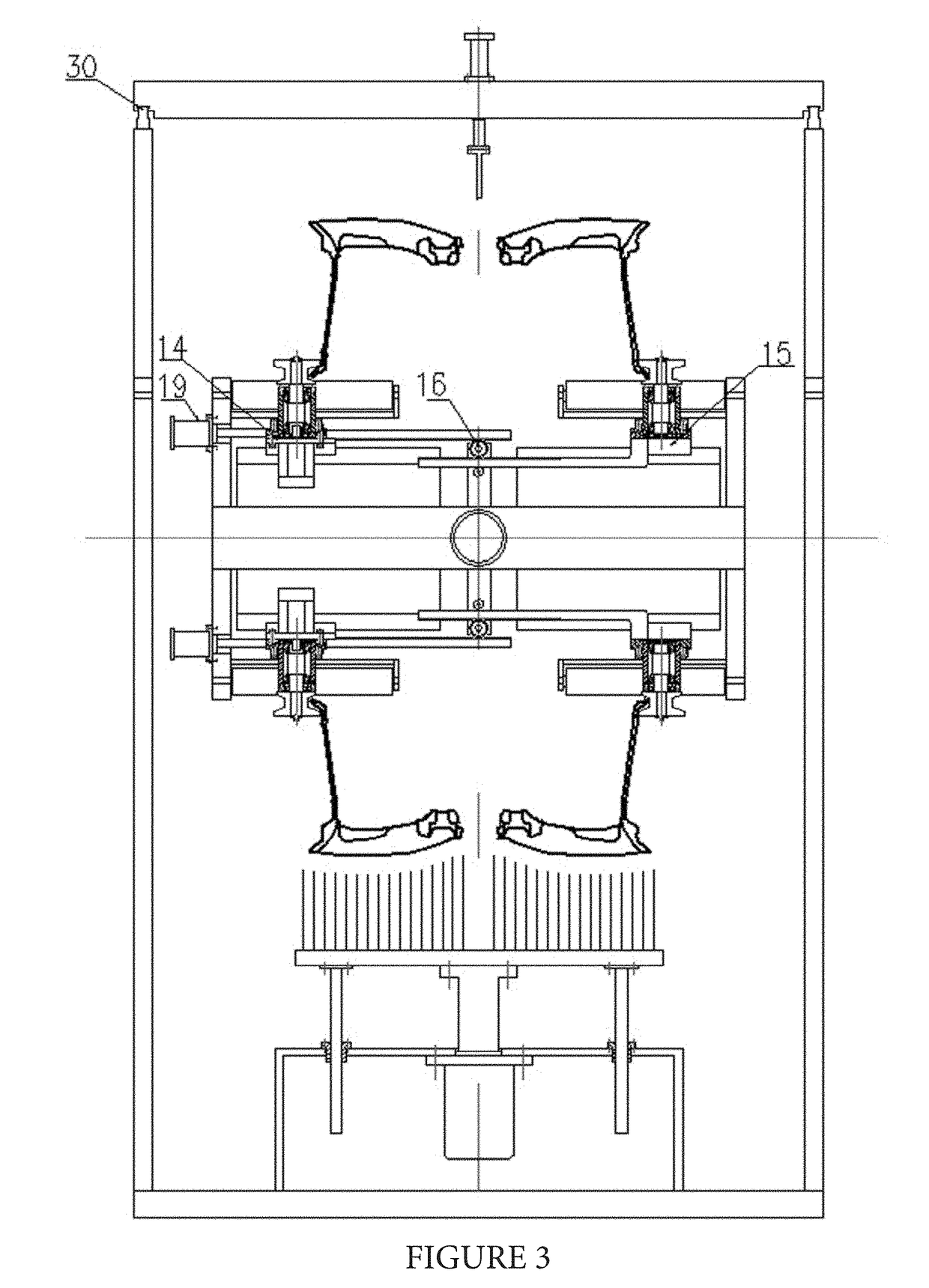

ActiveUS10464308B2Avoiding long-time waitingShorten the overall cycleRotary pressesStampingEngineeringWorkstation

Disclosed is a double-station printing device for printing a steel grade on rims, comprising a first station driving cylinder, a second station driving cylinder, a second moving platform, sensor supports, visual sensors, support frames, lifting cylinders, guide posts, lifting platforms, steel grade printers and the like. In the working process of the device, a wheel inlet roller bed continuously feeds wheels, and a first station and a second station alternatively receive the wheels, thereby avoiding long-time waiting of the wheels on the wheel inlet roller bed.

Owner:CITIC DICASTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com