Imbedded wireless stress/strain/temperature sensor test platform

A temperature sensor, strain sensor technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problem of not being able to be reused, and achieve the effect of low total cost and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

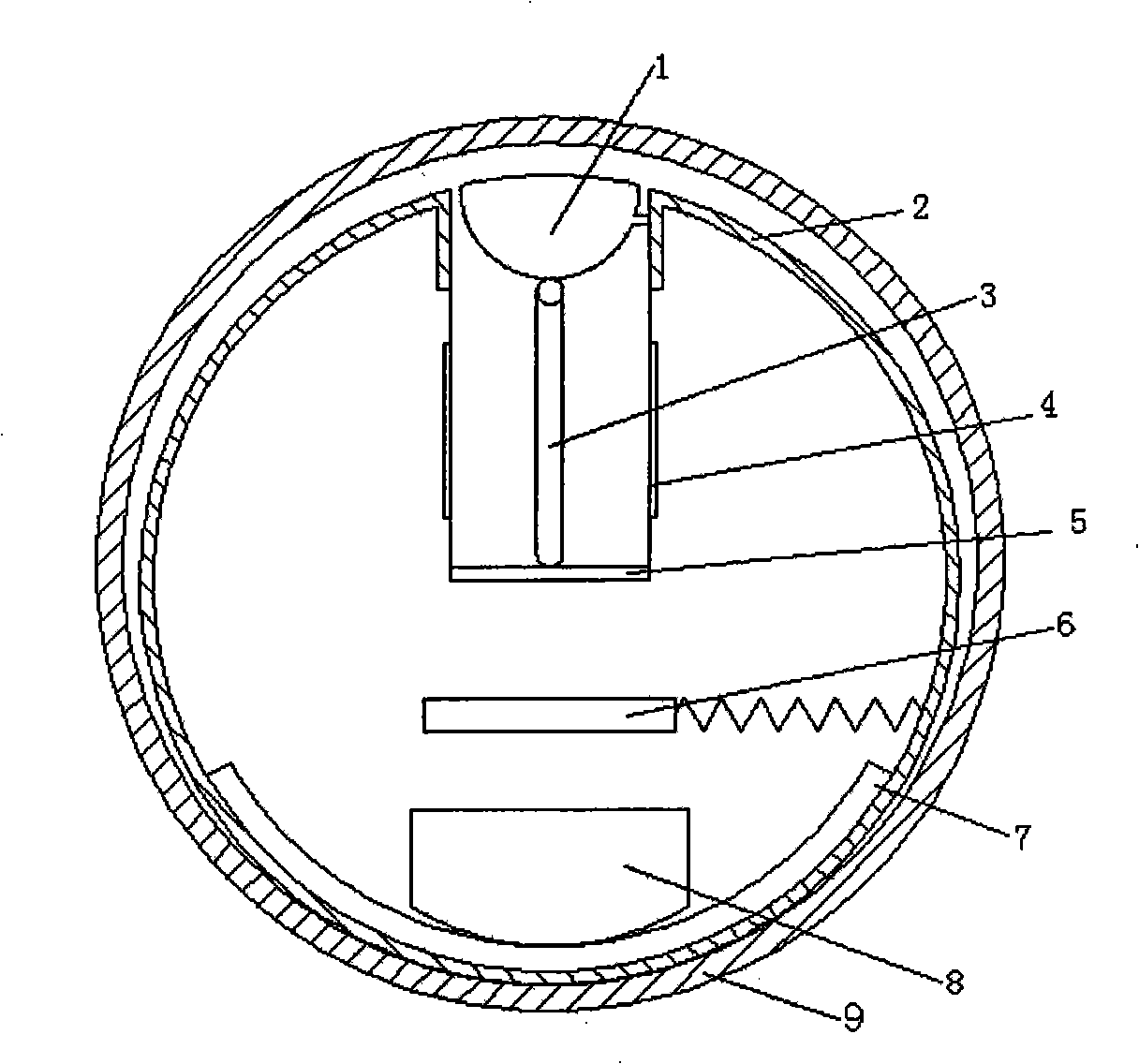

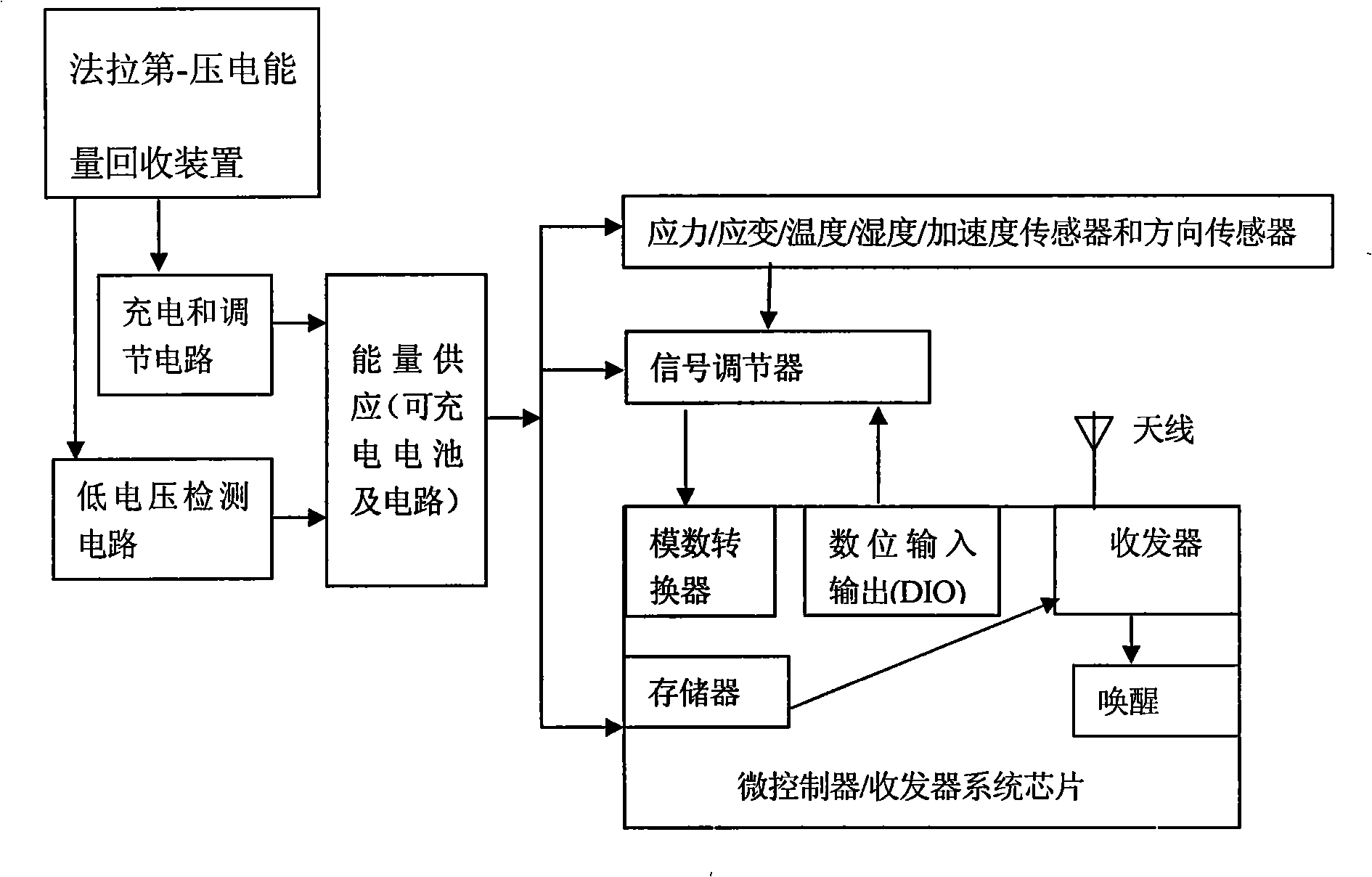

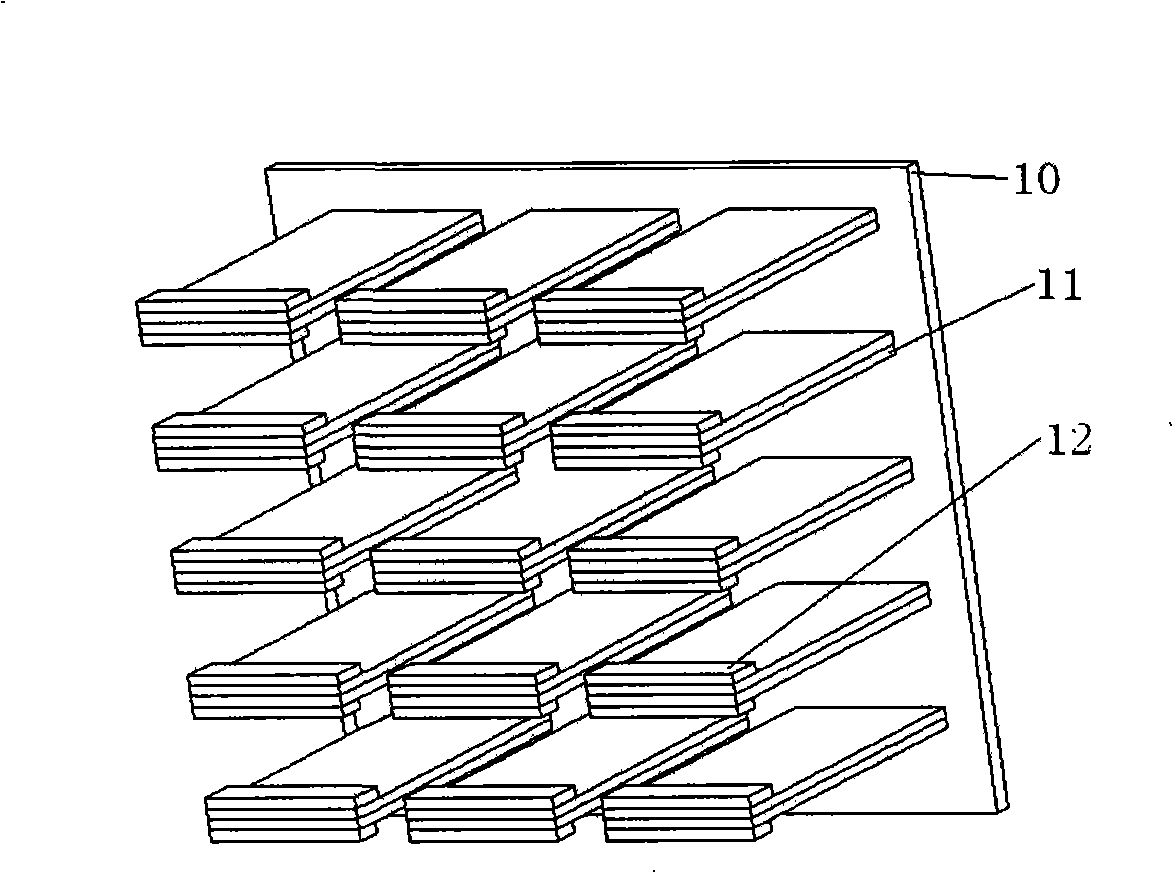

[0014] see figure 1 , the present invention includes a spherical brittle shell 9 made of ceramic or glass brittle material and a spherical rigid shell 2 arranged in the brittle shell 9, the rigid shell 2 is strong enough to resist the mechanical force transmitted from the ground , and resistant to environmental corrosion, a spherical joint 1 is hinged in the rigid shell 2, a dowel 3 is arranged at the lower end of the spherical joint 1, and a strain gauge 5 is placed at the bottom of the dowel 3, and is consolidated on both On a linear metal strain bar 4, the spherical connection 1, the dowel 3, the strain bar 4 and the strain gauge together form a sensor, and a magnetic field strength of at least 2000 Oersted is arranged on the opposite side of the spherical 1 connection in the rigid shell 2. The permanent magnet 7, and the electronic device 8 is arranged on the permanent magnet 7, and the farad first piezoelectric energy recovery device 6 connected with the electronic device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com