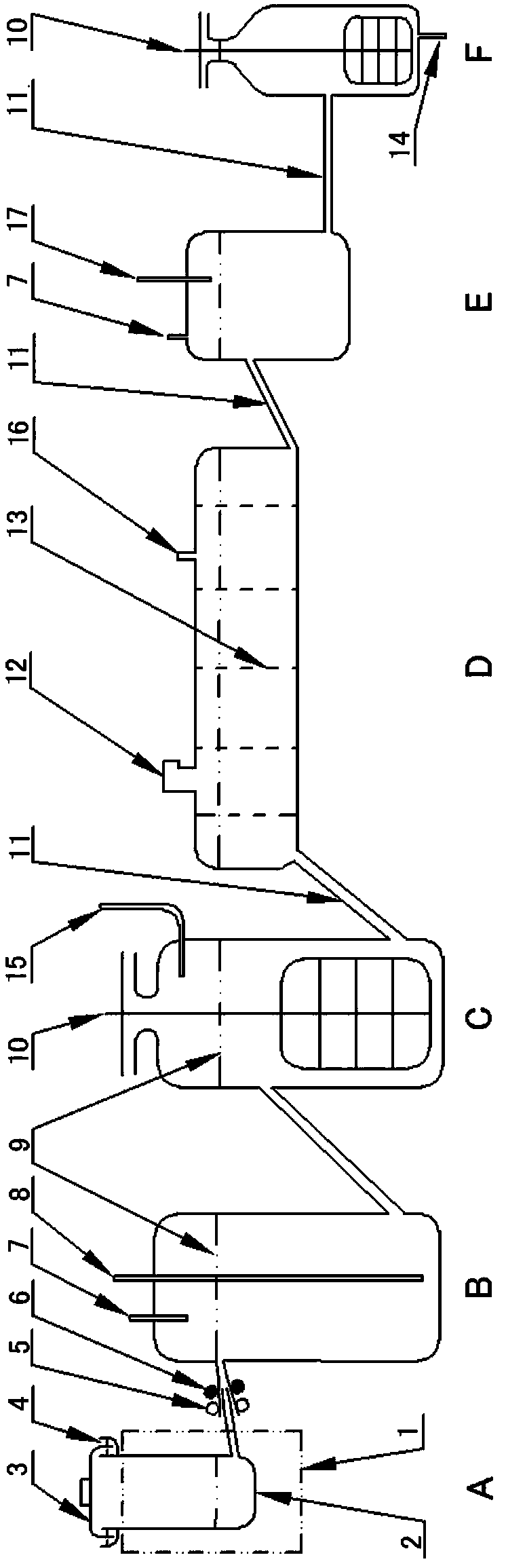

Glass continuous melting furnace and melting method

A continuous melting furnace and glass technology, used in glass furnace equipment, glass manufacturing equipment, glass production and other directions, can solve problems such as erosion, and achieve the effect of improving yield, reducing production costs and improving internal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0042] Using Al 2 o 3 75%, SiO 2 The melting pot A is made of 5% ceramic material, and the distance between the neck of the homogenizing pot C and the working pot F and the agitator 10 is set to 2 cm, and on this basis, the welding and repairing of the above continuous melting furnace is carried out and the fluorine Continuous melting production of phosphorous glass. After the implementation, the loss of fluorine-containing components in the product was significantly reduced. The life of melting furnace 1 and melting pot A was 18 days, and the life of platinum crucible was 6 months. 3 down to 0.04 / cm 3 .

Embodiment B

[0044] Using Al 2 o 3 85%, SiO 2 The melting pot A is made of 6% ceramic material, and the distance between the necks of the homogenizing pot C and the working pot F and the agitator 1 is set to 1 cm. Continuous melting production of phosphorous glass. After the implementation, the loss of fluorine-containing components in the product was significantly reduced. The life of melting furnace 1 and melting pot A was 21 days, and the life of platinum pot was 6 months. The platinum foreign matter inside the product was reduced from 0.9 pieces / cm 3 down to 0.02 / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com