Preparation method of one-component oxime transparent silicone adhesive

A one-component, silicone adhesive technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of unsatisfactory appearance, insufficient shear force, increase cost, etc., and achieve unqualified appearance. The effect of reducing the rate, reducing the construction time and improving the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

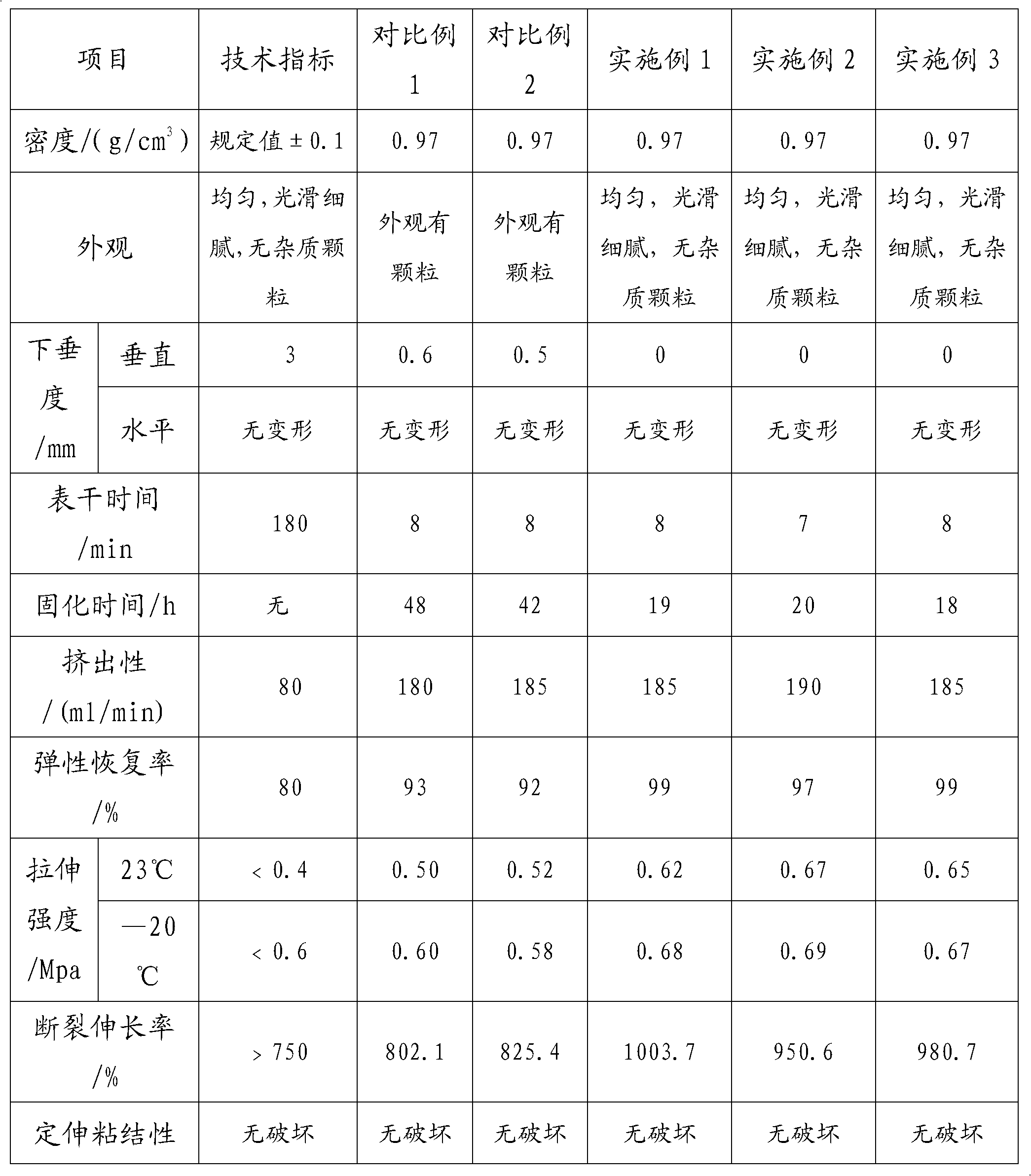

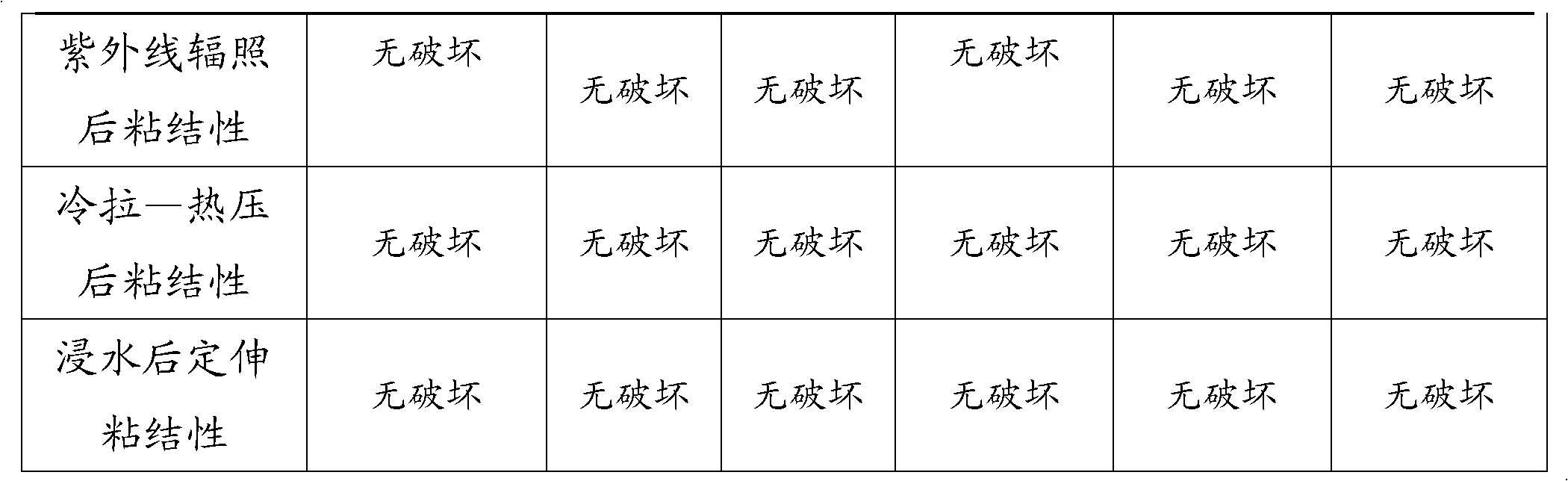

Examples

Embodiment 1

[0048] A preparation method of a one-component ketoxime transparent silicone adhesive, comprising the following steps:

[0049] (1) Put 100 parts of 80000 centipoise α, ω-dihydroxy polydimethylsiloxane and 60 parts of white oil (accounting for 76.9% of the required amount of white oil) and 0.04 parts of color paste into the 1000L high-speed dispersion planet Mixer, stirring at a speed of 300 rpm for 10 minutes, while passing cooling water into the jacket of the planetary mixer, the temperature of the cooling water is 10°C, and vacuumize to -0.1MPa;

[0050] (2) Add 15 parts of cross-linking agent by blowing nitrogen to release the vacuum, stir at 300 rpm for 10 minutes, and keep the vacuum degree at -0.1MPa during the stirring process;

[0051] (3) Nitrogen was released to remove the vacuum, and 1.5 parts of γ-(2,3-glycidyloxy)propyltriethoxysilane and 0.15 parts of dibutyltin dilaurate were added, and stirred at a speed of 300 rpm for 10 minutes. Keep the vacuum at -0.1MPa; ...

Embodiment 2

[0055] A preparation method of a one-component ketoxime transparent silicone adhesive, comprising the following steps:

[0056] (1) Put 100 parts of 80000 centipoise α, ω-dihydroxy polydimethylsiloxane and 50.4 parts of white oil (accounting for 80% of the required amount of white oil) and 0.04 parts of color paste into the 1000L high-speed dispersion planet Mixer, stirring at a speed of 300 rpm for 10 minutes, while passing cooling water into the jacket of the planetary mixer, the temperature of the cooling water is 20°C, and vacuumize to -0.09MPa;

[0057] (2) Add 15 parts of cross-linking agent by blowing nitrogen to release the vacuum, stir at 300 rpm for 10 minutes, and keep the vacuum at -0.09MPa during the stirring process;

[0058] (3) Nitrogen was released to remove the vacuum, and 1.5 parts of γ-(2,3-glycidyloxy)propyltriethoxysilane and 0.15 parts of dibutyltin dilaurate were added, and stirred at a speed of 300 rpm for 10 minutes. Keep the vacuum at -0.09MPa;

[...

Embodiment 3

[0062] A preparation method of a one-component ketoxime transparent silicone adhesive, comprising the following steps:

[0063] (1) Put 100 parts of 80000 centipoise α, ω-dihydroxy polydimethylsiloxane and 48 parts of white oil (accounting for 70% of the required amount of white oil) and 0.04 parts of color paste into the 1000L high-speed dispersion planet Mixer, stirring at a speed of 300 rpm for 10 minutes, while passing cooling water into the jacket of the planetary mixer, the temperature of the cooling water is 30°C, and vacuumize to -0.08MPa;

[0064] (2) Add 15 parts of cross-linking agent by blowing nitrogen to release the vacuum, stir at 300 rpm for 10 minutes, and keep the vacuum at -0.08MPa during the stirring process;

[0065] (3) Nitrogen was released to remove the vacuum, and 1.5 parts of γ-(2,3-glycidyloxy)propyltriethoxysilane and 0.15 parts of dibutyltin dilaurate were added, and stirred at a speed of 300 rpm for 10 minutes. Keep the vacuum at -0.08MPa;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com