Solid lightweight wall partition and production technology thereof

A lightweight partition board and production process technology, which is applied in the field of building materials to achieve the effects of improving fireproof and waterproof performance, increasing bending resistance and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

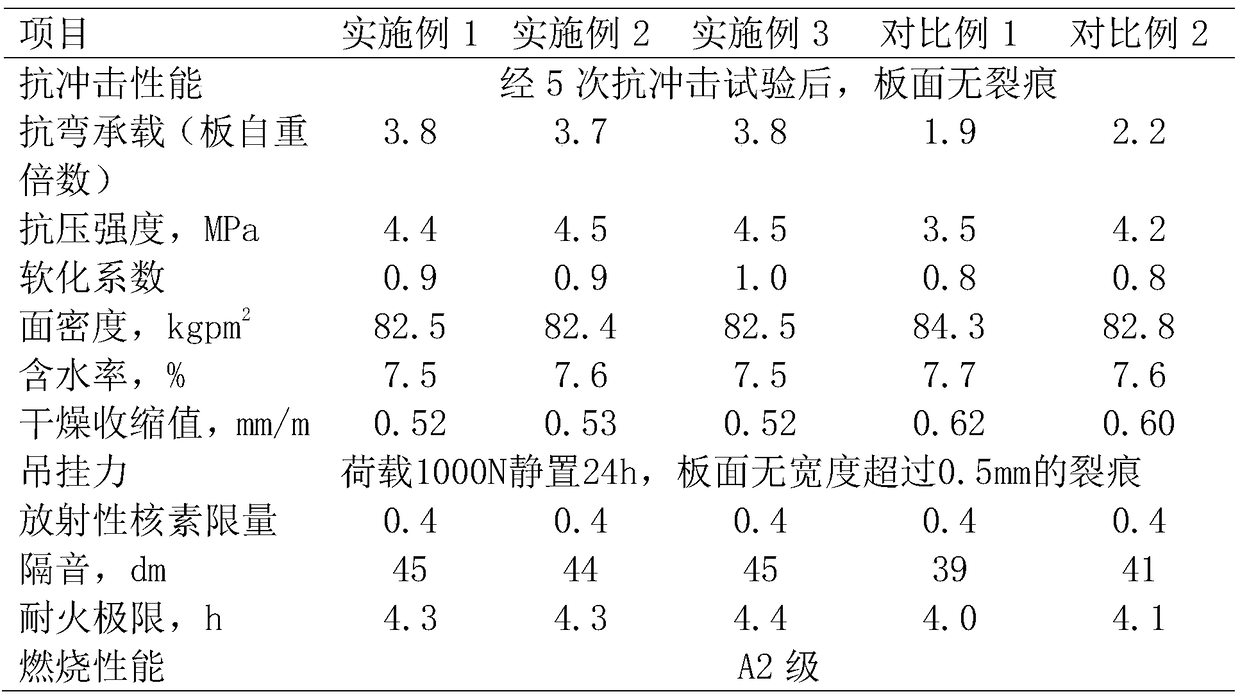

Examples

Embodiment 1

[0028] A production process of a solid lightweight partition board, comprising the steps of:

[0029] 1) Raw material preparation: Prepare cement, fly ash, granules obtained after disintegrating unqualified products, water, polypropylene (EPS) foam, additives, according to the weight ratio of 28:32:33:16:9:4;

[0030] 2) Mixing and stirring: crush the above-mentioned granular raw materials into 4-6mm, add water and 60-70% by weight of polypropylene (EPS) foam, and mix evenly;

[0031] 3) Mix the additive and the remaining polypropylene (EPS) foam evenly and then mix evenly with the material obtained in the previous step through a mixer;

[0032] 4) Pouring forming: the steel wire mesh with the same size as the mold is laid on both sides in the mold, the material obtained in the previous step is poured, and the mechanical mold is formed;

[0033] 5) Forming and demoulding, finished product inspection, storage;

[0034] Described additive obtains by following preparation metho...

Embodiment 2

[0039] A production process of a solid lightweight partition board, comprising the steps of:

[0040] 1) Raw material preparation: prepare cement, fly ash, granules obtained after disintegrating unqualified products, water, polypropylene (EPS) foam, additives, according to the weight ratio of 32:28:37:14:11:6;

[0041] 2) Mixing and stirring: crush the above-mentioned granular raw materials into 4-6mm, add water and 60-70% by weight of polypropylene (EPS) foam, and mix evenly;

[0042] 3) Mix the additive and the remaining polypropylene (EPS) foam evenly and then mix evenly with the material obtained in the previous step through a mixer;

[0043] 4) Pouring forming: the steel wire mesh with the same size as the mold is laid on both sides in the mold, the material obtained in the previous step is poured, and the mechanical mold is formed;

[0044] 5) Forming and demoulding, finished product inspection, storage;

[0045] Described additive obtains by following preparation meth...

Embodiment 3

[0050] A production process of a solid lightweight partition board, comprising the steps of:

[0051]1) Raw material preparation: prepare cement, fly ash, granules obtained after disintegrating unqualified products, water, polypropylene (EPS) foam, additives, according to the weight ratio of 30:30:35:15:10:5;

[0052] 2) Mixing and stirring: crush the above-mentioned granular raw materials into 4-6mm, add water and 60-70% by weight of polypropylene (EPS) foam, and mix evenly;

[0053] 3) Mix the additive and the remaining polypropylene (EPS) foam evenly and then mix evenly with the material obtained in the previous step through a mixer;

[0054] 4) Pouring forming: the steel wire mesh with the same size as the mold is laid on both sides in the mold, the material obtained in the previous step is poured, and the mechanical mold is formed;

[0055] 5) Forming and demoulding, finished product inspection, storage;

[0056] Described additive obtains by following preparation metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com