Scrapped autotruck and heavy passenger car disassembling technology

A technology for heavy passenger vehicles and large trucks, which is applied in the dismantling process of scrapped large trucks and heavy passenger vehicles. It can solve the problems of waste vehicle sorting and recycling, waste of resources and environment, and low efficiency, so as to achieve beneficial resource recovery, high dismantling efficiency, and avoid Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

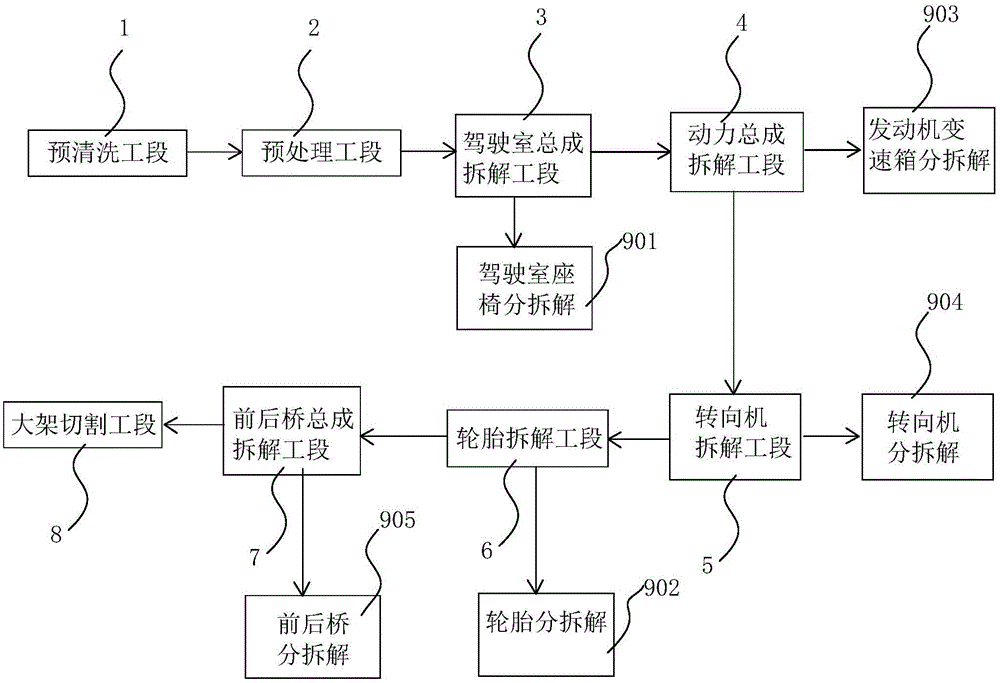

[0025] figure 1 It is a schematic diagram of the overall structure of the present invention. like figure 1 Shown: the dismantling process of scrapped large trucks and heavy passenger cars provided by the present invention includes the following sections in turn: pre-cleaning section 1, pretreatment section 2, cab assembly dismantling section 3, power assembly dismantling section 4, steering gear Dismantling section 5, tire dismantling section 6, front and rear axle assembly dismantling section 7, large frame cutting section 8 and sub-disassembly section.

[0026] In the pre-cleaning section 1, after the appearance of the vehicle is cleaned, the vehicle to be dismantled is transported to the area to be dismantled by a battery trailer.

[0027] Pretreatment section 2 uses a hydraulic li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com