Patents

Literature

157results about How to "Fast curing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

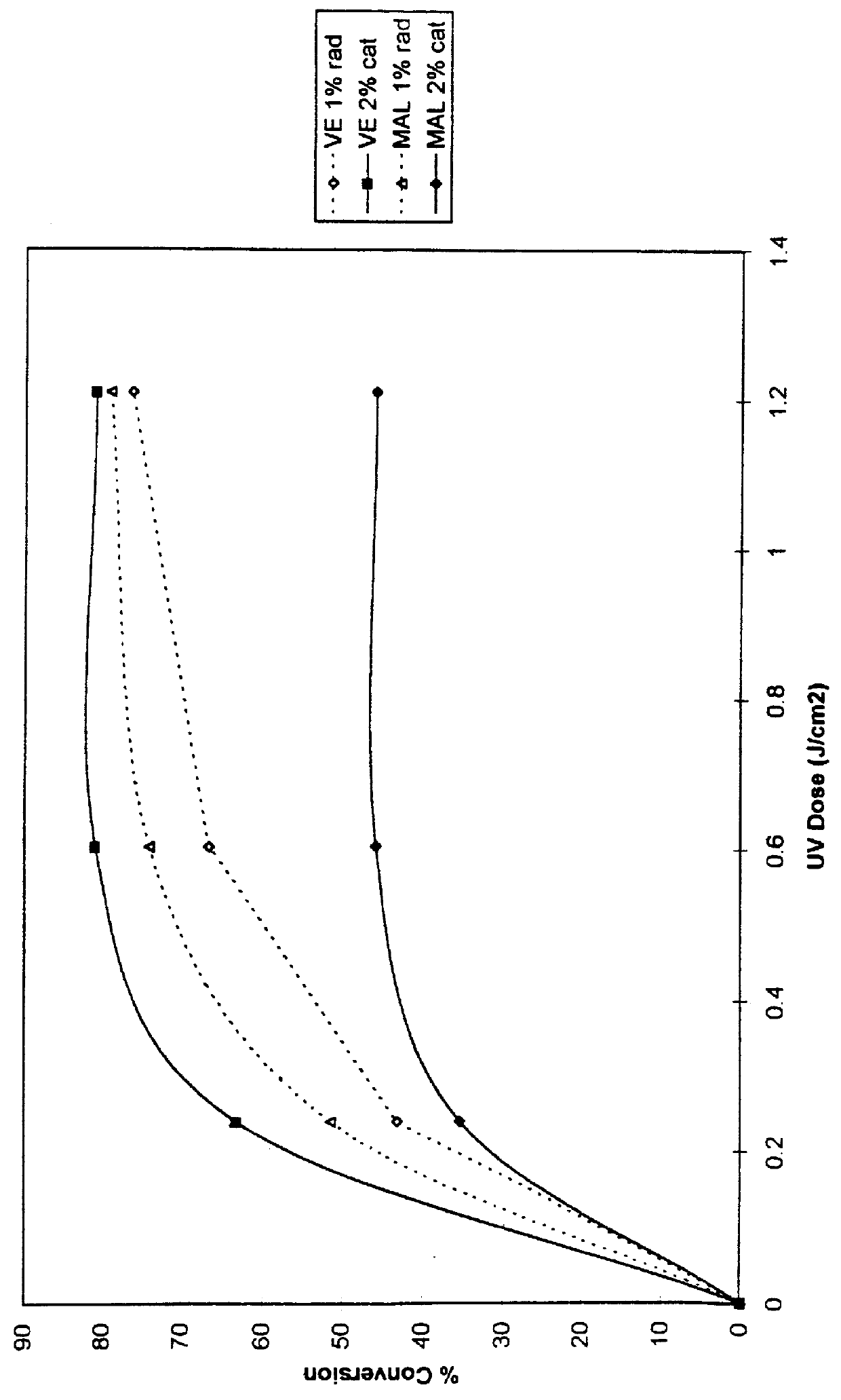

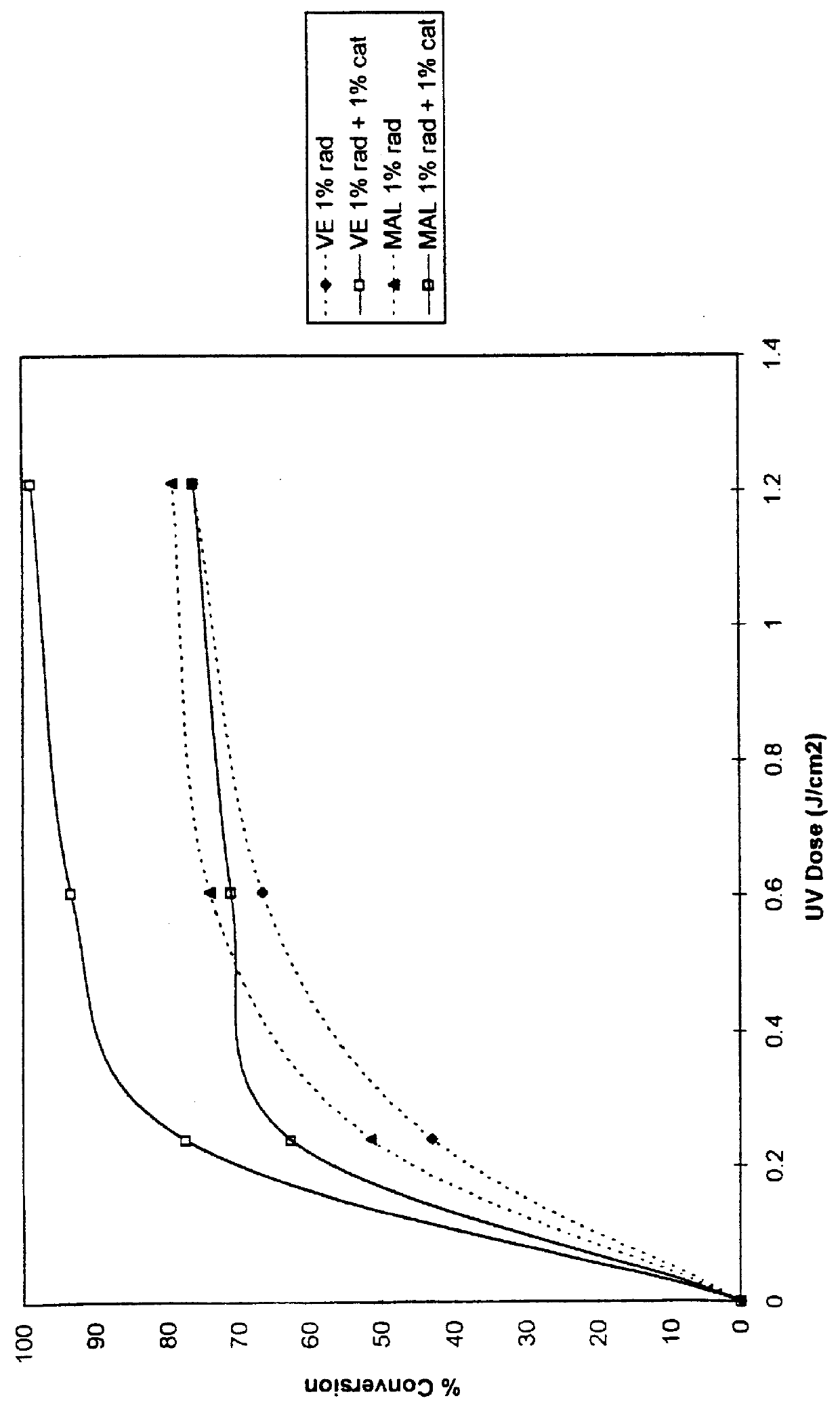

Photopolymerization process and composition employing a charge transfer complex and cationic photoinitiator

InactiveUS6127447AAccelerating polymerizationExtend curing timePhotomechanical apparatusOptical articlesVinyl etherCharge-transfer complex

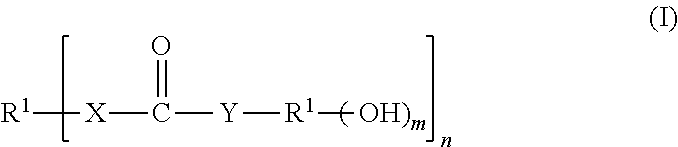

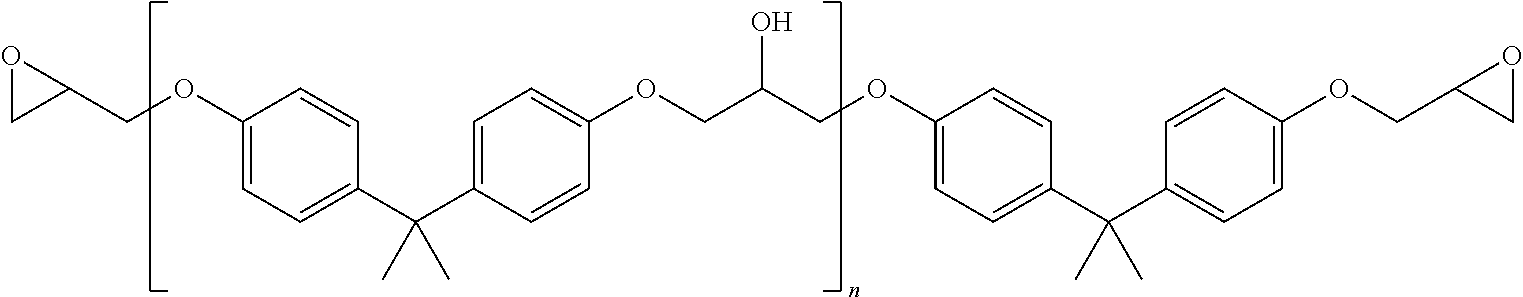

A radiation curable coating composition is provided and includes an effective amount of cationic photoinitiator, in combination with a charge transfer complex, the charge transfer complex comprising at least one electron withdrawing reactant component and at least one electron donating reactant component free radically reactive therewith, the electron withdrawing reactant component comprising an unsaturated nitrogen containing compound and the electron donating reactant component comprising an unsaturated compound having at least one vinyl ether group, the electron donating reactant component may be separate from or structurally incorporated within the electron withdrawing reactant component and an effective amount of a cationic photoinitiator. A photopolymerization process employing the composition is also provided.

Owner:FUSION UV SYST

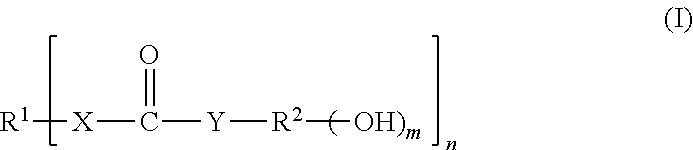

Accelerated and toughened two part epoxy adhesives

InactiveUS20150184039A1High dynamic impact peel strengthFast curing timeMacromolecular adhesive additivesEpoxy resin adhesivesFiberGlass fiber

A 2K epoxy adhesive is provided that has rapid cure time and good strength characteristics. Both the epoxy resin composition and the hardener composition of the 2K epoxy comprise a reactive toughener. Such adhesives are useful in the manufacture and / or repair of large machinery (e.g., automobiles), and are useful for bonding like or unlike materials, such as metal and composites (e.g., carbon fiber or glass fiber composites).

Owner:DOW GLOBAL TECH LLC

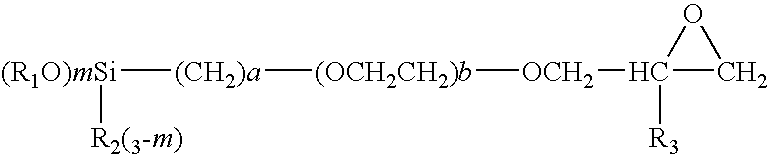

Intumescent composition

ActiveUS20120174508A1Improve expansion efficiencyFast curing timePretreated surfacesPolyurea/polyurethane coatingsSilanesPlasticizer

An intumescent composition which comprises a polymer selected from a silane-terminated polyurethane or a silane-terminated polyether, a plasticizer that is compatible with the polymer and an intumescent ingredient. Processes of forming a cured intumescent substance, and methods of fire protecting a building are also provided.

Owner:TREMCO ILLBRUCK COATINGS

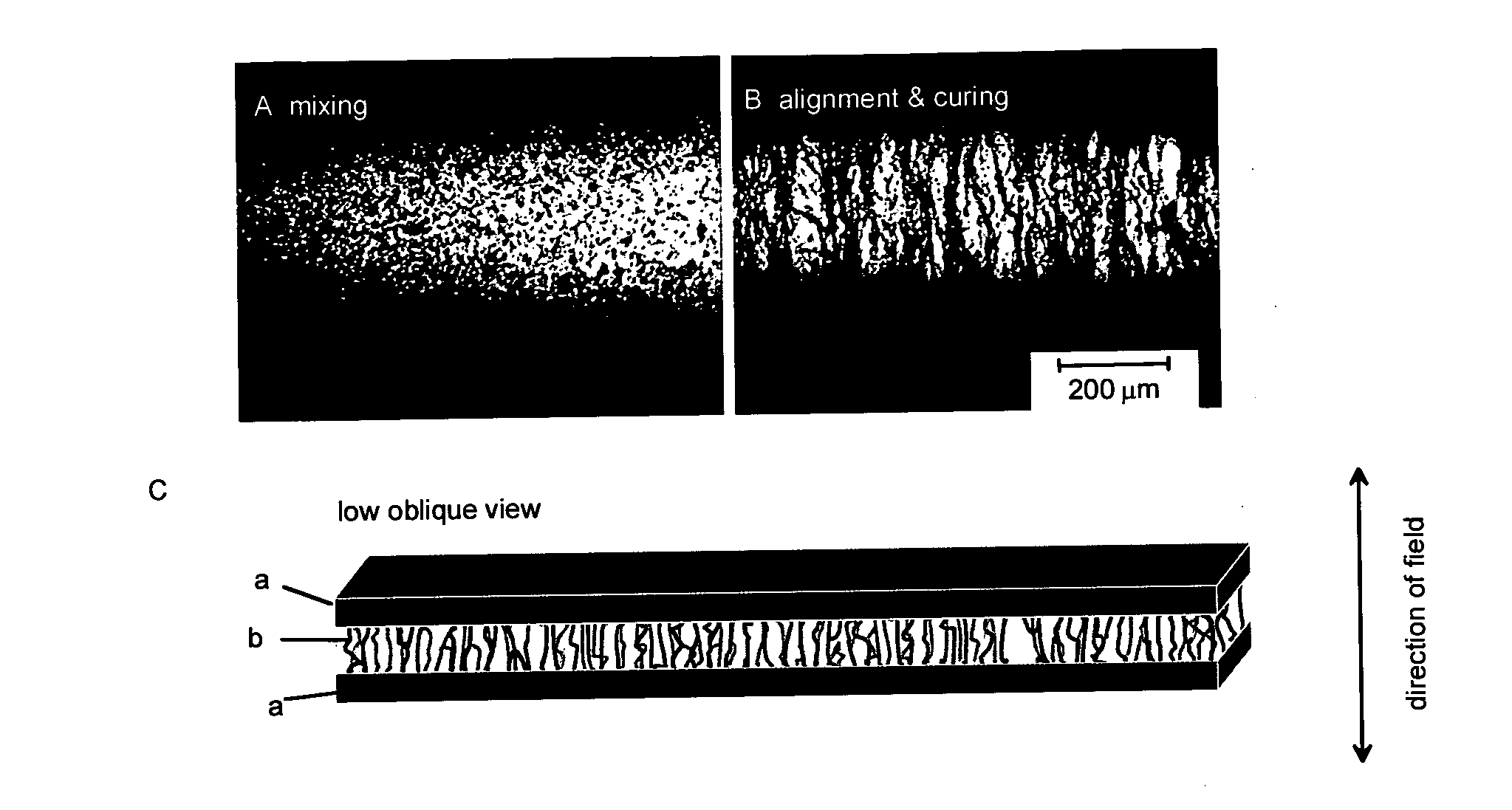

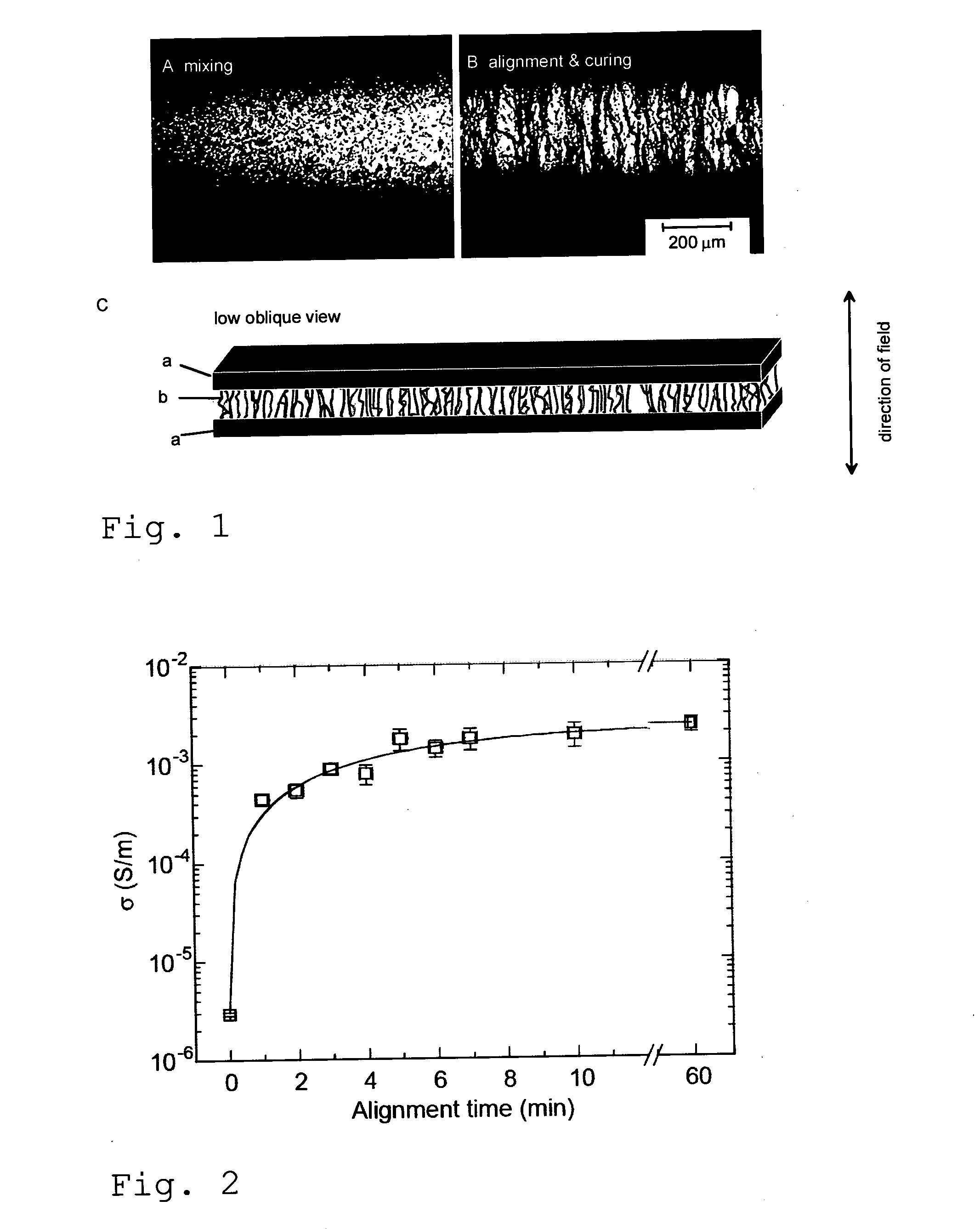

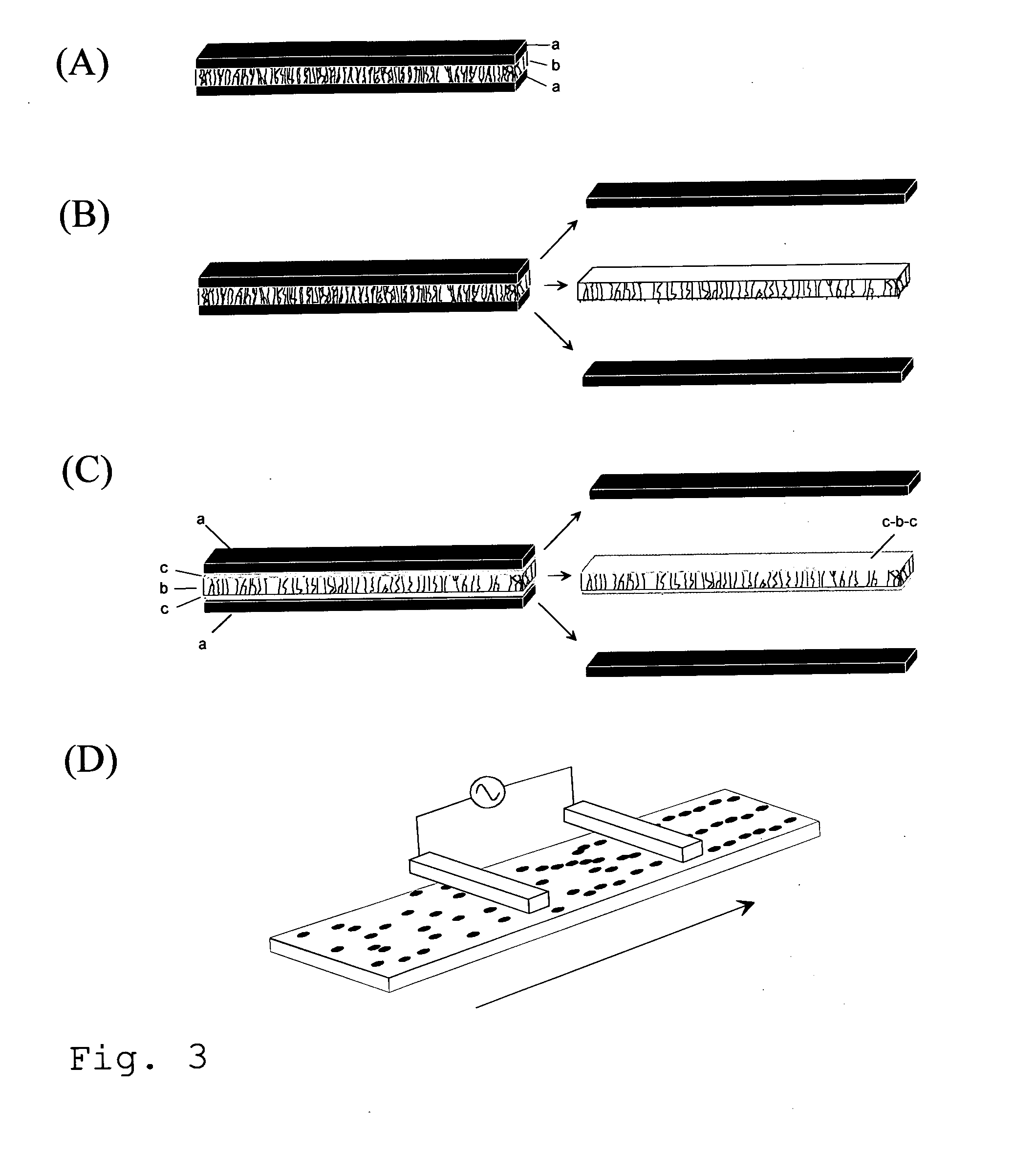

Anisotropic conductive polymer material

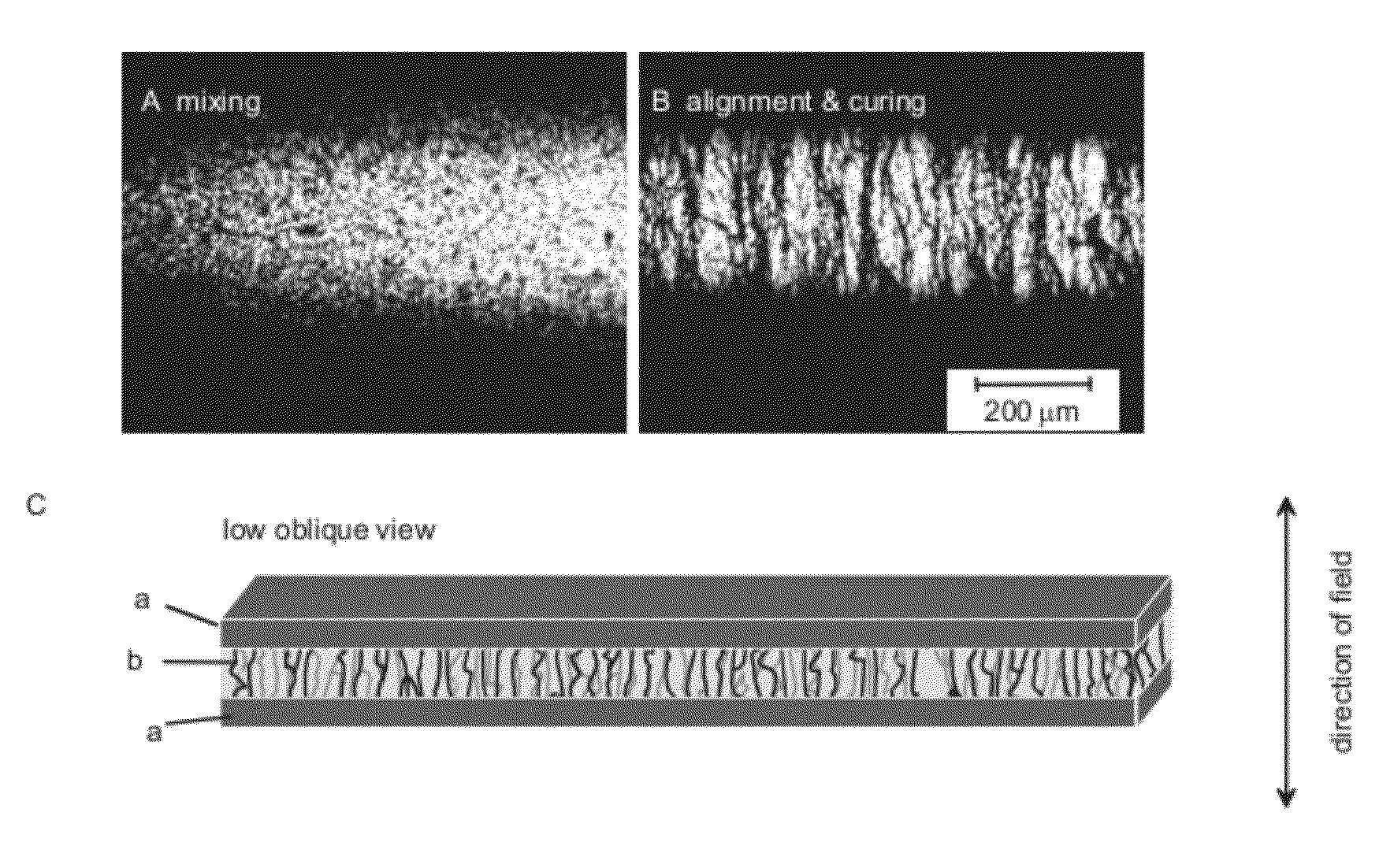

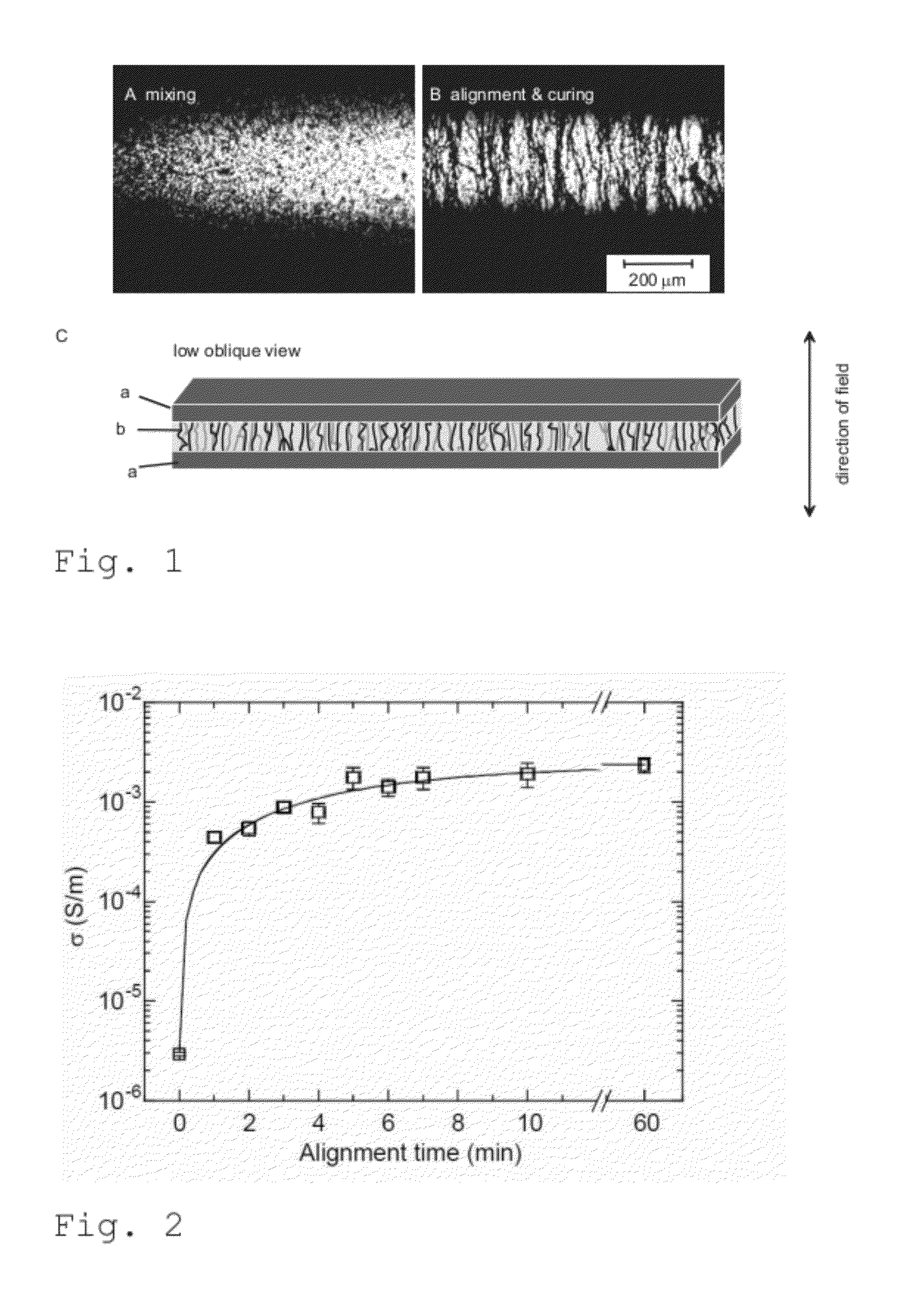

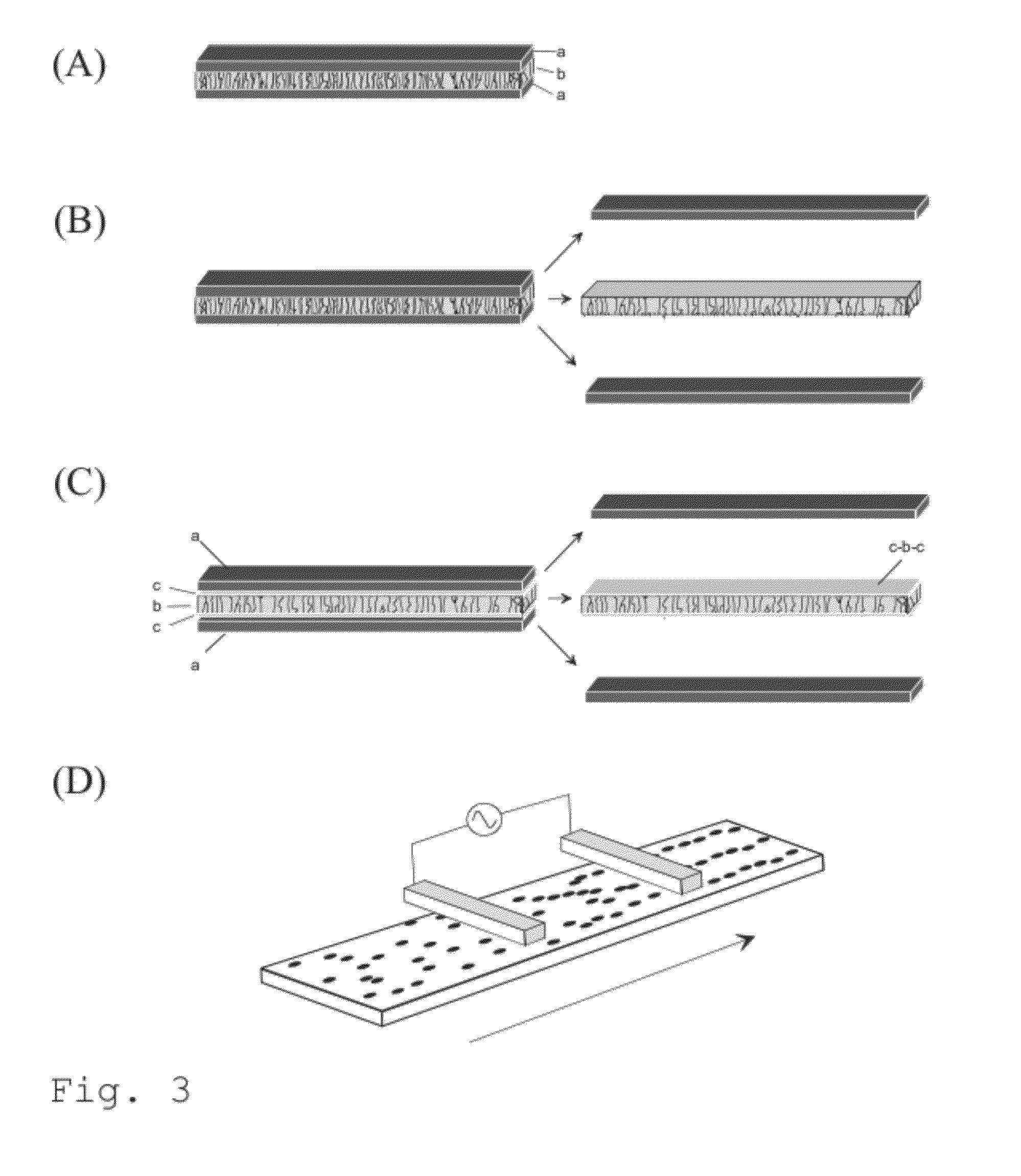

ActiveUS20120145315A1Fast curing timeHigh bonding strengthMaterial nanotechnologyNon-macromolecular adhesive additivesConductive polymerPercolation threshold

A method for forming a body comprising a mixture of a matrix and conductive particles, whereby the conductive particles are formed into aligned conductive pathways in an alignment step by applying an electric field between alignment electrodes and thereafter stabilizing the mixture wherein the conductive particles have a low aspect ratio; and a polymeric composition and method for producing such composition which is curable by UV light to an anisotropic electrically conductive polymer layer, comprising i) providing a non-conductive matrix of a flowable polymer composition having inherent photocurability, ii) adding to matrix conductive particles having low aspect ratio in an amount to allow the concentration of the conductive particles to be maintained at a level lower than the percolation threshold, and iii) placing the formed composition in a receptacle where exposure to UV light is prevented, and a method for establishing an anisotropic electrically conductive, optionally thermally conductive

Owner:CONDALIGN AS

Process for Preparing Composites Using Epoxy Resin Formulations

Epoxy composites are prepared by separately preheating an epoxy resin and a hardener; mixing the preheated epoxy resin and preheated hardener to form a hot reaction mixture and curing the hot reaction mixture in the presence of a reinforcement until the mixture cures to form a composite having a polymer phase with a glass transition temperature of at least 150° C.

Owner:SHAFI ASJAD +3

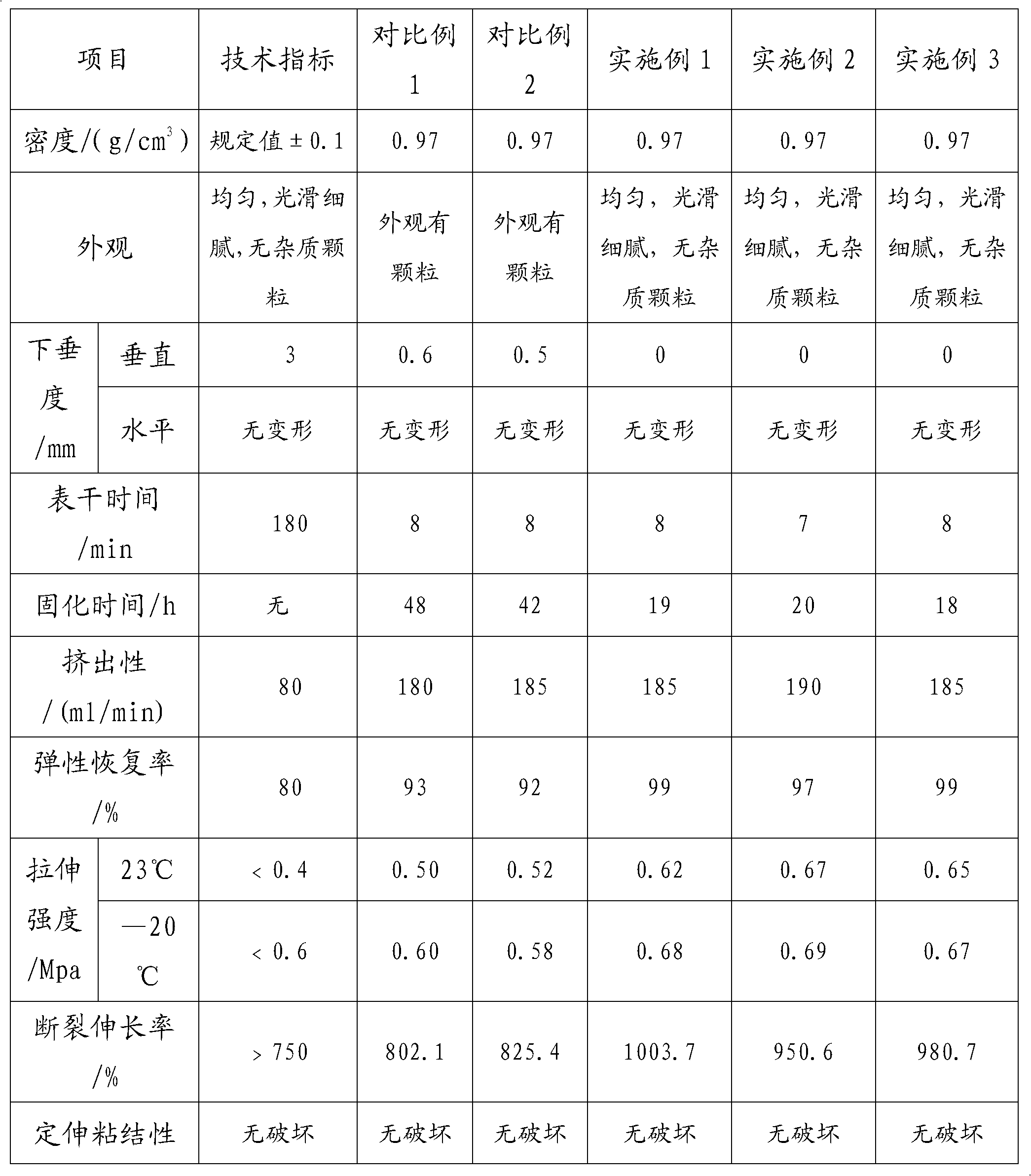

Method for preparing silicone sealant

ActiveCN103642452AIncrease the amount addedImprove stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

The invention discloses a method for preparing silicone sealant. The method comprises the following steps: adding alpha,omega-dyhydroxy polydimethylsiloxane, filler and dimethyl silicon oil into a vacuum kneading machine, vacuuming, heating and mixing for 2-5 hours; stopping heating, introducing nitrogen to change the vacuum state, adding a silane coupling agent, mixing for 0.5-1 hour at the vacuum degree of -0.06 to -0.1Mpa, introducing nitrogen to change the vacuum state; sealing and cooling to room temperature, subsequently transferring into a stirring machine, adding a cross-linking agent, a thickening agent and a catalyst, vacuuming, and uniformly stirring and mixing so as to obtain the silicone sealant. According to a product of the silicone sealant, the addition amount of the filler is increased, the product stability and the surface smoothness are improved, the thixotropy and the deep curing are also improved, the curing homogeneity is good, the tensile strength, the elasticity and the cohesiveness are greatly improved, expensive white carbon black can be replaced, the filling amount is large, the curing time is short, the construction efficiency is improved, the process is simple and feasible, the production cost is low, and good economic benefits and social benefits are achieved.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

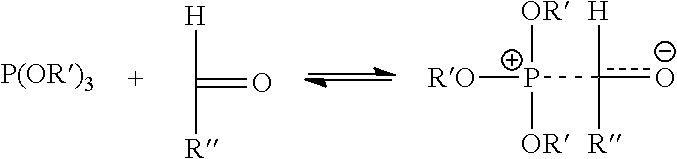

Photocurable inks and methods of use

InactiveUS20120207935A1Fast curing timeImprove performanceImpression capsPretreated surfacesSolventPhotoinitiator

A photocurable ink contains a colorant dissolved or dispersed within a solvent, a photoinitiator, an organic phosphite, and a photocurable compound. This photocurable ink can be used for imaging or other applications where a uniform or patterned image is desired. The photocurable ink can be cured partially before application, or totally cured after application.

Owner:EASTMAN KODAK CO

Lower temperature cure coating compositions

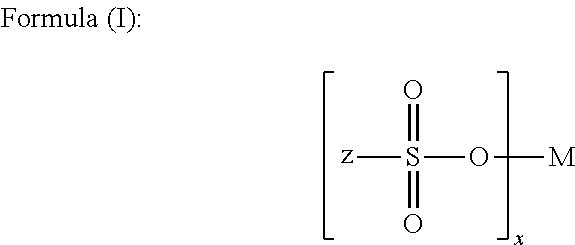

ActiveUS20150197665A1Excellent etch resistanceHigh hardnessElectric shock equipmentsPretreated surfacesEpoxyAcid catalyzed

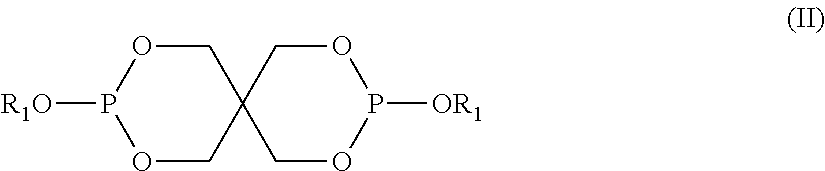

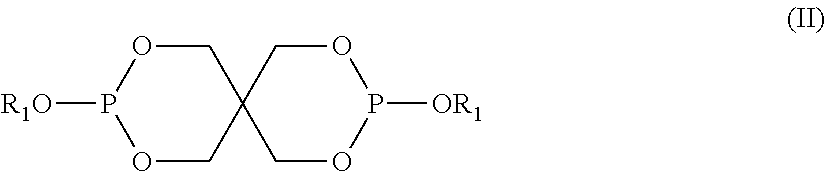

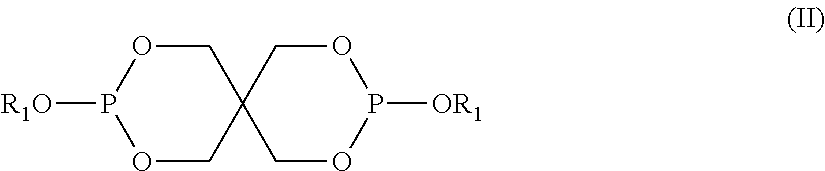

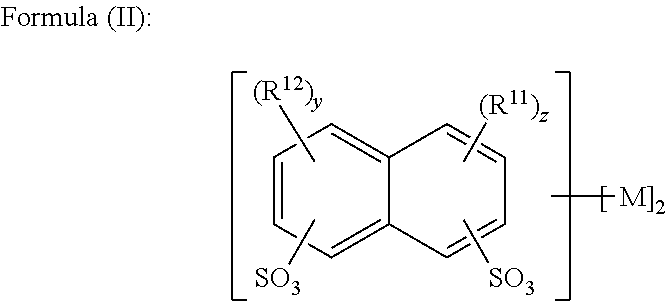

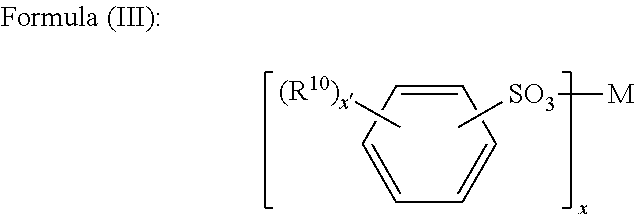

Select metal salts of mono and di aromatic sulfonic acids and aliphatic sulfonic acids are effective latent acid catalysts in coating compositions capable of acid catalyzed crosslinking and provide coating compositions with lower cure temperature and quicker cure times than encountered with conventional sulfonic acid catalysts, have excellent storage stability and avoid drawbacks of epoxy and amine blocked sulfonic acid catalysts.

Owner:KING INDUSTRIES INC

Anisotropic conducting body and method of manufacture

ActiveUS20120231178A1Fast curing timeHigh bonding strengthShielding materialsNanostructure manufactureOptoelectronicsViscosity

A layer of the mixture that contains polymer and conductive particles is applied over a first surface, when the mixture has a first viscosity that allows the conductive particles to rearrange within the layer. An electric field is applied over the layer, so that a number of the conductive particles are aligned with the field and thereafter the viscosity of the layer is changed to a second, higher viscosity, in order to mechanically stabilise the layer. This leads to a stable layer with enhanced and anisotropic conductivity.

Owner:CONDALIGN AS

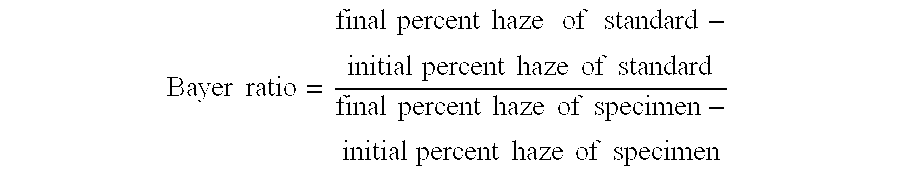

Spin application of thermally cured coatings

InactiveUS20040076838A1Fast curing timeHigh yieldPretreated surfacesCoatingsCombined useHigh productivity

A thermally curable coating is spin applied to the surface of a lens through a process that comprises the following steps: preparing a thermally curable coating composition, spin applying the coating onto one surface of a lens, and curing the coating. The process combines the best features both of the spin application technique and a thermally cured coating to obtain high productivity with high yield in the application process yet provide superior coating properties without requiring stripping or other pretreatment steps, which have negative attributes. The process can also incorporate the use of either a thermoset or a thermoplastic primer to enhance the coating adhesion.

Owner:HOYA OPTICAL LABS OF AMERICA INC +1

Stable ethylsilicate polymers and method of making the same

ActiveUS20160137841A1Reduce VOCsEliminates and reduces solventSemiconductor/solid-state device manufacturingVolatile organic compoundPolymer

Ethylsilicate polymers and a method of making, specifically ethylsilicate polymer binders with reduced levels of regulated volatile organic compounds (VOCs) for use in the coatings industry and casting industry, and more specifically to stable, fast cure ethylsilicate polymer binders with low levels of regulated VOCs.

Owner:SILBOND CORP

Preparation method of polyurethane elastomer

The invention provides a preparation method of a polyurethane elastomer, relating to polymers. The invention provides a preparation method of a polyurethane elastomer which has excellent impact resistance and machining characteristic and is especially suitable for preparing transparent polyurethane glasses frame products with high yields and low defects. The preparation method comprises the following steps: 1) preparing a prepolymer: mixing isocyanate with polyols to react to obtain the prepolymer; 2) preparing a curing agent: specifically, dehydrating the polyols, catalysts and anti-aging agents until the mass percent of the moisture is smaller than 0.05%, and adding chain extenders after reducing the temperature, thus obtaining the curing agent; and 3) mixing the prepolymer with the curing agent, then carrying out vacuum defoaming, injecting a reactive mixture after vacuum defoaming into a mold, then putting the mold in a microwave environment to be heated, and carrying out demolding, thus obtaining the polyurethane elastomer. The preparation method has the advantages of good processing properties, low material operating temperature, controllable operating time, high production efficiency and high yield.

Owner:XIAMEN MINGLAI TECH CO LTD

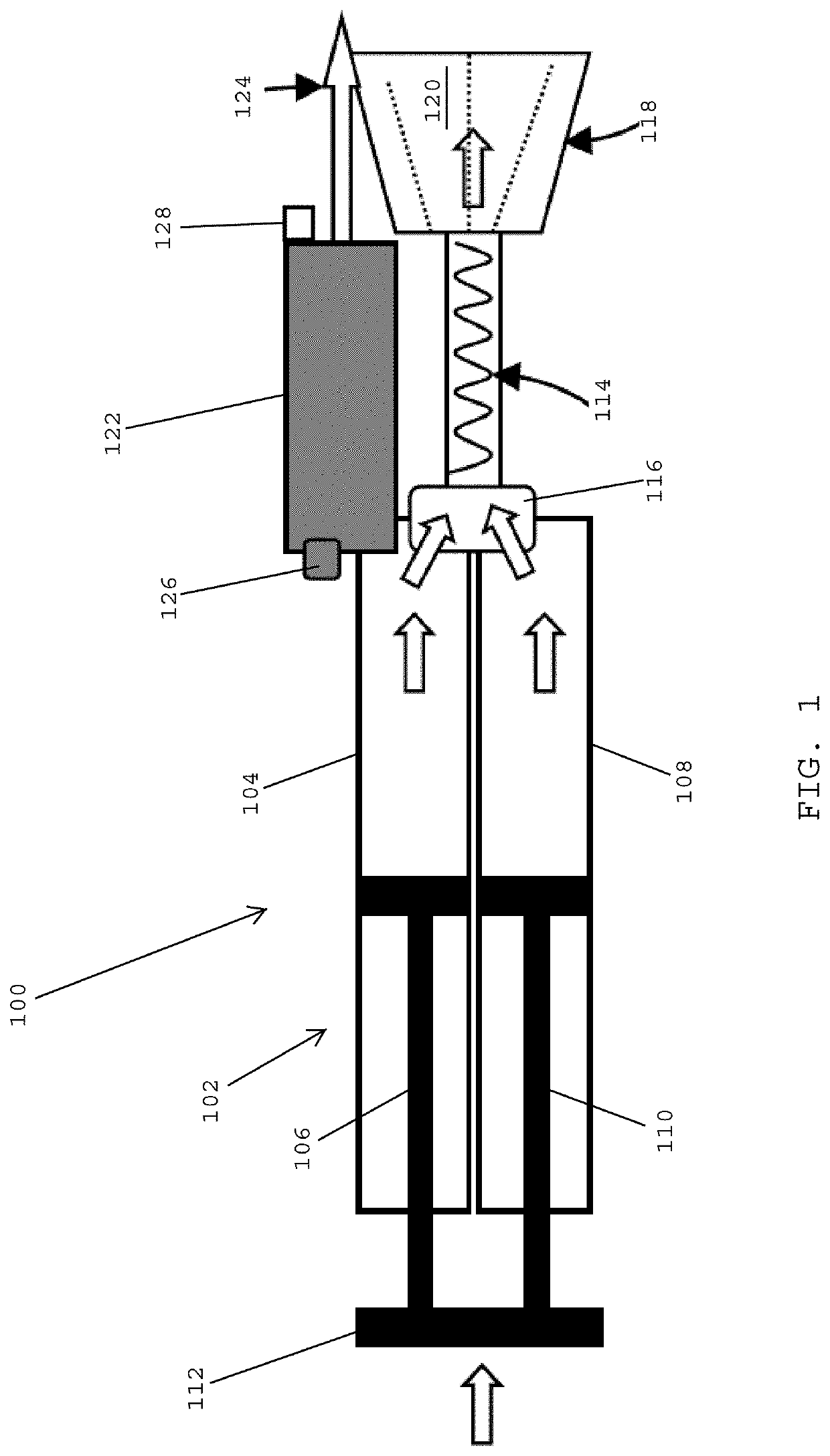

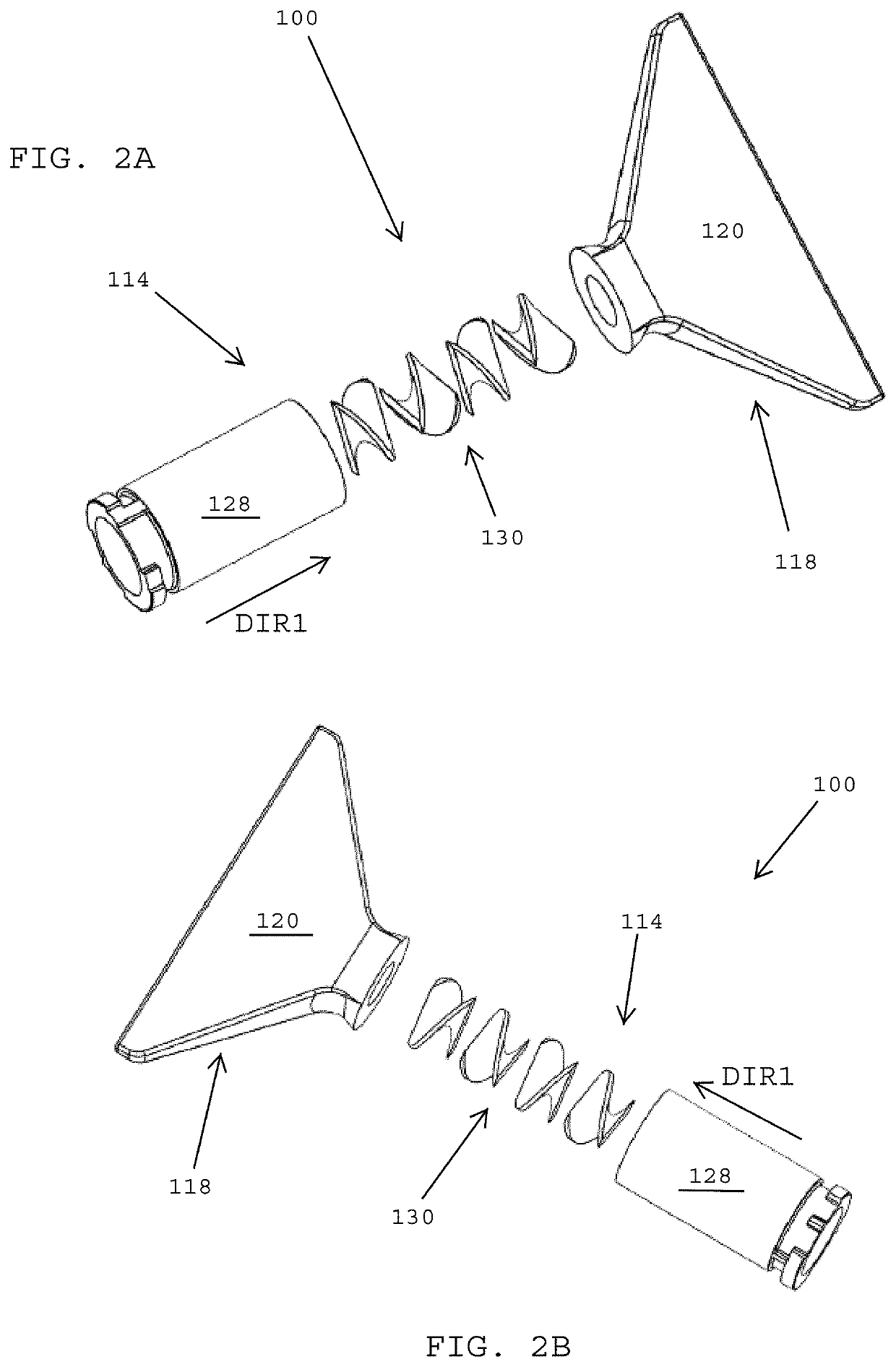

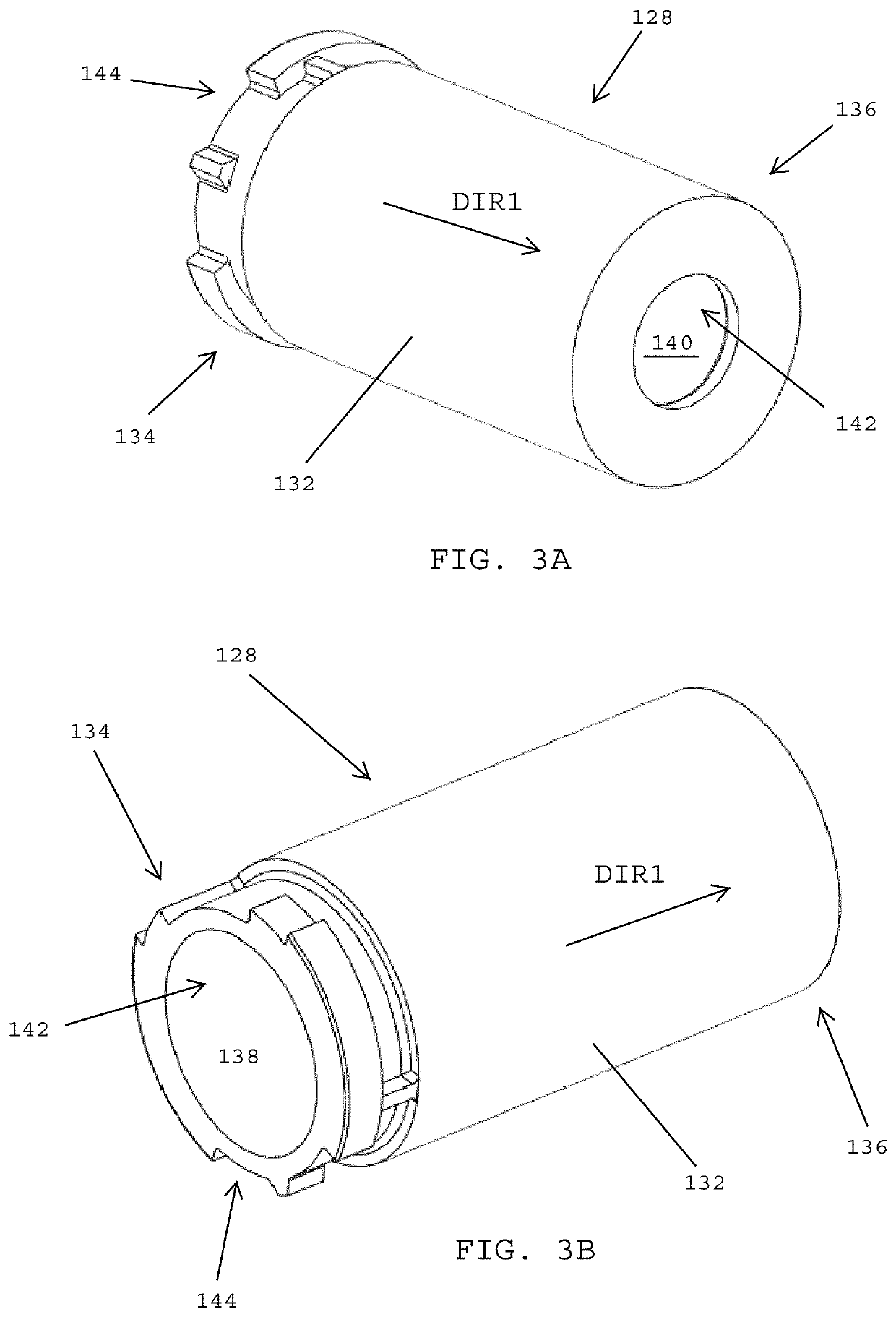

Systems, devices and methods for dispensing and curing silicone based topical skin adhesives

ActiveUS20210369258A1Effective compositionFast curing timeLiquid surface applicatorsInfusion syringesPolymer scienceAdhesive

A system for dispensing a curable composition includes a dual barrel syringe including a first syringe barrel with a first plunger, and a second syringe barrel with a second plunger. A static mixer is connected with distal ends of the first and second syringe barrels. The first and second plungers are moveable toward the distal ends of the first and second syringe barrels for expelling first and second components of a curable composition from the distal ends of the barrels into the static mixer for mixing the components to form the curable composition. A flexible spreader connected with a distal end of the static mixer has a flat dispensing opening, and a plurality of channels extending to the flat dispensing opening to dispense the curable composition. A hot gas blower generates a hot gas stream flowing distally over the distal end of the flexible spreader for curing the curable composition.

Owner:ETHICON INC

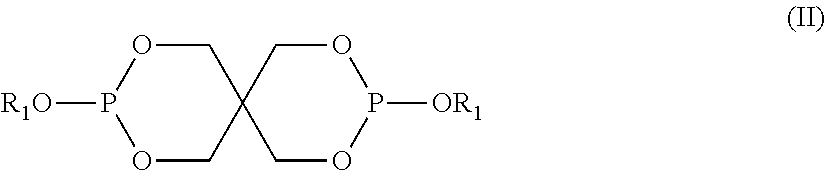

Photoinitiator compositions and uses

InactiveUS20120208914A1Fast curing timeImprove performanceImpression capsOther chemical processesPhotoinitiatorAldehyde

The photocuring efficiency of a photoinitiator is increased by mixing it with an organic phosphite and an aldehyde. This mixture or photoinitiator composition can be used to cure acrylates or other photocurable compounds, particularly in an oxygen-containing environment.

Owner:EASTMAN KODAK CO

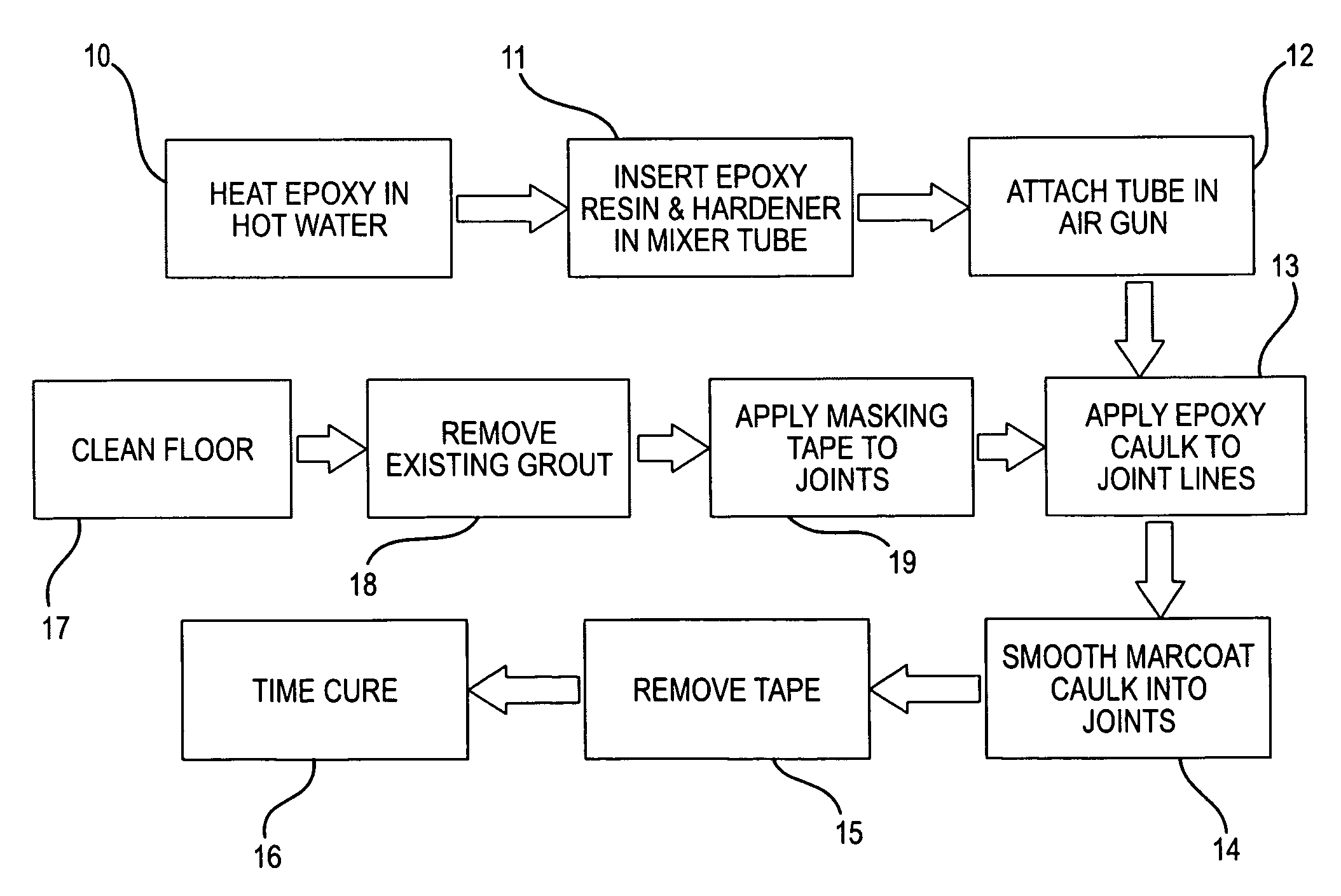

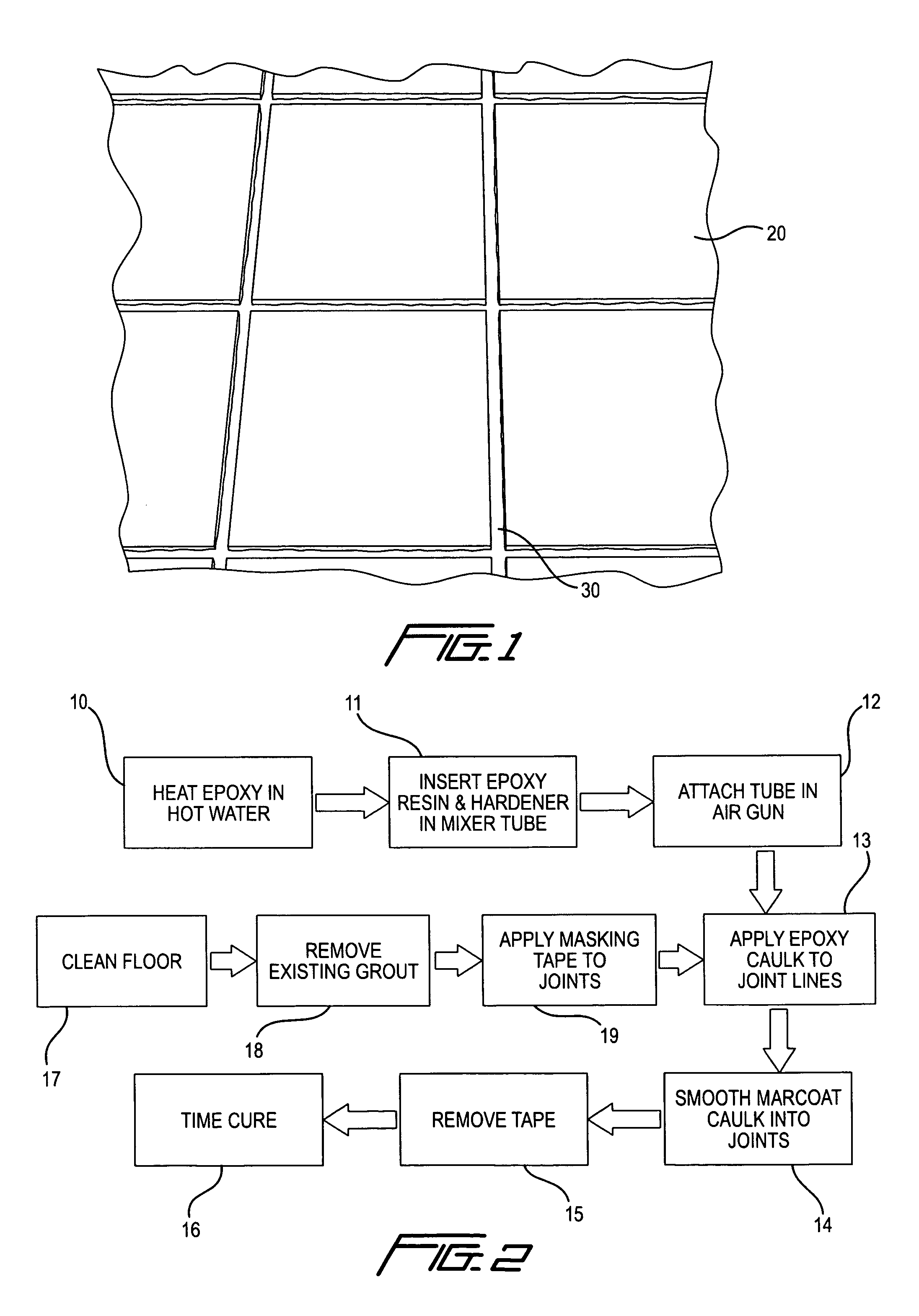

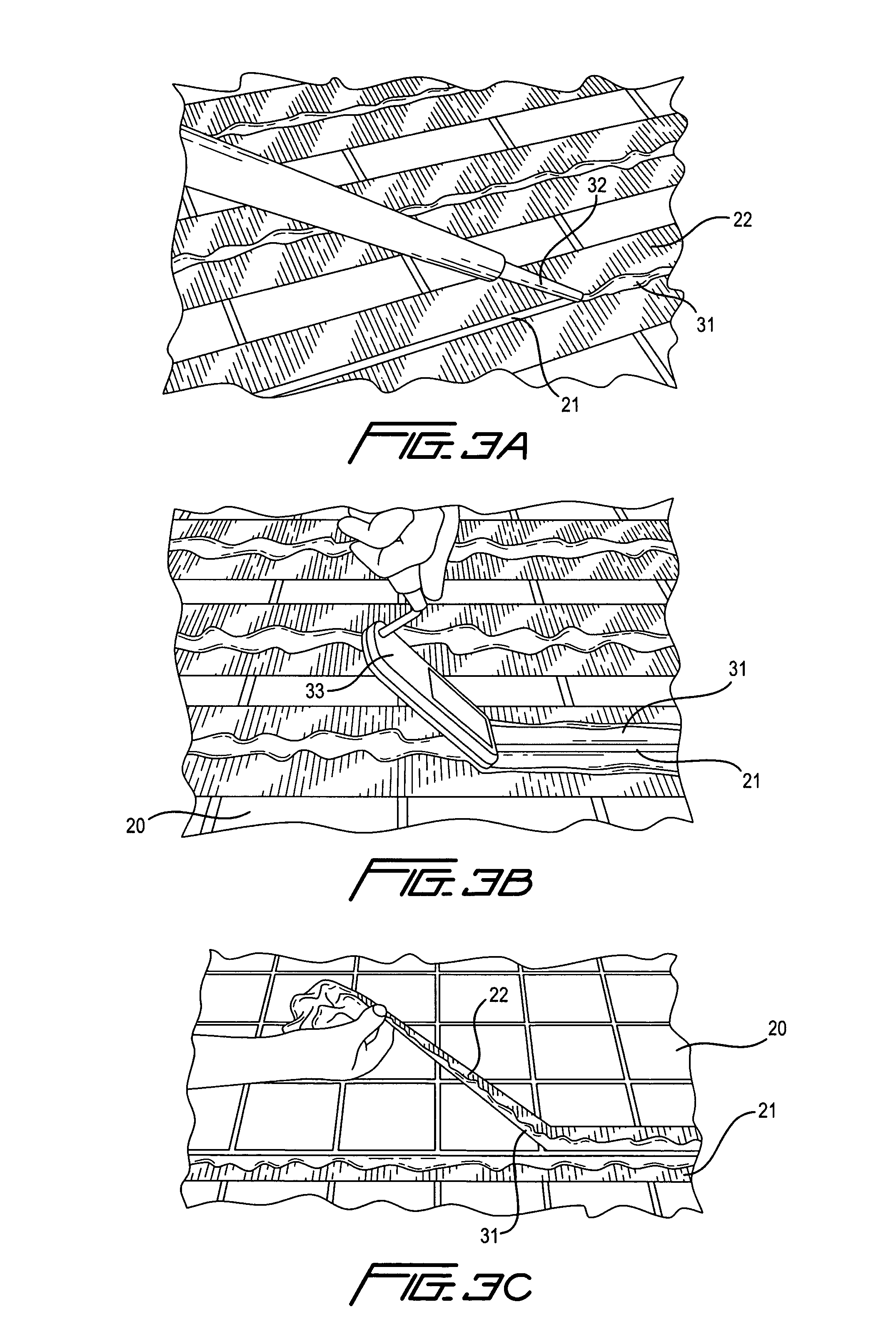

Method of grouting commercial kitchen floors using a two-part reactive epoxy grout

A process for grouting floors using a two-part reactive epoxy grout formulation comprising two distinct components (parts) which can utilize a two-part cartridge for storing, metering and having a means of attaching a static mixer tube to the front of the cartridge for inline mixing of the epoxy components as they are being dispensed directly into the grout joint. The cartridge contains a resin and pre-colored hardener, which maybe heated to accelerate the cure speed in cold environments if necessary, mixed, and applied to an empty grout joint-line by means of a static mixer tube that acts as a mixer-nozzle. Masking tape or other protective material is placed on both sides of the joint-line prior to grouting to prevent epoxy contacting tile faces. The grout is dispensed directly into the grout joint by the applicator gun pressurizing the cartridge pistons to flow epoxy resin and hardener in the correct mix ratio through the static mixing nozzle. A leveling tool is used to even out the dispensed grout into the grout joint and remove excess material before curing. By means of the reactivity of the hardener and resin, which are mixed in the proper stoichiometric ratios, the epoxy will cure in the designed period of time to allow full use within hours after application. A two-part methyl methacrylate grout formulation can be used in grouting new tiled floors or regrouting existing tiled floors with the same procedures as the two part reactive epoxy grout.

Owner:SQUITIERI JOHN

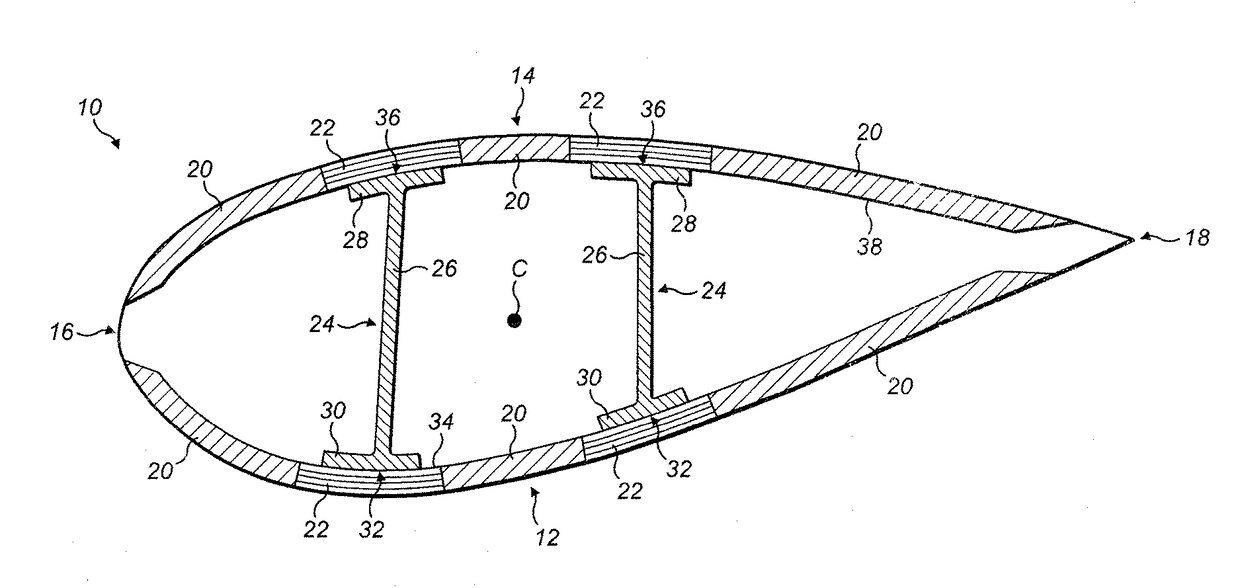

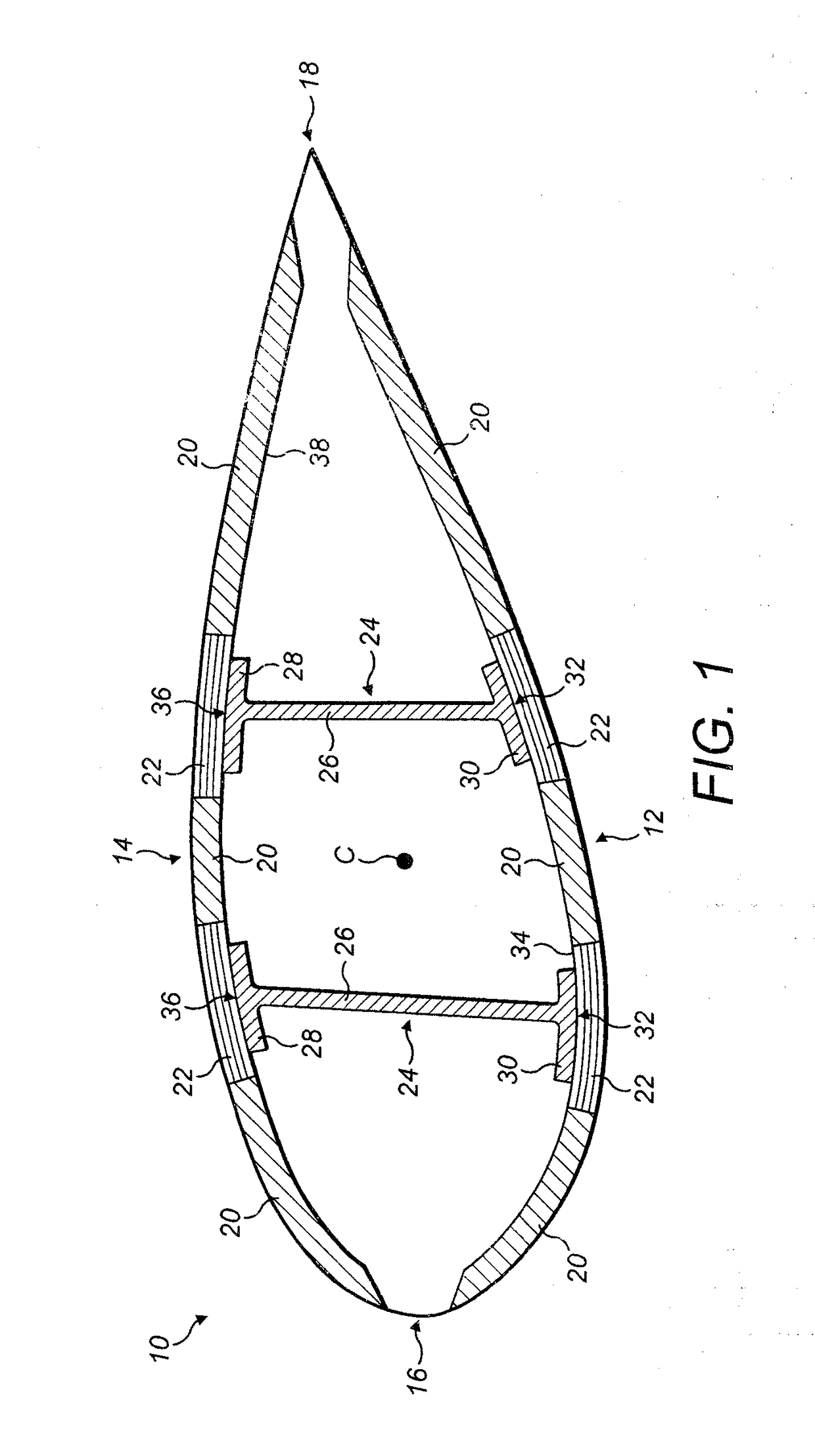

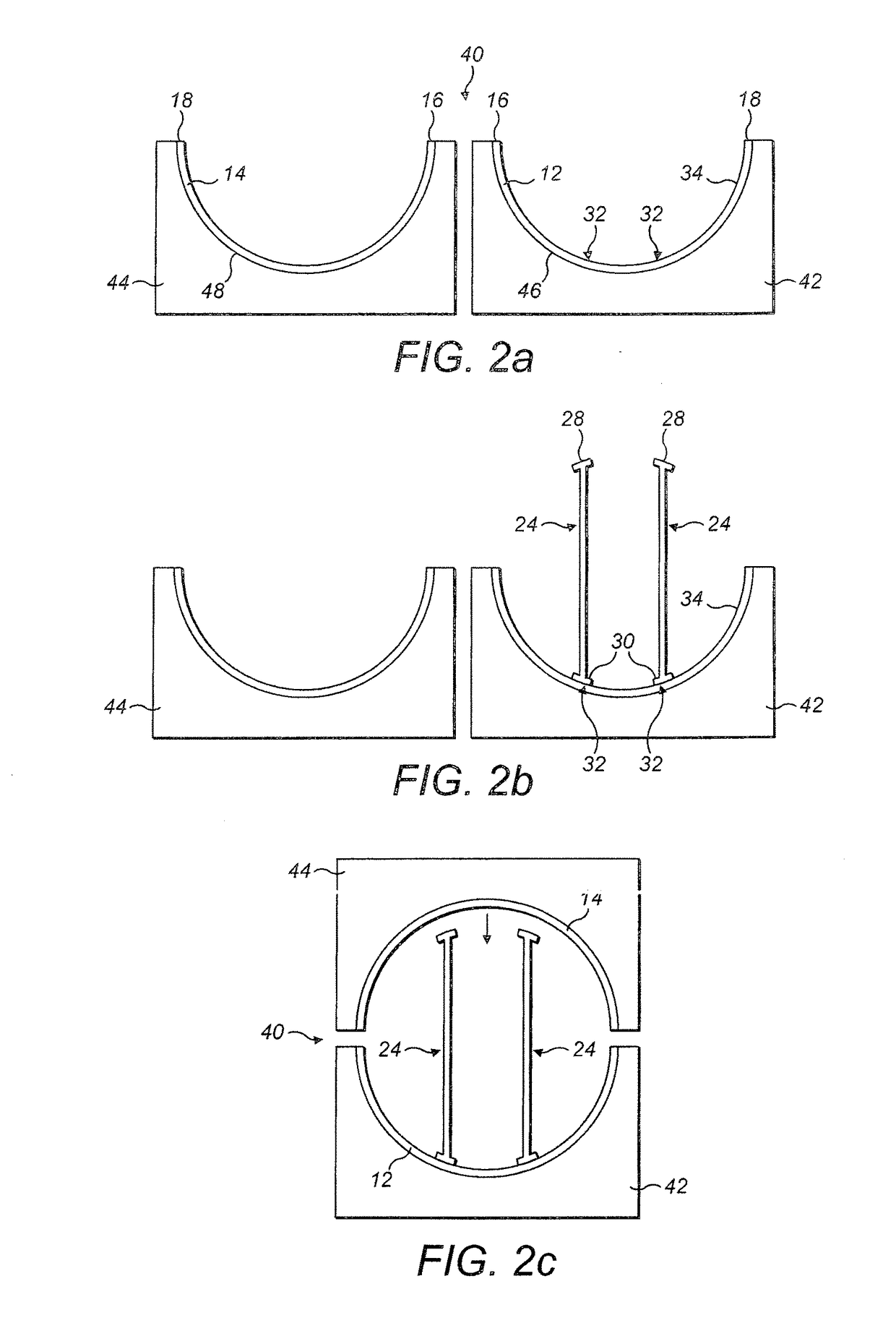

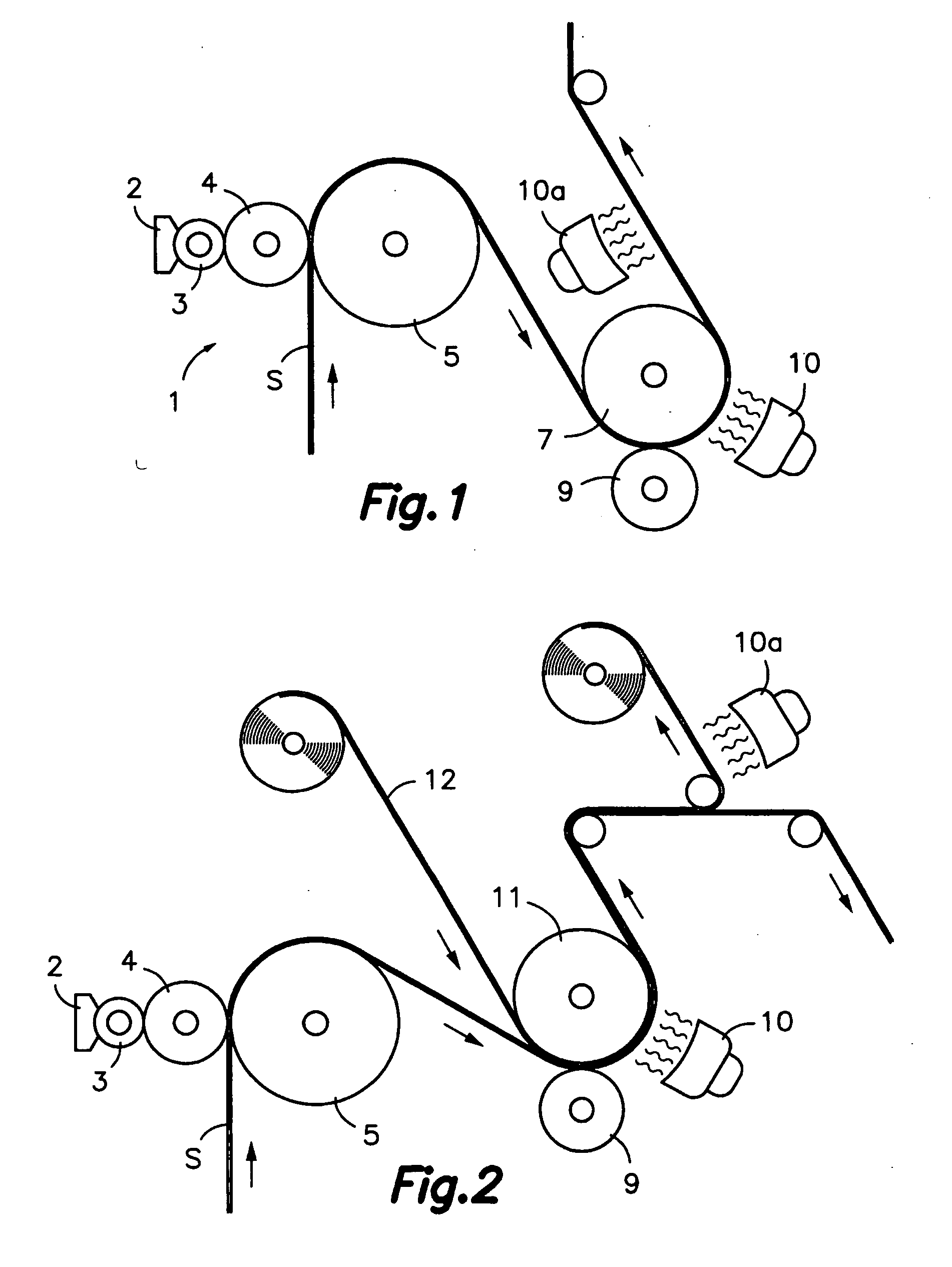

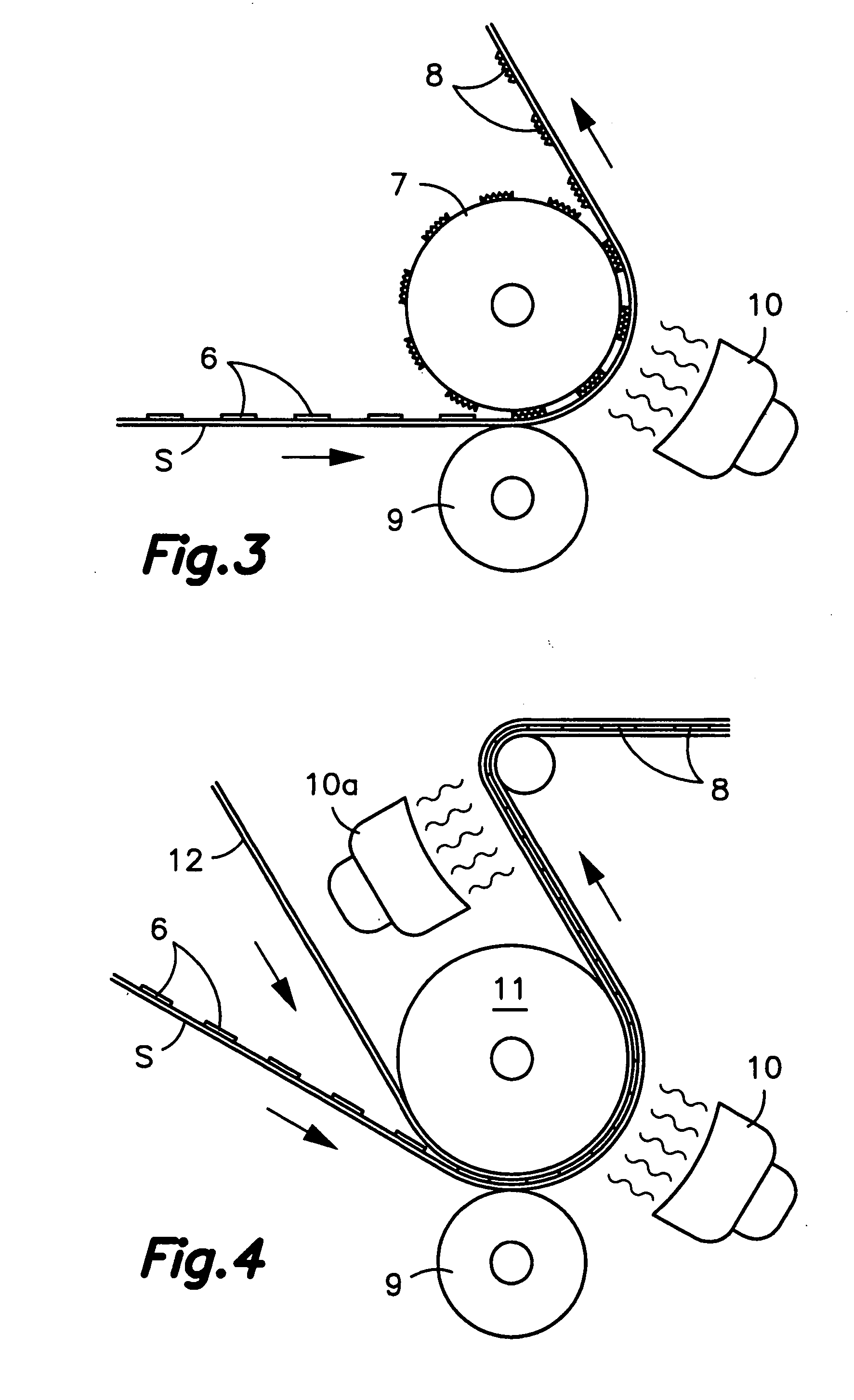

Improvements relating to wind turbine blade manufacture

ActiveUS20170241401A1Wastage of adhesive is eliminatedReduce weightEngine manufactureFinal product manufactureAdhesiveTurbine blade

Method of bonding a shear web (50) to a wind turbine blade shell (75) and the obtained blade, wherein the shear web (50) comprises a web and a mounting flange (56) oriented transverse to the web (50). The method involves: providing a seal (66, 68) on the mounting flange (56) of the shear web (50) such that when the mounting flange (56) is positioned against the blade shell (75), a cavity (76) is defined by the seal between the mounting flange (56) and the blade shell (75). The air of the cavity (76) is then evacuated and adhesive is injected into the cavity (76). The use of pieces (80) to keep the distance between the mounting flange (56) and the blade shell (75) is preferred.

Owner:VESTAS WIND SYST AS

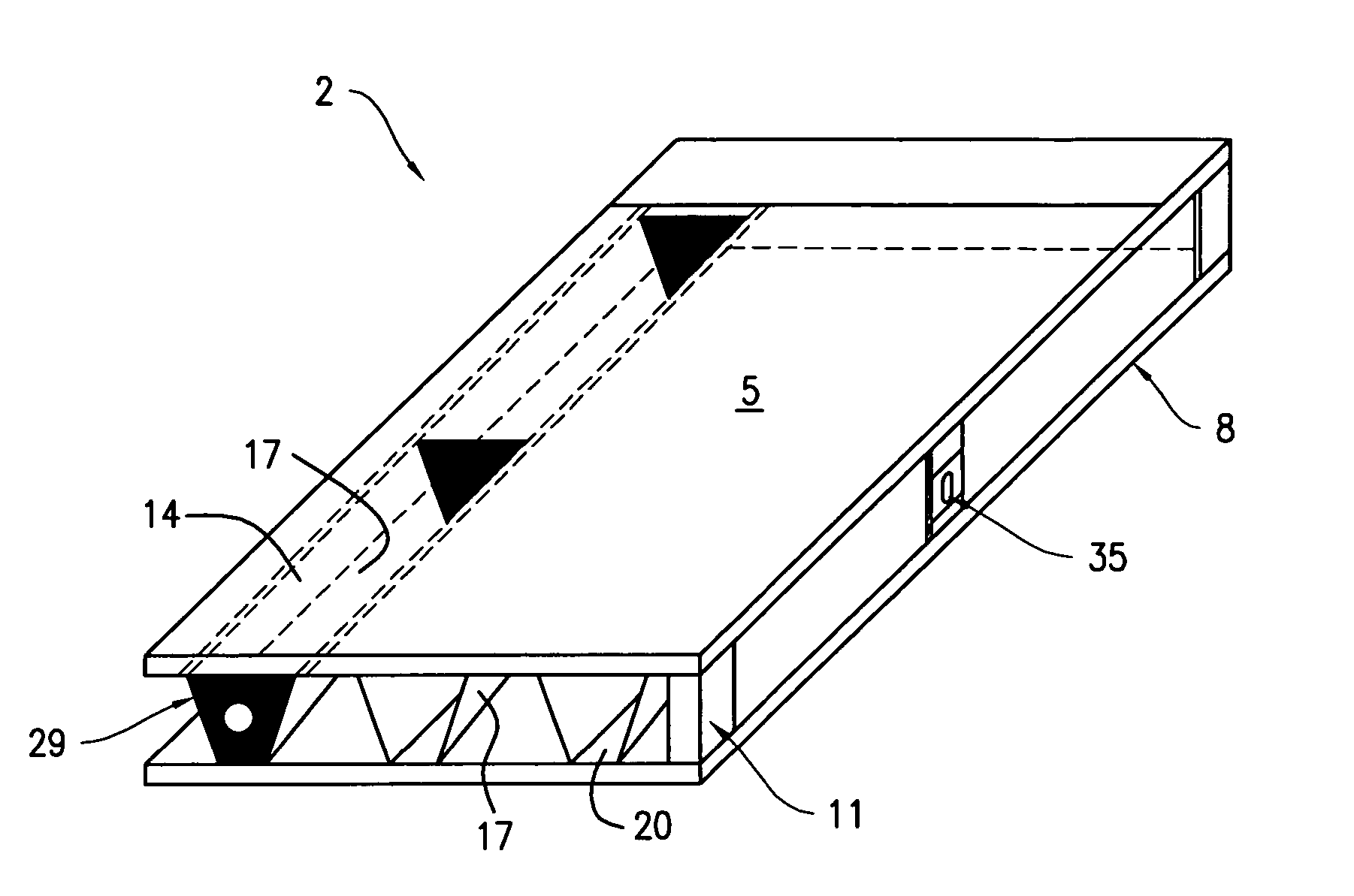

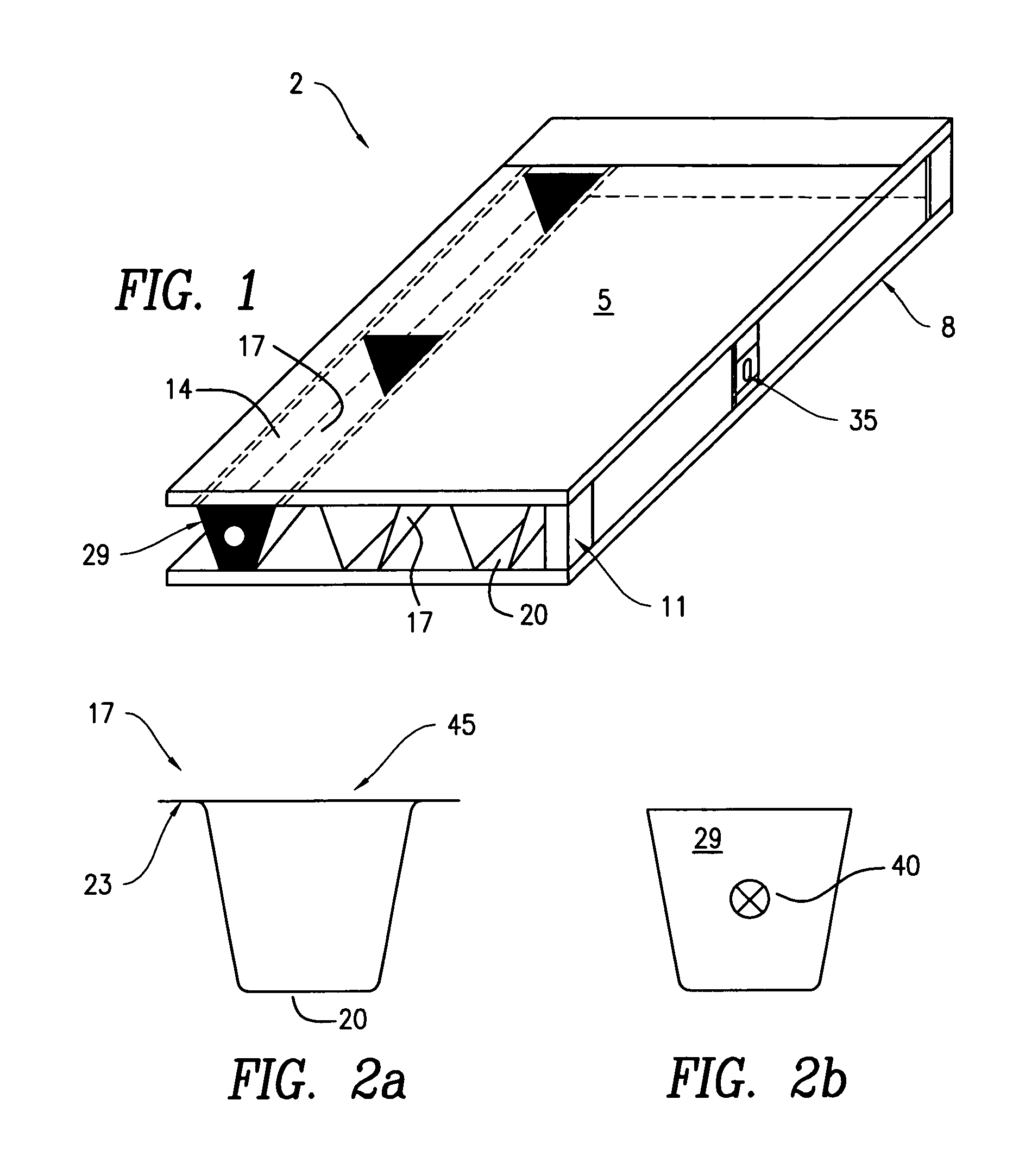

Composite steel-wood floor structure

Owner:HUBER ENGINEERED WOODS

Accelerated and Toughened Two-Part Epoxy Adhesives

InactiveUS20170335147A1Accelerate buildingHigh peel strengthMacromolecular adhesive additivesEpoxy resin adhesivesGlass fiberFiber

A 2K epoxy adhesive is provided that has rapid cure time and good strength characteristics. Both the epoxy resin composition and the hardener composition of the 2K epoxy comprise a reactive toughener. Such adhesives are useful in the manufacture and / or repair of large machinery (e.g., automobiles), and are useful for bonding like or unlike materials, such as metal and composites (e.g., carbon fiber or glass fiber composites).

Owner:DOW GLOBAL TECH LLC

Photocuring methods and articles prepared therefrom

Owner:EASTMAN KODAK CO

Combined foaming agent, hard polyurethane foam and manufacturing method of hard polyurethane foam

The invention provides a combined foaming agent. The combined foaming agent comprises, by mass, 1-9 parts of cyclopentane, 1-5 parts of isopentane and 2-30 parts of HFC-245fa. The hard polyurethane foam prepared by adopting the combined foaming agent comprises, by mass, 100 parts of combined polyether, 10-26 parts of the combined foaming agent and 120-150 parts of isocyanate. The invention also provides a manufacturing method of the hard polyurethane foam. The above foaming technology effectively reduces the heat conduction coefficient of the polyurethane foam, and reduces the energy consumption of a freezer; the strength of the foam with same density is enhanced, and the density of the foam required by the freezer is reduced, so the injection amount of the whole freezer is reduced, the raw material waste is reduced when the demand of the freezer is a certain amount, production of the hard polyurethane foam difficult to treat is reduced, and pollution to environment is reduced; and the solidification time of the foam is shortened by 10-15%, and the production efficiency is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

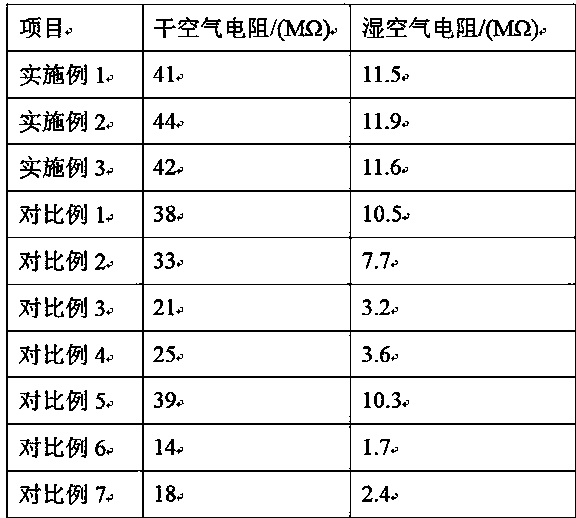

Preparation method of one-component oxime transparent silicone adhesive

ActiveCN102443375AAppearance ControlReduce the failure rateNon-macromolecular adhesive additivesGas phaseOmega

The invention discloses a preparation method of a one-component oxime transparent silicone adhesive. According to the preparation method, white oil is divided into two parts for feeding. One part of the white oil firstly reacts with alpha, omega-dihydroxy polydimethylsiloxane. Thus, viscosity of base rubber can be appropriately reduced; severe wearing of equipment can be avoided; the resistance of the product will not be greatly reduced after the addition of gas-phase silica; and the gas phase silica powder can be dispersed uniformly. The other part is added after the reaction so as to make the product appearance more uniform, smoother and more exquisite. In the meanwhile, the curing time of the product is obviously accelerated, thus substantially minimizing construction time and raising construction efficiency.

Owner:RIFENG TECH CO LTD

Composition and a process for the preparation of coloured holograms

InactiveUS20060275669A1Fast cure timeReduced hardening (cure) timeHalographic mechanical componentsSubstrate with hologramLacquerPolymer chemistry

A process of producing a coloured hologram is provided. The process comprises preparing a lacquer composition comprising a UV / EB-hardening acrylic resin and at least one pigment, said resin providing instant hardening upon irradiation; applying said lacquer composition to selected areas of a flexible support by means of a rotary printing machine; shaping the applied lacquer to impart in it a relief that forms a hologram; and irradiating said shaped areas with a UV light / EB radiation.

Owner:NEOPACK

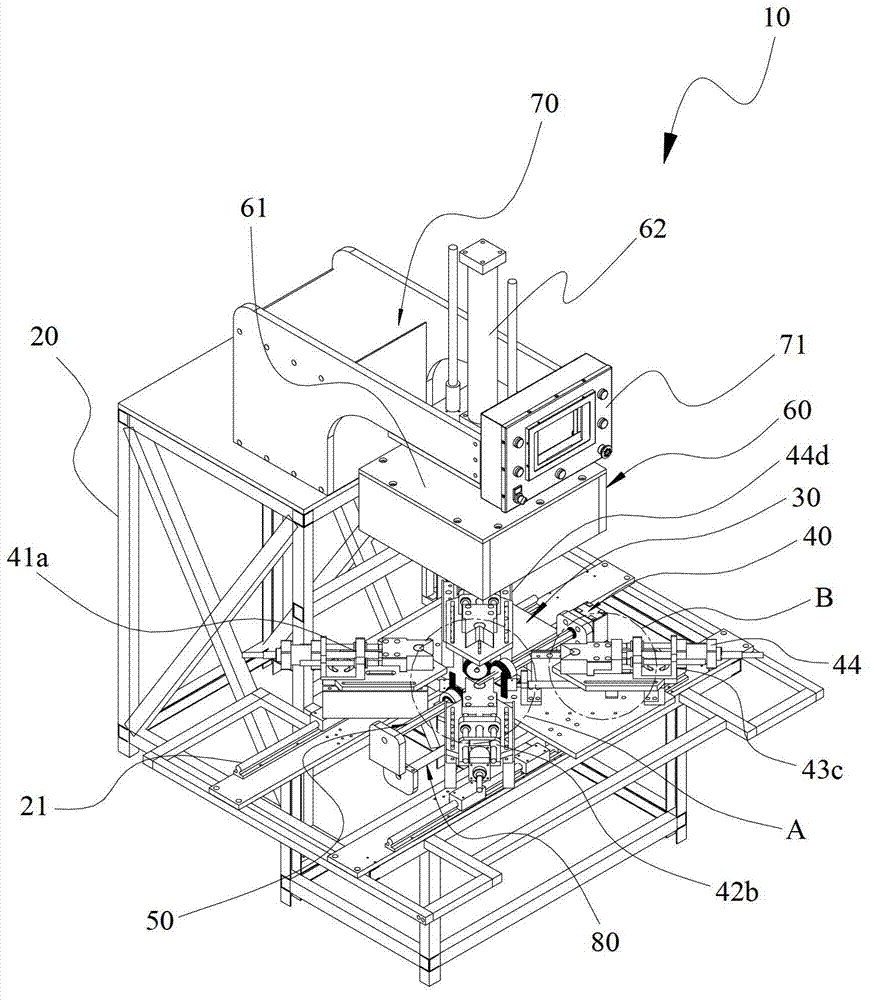

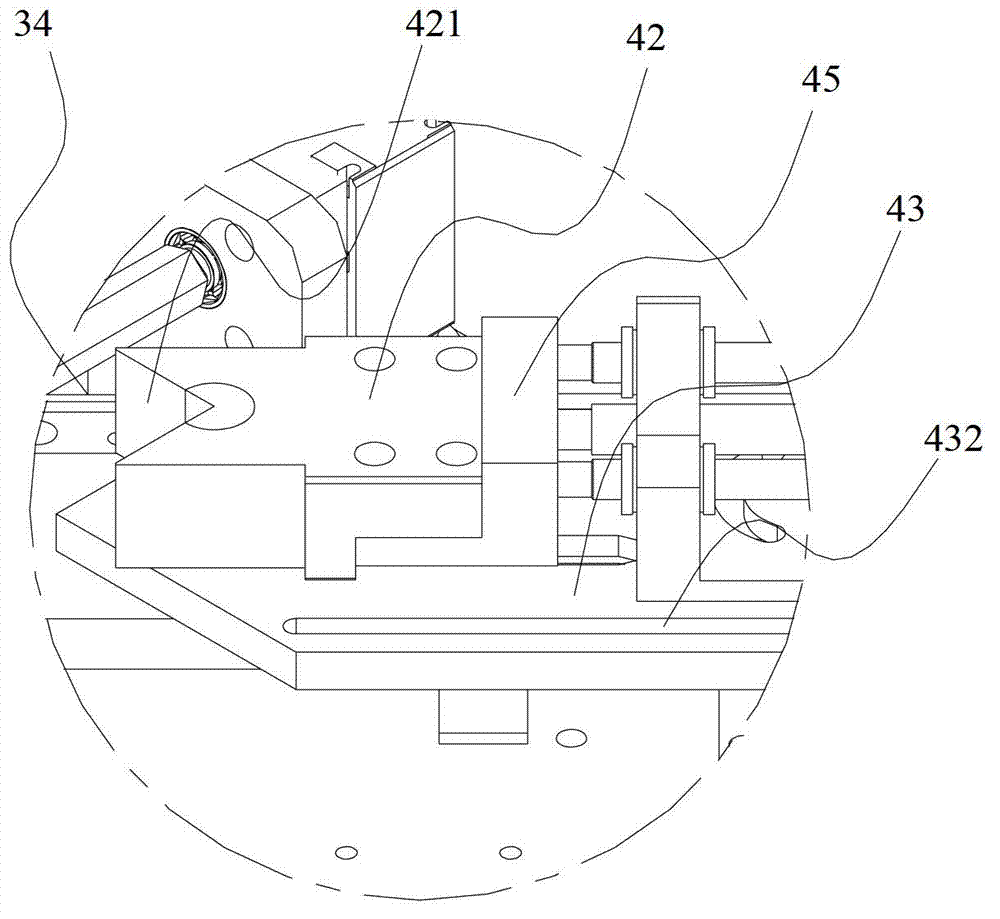

Polygon box body molding bonding machine and box body molding method using the same

InactiveCN103085324AFast formingQuality assuranceBox making operationsPaper-makingControl systemMechanical engineering

The invention provides a polygon box body molding bonding machine which comprises a rack, a working table, a box body clamp device, a synchronous feeding mechanism, a glue drying device and a control system. The working table is arranged on the rack. The box body clamp device comprises a plurality of clamping head devices which are equidistantly arranged on the working table at intervals along the circumference of the working table and are used for clamping boards in a telescopic mode so as to enable a plurality of boards to be clamped to be of a polygon box body structure. The synchronous feeding mechanism is respectively connected with the plurality of clamping head devices and drives the plurality of clamping head devices to synchronously move forward or draw back in an operable mode. The glue drying device is arranged over the working table and is close to polygon box bodies coated with glue or far from the polygon box bodies with dried glue in an operable mode. The control system is respectively and electrically connected with the clamping head devices and the glue drying device. According to the polygon box body molding bonding machine, just the boards forming the polygon box bodies are placed on the box boy clamp device and then can be extruded to form the polygon box bodies in a bonding mode through the control system. The invention further provides a box body molding method.

Owner:DONGGUAN ZHANNENG INFORMATION TECH

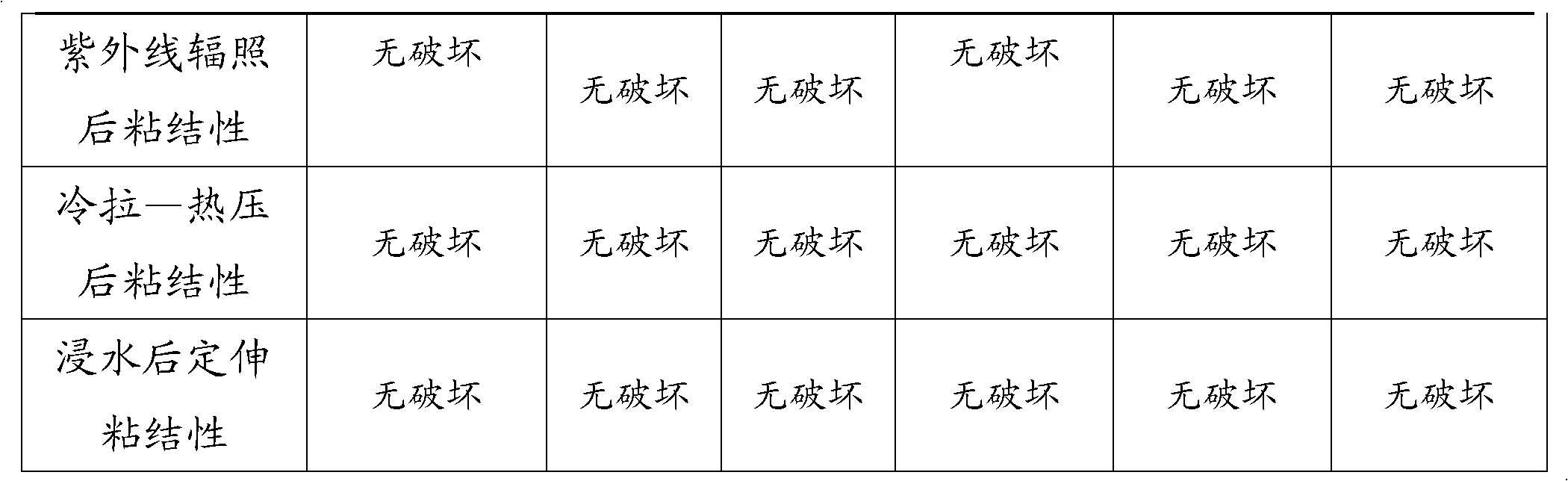

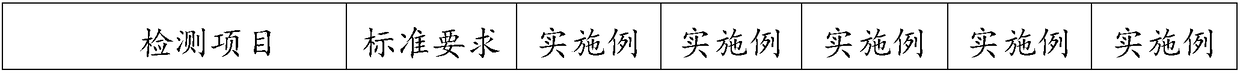

Back side pressure-resistant waterproof coating material for leaking stoppage and seepage resistance of back side and preparation method thereof

The invention discloses a back side pressure-resistant waterproof coating material for leaking stoppage and seepage resistance of a back side and a preparation method thereof. The back side pressure-resistant waterproof coating material is prepared from the following materials in parts by weight: 400 to 500 parts of Portland cement, 350 to 480 parts of sand filler, 20 to 50 parts of latex powder,5 to 10 parts of waterproof agent, 10 to 50 parts of coagulation accelerator, 20 to 50 parts of active master batch, 2 to 10 parts of thixotropic agent, 2 to 5 parts of fiber, 0 to 2 parts of cellulose ether, 1 to 3 parts of defoaming agent and 1 to 10 parts of pigment. The back side pressure-resistant waterproof coating material for the leaking stoppage and the seepage resistance of the back side, disclosed by the invention, is firmly adhered to a fundamental plane and is high in bending strength and compression strength, good in seepage resistance, excellent in aging resistance, long in service life, low in shrinkage rate and absorption rate and excellent in waterproof performance.

Owner:南通科顺建筑新材料有限公司

Anti-ultraviolet contact lens

InactiveCN101508751AFast curing timeDoes not affect the processOptical partsOptical elementsUltravioletUv absorber

An anti-UV contact lens mainly consists of a main substrate and an anti-UV material. The main substrate is hydroxyethylmethacrylate (HEMA), the anti-UV material contains an UV blocker and a photo initiator, wherein, the photo initiator basically consists of 2,4,6-trimethylbenzoyldiphenylphosphine oxide and benzoylformate initiator. The anti-UV contact lens can increase productivity without changing the original process, accelerate curing time of the UV blocker, and reduce defective rate.

Owner:GUODONG ENTERPRISE MANAGEMENT HLDG

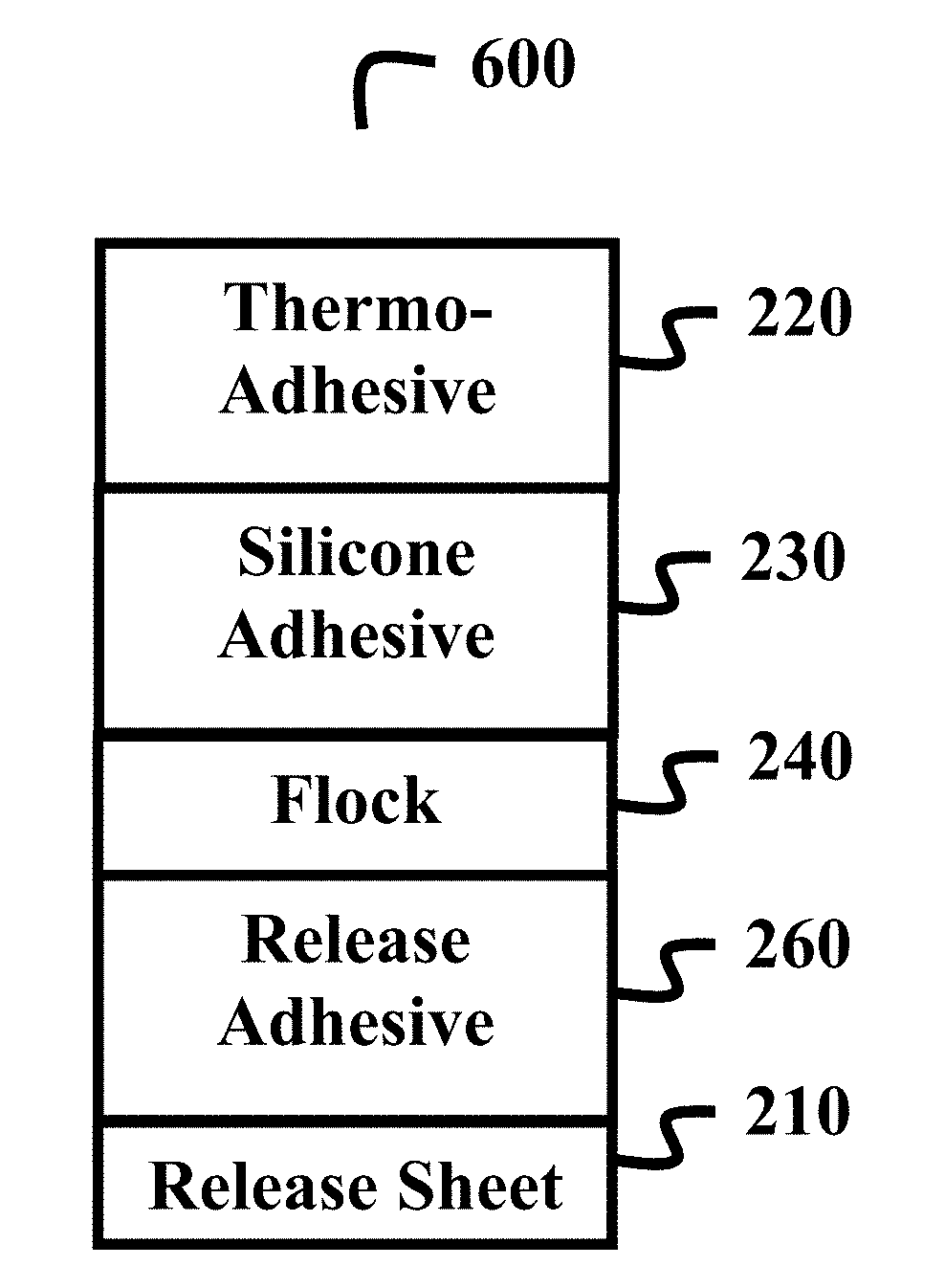

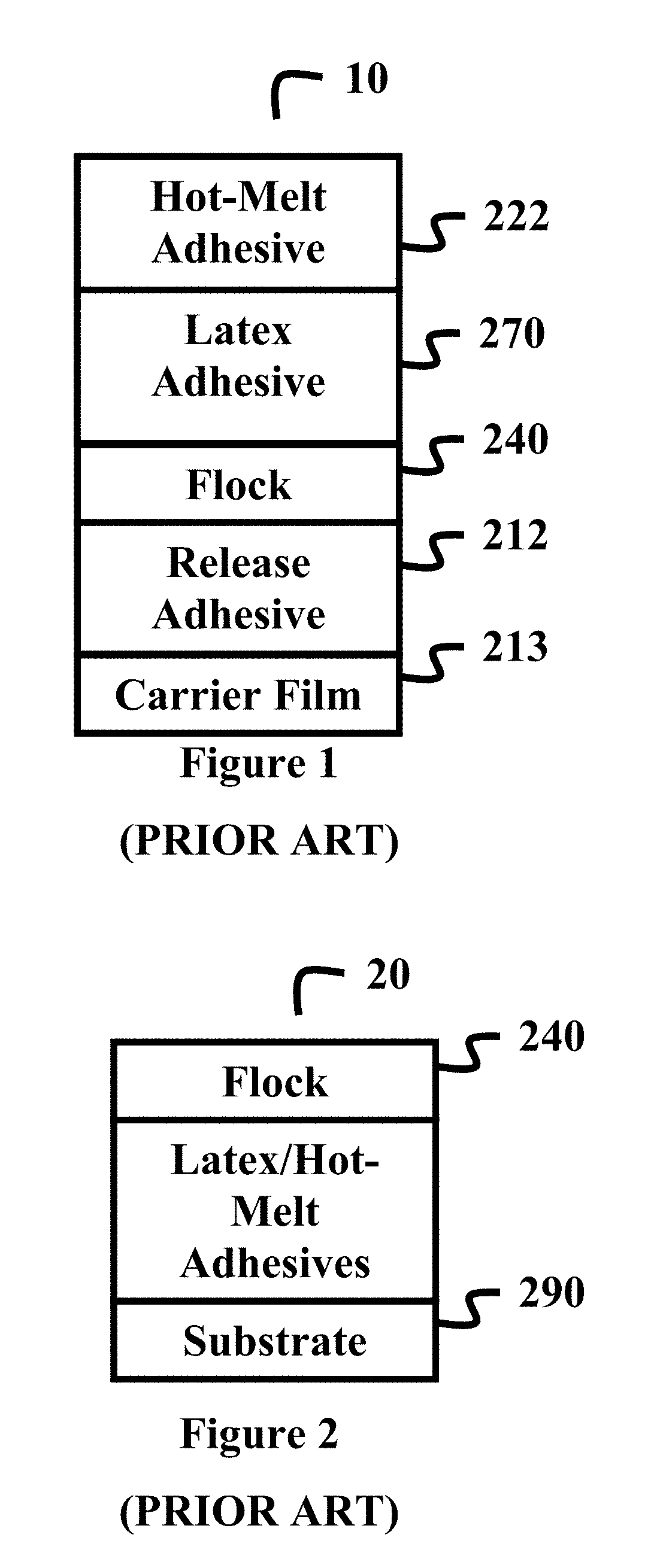

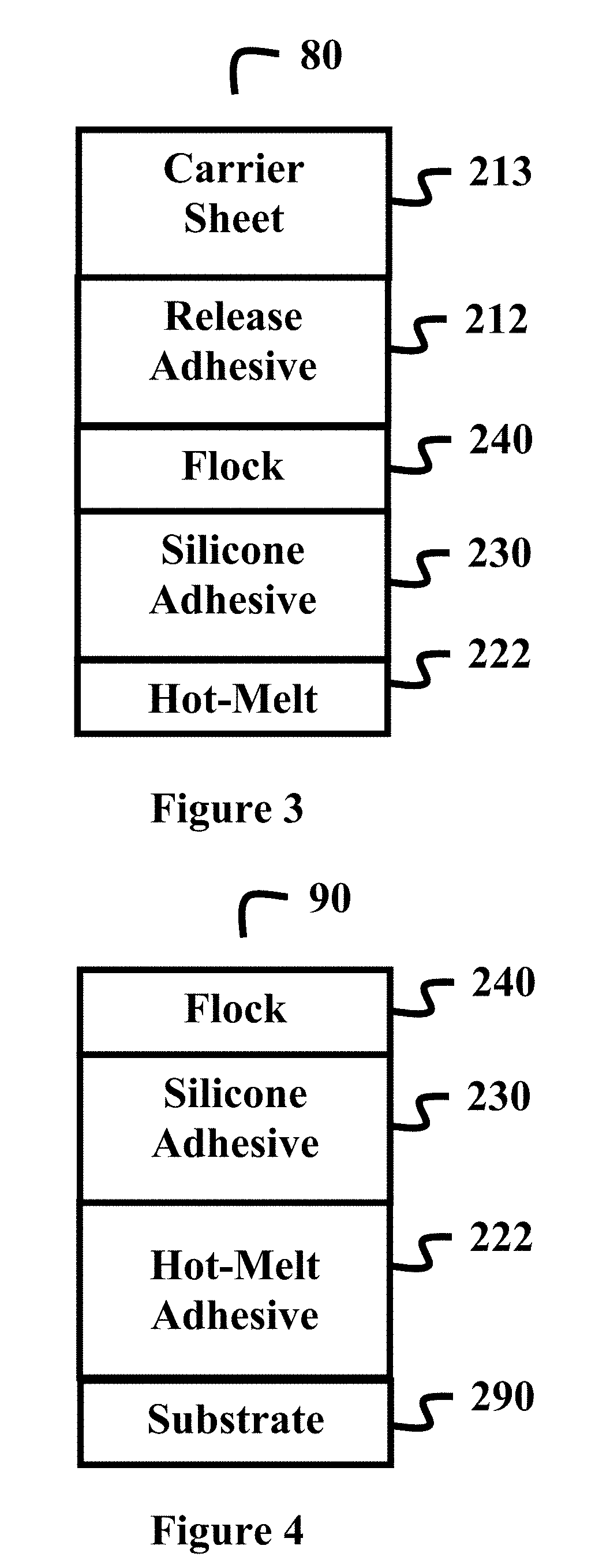

Flocked products having a silicone adhesive composition and methods of making and using the same

InactiveUS20180171192A1Fast curing timeSoft touchAdhesive processesPretreated surfacesPolymer scienceSilicone adhesive

Owner:SANDCORE TECH LLC +1

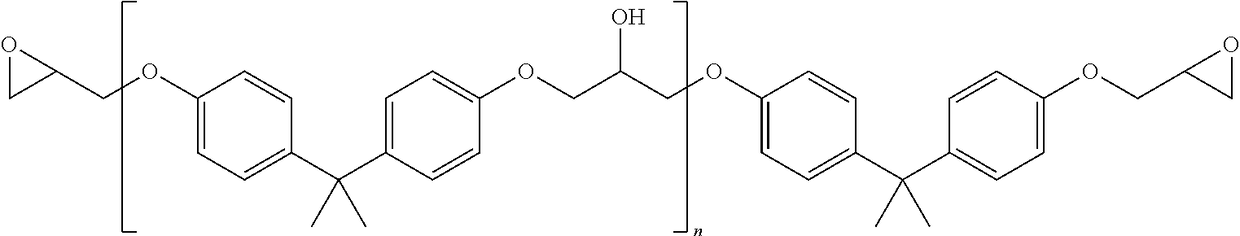

Antistatic wear-resistant epoxy terrace coating

InactiveCN109836969AImprove wear resistanceImprove antistatic performancePolyurea/polyurethane coatingsEpoxy resin coatingsWater basedWear resistant

The invention mainly relates to the technical field of epoxy terrace processing, and discloses an antistatic wear-resistant epoxy terrace coating which is prepared from the following raw materials: water-based bisphenol A epoxy resin, water-based UV resin, modified water-based polyurethane, calcium lignosulfonate, mica powder, hydroxypropyl methyl cellulose, fumed silica, negative ion powder, nano-silver and water; the antistatic wear-resistant epoxy terrace coating provided by the invention has the advantages that the paint film is smooth, the adhesive force is strong, the strength is high, the wear resistance is high, the generation of static electricity can be effectively prevented, the curing time is short, toxic components are not volatilized, the safety of the human body and the environment is guaranteed, the variety of the epoxy terrace coating on the market is increased, and the requirements of consumers are met; the water-based bisphenol A epoxy resin is placed in a reaction kettle for slow heating, and vacuum stirring is carried out, so that the activity of the water-based bisphenol A epoxy resin can be improved, and the subsequent preparation process is shortened.

Owner:严勇

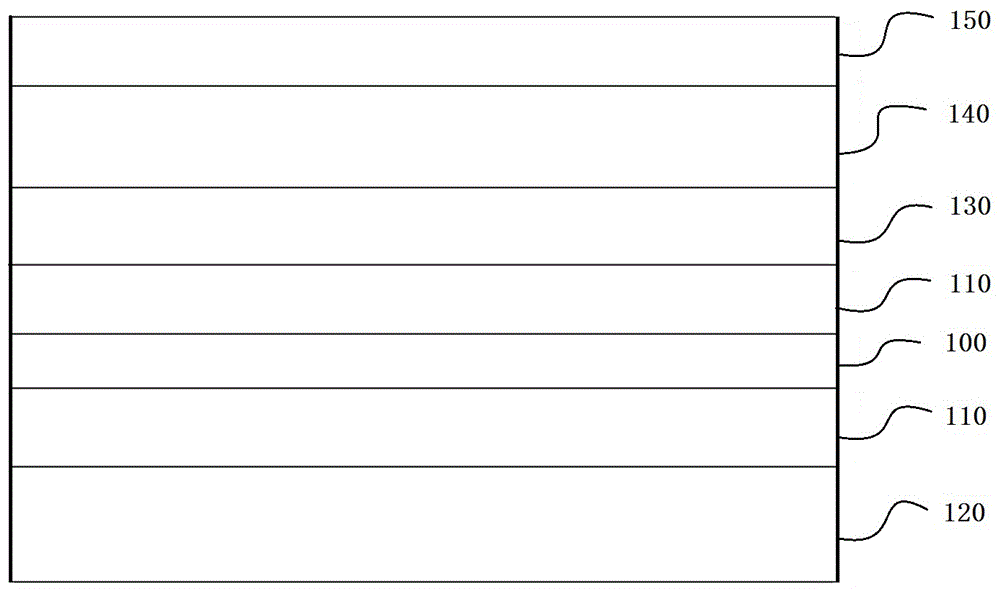

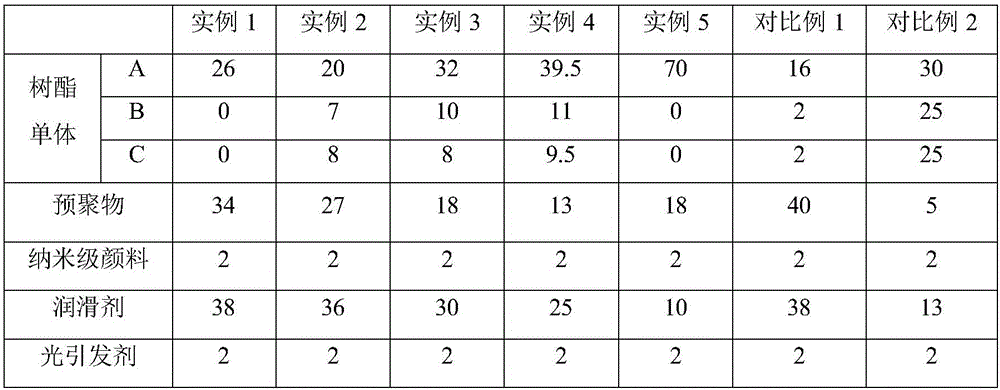

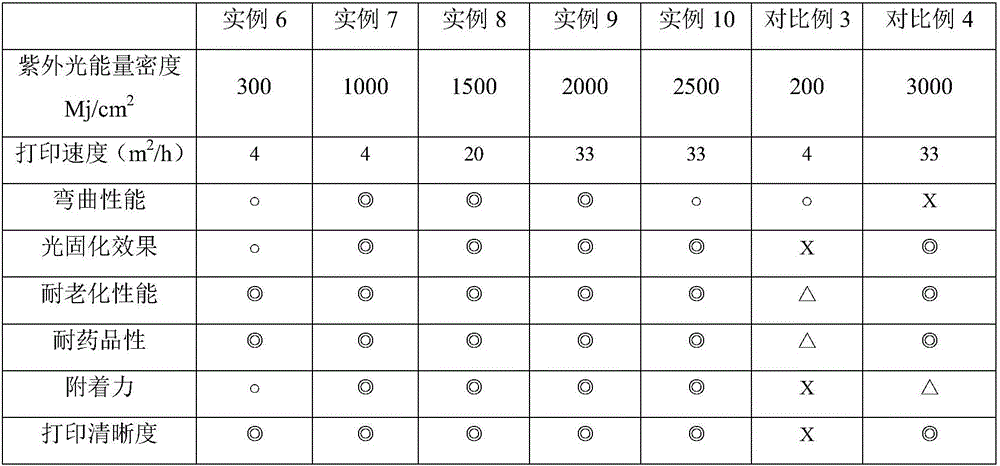

High-definition colorful three-dimensional touch decorative color board and manufacturing method thereof

The invention discloses a high-definition colorful three-dimensional touch decorative color board and a manufacturing method thereof. The high-definition colorful three-dimensional touch decorative color board comprises a metal plate base layer, a pretreatment layer, a primer layer, a printing layer and a protective film layer which are sequentially connected from bottom to top, wherein a formula of oil adopted by the printing layer is prepared from the following raw materials in parts by weight: 26 to 70 parts of resin monomer, 10 to 70 parts of prepolymer, 1 to 15 parts of nano-grade pigment, 1 to 30 parts of wax wetting agents, 1 to 15 parts of photoinitiator; the resin monomer is at least one of polyester acrylate, epoxy acrylate or neopentyl glycol propoxylate diacrylate. The invention realizes a method for directly printing patterns on a metal plate by using printing equipment.

Owner:青岛河钢复合新材料科技有限公司 +1

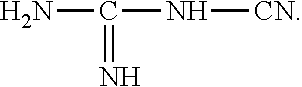

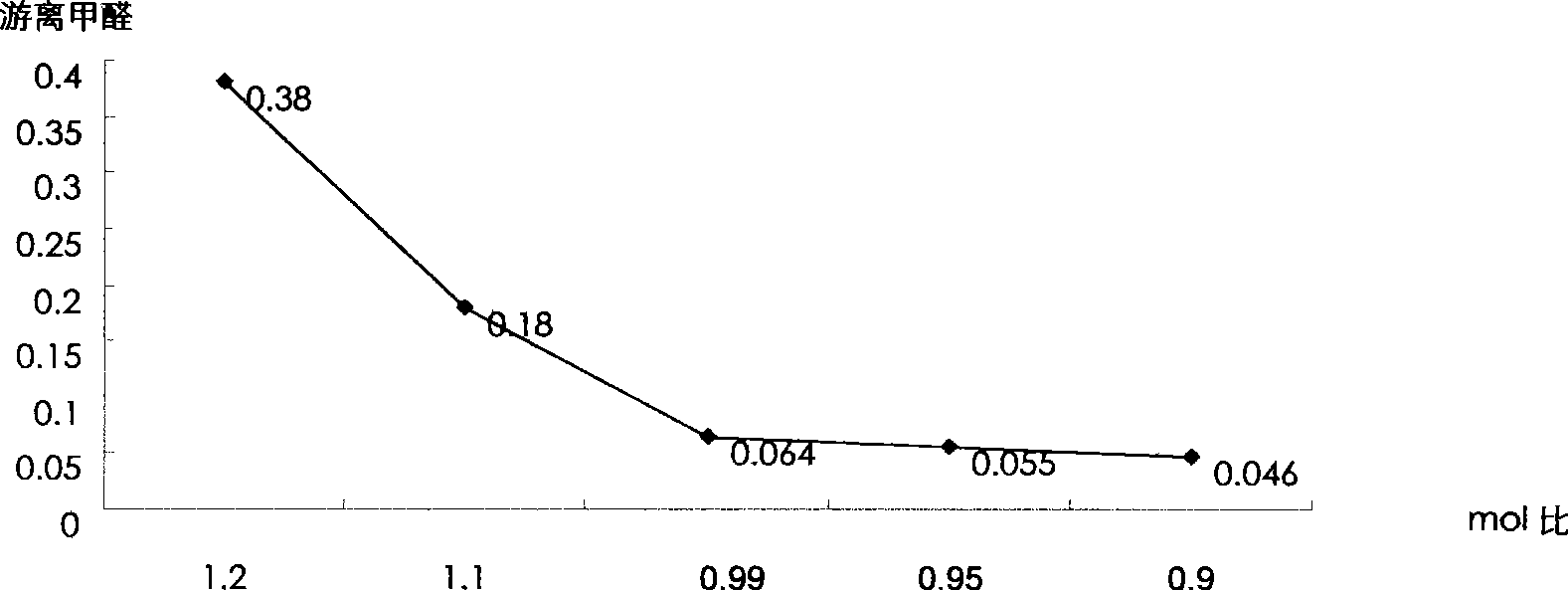

Synthetic resin adhesive for E1 grade fibreboard

ActiveCN101392167AReduce dosageImprove performanceWood working apparatusAldehyde/ketone condensation polymer adhesivesFiberAdhesive

The invention discloses a synthetic resin adhesive applied to an E1-class fiber board. The synthetic resin adhesive comprises the following components calculated by mass: 1050kg to 1650kg of melamine, 8300kg to 8650kg of urea, 11500kg to 12500kg of formaldehyde, 30kg to 40kg of borax and appropriate acid and alkali. The synthetic resin adhesive is obtained by reaction carried out to the materials. The synthetic resin adhesive applied to the E1-class fiber board manufactured by the formulation has free formaldehyde lower than or equal to 0.1 percent, which meets the requirement of the E1-class synthetic resin adhesive; meanwhile, the synthetic resin adhesive has good comprehensive performance and notably increased waterproof performance. The synthetic resin adhesive, on the premise of guaranteeing the comprehensive performance of the adhesive, can lower the manufacturing cost by about RMB 100 per ton by optimizing total mole ratio and decreasing the usage of melamine, thereby having good economic efficiency.

Owner:DAYA WOOD IND JIANGXI

High temperature resistant polyurethane complex adhesive

ActiveCN102732205AImprove yieldHigh bonding strengthPolyureas/polyurethane adhesivesPlastic recyclingPolyesterPolyol

The invention discloses a high temperature resistant polyurethane complex adhesive, which belongs to the technical field of complex adhesives. The high temperature resistant polyurethane complex adhesive comprises the following substances by weight: 160 parts of methylbenzene, 150 parts of dimethyl carbonate, 587.5 parts of aromatic polyester polyol, 30 parts of polyphthalate polyol ester, 1.63 parts of trimethylolpropane, 65 parts of methylbenzene-2,4-diisocyanate, 1.5 parts of catalyst CAT S102, 1.2 parts of 1,4-butanediol, 1.2 parts of 1,3-butanediol, 0.15 part of antioxidant and 3.02 parts of organic bismuth. The complex adhesive, provided by the invention, has the advantages of large binding strength, strong high temperature resistance, short curing time of chemical curing, and capability of saving energy, optimizing environment and reaching standards of export products of European Union.

Owner:ZHEJIANG DUOBANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com