A kind of mould casting equipment and method that can realize three-dimensional pattern

A mold casting and three-dimensional pattern technology, which is applied in the field of mold casting equipment that can realize three-dimensional patterns, can solve problems such as high environmental requirements and staff requirements, complicated ordinary printing processes, and many production processes, so as to avoid production safety hazards, Effective control of product appearance and improvement of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

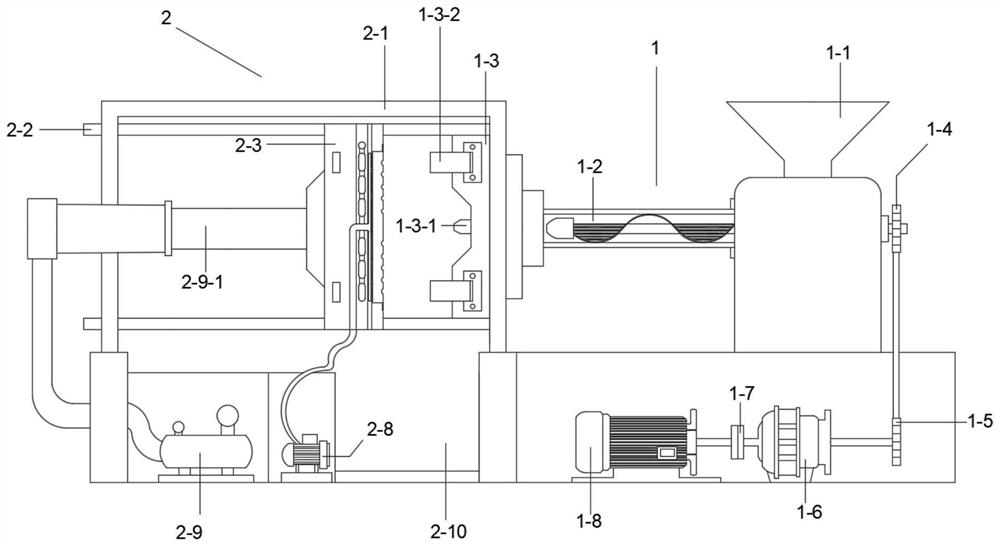

[0033] A mold pouring equipment and method capable of realizing three-dimensional patterns, including a feeding system 1 and a molding system 2;

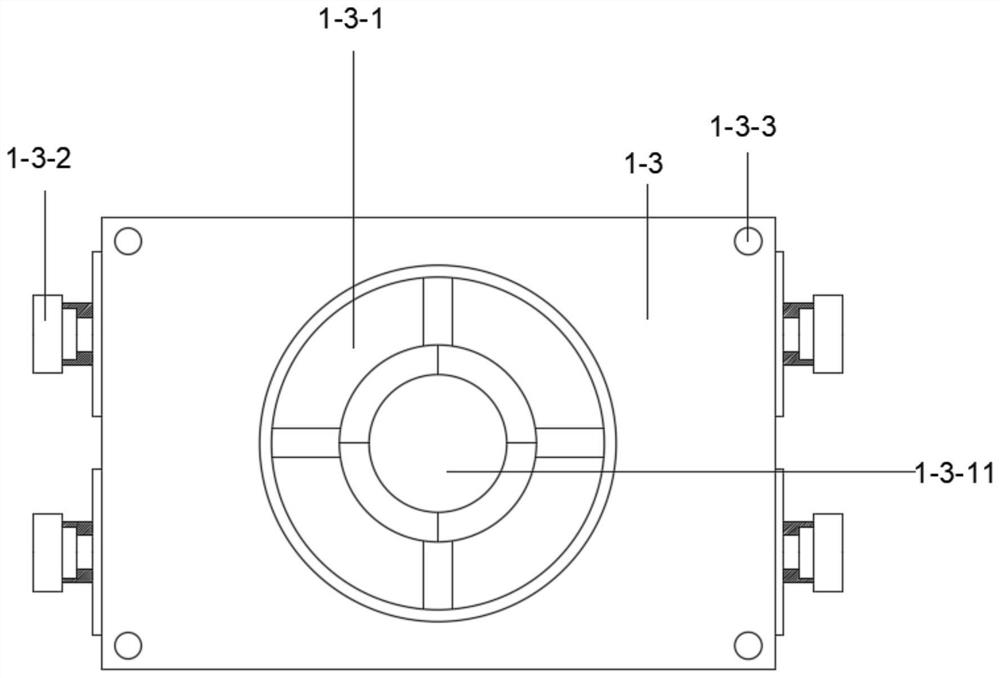

[0034] The feeding system 1 includes a locking mechanism 1-3, the molding system 2 includes a subject frame 2-1, and the locking mechanism 1-3 is fixed inside the main frame 2-1.

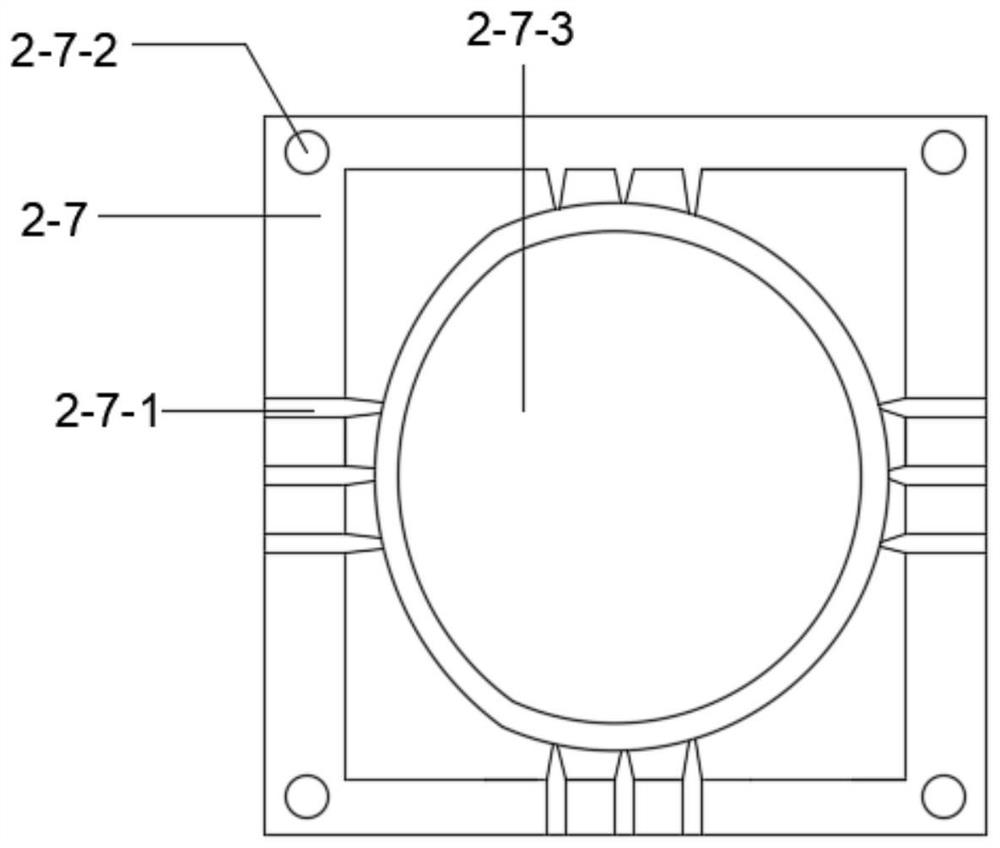

[0035] The molding system 2 also includes a mold 2-3, an ejector plate 2-6 and an ejector block 2-6-1, the ejector plate 2-6 is embedded in one side of the mold 2-3, and the ejector block 2-6 -1 is slidingly connected with the ejector plate 2-6. The main function of the ejector block 2-6-1 is to eject the molded product. Most equipment on the market uses ejector pins to eject products. The force surface is small, which is easy to cause damage to the surface of the molded pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com