Back side pressure-resistant waterproof coating material for leaking stoppage and seepage resistance of back side and preparation method thereof

A technology of waterproof coating and water-back surface, which is applied in the field of building waterproof materials, which can solve the problems of easy-aging adhesion of materials, affecting the appearance of buildings, and difficult construction methods, etc., achieves excellent resistance to acidic medium erosion, and improves operational performance , fast drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

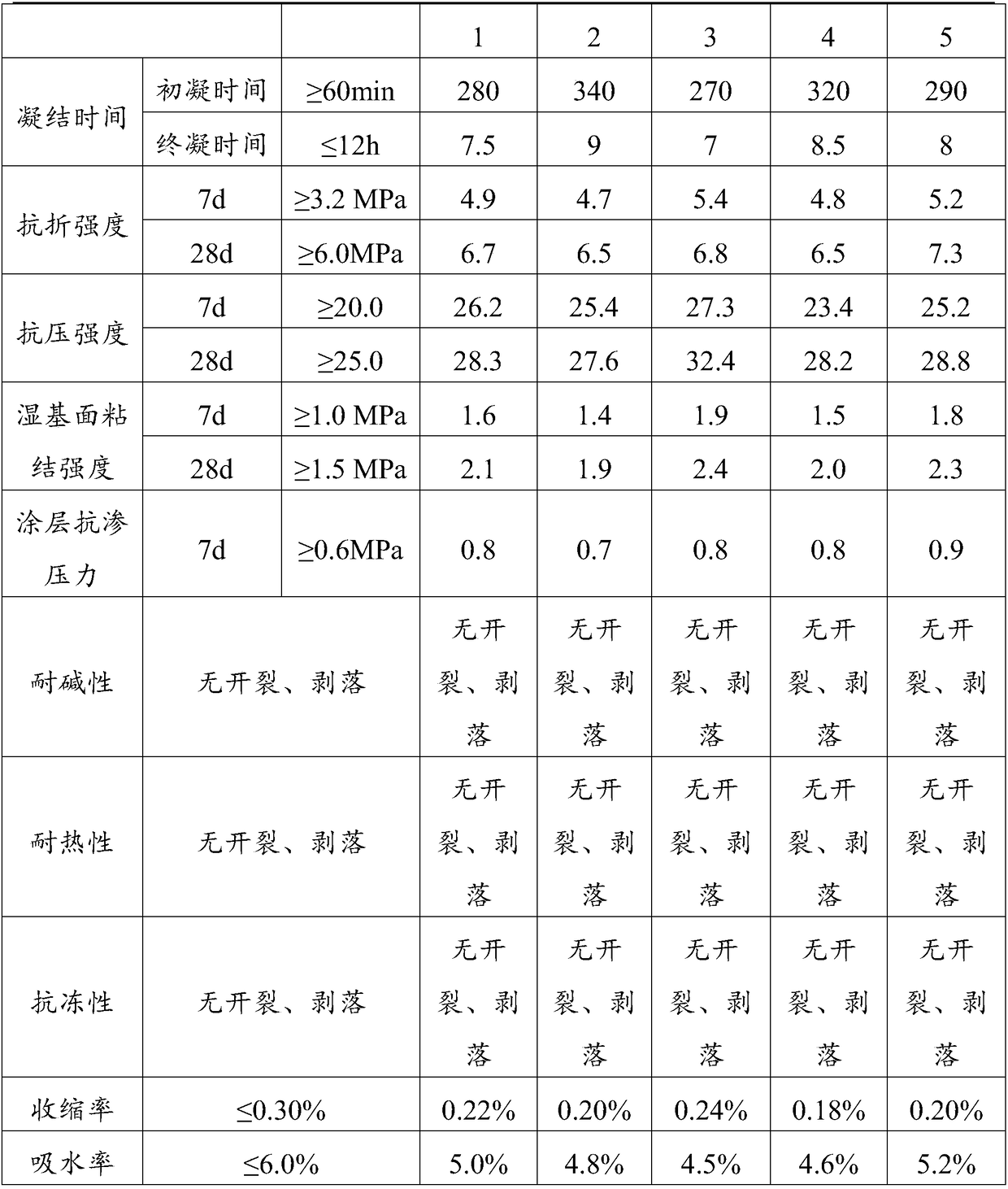

Embodiment 1

[0039] A backwater pressure waterproof coating used for plugging and anti-seepage on the backwater surface, prepared from the following raw materials in parts by weight:

[0040] Portland cement (52.5R Portland cement) 450 parts;

[0041] 400 parts of quartz sand;

[0042] 26.5 parts of VAE rubber powder;

[0043] 8.5 parts of hydrophobic silane-based powder waterproofing agent;

[0044] Coagulant (DENKA SC-1) 25 parts;

[0045] Active masterbatch (Benike 88) 28.5 parts;

[0046] 5 parts of calcium bentonite;

[0047] 3 parts polypropylene fiber;

[0048] 1 part of cellulose ether;

[0049] 2 parts of defoamer;

[0050] 5 parts of inorganic powder pigments.

[0051] The preparation process of the back water pressure waterproof coating for plugging and anti-seepage on the back water surface is as follows:

[0052] (1) According to the formula quantity, Portland cement and quartz sand are accurately weighed and put into the batching bin;

[0053] (2) Accurately weigh V...

Embodiment 2

[0057] A backwater pressure waterproof coating used for plugging and anti-seepage on the backwater surface, prepared from the following raw materials in parts by weight:

[0058] Portland cement (52.5R Portland cement) 410 parts;

[0059] 470 parts of quartz sand;

[0060] 21.5 parts of VAE rubber powder;

[0061] 9.5 parts of hydrophobic silane-based powder waterproofing agent;

[0062] Coagulant (DENKA SC-1) 10.5 parts;

[0063] Active masterbatch (Benike 88) 50 parts;

[0064] 10 parts of calcium-based bentonite;

[0065]5 parts of polypropylene fiber;

[0066] 1 part of cellulose ether;

[0067] 3 parts of defoamer;

[0068] 1 part of inorganic powder pigment.

[0069] The preparation method of the back water pressure waterproof coating for plugging and anti-seepage on the back water surface is the same as that in Example 1.

Embodiment 3

[0071] A backwater pressure waterproof coating used for plugging and anti-seepage on the backwater surface, prepared from the following raw materials in parts by weight:

[0072] Portland cement (52.5R Portland cement) 500 parts;

[0073] 360 parts of quartz sand;

[0074] 50 parts of VAE rubber powder;

[0075] 5 parts of hydrophobic silane-based powder waterproofing agent;

[0076] Coagulant (DENKA SC-1) 48.5 parts;

[0077] 20 parts of active masterbatch (Benike 88);

[0078] 2.5 parts of calcium-based bentonite;

[0079] 5 parts of polypropylene fiber;

[0080] 2 parts of cellulose ether;

[0081] 1 part of defoamer;

[0082] 6 parts of inorganic powder pigments.

[0083] The preparation method of the back water pressure waterproof coating for plugging and anti-seepage on the back water surface is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com