Environment-friendly linear forward swing type bulk cement ship loader

A bulk cement, environmentally friendly technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of difficulty in achieving energy saving and emission reduction, difficulty in implementing airtight measures, and high energy consumption of the dust collection system, so as to facilitate efficient dust collection. , The effect of reducing the cost of hydraulic investment and reducing the width of the wharf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

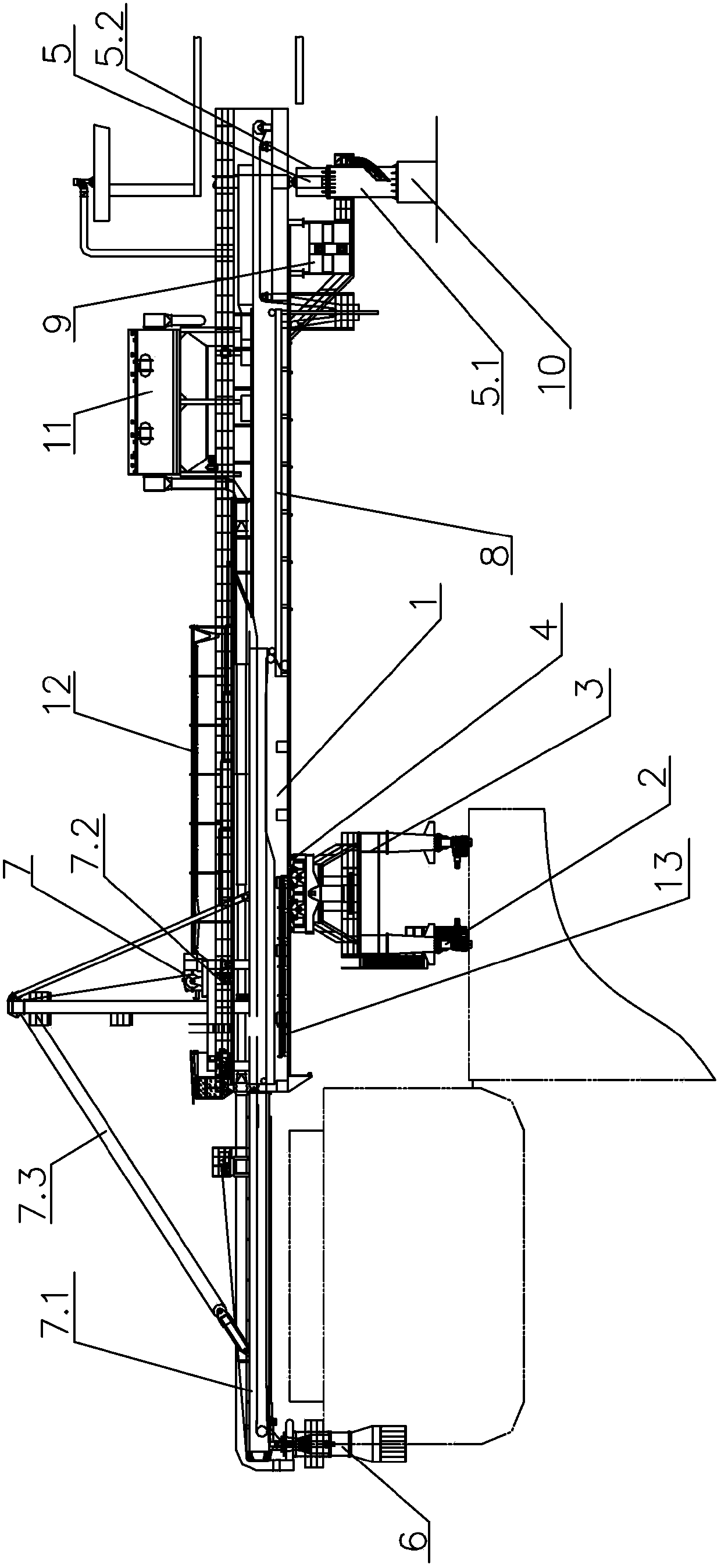

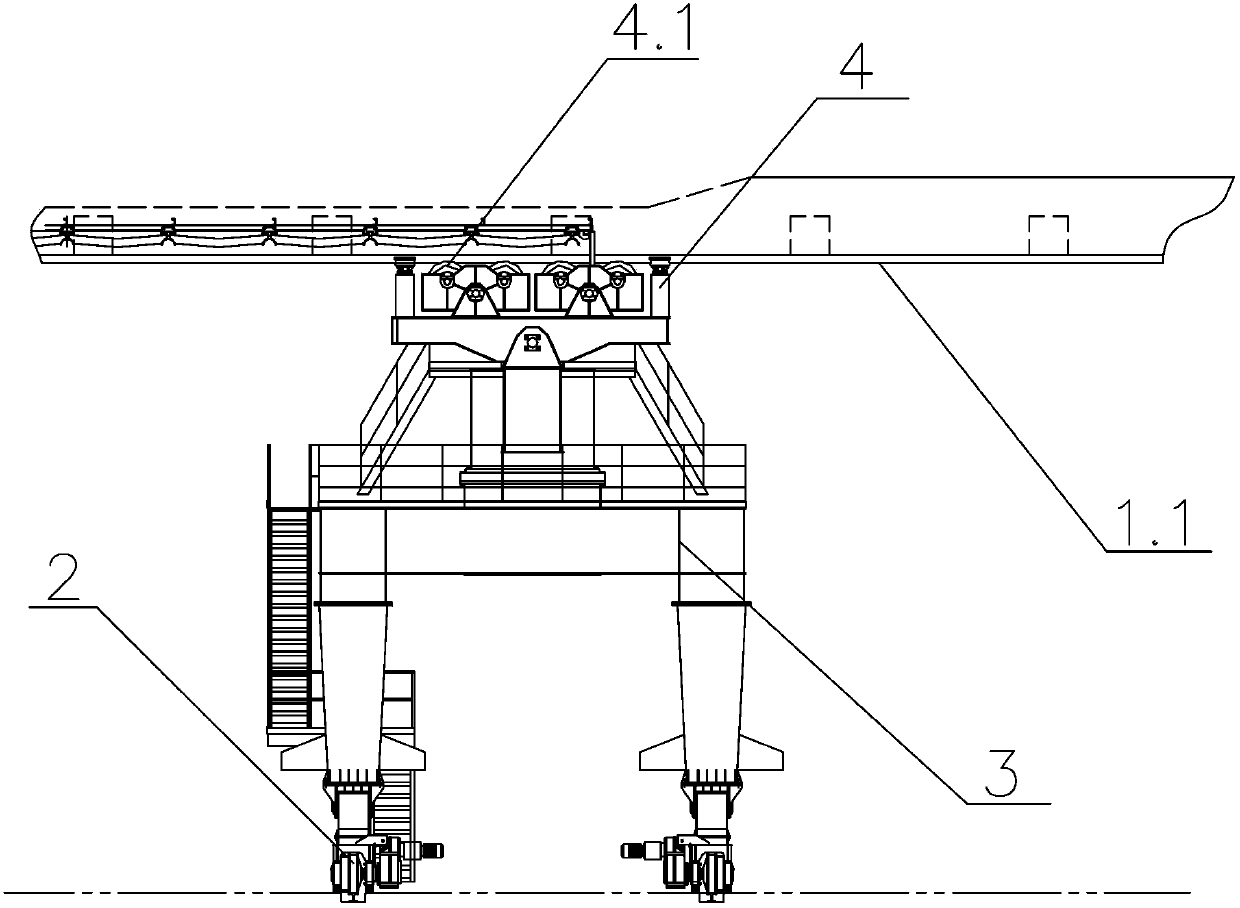

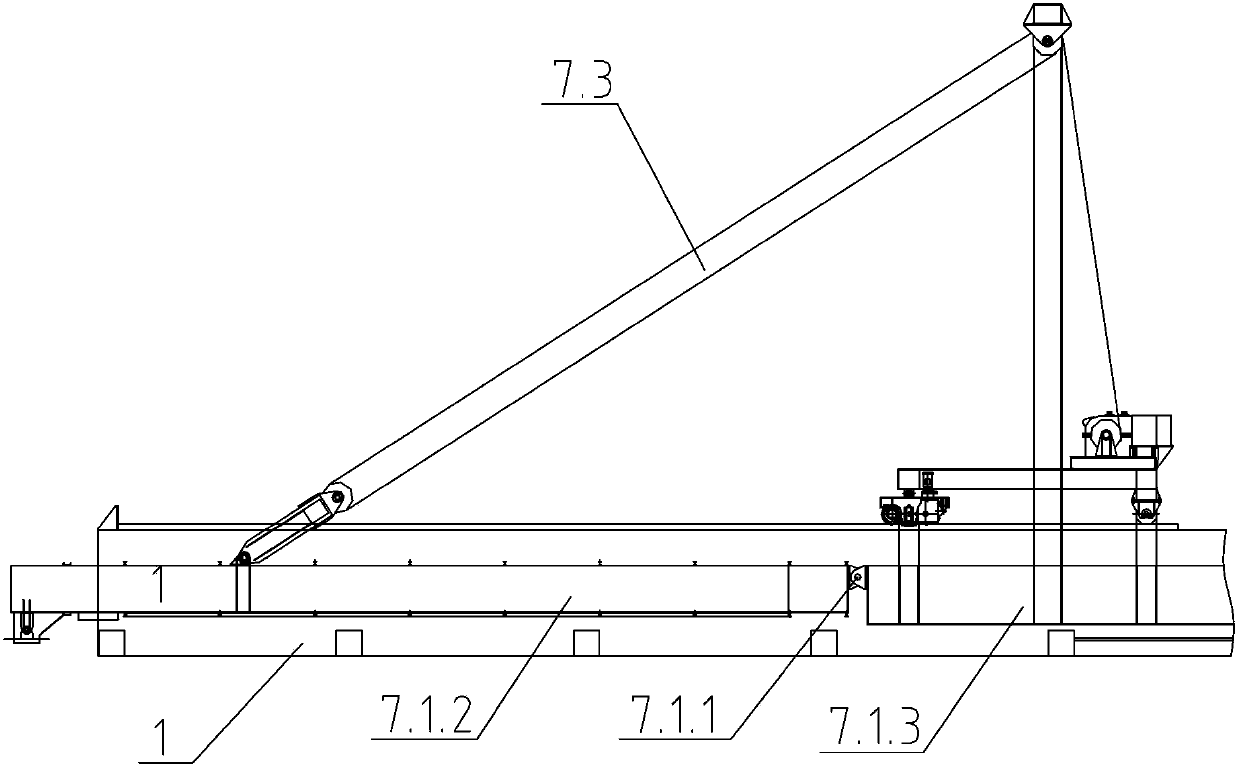

[0019] figure 1 , 2 The shown environment-friendly linear front-swing bulk cement ship loader includes a swing beam 1, a cart traveling mechanism 2 installed below the swing beam 1, a door frame 3, a front support system 4 and a rear support system 5 and installed on Telescopic chute system 6, boom system 7, belt conveyor system 8 and electric transmission system 9 above the swing beam 1. The swing beam 1 is provided with a boom sliding power supply mechanism 12 for providing power to the boom system 7 and a cart sliding power supply mechanism 13 for the cart traveling mechanism 2 .

[0020] The rear support system 5 includes a fixed support 5.1 and a slewing support 5.2, the fixed support 5.1 and the slewing support 5.2 are connected through a slewing bearing, the fixed support 5.1 is fixedly connected with the poured rear foundati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com