Patents

Literature

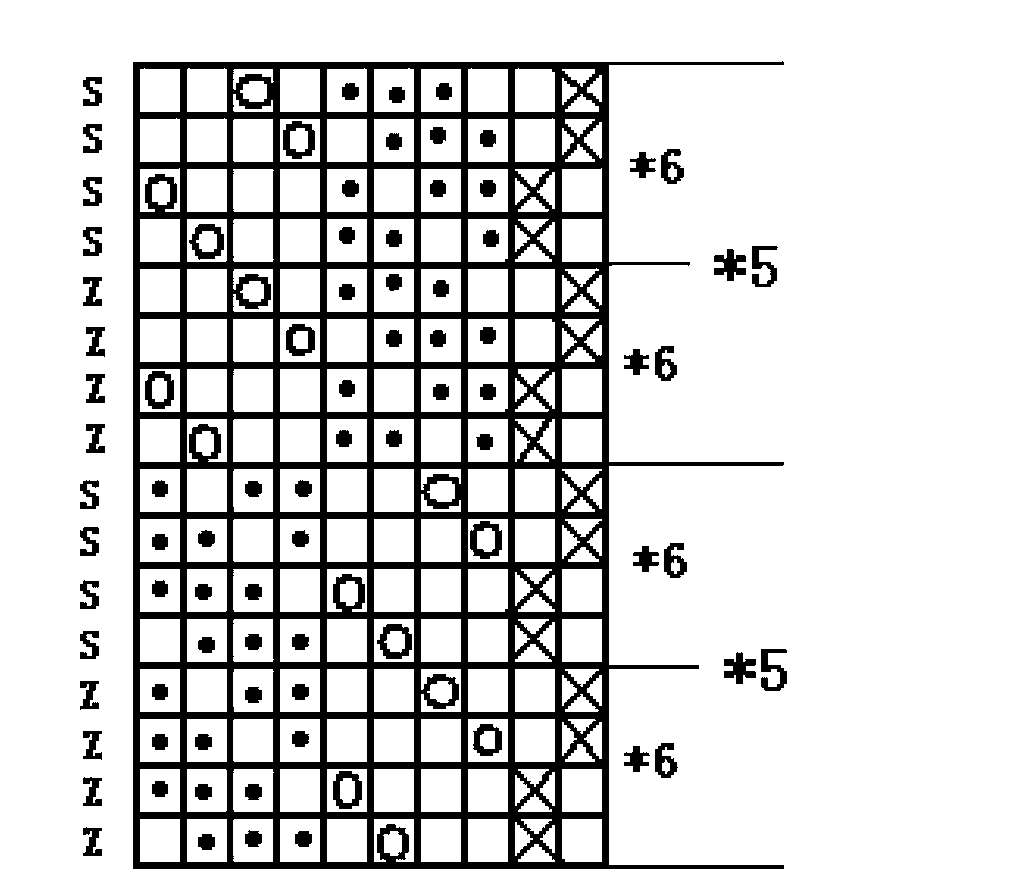

89results about How to "Increase production difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

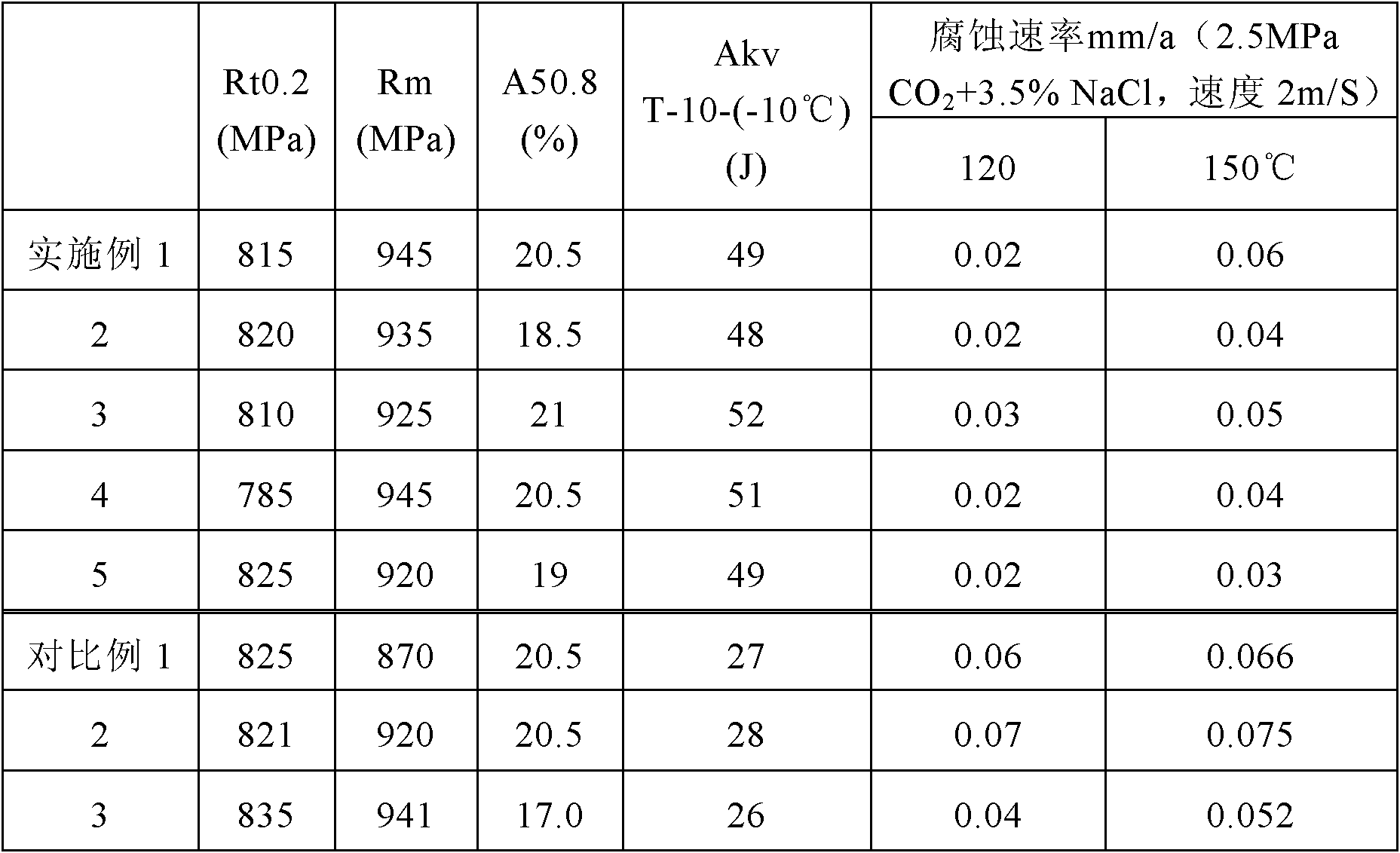

110 ksi-grade oil sleeve having high resistance to co2 corrosion and its preparation method

InactiveCN102851607AMeet the needs of mining and developmentIncrease production difficultyDrilling rodsDrilling casingsHigh resistanceMartensitic stainless steel

Disclosed are a 110 ksi-grade oil sleeve having high resistance to CO2 corrosion and its preparation method. The oil sleeve contains C 0.05-0.14 wt%, Si 0.2-0.5 wt%, Mn 0.20-1.0 wt%, Cr 12.0-14.0 wt%, Ni 0.5-1.5 wt%, Mo 0.2-1.0 wt%, N 0.03-0.08 wt%, and Fe and unavoidable impurity elements in balance. Through low carbon and nitrogen microalloying, the invention solves the problem of low toughness of steel for high-strength high-carbon 13Cr martensitic stainless steel oil sleeve.

Owner:BAOSHAN IRON & STEEL CO LTD

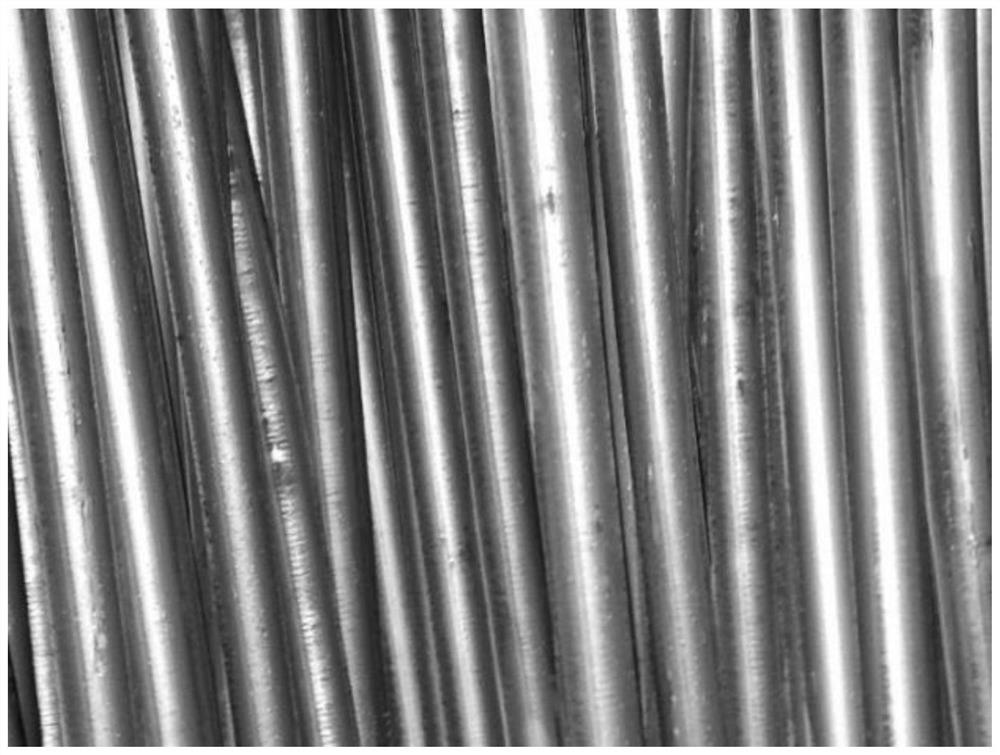

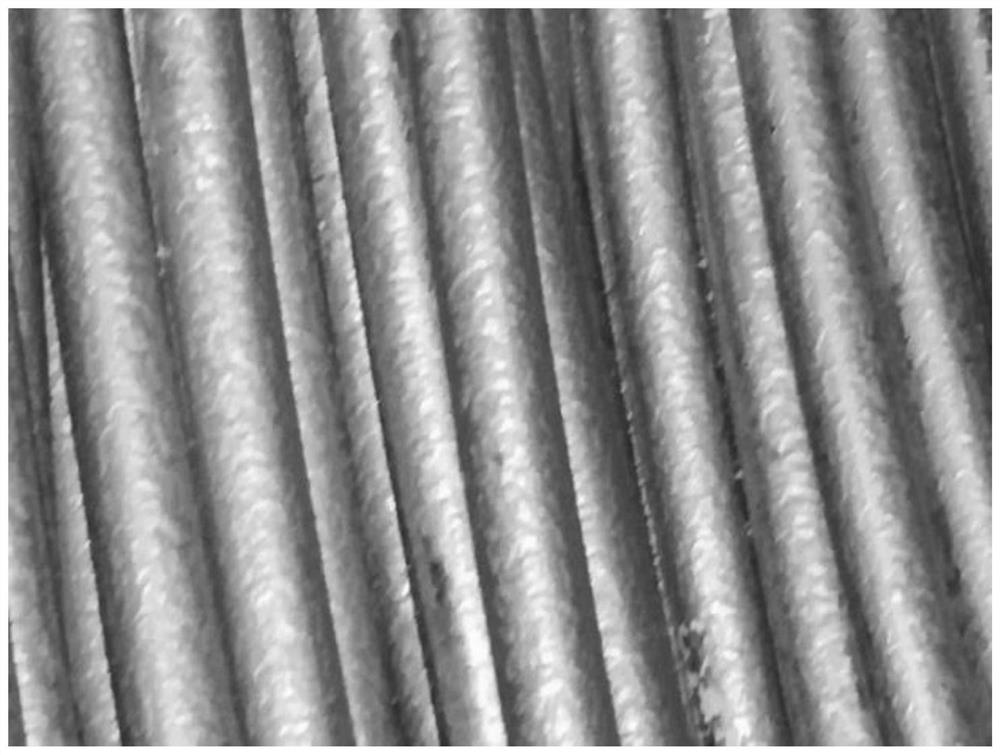

Rolling process for medium-carbon and high-sulfur alloy steel wire rod

ActiveCN111687209AIncrease production difficultyReduce depthFireproof paintsTemperature control deviceWire rodIron oxide

The invention belongs to the technical field of rolling, and relates to a rolling process for a medium-carbon and high-sulfur alloy steel wire rod. A continuously-cast blank is subjected to corner peeling, coated with a high-temperature coating material, and heated at a high temperature of 1230-1290 DEG C, and the heating time is not greater than 120min; high-temperature rolling at 1130-1190 DEG Cis adopted during initial rolling, and high-temperature rolling at a temperature of not lower than 1030 DEG C is adopted in a whole steel rolling process; and no cracks and no slip in a rolling process are ensured while the depth of a decarburization layer of the wire rod is controlled. The thickness of an iron oxide scale can be reduced separately by turning on a water tank, controlling a finishrolling temperature and controlling a laying temperature to be 895-920 DEG C, turning on three fans and carrying out air-cooling to reach a low temperature in the earlier stage of controlled cooling,and turning off the fans and opening a heat-insulation cover in the later stage of controlled cooling. Through the controlled rolling and controlled cooling process, the depth of the surface decarburization layer of the medium-carbon and high-sulfur alloy steel wire rod can be effectively controlled to be not greater than 0.5d%, the thickness of the iron oxide scale can be effectively controlledto be not greater than 15[mu]m, and the surface crack and pit defects of the wire rod are effectively controlled.

Owner:ZENITH STEEL GROUP CORP +1

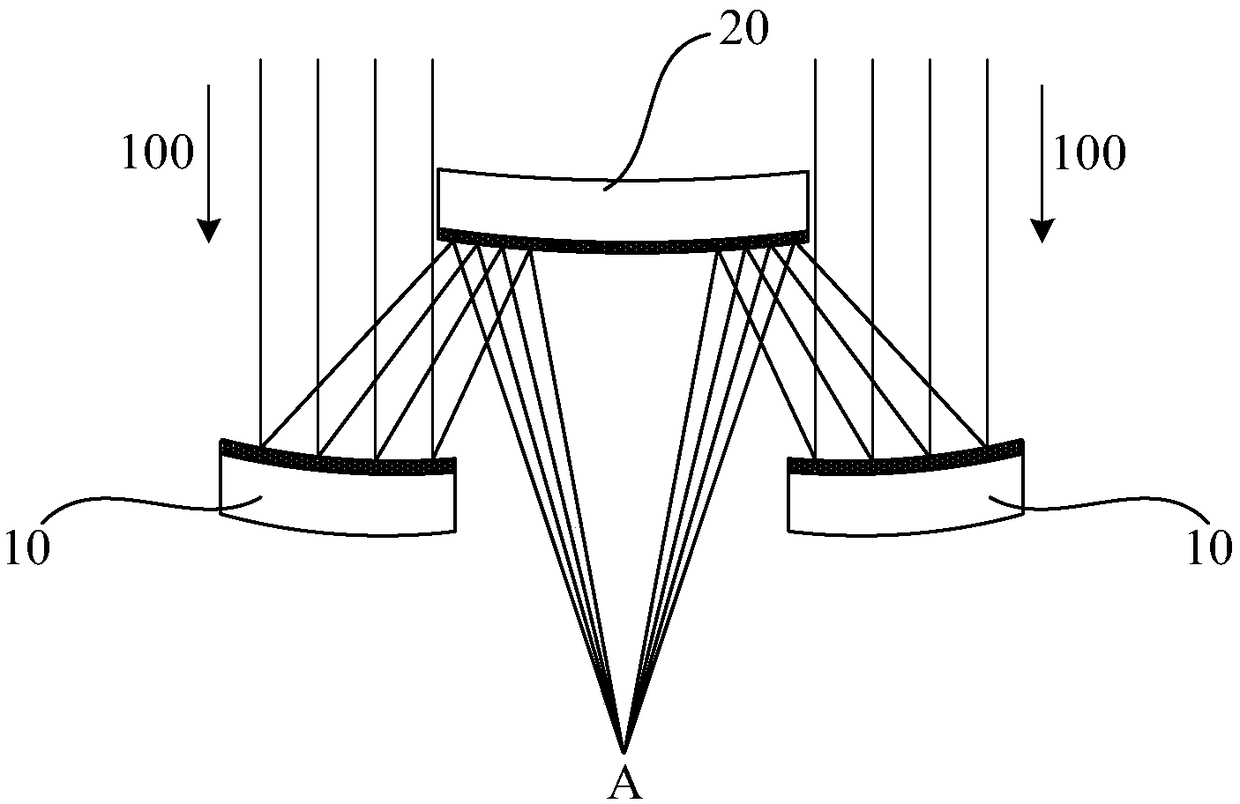

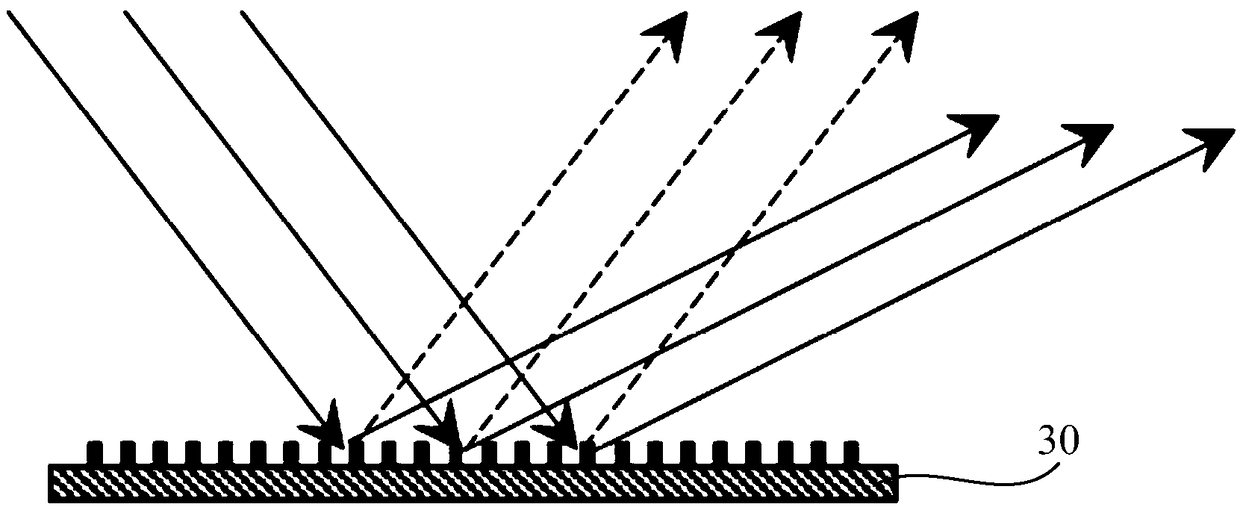

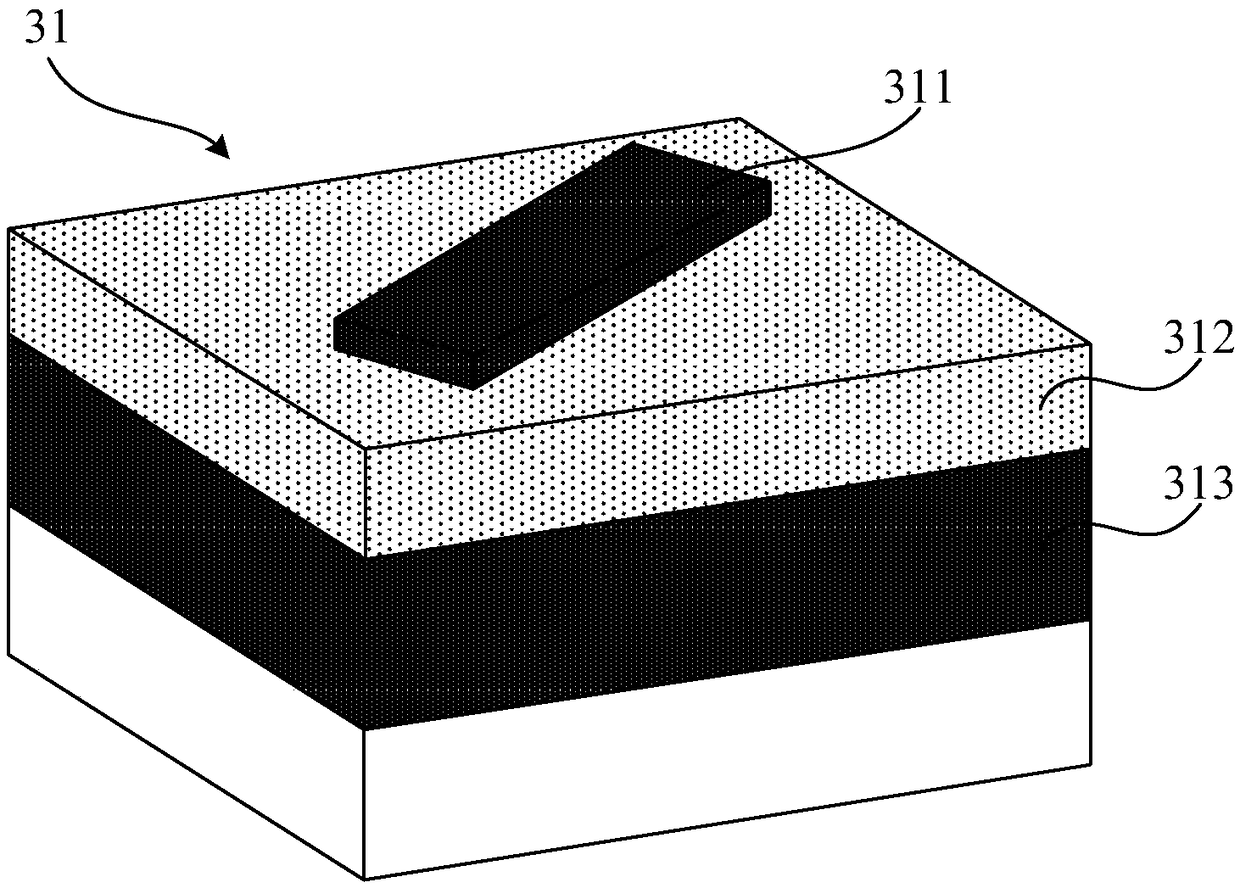

Reflective superstructure surface primary mirror, auxiliary mirror and telescope system

PendingCN109143567ASolve the difficulty of preparationThin and compact integrationMirrorsTelescopesSurface functionAuxiliary memory

The invention discloses a reflective superstructure surface primary mirror, a reflective superstructure surface auxiliary mirror and a telescope system. The reflective superstructure surface primary mirror includes a transparent substrate and a primary mirror superstructure surface function unit pattern on the transparent substrate, wherein the primary mirror superstructure surface function unit pattern satisfies primary mirror phase distribution, the primary mirror superstructure surface functional unit pattern includes a primary mirror superstructure surface function structure located withina set annular region, the primary mirror superstructure surface function structure includes multiple primary mirror superstructure surface function units, the primary mirror superstructure surface function units include anisotropic primary mirror subwavelength structures, phases introduced by the anisotropic primary mirror subwavelength structures satisfy primary mirror phase distribution, the set annular region forms a light transmission hole, and light reflected by the reflective superstructure surface auxiliary mirror is focused through the light transmission hole. The reflective superstructure surface primary mirror is advantaged in that a planar reflective superstructure surface is realized for the design of the reflective telescope system, and problems of high difficulty in preparation, slow processing speed, high cost and large volume of a conventional reflective telescope system are solved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

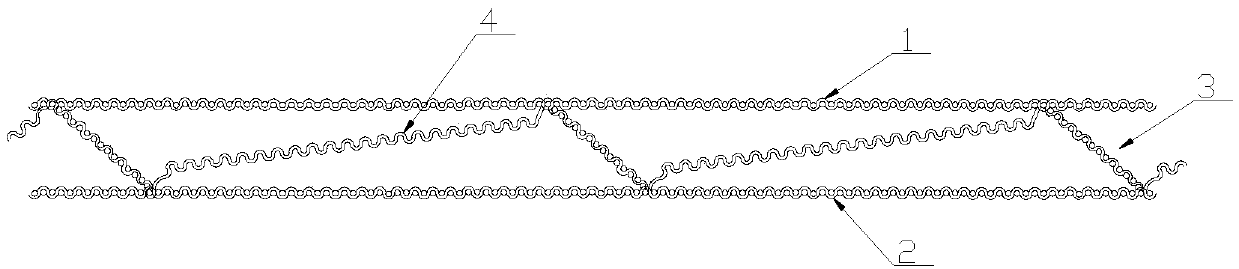

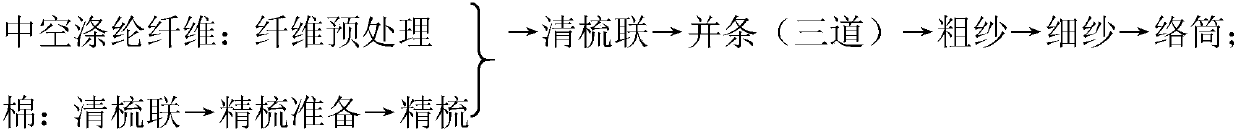

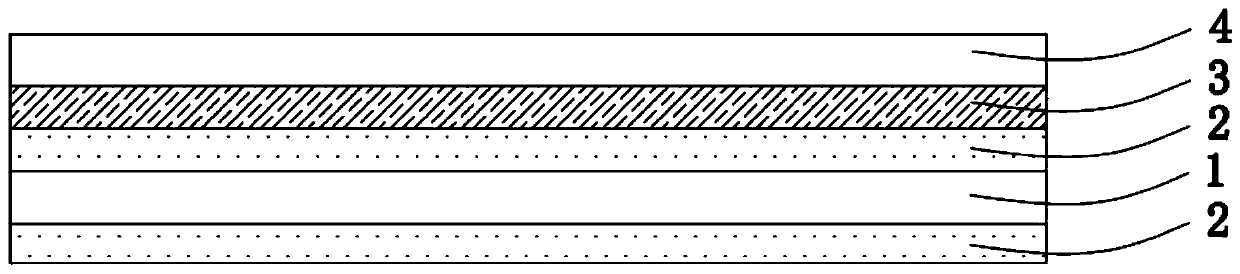

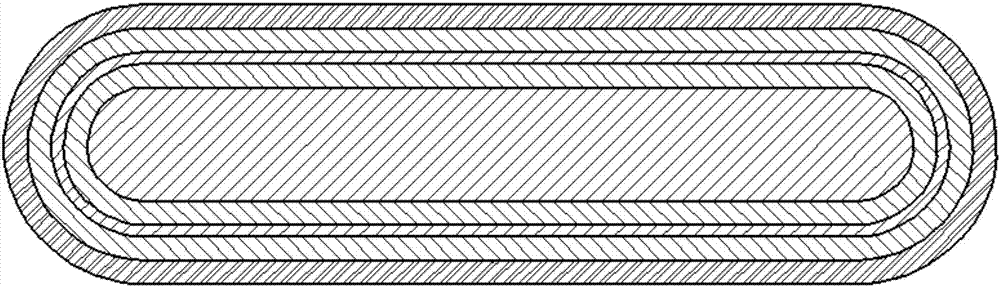

Design method and production technology of multi-layer heat preserving shell fabric

ActiveCN109537126AStrong three-dimensional structureAvoid breakingMulti-ply fabricsPolyesterSurface layer

The invention discloses a design method and a production technology of a multi-layer heat preserving shell fabric. The design method is characterized in that a woven fabric on the surface layer is prepared by blending polyimide fiber and hollow polyester fiber with compact sirospun yarn; the shell fabric is high in strength, high in friction resistance and high in heat preserving performance; warpyarn of the woven fabric on the intermediate layer is cotton and hollow polyester fiber blended yarn; weft yarn is OUTLAS phase-changed fiber and coffee carbon polyester fiber blended yarn; a relatively long floating line of the weft yarn is positioned between the woven fabrics on the surface layer and the inner layer, so that the yarn is in a loose state and supports the woven fabrics on the surface layer and the inner layer, and as a result, a heat preserving layer is formed; the yarn in the intermediate layer is relatively thick, the twisting coefficient is small, and heat absorbing and preserving fibers are adopted, so that the heat preserving performance of the woven fabrics can be ensured. The inner layer is the cotton and hollow polyester fiber blended yarn, so that the heat preserving effect is good; the shell fabric is skin friendly, can absorb moisture and is breathable, so that the problem of discomfort caused by that a woven fabric with too high moisture regain absorbs moisture and adheres to the body can be avoided.

Owner:泰州虹纬纺织有限公司

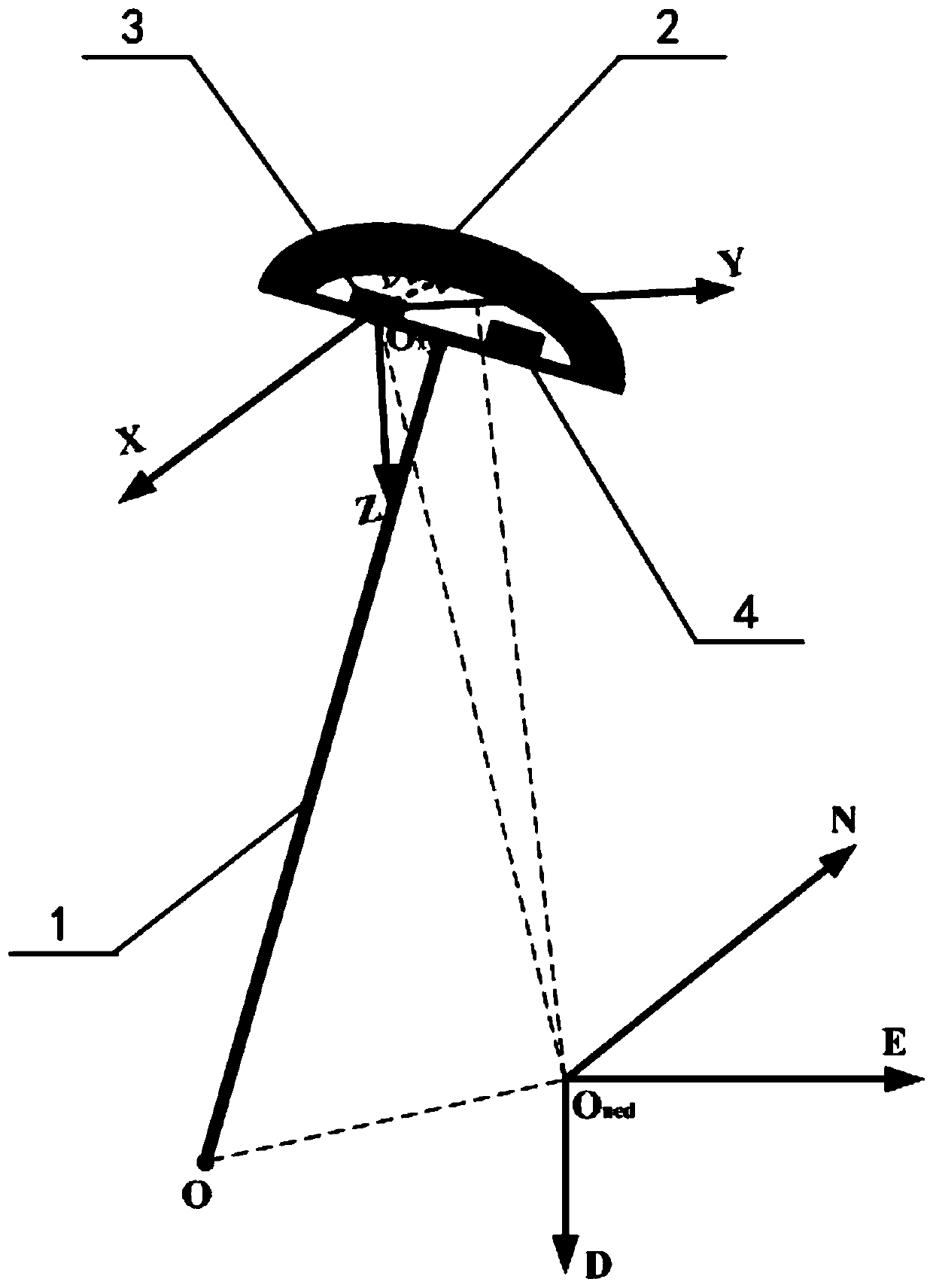

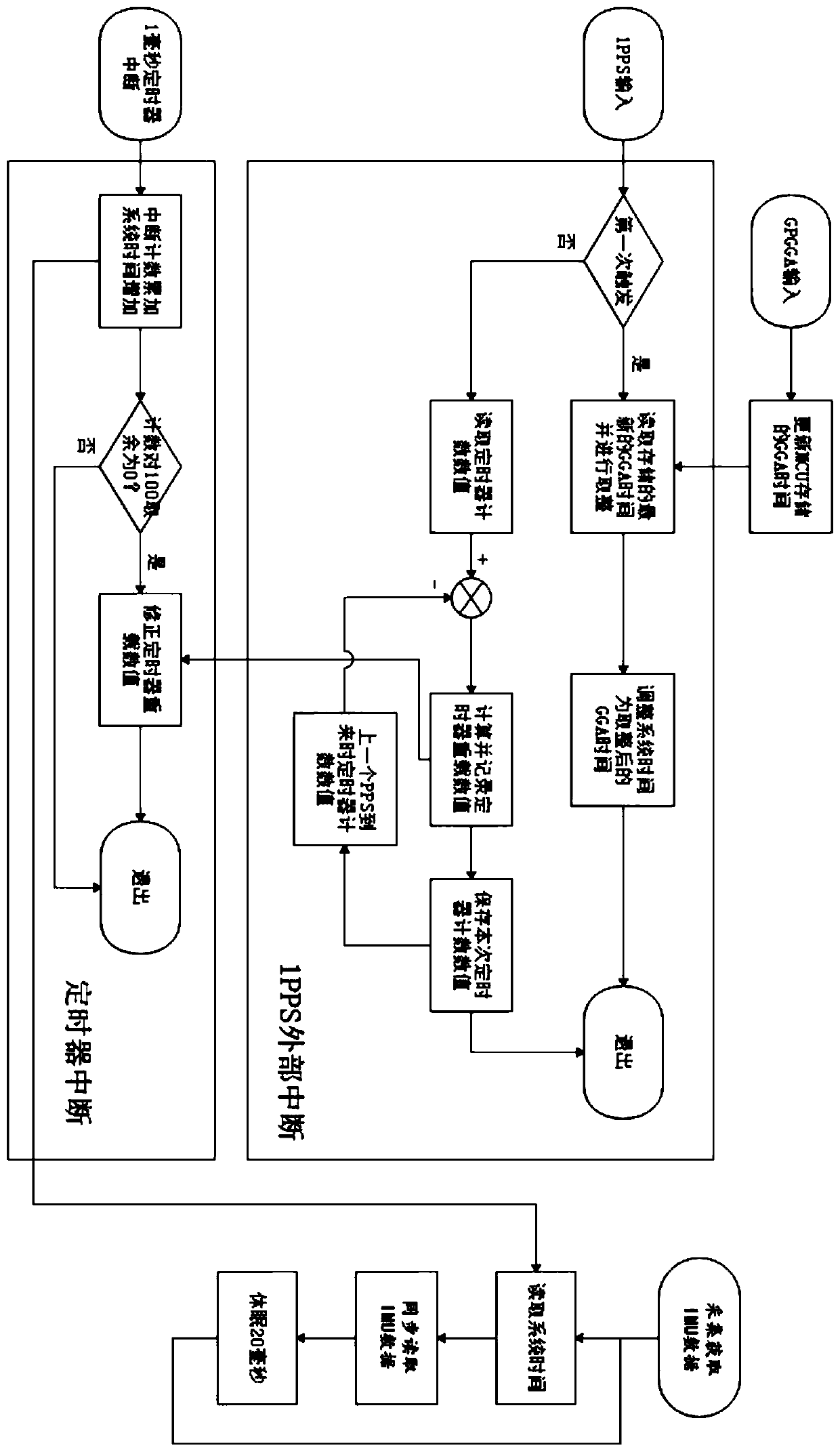

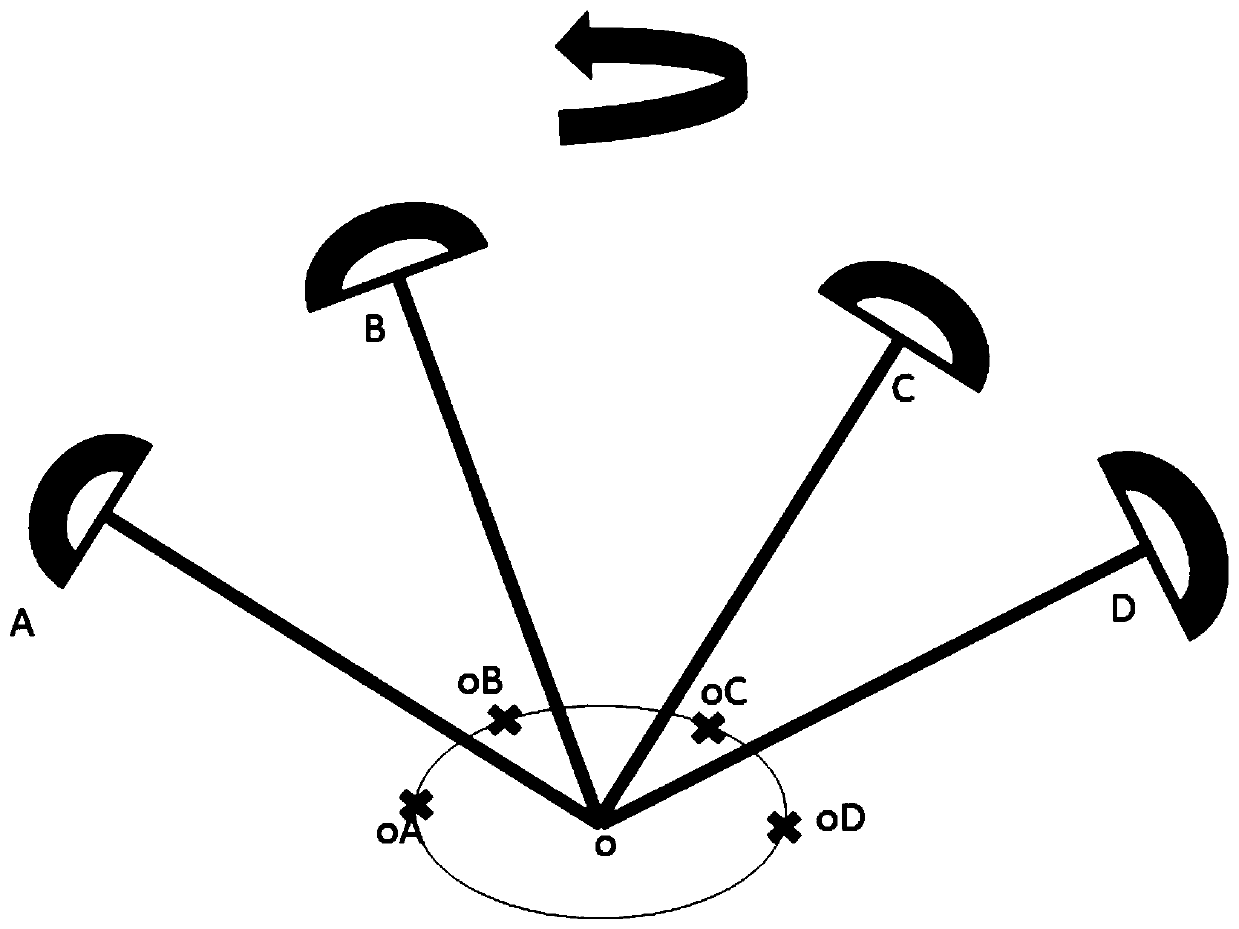

Tilt measurement method of surveying and mapping integrated machine based on GNSS receiver and IMU sensor

ActiveCN110017849AImprove work efficiencyAvoid tilt measurement errorsSurveyor's staffsMovable markersSurveyorGeometric transformation

The invention relates to the technical field of surveying and mapping, and discloses a tilt measurement method of a surveying and mapping integrated machine based on a GNSS receiver and an IMU sensor.Through the creation of the tilt measurement method, repeated mutual circulation between prediction and correction of designed multi-dimensional unknown state variables is carried out by utilizing akalman filter algorithm principle, so that the multi-dimensional unknown state variables continually approach true values, and then newest three-dimensional attitude angles and newest rotation matrixes from an XYZ coordinate system to a NED coordinate system can be efficiently and accurately obtained based on the multi-dimensional unknown state variables; and finally, coordinates of an antenna phase center of the GNSS receiver are mapped to coordinates at the tail end position of a centering rod through geometric transformation, and thus tilt measurement is completed. According to the tilt measurement method of the surveying and mapping integrated machine based on the GNSS receiver and the IMU sensor, a measurement worker can be completely liberated from a task of bubble centering leveling, and work efficiency is improved; and in addition, any factory calibration does not need to be carried out, self-calibration can always be carried out in the operation process, the work efficiency and the accuracy rate are greatly improved, and unnecessary production processes are reduced.

Owner:菲曼(北京)科技有限公司 +1

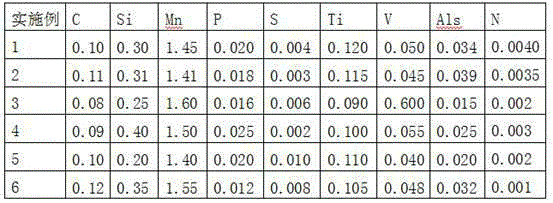

800MPa grade automobile box steel and production method thereof

The invention discloses an 800MPa grade automobile box steel and a production method thereof. The production method comprises the steps of heating, rough rolling, finish rolling, cooling and coiling; the slab adopted contains the following components in percentage by mass: 0.08-0.12% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, less than or equal to 0.025% of P, less than or equal to 0.010% of S, 0.040-0.060% of V, 0.090-0.120% of Ti, greater than or equal to 0.015% of Als, less than or equal to 0.004% of N and the balance of Fe and inevitable impurities. The steel is strengthened by both vanadium and titanium and a precipitation strengthening effect can be developed more thoroughly, and the overall properties of the steel plate can be improved; besides, the load of rolling can be reduced thoroughly and the production difficulty can be reduced; the steel has the characteristics of low cost, high quality and easiness in machining. According to the method, the precipitation of carbon and carbonitrides, the recrystallization of the austenite and the deformation state of the austenite are controlled by controlling the tapping temperature of the rolled steel, the temperature of the intermediate slab, the finish rolling temperature and the coiling temperature; the strength index and the overall properties of the obtained product are guaranteed, and the product is low in production cost and easy to machine.

Owner:HEBEI IRON AND STEEL

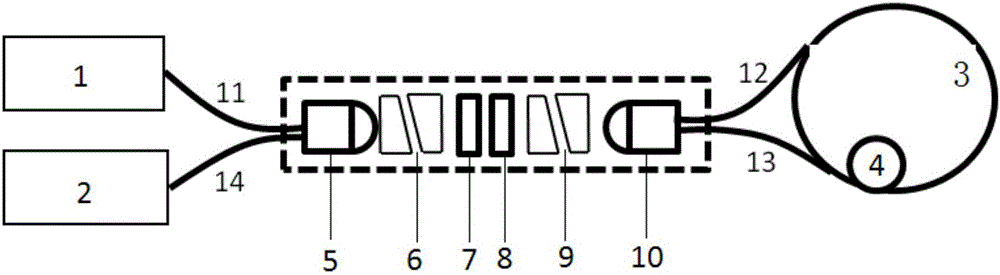

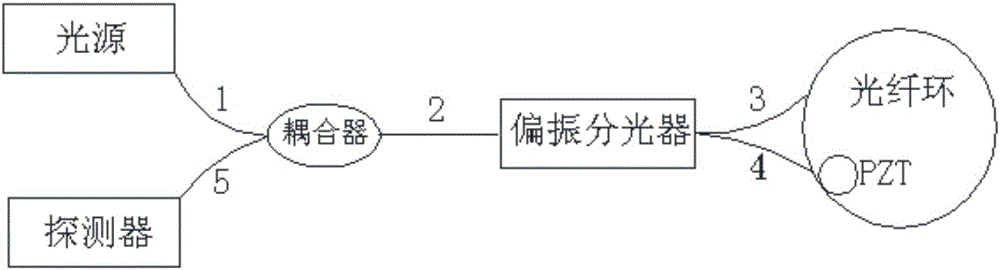

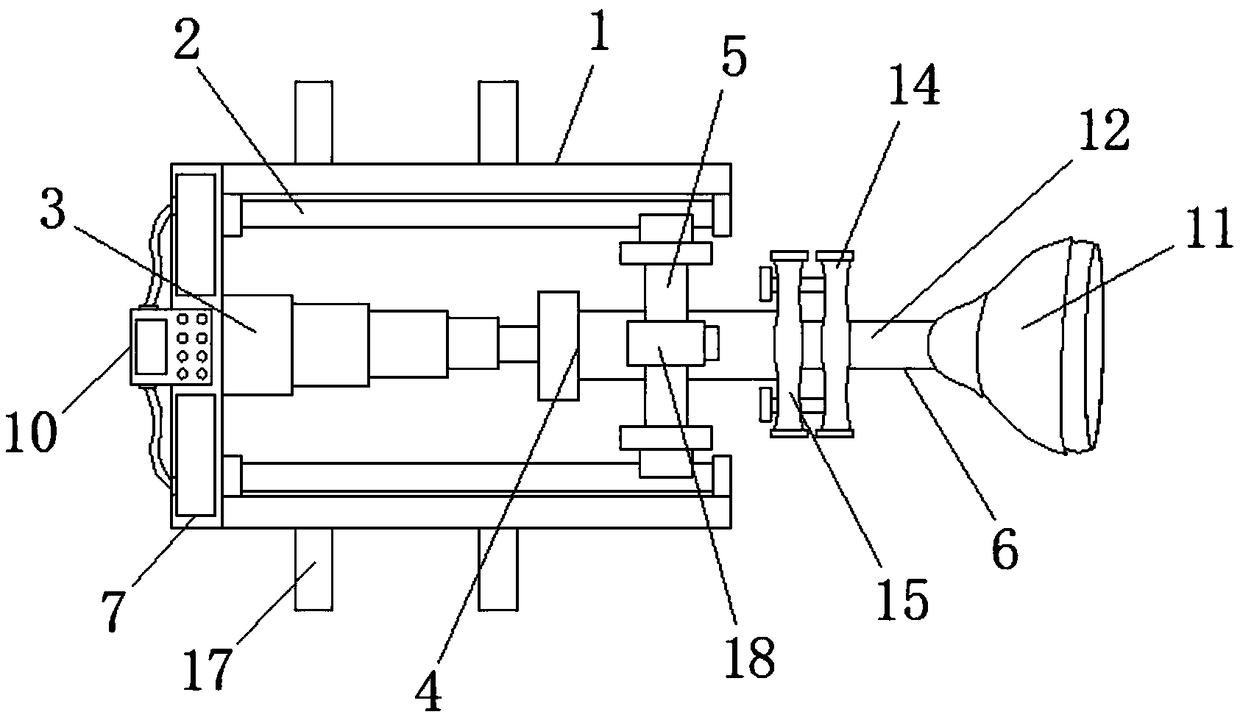

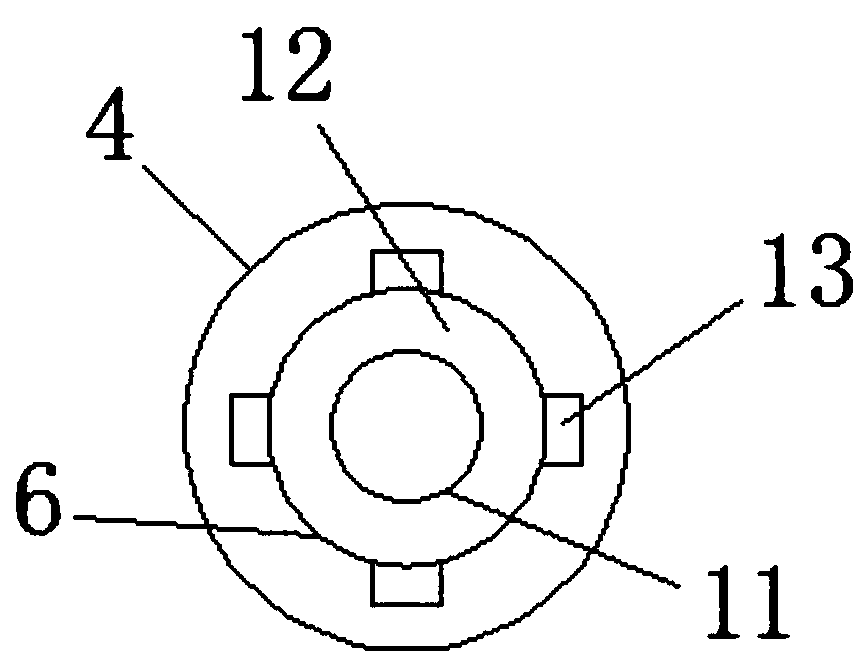

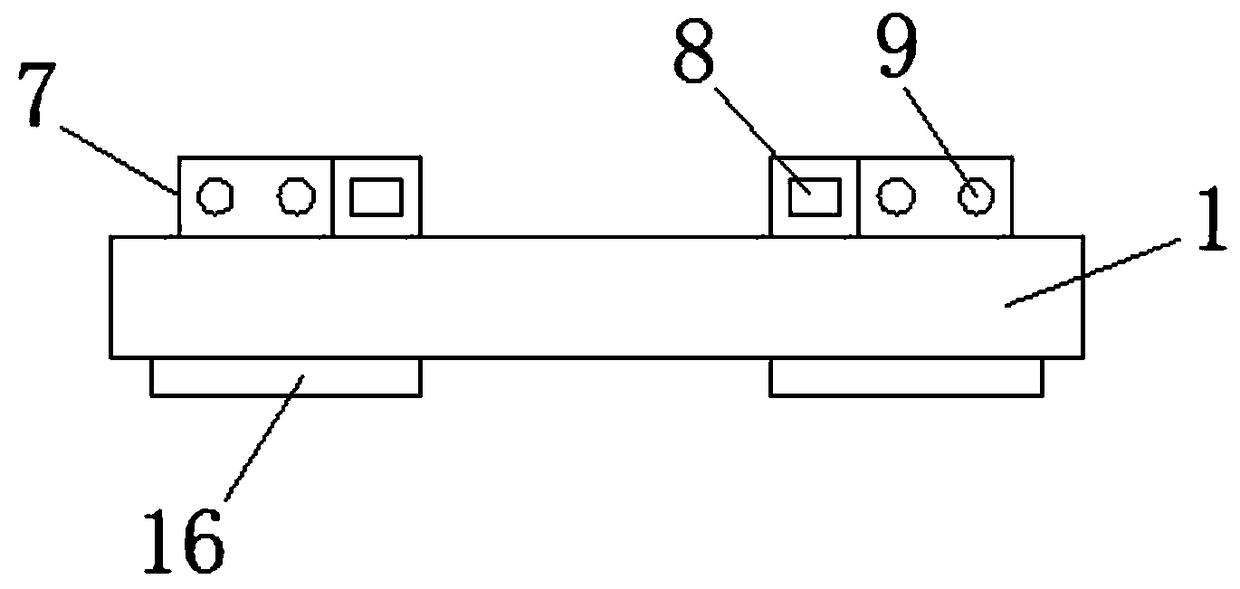

Integrated optical circuit structure fiber-optic gyroscope and work method thereof

The invention discloses an integrated optical circuit structure fiber-optic gyroscope and a work method thereof. The integrated optical circuit structure fiber-optic gyroscope comprises a light source. The light source is connected to a first lens through a first optical fiber. The rear side of the first lens is orderly provided with a first polarizing beam splitter, a Faraday rotating plate, a polarizing film, a second polarizing beam splitter and a second lens. The integrated optical circuit structure fiber-optic gyroscope also comprises an optical fiber ring and a phase modulator connected to the optical fiber ring. The optical fiber ring is connected to the second lens through a second optical fiber and a third optical fiber. Each one of the first polarizing beam splitter and the second polarizing beam splitter comprises two optical axis orthogonal homotaxial birefringent crystals. The integrated optical circuit structure fiber-optic gyroscope also comprises a detector. The detector is connected to the first lens through a forth optical fiber. The integrated optical circuit structure fiber-optic gyroscope is free of a thin special optical fiber and a high-precision optical device online production platform, greatly reduces product assembling process difficulty, guarantees a product precision, improves product reliability and lays a foundation for fiber-optic gyroscope market popularity.

Owner:XIAN SINO HUAXIN MEASUREMENT & CONTROL

Rolling method of wide-width thin-specification 6Mo super austenitic stainless steel plate

ActiveCN110756580AIncrease widthReduce the number of weldsTemperature control deviceMetal rolling stand detailsHeating timeSS - Stainless steel

The invention discloses a rolling method of a wide-width thin-specification 6Mo super austenitic stainless steel plate. The rolling method includes the following steps that a blank which has the thickness of 110-125 mm, the width of 1500 mm or above and the length of 2550-2620 mm is adopted; the steel blank is sent to a stepping type heating furnace, the ratio of the total heating time to the thickness of the steel blank is controlled to be 15-22 min / cm, the temperature of a uniform heating section is 1230-1270 DEG C, the time for the uniform heating section is at least 30 min, and the tappingtemperature is 1240-1260 DEG C; full transverse rolling is performed through 12+1 rounds, the reduction rate is increased from 17% in the first round to 30-40% in the fifth round and is then gradually reduced, the reduction rate in the eleventh round is 7-9%, the reduction rate of the twelfth round is 4-6%, and air cooling is performed after rolling; and the solid solution temperature is 1160 DEGC, heat preservation is performed for 20 min, and water cooling is performed. The width of this type of finished products can be increased from 2000 nm in the prior art to 2500 mm.

Owner:NANJING IRON & STEEL CO LTD

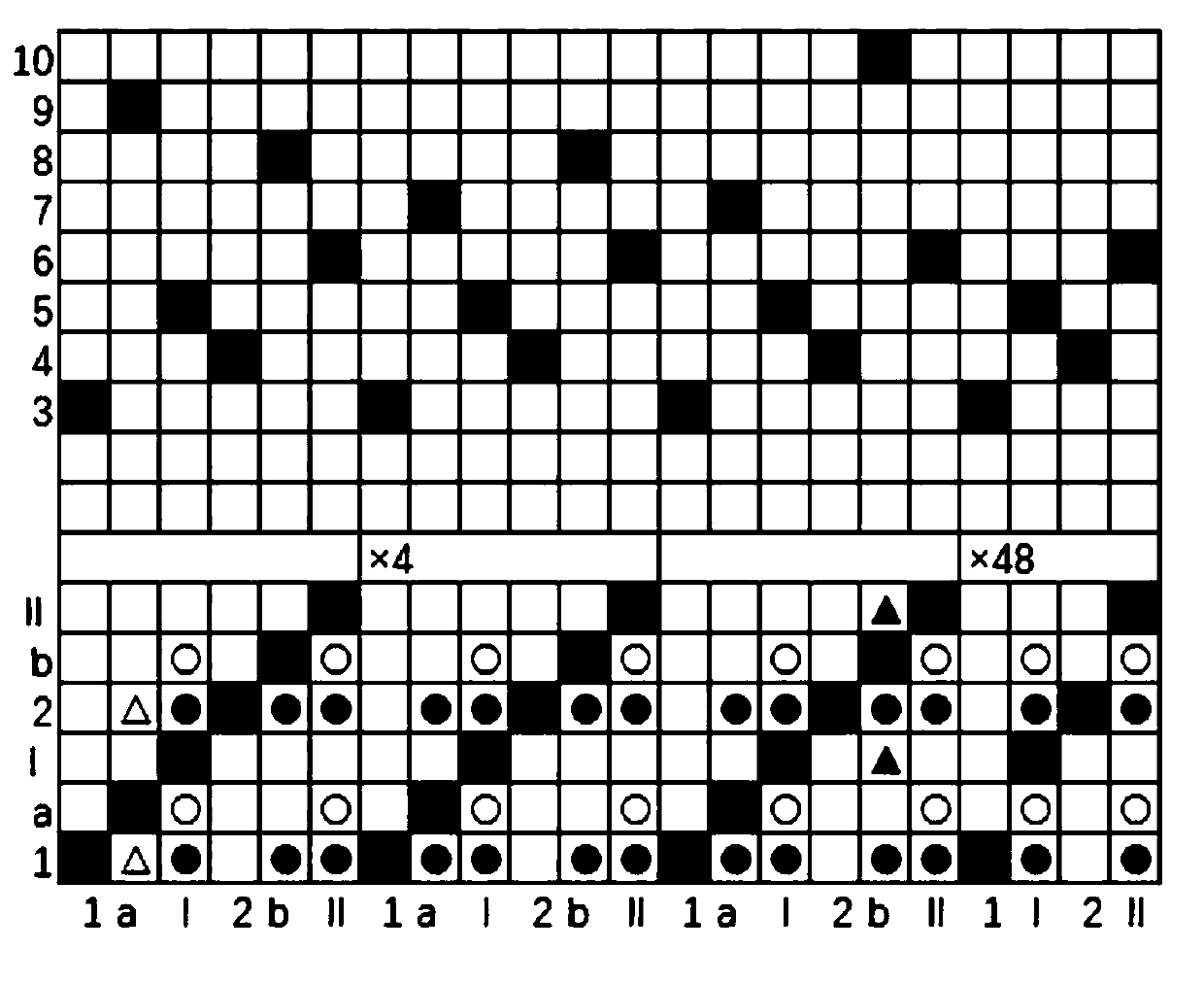

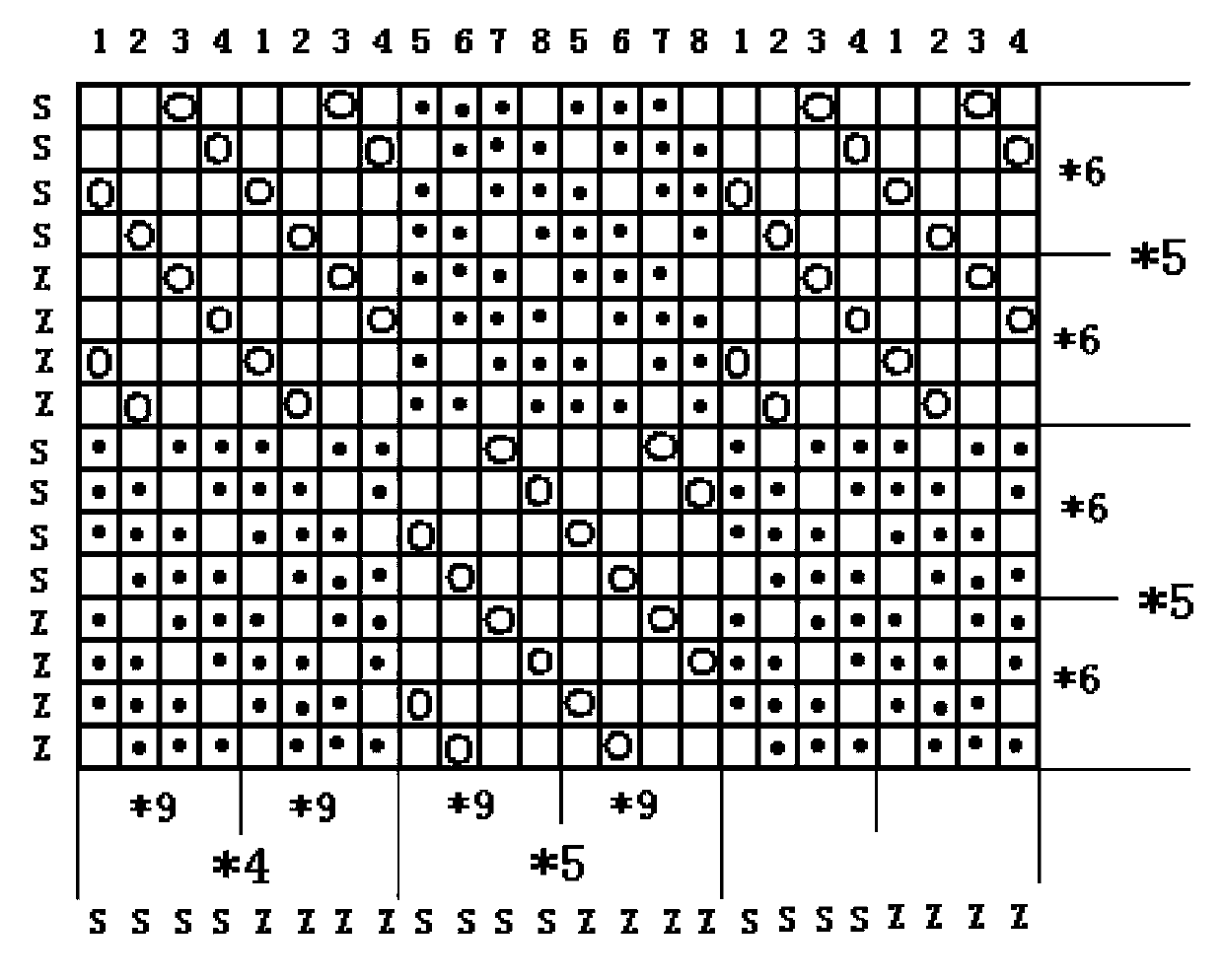

Hand-weaved style fabric and processing technology thereof

InactiveCN103866457ASubtle EffectAchieve satisfactory goalsSwivel-woven fabricsLappet-woven fabricsTexture designYarn

The invention relates to a hand-weaved style fabric and a processing technology thereof. Warps of the fabric adopt CJ9.7tex / S twist directions and Z twist directions, wefts adopt 1950 twists per meter in the CJ9.7tex / S twist directions and Z twist directions, and a fabric texture is a 3 / 1+1 / 3 change square texture which is subjected to flower type arrangement; the ratio of the warps in the S twist directions and the Z twist directions is 36: 36, and the ratio of the wefts in the S twist directions and the Z twist directions is 24: 24. According to the processing technology, special craft technologies are used in processes of warping, slashing, weaving, dyeing and finishing, and the like. The hand-weaved style fabric and the processing technology thereof have the advantages that texture designs are matched with yarn twist directions, twist degree changes and positioning applications to weave the novel hand-weaved style fabric; conventional pure cotton raw materials are applied, and matching of twist directions, twist degrees, and textures of the yarn is used for novel design, so that the fabric obtains a subtle square effect, a hand-weaved style is achieved, and purposes of market acceptance and customer satisfaction are achieved.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Manufacturing method of cotton lotus root silk blended yarn

The invention provides a method for manufacturing cotton lotus root silk blended yarn, which comprises: a blowing process, a carding process, a drawing process, a roving process, a spun yarn process and the like. Among them, the carding process adopts a small drain bottom with a chord length of 200mm to enhance the supporting effect on the fibers, and the dust removal knife adopts a flat knife to enhance the supporting effect on the lotus root silk fibers. The roving and spinning process adopts tight gauge and heavy pressure, and at the same time, the speed of the machine is low, which is 20% lower than that of spinning cotton. Cotton and lotus root silk blended products have high technical content and are difficult to produce; the present invention solves the technical problems existing in the prior art and obtains a blended cotton / lotus root silk blended product. The test results show that it has better single yarn breaking strength and Evenness CV% and other indicators.

Owner:LUOLAI LIFESTYLE TECH CO LTD

Positioning distributed fiber anti-counterfeiting paper and manufacturing method thereof

ActiveCN102182114AIncrease production difficultyEasy to identifyWater-repelling agents additionPaper/cardboardFiberEllipse

The invention relates to positioning distributed fiber anti-counterfeiting paper and a manufacturing method thereof, and belongs to the technical field of papermaking. The positioning distributed fiber anti-counterfeiting paper is characterized in that: anti-counterfeiting fibers are regularly distributed on the plane of the paper; the anti-counterfeiting fibers are positioned on one side of the paper; and in raised discontinuous rectangle or square, rhombus, roundness, ellipse, triangle, tetragon, polygon, sector or other irregular geometric pattern shape, the anti-counterfeiting fibers are plant fibers, chemical fibers, animal fibers, colored fibers or fluorescent fibers. The manufacturing method comprises the following steps of: 1) selecting the anti-counterfeiting fibers, and manufacturing a positioning distributed fiber mesh; 2) breaking; 3) pulping and regulating; 4) separating pulp; 5) forming paper; 6) squeezing and dehydrating; 7) drying; 8) applying the glue to the surface; and 9) calendering. The appearance of the paper has two-layer anti-counterfeiting measures of positioning distributed fiber anti-counterfeiting and geometric pattern anti-counterfeiting, the paper can be identified easily by the public, the anti-counterfeiting patterns are variable and high in production difficulty, and the anti-counterfeiting effect is good.

Owner:莱阳银通纸业有限公司

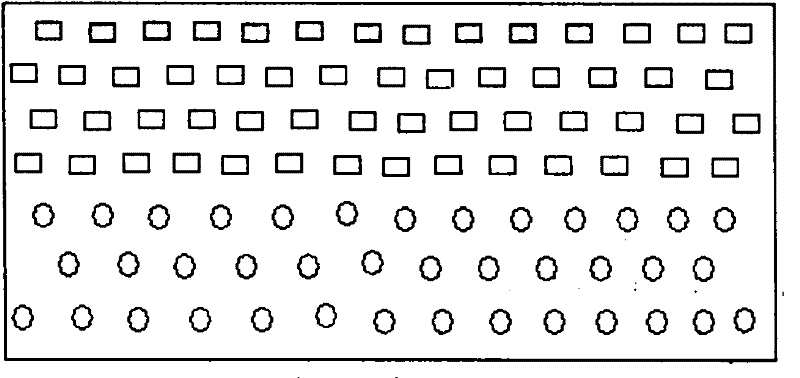

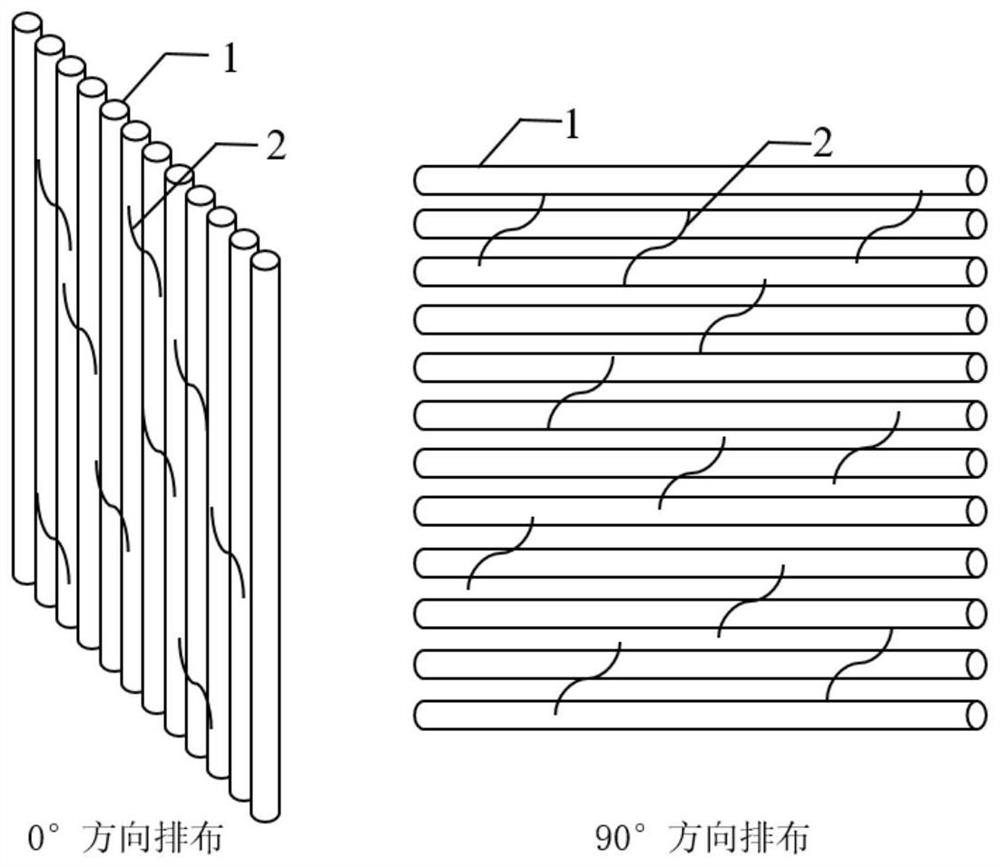

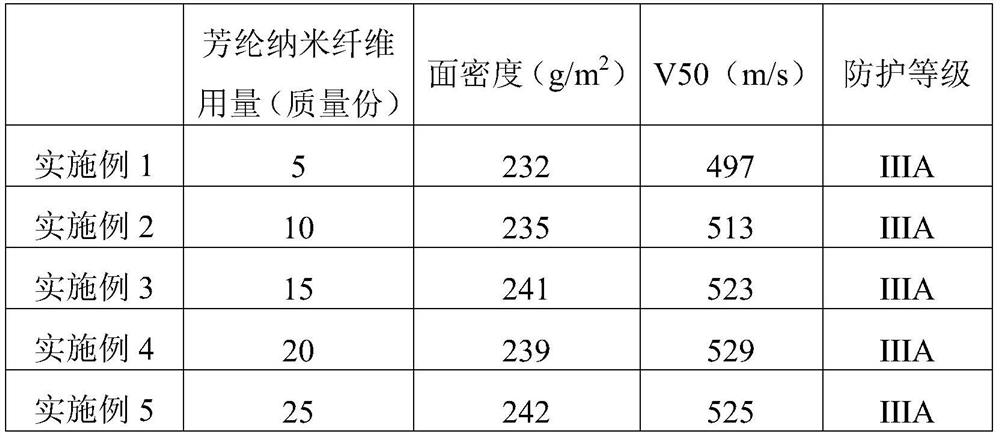

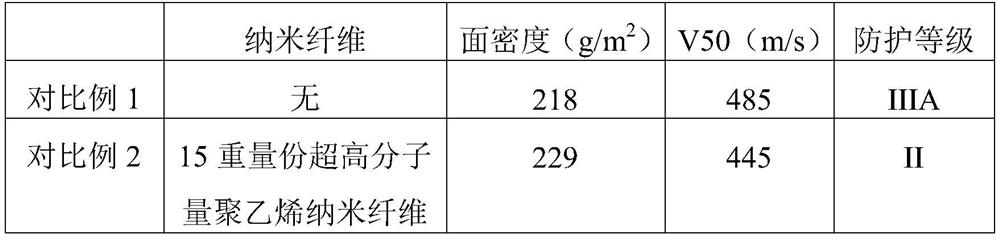

Aramid nanofiber composite unidirectional fabric and preparation method thereof

PendingCN112549711ALarge specific surface areaHigh strengthProtective equipmentFibre treatmentAdhesiveNanofiber

The invention relates to an aramid nanofiber composite unidirectional fabric and a preparation method thereof. The aramid nanofiber composite unidirectional fabric comprises unidirectional sheet layers, the unidirectional sheet layers comprise aramid fibers arranged in a unidirectional mode and an adhesive, and the adhesive comprises aramid nanofibers. According to the invention, the bonding strength of the adhesive is improved, and the interface performance of the aramid fibers and the adhesive is improved. A bulletproof product prepared by cutting, laminating, compounding and molding the aramid nanofiber composite UD fabric has the advantages that the shrapnel impact resistance is improved while the quality of the product is not greatly improved, and the safety index is higher.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD +1

Method for preparing reaction-sintered grouting-formed silicon carbide ceramics

InactiveCN108298989ALow residual free siliconEvenly distributedTetramethylammonium hydroxidePolyvinyl alcohol

The invention discloses a method for preparing reaction-sintered grouting-formed silicon carbide ceramics. Two kinds of silicon carbide micro-powders which are produced by a jet mill and which are saturated by particle shaping have a particle diameter of 50 [mu]m and 5 [mu]m, and the relative blending ratio ranges from 1:1 to 10:1, pigment carbon black or metallurgical carbon black with a particlesize of 20 nm to 100 nm is taken as a carbon source, the ratio of addition is 1% to 15%, novel high-efficiency binders are adopted and are multiple or all of a group consisting of acrylamide, polyvinylpyrrolidone, polycarboxylic acid, polyvinyl formal, amino ethanol, tetramethylammonium hydroxide, maleic anhydride and polyacrylic acid, and deionized water in a volume ratio of 10% to 40% is adopted. By controlling the suitable silicon carbide raw material particle size and particle size grading, the suitable proportion of carbon and the suitable binders, the carbide ceramics which are low in free silicon residue uniformly distributed, are basically free of free carbon and have high product density and product strength can be prepared, and the reaction-sintered grouting-formed silicon carbide ceramics can be applied to the fields such as lightweight armor, aerospace materials, and reactor vessels.

Owner:河南航瑞碳化硅制品有限公司

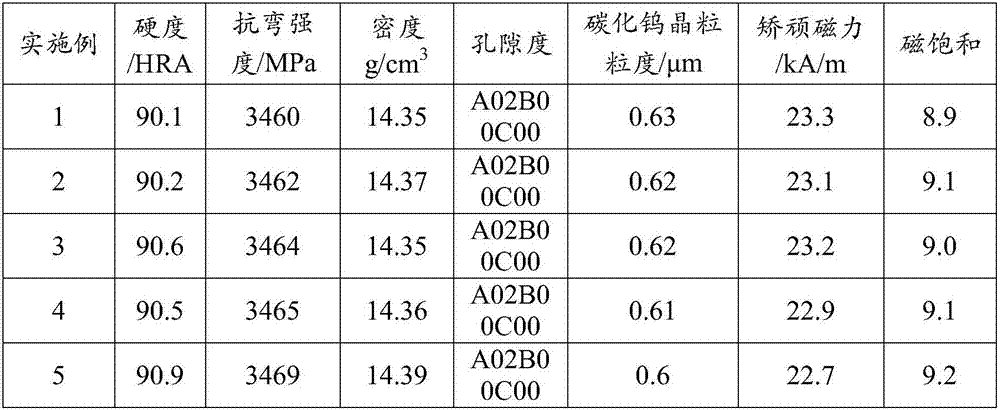

Hard alloy product, preparation method thereof and device for preparing hard alloy product

ActiveCN107321990ARealization of moldless 3D moldingEasy to makeTransportation and packagingMetal-working apparatusNumerical controlAlloy

The invention discloses a hard alloy product, a preparation method thereof and a device for preparing the hard alloy product, and belongs to the field of powder metallurgy. The preparation method of the hard alloy product includes the steps that hard alloy powder and an adhesion agent are mixed and feedstock is prepared; the feedstock is stored in an extruding machine so that the feedstock can be extruded out from a nozzle of a numerical control machine tool which is connected with the extruding machine; and the numerical control machine tool controls the extruded feedstock to be layered-deposited, and the hard alloy product is prepared. The device for preparing the hard alloy product comprises the extruding machine and the numerical control machine tool; the numerical control machine tool comprises a heatable nozzle, the nozzle is the executive component of the numerical control machine tool, and connected with a driving component of the numerical control machine tool; and a material outlet of the extruding machine is connected with the nozzle through a material pipe. According to the hard alloy product, the preparation method thereof and the device for preparing the hard alloy product, a die does not need to be manufactured, complex shapes can be formed, the density of each part of the product is even, deformation is small, and the comprehensive property is high.

Owner:成都岷江精密刀具有限公司

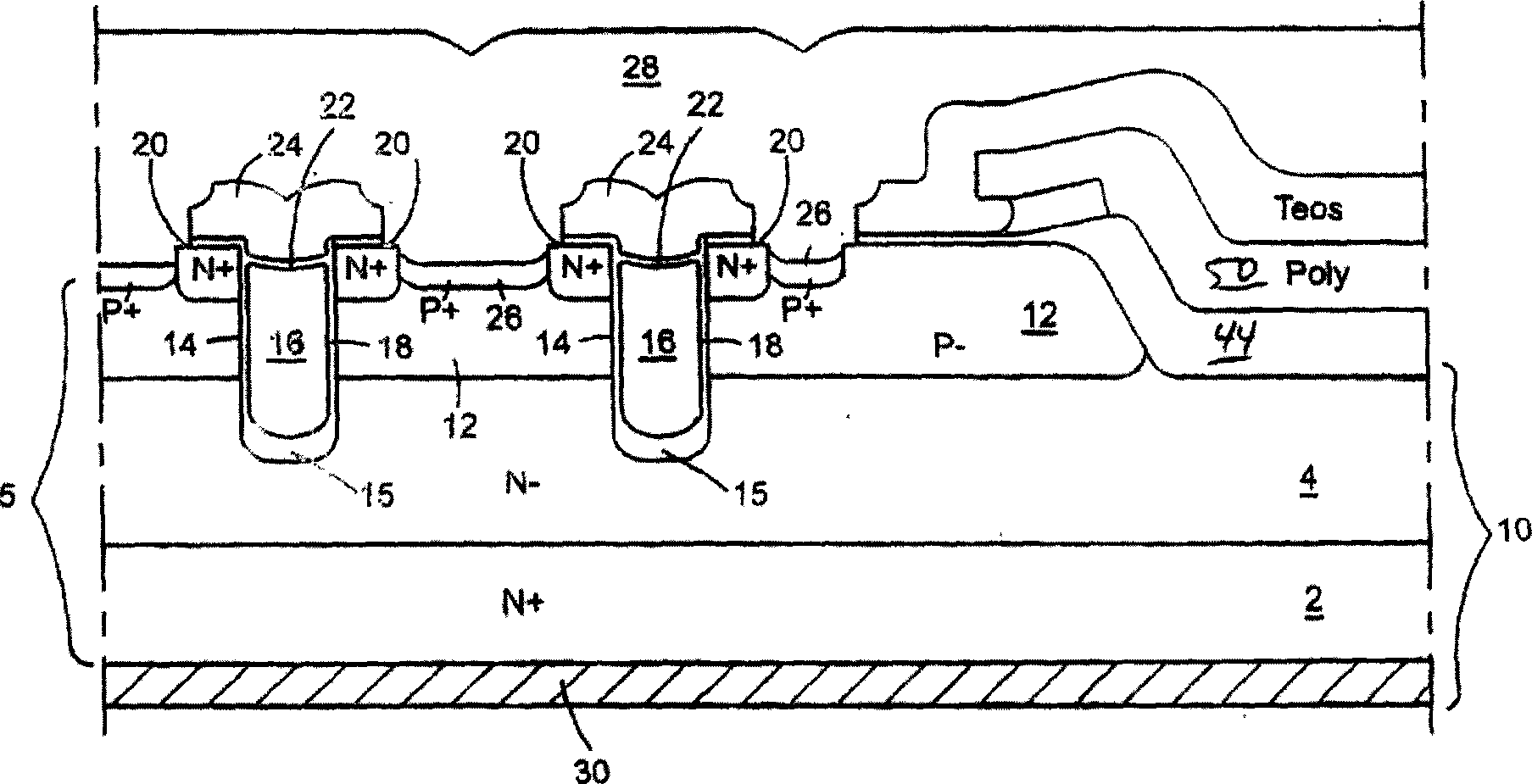

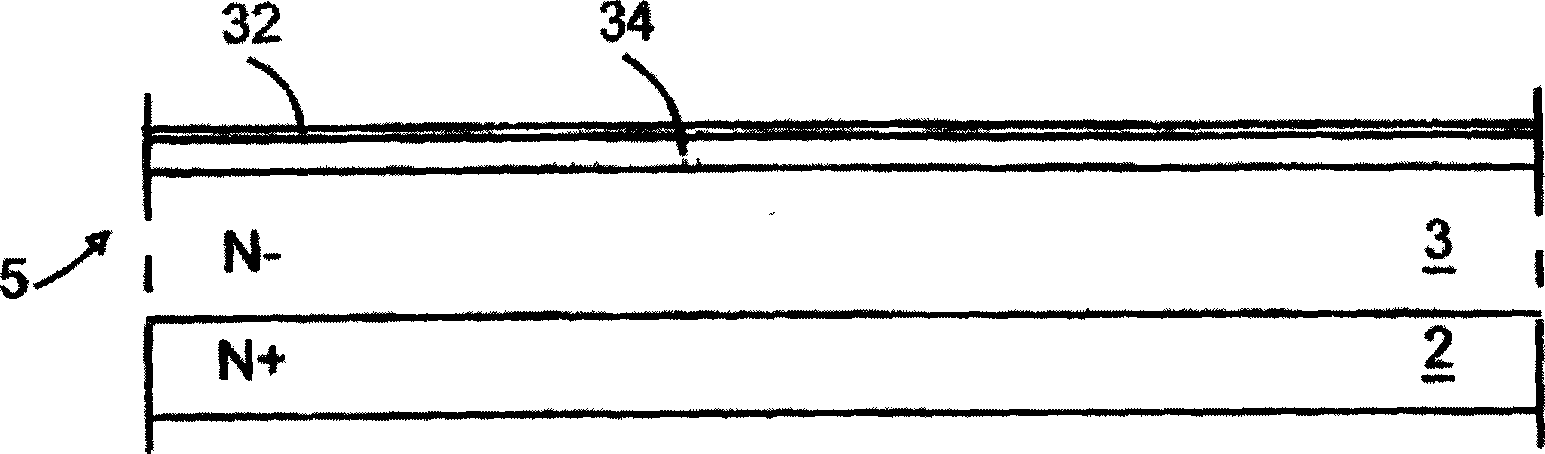

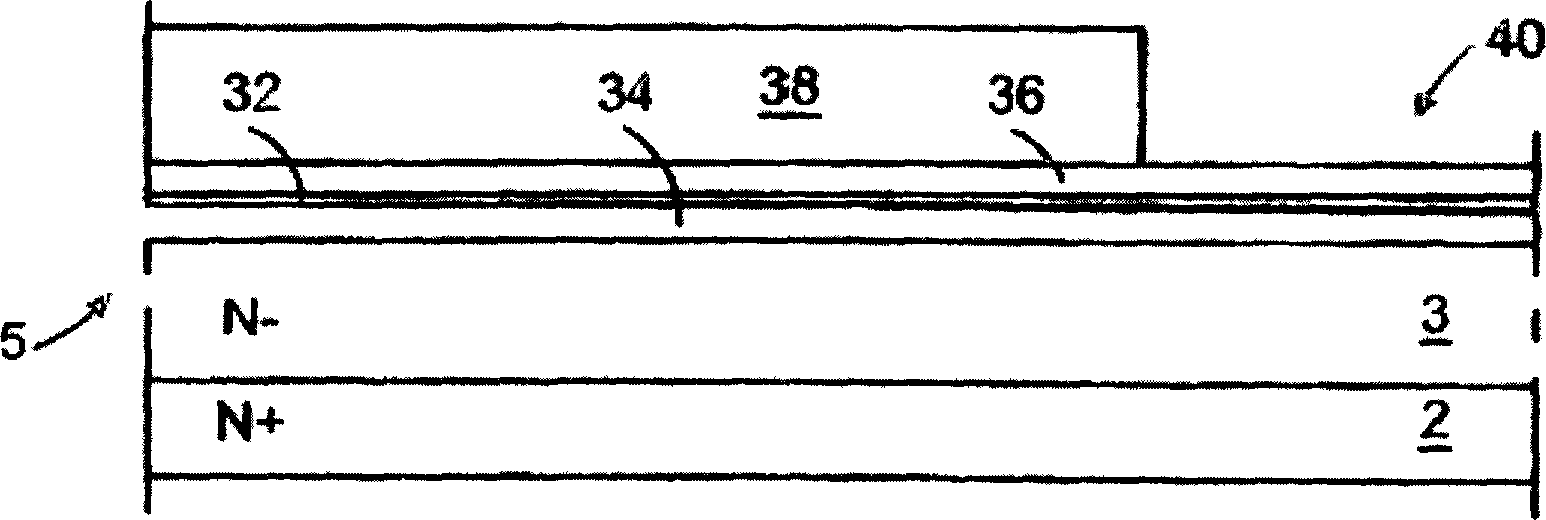

Trench MOSFET technology for DC-DC converter applications

InactiveCN1742377AImprove boot resistanceImprove featuresSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceDc dc converter

Owner:INTERNATIONAL RECTIFIER COEP

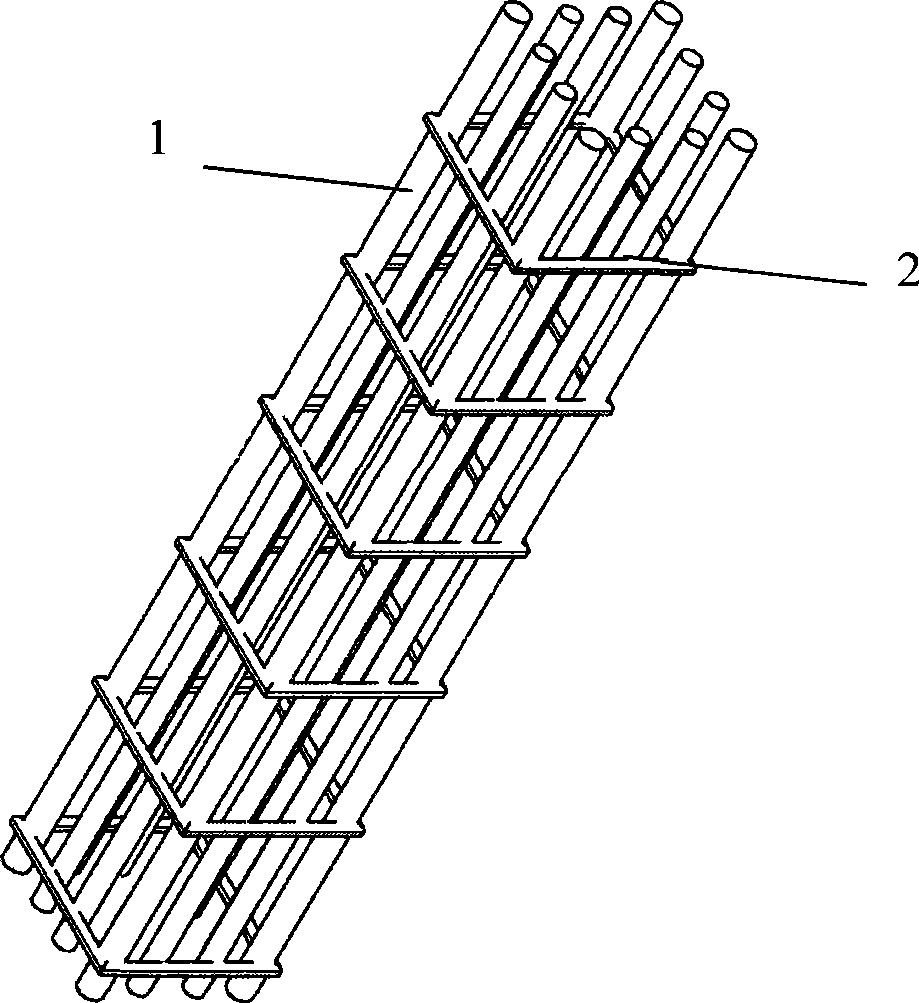

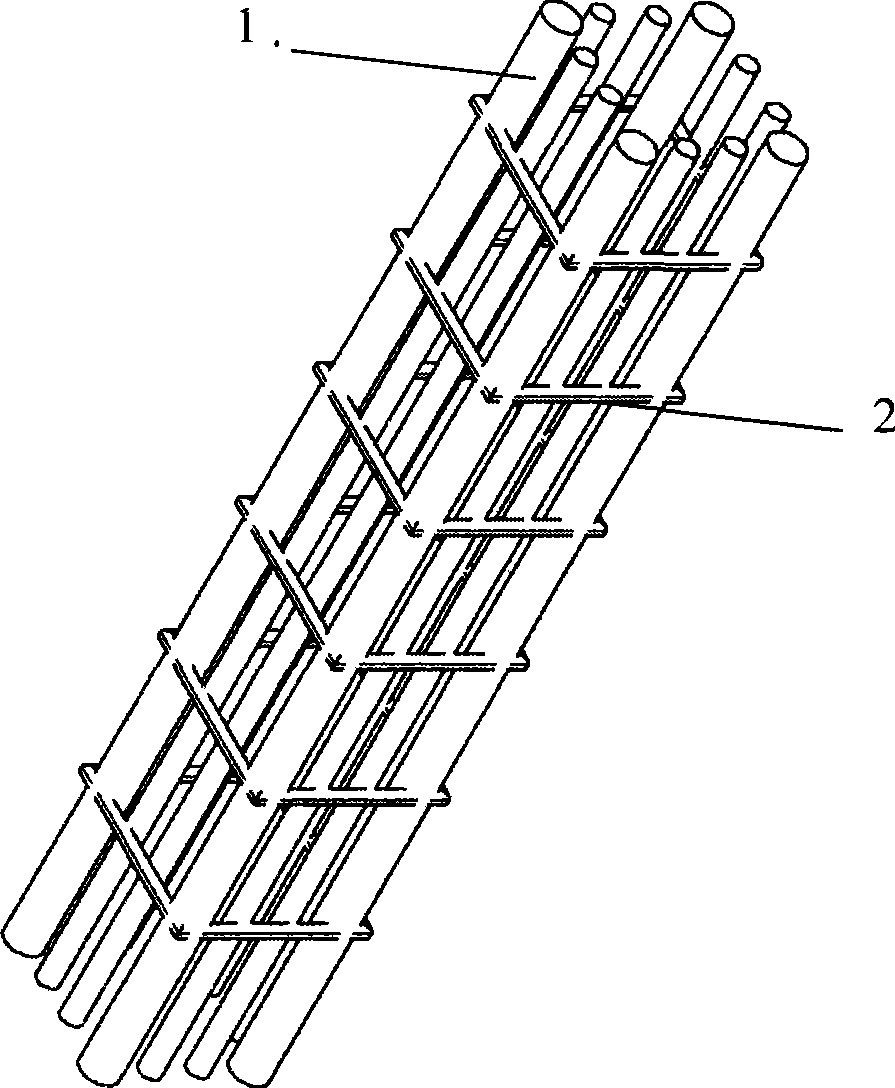

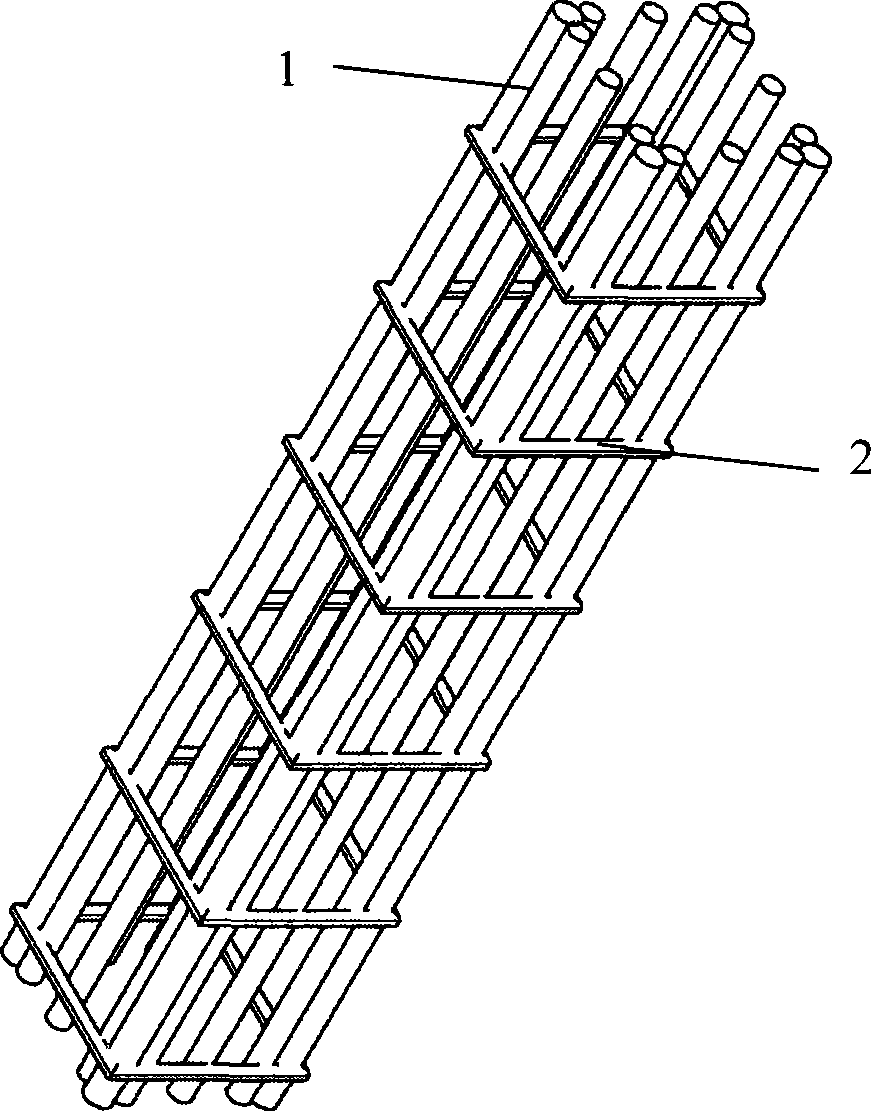

Concrete electrical pole and preparation thereof

The invention provides a concrete pole and a manufacturing method thereof in order to solve the problems of a concrete pole in the prior art of incapability of effectively increasing the counter bending strength, resource waste, increased difficulty in production or construction and so on. The manufacturing method adopts angle steels instead of screw-threaded steel vertical bars to be a main stress supporting body, and triangular supports are arranged between the angle steels, so that the manufacturing method not only can effectively improve the counter bending strength but also can effectively reduce the weight of a metal framework of the concrete pole, and reduces the resource waste, the cost, the production and construction difficulty. Under the condition of the same counter bending moment, the weight of the framework of the concrete pole is reduced by more than 20 percent compared with the prior art, so that the manufacturing method reduces the resource waste, the cost and the production and construction difficulty, and has good economic benefit and social benefit.

Owner:杨兴明

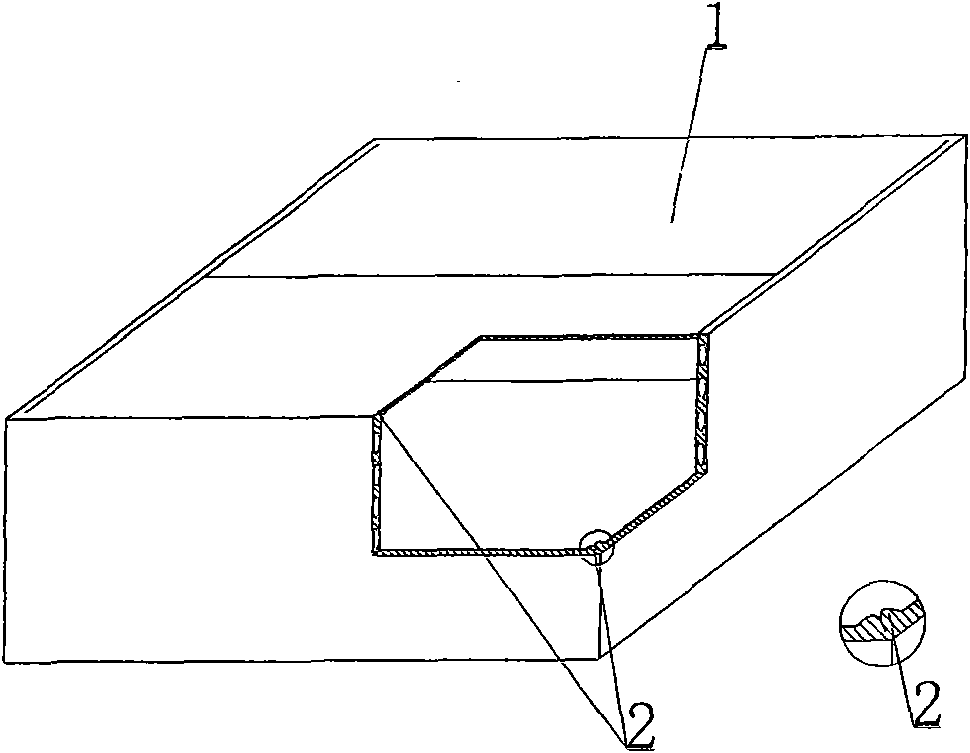

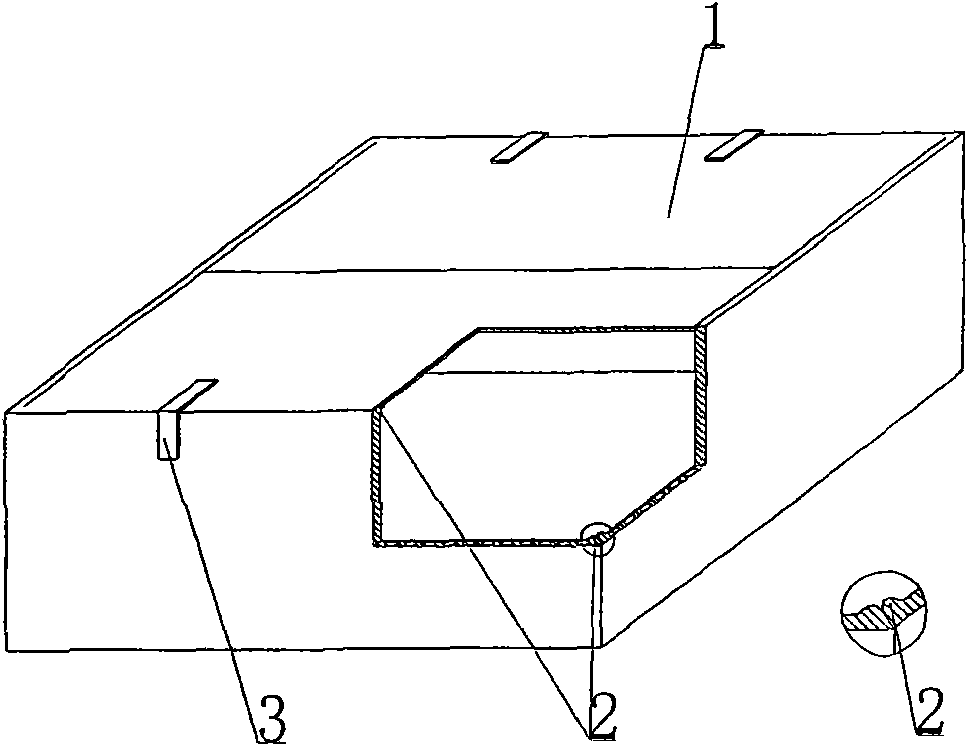

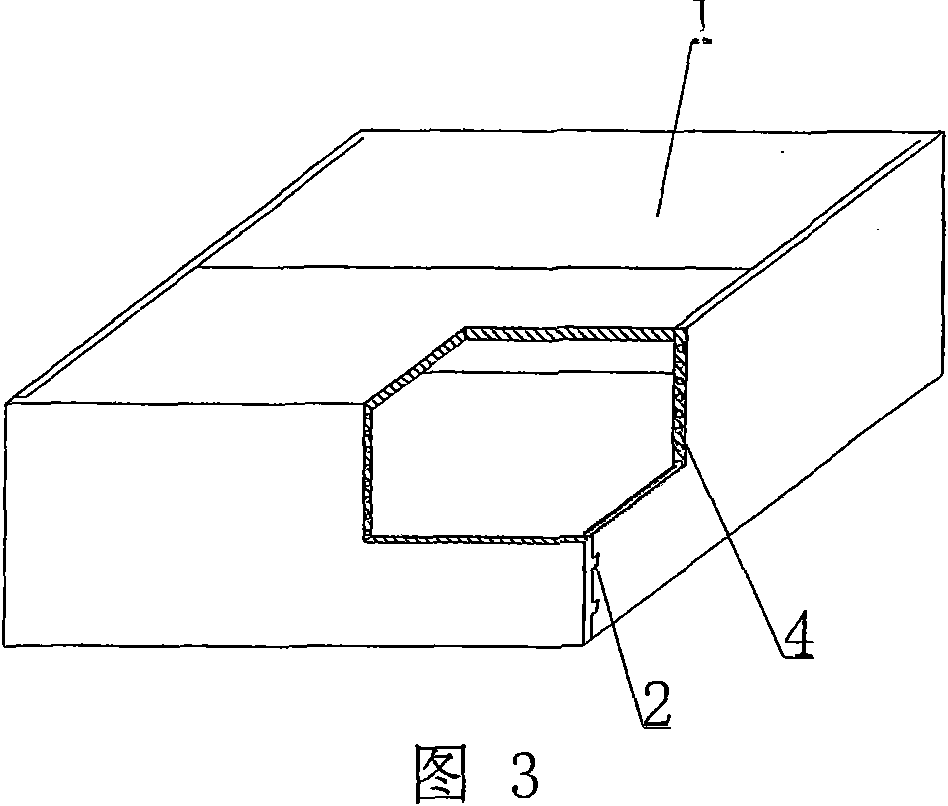

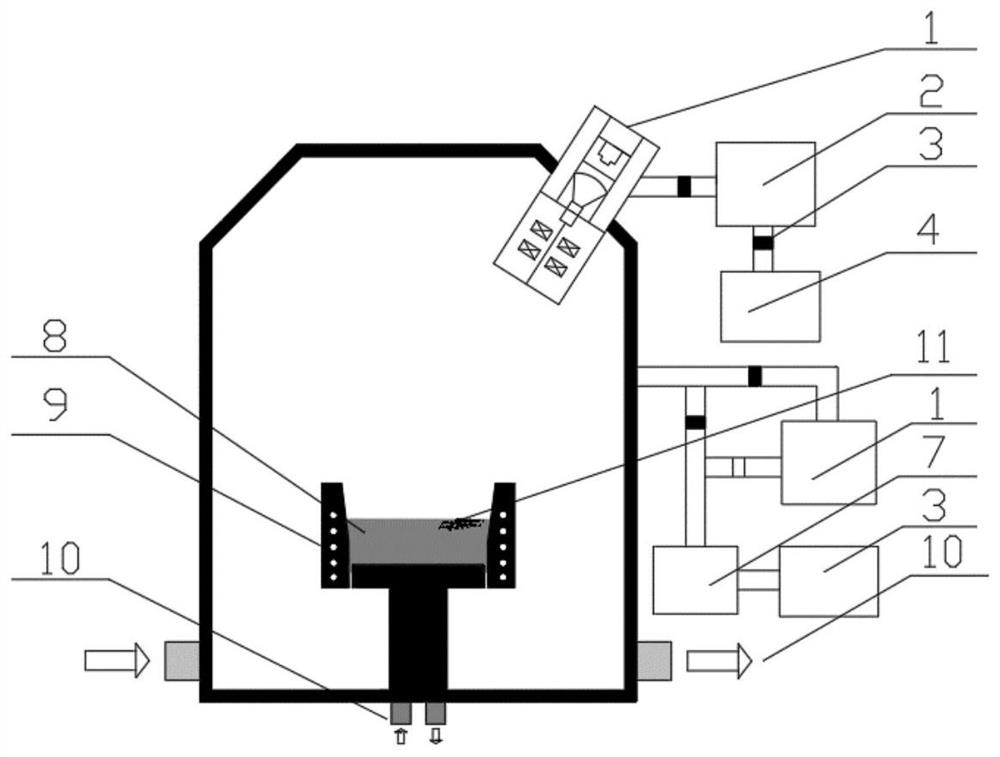

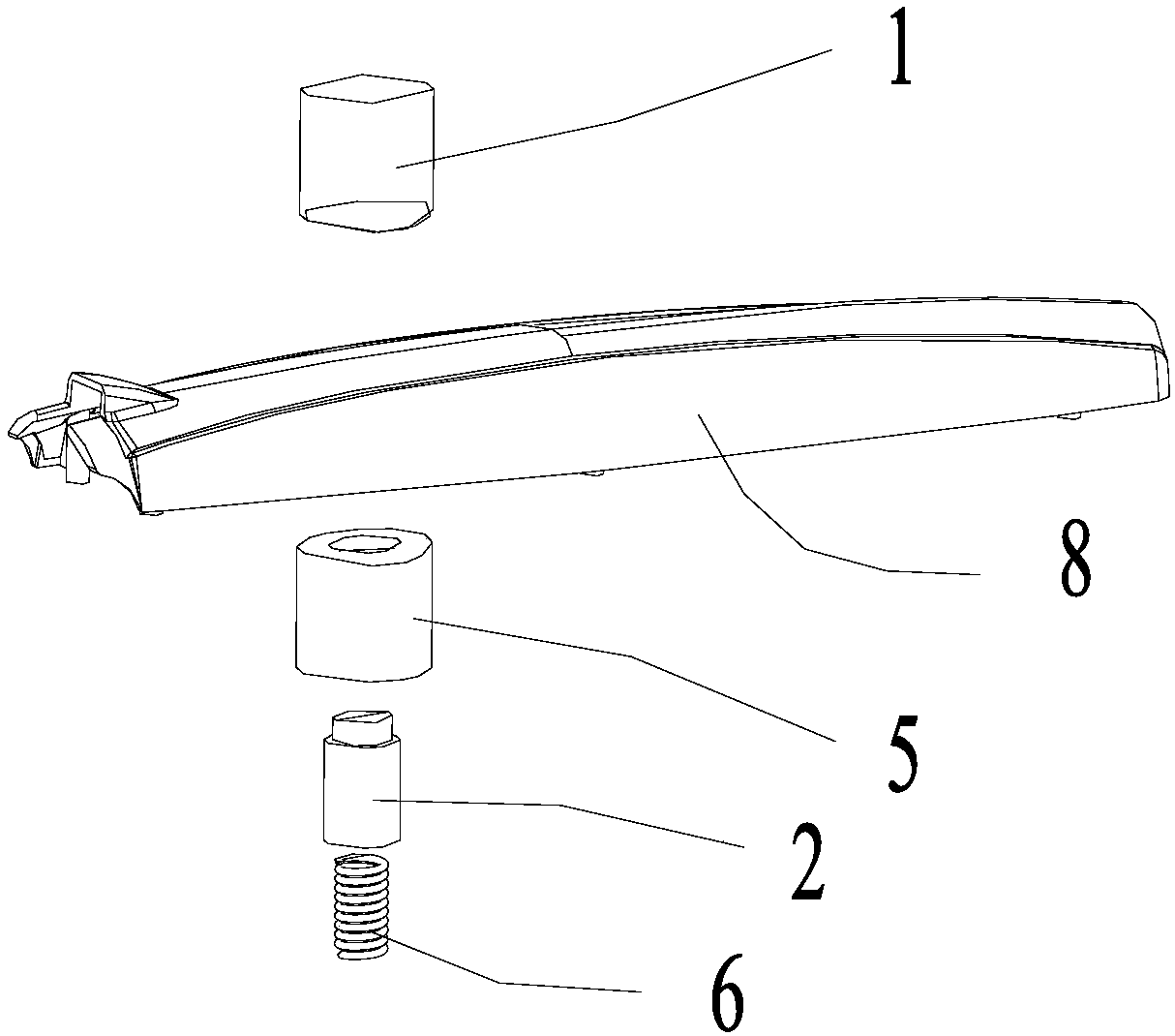

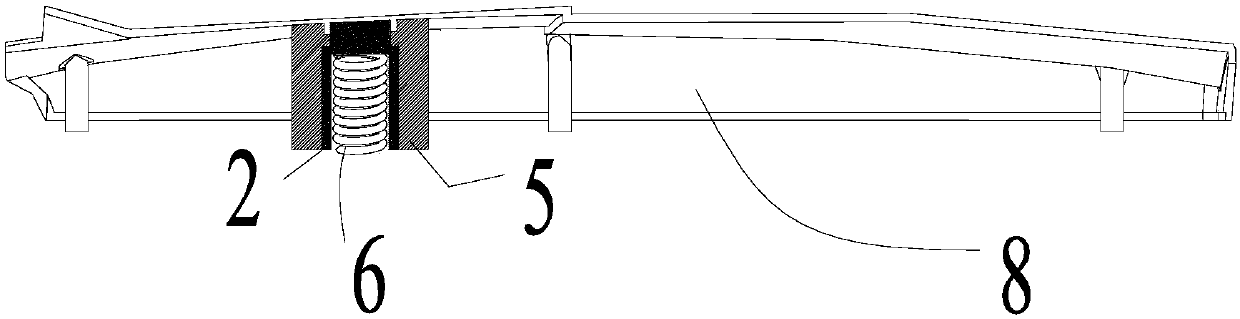

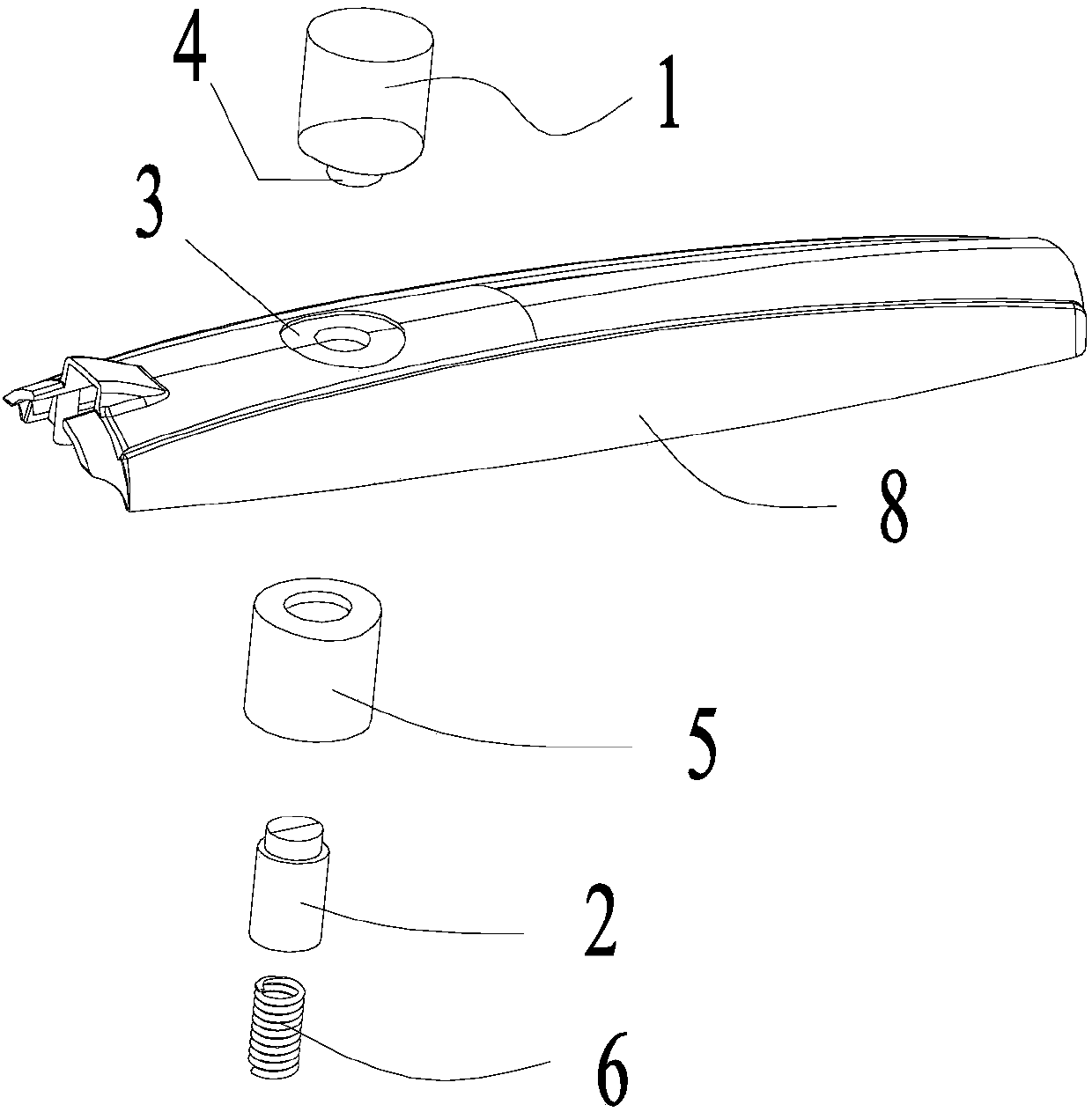

Hollow core die for cast-in-place concrete hollow filling

The invention discloses a hollow core die for cast-in-place concrete hollow filling, which comprises plates (12), wherein at least two connected plates (12) form a hollow member. The hollow core die is characterized in that: the plates (12) are connected with at least one hinge (2), the side of the hinge (2) is provided with a reinforcing rib (5), the plates (12) are hollow plates (12), and parallel hollow tubular holes (15) are formed in the plates (12). When the outer wall is a hollow porous outer wall and the hollow outer wall is provided with at least one hinge, the hollow core die has low dead weight, can be folded in a plate state, can save a large amount of transportation space and stacking space during transportation and stacking, and can exponentially improve the transportation quantity and reduce the transportation and storage costs in a small space; when the hollow core die is applied, the hollow core die in a folded state is unfolded; and the hollow core die is convenient for application and construction, and is suitable for various hollow slabs, hollow floors, roofs, foundation bottom plates, walls and open web bridges of cast-in-place reinforced concrete or pre-stressed reinforced concrete, especially hollow girder-less floors.

Owner:湖南邱则有专利战略策划有限公司

Method for promoting desulfuration of electron beam refined high-temperature alloy

The invention provides a method for promoting desulfuration of an electron beam refined high-temperature alloy. The method comprises the following steps: S1, pre-treatment of a high-temperature alloy raw material; and S2, electron beam refining and purification of the nickel-based high-temperature alloy to obtain a high purity FGH4096 high-temperature alloy cast ingot. The high-temperature alloy is desulfurated by means of electron beam refining, and a degassing reaction of S impurity element is intensified by means of characteristics of high electron beam refining vacuum degree and high temperature in a beam spot area. According to a characteristic that a water cooling copper crucible is free of pollution in the refining process, problems of erosion of a refractory matter of a conventional process crucible such as VIM and the like are solved. The problem of ultra-purification of a high-temperature alloy base metal is solved by means of density difference of occluded foreign substances and melt and a special inducible solidification mechanism of the electron beams in promoting migration and enrichment of the occluded foreign substances.

Owner:DALIAN UNIV OF TECH

Mold

Owner:GREE ELECTRIC APPLIANCES INC

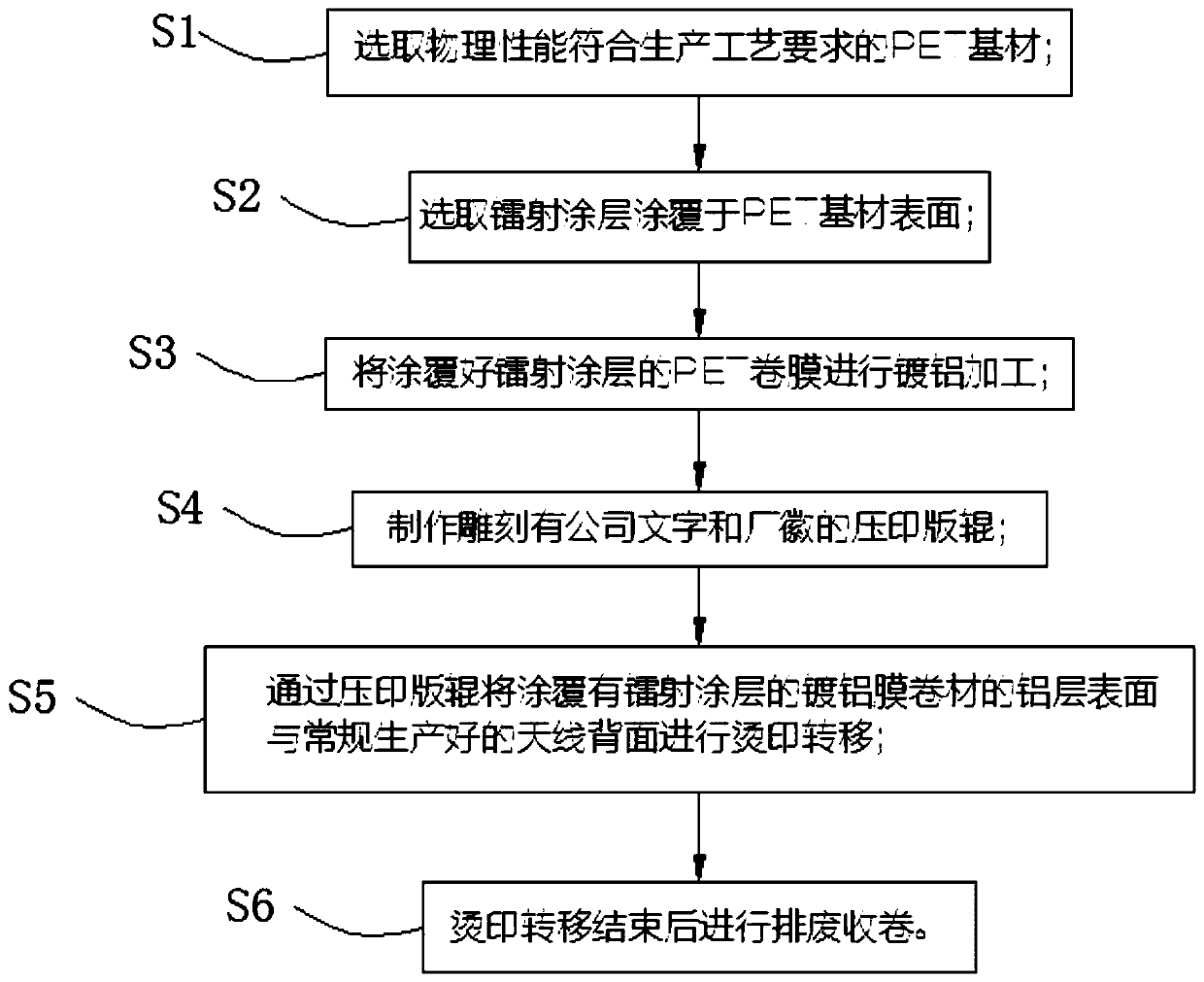

Novel laser anti-counterfeiting ultrahigh-frequency RFID tag antenna and production process thereof

InactiveCN110957556AUnique anti-counterfeiting recognitionRealize functionStampsAntenna supports/mountingsHot stampingCoated surface

The present invention discloses a novel laser anti-counterfeiting ultrahigh-frequency RFID tag antenna. The antenna comprises a PET base material, laser coatings are arranged on the upper end surfaceand the lower end surface of the PET base material, and an aluminum foil layer is arranged on the surface of the laser coating at the upper end of the PET base material. The novel laser anti-counterfeiting ultrahigh-frequency RFID tag antenna is technically characterized in that: 1, the laser coatings of which the physical properties meet the requirements of a production process are selected; 2, an impression plate roller with unique anti-counterfeiting identification degree is manufactured; and 3, a hot stamping transfer process is controlled. The novel laser anti-counterfeiting ultrahigh-frequency RFID tag antenna adopted by the invention has the following main advantages: the laser anti-counterfeiting antenna realizes the self anti-counterfeiting and tracing functions of the tag antenna; and the laser hot stamping process is combined with the process requirements of the PET base material, so that the production difficulty is increased, and imitation is completely eradicated.

Owner:江苏科睿坦电子科技有限公司

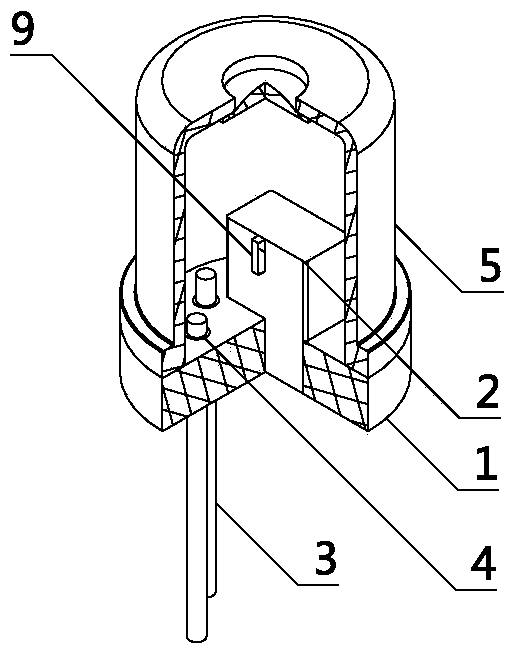

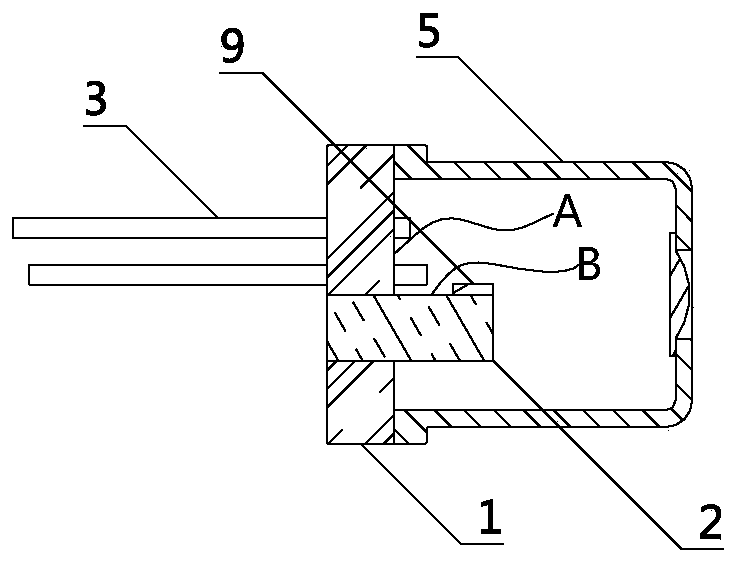

TO tube socket packaging structure and manufacturing method thereof

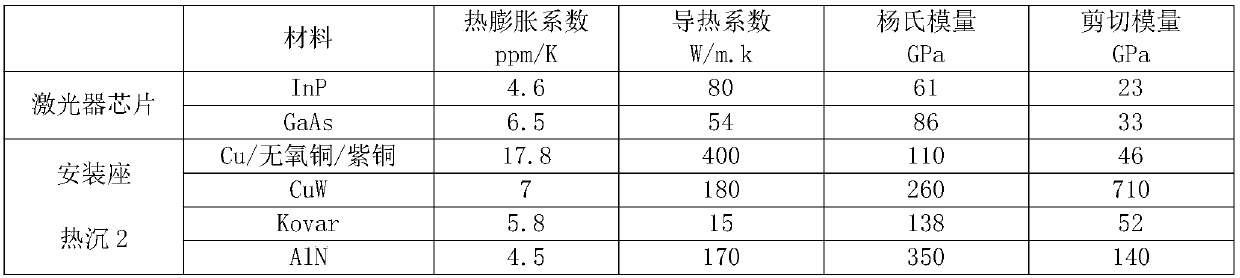

PendingCN110854669AImprove stabilityReduce the temperatureLaser detailsSemiconductor lasersTube socketOptical communication

The invention belongs to the technical field of optical communication device designing and manufacturing, and particularly relates to a TO tube socket packaging structure and a manufacturing method thereof. The TO tube socket packaging structure comprises a TO tube socket, and the TO tube socket comprises a mounting base made of a kovar alloy material and a heat sink arranged on the mounting base.A plurality of lead holes are formed in the mounting base, and leads are arranged in the lead holes respectively. A mounting hole is further formed in the mounting base, the mounting hole penetratesthrough the mounting base, and the heat sink is inserted into the mounting hole and connected in a sealed mode through silver-copper brazing. The invention further relates to a manufacturing method ofthe TO tube socket packaging structure, which comprises the following steps: machining a mounting base 1; welding leads 3; and machining a heat sink 2. The TO tube socket structure has high heat efficiency, long service life and high electro-optical conversion efficiency. The structure and the manufacturing method of the invention have the characteristics of easy-to-guarantee positioning precision, high mounting efficiency and the like. The structure is simplified, the production difficulty and cost are reduced, and the product performance is improved.

Owner:WUHAN UNICELL TECH CO LTD

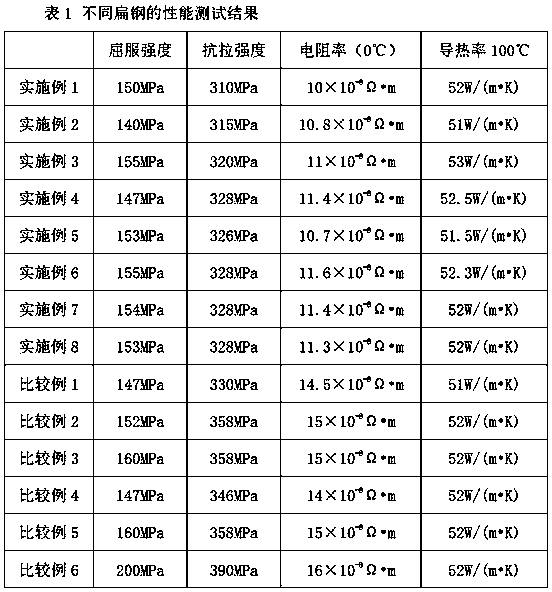

Low-cost high-conductivity electrode flat steel and smelting method thereof

The invention belongs to the field of electrode flat steel for aluminum electrolysis industry, and discloses low-cost high-conductivity electrode flat steel and a smelting method thereof. The low-costhigh-conductivity electrode flat steel contains, by weight: less than or equal 0. 005% of C, less than or equal 0.05% of Si, less than or equal 0.15% of Mn, less than or equal 0.02% of P, less than or equal 0.01% of S, and the balance Fe. The smelting method comprises the following steps: converter smelting, LF refining, RH refining of molten steel, and rolling forming. The electrode flat steel has lower cost and higher conductivity, and the resistivity delta is less than or equal to 12*10<-8> omega.m (20 DEG C). The low-cost and high-conductivity flat steel is used as a cathode material of aluminum electrolysis process, and can greatly save electric energy in the production process, greatly reduce production cost of aluminum electrolysis, and achieve the optimum combination of low cost and high performance. The smelting method can accurately control content of each component in the flat steel, and reduce crystal defects under the premise of satisfying mechanical properties and processing performance; electric resistance is reduced to the greatest extent; and electrical conductivity is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

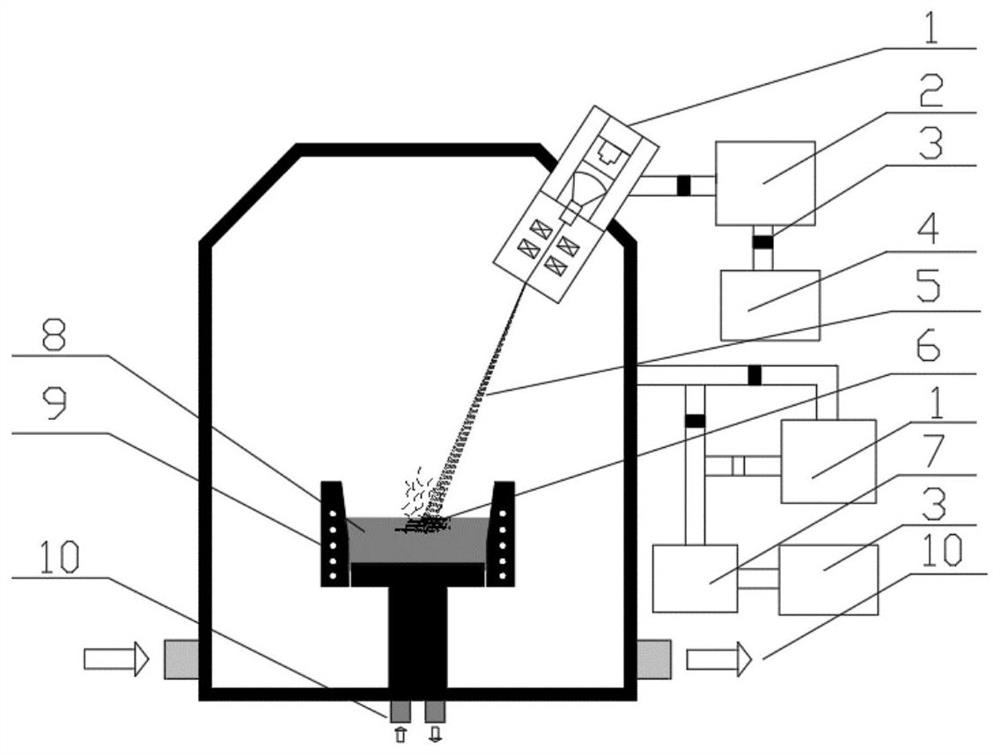

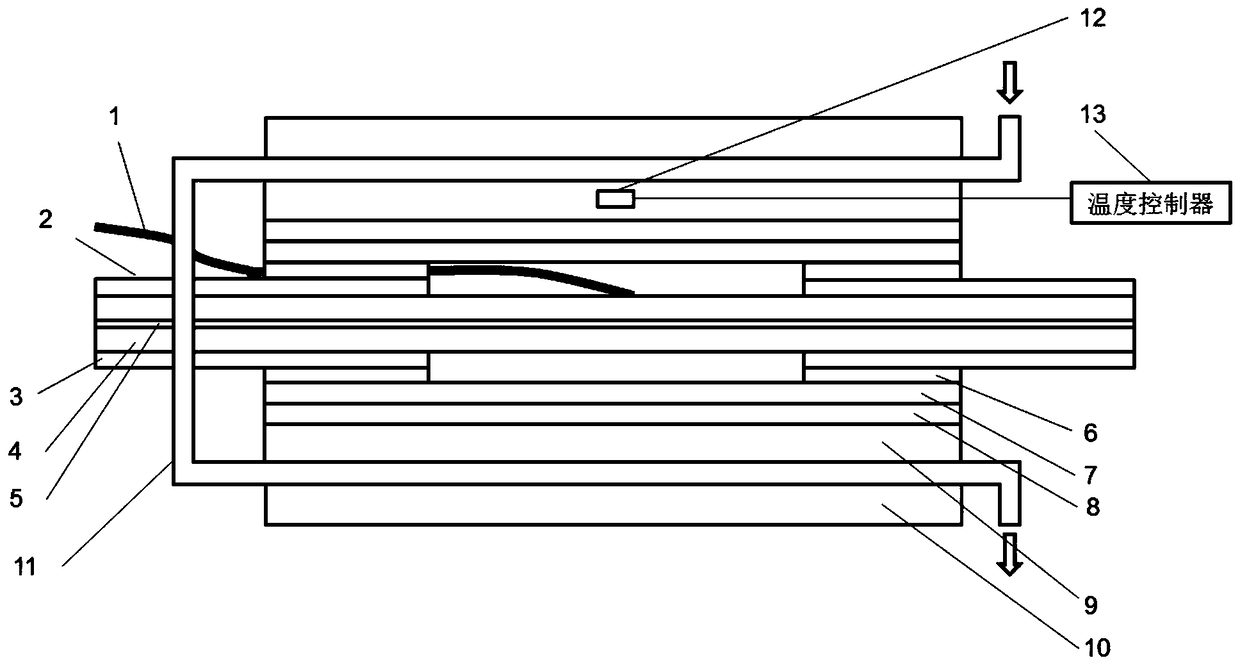

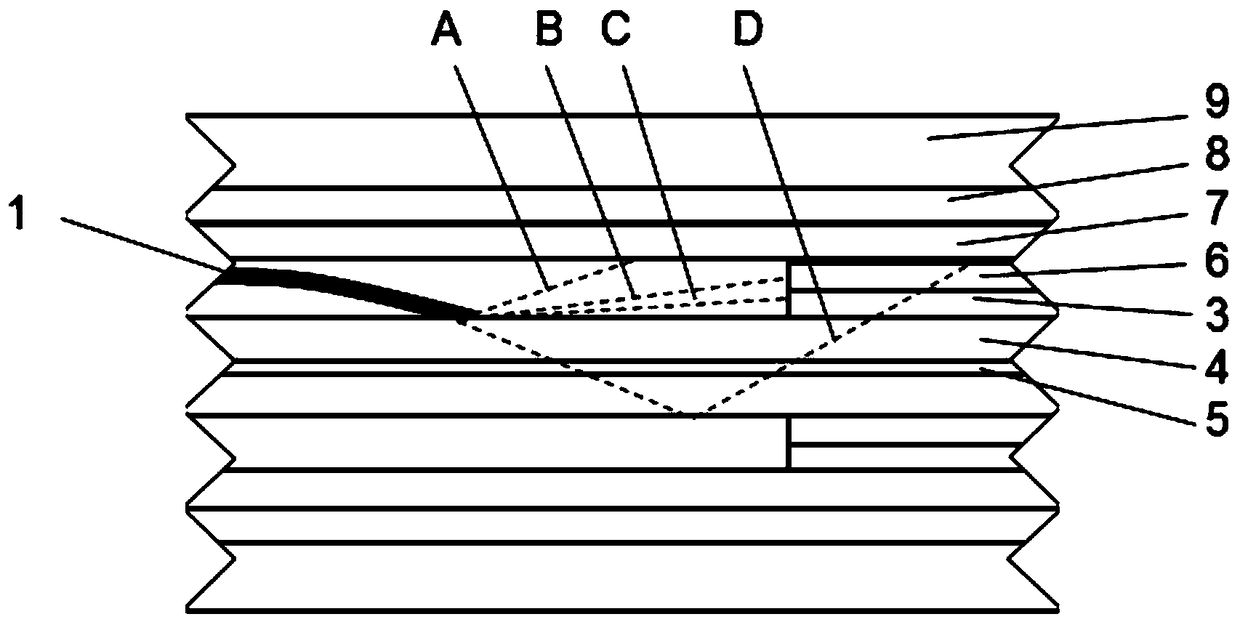

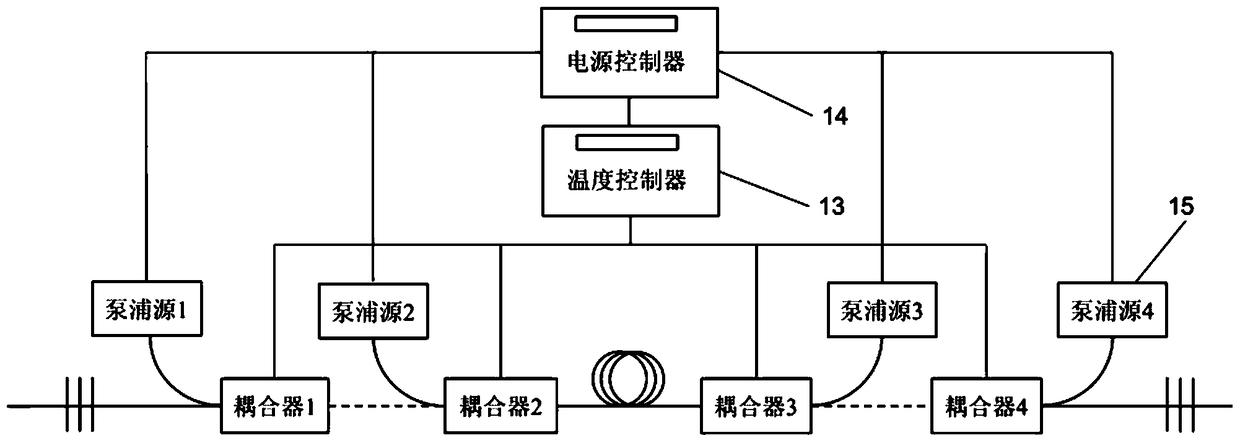

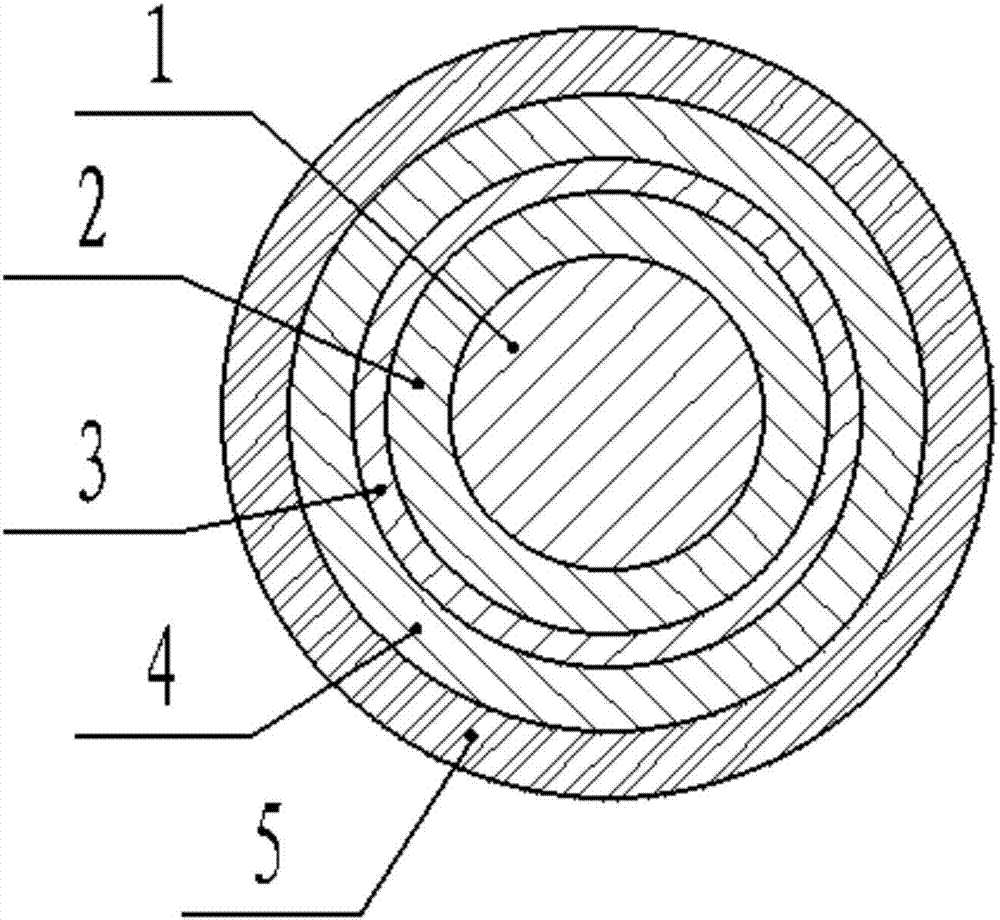

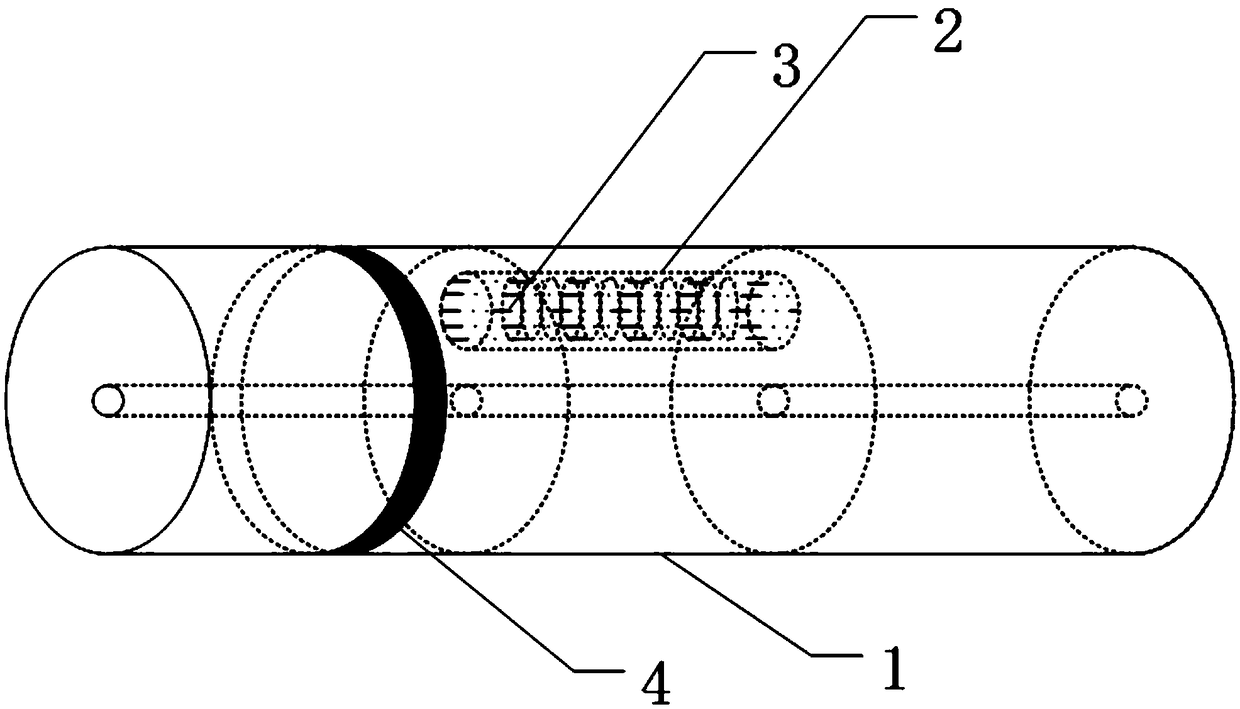

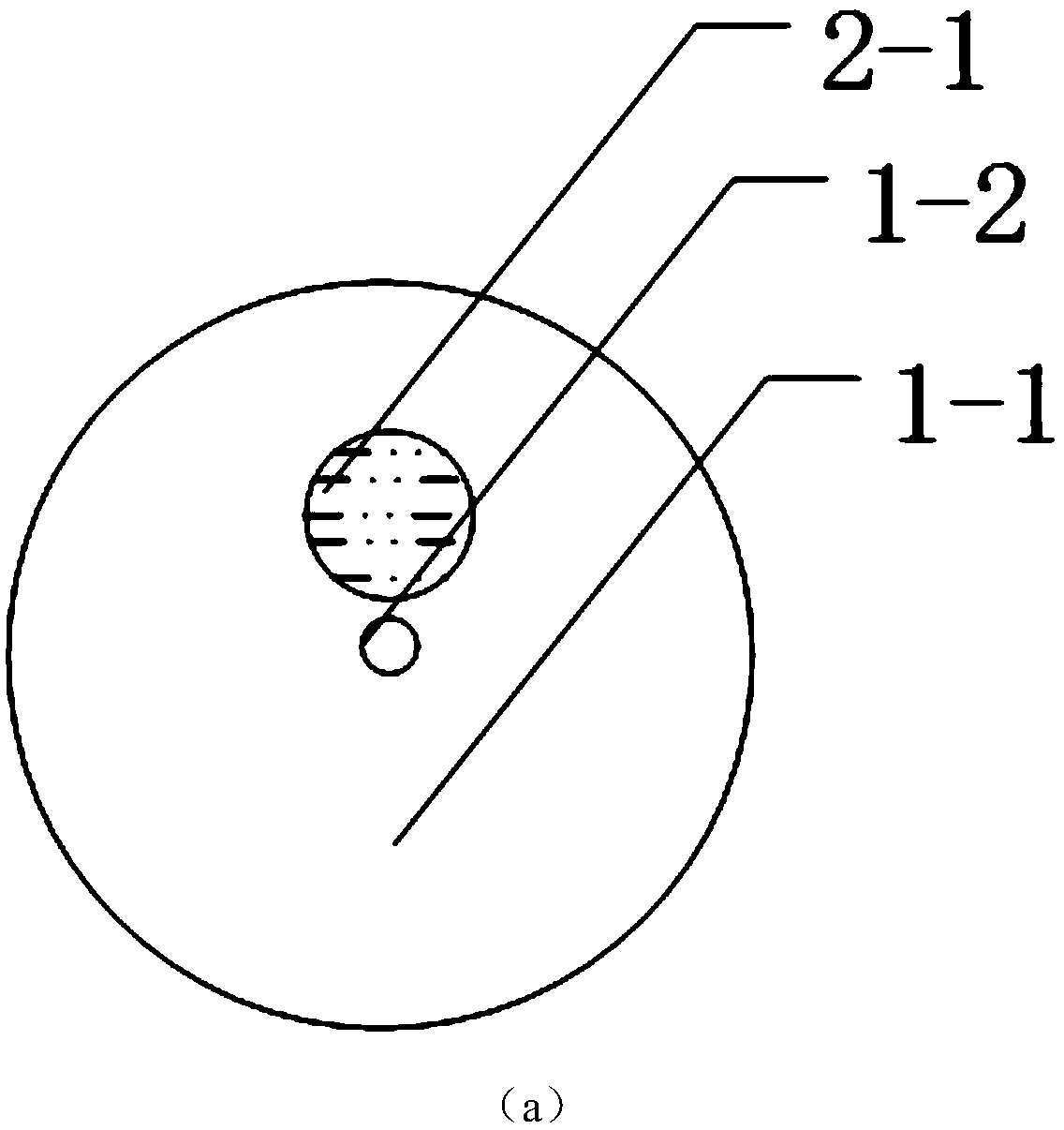

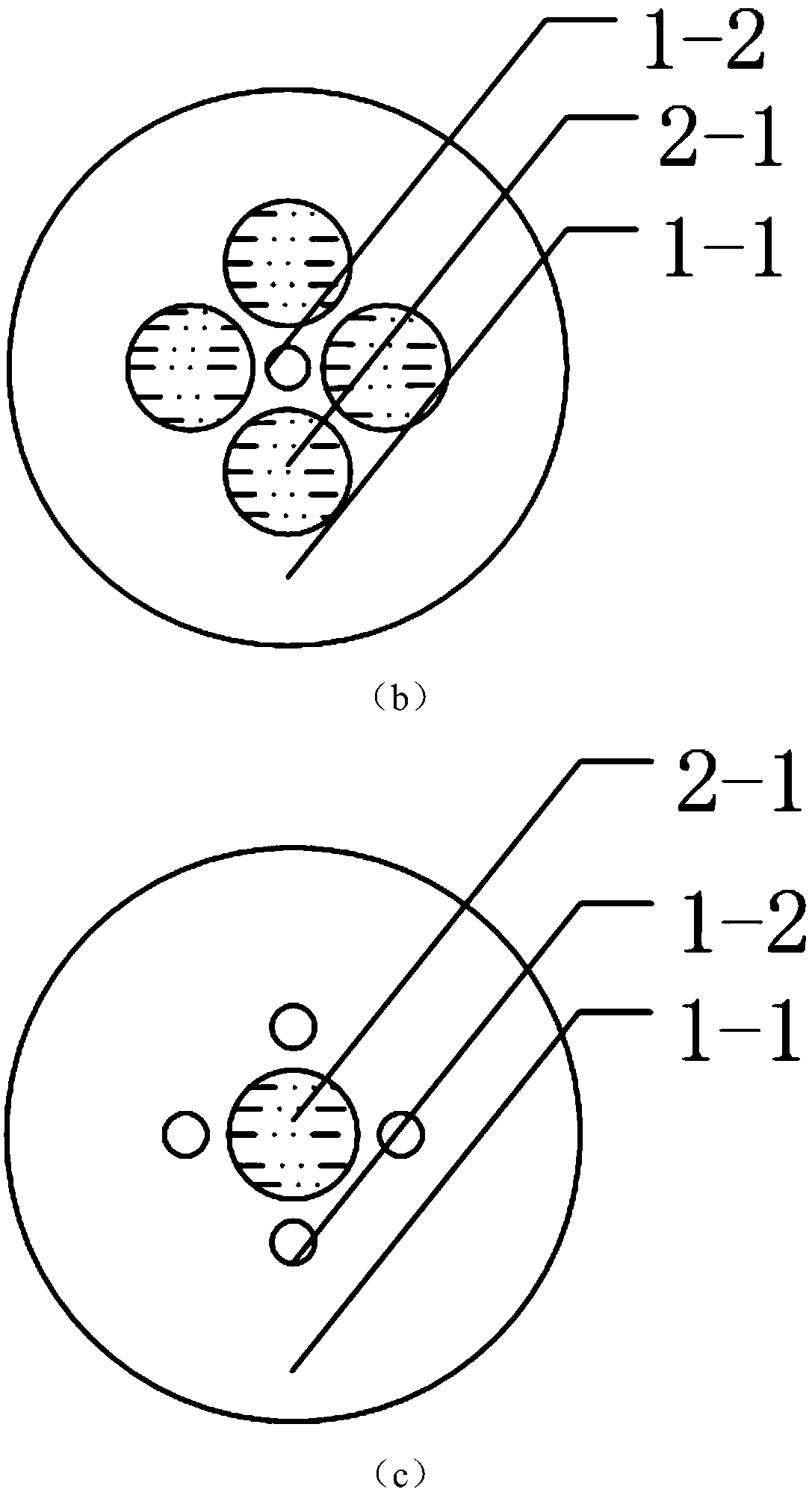

A pump coupler for kilowatt-scale fiber lasers

ActiveCN105244736BStable jobIncrease production difficultyActive medium shape and constructionFiberLight guide

The invention discloses a pumping coupler for a kilowatt-level fiber laser, comprising: a pumping fiber, a main fiber and a packaging shell; the pumping fiber is connected to the main fiber, and at the access point of the pumping fiber and the main fiber The encapsulation shell is arranged at the place; the encapsulation shell includes an external copper tube, a heat-conducting copper tube and a light-conducting glass layer; the external copper tube is coaxially arranged on the outside of the heat-conducting copper tube; the cavity formed by the external copper tube and the heat-conducting copper tube is pierced with water pipes; heat conduction The inner wall of the copper tube is provided with a light-conducting glass layer; at the port of the heat-conducting copper tube, an optical adhesive layer is provided between the light-conducting glass layer and the main optical fiber, and the access point is sealed in the cavity of the heat-conducting copper tube. The pump coupler disclosed in the present invention can be used in kilowatt-level fiber lasers, and has low manufacturing difficulty and low production cost; at the same time, it can work stably for a long time in kilowatt-level fiber lasers, and is especially suitable for the environment of uninterrupted production in factories throughout the day .

Owner:BEIJING UNIV OF TECH +2

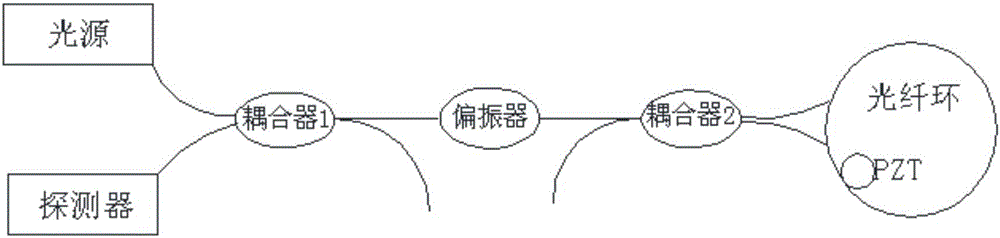

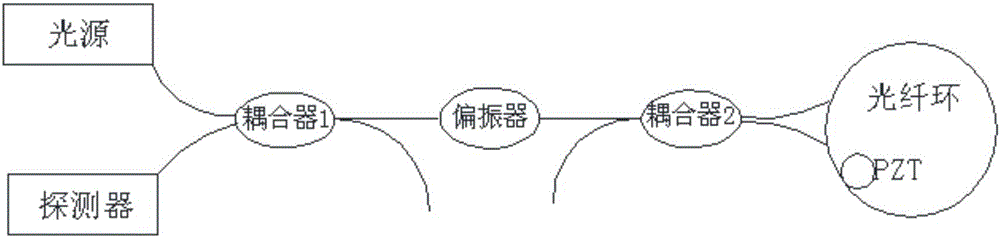

Optical-path-structure open-loop gyroscope and working method thereof

The invention discloses an open-loop gyroscope with an optical path structure and its working method. The optical fiber and the fourth port fiber are connected to the fiber ring, and a detector is also included, and the detector is connected to the coupler through the fifth port fiber, and a phase modulator is arranged in the fiber ring. The invention does not require special thin-diameter optical fibers, nor does it require a high-precision online manufacturing platform for optical devices, which greatly reduces the difficulty of product assembly technology, improves product reliability while ensuring product accuracy, and lays the foundation for the market popularization of open-loop gyroscopes. Base.

Owner:XIAN SINO HUAXIN MEASUREMENT & CONTROL

Carbon fiber continuous sucker rod provided with continuous flocculent wear-resistant layer internally

InactiveCN106968609AImprove wear resistanceEliminate performance blind spotsDrilling rodsDrilling casingsEpoxyYarn

The invention belongs to the field of oil production equipment, and particularly relates to a carbon fiber continuous sucker rod provided with a continuous flocculent wear-resistant layer internally. The carbon fiber continuous sucker rod comprises a carbon fiber core body, the wear-resistant layer and an epoxy resin layer, a rough yarn layer is arranged at the outside of the carbon fiber core body, the wear-resistant layer is arranged at the outside of the rough yarn layer, a spun yarn layer is arranged at the outside of the wear-resistant layer, and the epoxy resin layer is arranged at the outside of the spun yarn layer; the rough yarn layer is made of aramid fibers with the fineness of 3000 D, the wear-resistant layer is made of flocculent polypropylene fiber strips in a coating mode, and the spun yarn layer is made of aramid fibers with the fineness of 1100 D; and the length directions of the carbon fibers, the aramid fibers and the polypropylene fiber strips are all consistent with the axis direction of the sucker rod. According to the carbon fiber continuous sucker rod provided with the continuous flocculent wear-resistant layer internally, polypropylene fiber adopted is of a flocculent structure, epoxy resin can be more fully immersed among all fiber filaments in the polypropylene fiber strips, so that the combination degree of wear-resistant materials and the epoxy resin and the immersing degree of the epoxy resin are enhanced greatly, and therefore the wear-resistant performance of the wear-resistant materials can be exerted fully.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Online tunable in-fiber integrated supersonic grating

ActiveCN109143468ARefractive Index Periodic ControlSimple structureOptical light guidesFiberSonification

The invention provides an online tunable in-fiber integrated supersonic grating, and belongs to the technical field of fiber sensing and fiber communication. A fiber, an air vent, an air vent fillingliquid and a supersonic wave source are included, the air vent is positioned in the fiber and filled with the air vent filling liquid, the supersonic wave source is attached to the surface of the fiber, supersonic waves generated by the supersonic wave source spread in the air vent filling liquid to form standing waves, the refractive index of the liquid is distributed periodically according to weakness via intensity change of the supersonic waves, a grating whose period is related to the supersonic wave length is formed in the axial direction of the fiber, and a light beam in a fiber core canbe tuned and filtered online via the supersonic wave length. The online tunable in-fiber integrated supersonic grating has the advantages of small size, high wavelength selectivity, high coupling performance, easy tuning and low cost, can be compatible with fiber function devices, and can be used for in-fiber integration of a photonic device and system.

Owner:HARBIN ENG UNIV

Midwifery device with obstetric suction cup

The invention discloses a midwifery device with an obstetric suction cup, including a support frame, wherein electric slide rails are arranged inside the support frame; the electric slide rails are axisymmetrically distributed; the electric slide rails and the support frame are fixedly connected through bolts and screw holes; a telescopic rod is arranged between the electric sliding rails; a connecting sleeve is arrange at one end of the telescopic rod; a connecting plate is arranged outside the connecting sleeve; the connecting plate and the electric slide rails are fixedly connected; an attractor is arranged inside the connecting sleeve; and one end of the attractor is arranged inside the connecting sleeve for sliding connection. By positioning the suction device inside the connecting sleeve, The invention is convenient for fixing the suction device, improving the stability of the suction device when working, simultaneously cooperating with the electric slide rail to control the connecting sleeve, facilitating the left and right movement of the connecting sleeve, at the same time cooperating with the telescopic use is conducive to adjusting the length of the suction device, thereby facilitating the delivery assistance and improving the convenience of use.

Owner:佟玲

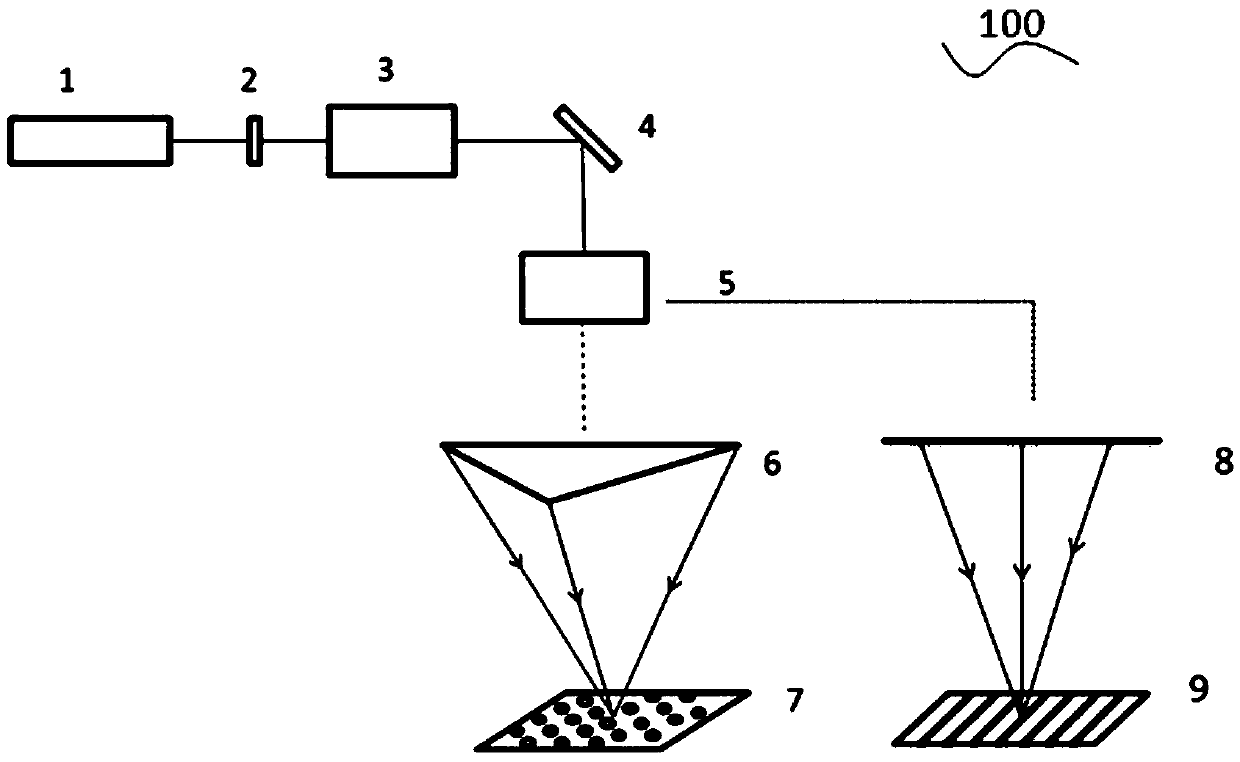

Method and system for manufacturing modulation-free array structure by adopting laser interference photoetching technology

InactiveCN111077734AReduce the difficulty of productionImprove stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splittingLight beam

The embodiment of the invention discloses a system for manufacturing a modulation-free array structure by adopting a laser interference photoetching technology and a corresponding method. According tothe system, laser is adopted as a light-emitting light source; three coherent light beams are formed through shaping, collimation and beam splitting; the three coherent light beams converge and interfere on the plane of a substrate, so that light intensity is redistributed in an interference field, and therefore, periodic structures which are consistent in size and are uniformly distributed can be easily obtained. Modulation does not occur in a manufacturing process. The periodic pattern structure can be widely applied to the fields of functional surfaces, devices and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

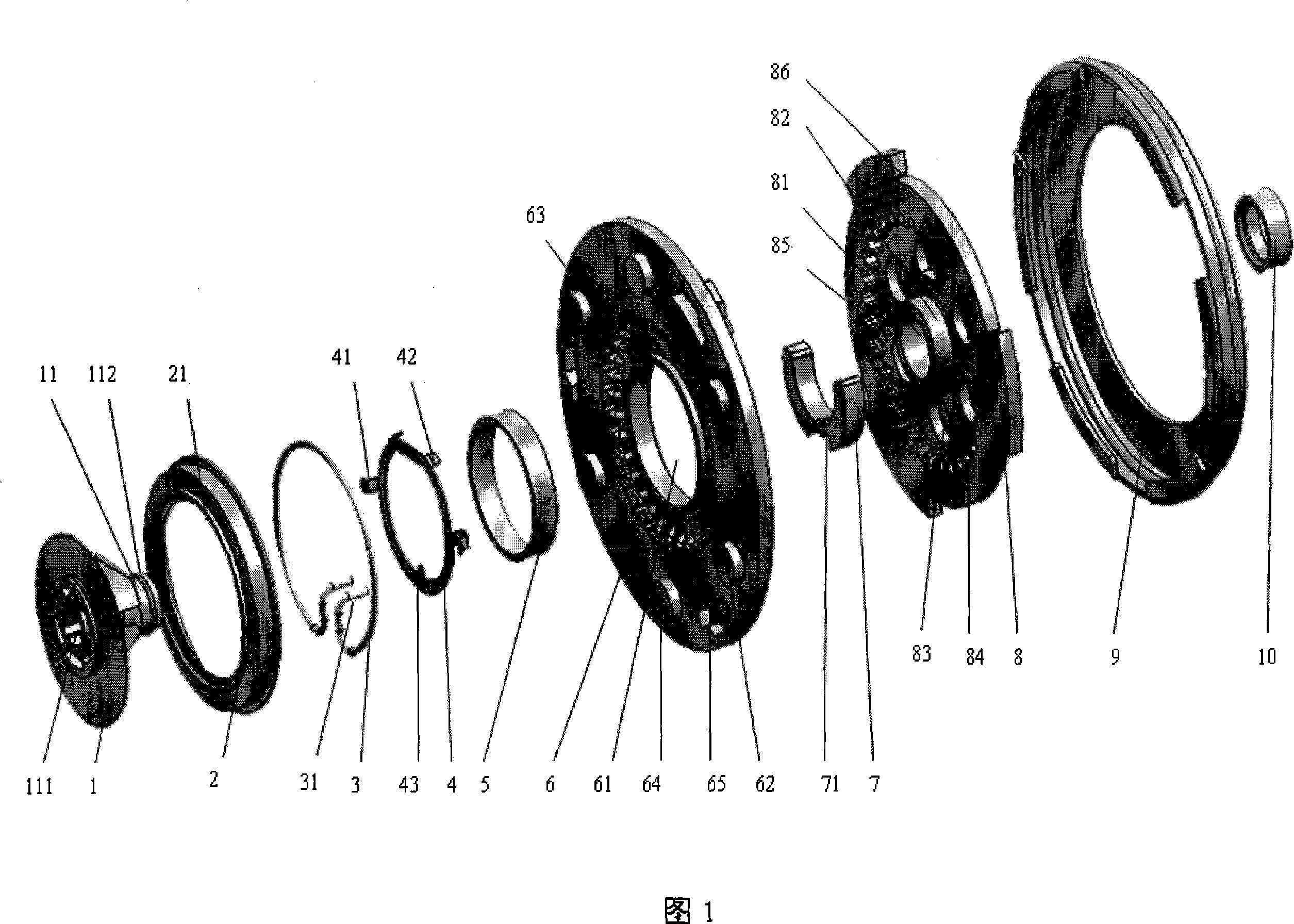

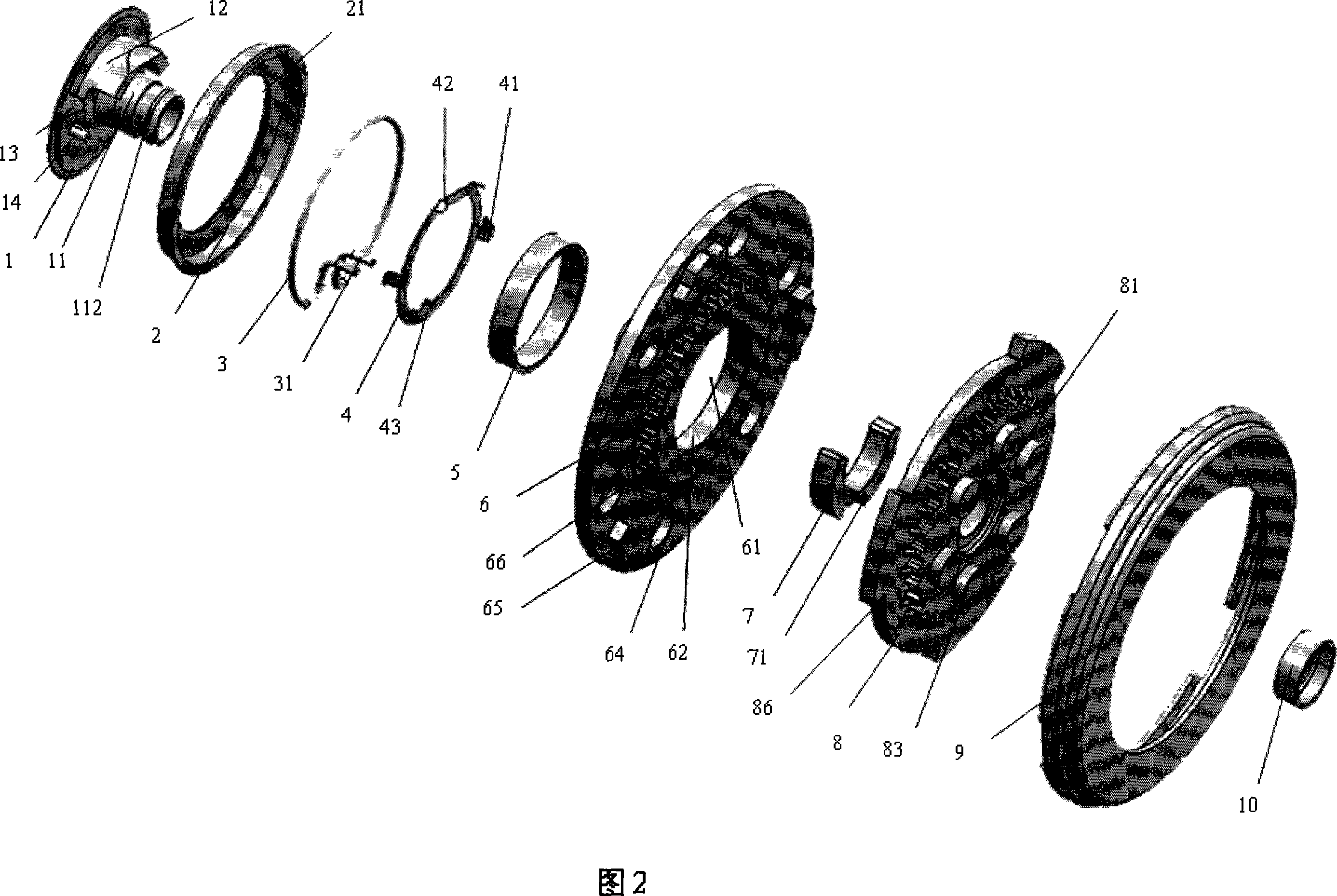

Disc type gapless chair angle modulation device

The invention provides a disc-shaped no-clearance seat angle adjuster, belonging to automobile parts. The invention comprises a movable gear plate, a fixed gear plate, a pair of clearance removal blocks, a built-in bracket, a clamping spring, a dustproof cover, a cover plate, and a closed ring; the middle of the movable gear plate is provided with a first shaft hole, a first concave chamber with an internal tooth ring at one side and a first connecting bulge at the other side; one side of the first shaft hole is convexly provided with a shaft sleeve seat; the middle of the fixed gear plate is provided with a second shaft hole, a second concave chamber and a second connecting bulge at one side, and an external tooth at the other side; one side of the second shaft hole is convexly provided with a shaft seat; the clearance removal blocks are in waist-shape where a trough is arranged; the built-in bracket is provided with a clamping spring foot position limit block; the opening end of the clamping spring forms a clamping spring foot; the dustproof cover covers the second concave chamber; the middle part of the cover plate is provided with a rotary shaft sleeve with a semi-cirque arranged at one side and fixed by a retaining ring; the closed ring is sealed at the external circumference of the fixed gear plate and the movable gear plate. The invention has the advantages of low production cost, easy assembly, firm locking, strong generalization, and firm connection with a seat.

Owner:邹耀忠

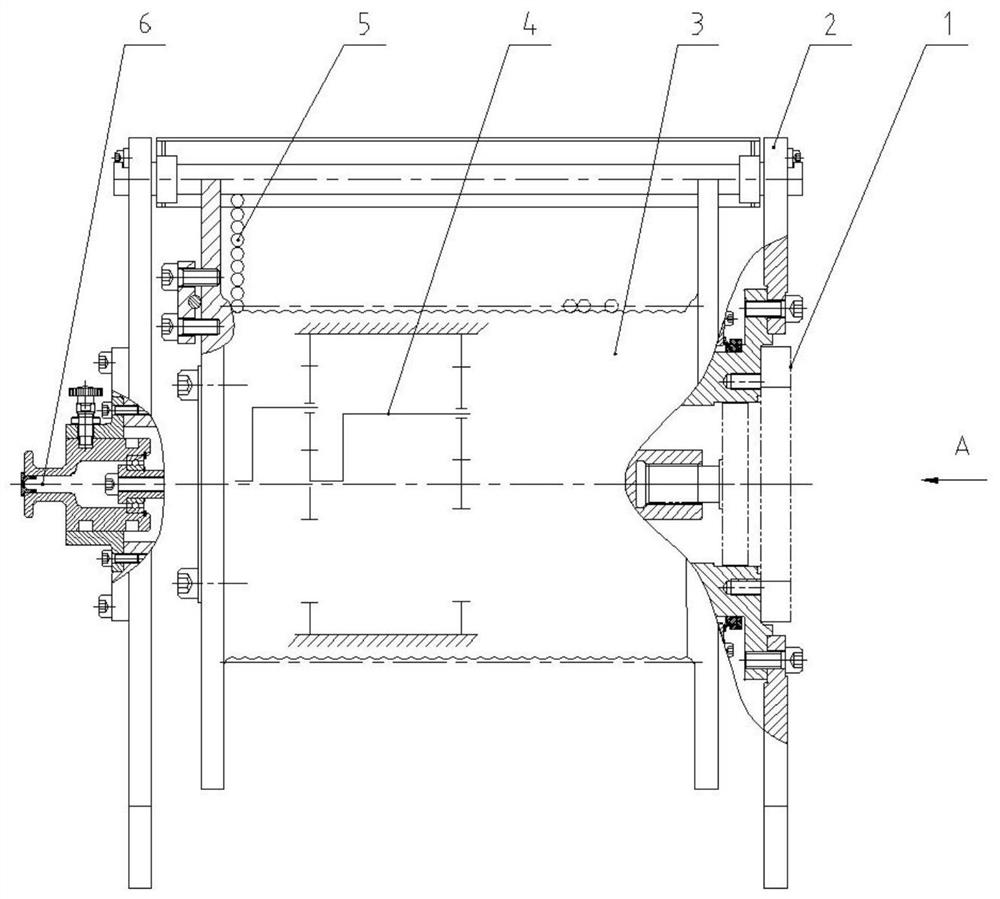

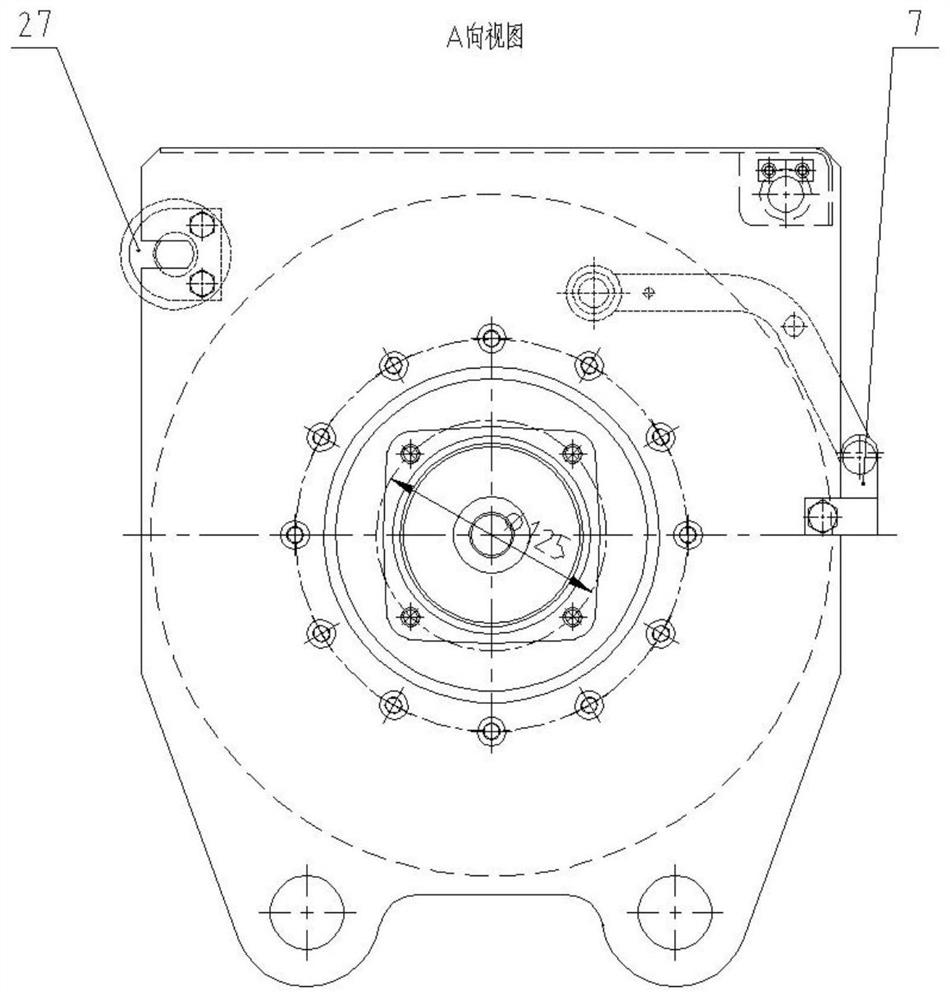

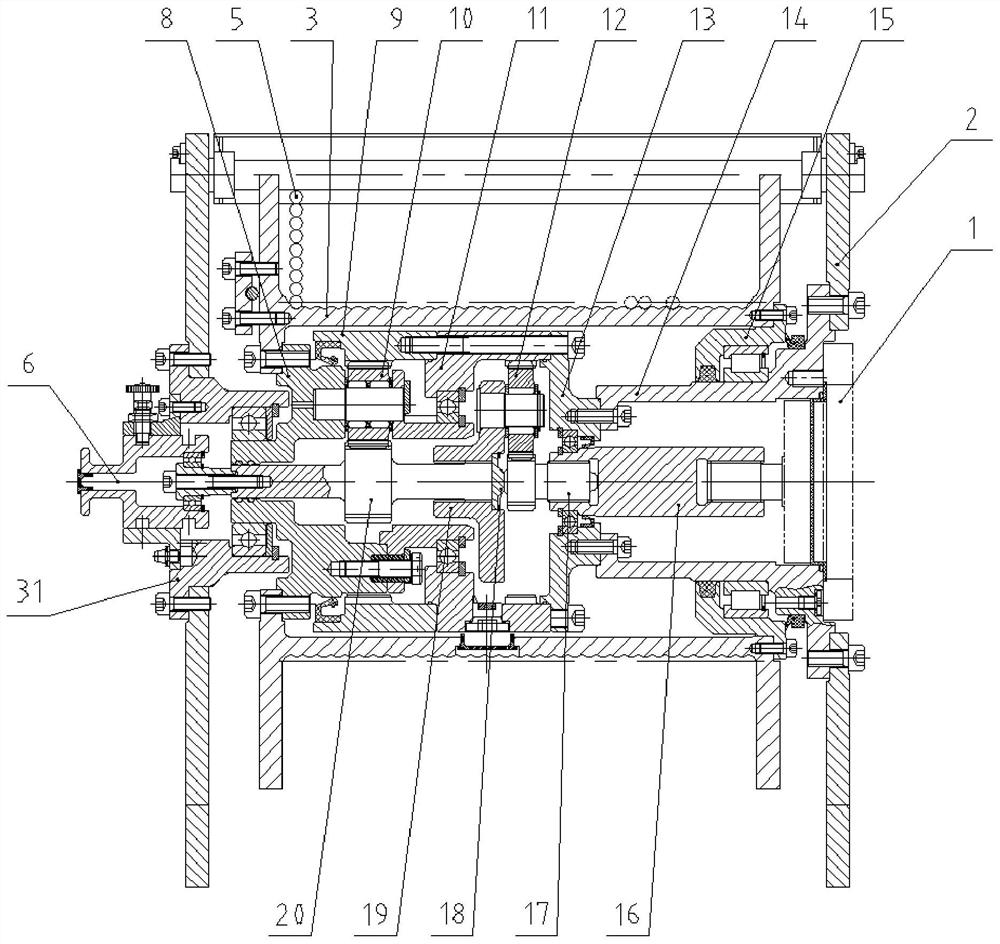

Clutch type rope threading hoisting mechanism for crane

PendingCN111924735AGuaranteed StrengthEasy to produceMechanical actuated clutchesGear lubrication/coolingClutchWire rope

The invention discloses a clutch type rope threading hoisting mechanism for a crane, relates to the technical field of clutch type hoisting mechanisms, and particularly relates to a hoisting mechanismwhich is applied to a large crane and is used for threading and tensioning a hoisting steel wire rope on an arm frame. The clutch type rope threading hoisting mechanism comprises a hydraulic motor, arack, a winding drum, a planetary gear train, a steel wire rope, a clutch, a rope pressing device and a guide device, wherein the rack is connected to the crane through a pin shaft; the winding drumis arranged inside the rack and can rotate inside the rack; the planetary gear train is arranged in the winding drum; the input end of the planetary gear train is connected with the hydraulic motor arranged on one side of the rack, and the output end of the planetary gear train is connected with the clutch arranged on the other side of the rack; the steel wire rope is wound on the outer wall of the winding drum; the guide device is arranged on the rack in the rope outlet direction of the steel wire rope; the rope pressing device is arranged on the rack on the side opposite to the rope outlet direction of the steel wire rope; and the hydraulic motor is connected with the winding drum through the planetary gear train and drives the winding drum to rotate, and after speed reduction and torqueincrease, the steel wire rope is finally output to the steel wire rope through the winding drum, so that winding and unwinding of the steel wire rope are realized.

Owner:DALIAN HUARUI HEAVY IND GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com