Patents

Literature

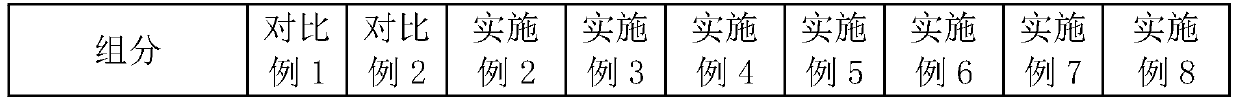

87results about How to "Solve erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

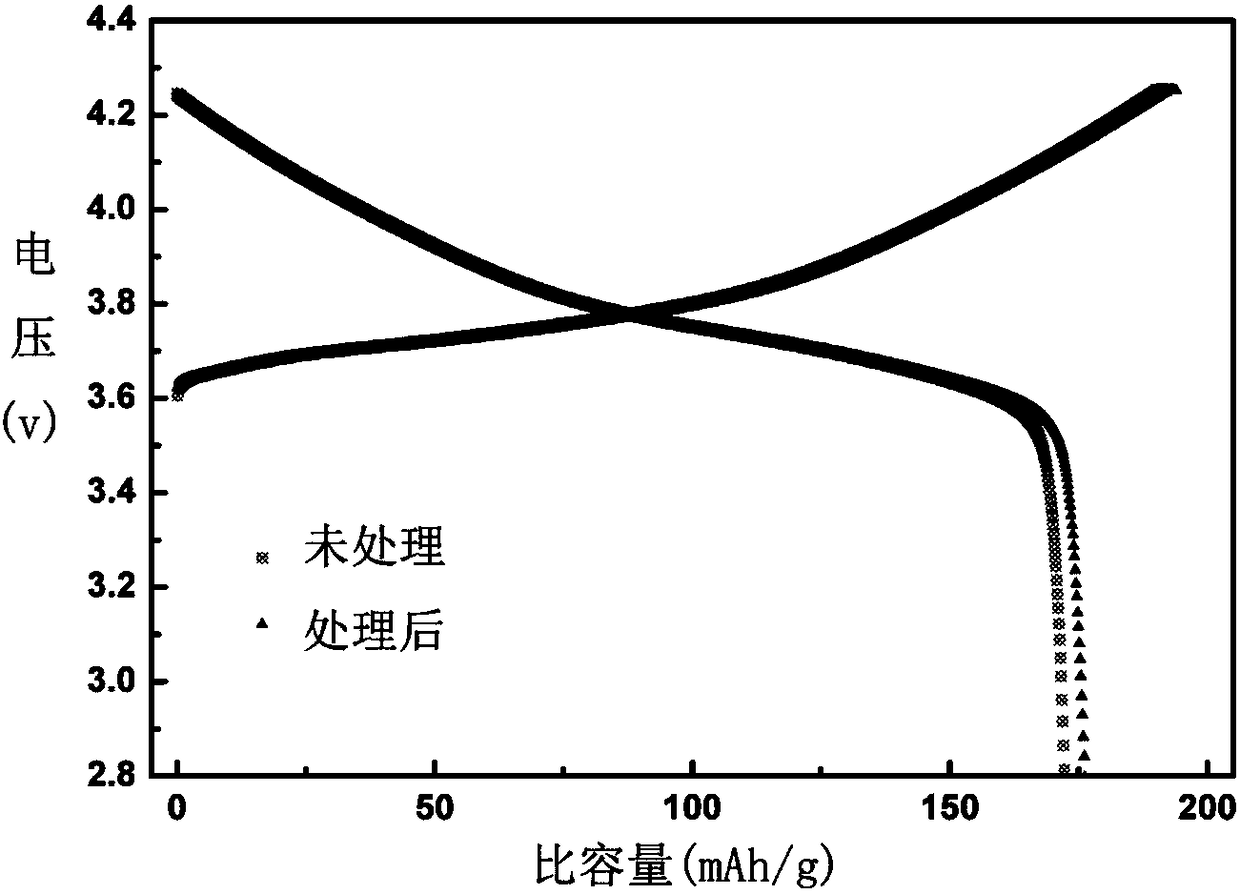

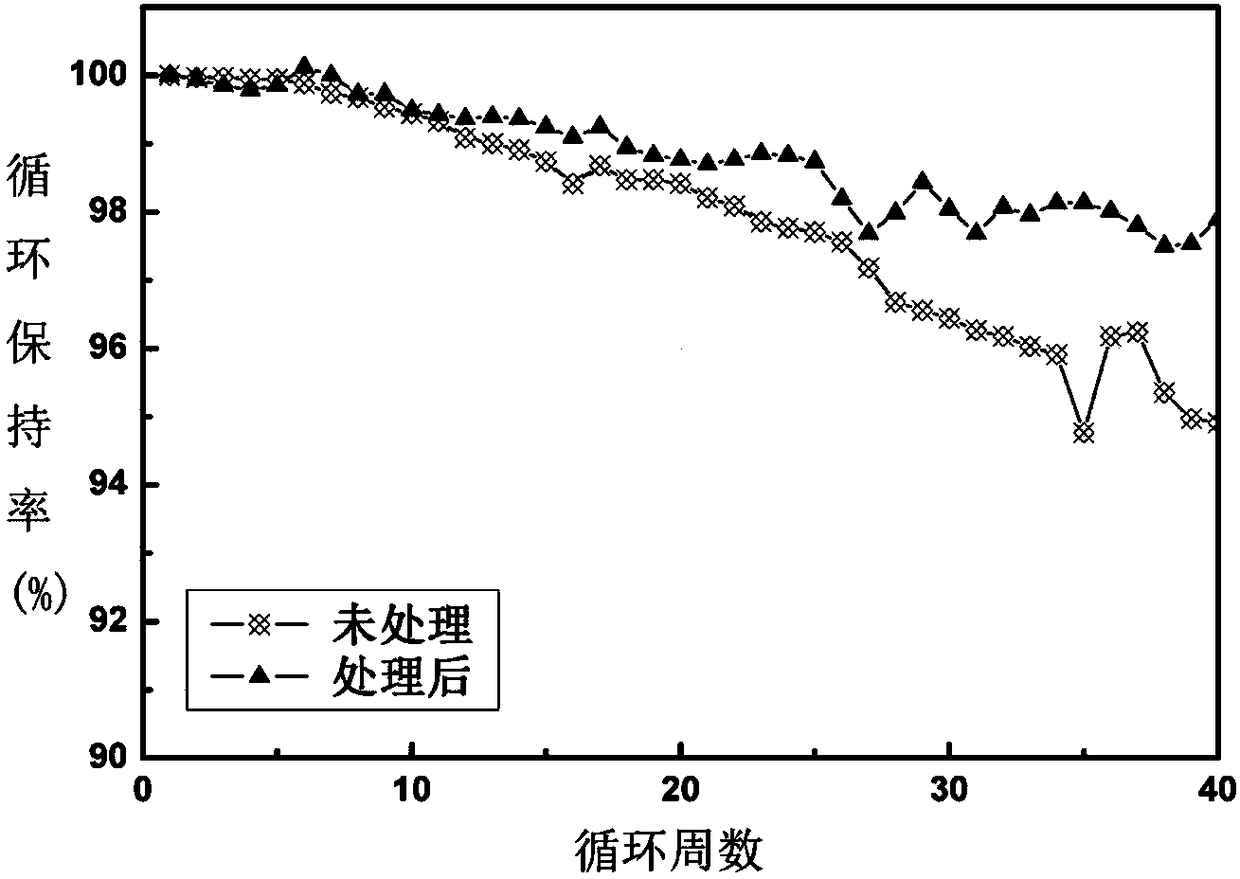

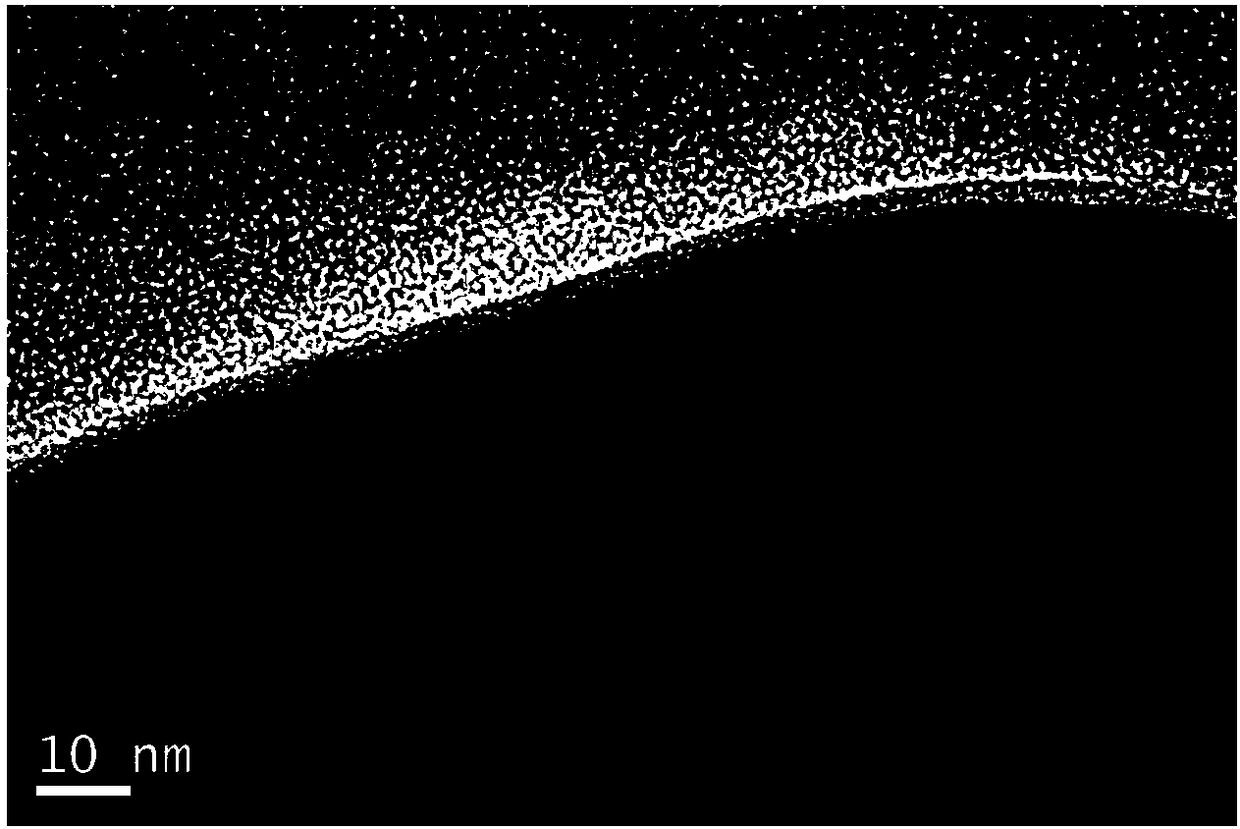

Composite modification method for lithium ion battery positive electrode material

InactiveCN108134069AInhibition of dissolutionInhibit migrationCell electrodesSecondary cellsSolventThermal treatment

The invention discloses a composite modification method for a positive electrode material. The method comprises the following steps: 1) removing impurities from a positive electrode material precursorto obtain a cleaned and impurity-removed positive electrode material precursor; 2) mixing the clean and impurity-removed positive electrode material precursor obtained in step 1) with a lithium source; 3) sintering the above obtained mixture to obtain a positive electrode material matrix; 4) dispersing and dissolving the source substance and the coating aid of a coating material in a solvent to obtain a dispersion system, adding the positive electrode material matrix obtained in step 3) to the dispersion system, performing stirring, then performing solid-liquid separation to obtain a coated solid substance, and finally performing heat treatment to obtain a material having a coating material layer; and 5) washing and drying the material obtained in step 4) to obtain a composite modified lithium ion battery positive electrode material. The high-nickel positive electrode material with a good stability is prepared through the method, and can be washed to effectively reduce residual alkaliwhile keeping the structure stable without causing deterioration of performances.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

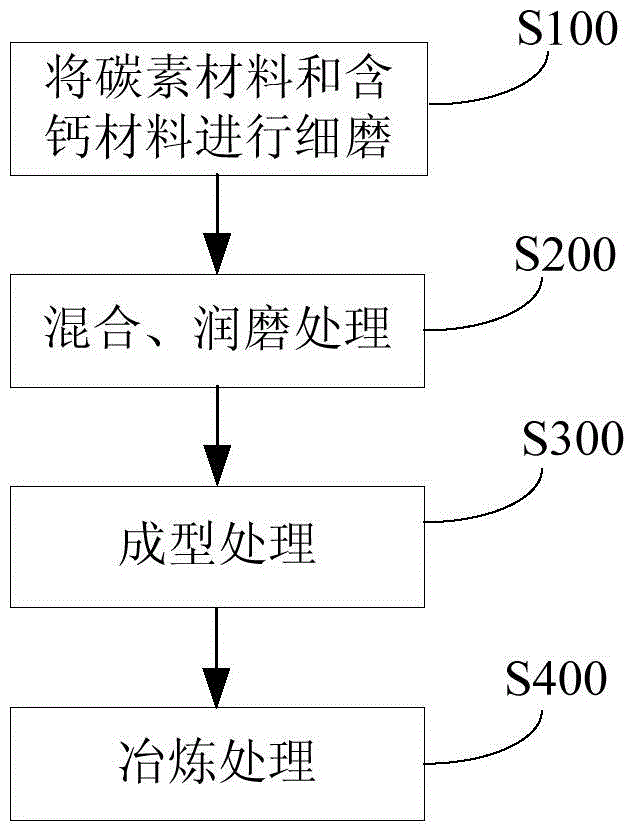

Method for preparing solid calcium carbide

The invention discloses a method for preparing solid calcium carbide. The method comprises steps as follows: (1) a carbon material and a calcium containing material are ground fine, so that carbon material powder and calcium containing material powder can be obtained respectively; (2) a mixture containing the carbon material powder, the calcium containing material powder and iron powder is mixed and wet-ground with a bonding agent, and a mixed material is obtained; (3) the mixed material is shaped to obtain a material pellet; (4) the material pellet is smelted at the temperature of 1,200-1,380 DEG C so as to obtain the solid calcium carbide. The solid calcium carbide can be effectively prepared with the method, and the production cost of the calcium carbide is obviously reduced.

Owner:SHENWU TECH GRP CO LTD

Method of shallow reinforcement and surface reinforcement of loess slope

ActiveCN102926390ASolve weathering and peelingSolve the problem of slope erosionExcavationsSoil preservationUltimate tensile strengthCold resistance

The invention provides a method of shallow reinforcement and surface reinforcement of a loess slope. The method of shallow reinforcement and surface reinforcement of the loess slope comprises steps as below: excavation of intercepting drains, molding of intercepting drains, hole-drilling, grouting and preparation of a consolidation layer, wherein the molding of the intercepting drains means that waterborne polyurethane resin is sprayed on the surfaces of the intercepting drains. The hole-drilling means that holes are drilled perpendicularly to a slope surface. The grouting means that after drilling, the holes are grouted. The preparation of the consolidation layer means that the waterborne polyurethane is sprayed on the slope face with shallow drilling grouting reinforcement and a consolidation layer is formed on the slope surface. Due to the fact that shallow reinforcement and surface reinforcement of silty loess, the stability of the slope is effectively enhanced, shear strength of soil body of the reinforcement layer is improved almost three times than the shear strength of raw soils, and the consolidation layer with good elasticity, strength, cold resistance and anti-leakage functions is formed on the slope surface. The problems of efflorescing off of the surface and slope erosion are solved.

Owner:江苏绿之源生态建设有限公司

Technology for producing ladle furnace (LF) submerged arc refining agent by utilizing electrolytic aluminum overhaul slag

InactiveCN109628695ARealize resource utilizationReduce adverse effectsProcess efficiency improvementIon contentProduction line

The invention discloses a technology for producing a ladle furnace (LF) submerged arc refining agent by utilizing electrolytic aluminum overhaul slag. The technology for producing the LF submerged arcrefining agent by utilizing electrolytic aluminum overhaul slag comprises the steps that carbon blocks and electrolytes in overhaul slag of an electrolytic aluminum factory are sorted and crushed, with carbon block particle size being smaller than 1mm and electrolytes crushed to 5 + / - 0.53mm; magnesium oxide powder with magnesium oxide content larger than 80% is purchased and transported to a ball-pressing production line, waiting to be used; the adding amount of carbon block powder and electrolyte powder is determined according to the carbon content, and the carbon content in the middle ofa submerged arc agent is guaranteed to be controlled below 35%; according to the fluorine ion content, it is determined that the adding amount of magnesium oxide is 10% of the fluorine ion concentration; various raw materials are mixed uniformly; and a spheric submerged arc refining agent with diameter being 30-50 mm is manufactured through dry type ball pressing, wherein main components of the refining agent comprises, by weight, 15-35% of carbon, less than 35% of fluorine ion, 5-9 % of magnesium oxide and no requirements for sodium ion and aluminum oxide. In the smelting process of a LF refining furnace, the adding amount of the refining agent is 2-5 kilograms per ton of steel, and the specific usage amount is determined according to the situation of refined molten steel.

Owner:新疆中合大正冶金科技有限公司

Saturated saltwater mud

The invention relates to a saturated saltwater mud which comprises the following components: 55-65 Kg / m<3> of sodium bentonite, 15-25 Kg / m<3> of sodium carbonate, 25-40 Kg / m<3> of sodium hydroxide, 2.4-2.6 Kg / m<3> of polyacrylamide of which the molecular weight is 17-20 million, 2.6-3.1 Kg / m<3> of sodium carboxymethyl cellulose, 2.8-3.2 Kg / m<3> of 5# white oil lubricant, 1-2 Kg / m<3> of bis-imidazoline quaternary ammonium salt corrosion inhibitor, and the balance of saturated saltwater or sea water. The saturated saltwater mud provided by the invention is suitable for horizontal directional drilling under the ocean or karst stratum condition. The invention can be used for implementing large-diameter long-distance pipeline horizontal directional drilling under the ocean or coastal area and karst construction conditions.

Owner:DAQING PETROLEUM ADMINISTRATION +2

Slag removing and furnace protecting agent

InactiveCN101054611ASolve erosionSolve the problem of adsorption of molten steel inclusionsManufacturing convertersRheniumSlag

A slag-adjusted furnace-protected agent is composed by the following substances in percentage, 45-80% MgO2, 6-22% CaO, 6-22% C, 5-12% Al2O3 and 1-4% rhenium. The agent is prepared by taking the above raw materials in proportion, mixing them uniformly and molding and forming particles in a granulator to produce spheroids with the diameter of 10-13mm. The invention has the advantages of (1) solving the problem of spraying before smelting; (2) solving the problem of corroding to the furnace lining of the slag during smelting; (3) solving the problem of absorbing liquid steel impurities of the slag; (4) prolonging the service life of the steel-tapping hole bushing and (5) improving the efficiency of slag adjusting and furnace protecting.

Owner:江西华东实业有限公司

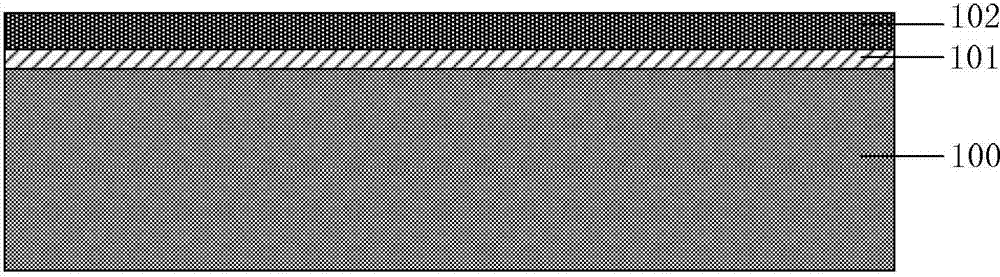

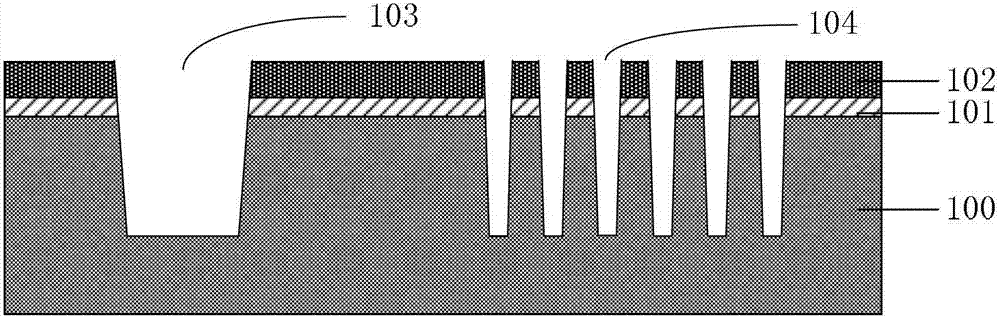

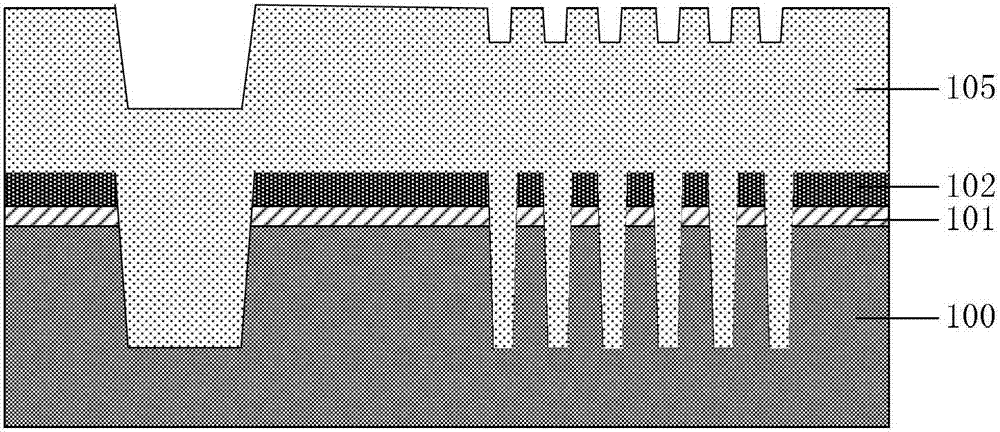

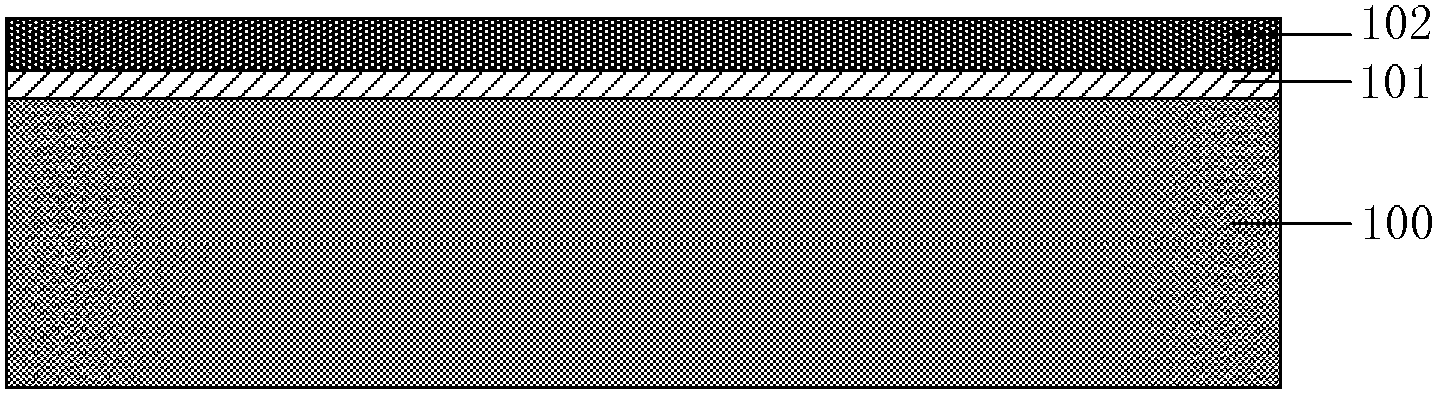

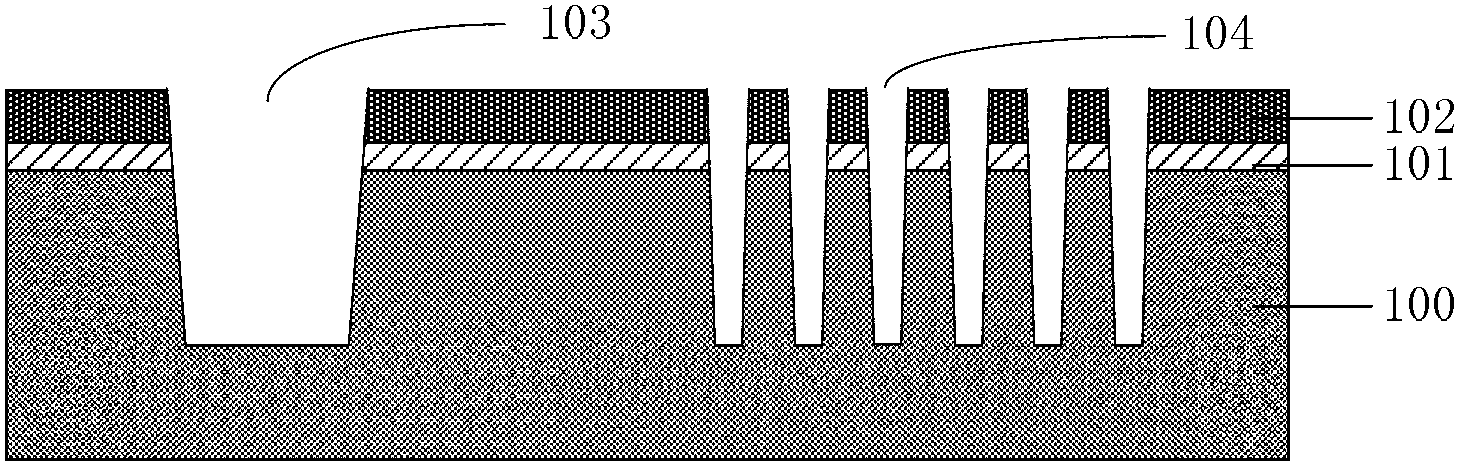

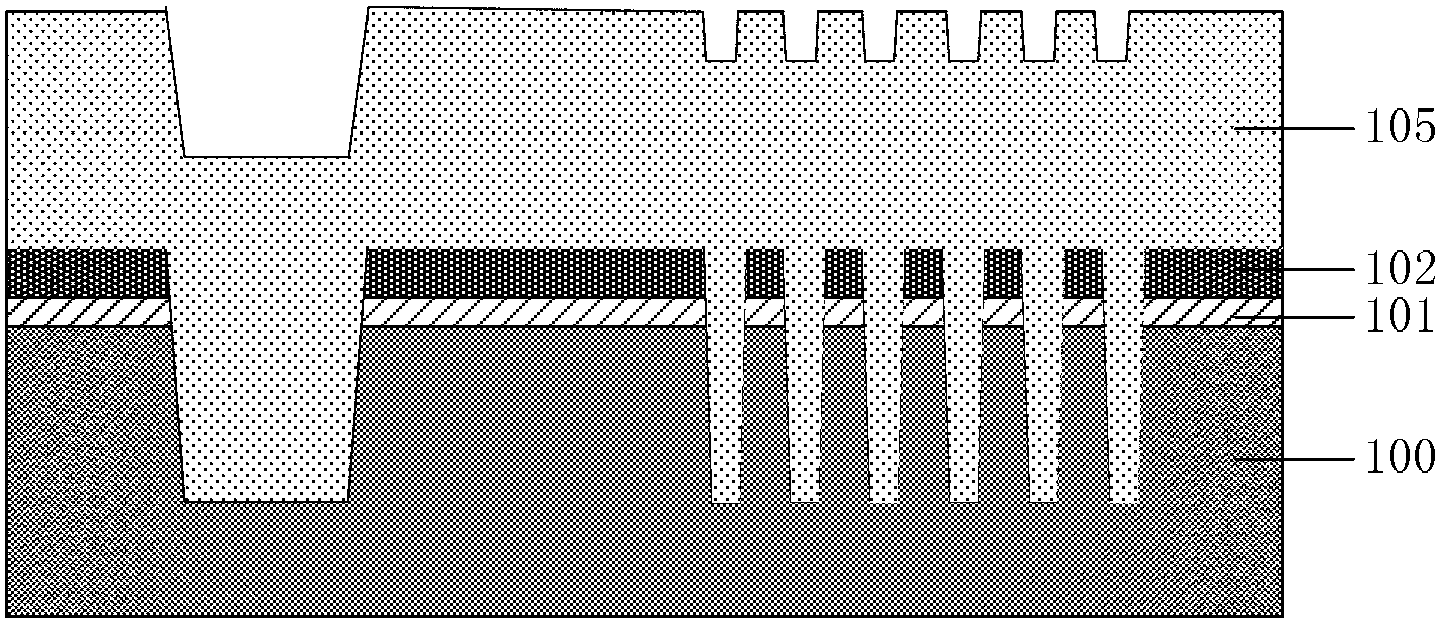

Manufacturing method for shallow trench isolation structure

InactiveCN103199052AReduce use costTo achieve a flattening effectSemiconductor/solid-state device manufacturingEtchingIsolation layer

The invention provides a manufacturing method for a shallow trench isolation structure. The method includes the following steps: covering a semiconductor substrate with an oxide layer and a nitride layer sequentially; carrying out exposure and etching process to form a shallow trench figure; depositing an isolation layer to fill the shallow trench figure; carrying out flattening processing on the isolation layer, and leaving part of the isolation layer; and removing the remaining isolation layer by adopting the method of wet etching, and then removing the nitride layer. According to the manufacturing method for the shallow trench isolation structure, in the process of flattening processing, the nitride layer is not contacted, flattening can be achieved by adopting common lapping fluid, cost of the lapping fluid is reduced, and meanwhile, the phenomena of indentation and corrosion caused by chemical and mechanical lapping are avoided due to the fact that the remaining isolation layer on the nitride layer is removed by using the method of wet etching.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for manufacturing shallow trench isolation structure

InactiveCN103236416AReduce use costAddressing Sag and ErosionSemiconductor/solid-state device manufacturingOxideSemiconductor

The invention provides a method for manufacturing a shallow trench isolation structure. The method includes sequentially covering an oxide layer and a nitride layer on a semiconductor substrate; carrying out exposure and etching processes to form shallow trench patterns; settling isolation layers and filling the isolation layers in the shallow trench patterns; flattening the isolation layers and reserving parts of the isolation layers; removing remaining parts of the isolation layers by means of dry etching; and removing the nitride layer by means of wet etching. The method for manufacturing the shallow trench isolation structure has the advantages that the nitride layer is unaffected when the isolation layers are flattened, the isolation layers can be flattened by common grinding fluid, the cost of the grinding fluid is reduced, the remaining parts, which are positioned on the nitride layer, of the isolation layers are removed by means of dry etching, and accordingly problems of depression and erosion due to chemical mechanical polishing are solved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Resistance welding method for windowed rigidity-flexibility combined circuit board

InactiveCN104797088AFull Coverage GuaranteedSolve erosionNon-metallic protective coating applicationScreen printingRigid core

The invention discloses a resistance welding method for a windowed rigidity-flexibility combined circuit board and relates to the field of production of circuit board products. The resistance welding method sequentially includes screen printing, exposure and development. A block spot screen is adopted for ink printing during screen printing, block spots on the block spot screen correspond to flexible areas on the circuit board, and each block spot is smaller than a single side of the corresponding flexible area by 0.15-0.25mm. By size adjustment of the block spots of the block spot screen, exposure of window edges of a rigidity core board outside a substrate is avoided after screen printing and resistance welding, the problem of ink accumulation in the flexible areas is prevented, and the problem of excessive glue or internal circuit erosion in lamination of the rigid core board and flexible boards is solved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

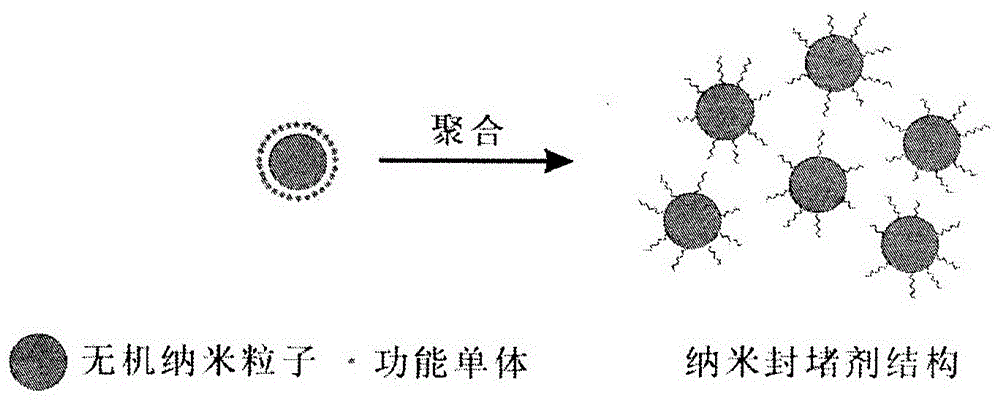

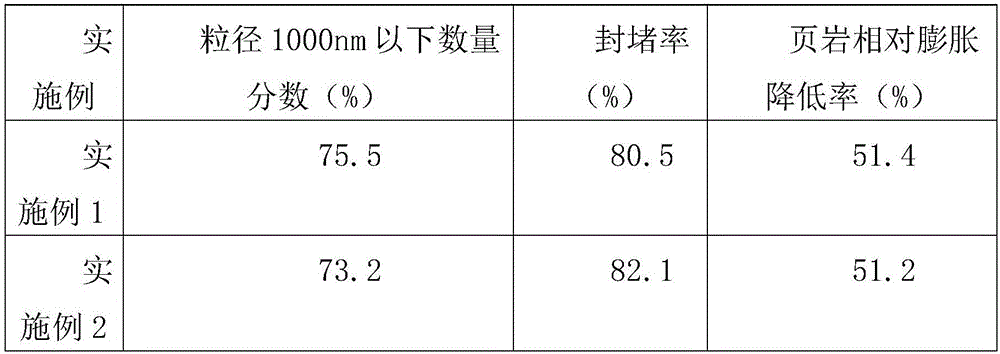

Bionic nanometer blocking agent for drilling fluid and preparation method thereof

ActiveCN106634879AImprove performanceImprove stabilityDrilling compositionPotassium persulfateCross-link

The invention relates to a bionic nanometer blocking agent for drilling fluid and a preparation method thereof. The bionic nanometer blocking agent is prepared from the following raw materials in parts by weight: 60 to 70 parts of distilled water, 1 to 2 parts of 2-acrylamide-2-methylpropanesulfonic acid, 20 to 30 parts of lactic acid, 5 to 10 parts of cross-linking agent, 0.7 to 1.5 parts of nanometer titania, 0.7 to 1.5 parts of molecular weight regulator, 0.1 to 0.5 part of potassium persulfate and 0.2 to 0.5 part of sodium hydroxide. The cross-linking agent is one of ethylene glycol dimethacrylate, polyethylene glycol and trimethylolpropane; the molecular weight regulator is isooctyl 3-mercaptopropionate. The preparation method comprises the following process steps of preparing alkyl solution; preparing titanium-based solution; preparing the bionic nanometer blocking agent. The bionic nanometer blocking agent for the drilling fluid, which is disclosed by the invention, solves the problems of shale hydration and extraneous water erosion in the existing drilling process; meanwhile, the bionic nanometer blocking agent has high biodegradability, so that pollution to a reservoir is effectively reduced.

Owner:石家庄华莱鼎盛科技有限公司

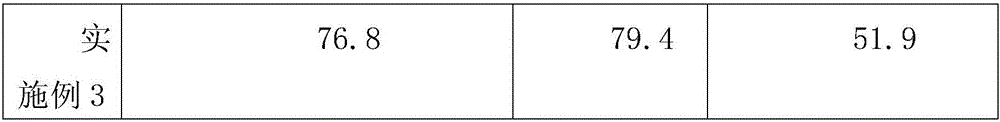

Anti-erosion system based on hydraulic jet fracturing anti-vortex erosion valve

InactiveCN102226391AMeet the requirements of settingWith pressureFluid removalWell/borehole valve arrangementsWear resistantEngineering

The invention relates to an oilfield device and in particular relates to an anti-erosion system based on a hydraulic jet fracturing anti-vortex erosion valve, and the system provided by the invention can be used for improving the seepage capability of a near-wellbore zone. The anti-erosion system comprises an oil pipe, wherein a hydraulic ejector, a packer and a check valve are sequentially arranged in the oil pipe, and the anti-erosion system is characterized in that the upper end of the hydraulic ejector is connected with a first anti-erosion pipe, the lower end of the hydraulic ejector is connected with a second anti-erosion pipe, the lower end of the second anti-erosion pipe is connected with the anti-vortex erosion valve, and the lower end of the anti-vortex erosion valve is sequentially connected with the packer and the check valve; a wear-resistant material is coated in the first anti-erosion pipe and the second anti-erosion pipe; the first anti-erosion pipe and the second anti-erosion pipe are oil pipe pup joints made of P110 steel; and the length of each of the first anti-erosion pipe and the second anti-erosion pipe is 1 to 2m. The invention provides the jet fracturing anti-vortex erosion valve and the anti-erosion system which are applicable to great flow rate of sand fluid, not affected by the direction of fluid flow, strong in anti-erosion capability and good in process property.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO +1

Method for promoting desulfuration of electron beam refined high-temperature alloy

The invention provides a method for promoting desulfuration of an electron beam refined high-temperature alloy. The method comprises the following steps: S1, pre-treatment of a high-temperature alloy raw material; and S2, electron beam refining and purification of the nickel-based high-temperature alloy to obtain a high purity FGH4096 high-temperature alloy cast ingot. The high-temperature alloy is desulfurated by means of electron beam refining, and a degassing reaction of S impurity element is intensified by means of characteristics of high electron beam refining vacuum degree and high temperature in a beam spot area. According to a characteristic that a water cooling copper crucible is free of pollution in the refining process, problems of erosion of a refractory matter of a conventional process crucible such as VIM and the like are solved. The problem of ultra-purification of a high-temperature alloy base metal is solved by means of density difference of occluded foreign substances and melt and a special inducible solidification mechanism of the electron beams in promoting migration and enrichment of the occluded foreign substances.

Owner:DALIAN UNIV OF TECH

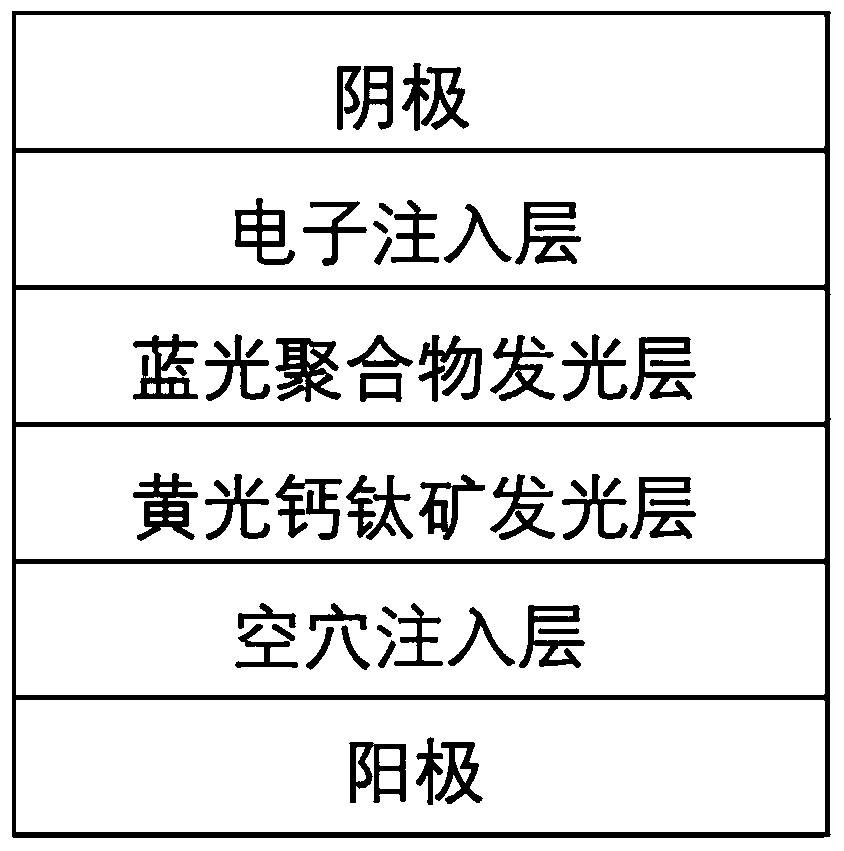

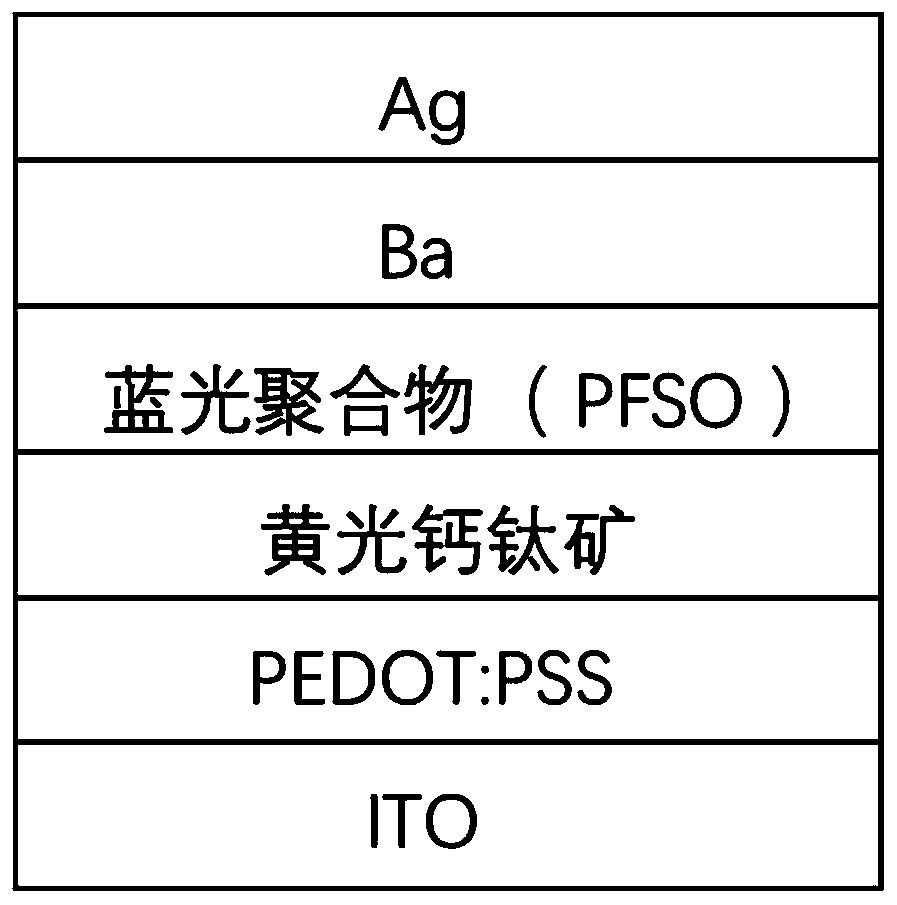

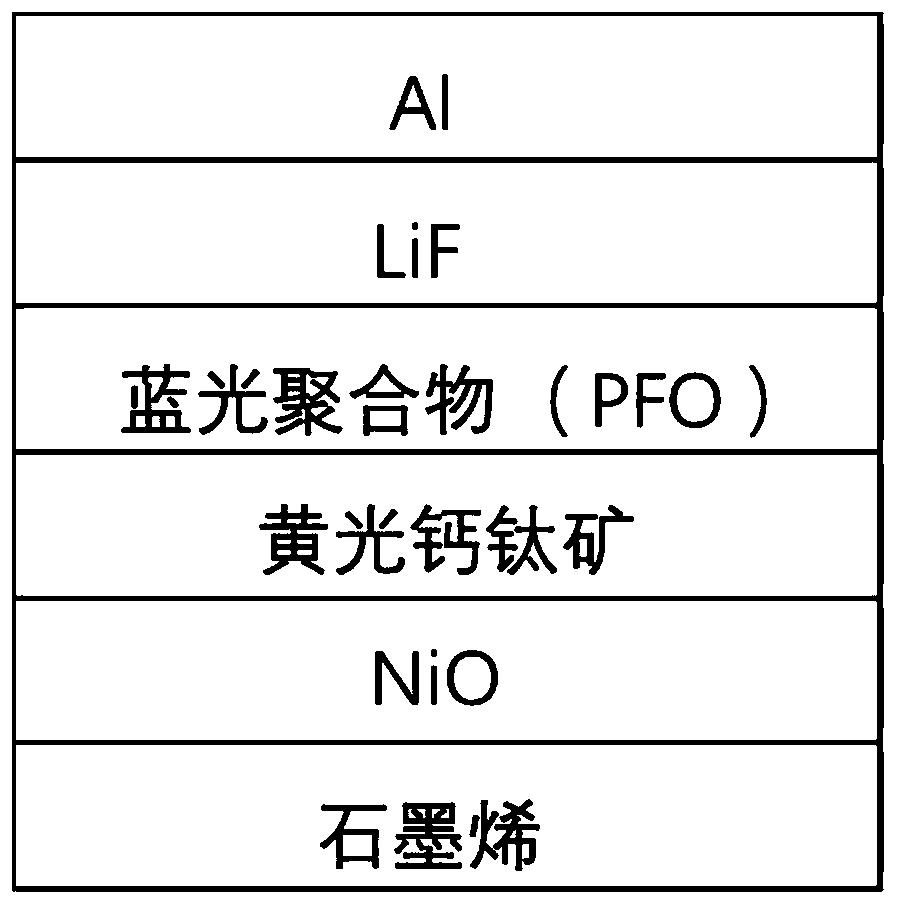

White-light LED based on perovskite electroluminescence and preparation method thereof

ActiveCN111048672ASimple structure and processSimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyGlass cover

The invention discloses a preparation method of a white-light LED based on perovskite electroluminescence. The method comprises the steps of (1) cleaning an anode, drying after the cleaning, and carrying out the pre-treatment on the dried anode; (2) depositing a hole injection layer by adopting a spin-coating process, and carrying out heat treatment; (3) preparing a yellow-light perovskite solution and a blue-light polymer solution, sequentially spin-coating a yellow-light perovskite layer and a blue-light polymer layer, and carrying out heat treatment after the spin coating of each layer, wherein the processed yellow-light perovskite layer and blue-light polymer layer form a light-emitting active layer; (4) transferring the device into a vacuum evaporation bin, and carrying out evaporation on an electron injection layer and a cathode; and (5) packaging the device with epoxy resin and a glass cover plate. The invention provides a new thought for realizing electroluminescent white light, that is, the white-light LED based on perovskite electroluminescence is prepared by adopting yellow light perovskite and a blue light polymer, and the electroluminescence spectrum of the white-lightLED can cover the whole visible light region.

Owner:SOUTH CHINA UNIV OF TECH

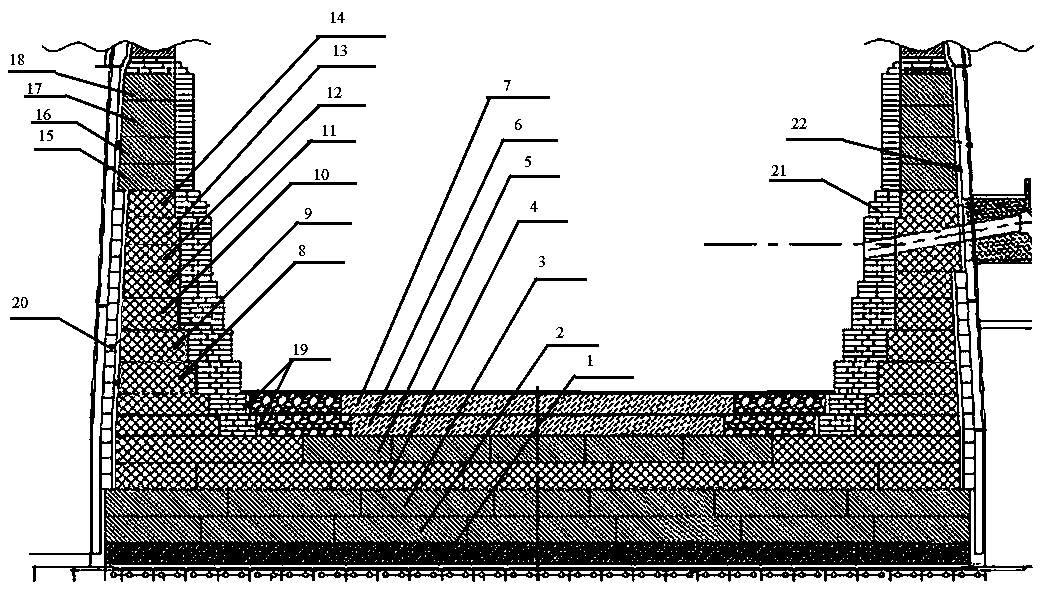

Method for differentially treating blast furnace hearth structure

InactiveCN111349732ASolve erosionExtend furnace service lifeBlast furnace componentsBlast furnace detailsHearthMullite

The invention discloses a method for differentially treating a blast furnace hearth structure. The method comprises the following steps of: arranging two differential treatment layers which are distributed up and down at the bottom of a blast furnace hearth contacted with molten iron in the early stage of furnace service in blast furnace production and smelting, wherein the upper differential treatment layer is close to the molten iron, and the other layer is the lower differential treatment layer; the upper differential treatment layer is provided with a first ultra-microporous carbon brick layer, a microporous corundum ceramic cup layer, a first corundum mullite ceramic cushion layer, and a second corundum mullite ceramic cushion layer in turn from outside to inside; and the lower differential treatment layer is provided with a second ultra-microporous carbon brick layer and a microporous carbon brick layer in turn from outside to inside. In the method, conventional 'elephant foot' erosion is changed into 'pan bottom' erosion in the erosion process of the bottom of the blast furnace hearth by mainly utilizing the difference between the physical and chemical properties of ultra-microporous carbon bricks, microporous carbon bricks and other materials, so that the problem of 'elephant foot' erosion occurring at an iron notch of the hearth and in the area around the iron notch during the conventional blast furnace production is solved, and the service life of the furnace is prolonged.

Owner:LIUZHOU IRON & STEEL CO LTD +1

Device and method for spraying carbon to deoxidize by using slag stopping system

ActiveCN112226576ASolve difficultySolve many restrictive linksManufacturing convertersProcess efficiency improvementSteelmakingAlloy

The invention discloses a device for spraying carbon to deoxidize by using a slag stopping system. The device comprises an injection tank, a specially-made slag stopping cone vehicle and a specially-made slag stopping cone, a fluidistor is installed on the lower portion of the injection tank, powder is driven by main blowing gas after being fluidized and passes through a pipeline in the middle ofa large arm of the slag stopping cone vehicle and a rotary joint at the tail end of the pipeline, finally, the powder enters molten steel through an injection pipeline in the center of the specially-made slag stopping cone, a powder conveying pipeline in the middle of a large arm of the slag stooping cone is in close fit with the injection pipe in the center of the slag stopping cone through the rotary joint, and positioning is carried out on a slag stopping cone vehicle clamping head by clamping an outer pipe of a slag stopping cone rod, so that positioning of the slag stopping cone in the injection process is guaranteed. According to the method, online powder spraying deoxidation in the steelmaking and tapping process is realized, the initial oxygen content of the molten steel before reaching a steel ladle is reduced, the usage amount of deoxidized alloy and the generation of deoxidized inclusions are reduced, the yield of high-value alloy is increased, and a good foundation is laidfor improving the product quality.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

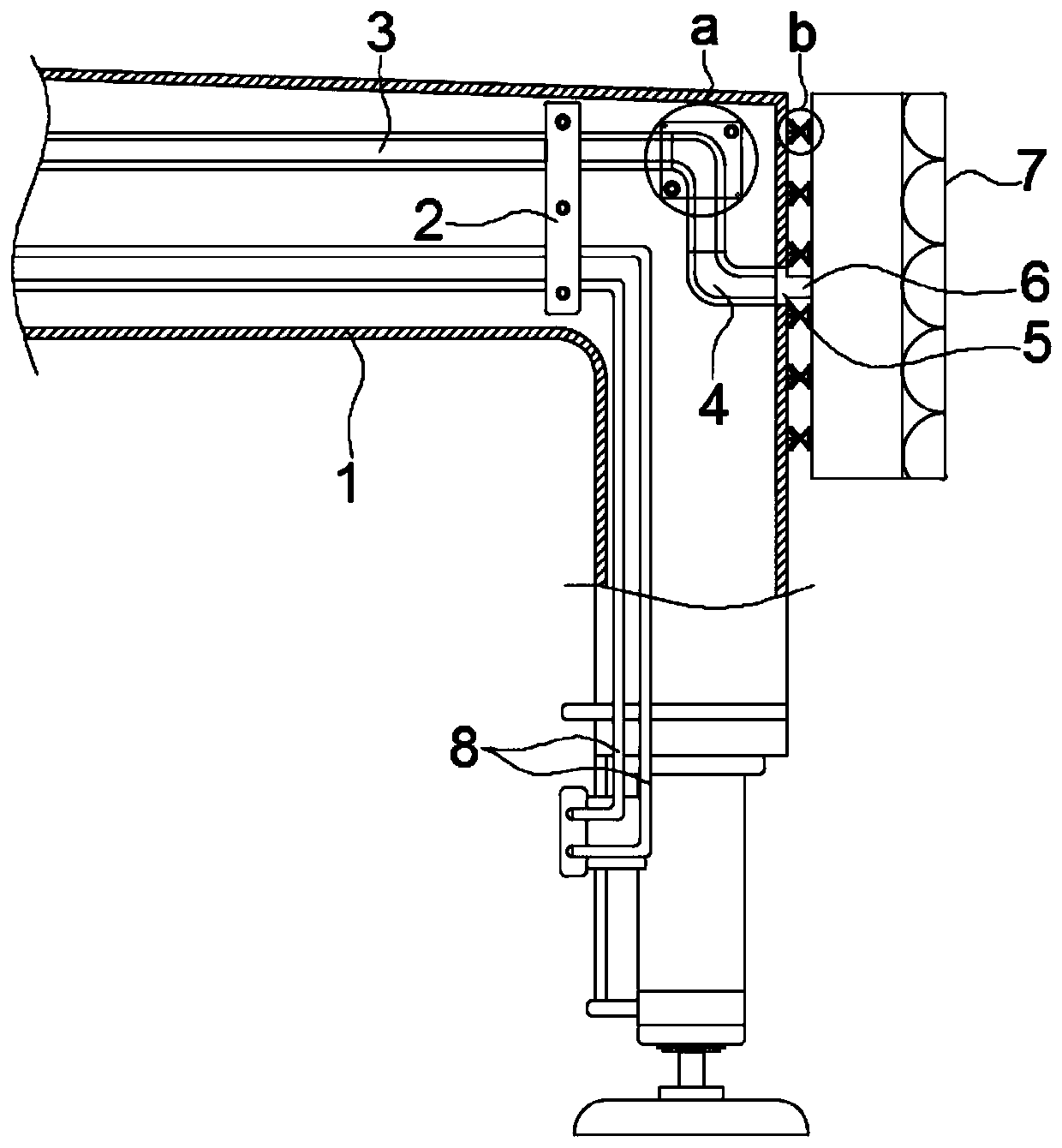

Glass continuous melting furnace and melting method

ActiveCN108529853ASolve erosionImprove yield ratePot furnacesCharging furnaceCrucibleRefractive index

The invention relates to a glass continuous melting furnace and a melting method. The invention belongs to the technical field of optical glass smelting production equipment. The method mainly solvesthe problems that the local refractive index difference exists in the fluorine-phosphorus glass continuous smelting furnace and the internal stripes of the product are thickened. The device is mainlycharacterized by comprising an oxidation crucible, a homogenizing crucible, a clarification tank, a cooling crucible and a working crucible which are made of a platinum material, a melting crucible ismade of a high-aluminum ceramic material; the oxidation crucible, the homogenizing crucible, the clarification tank and the cooling crucible are respectively provided with a first gas inlet pipe, a second gas inlet pipe, a third gas inlet pipe and a fourth gas inlet pipe, the opening of the first air inlet pipe is arranged below the liquid level of the glass, the openings of the second air inletpipe, the third gas inlet pipe and the fourth air inlet pipe are arranged above the liquid level of the glass; the method comprises the following steps: (1) enabling the melting crucible to be in buttjoint with the oxidation crucible; (2) opening a crucible cover for loading, introducing O2 into the first gas inlet pipe, the second gas inlet pipe, the third gas inlet pipe and the fourth gas inletpipe; (3) melting, homogenizing, clarifying, and then slowly cooling; and (4) performing leakage injection molding. The method is used for continuous smelting production of the fluorine-phosphorus glass, and the internal quality of the product is improved, the yield of the fluorine-phosphorus glass product is improved, and the cost is reduced.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

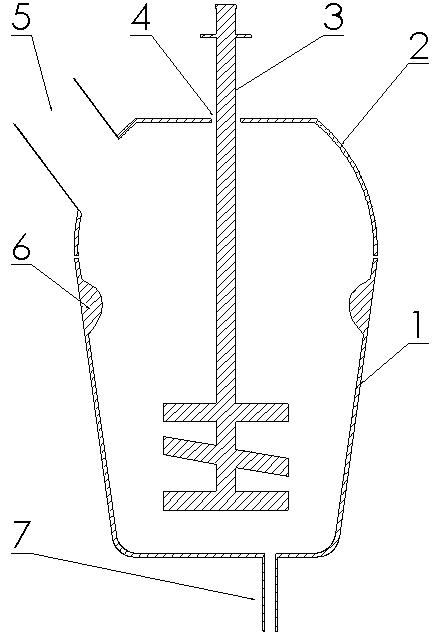

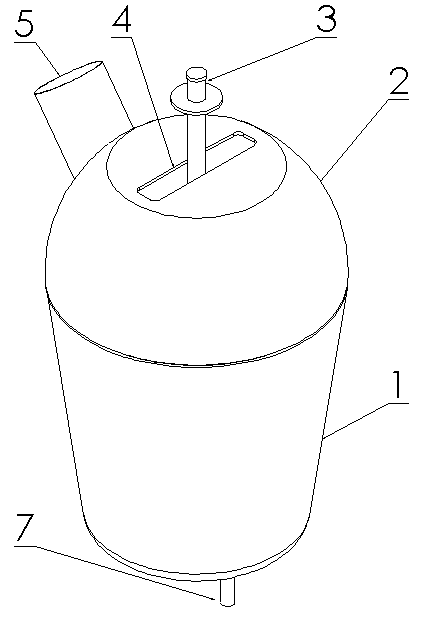

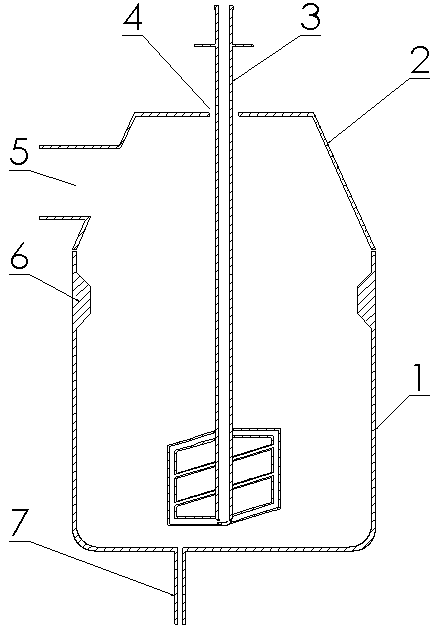

Glass material preparation crucible and preparation method

InactiveCN108395074AReduce erosionTo achieve the purpose of anti-glass liquid erosionPot furnacesGlass furnace apparatusLong axisWater cooling

The invention discloses a glass material preparation crucible and a preparation method, belonging to the technical field of optical glass smelting production equipment, and mainly used for solving theproblem of corrosion to a platinum crucible wall during fluorophosphate melting. The glass preparation crucible is mainly characterized by comprising a crucible body, a crucible cover and a stirrer;a charging opening and a stirring hole are formed in the crucible cover; the lower part of the crucible body is provided with a material leakage pipe; the charging opening is formed in a side face ofthe crucible cover in a horizontal or slantly upward direction; the stirring hole is shaped like an oval or rectangle, and a long axis direction thereof is used for the stirrer to enter and stir. Themethod comprises the following steps: (1) lifting the stirrer out of a crucible, and then charging from the charging opening; (2) enabling the stirrer to enter and stir, heating, and homogenizing; (3)when smelting is ended, after molten glass is leaked from a material pipe and discharged, directly leaking the molten glass onto a water cooling dry-type preparation platform and quenching to form glass splinter, thus achieving the preparation of a clinker. The glass material preparation crucible and the preparation method are used for fluorophosphate glass melting production by multi-crucible continuous preparation, solving the problem of powder corrosion to a platinum crucible wall during a fluorophosphate melting stage, and facilitating improving product interior quality, increasing yieldand lowering production cost.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

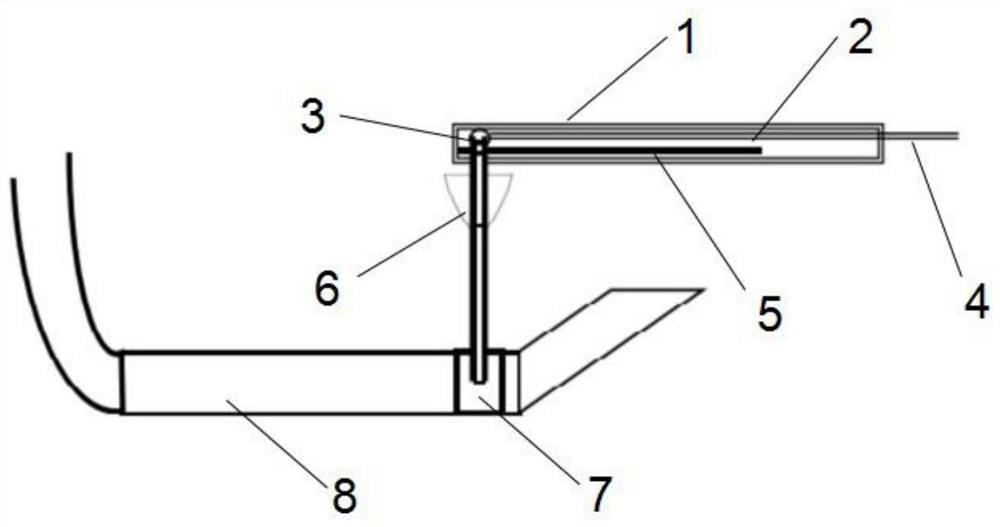

Cable protection device for taillight on rear leg of X-leg pump truck

The invention discloses a cable protection device for the taillight on the rear leg of an X-leg pump truck, comprising a pump leg which is internally provided with an oil pipe. The outer side of the pump leg is fixedly connected with a taillight through a shock absorber. A cable is connected with a run-through protection pipe. The run-through protection pipe is fixedly connected with the pump leg.The run-through protection pipe is fixedly connected with a bent protection pipe. The bent protection pipe is fixedly connected with a linear protection pipe. The linear protection pipe and the oil pipe are fixedly connected with a clamping plate part. The clamping plate part is fixedly connected with the pump leg. The linear protection pipe and the bent protection pipe are arranged inside the pump leg to prevent the erosion of the cable by various substances inside the pump leg. The run-through protection pipe composed of a connecting pipe, a second spring, an outer cylinder, an inner cylinder, a steel ball and a hose is arranged at the place where the cable runs through the pump leg. The shock of the cable is absorbed by the cable. The rolling of the steel ball, the outer cylinder and the inner cylinder increases the rotation effect of the cable in the protection pipe and reduces the cable damage caused by rotation wear.

Owner:QINGDAO CO NELE GRP CO CO LTD

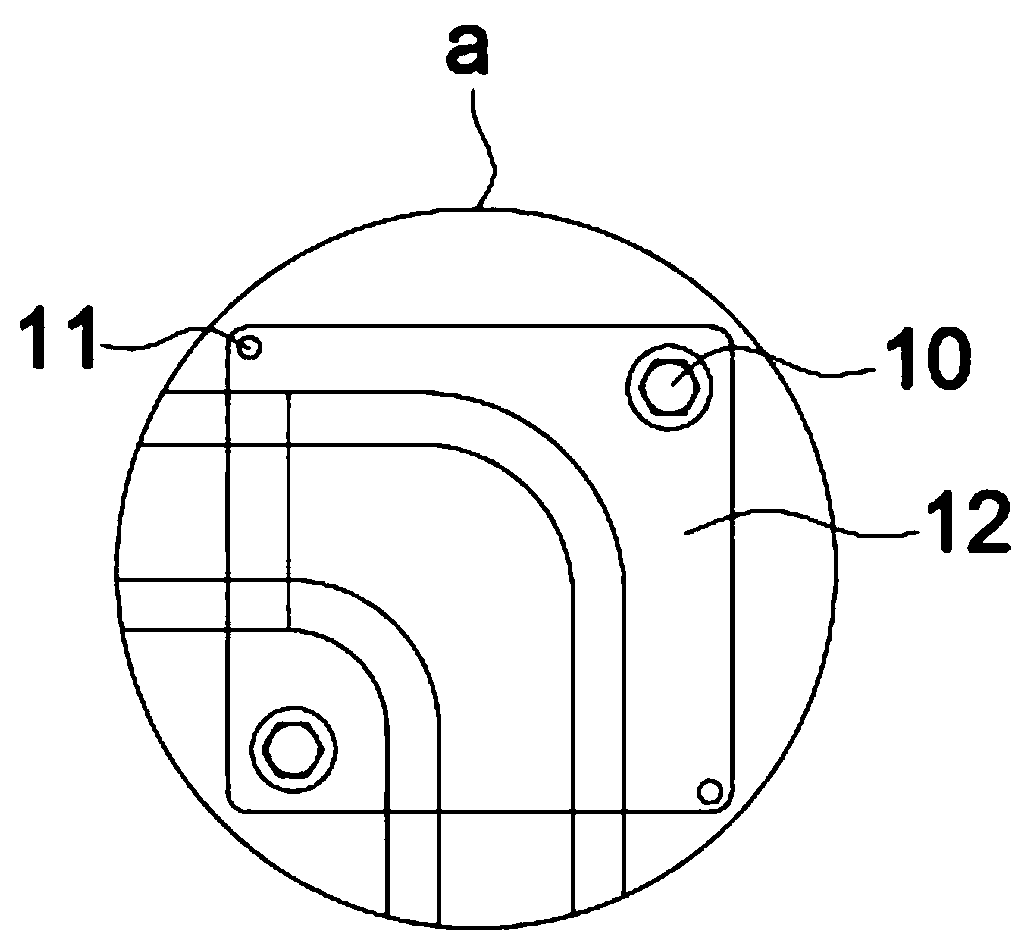

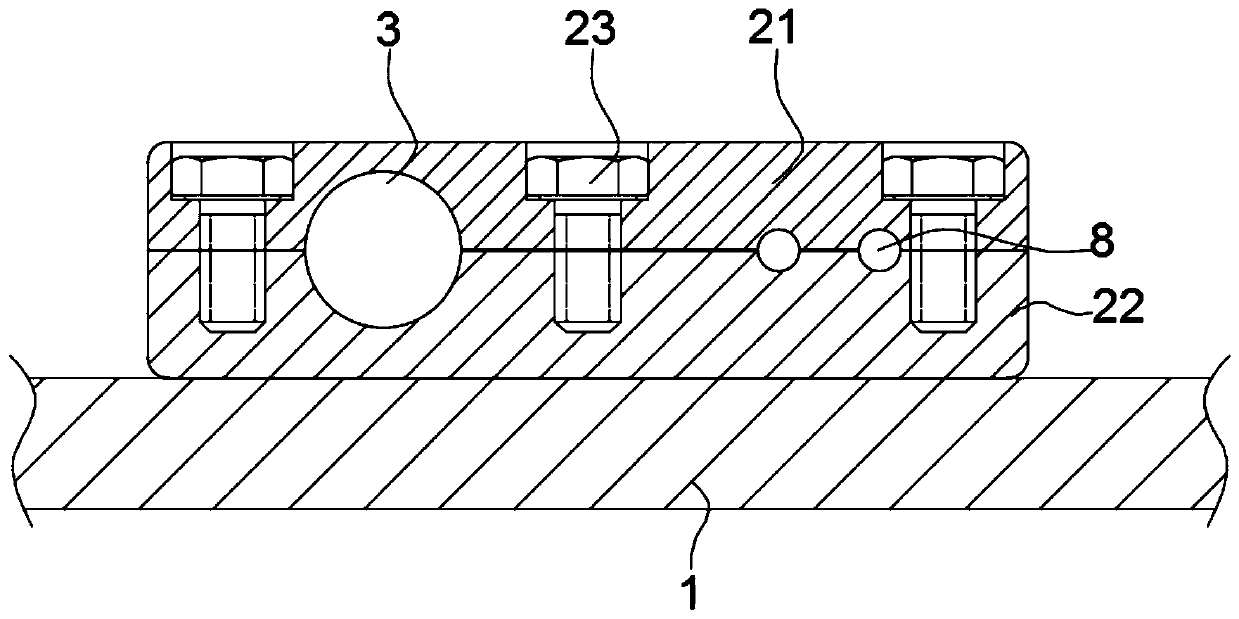

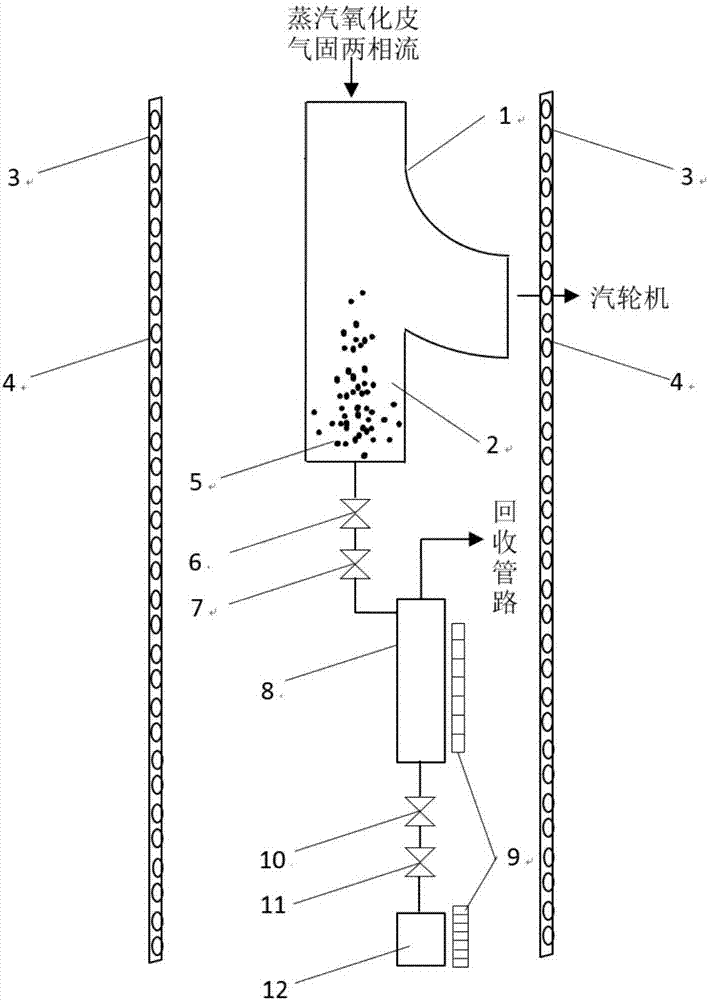

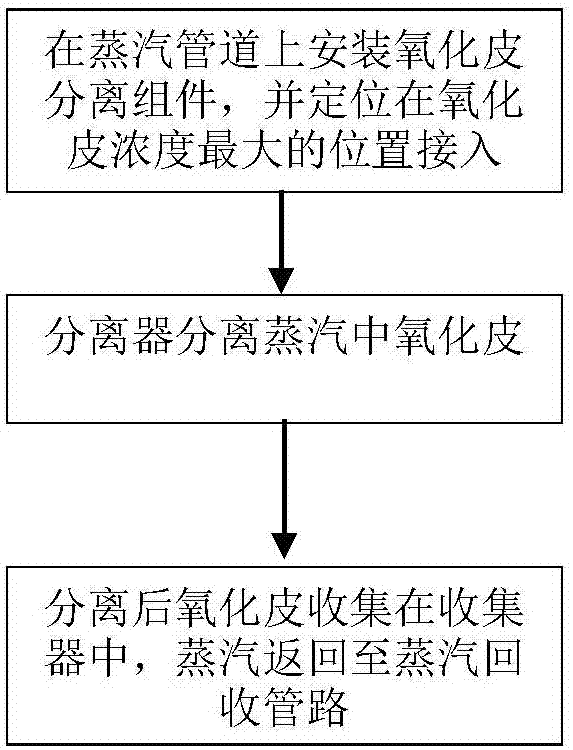

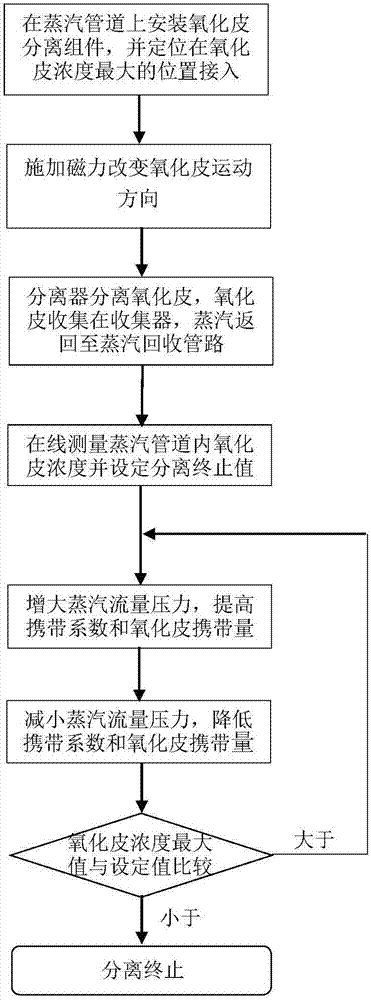

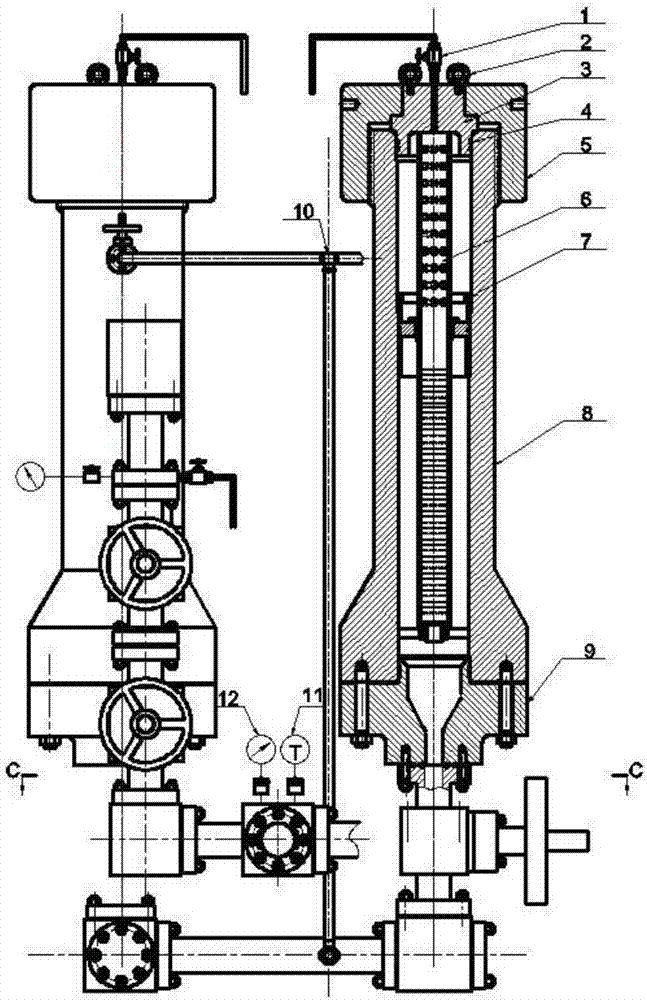

Oxide skin separation assembly and method

PendingCN107262277ASolving Solid Particle Erosion ProblemsIncrease collection rateMagnetic separationCorrosionEngineering

The invention relates to an oxide skin separation assembly and an oxide skin separation method, which can efficiently remove oxide skin and eliminate corrosion of oxide skin particles to solid particles of a steam turbine. The separation assembly comprises a separation device, wherein the separation device is used for separating and collecting oxide skin in steam in a steam pipeline; the separation device comprises a sampling pipe, a separator and a collector which are connected in sequence; and the sampling pipe is connected to the steam pipeline, the separator is used for separating gas and solid of the oxide skin in the steam, the oxide skin outlet end of the separator is connected with the collector, and the steam outlet end of the separator is connected to a steam recycling pipeline. The separation method comprises the following steps of positioning and installing the separation device in the oxide skin separation assembly on the steam pipeline, and correspondingly arranging the separation device in a position with the maximum oxide skin concentration in the steam pipeline under the action of gravity and centrifugal force; accessing by virtue of the sampling pipe, separating the oxide skin in the steam by the separator, collecting the obtained oxide skin in the collector, and returning the steam of which the oxide skin is separated to the steam recycling pipeline.

Owner:XIAN THERMAL POWER RES INST CO LTD

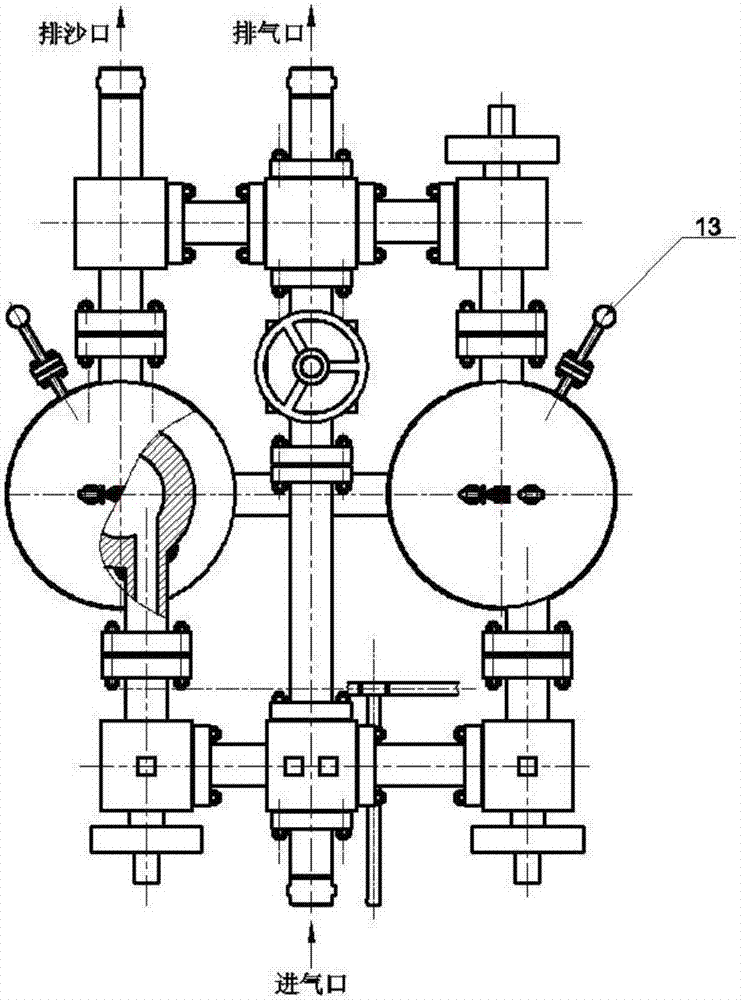

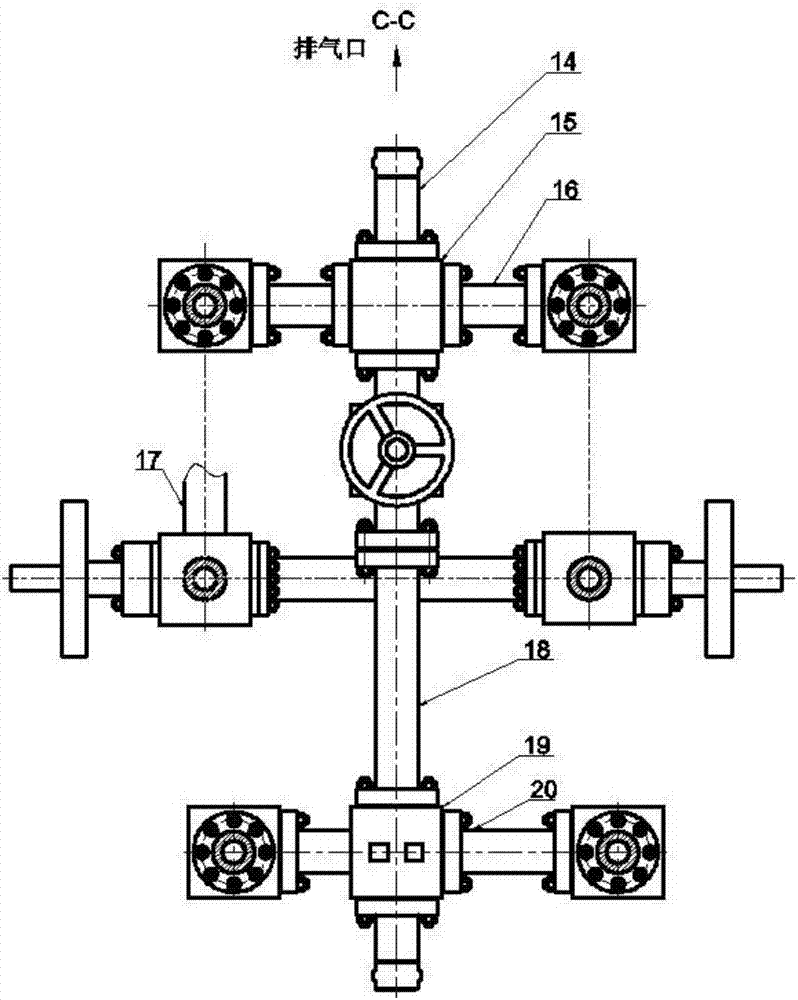

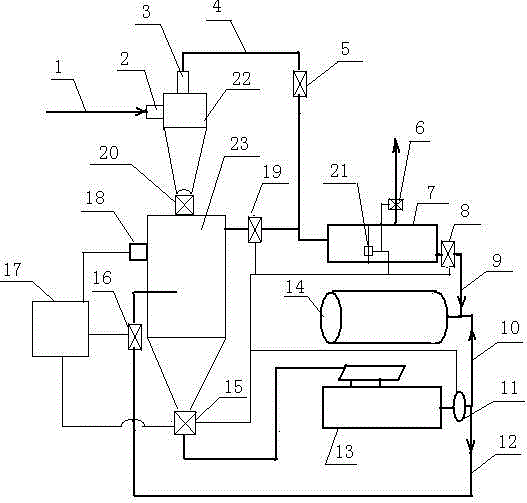

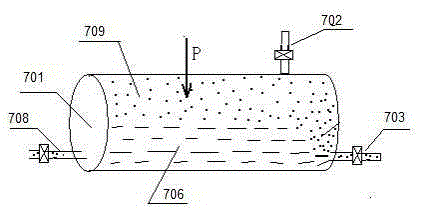

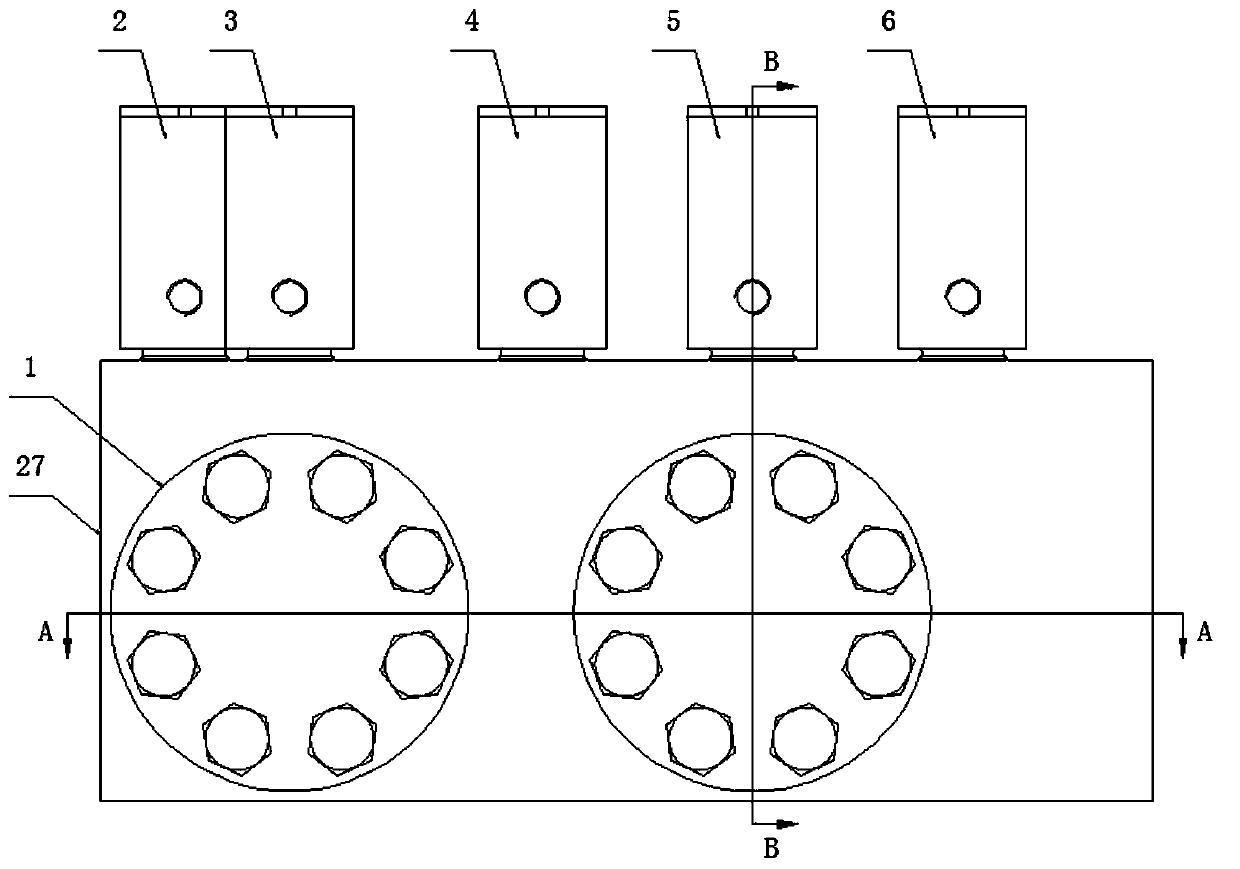

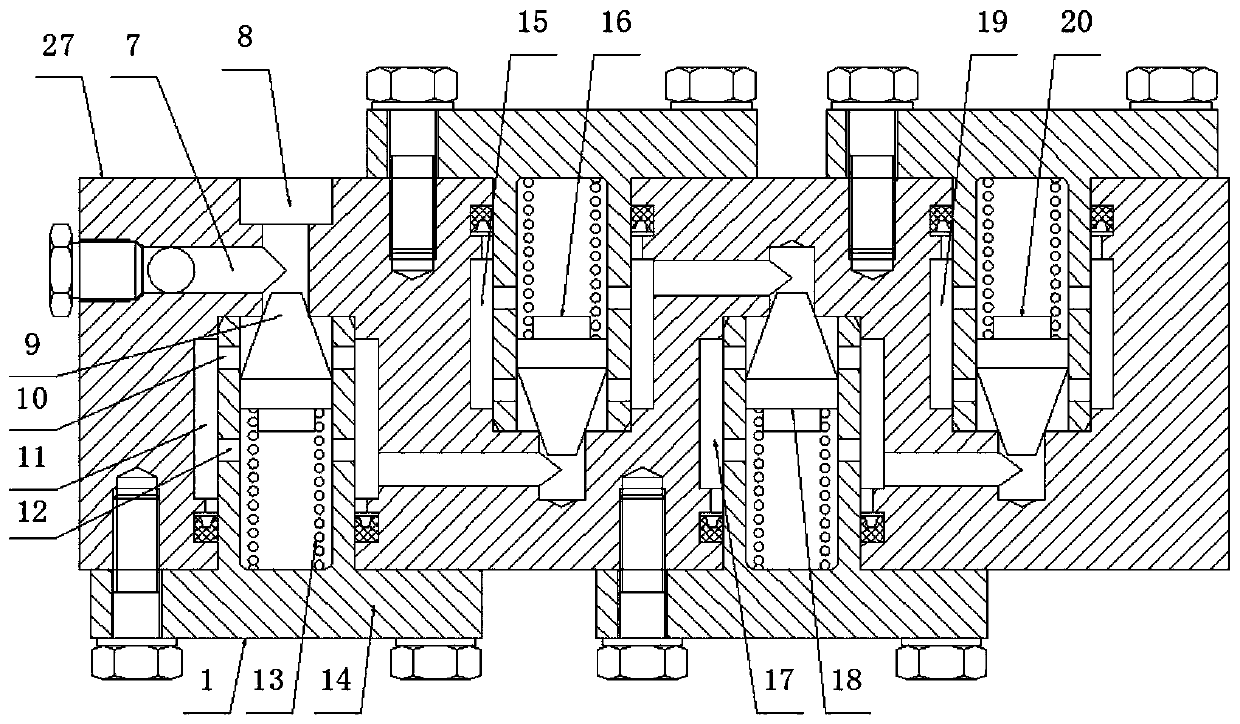

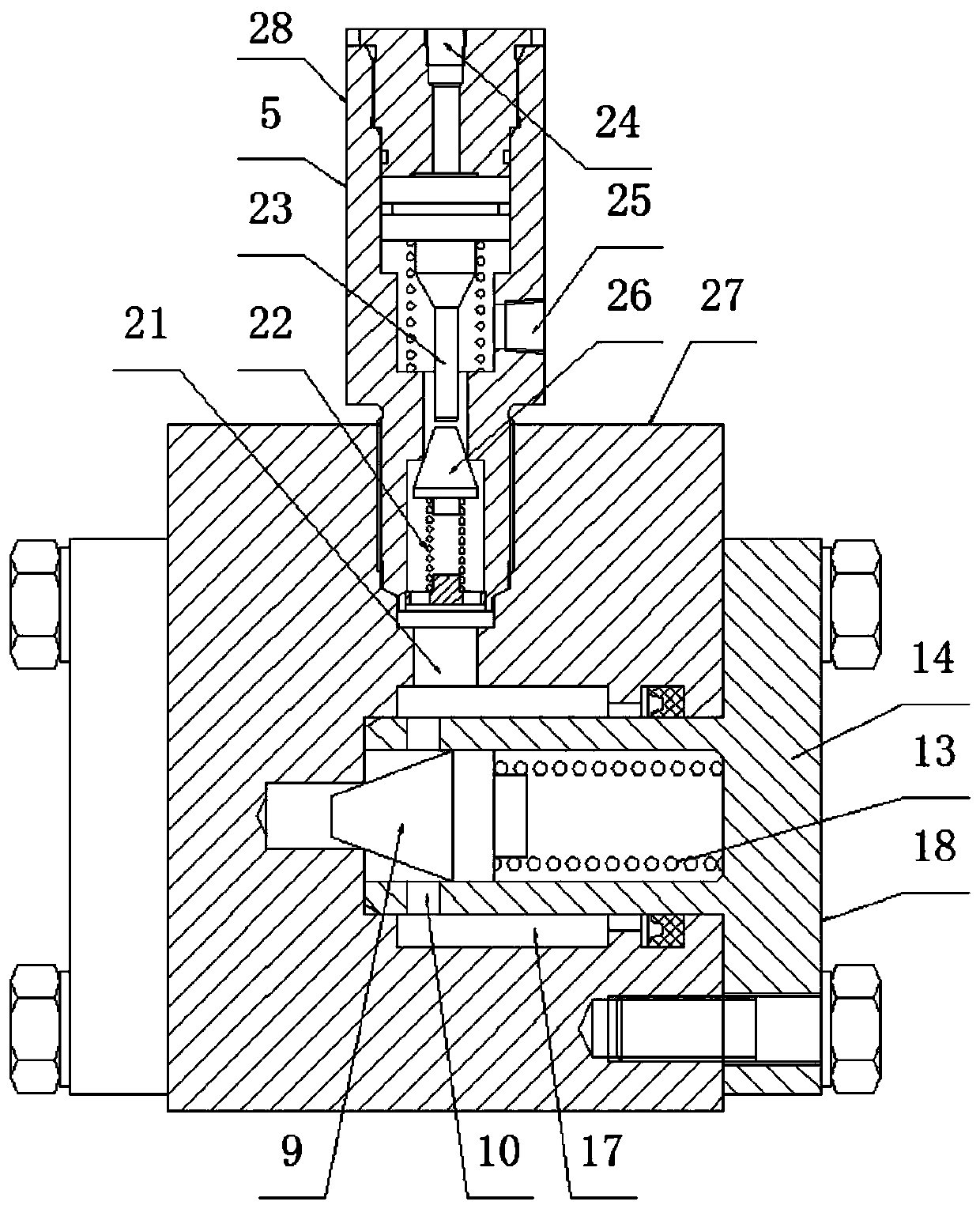

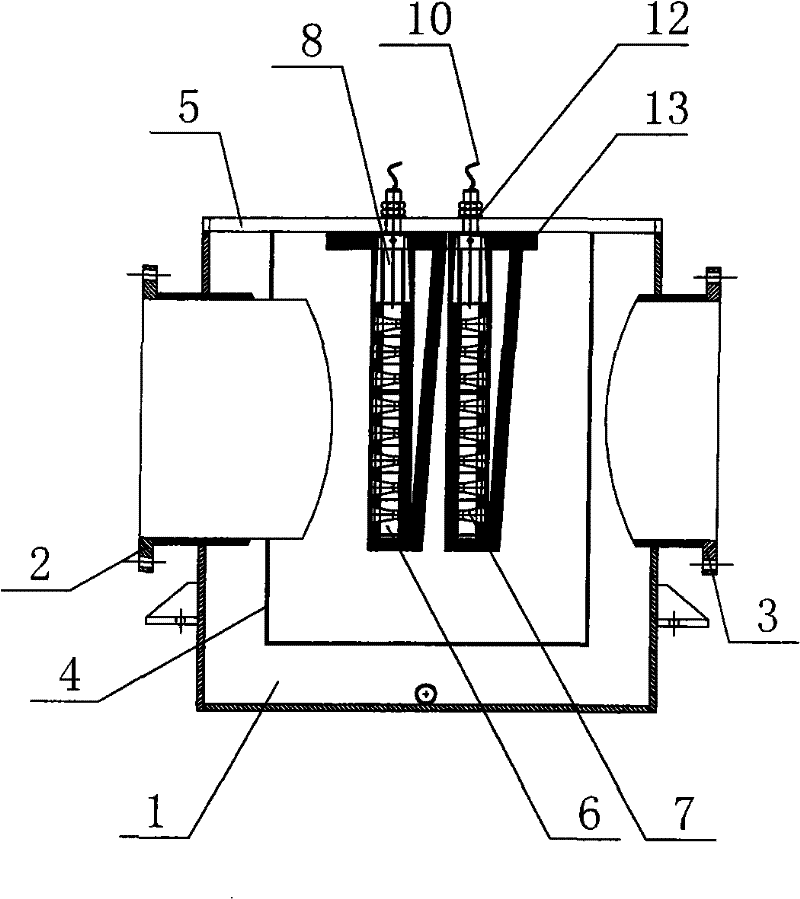

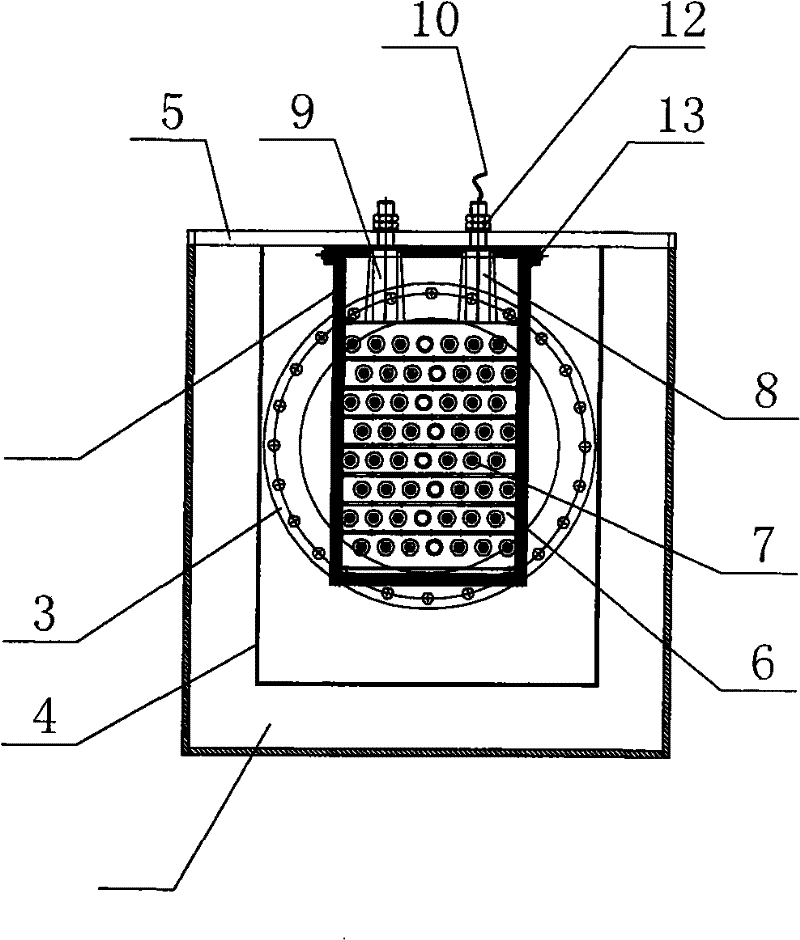

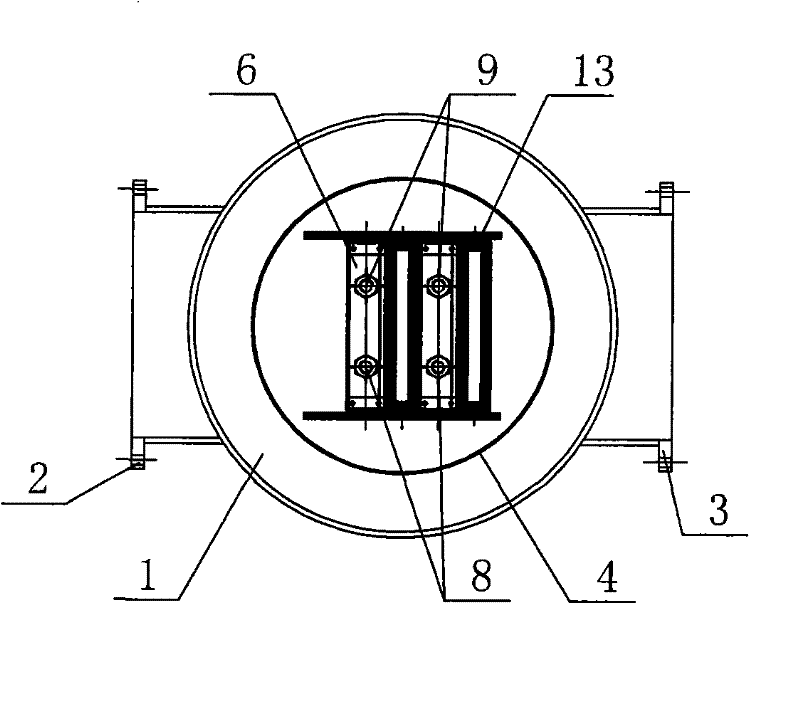

High-pressure flow rotating and filtering type natural gas sand remover

The invention belongs to natural gas discharge and exploiting equipment and particularly relates to a high-pressure flow rotating and filtering type natural gas sand remover used for solving the problem that natural gas exploited in a gas field fractured well or a stratum sand outlet well contains a large number of sand particles. The device comprises six parts of a sand removing device, a pipeline system, a mounting frame, a worm wheel and worm lifting device, a back flushing device and a high-pressure liquid volume measurement device and is composed of a pressure releasing valve, a filtering cylinder, an abrasion preventing sleeve, cylinder bodies, slab gate valves, the back flushing device, the worm wheel and worm lifting device and the like; the sand removing device is connected with a gas inlet pipeline, a gas outlet pipeline, a sand discharging pipeline and the back flushing device, wherein the gas inlet pipeline, the gas outlet pipeline and the sand discharging pipeline are located in the pipeline system; and gas enters the sand removing device, is subjected to flow rotating and filtering and then is output from the gas outlet pipeline, and the sand particles are discharged from the sand discharging pipeline at the bottom. According to the high-pressure flow rotating and filtering type natural gas sand remover, ground procedure equipment can be effectively protected from being flushed by a high-speed sand-containing scrap-containing fluid, damage to the downstream ground equipment is effectively reduced, stratum outlet sand is prevented from blocking the pipeline or the equipment, and considerable economic benefits can be created.

Owner:胜利油田瑞特石油机械制造有限责任公司 +1

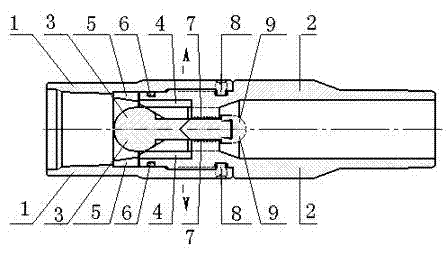

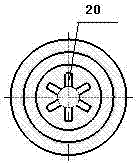

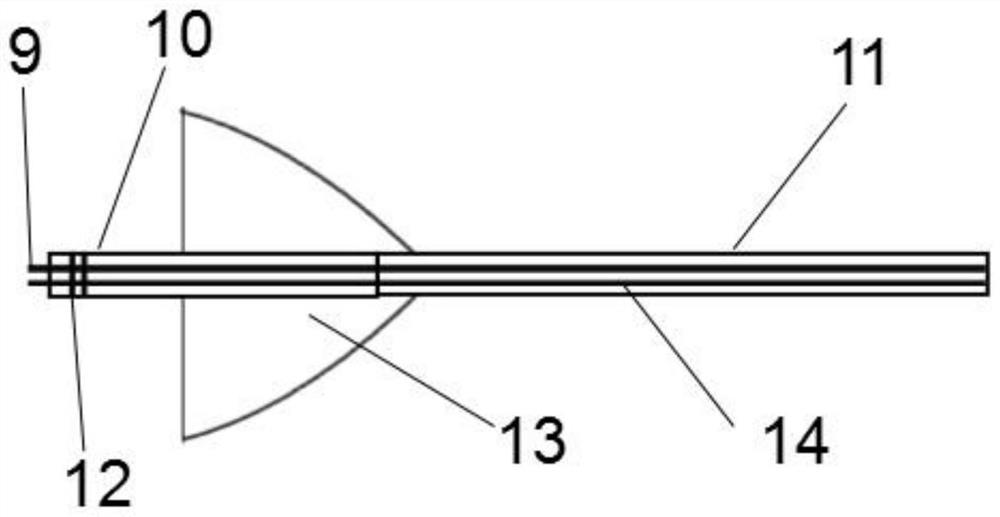

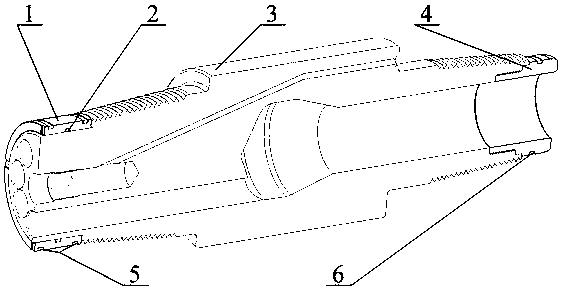

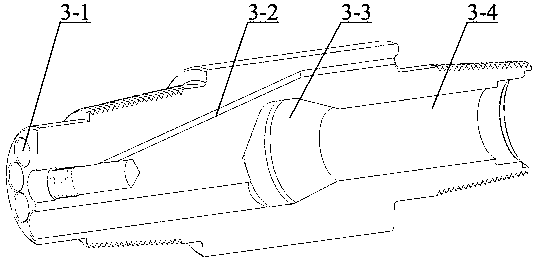

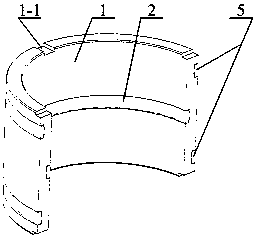

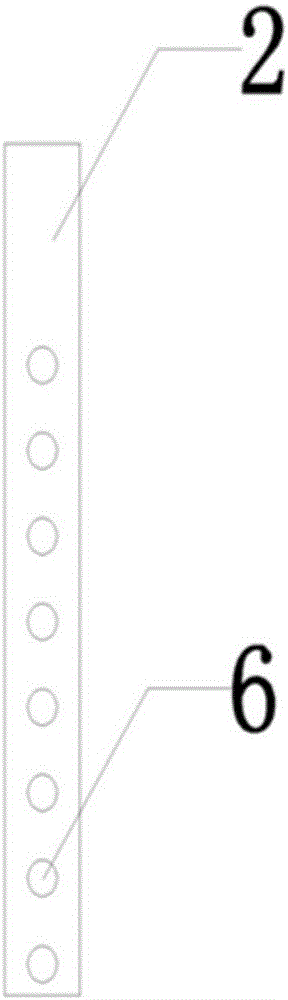

Connecting nipple of logging-while-drilling instrument

ActiveCN109882087AExtended service lifeReduced eddy current effectSurveyDrilling rodsWell drillingEddy current effect

The invention relates to the technical field of measurement-while-drilling instruments for petroleum drilling, in particular to a connecting nipple of a logging-while-drilling instrument. The connecting nipple is mainly composed of a copper ring, an inner sealing ring of the copper ring, a connecting nipple body, a sealing joint, an outer sealing ring of the copper ring and a sealing joint sealingring, wherein the copper ring and the sealing joint are arranged at the two ends of the connecting nipple body correspondingly, and corresponding center adapting joints and side wall single-core pinsare installed on the two sides of the connecting nipple correspondingly. The side, where the center adapting joints are installed, of the connecting nipple body adopts a circumferential hole distribution design, seven small flow-through holes are symmetrically formed, the size of the small flow-through holes is consistent with the size of large flow-through holes in the side where the side wall single-core pins are installed, and transition holes with a larger flow-through area are formed between the large flow-through holes and the small flow-through holes. According to the connecting nipple, the matching use of logging-while-drilling instruments with different structures is realized, flow-through hole passages are optimized, the eddy current effect of flow-through slurry caused by the change of the flow-through area is effectively reduced, and the underground service life of the connecting nipple and the matching connected logging-while-drilling instrument can be effectively prolonged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

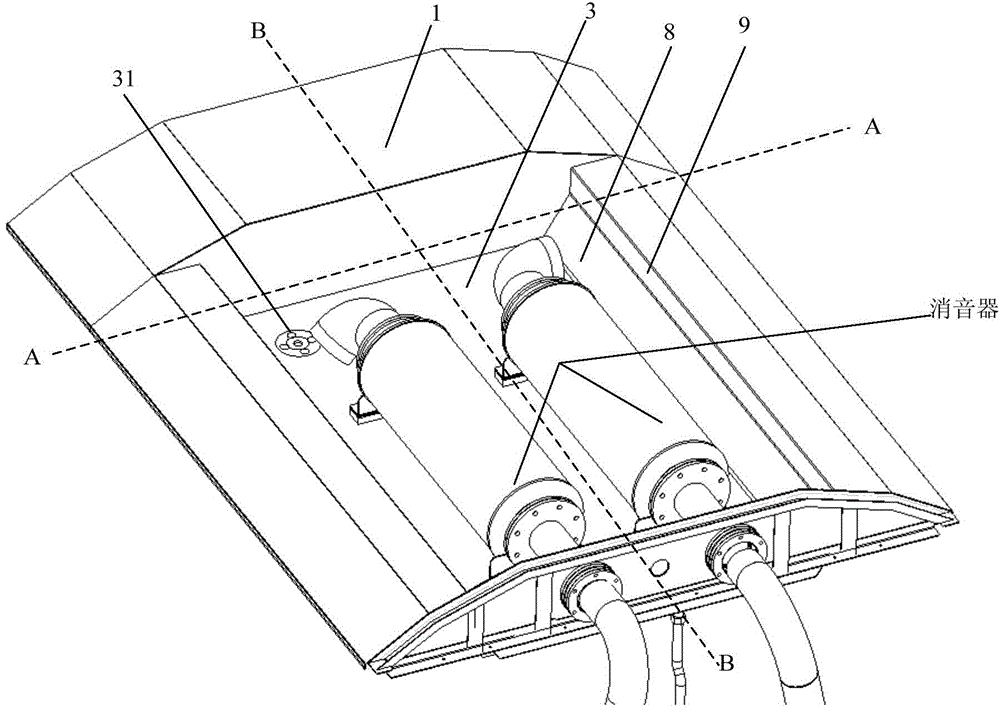

Top cover device and silencer overhead system

InactiveCN104527681AOptimize layoutImprove cooling effectRailway roofsExhaust apparatusEngineeringSewage

The invention provides a top cover device and a silencer overhead system. The top cover device comprises a concave top cover and a sewage draining pipeline system. A downwards-concave installation groove is formed in the concave top cover, at least one funnel communicated with the installation groove is formed below the bottom face of the installation groove, and the funnel is connected with the sewage draining pipeline system. The silencer overhead system comprises a silencer and the top cover device. The silencer is arranged in the installation groove in the concave top cover in the top cover device. The silencer is arranged on the top cover of a locomotive, the problem that the installation space below the locomotive is compact is solved, the heat dissipating problem of the silencer is solved, and the arrangement difficulty of a silencer pipeline is lowered. Meanwhile, the top cover device is arranged for the silencer in a targeted mode and used for fixation and sewage drainage, the problem that the overhead silencer is more likely to be corroded by dirt such as rain and snow is solved, and the service life of the silencer is prolonged.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

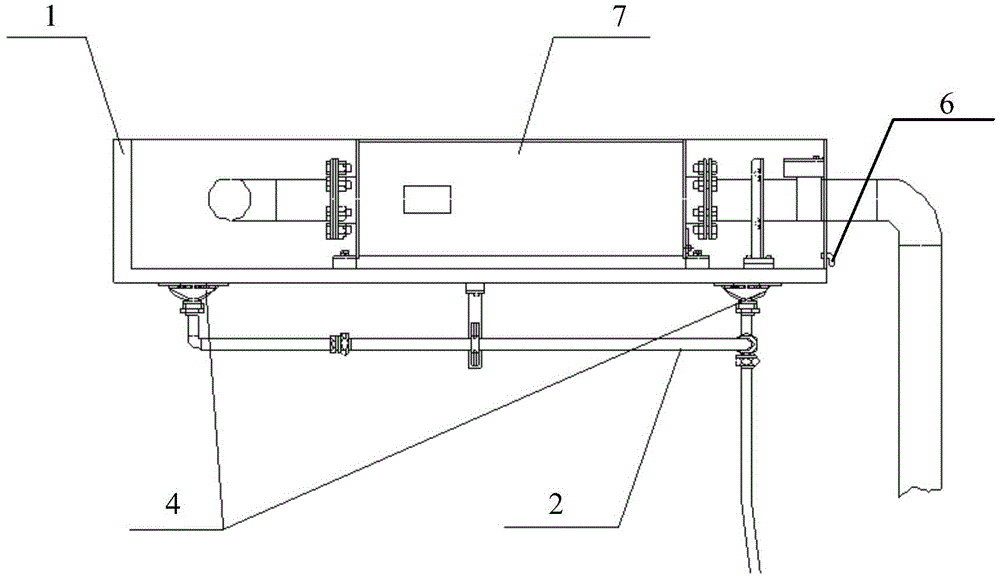

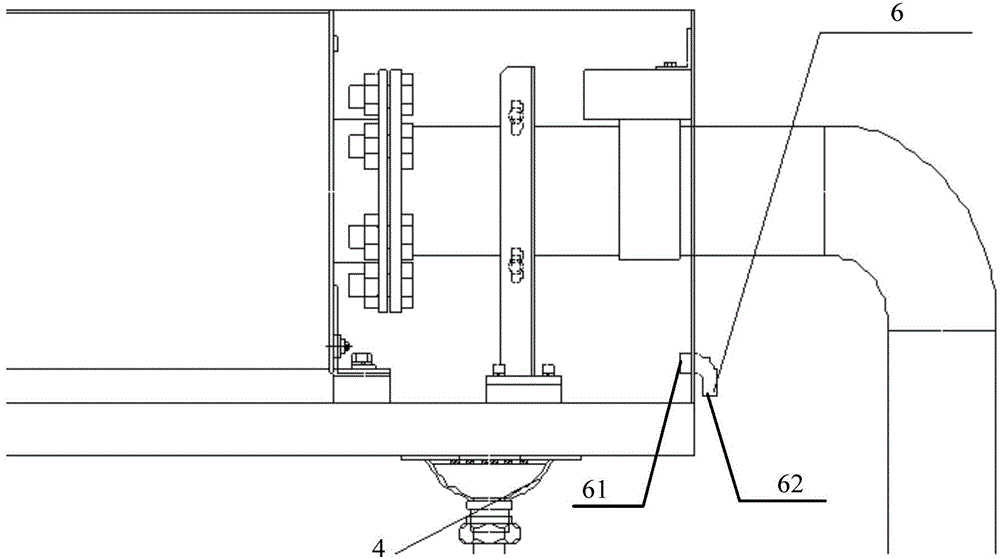

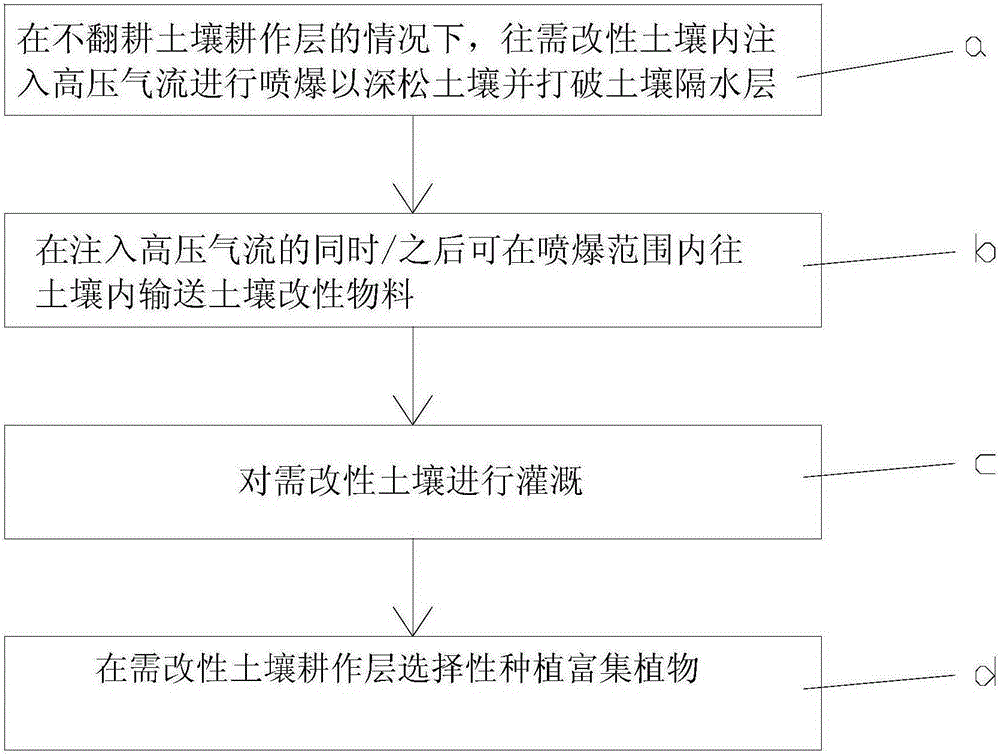

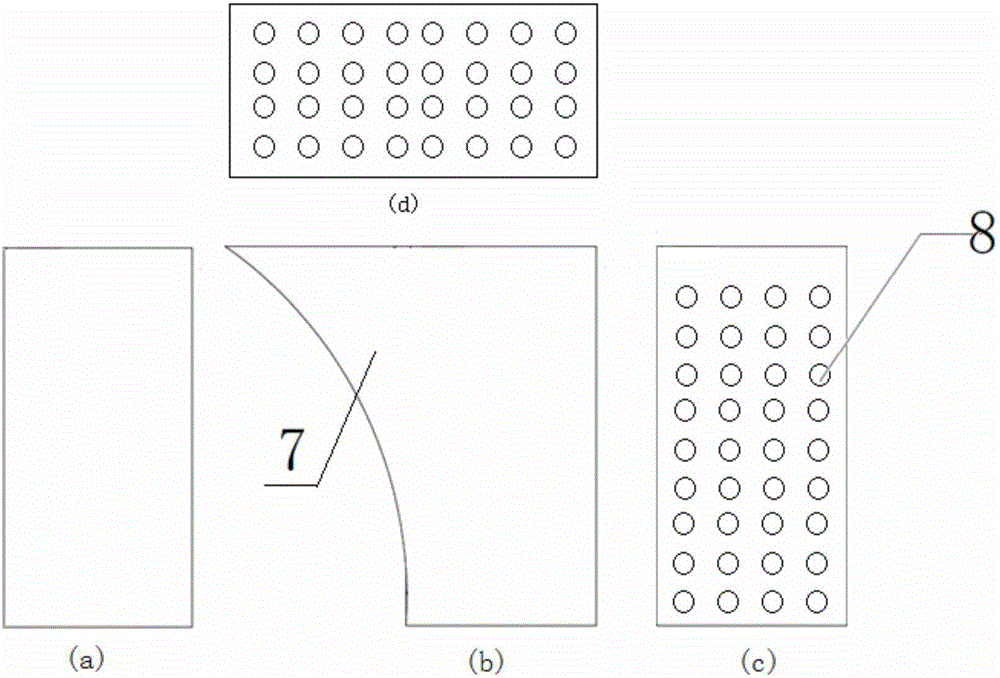

Soil improvement method for tillage-free three-dimensional material embedding

InactiveCN105210495ASolve erosionSolve desertificationClimate change adaptationAgriculture gas emission reductionSoil porosityHigh pressure

The invention discloses a soil improvement method for tillage-free three-dimensional material embedding. The method includes the following steps that under the condition that a soil tillage layer is not turned over, high-pressure airflow is injected to soil needing to be modified to perform spray explosion so that the soil can be deep loosened and a soil water partition layer can be broken; while the high-pressure airflow is injected, soil modifying materials can be conveyed into the soil within the spray explosion range; while the degraded soil problems about soil erosion, desertification, gleying and like are solved, deep placement is performed on the soil by injecting the high-pressure airflow for jetting and spray explosion under the condition the soil is not turned over, soil porosity is increased, the air injection amount is increased, the volume weight of degraded soil is lowered, the soil can be loose and breathable, rainwater penetration speed and rainwater penetration amount are enhanced, the water-holding capacity of the soil is improved, soil moisture preservation is facilitated, erosion is reduced, more rainwater can be absorbed, generation of a runoff can be delayed, the strength of the runoff is weakened, scouring of the surface runoff on the soil is relieved, and water and soil loss is reduced.

Owner:SICHUAN TOBEST BIO TECH CO LTD

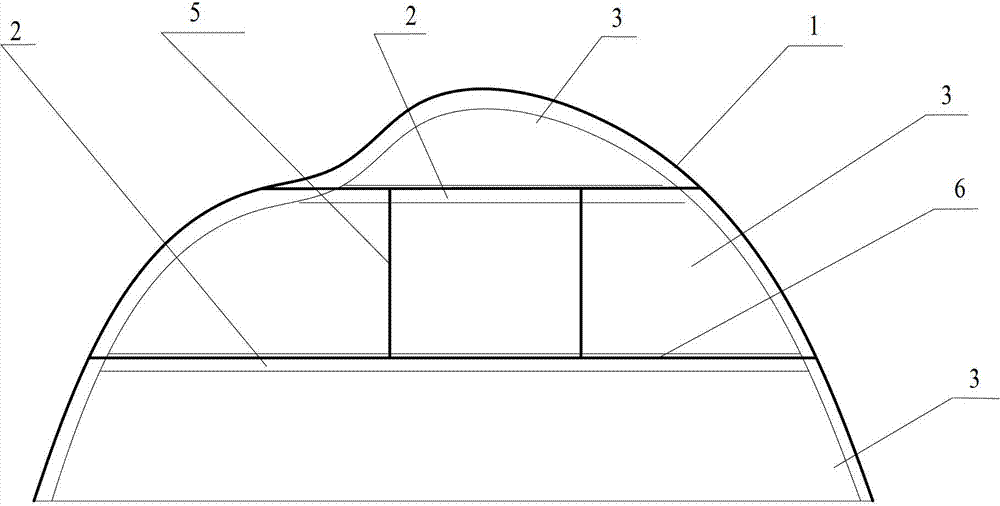

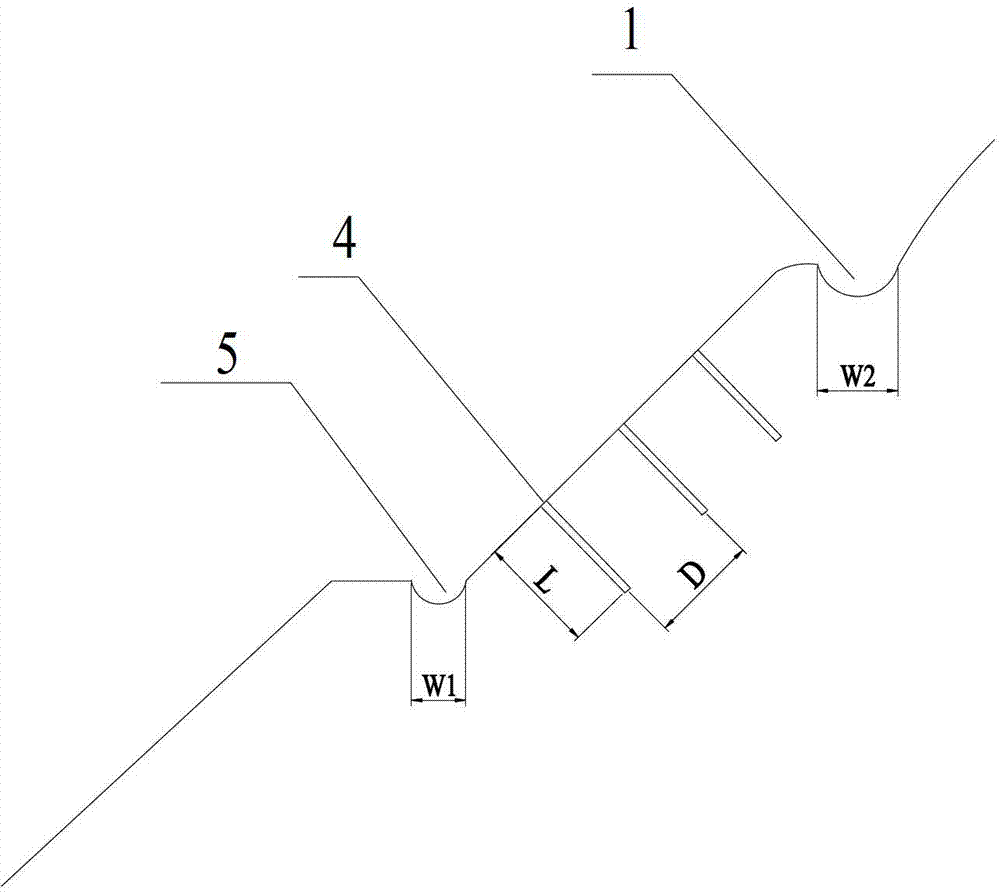

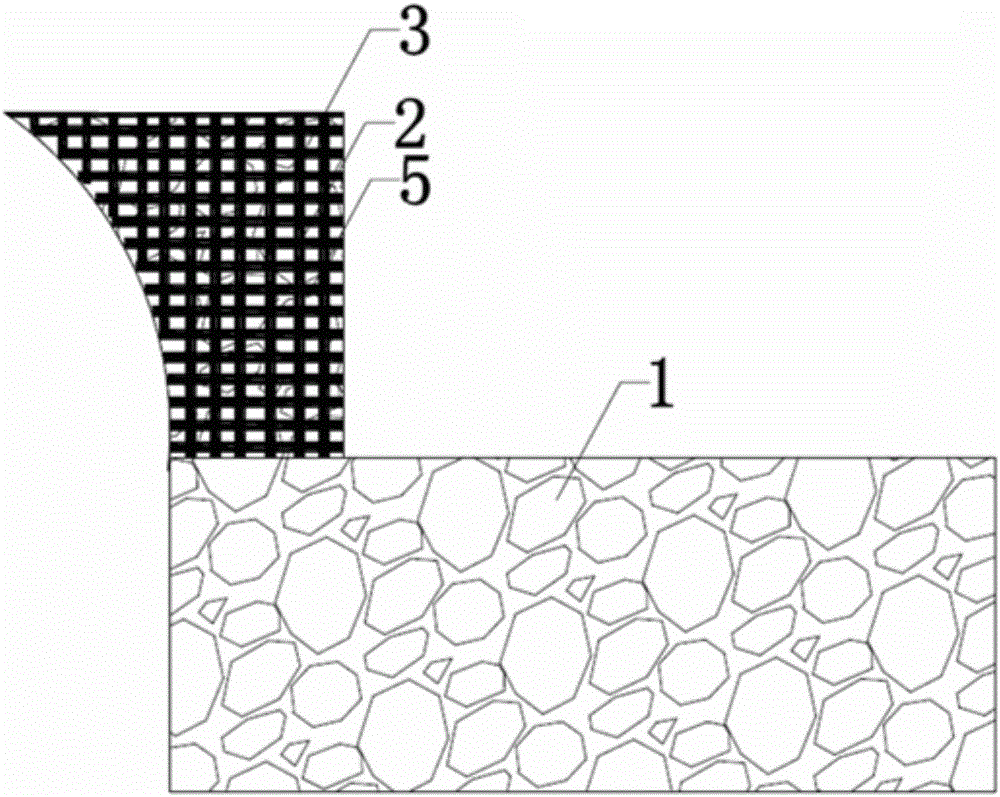

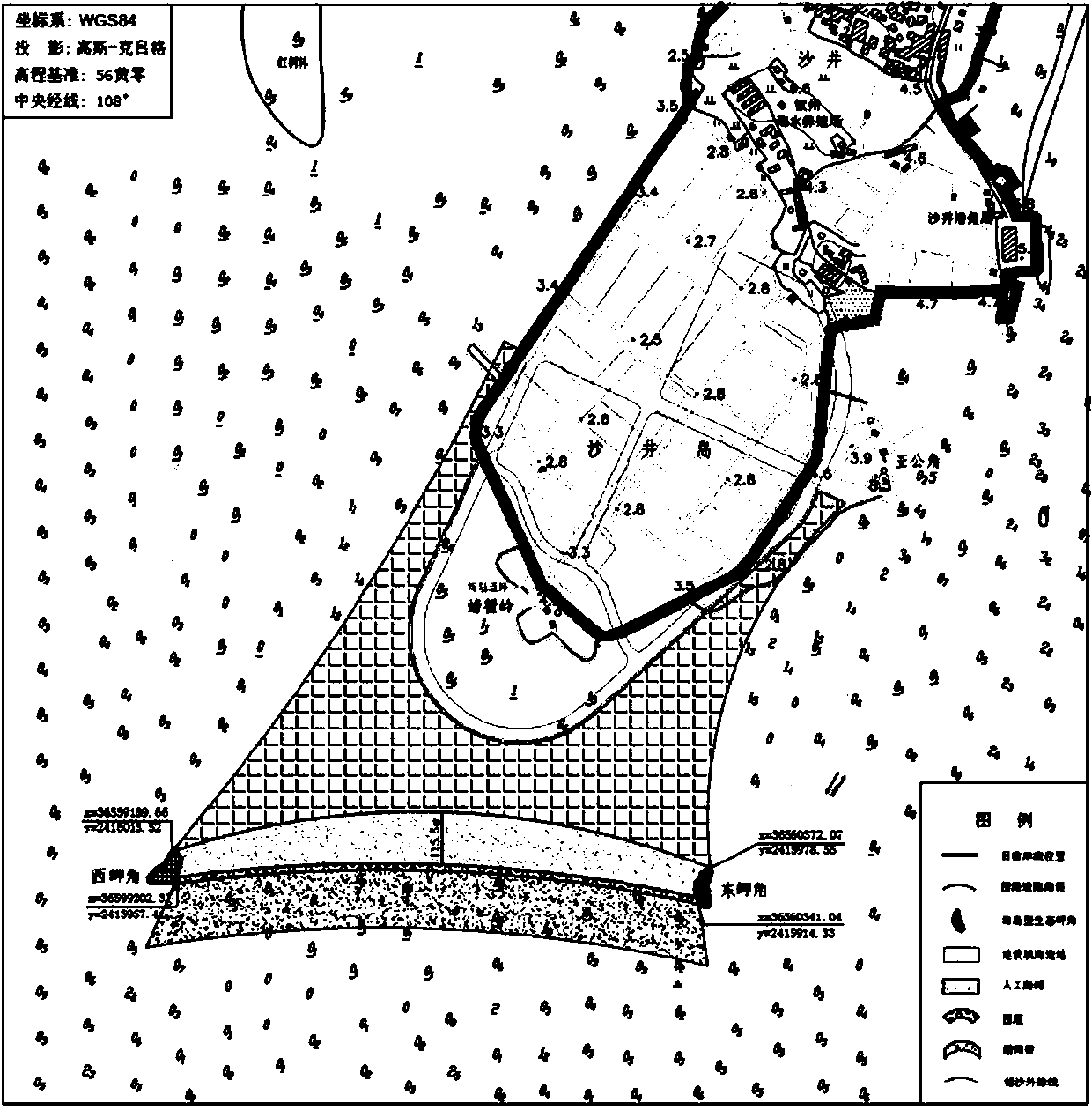

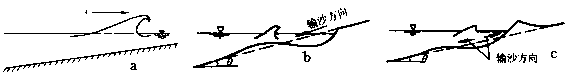

Strengthening method of high polymer grouting and flexible revetment of coral reef island airport revetment

ActiveCN106544986AGood anti-wave energy dissipationDamage reductionCoastlines protectionSeawaterCoral reef

The invention discloses a strengthening method of a high polymer grouting and flexible revetment of a coral reef island airport revetment. High polymer is injected into materials such as coral sand or coral stone, a three-dimensional latticed structure is formed by a high polymer material, and the coral sand or coral stone is wrapped to form a flexible strengthening body. The shape of the side, close to the sea, of the strengthening body is arranged to be arc, and the side, close to islands, of the strengthening body is arranged to be in erect type. After formed, the strengthening body has elasticity and belongs to the flexible revetment. After waves effect on the revetment, seawater flows along the arc side and returns to the sea after self energy dissipation. The invention further discloses a construction method of the revetment. By means of the strengthening method, the defect of traditional cement slip casting can be overcome; and the flexible revetment manner is adopted, so that the problems of wave prevention and leakage prevention are solved, the structure is simple, the construction is convenient, and the wide application scope is achieved.

Owner:CHONGQING UNIV

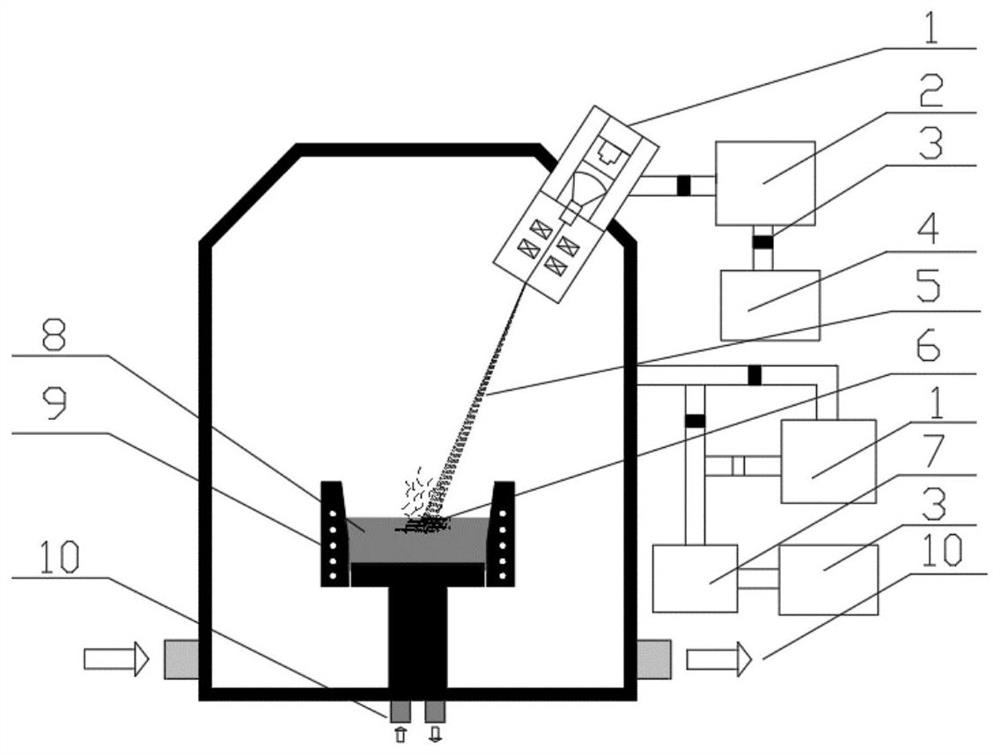

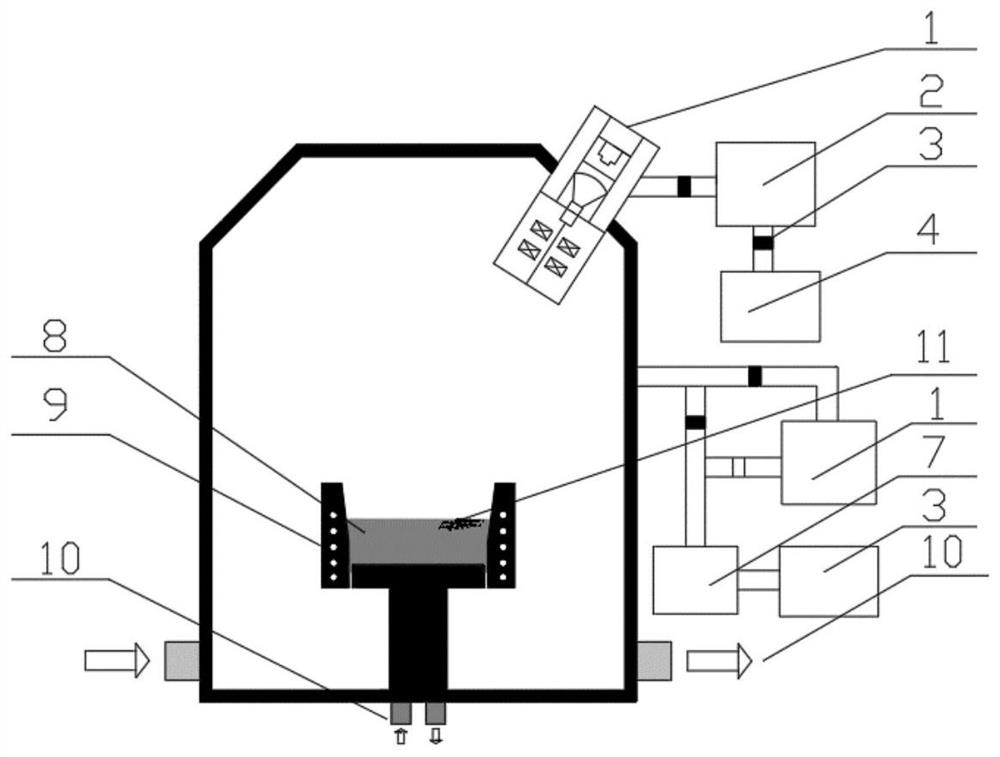

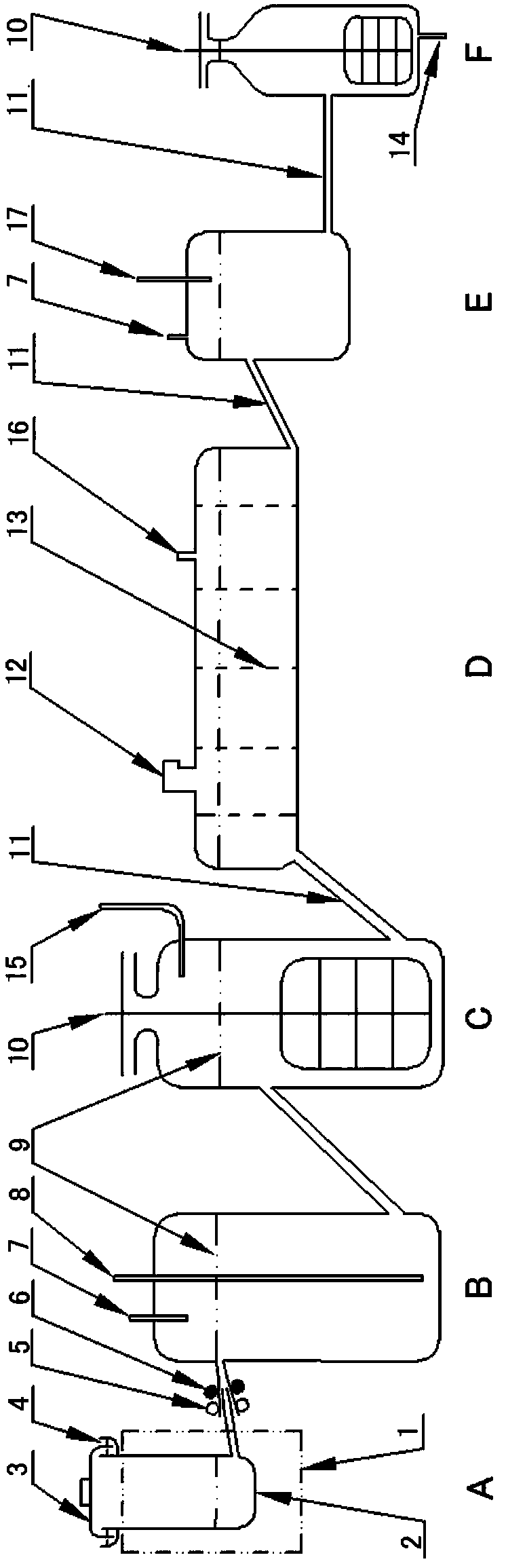

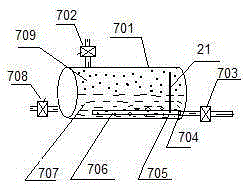

Fracturing fluid recovery erosion-prevention sand-removal system and method

InactiveCN105385432ASolve erosionEasy to control the discharge speedLiquid degasificationCentrifugal force sediment separationFracturing fluidLiquid storage tank

The invention relates to a fracturing fluid recovery erosion-prevention sand-removal system and method. The system at least comprises a cyclone sand remover, a gas-liquid separator and a sand storage tube, wherein a gas outlet of the gas-liquid separator is provided with a natural gas outlet needle valve; a liquid outlet of the gas-liquid separator is communicated and connected with a fracturing fluid recovery tank; the upper part of the sand storage tube is connected with an inlet of the gas-liquid separator; a sand outlet of the sand storage tube is provided with a sand storage tube sand discharge remote control valve; an outlet of the sand storage tube sand discharge remote control valve is connected with a vibration sieve; an outlet of a liquid storage tank of the vibration sieve is provided with a remote control liquid discharge pump; an outlet of the remote control liquid discharge pump is divided into two branches; one branch is connected with the fracturing fluid recovery tank; the other branch is connected with a liquid inlet formed in the middle part of the sand storage tube; the system also comprises a PLC (programmable logic controller); the PLC is respectively and electrically connected with an ultrasonic wave detector, a sand-containing fluid flushing remote control value, a gas separator liquid level meter, a remote control high-pressure valve, a pressure release switch and the sand storage tube sand discharge remote control valve. The erosion of blasting sand-containing fluid on a ground pipe manifold is relieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Ultra-high pressure unloading valve

PendingCN109723695AWork lessReduce the pressure difference across theServomotor componentsFluid-pressure actuator componentsUltra high pressureEngineering

The invention discloses an ultra-high pressure unloading valve, and relates to a valve unloading device. The ultra-high pressure unloading valve comprises a main valve body, wherein a plurality of pressure reducing valves which sequentially communicate with one another and can reduce pressure step by step are arranged in the main valve body; the pressure reducing valves communicate with one another through a pressure reducing chamber and pipelines; the main valve body is provided with a plurality of one-way valves for balancing the pressure of the pipelines in front of the corresponding pressure reducing valve; the one-way valves communicate with the chamber through a connecting channel; and connecting pipelines communicate with a control oil openings in the upper ends of the one-way valves. By connecting the pressure reducing valves in series, the ultra-high pressure liquid in the pressure reducing valves can be subjected to pressure reducing in stages so as to reduce the flow rate ofliquid at a nozzle of the unloading valve, the pressure difference at the two ends of an unloading opening of the unloading valve is reduced, the pressure of the ultra-high pressure liquid is reducedto a certain range after penetrating through the unloading valve, and the erosion and vaporization problems generated during direct unloading in the prior art is solved; and in addition, the pressuredifference of the liquid in front of the pressure reducing valves is maintained as much as possible through the one-way valves, so that the pressure reducing valves normally work.

Owner:GUANGDONG NACRE HYDRAULIC CO LTD

Resource utilization type artificial sandy coast protection facility and construction method thereof

PendingCN110205979ASolve erosionHigh protection levelBreakwatersQuaysCarrying capacityResource utilization

The invention discloses a resource utilization type artificial sandy coast protection facility and a construction method thereof. The resource utilization type artificial sandy coast protection facility comprises one or more sets of wave-breaking and sand-blocking units; each set of wave-breaking and sand-blocking unit comprises a plurality of waste tires and protection layers, and the multiple waste tires are vertically arranged and sequentially connected to form a row to be parallel to a water edge line; each protection layer is formed by a plurality of protection units which are connected in series, the protection units comprise combination pieces remanufactured by the corresponding waste tires, and protection face layers remanufactured by the corresponding waste tires, and the toe opening parts of the protection face layers are connected with the toe opening parts of the combination pieces; and the combination pieces are arranged on the waste tires. The waste tires are subjected toresource utilization, and the problem of beach erosion caused by the insufficient sand carrying capacity of an artificial beach under the weak power environment is also solved; on the one hand, the artificial beach which is to be destroyed is subjected to segmented protection; and on the other hand, a reference benchmark is also provided for restoring of the beach natural form by beach managementand protection personnel, and the protection level of the artificial beach is greatly improved.

Owner:BEIBU GULF UNIV

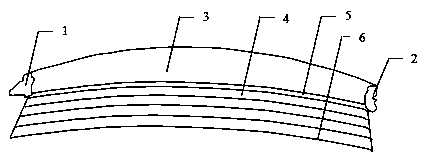

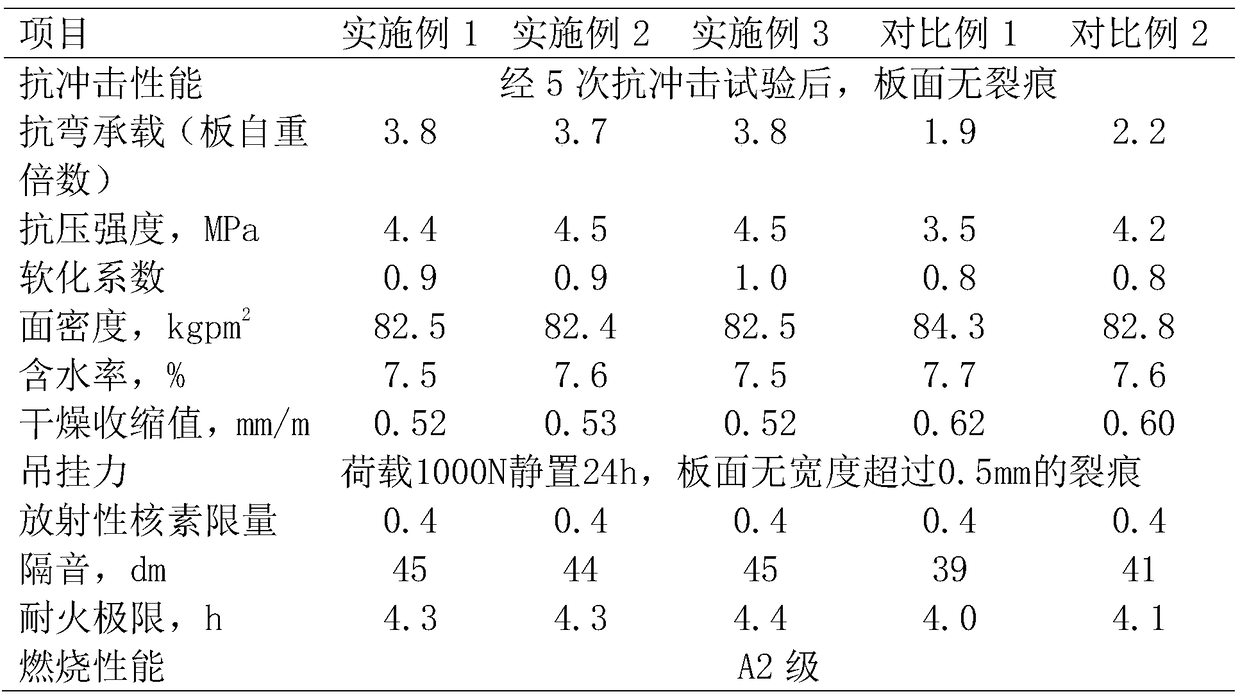

Solid lightweight wall partition and production technology thereof

InactiveCN108947345AImprove bending resistanceImprove impact resistanceSolid waste managementCeramicwarePolystyrenePulverized fuel ash

The invention discloses a production technology of a solid lightweight wall partition. The production technology comprises the following steps: 1) preparation of raw materials: preparing cement, pulverized fuel ash, waste residues, water, polystyrene foam and an additive according to the weight ratio of (28-32):(28-32):(33-37):(14-16):(9-11):(4-6); 2) mixing and stirring: crushing the particular raw materials, adding water and 60-70% by weight of polystyrene foam, and evenly mixing; 3) evenly mixing the additive and the remaining polystyrene foam, and then evenly mixing together with the materials obtained in the step through a stirrer; 4) pouring and forming: paving a steel wire net in a mold, pouring the materials obtained in the steps, and mechanically modeling; and 5) forming and demolding, inspecting finished products, and storing.

Owner:广西易筑装配式建材科技有限公司

Apparatus with sea marine organism pollution preventing function

ActiveCN101503221BPlay a driving rolePowerful shock waveVessel cleaningWater/sewage treatment with mechanical oscillationsGratingWater filter

The invention discloses a device with the function of preventing marine creatures from dirt fouling. The interior of a filtering net of a sea water filter is provided with two ultrasonic oscillatory plates, sound production surfaces of which respectively face an inlet pipe and an outlet pipe of the sea water filter; and the interior of a sea chest also can be provided with the ultrasonic oscillatory plates directly above 25-35cm of vertical distances of a grating plate; the sound production surfaces of the ultrasonic oscillatory plates face the grating plate. The ultrasonic oscillatory platesare fixed on a cover plate of the sea water filter and a crest slab of the sea chest by a positioning rod and a connection pipe; the connection pipe leads out a power cord connected with an ultrasonic signal generator. The device can effectively hold up sea creature, cleans the sea water filter and the grating plate of the sea chest, and prevents the filtering net of the sea water filter and the grating plate of the sea chest from being blocked and the attachment of other sea creatures, thus achieving the purpose of effectively preventing marine creatures from dirt fouling.

Owner:CNOOC ENERGY TECH & SERVICES

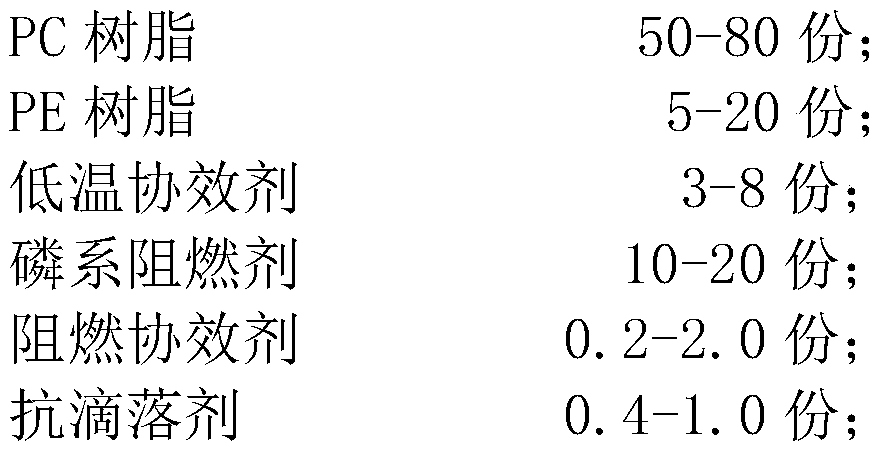

A kind of anti-termite-resistant low-temperature flame-retardant PC/PE alloy material and preparation method thereof

The invention discloses a termite-proof low-temprature-resisting and flame-retarding PC / PE (Polycarbonate / Polyethylene) alloy material and a preparation method thereof. The termite-proof low-temprature-resisting and flame-retarding PC / PE alloy material is prepared from the following components in parts by weight: 50 to 80 parts of PC resin, 5 to 20 parts of PE resin, 3 to 8 parts of a low-temperature synergist, 10 to 20 parts of a phosphorus-based flame retardant, 0.2 to 2.0 parts of a flame-retarding synergist, 0.4 to 1.0 part of an anti-dropping agent, 1 to 10 parts of termite-proof master batch and 0.4 to 1.0 part of an antioxidant. In a PC / PE alloy system, the PE resin is distributed in the PC resin in a dispersed phase manner; active groups of the PE resin and the PC resin are subjected to grafting reaction in a melting and blending process of the low-temperature synergist, so that a two-phase interface of PC and PE is improved, and the low-temperature toughening effect of the PEresin is sufficiently expressed; the phosphorus-based flame retardant is cooperatively matched with the flame-retarding synergist, so that flame-retarding requirements of large-size thin-wall parts are met. According to the termite-proof low-temprature-resisting and flame-retarding PC / PE alloy material, the termite-proof master batch is prepared firstly and then is used for synthesizing the PC / PEalloy material, so that the obtained termite-proof low-temprature-resisting and flame-retarding PC / PE alloy material keeps relatively good low-temperature-resisting and flame-retarding properties; meanwhile, the termite-proof low-temprature-resisting and flame-retarding PC / PE alloy material also has a long-effect termite-proof effect and is applicable to optical fibers and cable wiring boxes.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com