Aramid nanofiber composite unidirectional fabric and preparation method thereof

A nanofiber, aramid fiber technology, applied in fiber processing, chemical instruments and methods, protective equipment, etc., can solve problems such as poor comfort, high production difficulty, and hard products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

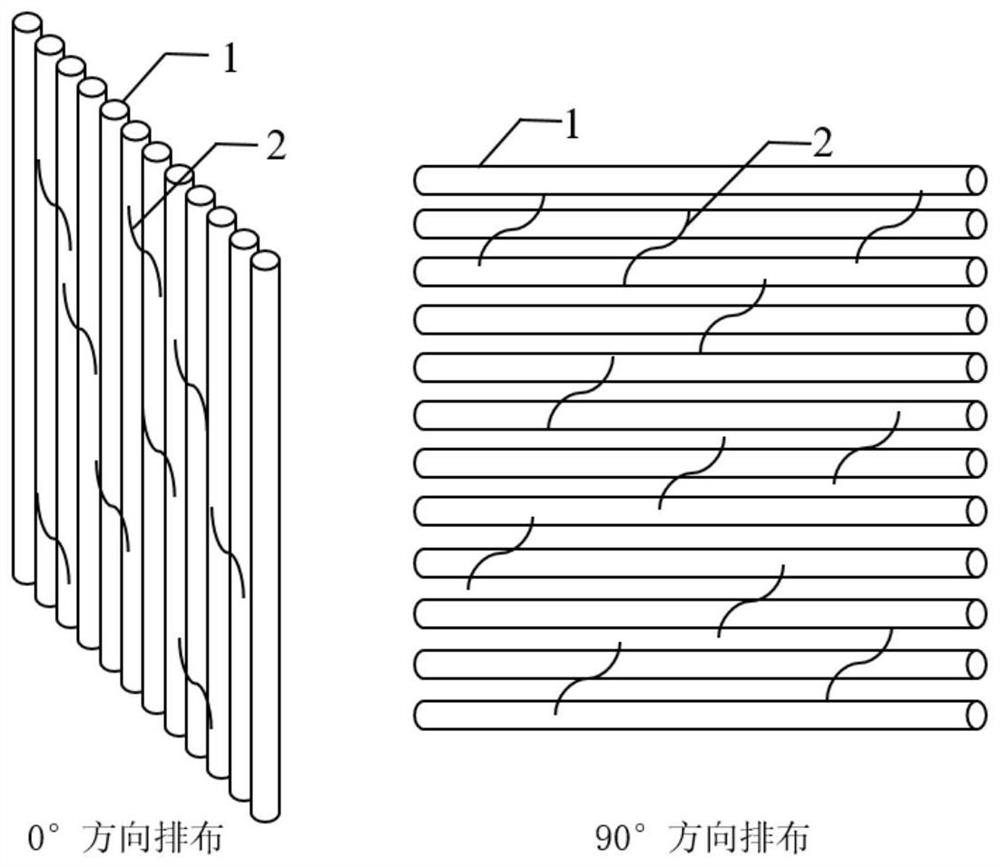

[0077] The preparation method of the UD cloth of aramid fiber nanofiber composite of the present invention comprises:

[0078] (1) preparing a unidirectional sheet comprising unidirectionally arranged aramid fibers and an adhesive, wherein the adhesive includes aramid nanofibers;

[0079] Optionally also include:

[0080] (2) Laminate the unidirectional sheets, and then optionally attach a protective layer to the upper and lower surfaces of the laminated unidirectional sheets; and / or

[0081] (3) The laminated unidirectional sheets are laminated by hot pressing to obtain a UD cloth including a plurality of unidirectional sheets.

[0082] In step (1), the unidirectional sheet can be prepared by methods known in the art, for example, the aqueous dispersion of the adhesive is uniformly attached to the aramid fiber and dried to obtain the unidirectional sheet. The present invention is characterized in that the adhesive comprises aramid nanofibers, that is, the aqueous dispersion...

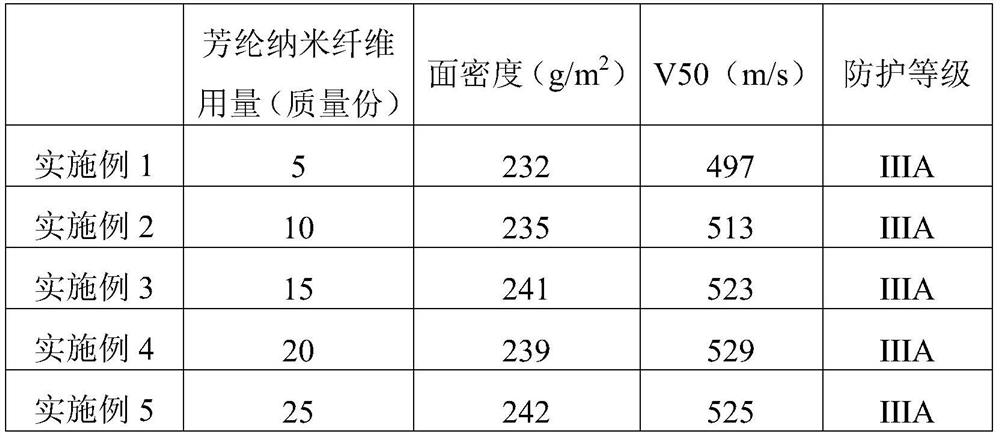

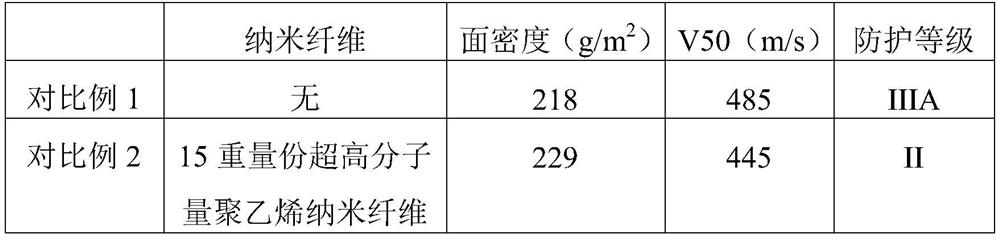

Embodiment 1-5

[0109] Embodiment 1-5 prepares the UD cloth of aramid fiber nanofiber composite of the present invention, comprises the following steps:

[0110] (1) Spreading wire dipping

[0111] The aramid fiber on the creel is spread on the master roller of the dipped thread through the tension controller and the drafting device, and the aramid fiber is passed through the glue tank equipped with the prepared adhesive water dispersion through the drafting roller, and then The aramid fiber is evenly spread and glued by the affinity roller, and the water in the adhesive water dispersion is evaporated to dryness through a circulating heating device, and then wound up to form a unidirectional sheet, wherein the thickness of the glue film is 0.02mm;

[0112] Wherein, the aqueous adhesive dispersion includes: resin matrix, resin modifier, tackifier, emulsifier, defoamer, antioxidant, pH regulator, deionized water and aramid nanofiber, embodiment 1-5 Use adhesive aqueous dispersions with differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com