Ultra-high pressure unloading valve

An unloading valve, ultra-high pressure technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, servo motor components, etc., can solve problems such as vaporization and erosion, and achieve the effect of solving erosion and vaporization problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

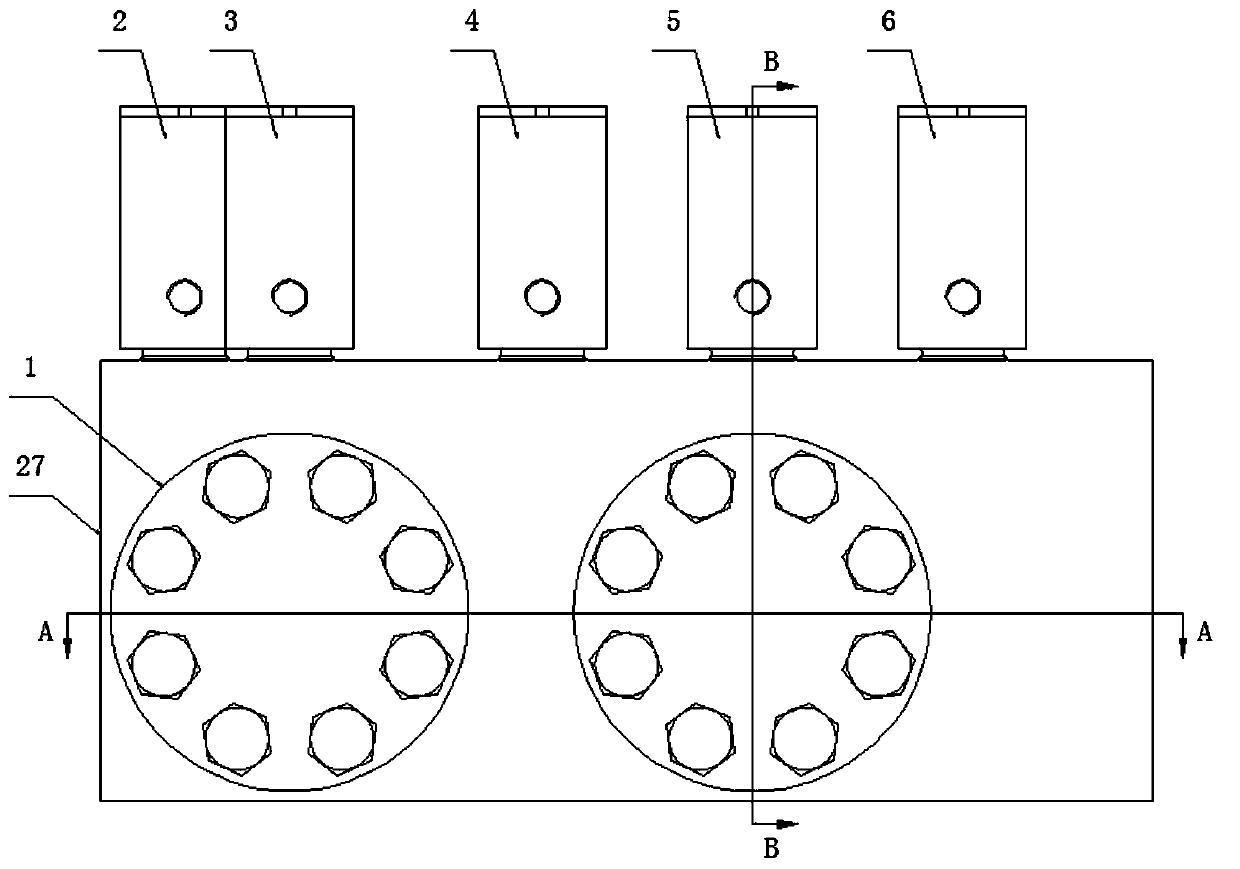

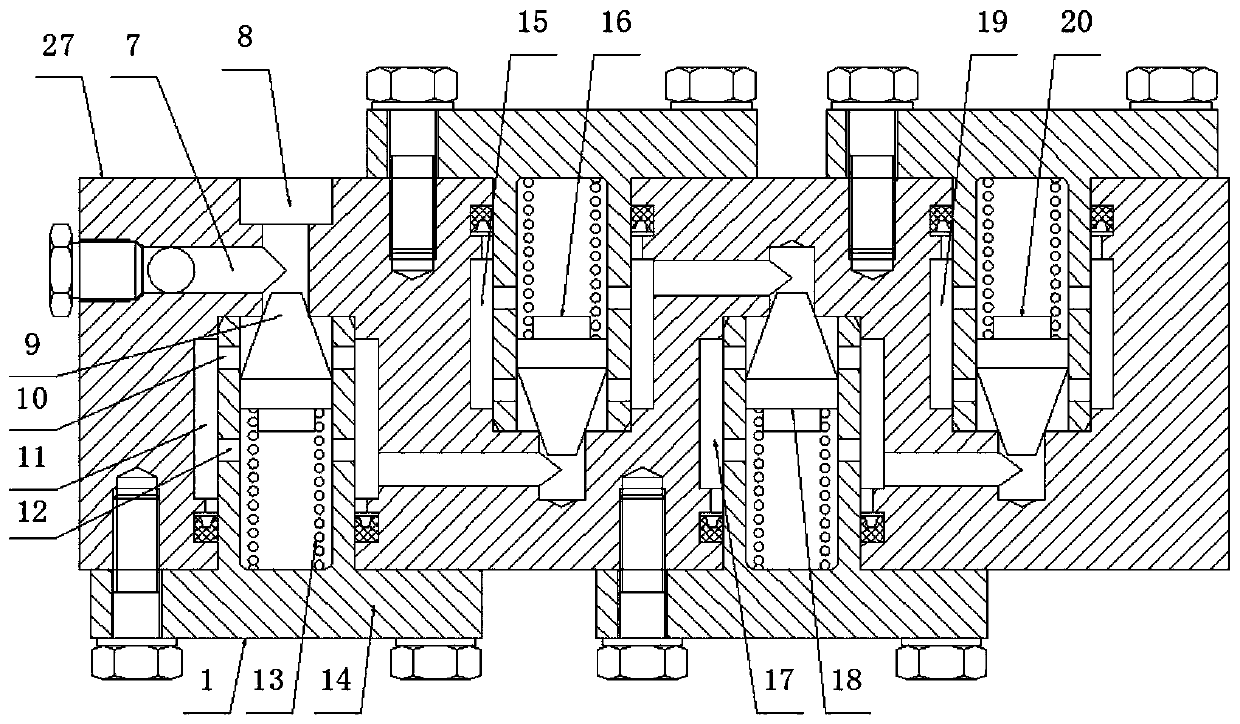

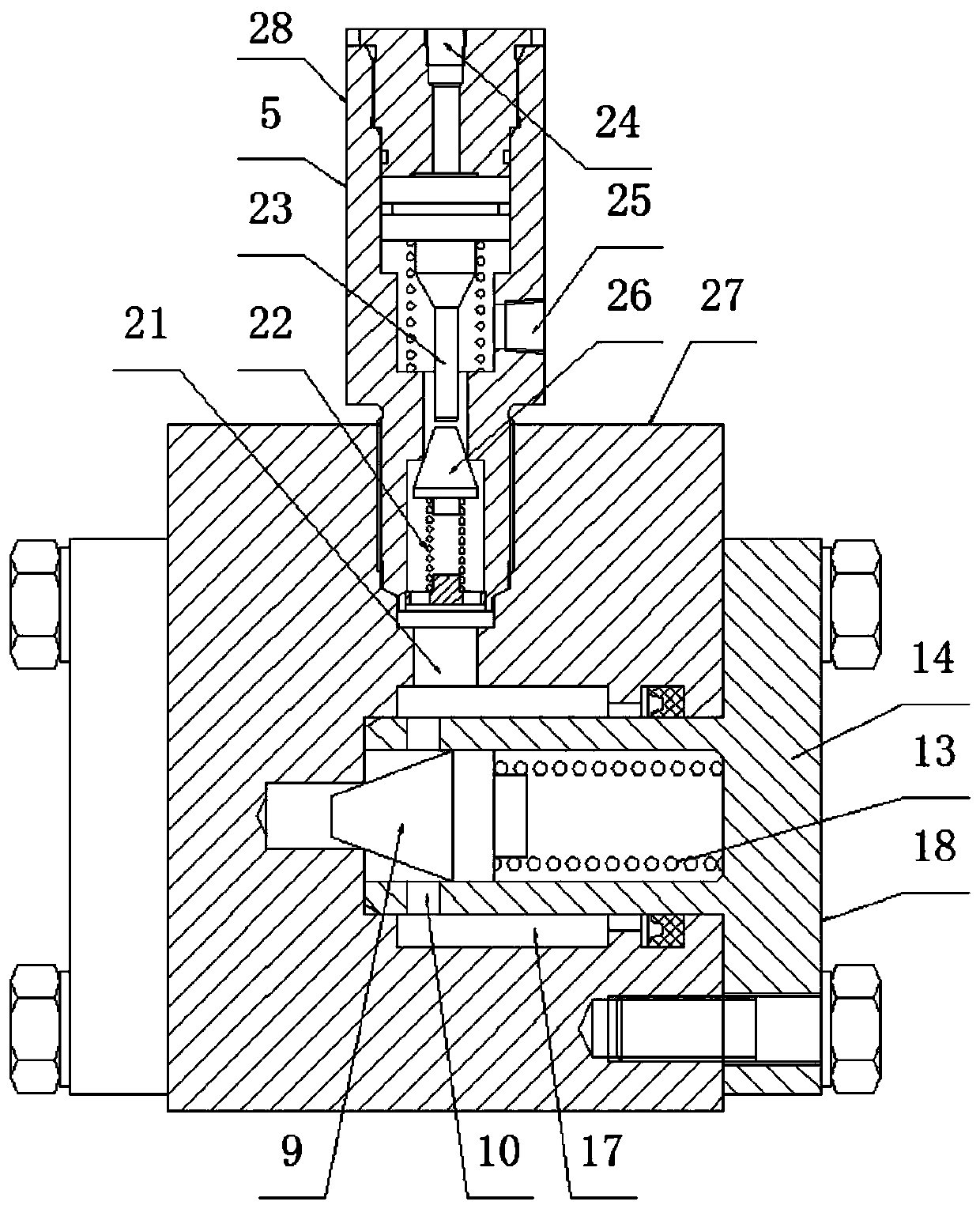

[0019] Preferably, an ultra-high pressure unloading valve includes a main valve body 27, and the main valve body 27 is provided with a plurality of sequentially connected pressure reducing valves that can be decompressed step by step, as described in this preferred embodiment The pressure reducing valve is provided with 4, and described pressure reducing valve comprises P1 cavity pressure reducing valve 1, P2 cavity pressure reducing valve 16, P3 cavity pressure reducing valve 18 and P4 cavity pressure reducing valve 20, described pressure reducing valve Corresponding chambers are provided on the outside, and the chambers include P1 chamber 11, P2 chamber 15, P3 chamber 17 and P4 chamber 19, and the decompression valves are connected in series through decompressible chambers and pipelines. Together, the P1 cavity pressure reducing valve 1 communicates with the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com