Rapid response electric heat exchanger

A technology for heat exchangers and rapid heating, applied in the field of fluid heat exchangers and fluid fluid heat exchangers, which can solve the problems of not being easy to manufacture, and the Rezabek system does not have a compact structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

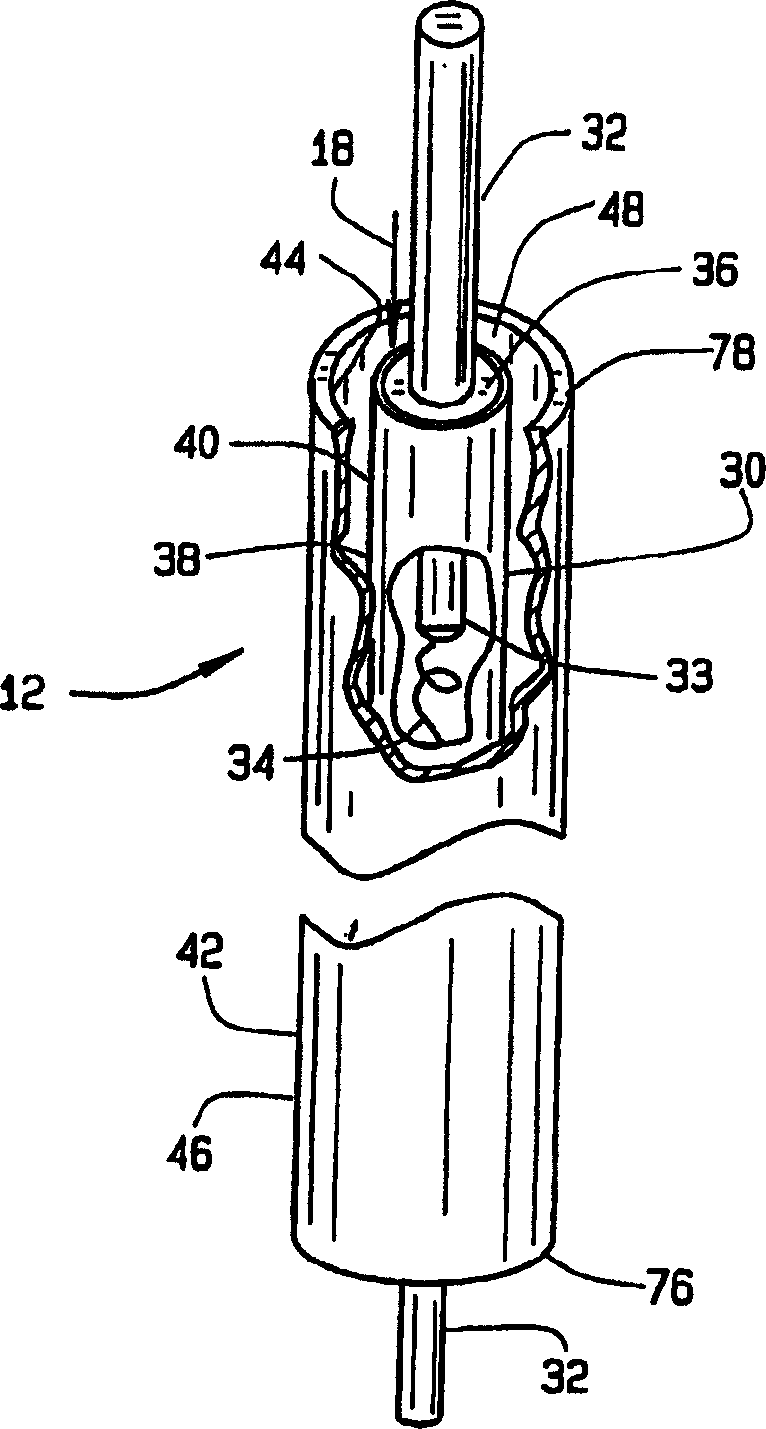

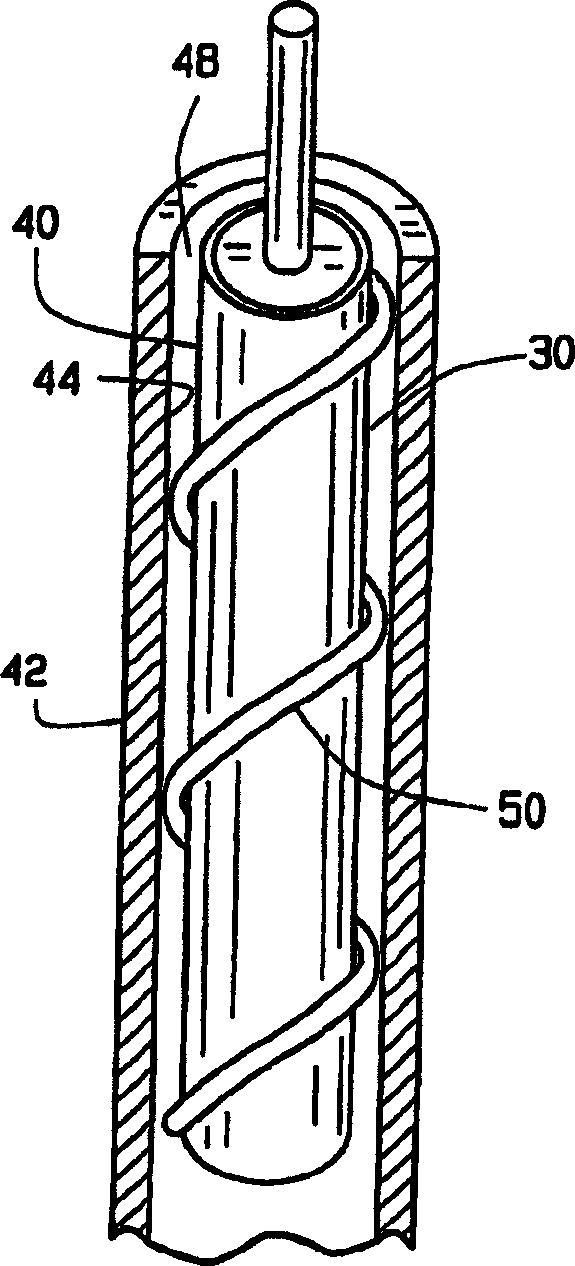

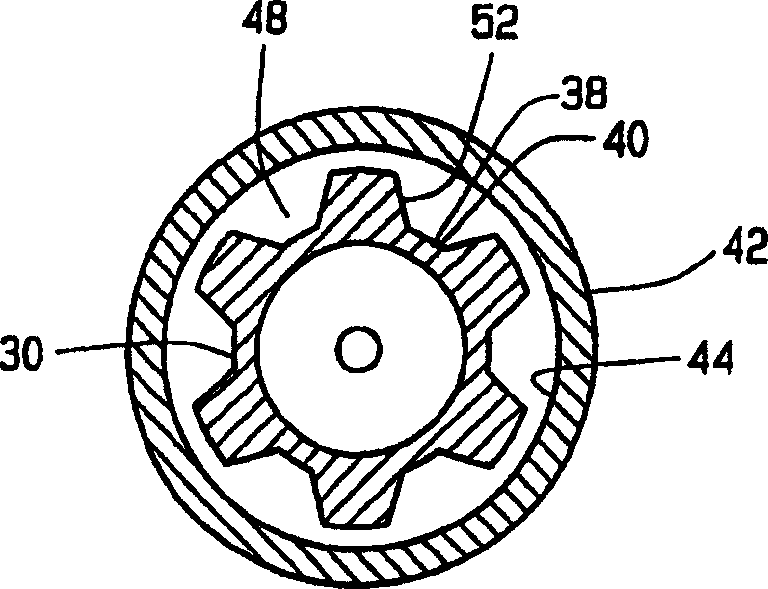

[0036] Referring to the drawings, a preferred embodiment of the fluid heating system of the present invention is shown in FIG. 4 and generally designated 10 . The fluid heating system 10 includes a housing 13 containing a body 17 defining an elongated upper portion 25 and a lower portion 26 having a fluid heat exchanger 12 disposed therein providing means for heating a fluid 18 to a predetermined temperature. heating equipment. Fluid 18 enters upper section 25 from return side 22 of fluid heating system 10 and is heated while flowing along upper section 25 and lower section 26 . The heated fluid 18 then exits the lower portion 26 and flows into the inlet side 24 and through the remainder of the fluid heating system 10 . Once circulated, the fluid 18 flows through the return side 22 so that the above process is repeated. The temperature level of the fluid 18 is maintained by a temperature control system 20 .

[0037] 1 and 4, the fluid heat exchanger 12 includes an elongated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com