Speed regulator

A technology of speed adjustment and constant speed, applied in the direction of vehicle gearboxes, machines/engines, transmissions, etc., can solve the problems of increased weight, dust and wear, and achieve the effects of cost saving, low wear and novel layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

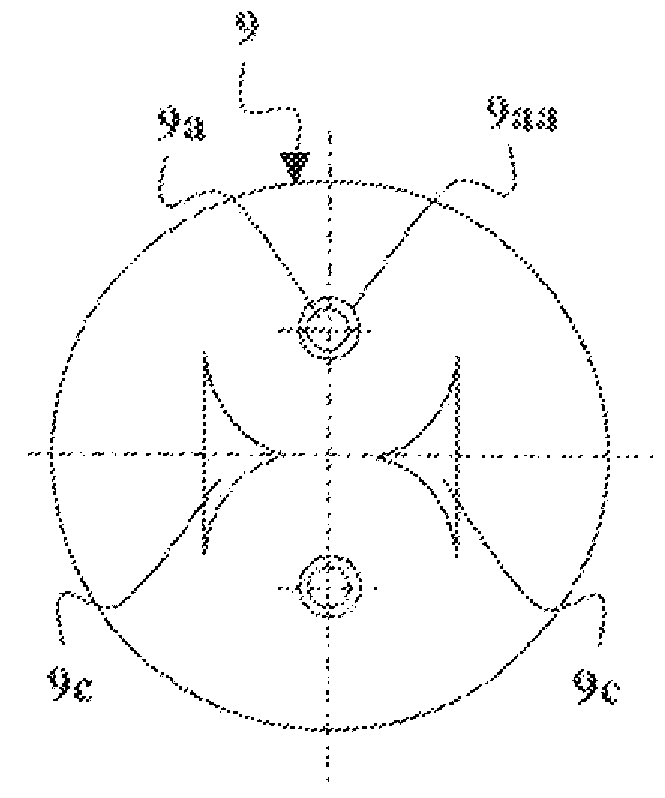

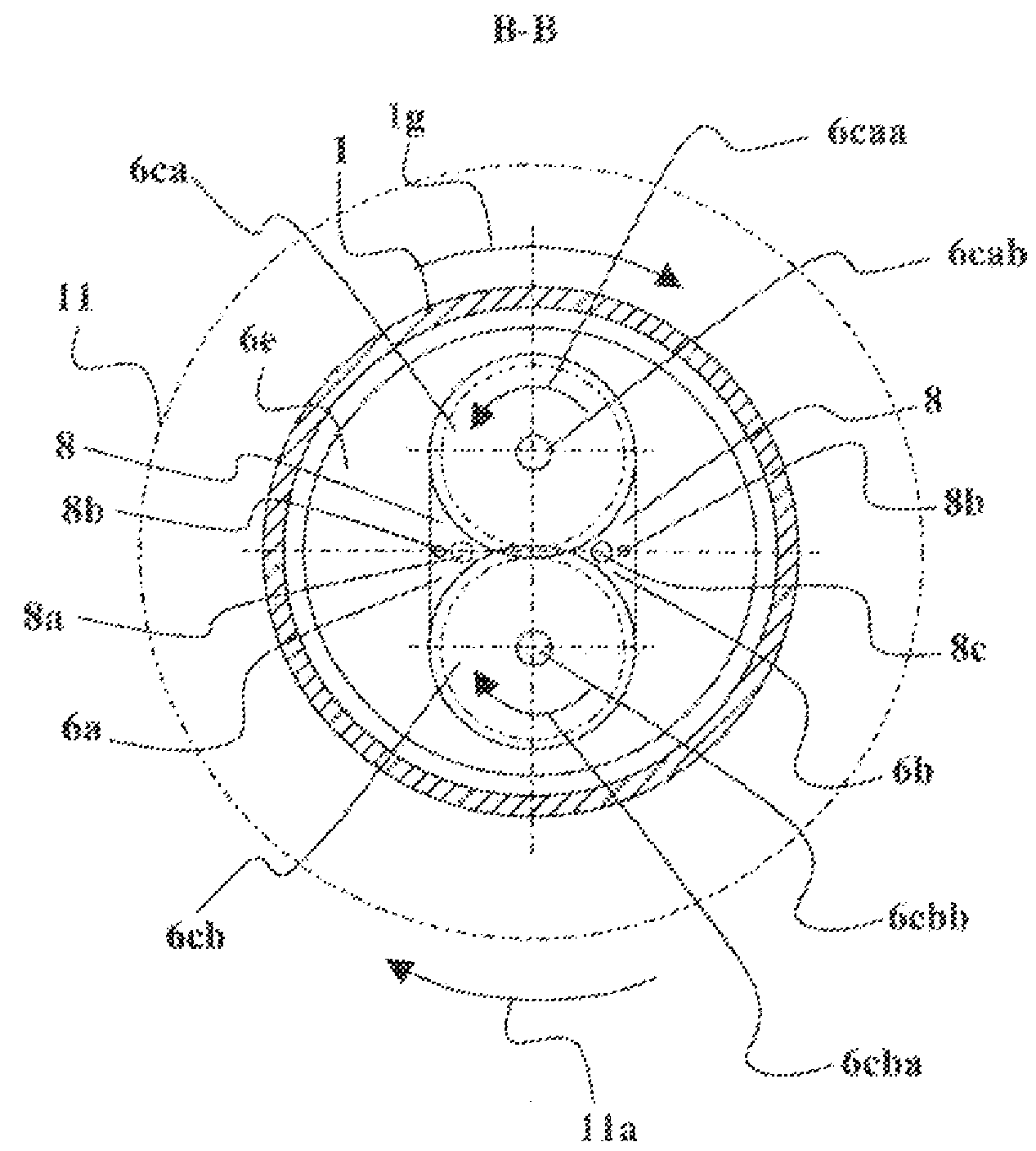

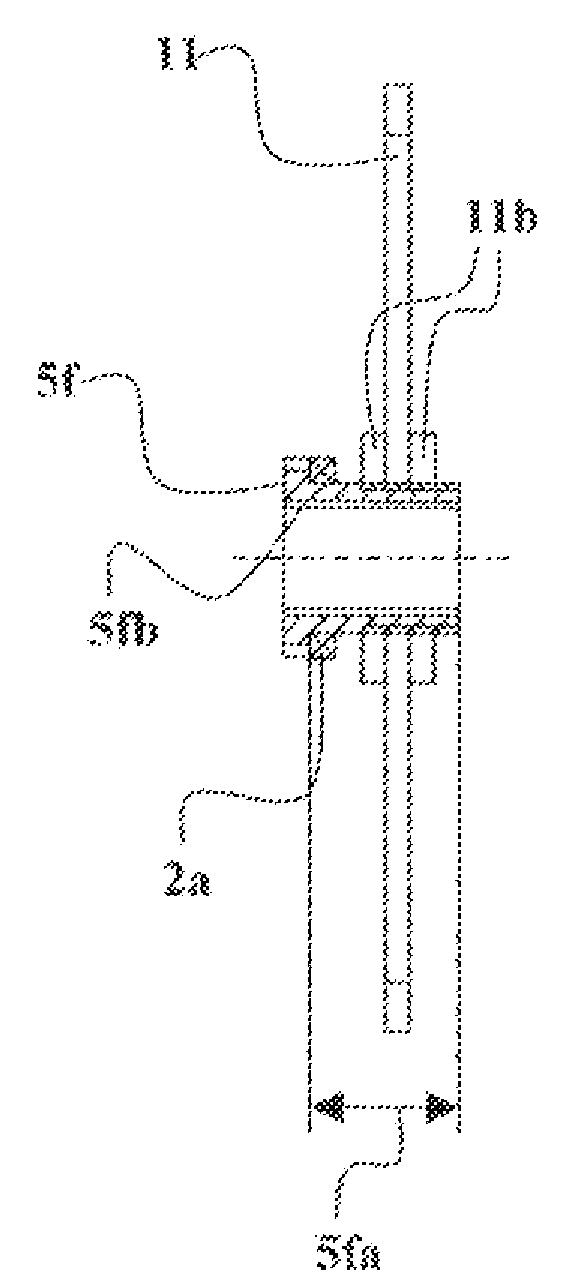

[0047]The figure shows the following components and items of the speed regulator: body 1 with outer surface 1a, inner surface 1b, collar 1c, shoulder 1d, internal thread 1f and rotation direction arrow lg of body 1. The outer surface 1a includes a rotating part laa, and the bicycle chainstay includes a mounted part lab. There is a drive end 2, in which there is a bearing 2a. There are ends 3. There is a shaft 4 in which there are a support shaft 4a, a mounting nut 4b, a collar 4c, a main bearing 4d and a hole 4e. The support shaft 4a includes threads 4aa for mounting nuts 4b. The collar 4c includes a mounting hole 4ca in which the seal 4caa is in a groove. There is a drive end shaft 5 in which there are a support shaft 5a, a mounting nut 5b, a collar 5c, a main bearing 5d, a hole 5 and a rotating gear 5f. The support shaft 5a includes threads 5aa for mounting nuts 5b. The collar 5c includes a bore 5ca and a pump shaft bearing 5cb. The rotary gear 5f includes a sleeve 5fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com