Patents

Literature

182 results about "3d patterning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

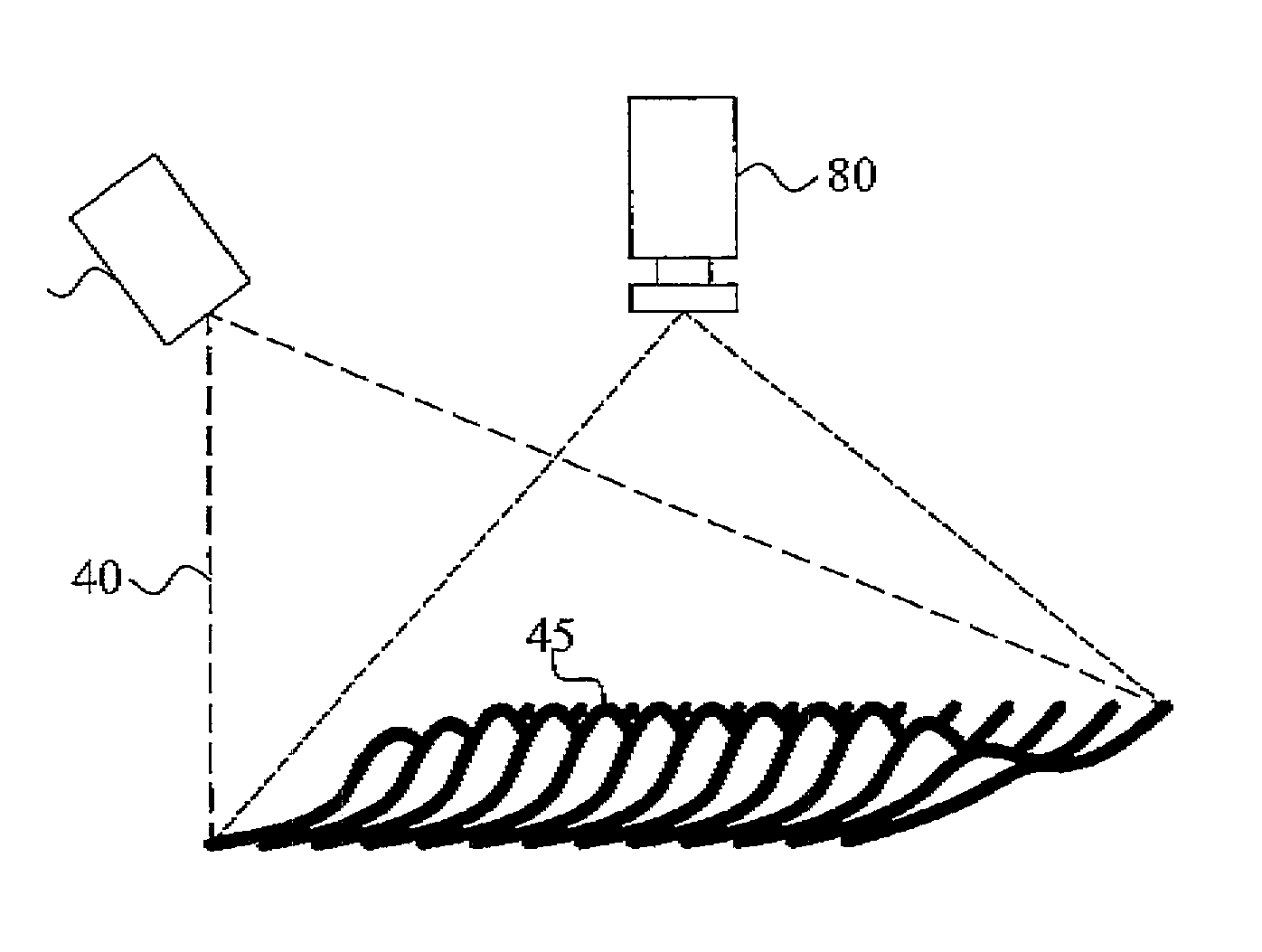

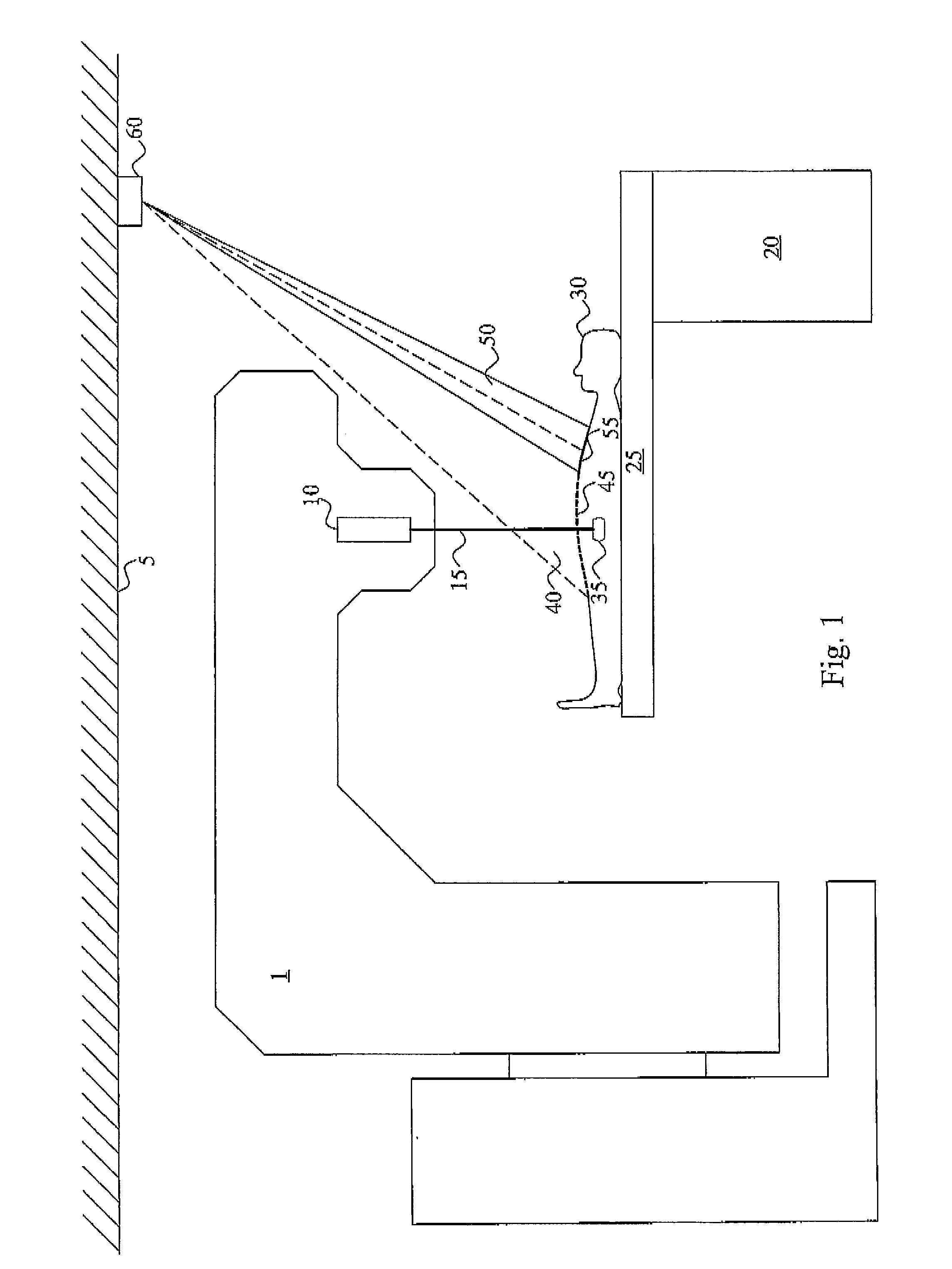

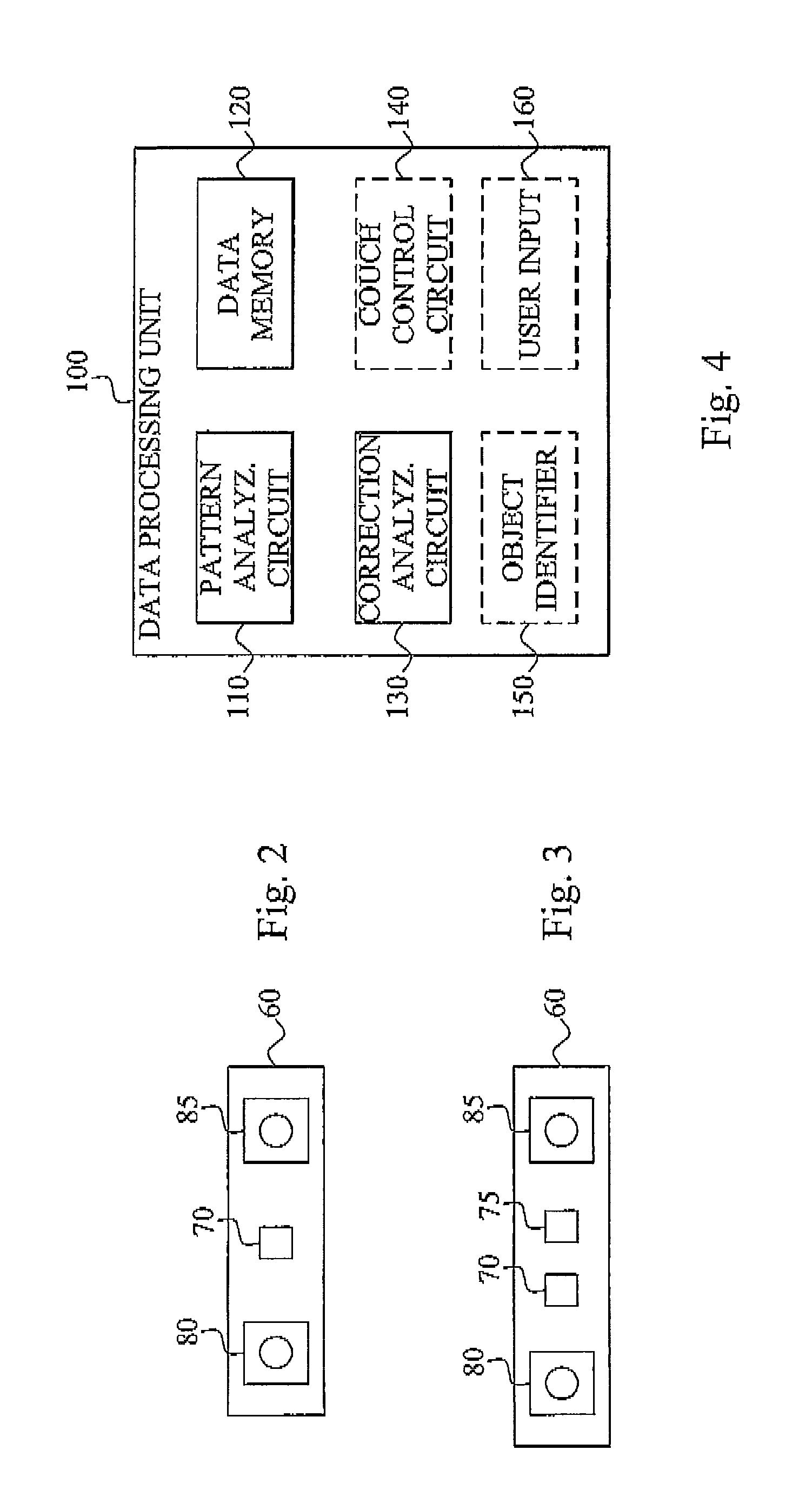

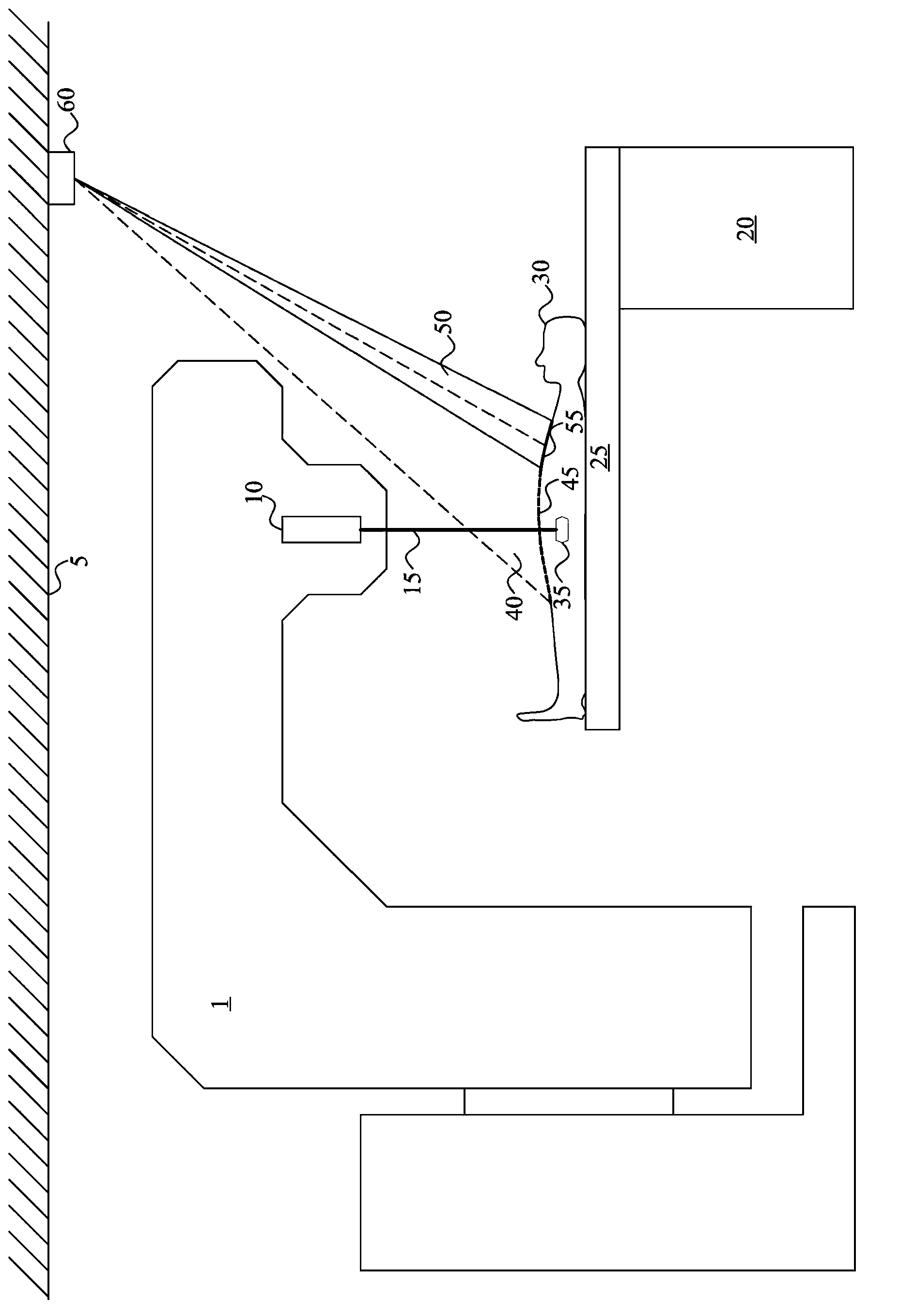

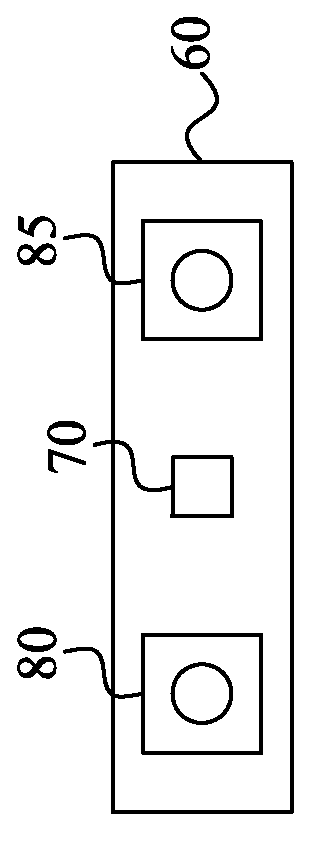

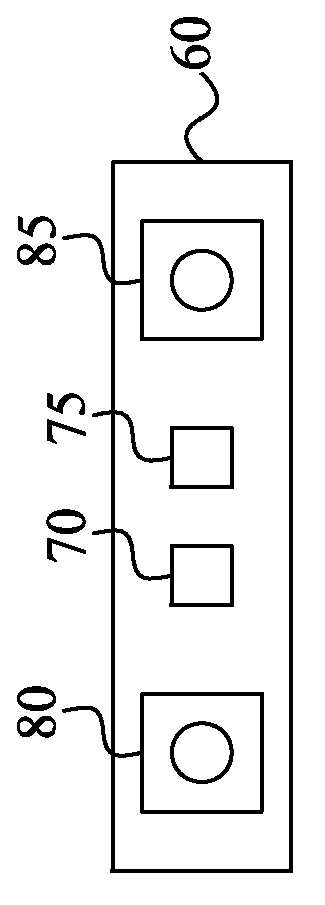

Object positioning with visual feedback

A positioning system comprises a pattern projector (70) for projecting a 2D / 3D pattern (45) onto an object surface. The 2D / 3D pattern (45) is detected by a detector (80, 85), which generates a detection signal that is employed by a pattern analyzing circuit (110) for generating a surface representation of the object surface. A correction analyzing circuit (130) generates a correction signal representative of a discrepancy in position and / or posture of the surface representation relative a stored reference surface representation. The correction signal is employed to generate information (55, 56) that is projected by a light projector (70, 75) onto the object surface. The projected information (55, 56) is indicative of the determined discrepancy in object position and / or posture.

Owner:C-RAD POSITIONING AB

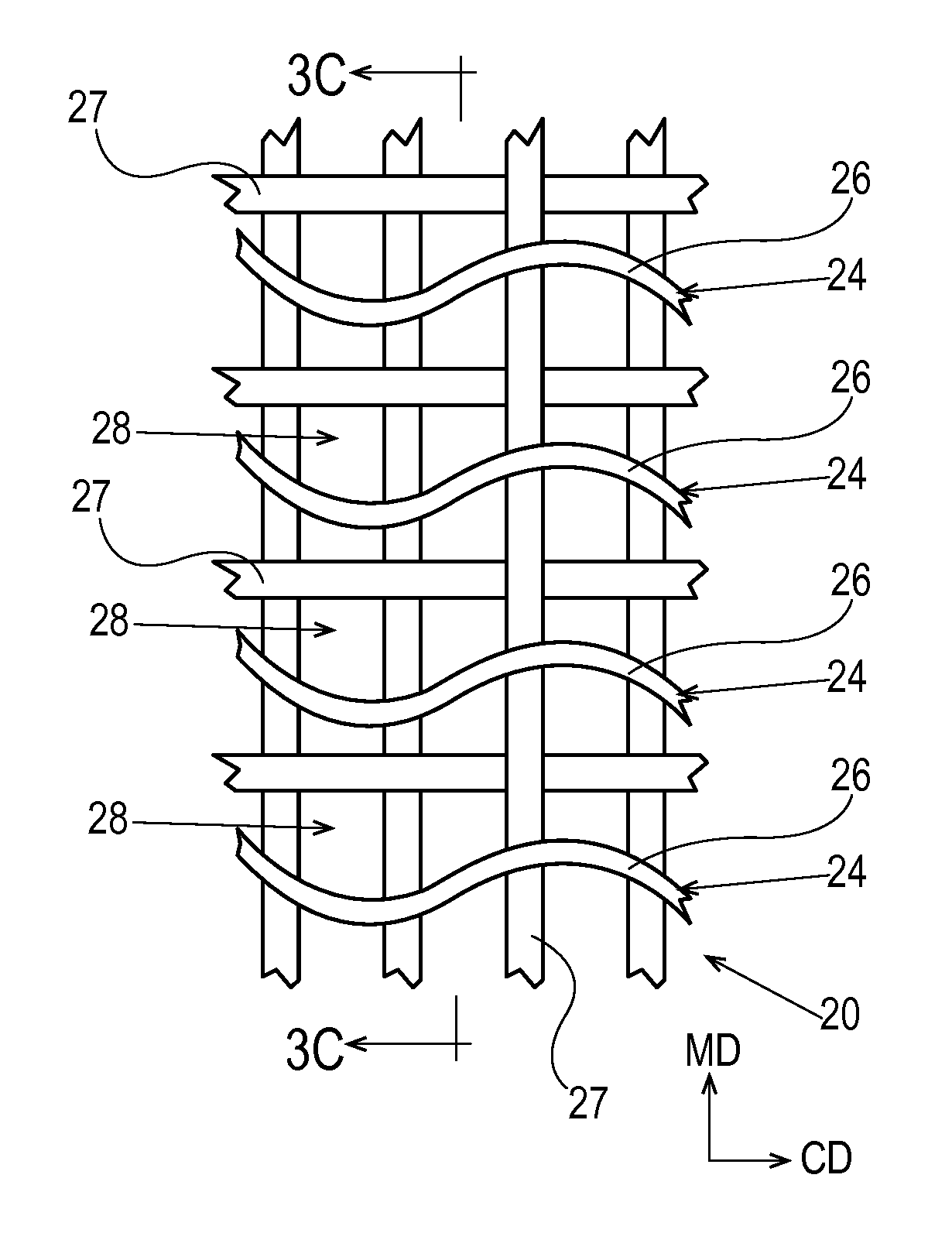

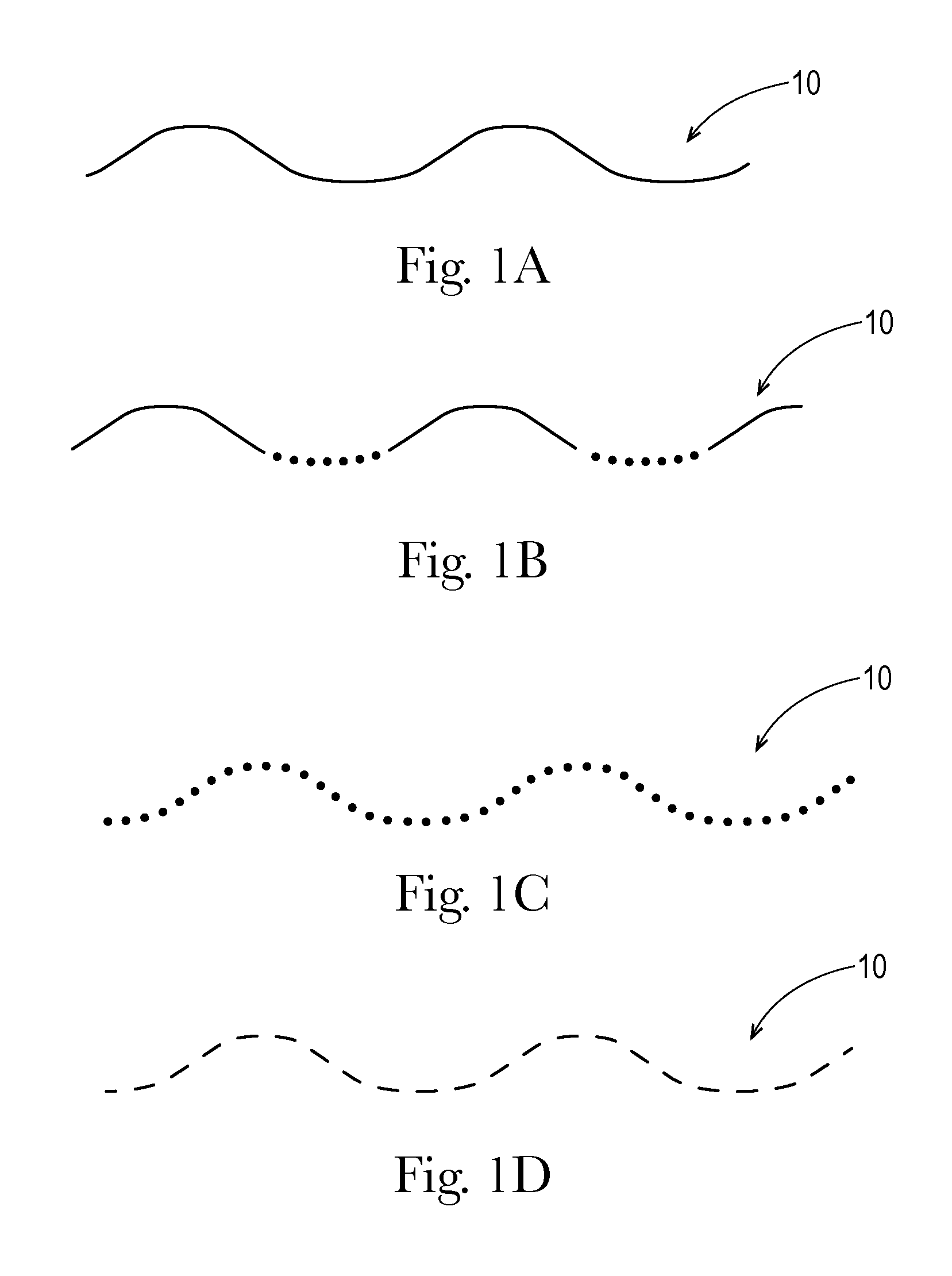

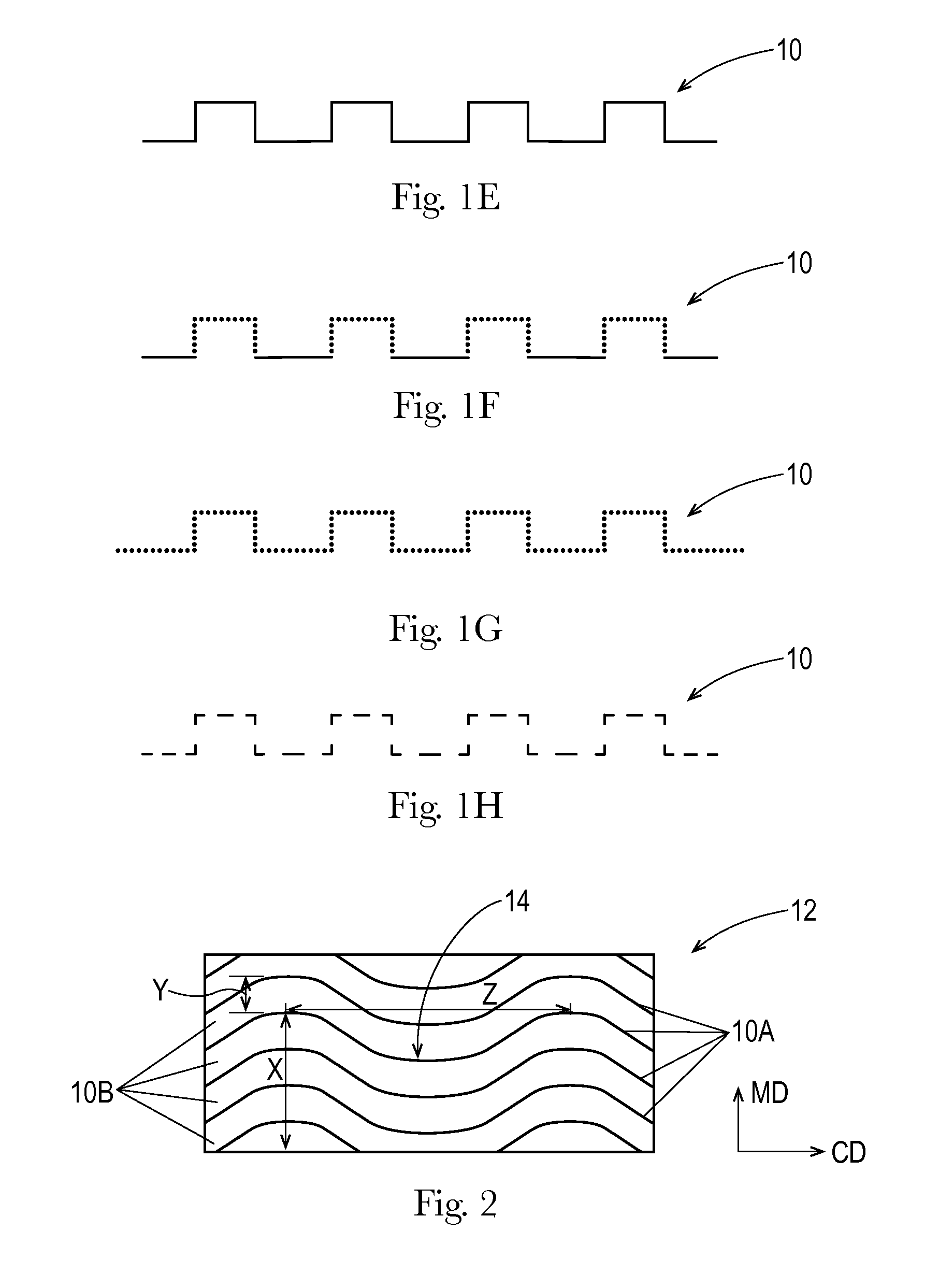

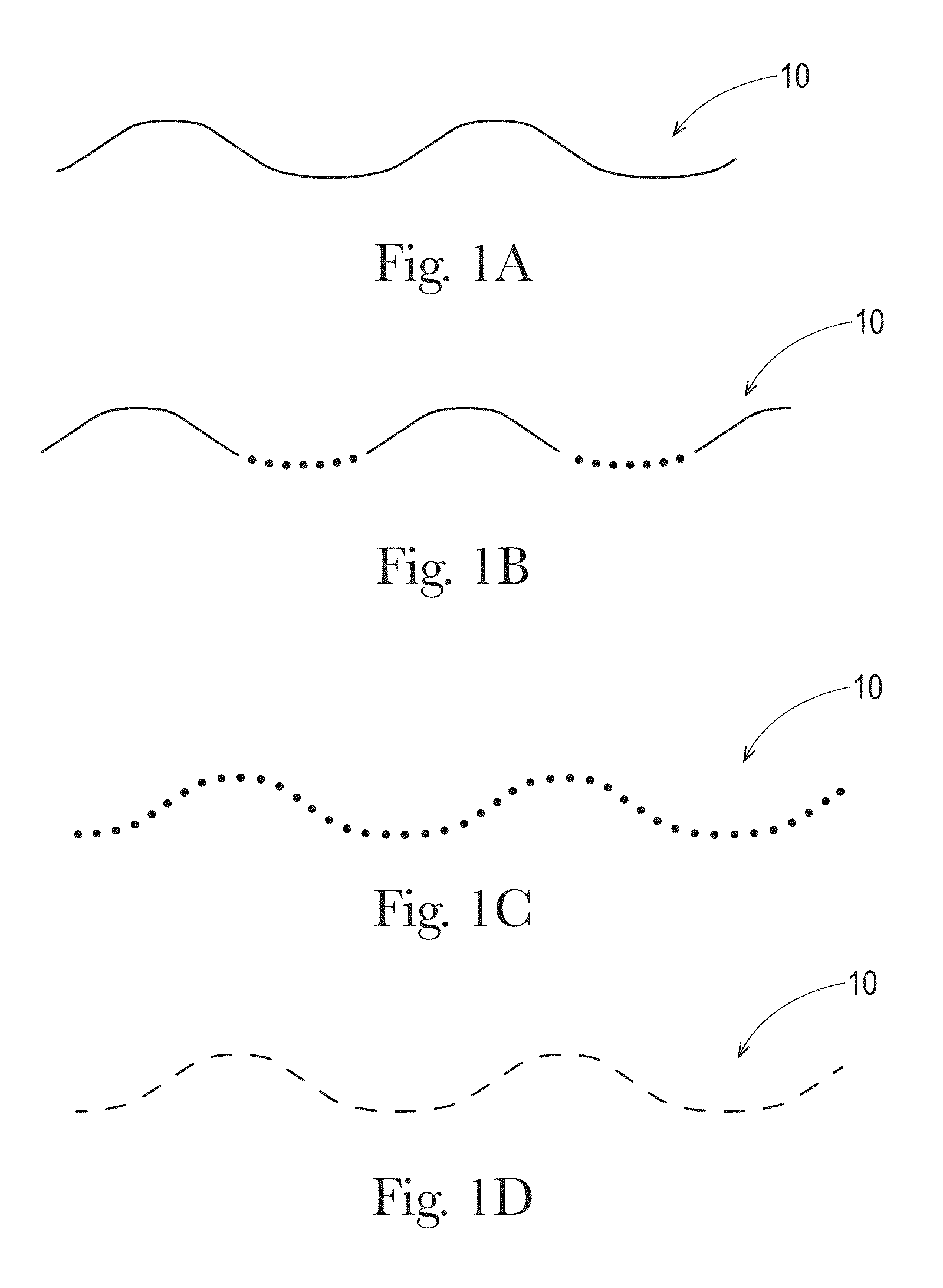

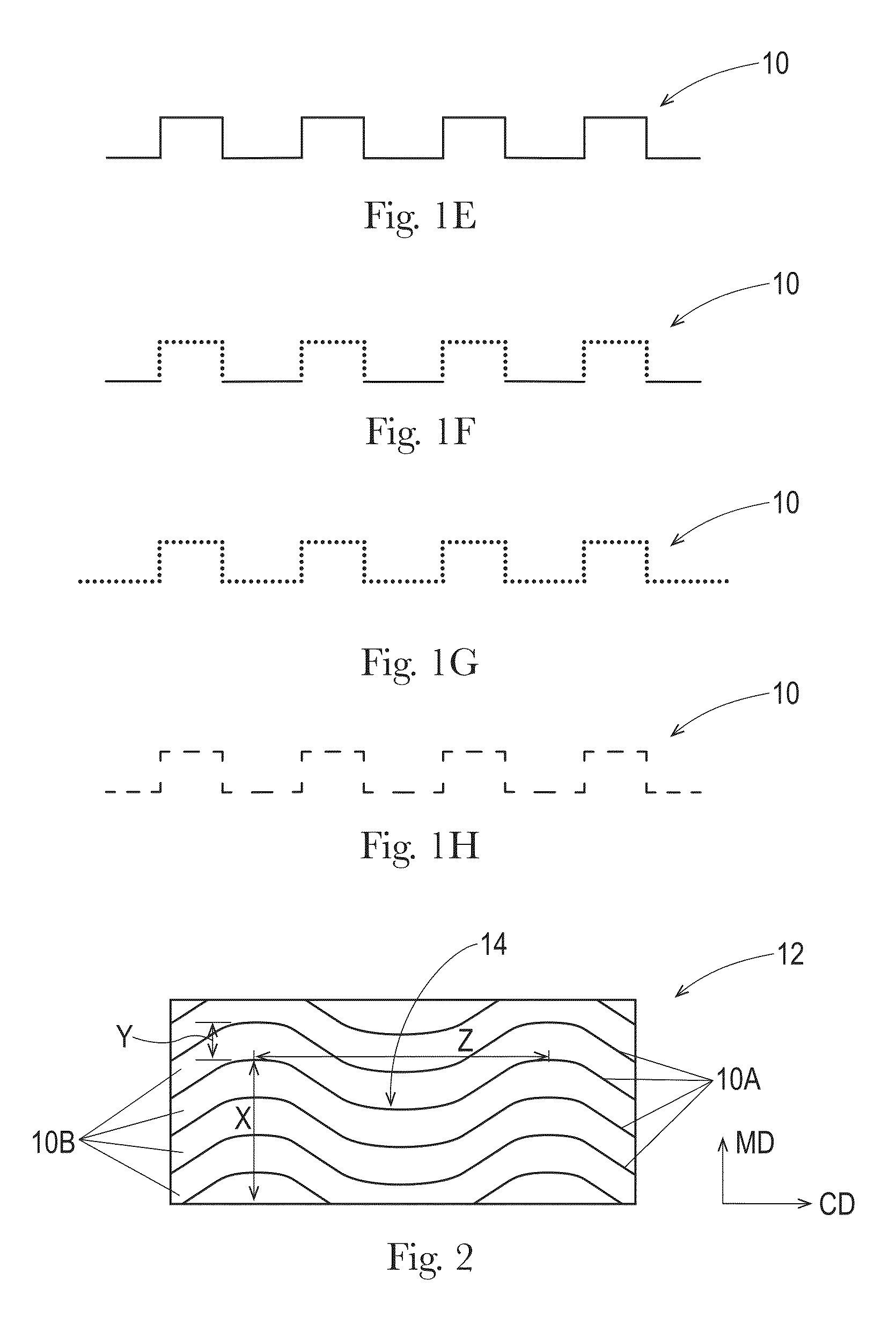

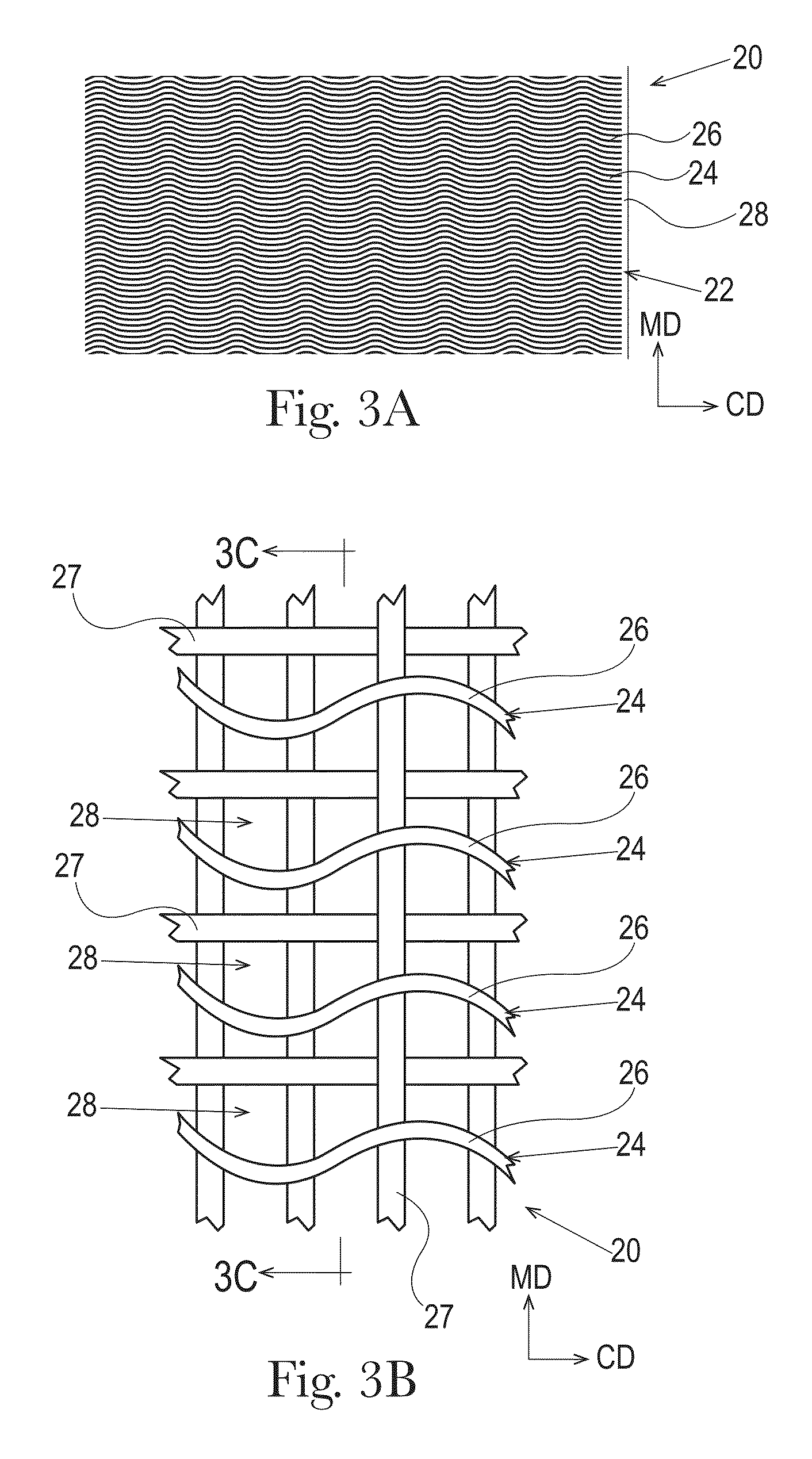

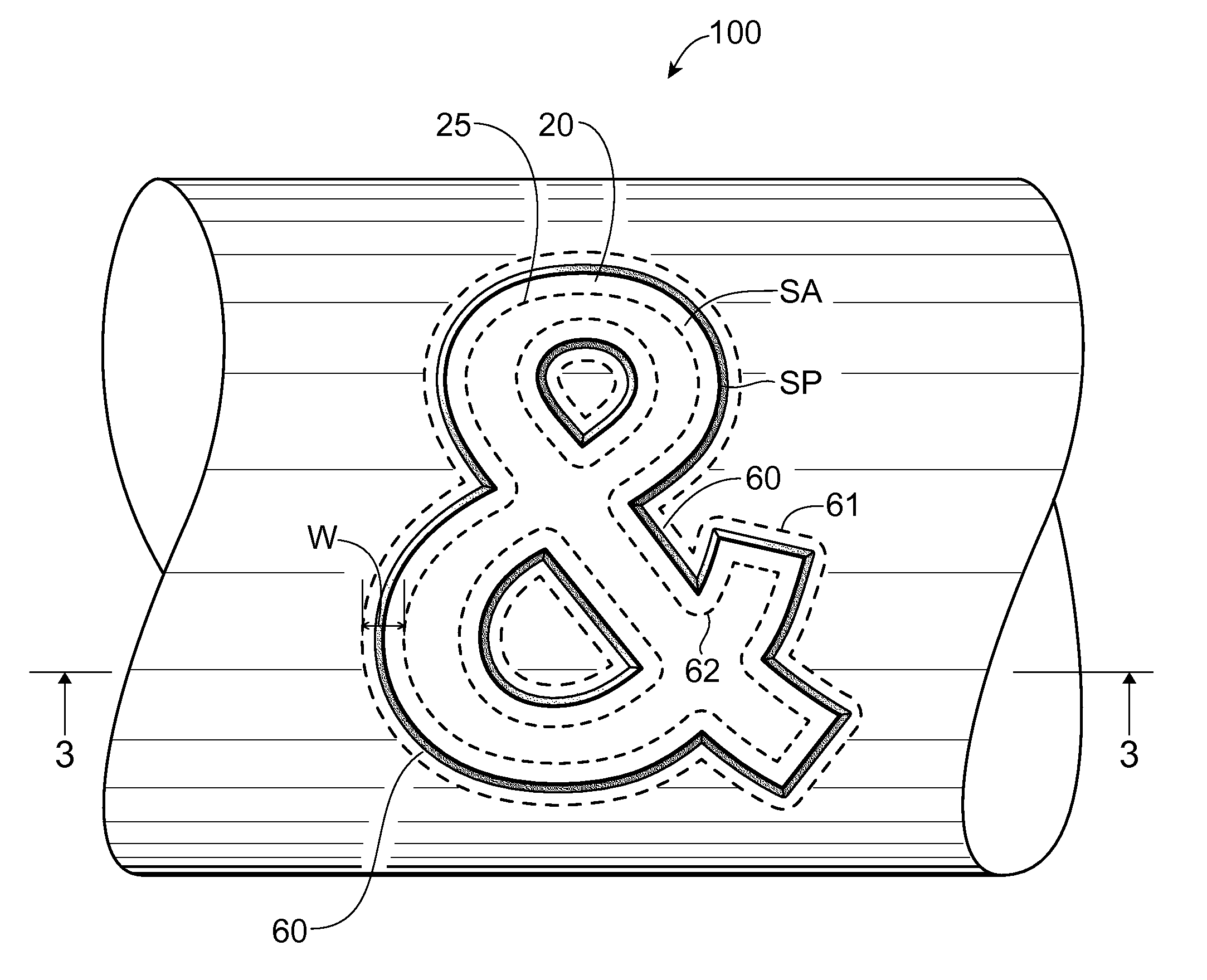

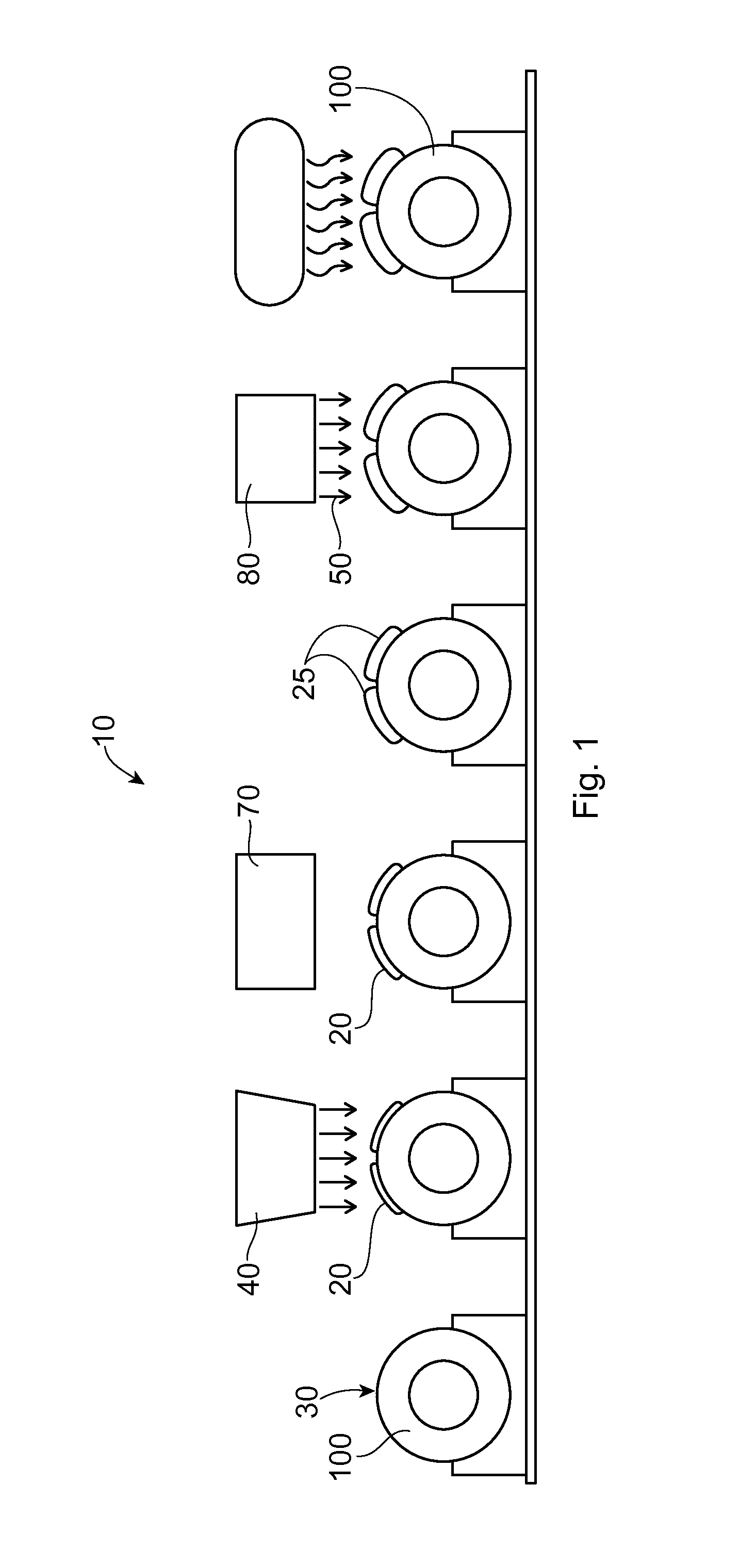

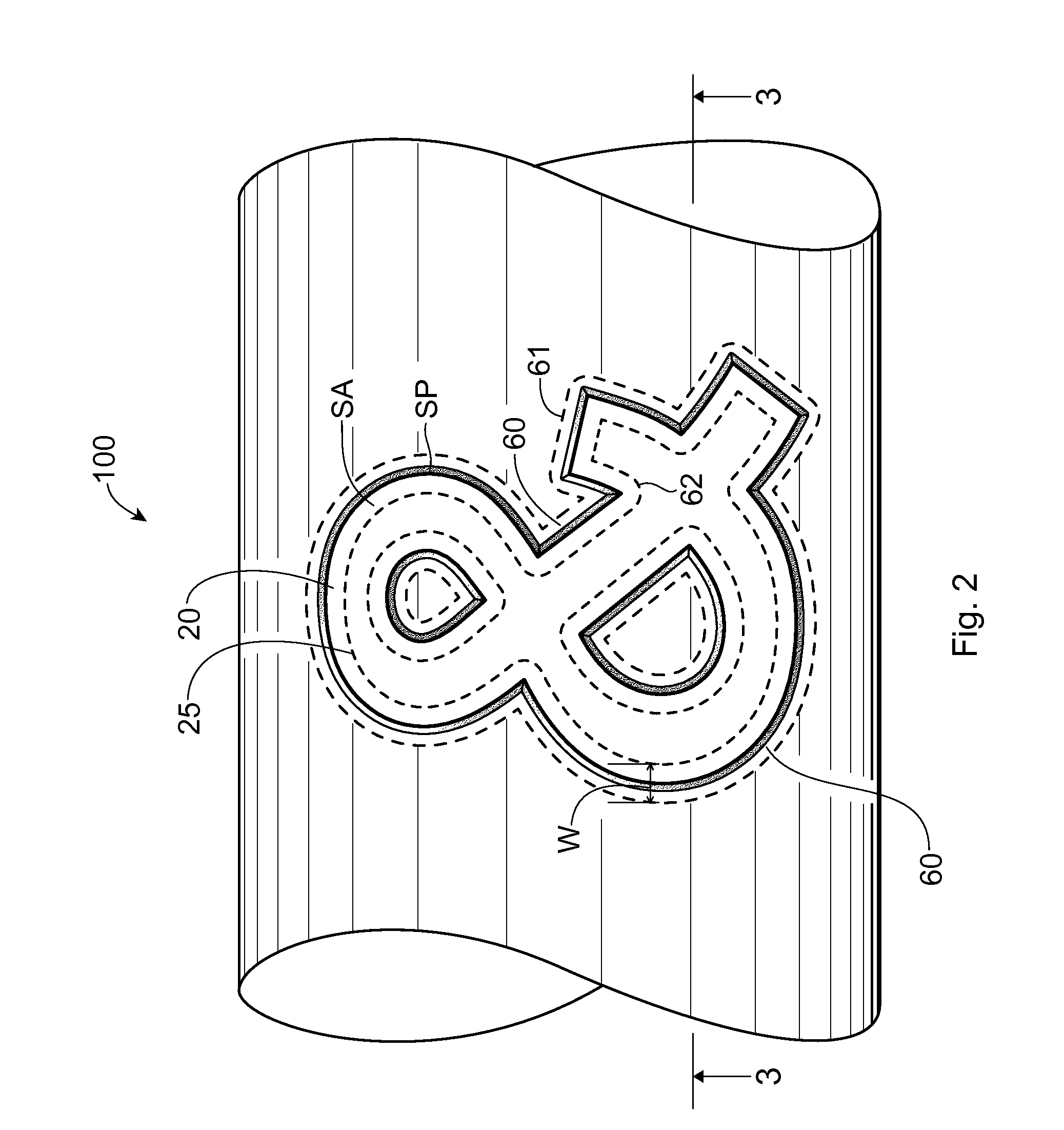

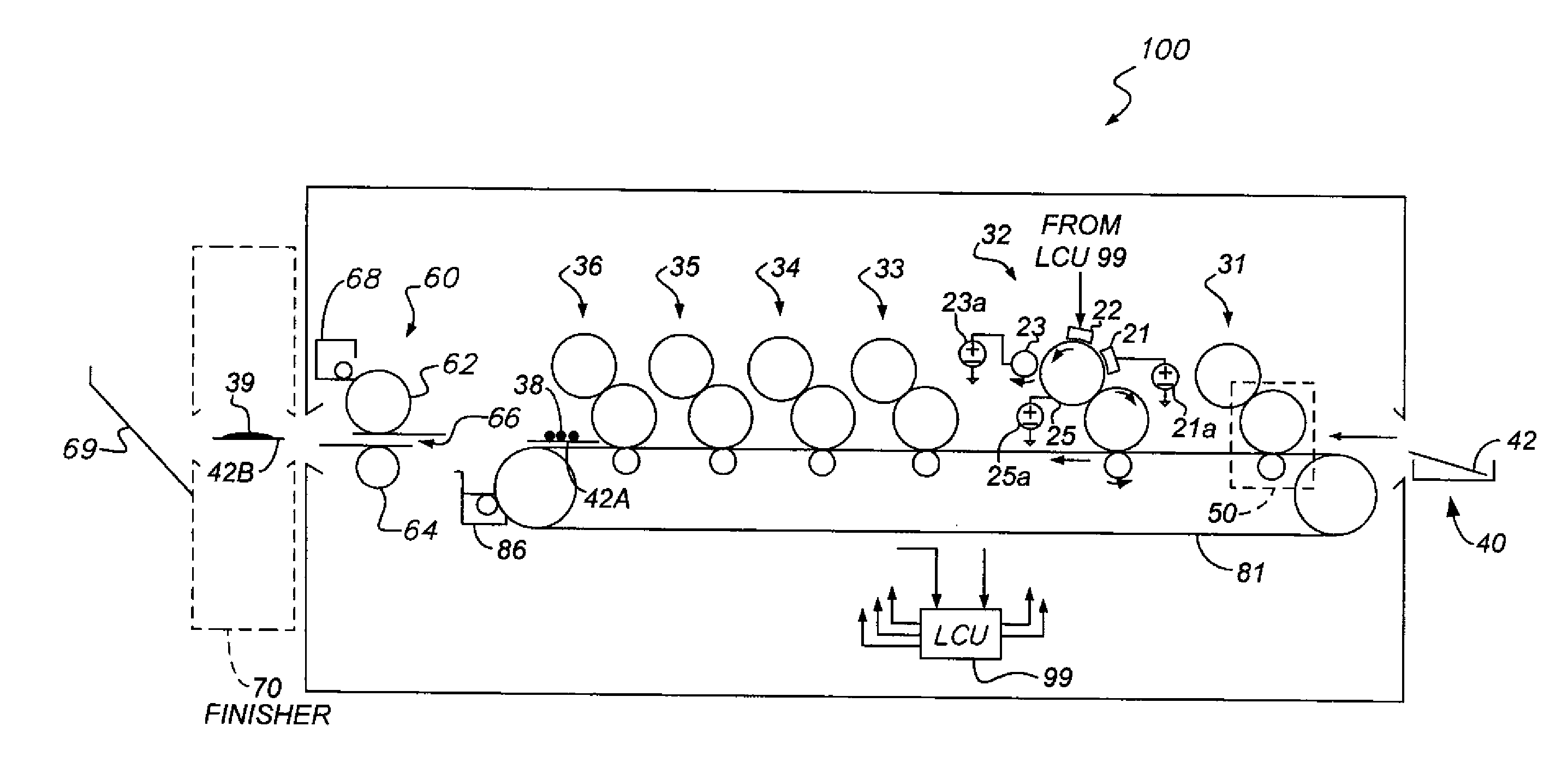

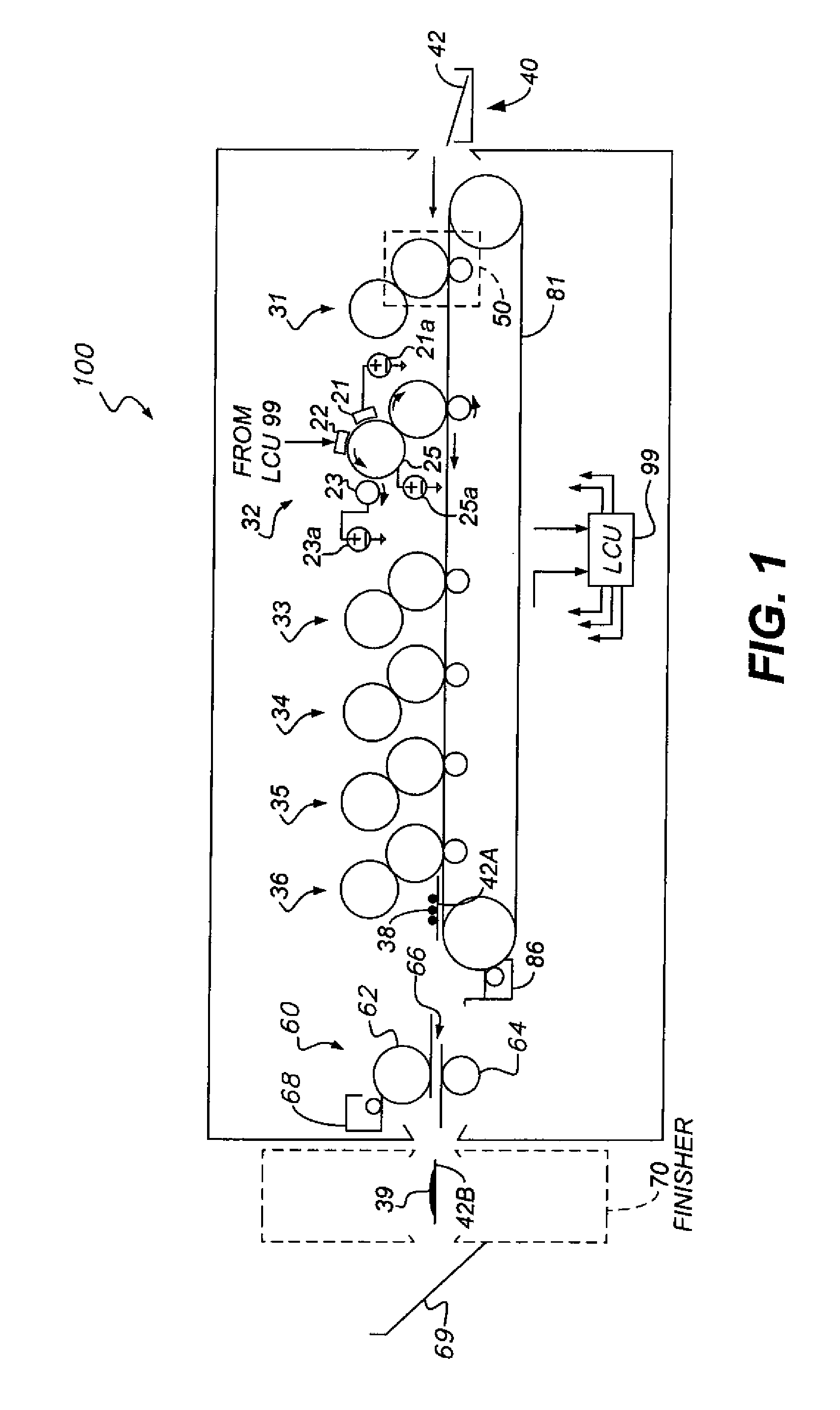

Sanitary Tissue Products and Methods for Making Same

ActiveUS20150176218A1Improve compression performanceIncrease stiffnessNon-fibrous pulp additionNatural cellulose pulp/paperFiber3d patterning

Sanitary tissue products employing 3D patterned fibrous structure plies having a surface comprising a novel three-dimensional (3D) pattern such that the 3D patterned fibrous structures and / or sanitary tissue products employing the fibrous structures exhibit novel cushiness as evidenced by compressibility of the fibrous structures and / or sanitary tissue products, novel flexibility as evidenced by plate stiffness of the fibrous structures and / or sanitary tissue products, and / or surface smoothness as evidenced by slip stick coefficient of friction of the fibrous structures and / or sanitary tissue products, and methods for making same, are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Sanitary tissue products and methods for making same

ActiveUS9315945B2Cushier, more flexibleImprove compression performanceMechanical working/deformationPaper/cardboardFiber3d patterning

Sanitary tissue products employing 3D patterned fibrous structure plies having a surface comprising a novel three-dimensional (3D) pattern such that the 3D patterned fibrous structures and / or sanitary tissue products employing the fibrous structures exhibit novel cushiness as evidenced by compressibility of the fibrous structures and / or sanitary tissue products, novel flexibility as evidenced by plate stiffness of the fibrous structures and / or sanitary tissue products, and / or surface smoothness as evidenced by slip stick coefficient of friction of the fibrous structures and / or sanitary tissue products, and methods for making same, are provided.

Owner:PROCTER & GAMBLE CO

Object Positioning With Visual Feedback

A positioning system comprises a pattern projector (70) for projecting a 2D / 3D pattern (45) onto an object surface. The 2D / 3D pattern (45) is detected by a detector (80, 85), which generates a detection signal that is employed by a pattern analyzing circuit (110) for generating a surface representation of the object surface. A correction analyzing circuit (130) generates a correction signal representative of a discrepancy in position and / or posture of the surface representation relative a stored reference surface representation. The correction signal is employed to generate information (55, 56) that is projected by a light projector (70, 75) onto the object surface. The projected information (55, 56) is indicative of the determined discrepancy in object position and / or posture.

Owner:C-RAD POSITIONING AB

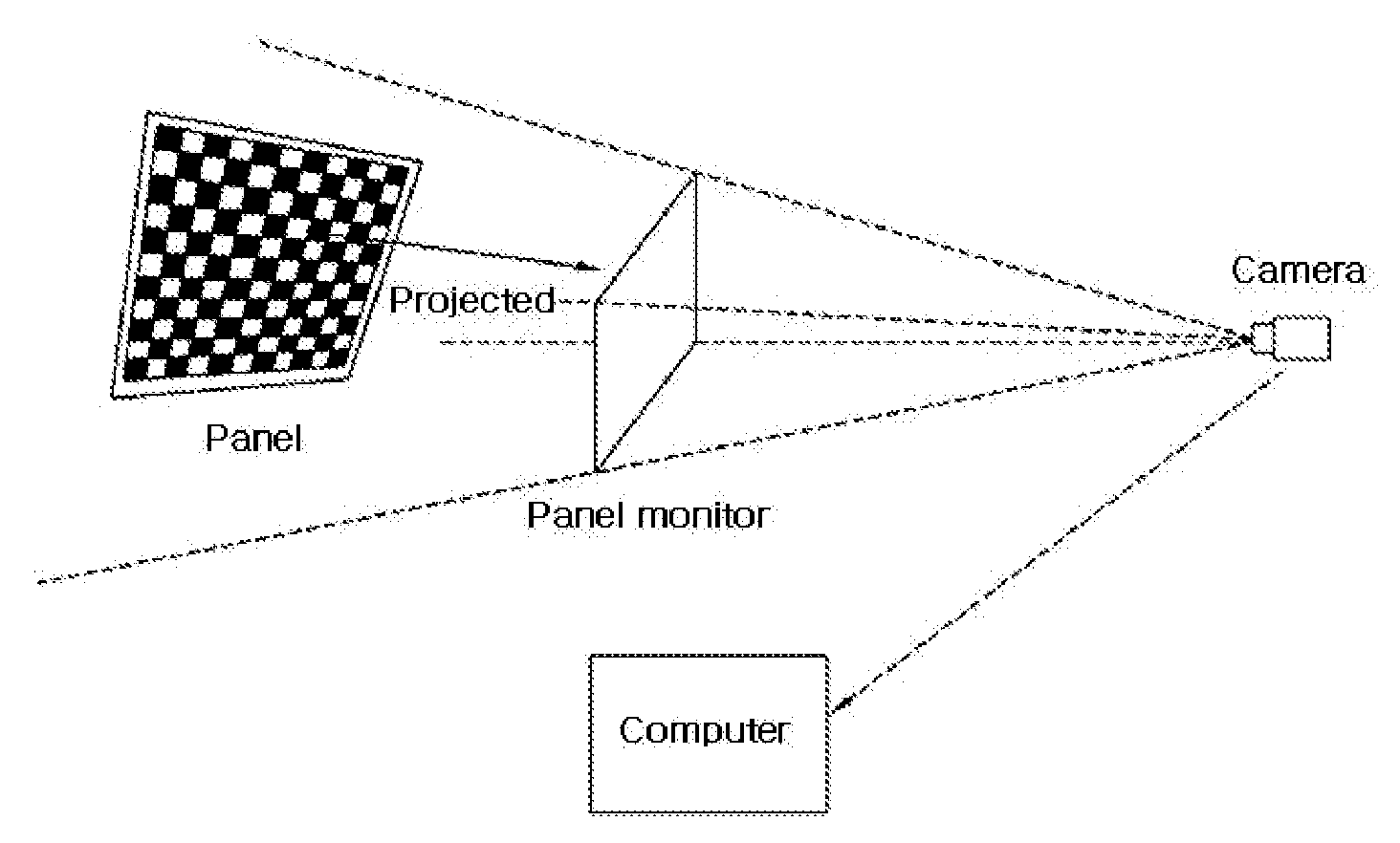

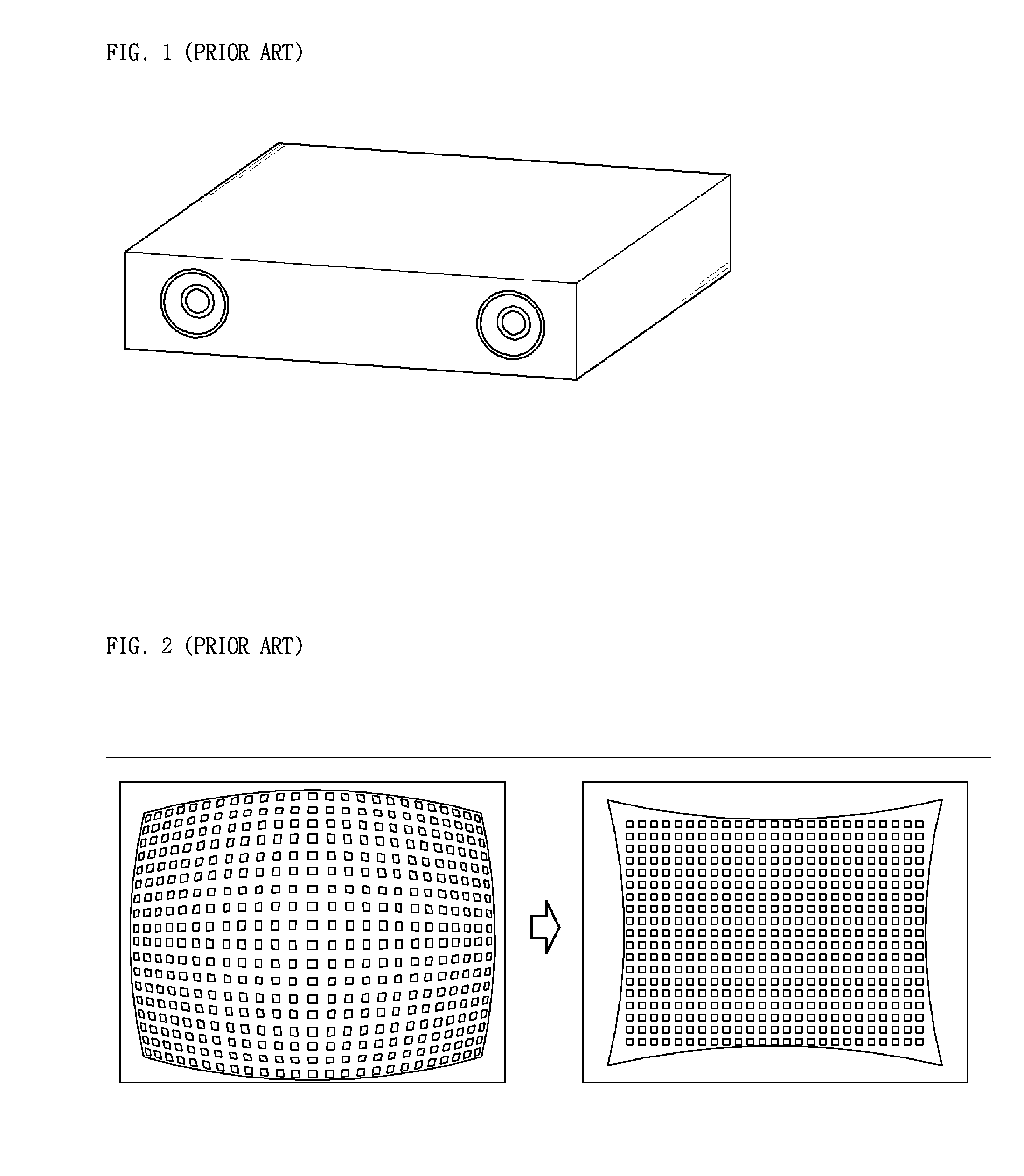

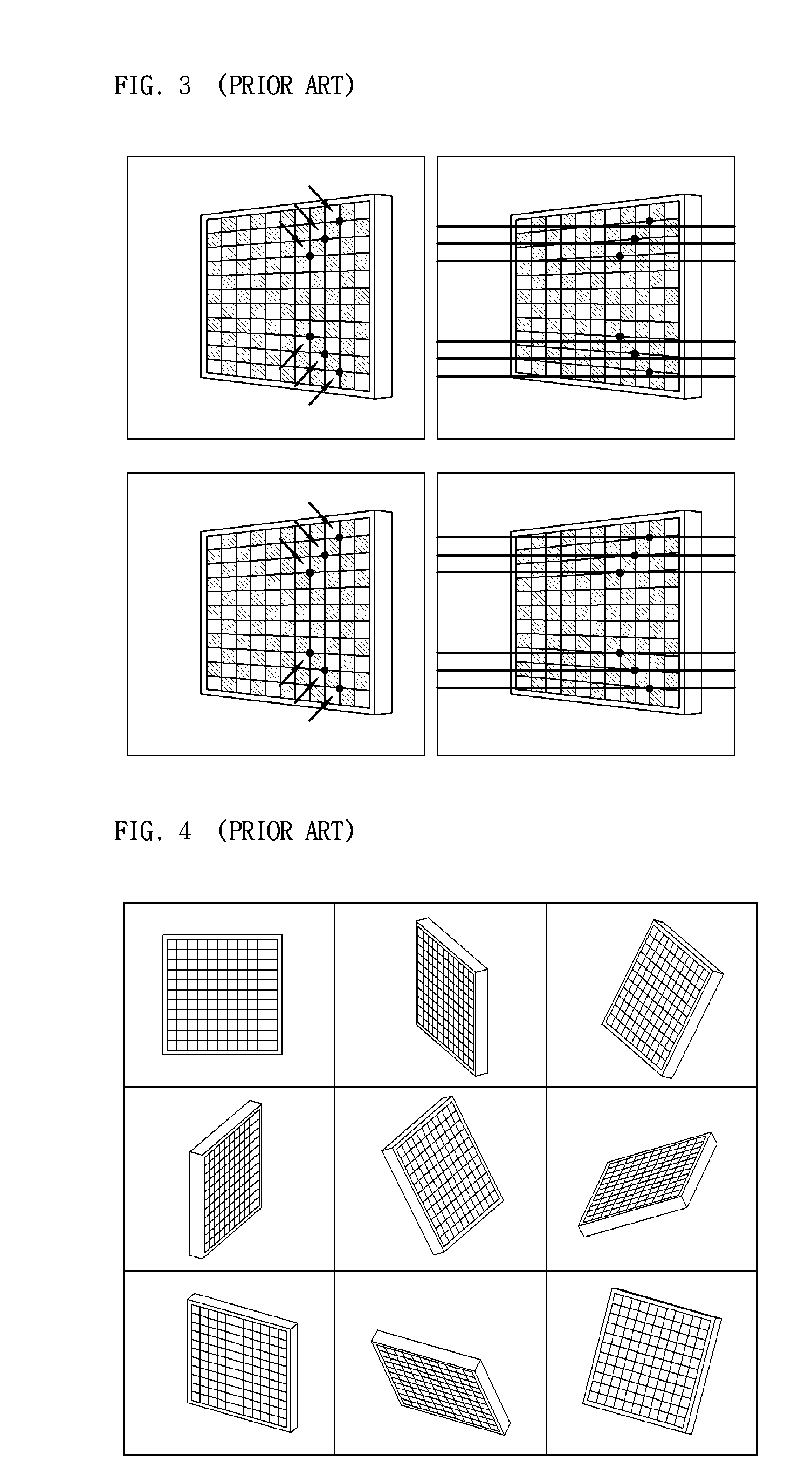

Method and apparatus for high-speed calibration and rectification of a stereo camera

ActiveUS20120105591A1Shorten the timeIncrease speedTelevision systemsSteroscopic systems3d patterningGraphics

Owner:VISION ST

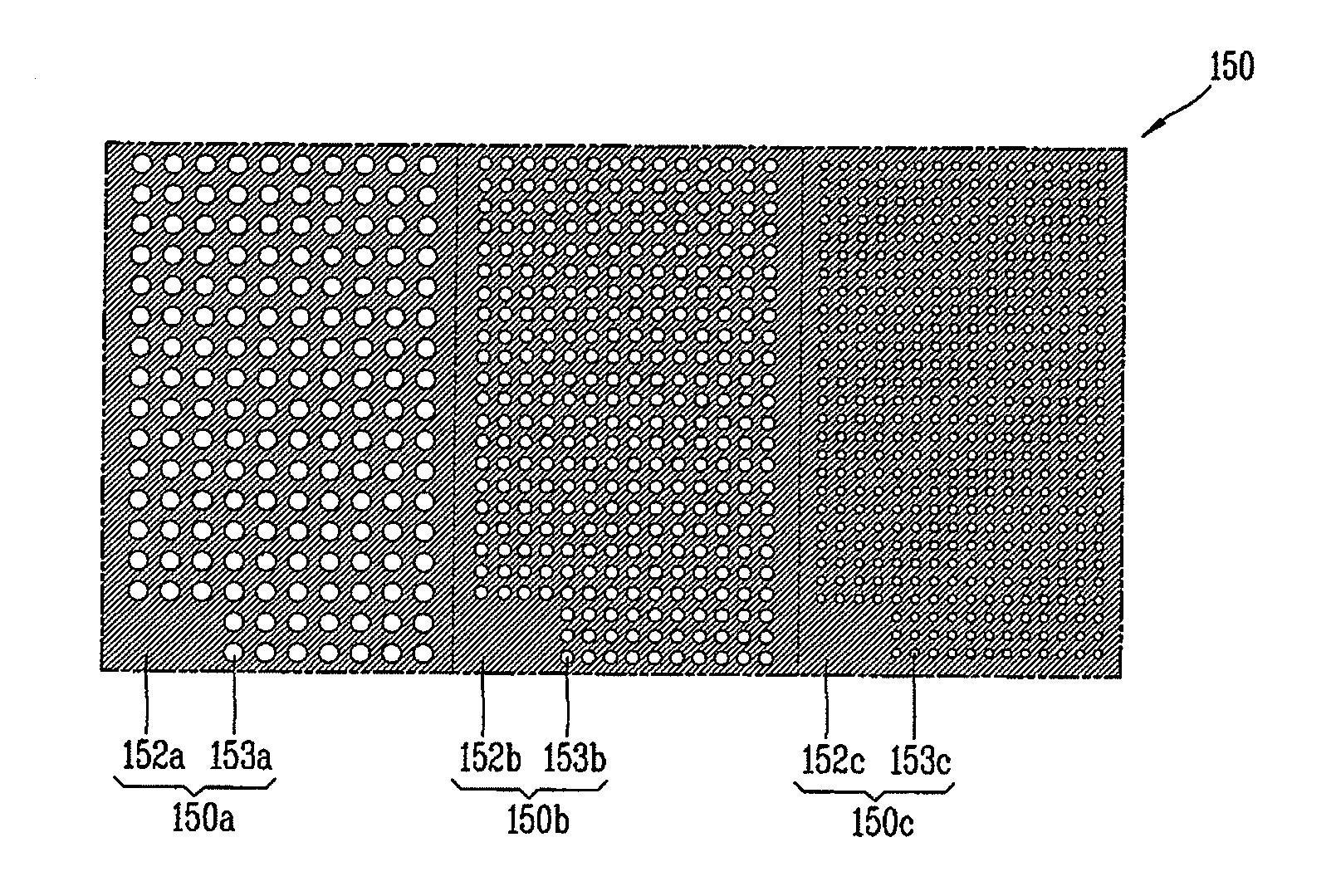

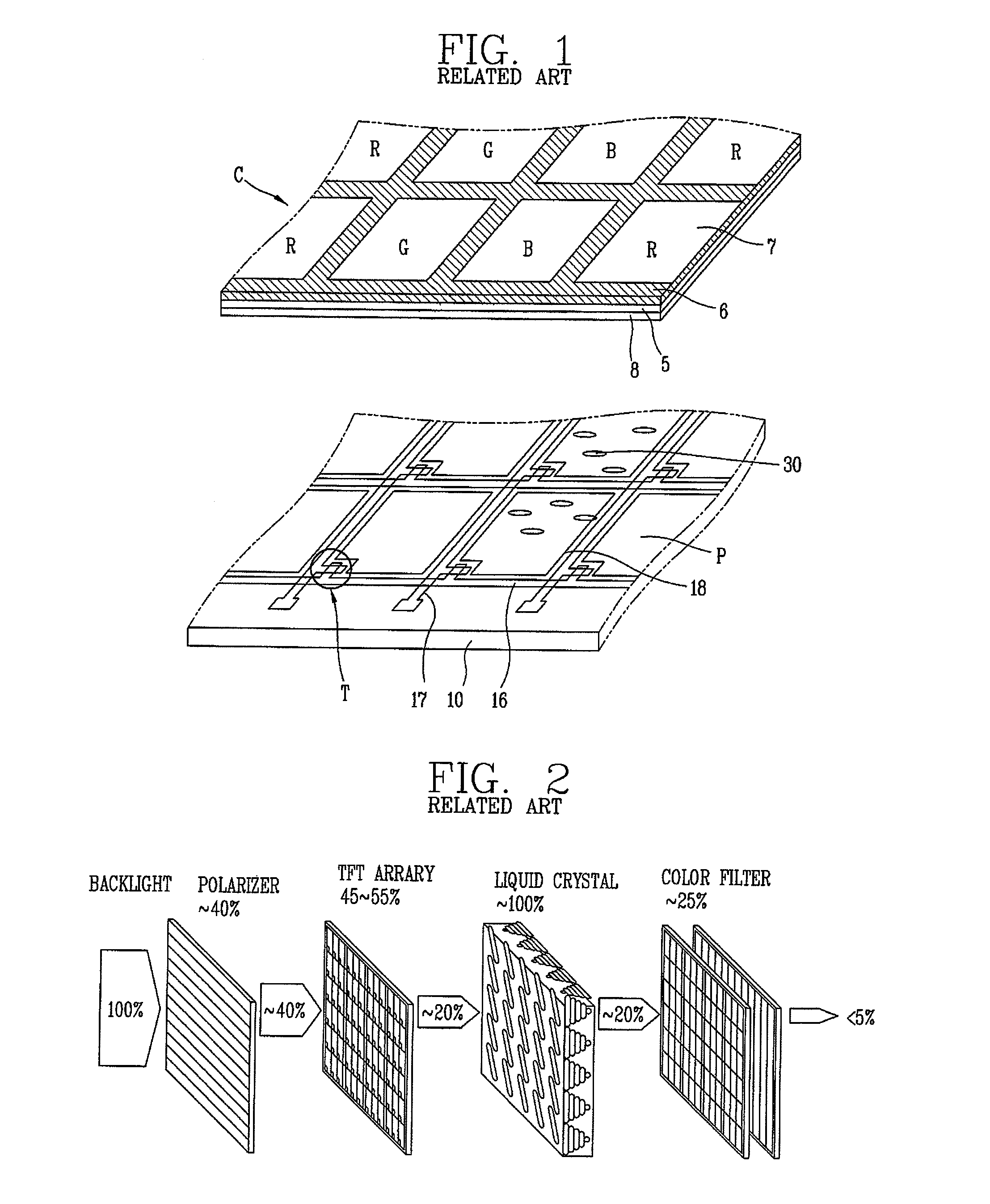

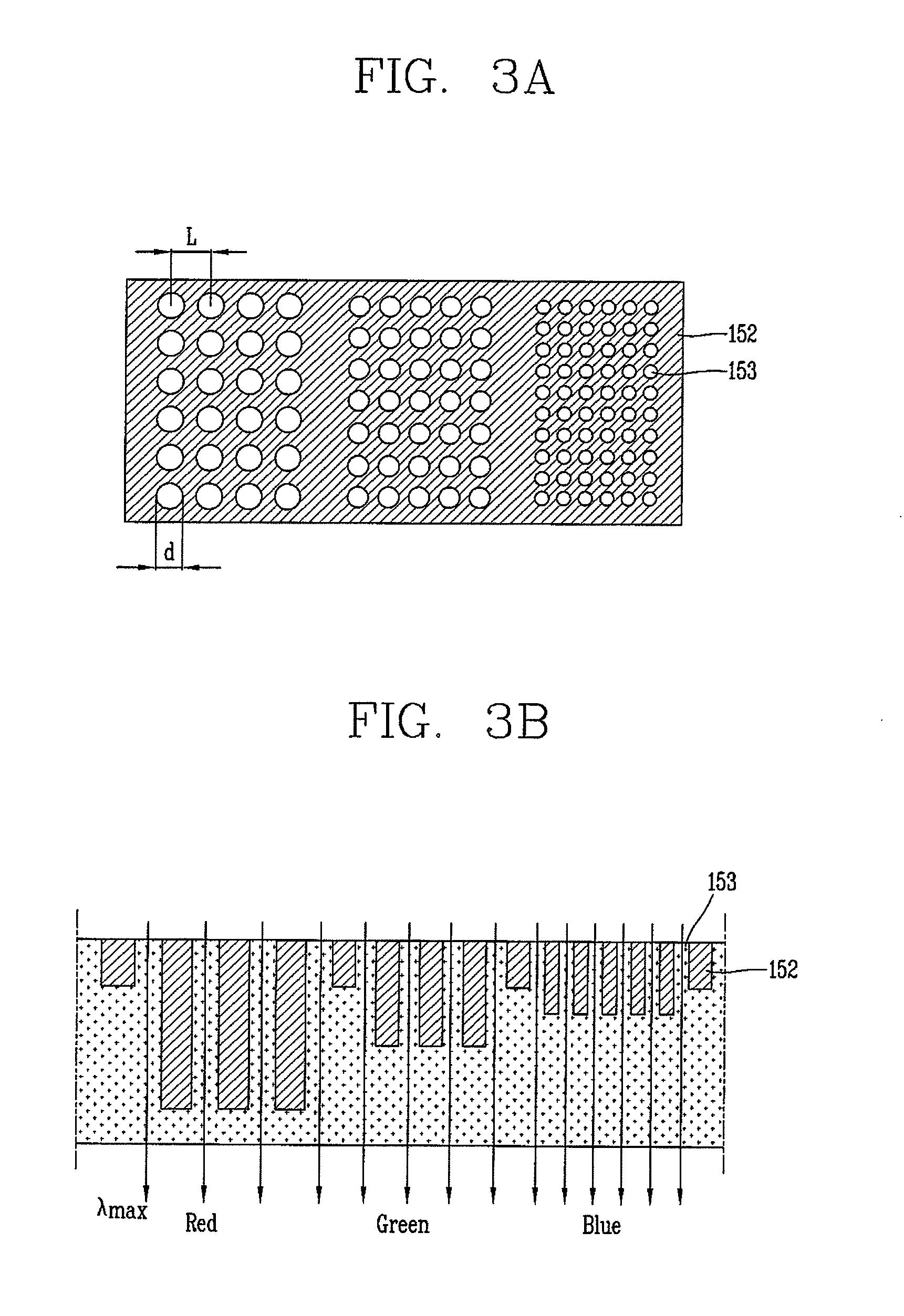

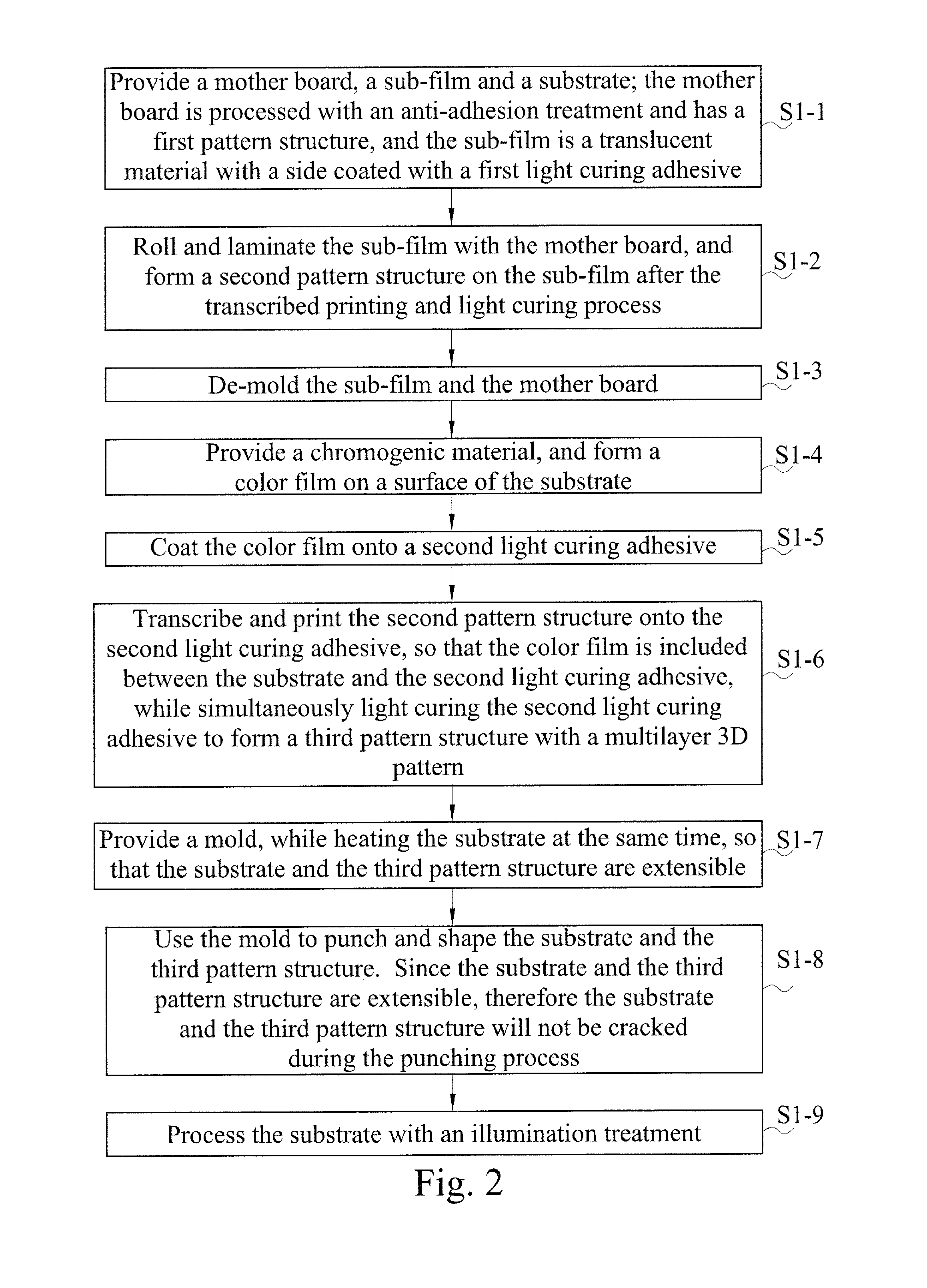

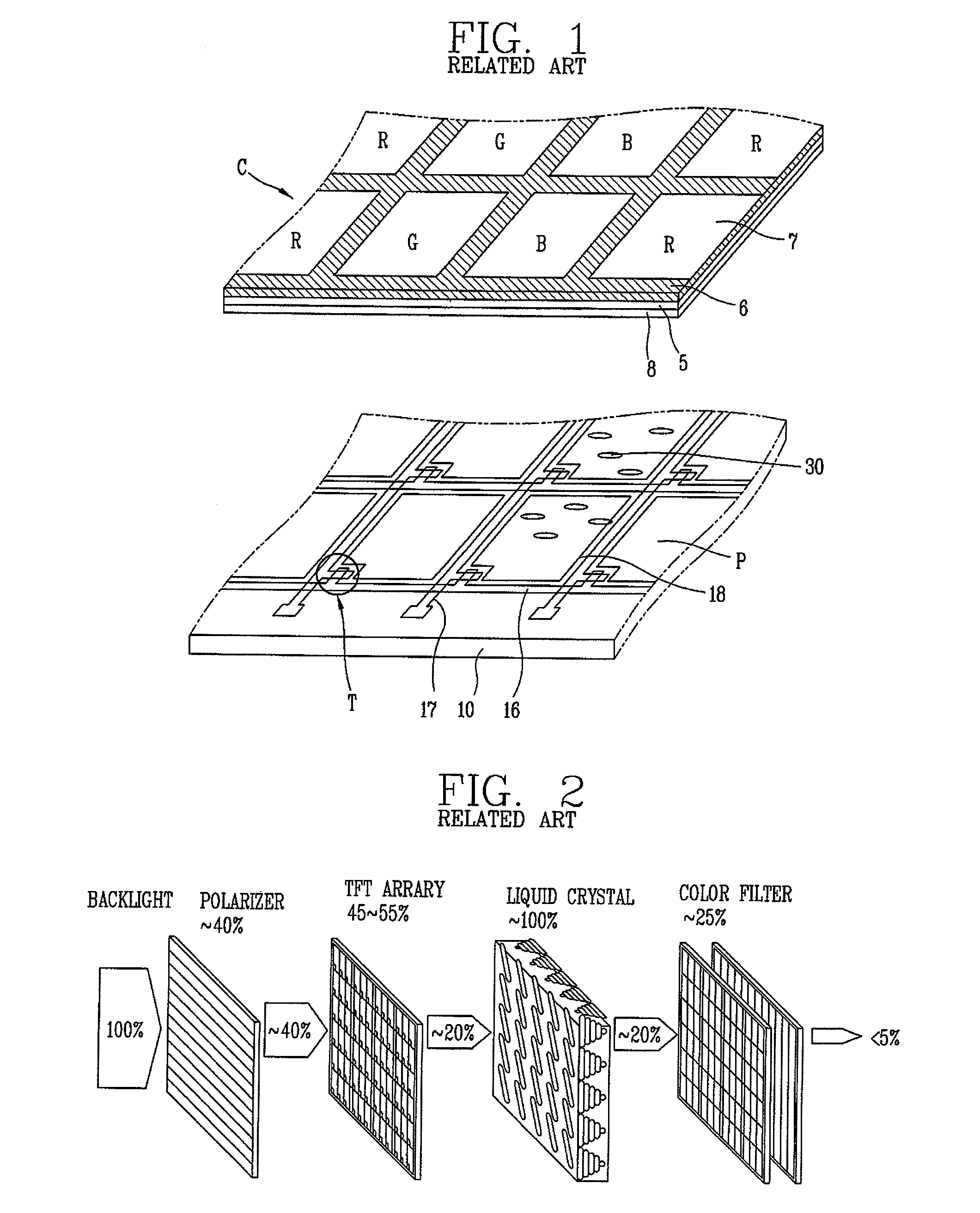

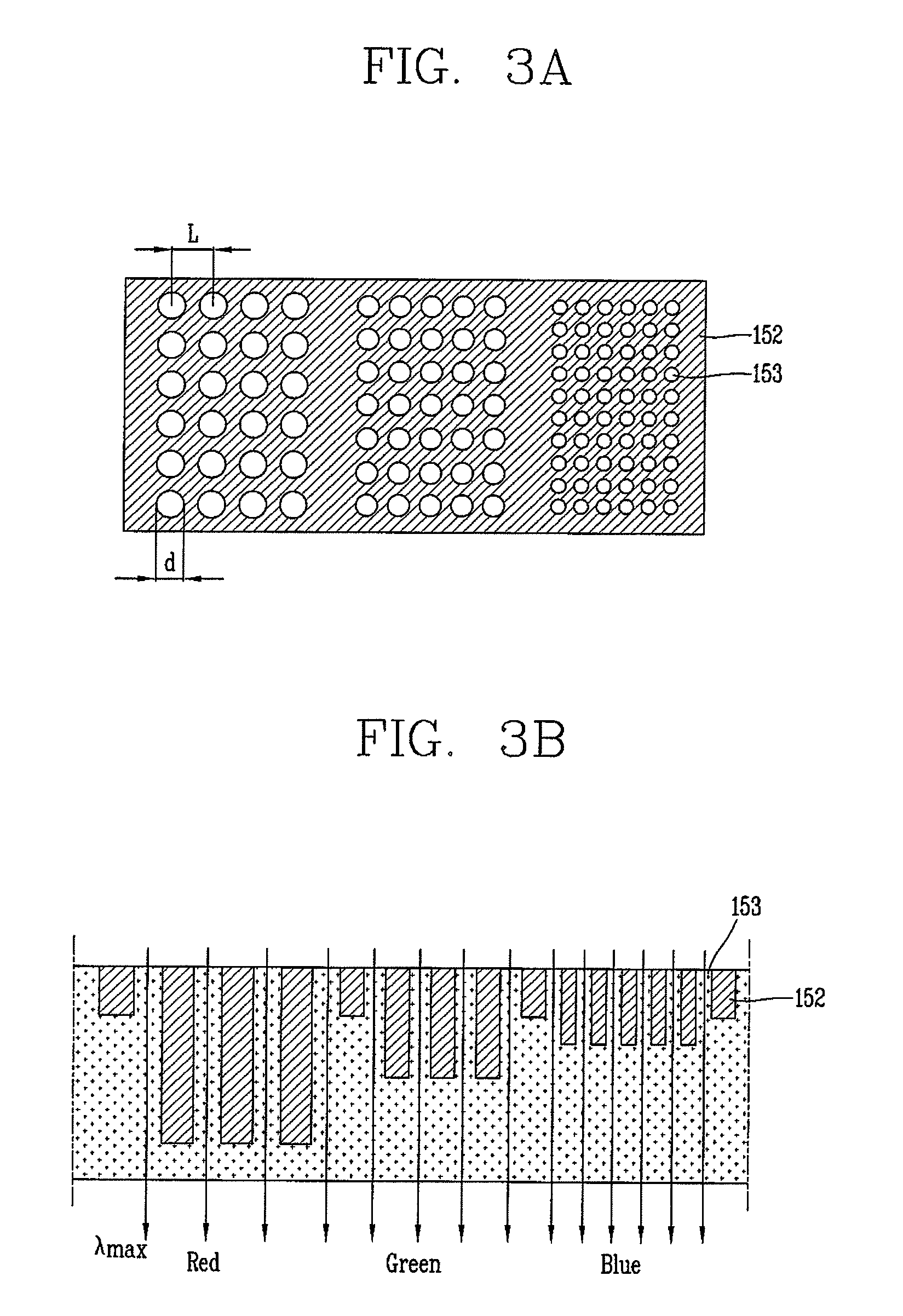

Color filter using surface plasmon and liquid crystal display device

InactiveUS20110102716A1Increase the aperture ratioEnhancing ratio transmittance ratioOptical filtersNon-linear optics3d patterningLiquid-crystal display

Discussed are a color filter using a surface plasmon and a liquid crystal display (LCD) device, the color filter capable of enhancing a transmittance ratio of an LC panel by having a 3D pattern structure of a transmissive pattern for selectively transmitting light of a specific wavelength, and capable of simplifying entire processes. According to the color filter using a surface plasmon and the LCD device, not only three colors of RGB but also multi-colors can be implemented, and color reproduction can be enhanced by optimizing arrangement of the transmissive pattern according to the number of colors to be implemented.

Owner:LG DISPLAY CO LTD

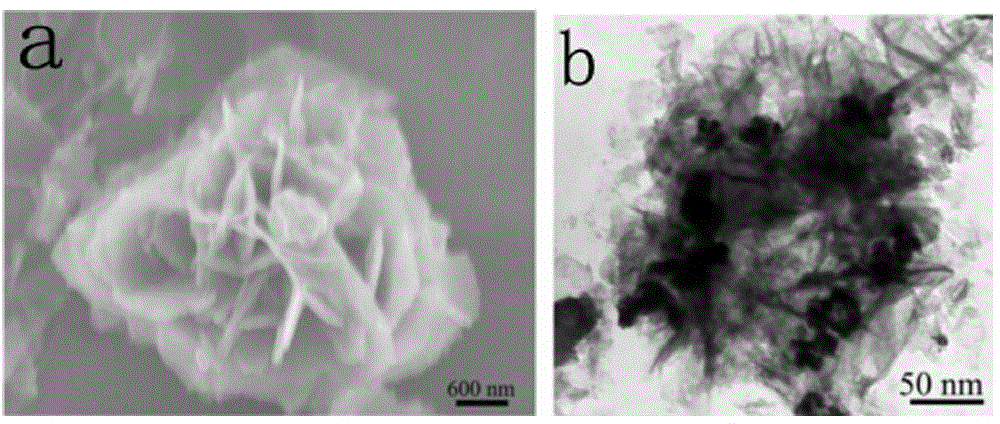

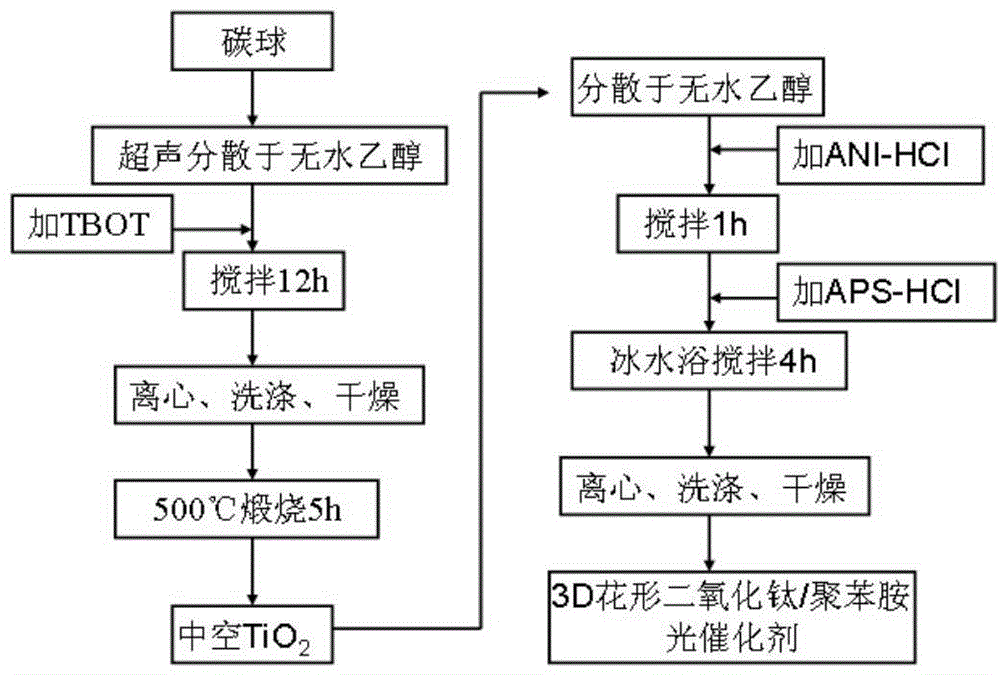

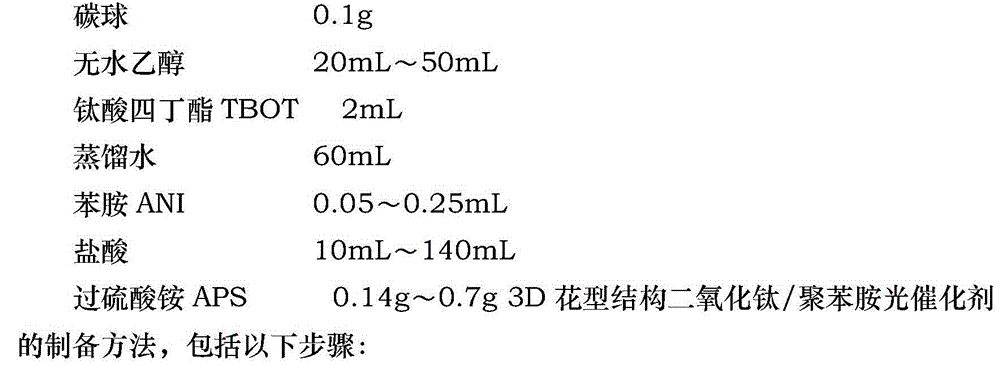

Titanium dioxide/polyaniline photocatalyst with 3D pattern structure and preparation method of titanium dioxide/polyaniline photocatalyst

InactiveCN104084241ATake advantage ofEfficient use ofOrganic-compounds/hydrides/coordination-complexes catalysts3d patterningSolar light

The invention relates to a titanium dioxide / polyaniline photocatalyst with a 3D pattern structure and a preparation method of the titanium dioxide / polyaniline photocatalyst. The preparation method comprises the steps of dispersing carbon balls in absolute ethyl alcohol, adding TBOT, dropping distilled water, centrifugally separating, and drying to obtain brown powder; calcining the brown powder to obtain hollow titanium dioxide nanometer particles, dispersing the hollow titanium dioxide nanometer particles in the absolute ethyl alcohol, dispersing ANI (aniline) in hydrochloric acid, agitating in an ice-water bath to obtain a deep green suspension; and centrifugally separating, and drying to obtain a deep green TiO2 / polyaniline (PANI) compound photocatalyst. Polyaniline is used as a sensitizer for modifying titanium dioxide, the operation is simple, reaction conditions are mild and the cost is low. Light is repeatedly refracted and absorbed by using polyaniline nanometer sheets which are mutually meshed, and thus full utilization on solar light is realized, the specific surface area of a composite material can be increased by the polyaniline nanometer sheets, more active sites are provided for light-catalyzed reaction, the light energy conversion efficiency and the photo-catalysis efficiency are improved, the PANI is high in absorption coefficient in a visible light region, and azo-dyes, namely MO and CR, can be directly degraded by using solar light.

Owner:JILIN UNIV

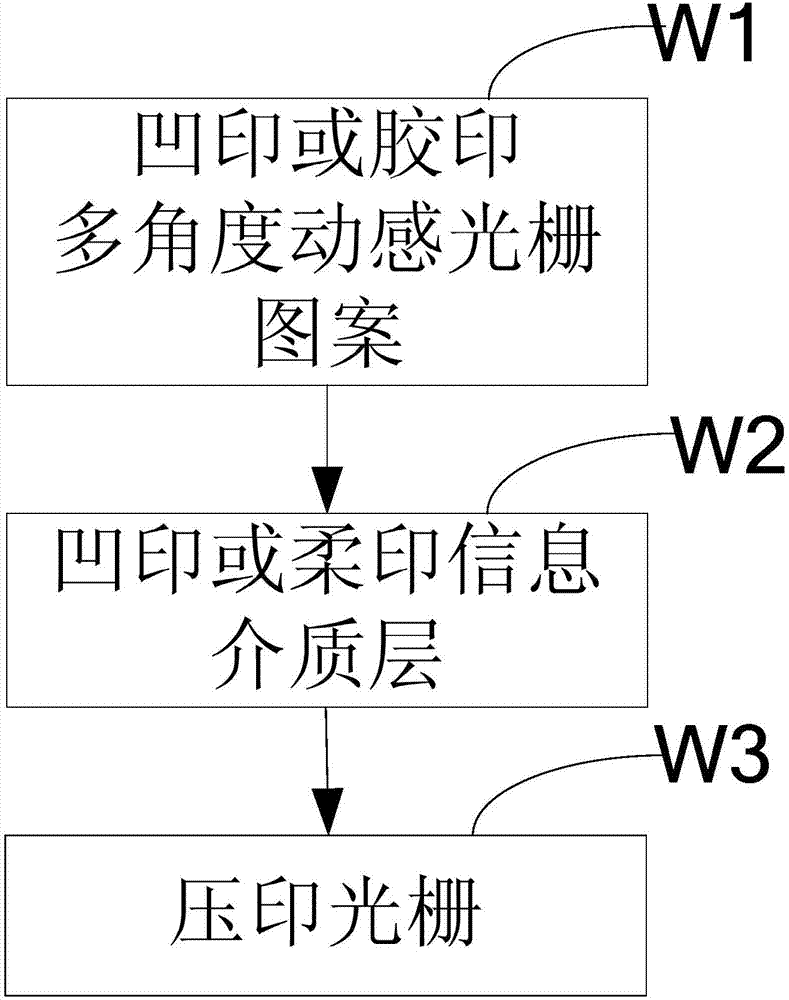

3D pattern printing method

The invention provides a 3D pattern printing method which comprises the following steps of first, manufacturing a multi-angle dynamic raster pattern, second, printing an information dielectric layer in a gravure or flexible mode, and third, coining a raster. The 3D pattern printing method has the advantages that offset printing or gravure printing is combined with the coining information dielectric layer to form the raster to achieve 3D pattern conversion, and the method can be achieved on a packaging box through direction printing.

Owner:何军

Method for manufacturing white-light LED fluorescent film based on 3D printing technology

InactiveCN104051599APrecise preparation made easyImprove uniformitySemiconductor devices3d patterningFluorescence

The invention discloses a method for manufacturing a white-light LED fluorescent film based on the 3D printing technology. The method for manufacturing the white-light LED fluorescent film based on the 3D printing technology comprises the following steps that (1) fluorescent powder slurry is prepared; (2) a 3D printer is introduced, and the fluorescent film is printed on an LED chip or on other transparent substrates under the control of a computer; (3) the printed film is cured simultaneously through hot wind scanning or ultraviolet light curing during printing; (4) integral curing is conducted according to an optimized heating technology or an optimized ultraviolet light curing method based on the property of colloid, and then the required fluorescent film is obtained. The method for manufacturing the white-light LED fluorescent film based on the 3D printing technology has the advantages that the printing precision is high, the automation degree is high, material waste is small, 3D patterns in various shapes and with various thicknesses can be printed on various substrates or various objects freely, the method is an advanced manufacturing technology, a complete 3D printer is available at present, automatic production can be achieved, and the method is quite suitable for manufacturing the white-light LED fluorescent film.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for treating coated layer on surface of metal material and making pattern

InactiveCN1390650AImprove adhesionGood filter layerPretreated surfacesCoatings3d patterningPolyester

A process for coating on the surface of metal material and then preparing pattern on it includes such steps as immersing metal material in solution of H2SO4, water flushing, drying, coating acetone, benzene and n-propyl acetate, blowing surface by air compressor, baking, electrostatic spraying of polyester epoxy powder, baking, making pattern with the mixture of epoxy resin powder, butyl acetate and pigment by rolling or manually, baking and spraying BJS varnish. Its advantages are low cost, high resistance to chemical corrosion and oxidation, and clear 3D pattern.

Owner:钟烈侯

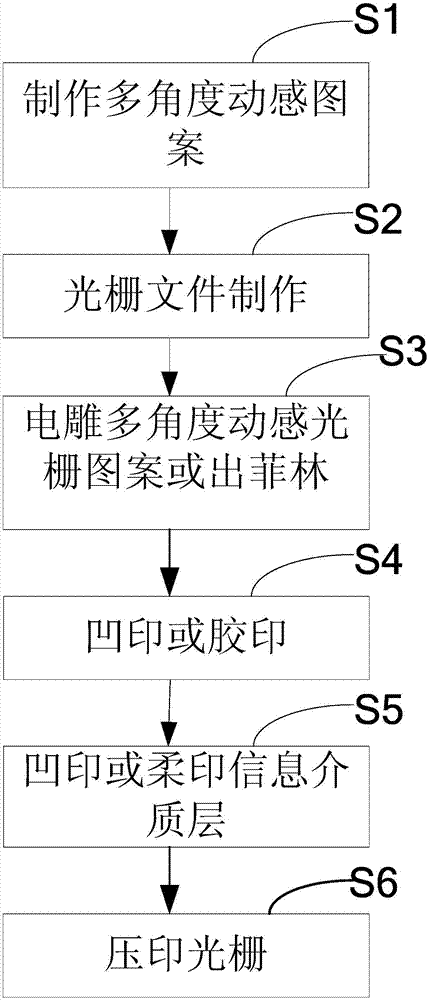

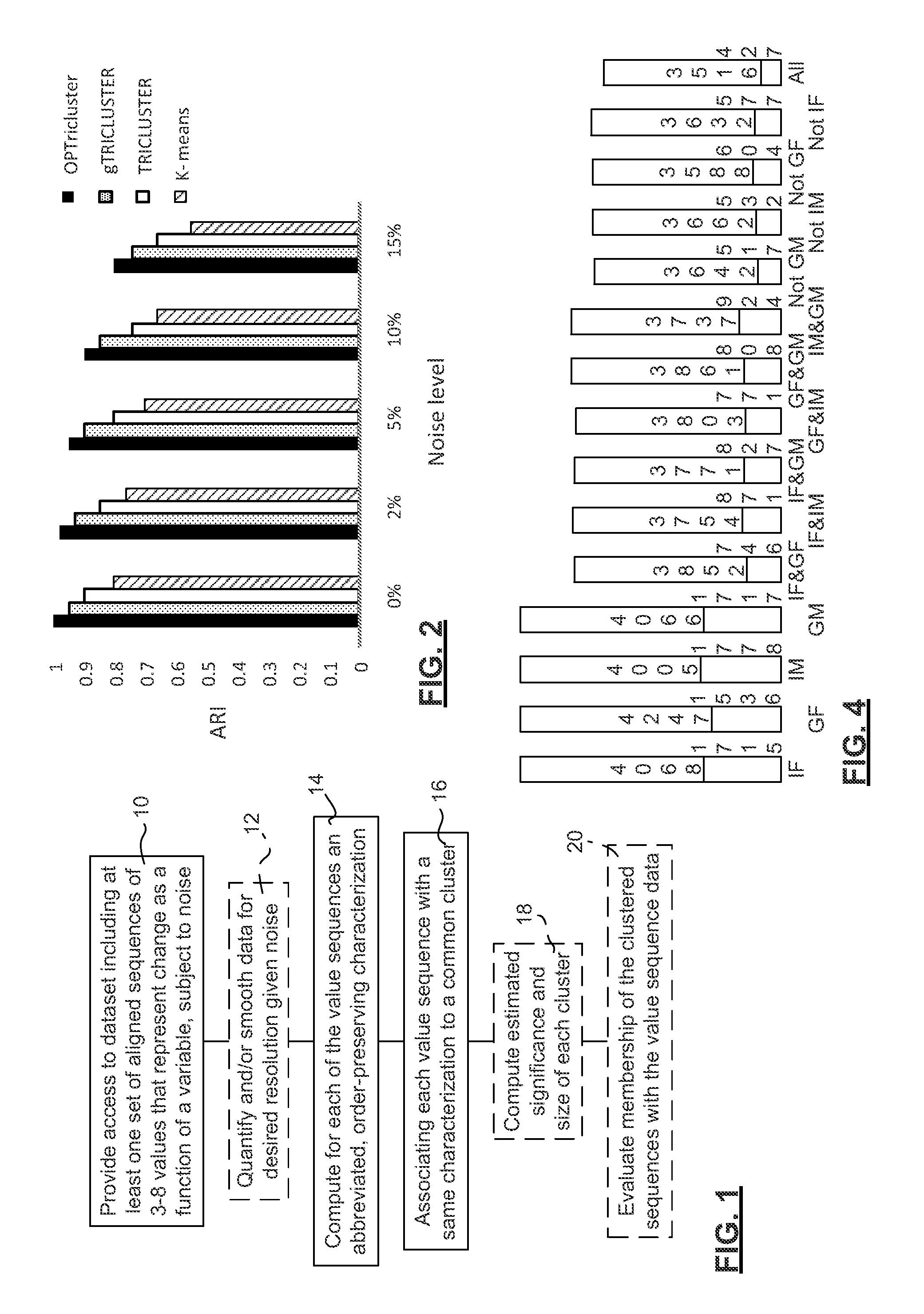

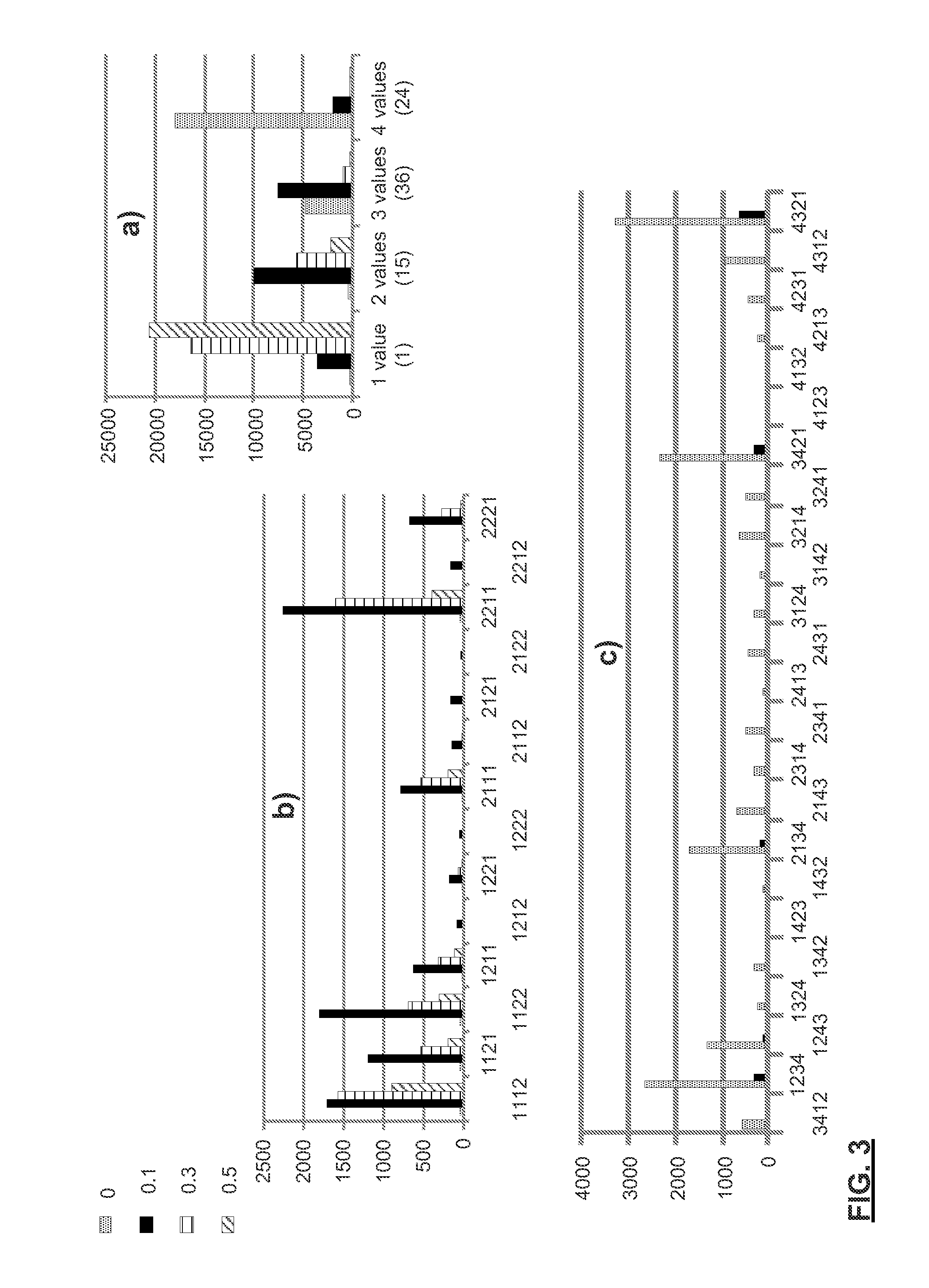

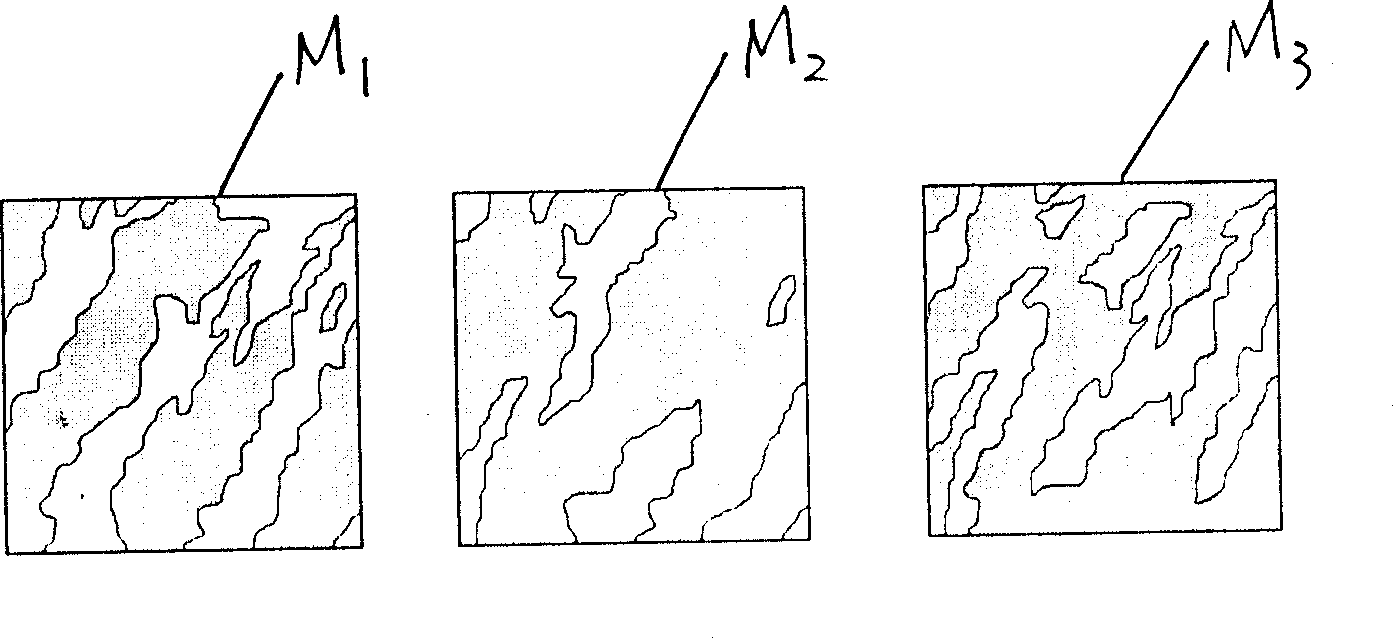

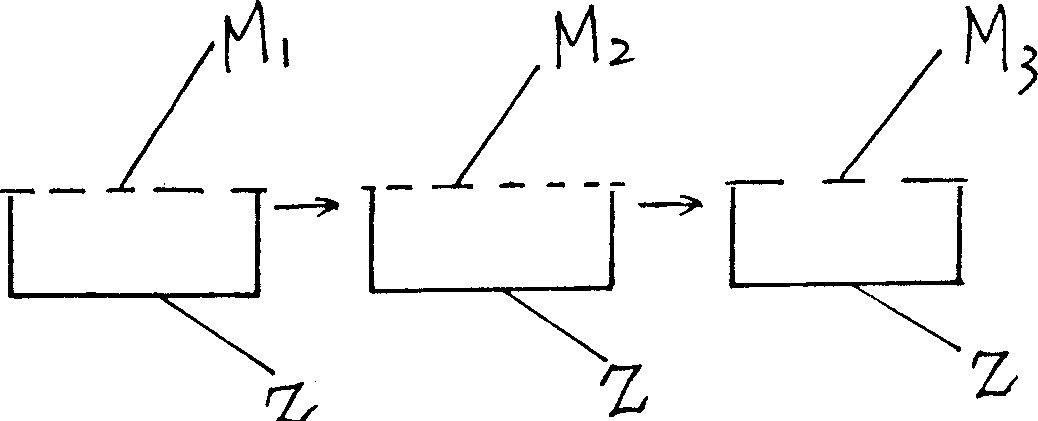

Order-preserving clustering data analysis system and method

InactiveUS20110282876A1Easy to compareReduce the effects of noiseDigital data processing detailsBiostatisticsClustered data3d patterning

Clustering data analysis that is robust to noise and is able to extract the most reliable information from sequential data comprises the ranking all of the measurement values across a third dimension of a 3D dataset in a selected one of an increasing order or a decreasing order and producing a three dimensional array of ranked values therefrom. It further comprises identifying coherent 3D patterns from the 3D array of ranked values, and counting the number of identified coherent 3D patterns. Each coherent 3D pattern parameters with a similar ranking and across subsets of the set of elements to a same group defines a cluster.

Owner:NAT RES COUNCIL OF CANADA

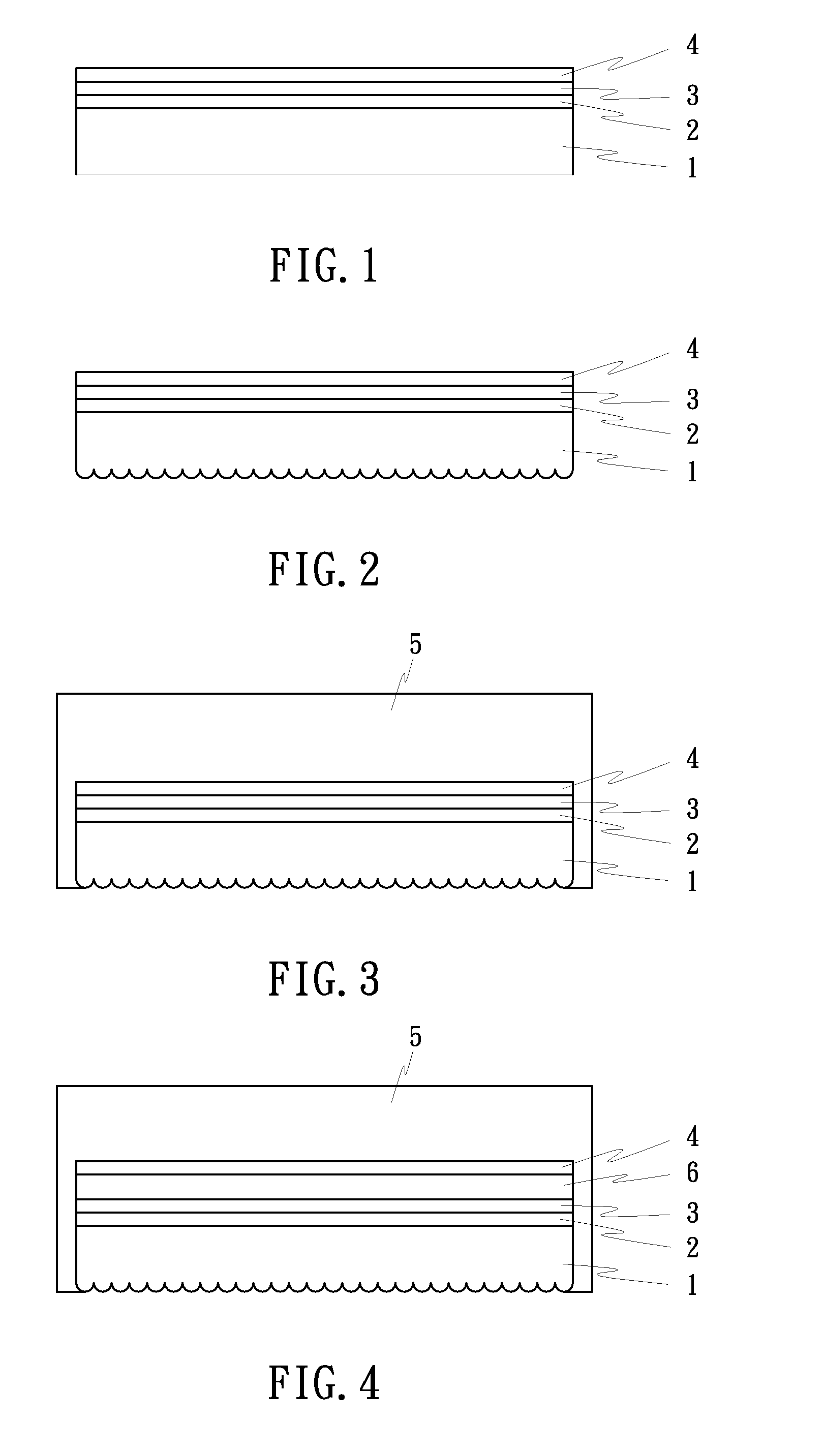

In-mold film with 2D or 3D pattern

InactiveCN101422978AHighlight the recognizable effectSynthetic resin layered products3d patterningGrating

An intramode film with 2D or 3D patterns comprises a substrate layer, a pattern layer, a protection layer and a bond layer, wherein, the pattern layer is a 2D pattern which appears like a mirror image and is printed on the inner surface of the substrate layer in advance, or is a 3D pattern printed on the substrate layer made from grating material, subsequently, a protection layer with the properties like high temperature and acid and alkaline resistance is printed on the 2D or 3D pattern layer, then the bond layer is coated on the protection layer, or according to requirements, a layer of materials resisting EMI is beforehand coated between the protection layer and the bond layer to avail the function of shielding electromagnetic wave. The intramode film is specially and directly compounded with a product component layer by matching with injection molding to lead the product component to have various integrally formed and selected patterns such as 2D or 3D patterns, and the like.

Owner:优利科技股份有限公司

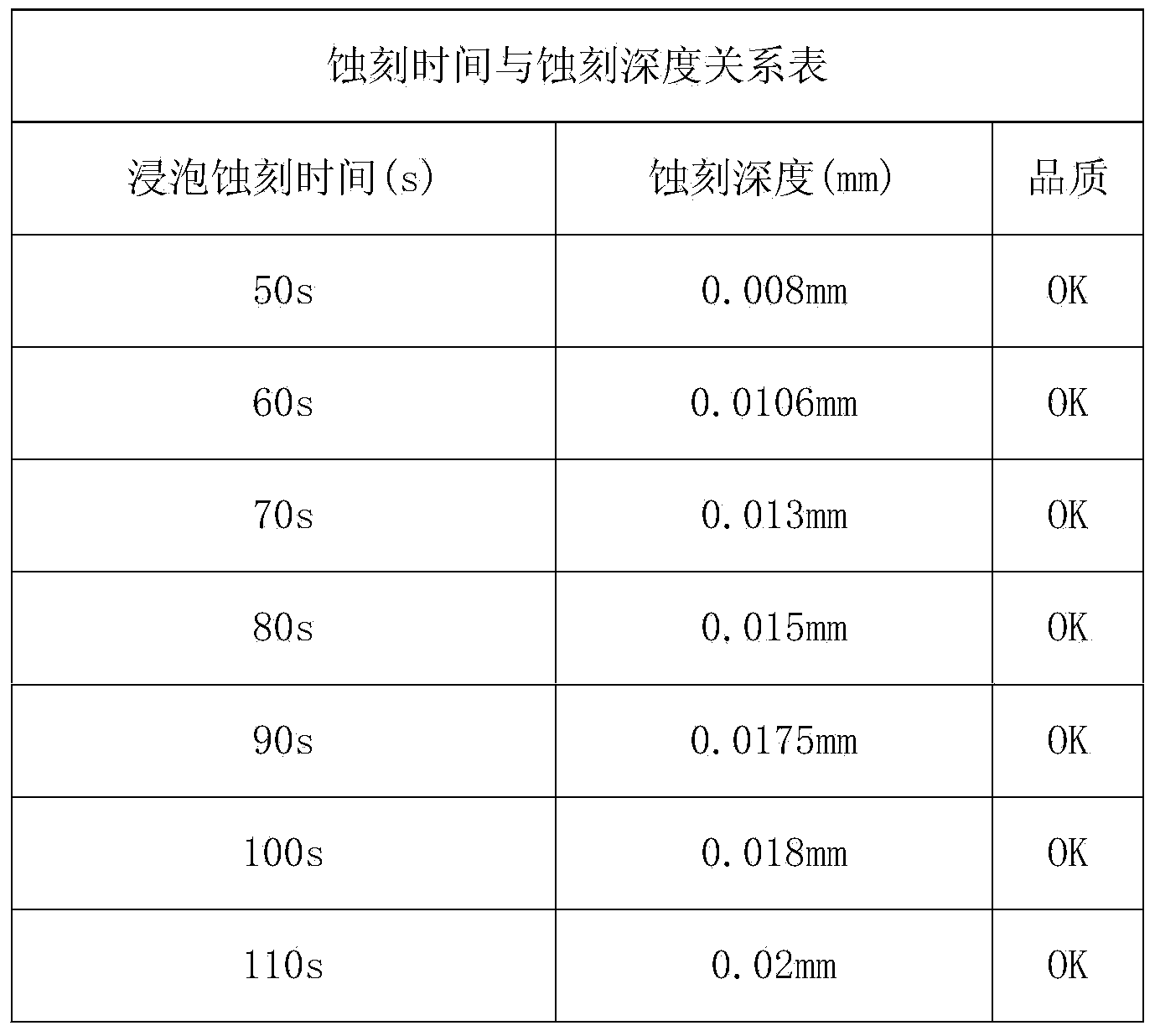

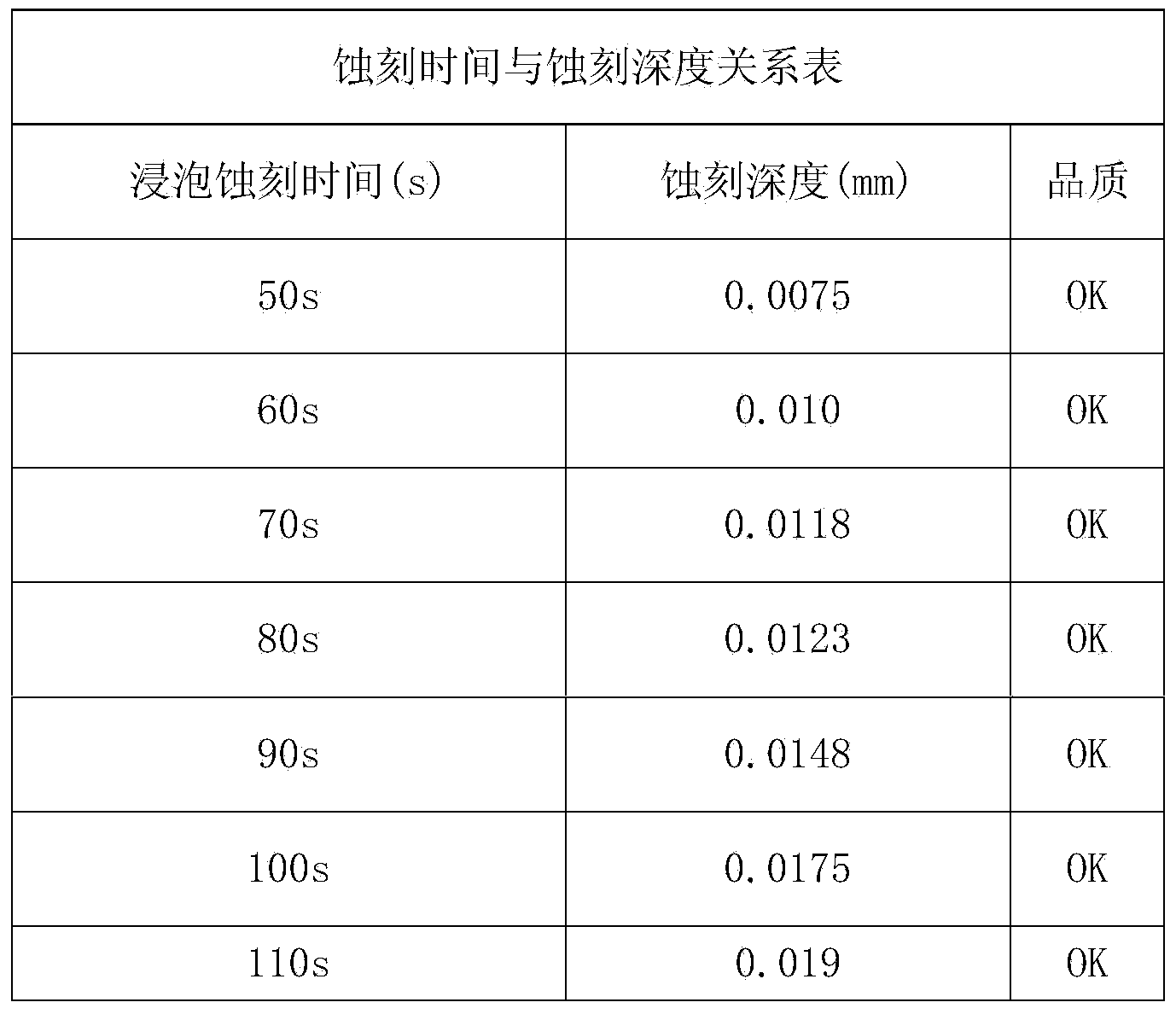

Method for producing 3D patterns on glass surface and etching solution for method

The invention discloses a method for producing 3D patterns on a glass surface. The method comprises the following steps: cleaning the surface of sheet glass before and after toughening, performing screen printing on patterns by using corrosion-resistant ink, putting the glass subjected to screen printing into etching solution, calculating the etching time according to the depth of the patterns and the rate of 0.01mm / 55-65seconds, taking out the processed glass, and putting the glass into water for cleaning the etching solution on the glass. The etching solution for the 3D patterns on the glass surface comprises the following components in parts by weight: 70-75 parts of water, 5-15 parts of a catalyst and 15-20 parts of hydrofluoric acid. The forming size of the patterns can be strictly controlled, so that the profile tolerance of the patterns is controlled to be + / -0.05mm.

Owner:LENS TECH CHANGSHA

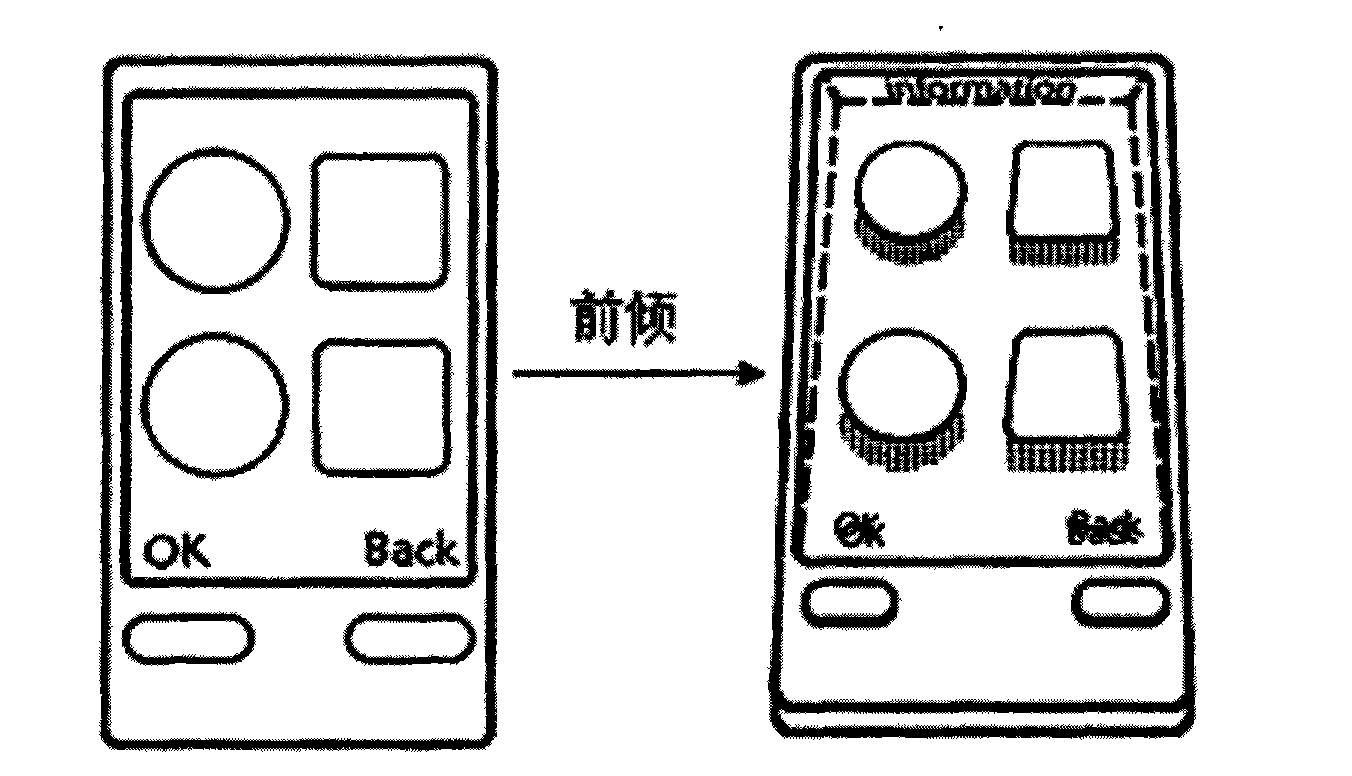

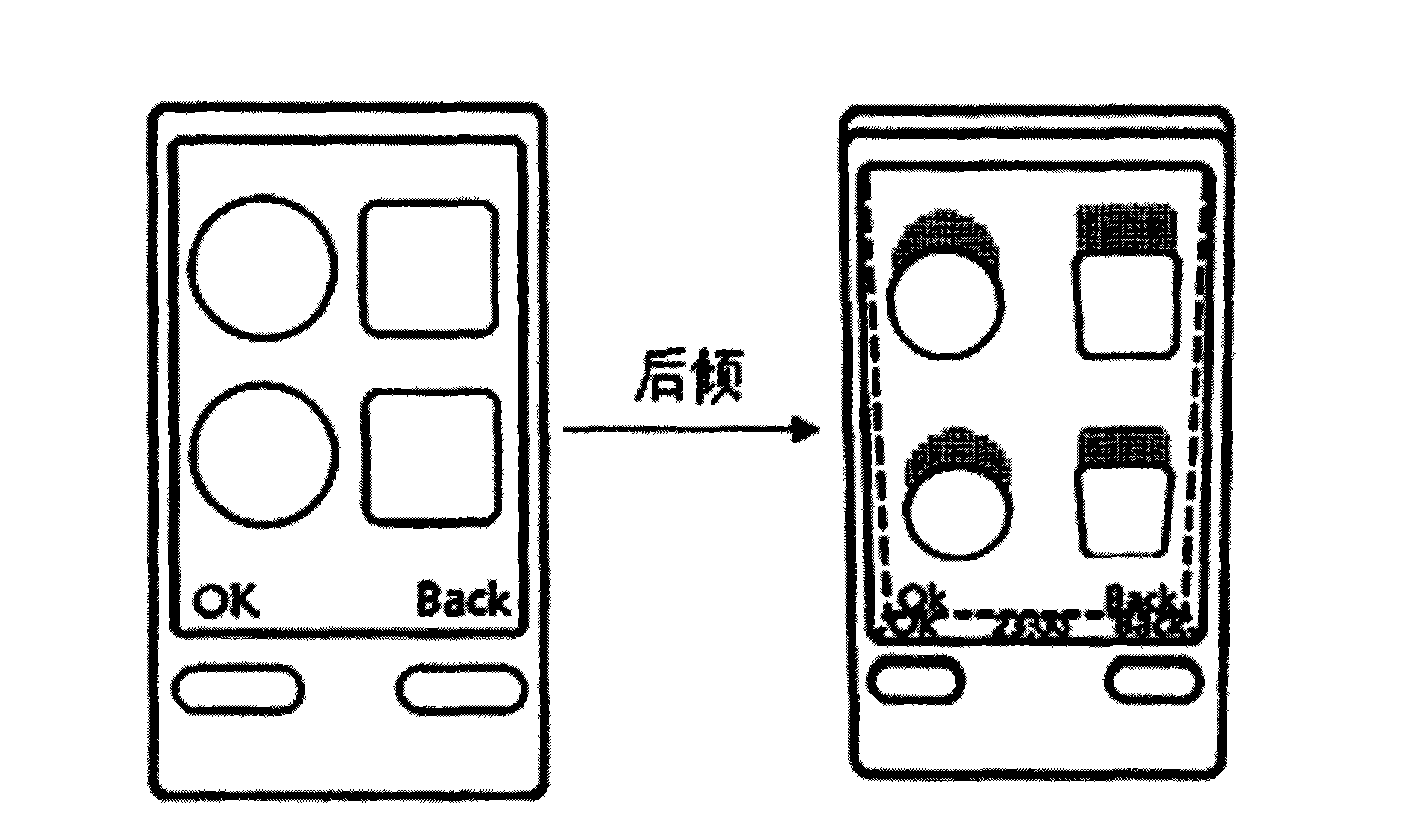

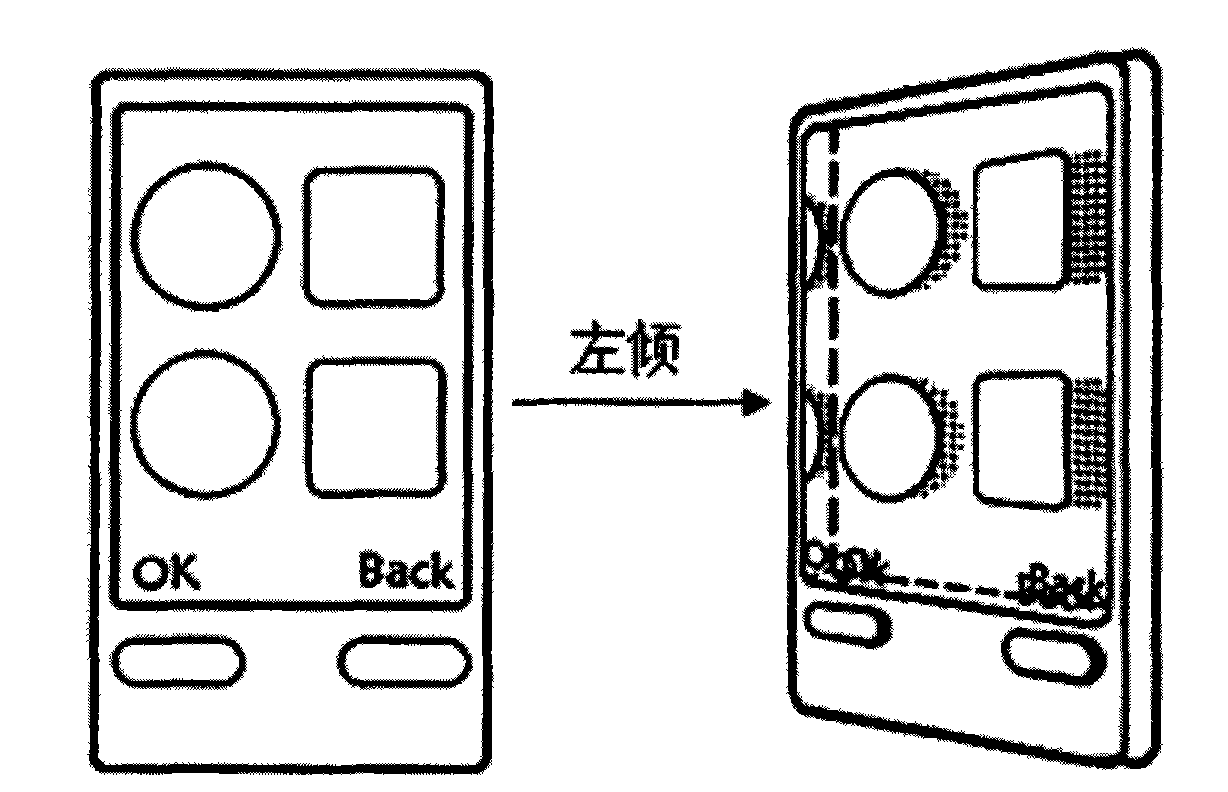

Display mode of mobile terminal supporting 3D (3-Dimensional) visual effect

The invention discloses a display mode of a mobile terminal supporting 3D (3-Dimensional) visual effect, which comprises the following steps of: setting and adding an acceleration sensor or an angle sensor on the mobile terminal; using the acceleration sensor to be matched with a pattern algorithm; obtaining the angle deflection values of the sensor in the X direction and the Y direction; dynamically regulating the 3D display effect; converting 3D patterns into 2D (2-Dimensional) patterns to be displayed on a display screen; and rotating a screen of the mobile terminal through forwards inclination, backwards inclination, leftwards inclination and rightwards inclination so that the protection of current interface elements can be seen and the 3D visual effect can be embodied. Meanwhile, the content display on other three-dimensional surfaces can also be seen, and the interesting effect of users to operate the mobile terminal is improved.

Owner:SHANGHAI LONGCHEER TECH CO LTD

Portable electronic device shell and method for manufacturing the same

InactiveCN101282369AImprove visual effectsReduce manufacturing costLamination ancillary operationsLayered product treatment3d patterningBiomedical engineering

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Hollow pattern mould system and method for producing multi-color area pattern article efficiently

InactiveCN1895866AObvious layered color changeEnhanced three-dimensional sense of visual hierarchyFeeding arrangments3d patterningEngineering

A mould system for making the products with multi-color 3D patterns is suitable for the decorative material or plate made of ceramics, glass, microcrystalline glass, resin-contained artificial stone, etc. It has 2-20 formworks with empty cavities for the raw materials. Each formwork has at least 1-10000 edge shapes and 1-10000 pattern edge shapes or general shapes relative to different colors. 1-30 color material carriers are arranged under 2-20 formworks. An immovable supporting plate is close to the top surface of each formwork and a color materials distributing box is carried by said supporting plate.

Owner:杨德宁

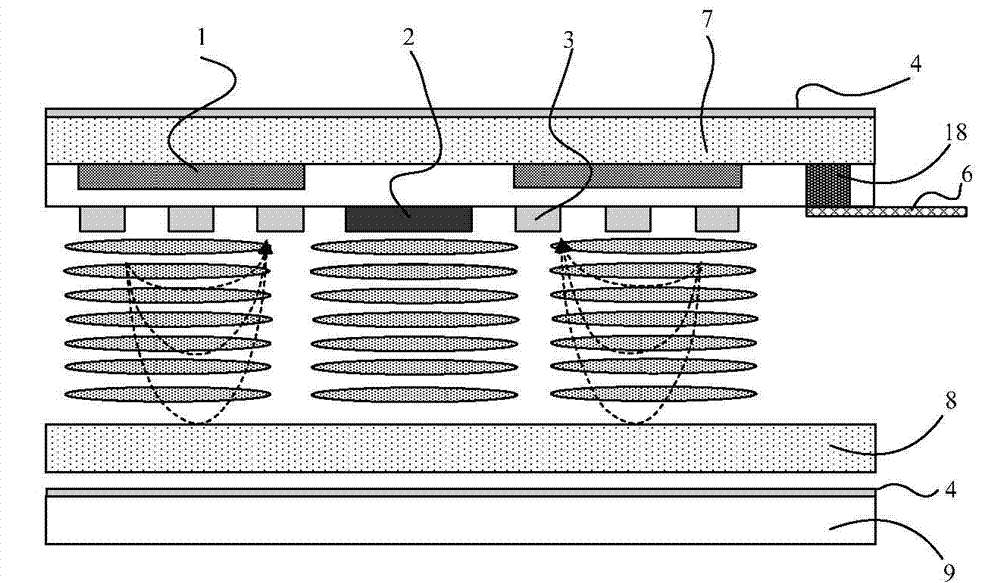

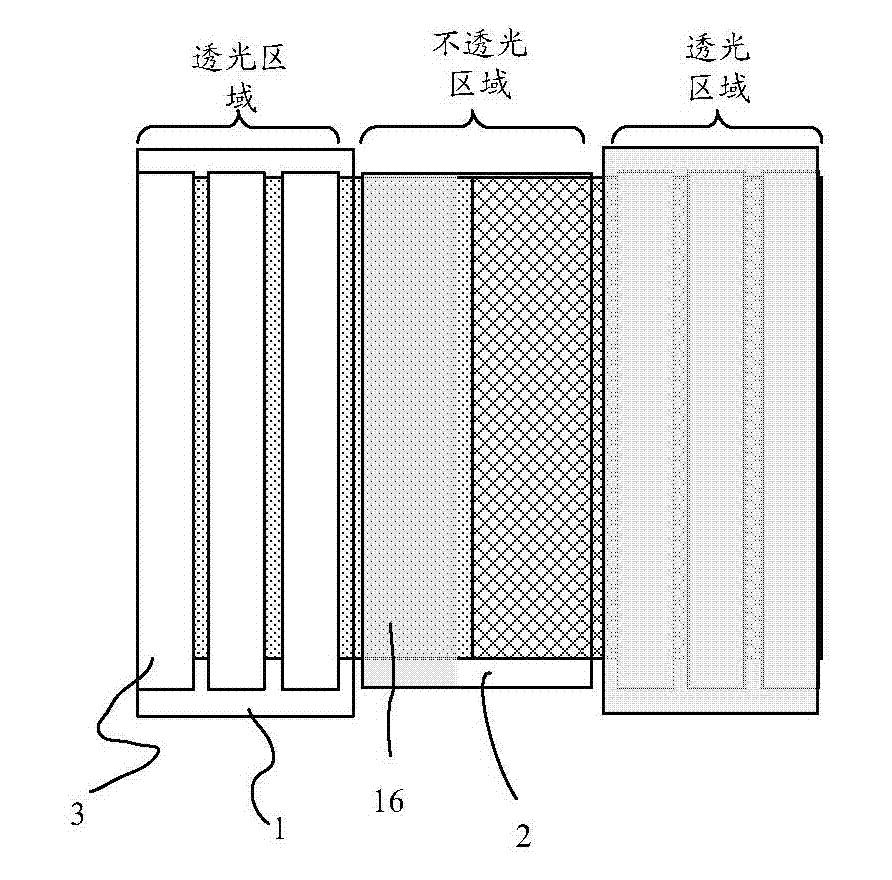

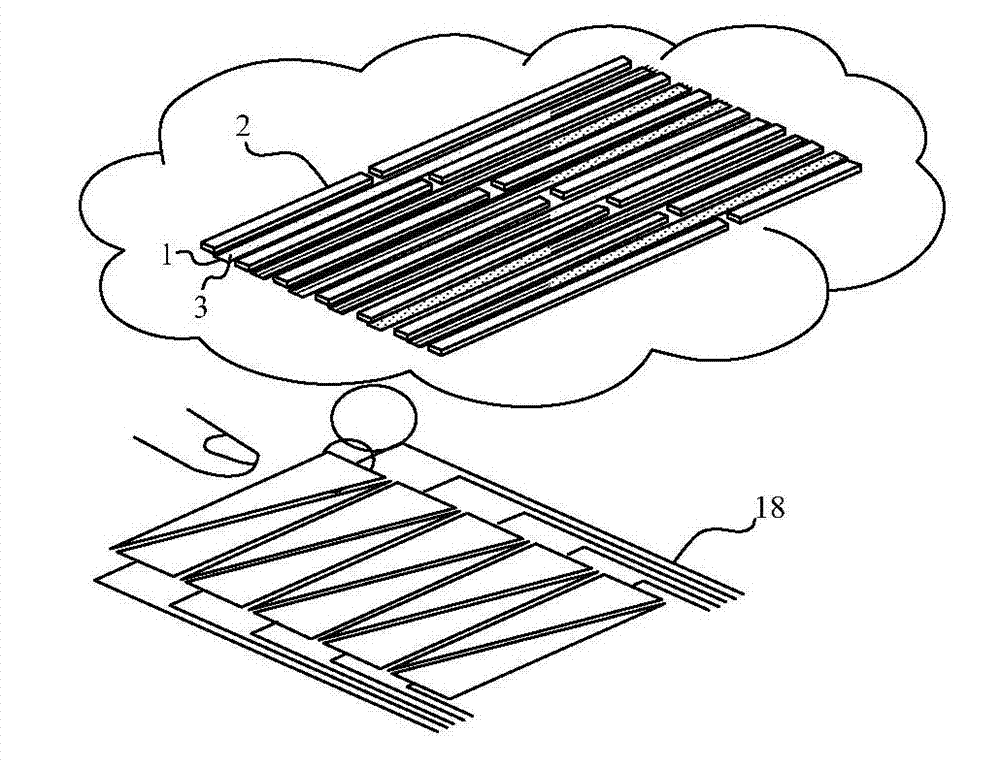

Naked eye 3D (Three Dimensional) touch device and production method thereof and display device

ActiveCN103529584ARealize the touch functionIncrease added valueNon-linear opticsInput/output processes for data processing3d patterningDisplay device

The invention discloses a naked eye 3D (Three Dimensional) touch device and a production method thereof and also discloses a display device which comprises the naked eye 3D touch device; the naked eye 3D touch device comprises a first substrate, a second substrate and a liquid crustal layer which is arranged between the first substrate and the second substrate; a surface of the first substrate, which is towards the liquid crystal layer, is sequentially provided with a public electrode, an insulating layer, slit electrode units and touch electrode units; the slit electrode units and the touch electrode units are oppositely arranged; the touch electrode units and the slit electrode units are arranged in an interval mode; every slit electrode unit comprises at least two slit electrodes; the touch electrode units comprise at least two touch electrodes; touch electrodes which are arranged in the same touch electrode unit are arranged in the same layer and insulated t each other. According to the naked eye 3D touch device, 3D display and touch are perfectly integrated and touch functions under 2D and 3D patterns are achieved under the premise that a 3D function is uniformly displayed.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

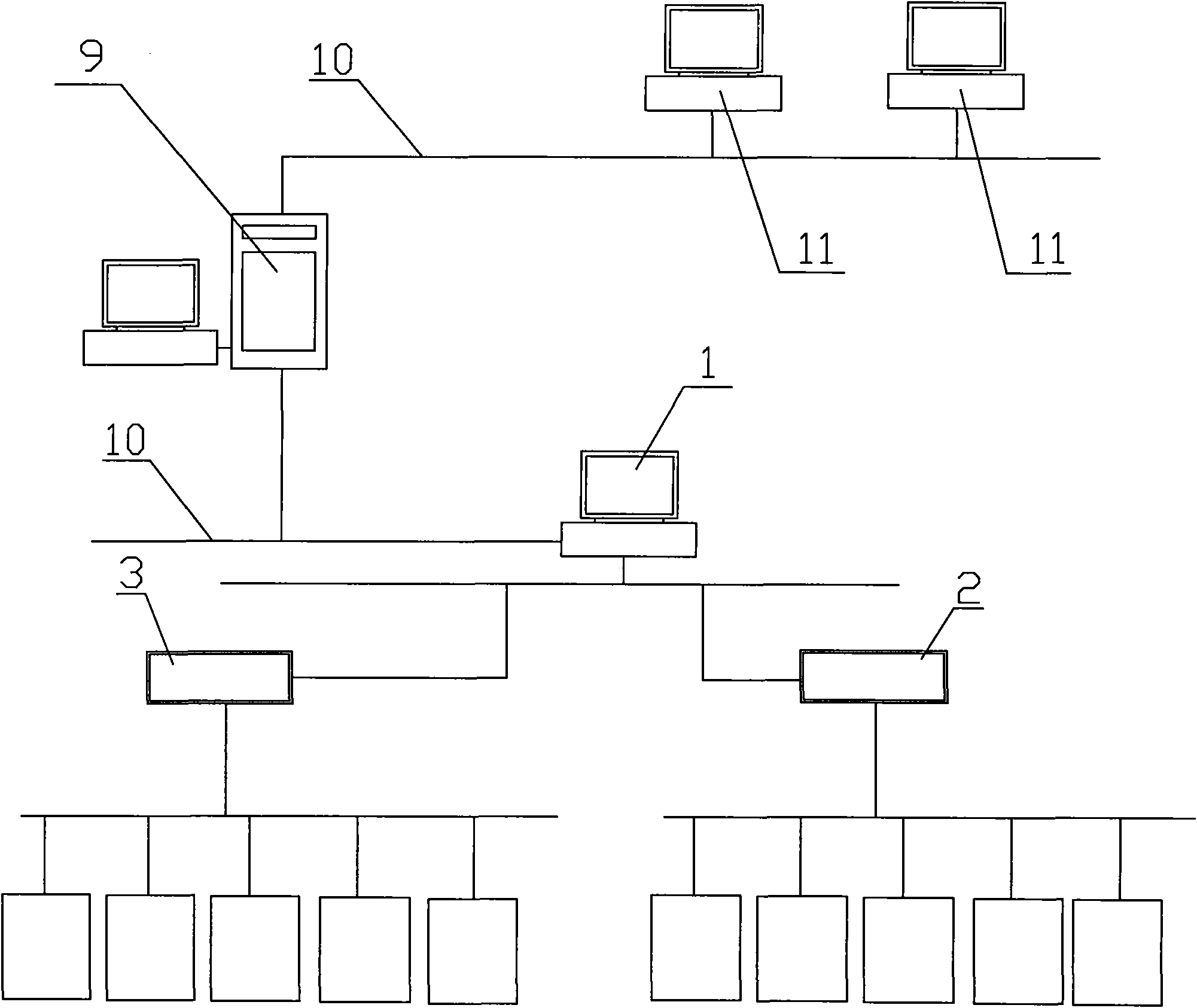

Monitoring system and method of aerobridge

ActiveCN101840629AAvoid failureComprehensive health monitoringTransmission systemsIndication of measured values3d patterningData acquisition

The invention relates to monitoring system and method of an aerobridge. The monitoring system of the aerobridge comprises a data acquisition device, a PLC (Programmable Logic Controller), a data processing unit and a display or output device, wherein the data acquisition device comprises a plurality of sensors arranged on the aerobridge, the display or output device comprises a display screen or a printer, and the PLC is used for transmitting data signals collected by the sensors to the data processing unit and displaying in 3D (three-dimensional) patterns. The monitoring method of the aerobridge comprises the following steps of: (1) establishing data signal acquisition points of the aerobridge; (2) establishing a data model of the aerobridge and naming each data signal acquisition point; (3) sending a signal to each data signal acquisition point and transmitting a feedback signal to the data processing unit; and (4) displaying in 3D patterns. In the invention, the working state of the aerobridge is displayed in real time by 3D patterns, and the fault position of the aerobridge is intuitively and remarkably displayed to favorably and fully monitor the operation conditions of the aerobridge and a whole airport and rapidly find and solve aerobridge faults.

Owner:THYSSENKRUPP AIRPORT SYSTEM (ZHONGSHAN) CO LTD

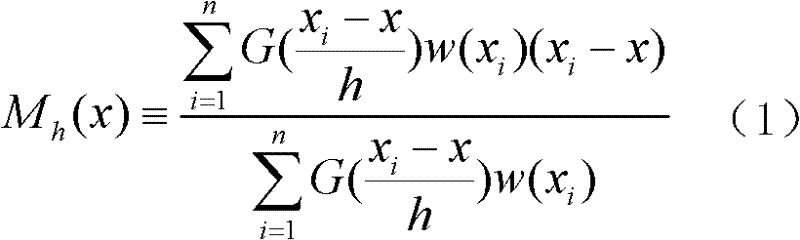

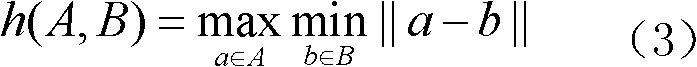

3D Pattern Recognition Method Based on Color and Shape Matching

ActiveCN102298708AHigh precisionCharacter and pattern recognitionSteroscopic systems3d patterningImaging processing

The invention relates to the 3D television technology and especially relates to a 3D mode identification method. In the prior art, the 3D mode does not possess an automatic identification function. The invention discloses the 3D mode identification method based on image processing, especially based on color and shape matching. The 3D mode identification method based on the color and shape matching is characterized by: dividing a video image into left and right eye images; then setting one image to be the image of the 3D mode; carrying out the color matching and the shape matching of the left and right eye images by using a mature color matching algorithm and a mature shape matching algorithm in an image processing technology; determining that the 3D mode of the video image is the set 3D mode when the color and the shape reach a matching condition, otherwise determining that the video image is not the 3D mode video image. By using the invention, 3D video mode identification accuracy ishigh; an identification algorithm is simple and high efficient. The method can be used in video equipment, such as a television and the like, so that automatic identification and mode switching can be performed.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

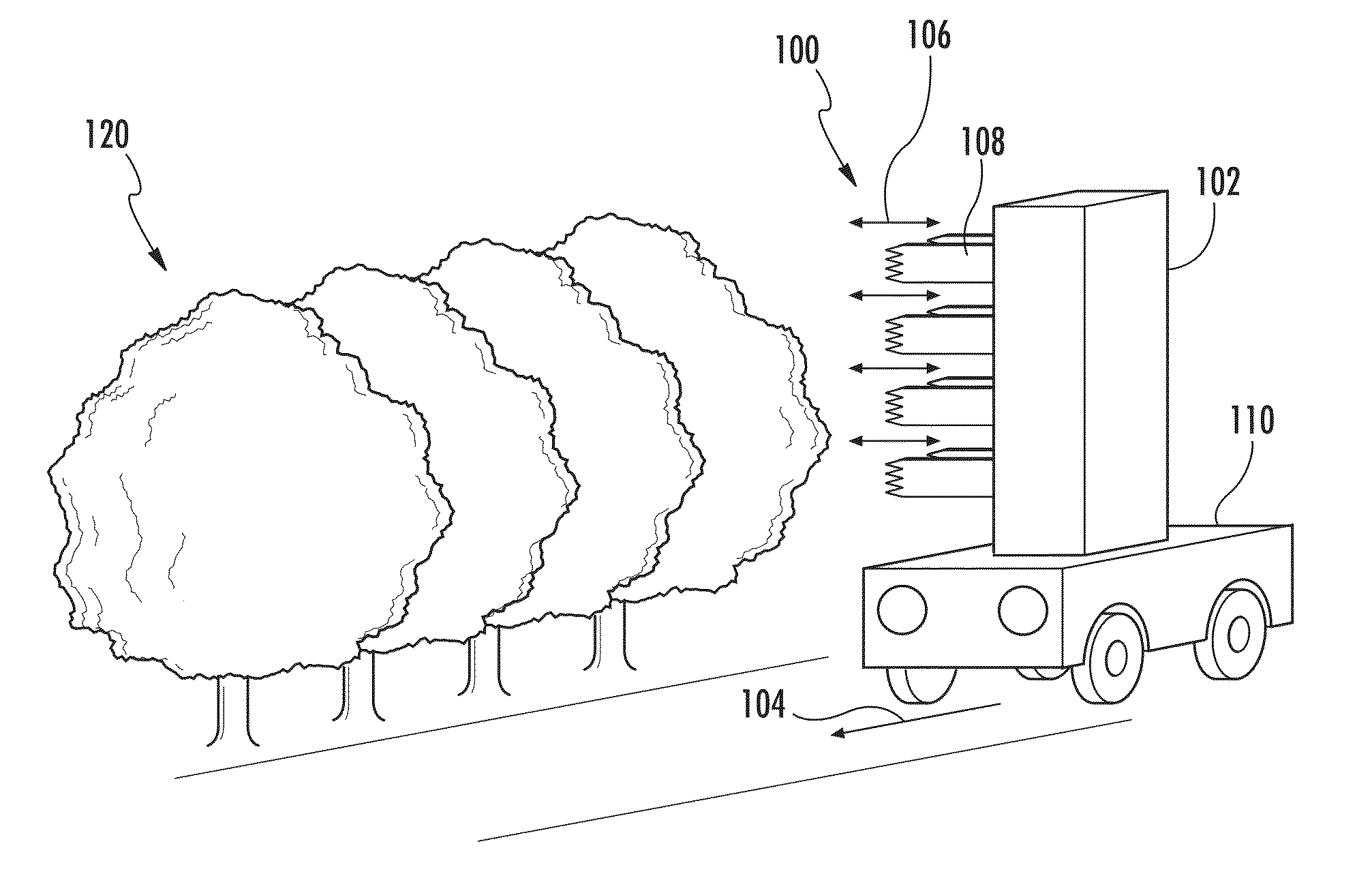

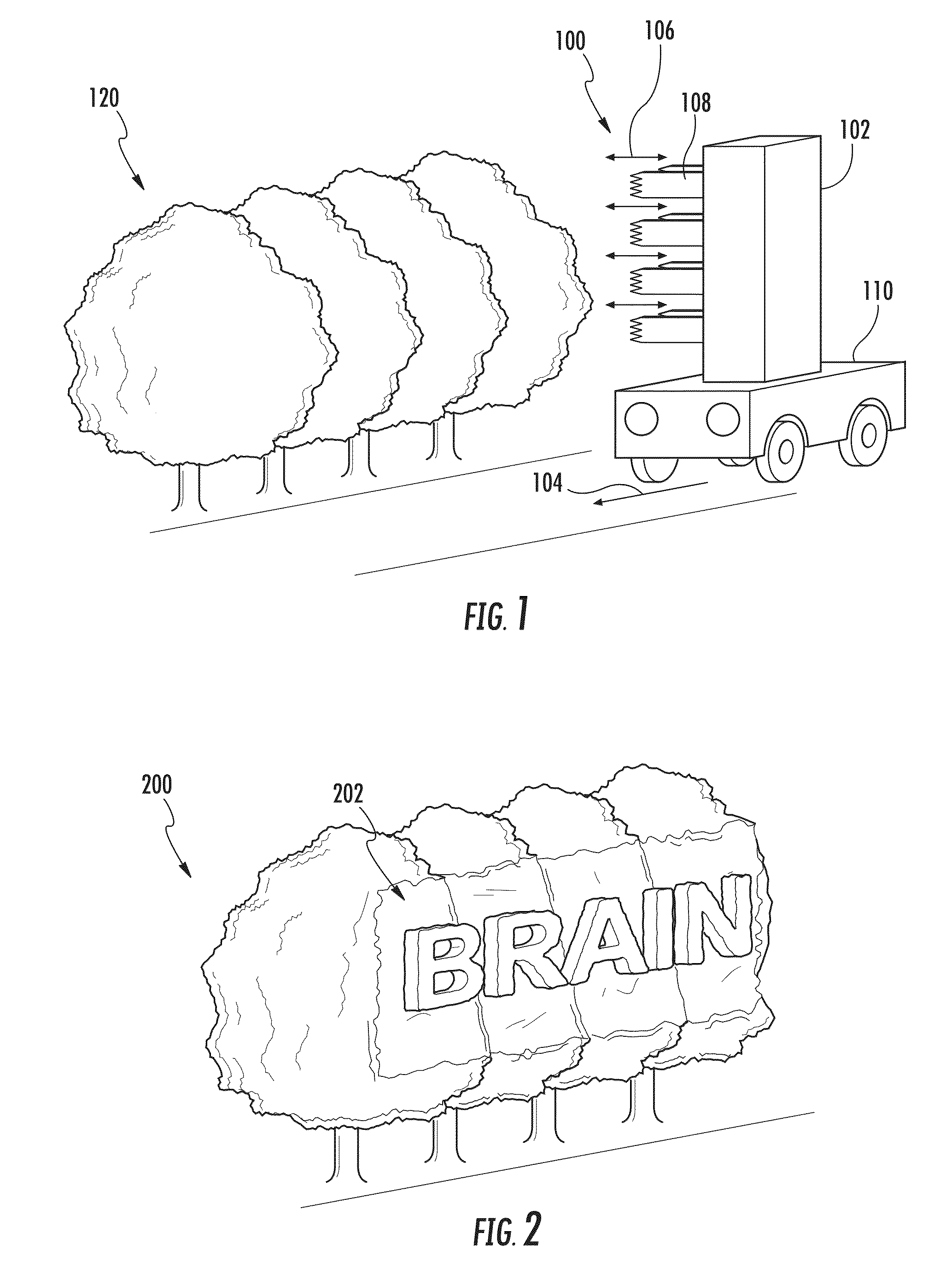

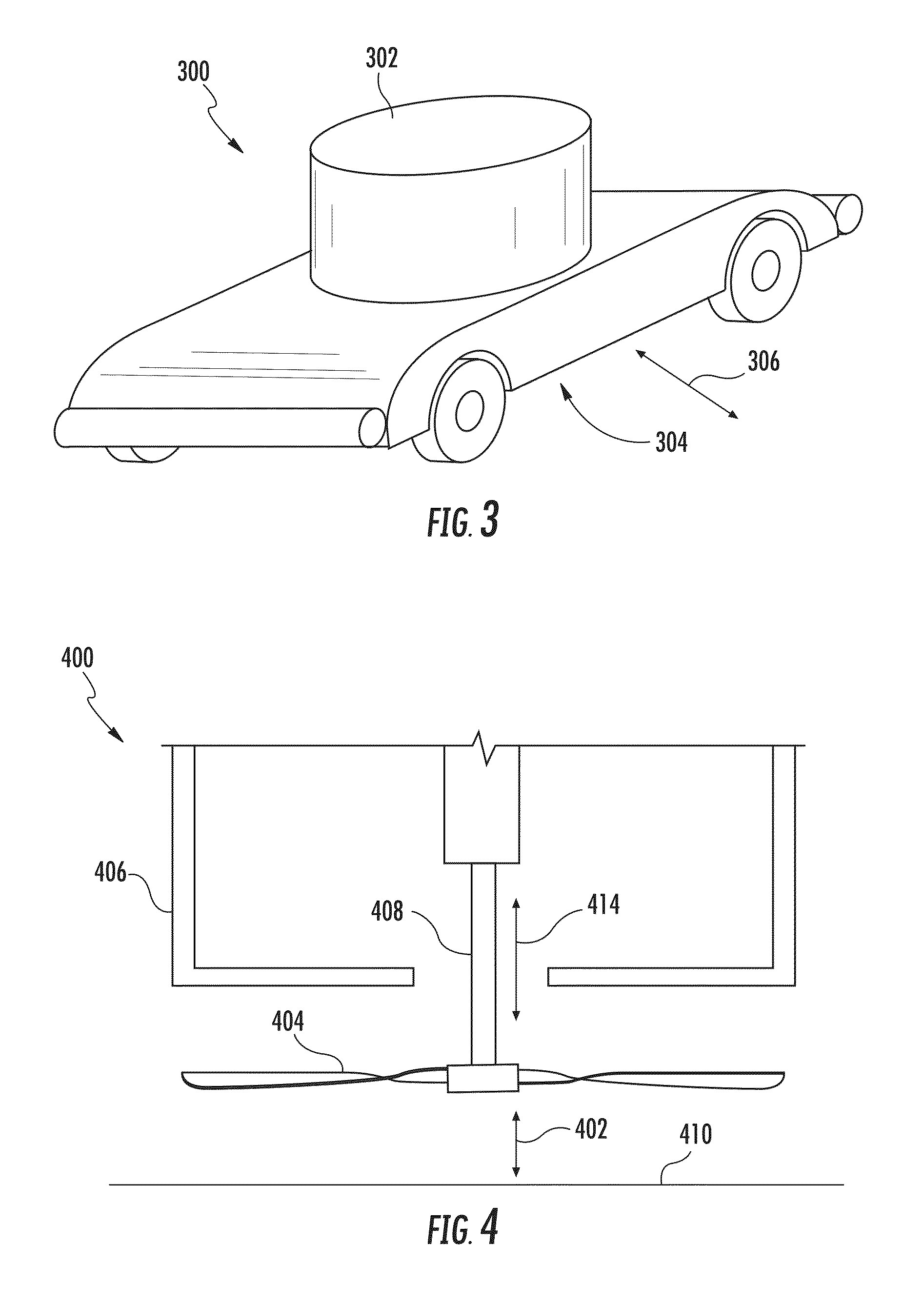

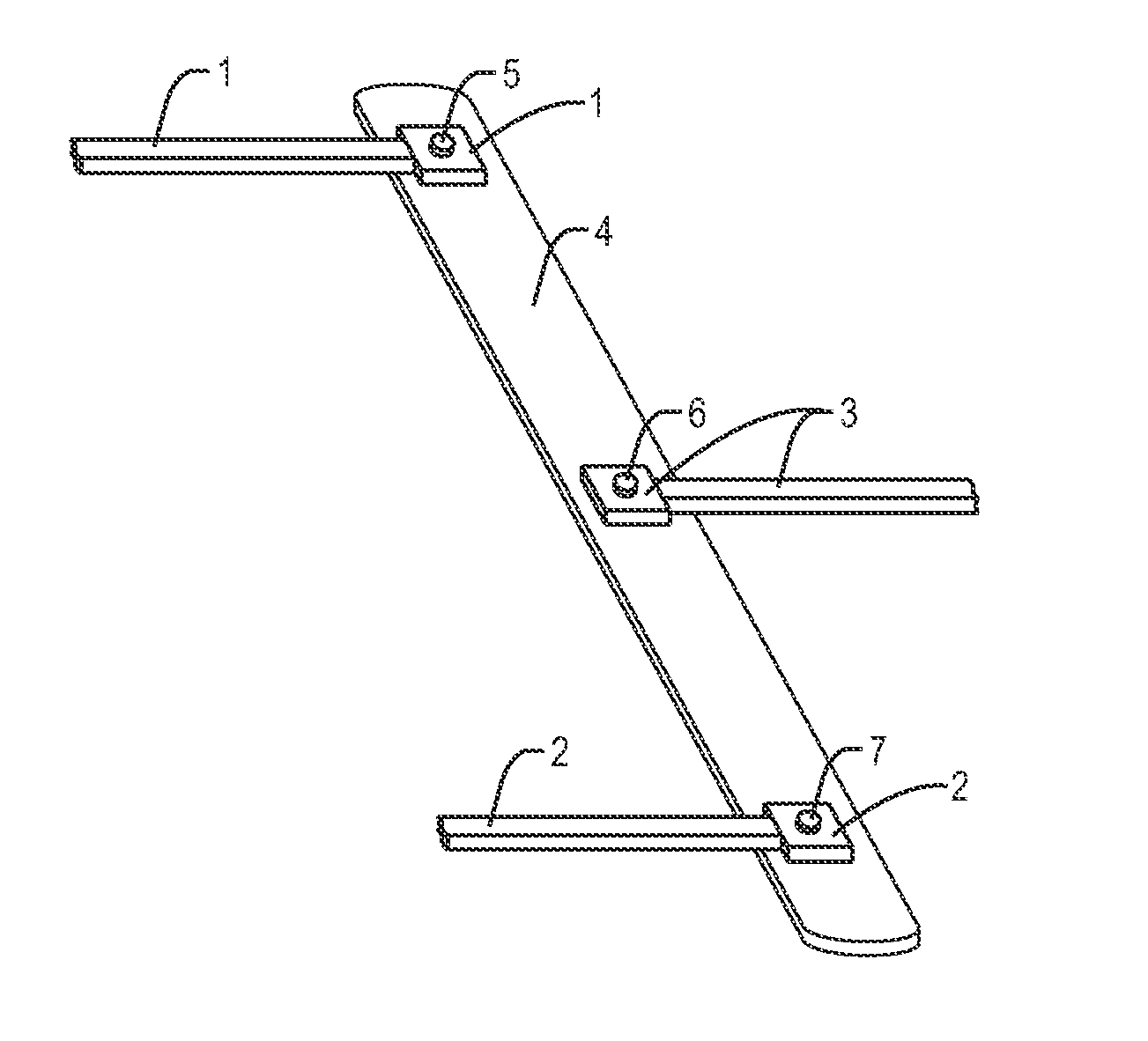

Computerized learning landscaping apparatus and methods

InactiveUS20160150739A1Autonomous decision making processHedge trimming apparatus3d patterningEngineering

A method and an apparatus for shaping of lawns and hedges into desired 3D patterns or shapes. The apparatus consists of a bStem and / or other computational device comprising storage, a motorized platform, and trimmer end effectors. The computational device instructs the end effectors to extend or retract as the platform moves along at a steady pace, thus producing a target pattern (e.g., a company logo) in a hedge, lawn, a wall or a ground-cover of any material suitable for such shaping. The apparatus may be configured to operate autonomously based on a pre-loaded pattern file. Software (e.g., such as BrainOS) may be used to provide real-time feedback to trimmers regarding the process and the results, and possibly to train the inverse model accordingly. The apparatus may learn to minimize predicted or current mismatches between the desired pattern and the one being produced. Users compete for the best designs.

Owner:BRAIN CORP

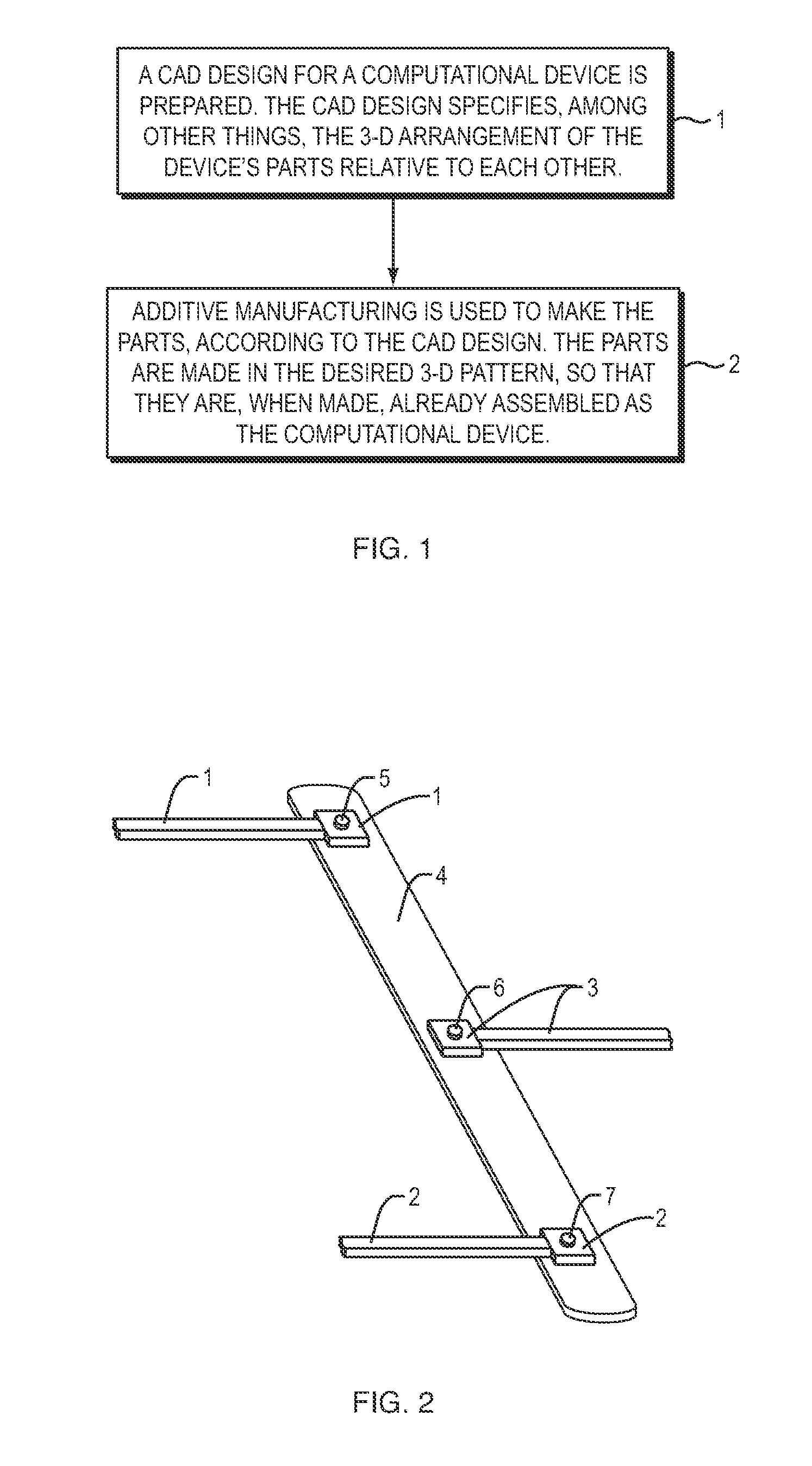

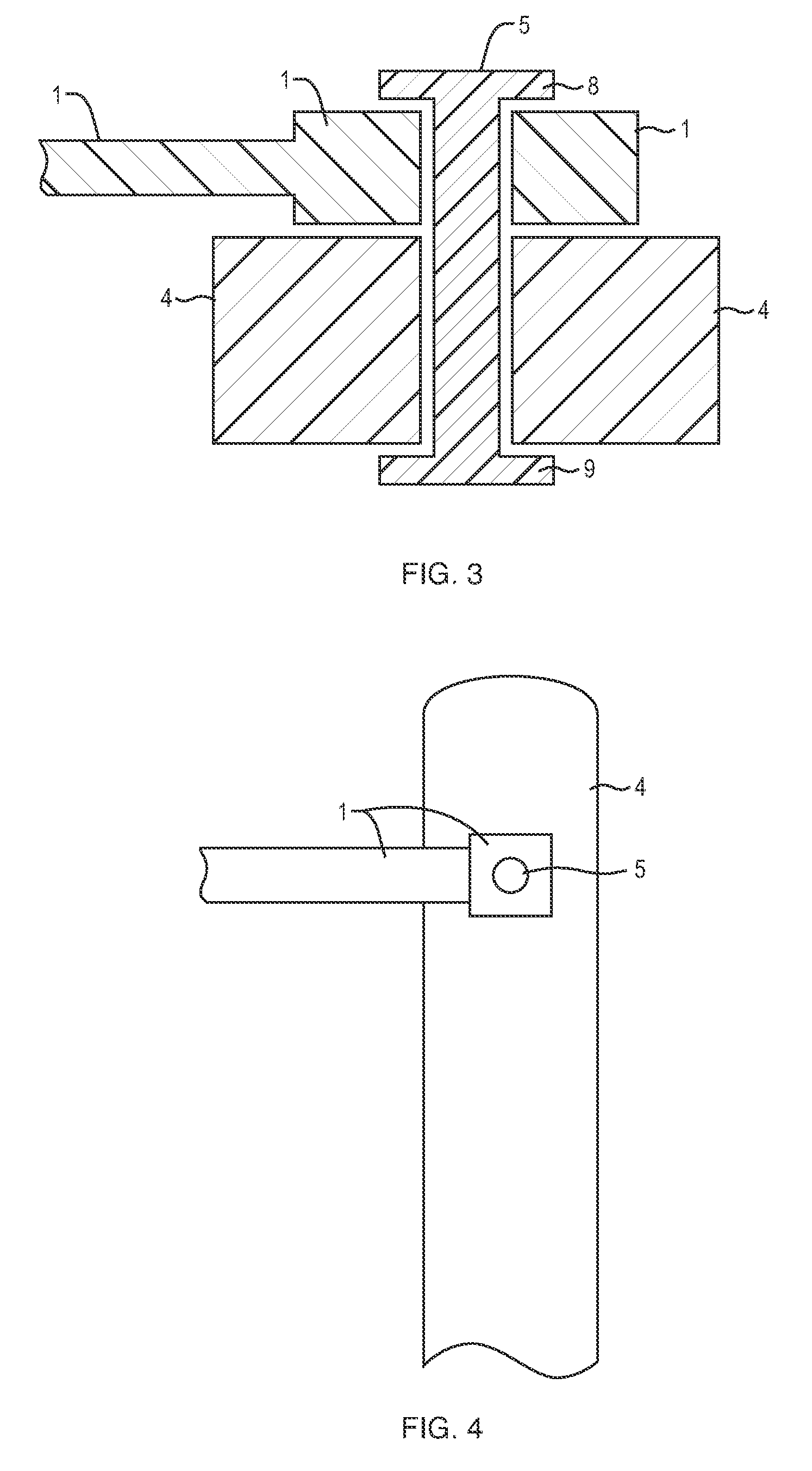

Methods and Apparatus for Manufacturing a Computer Without Assembly

ActiveUS20110278365A1Highly complex computationProgramme controlAdditive manufacturing apparatusMechanical computer3d patterning

In an illustrative implementation of this invention, a mechanical computer is manufactured without a separate step of assembly. This is achieved by producing parts in a three dimensional pattern (in relation to each other) such that, when this manufacturing is completed, the components are already assembled to form a computer or part of a computer. The second step of assembling the parts into a desired three dimensional pattern is avoided, because the parts, when made, are already arranged in that 3D pattern.

Owner:SWARTZ ROBERT

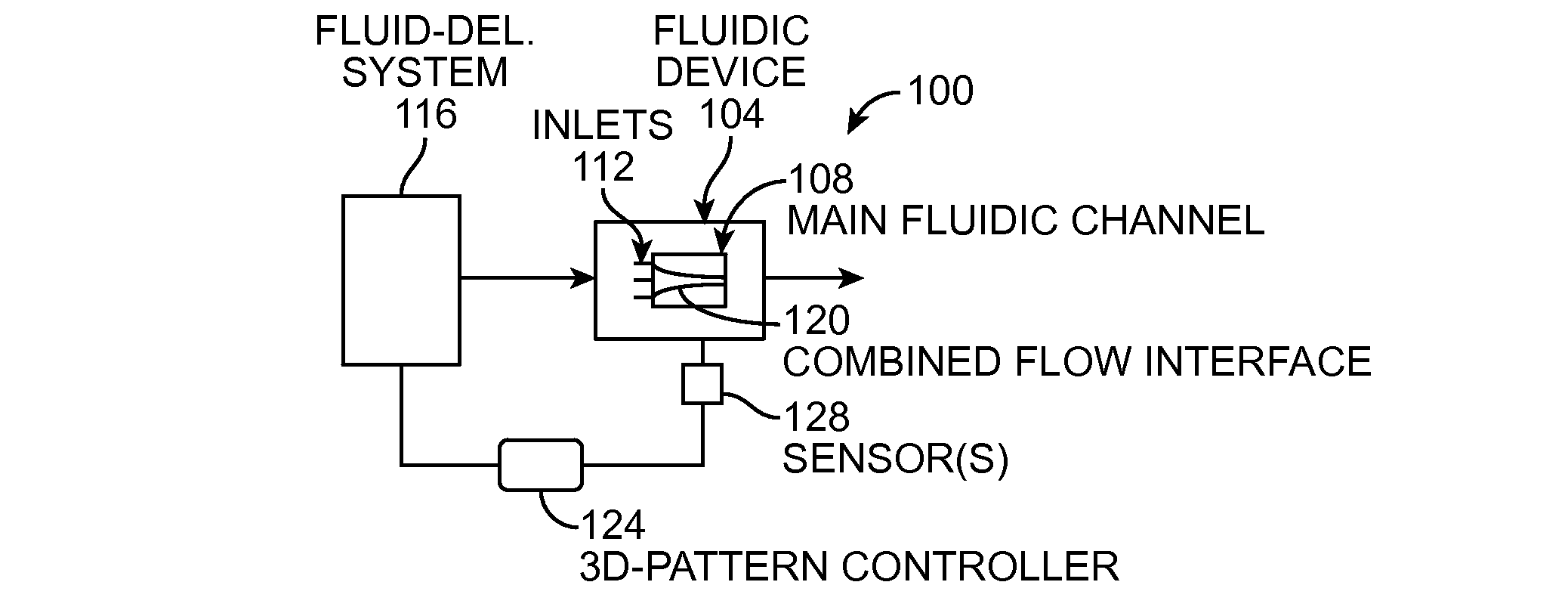

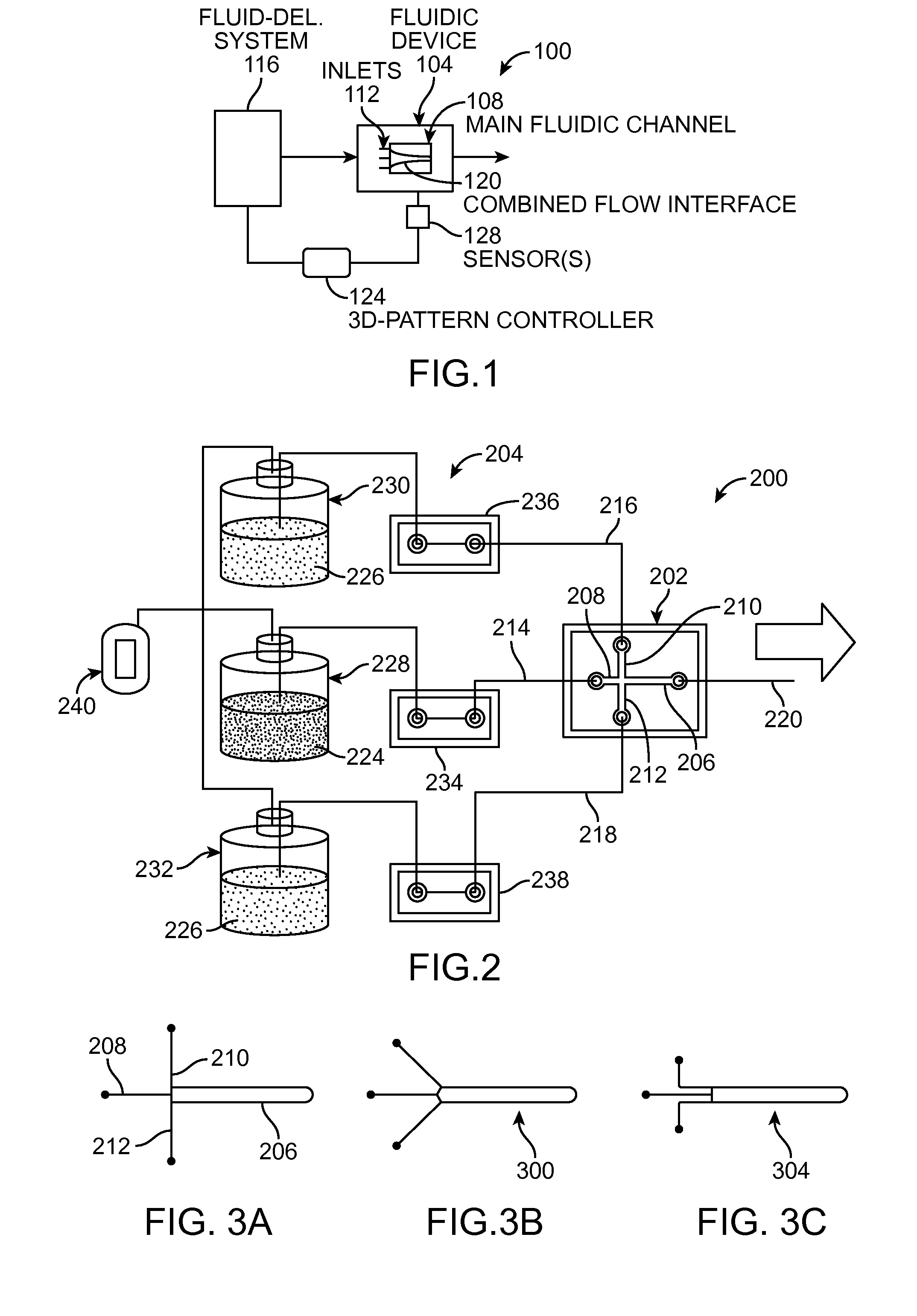

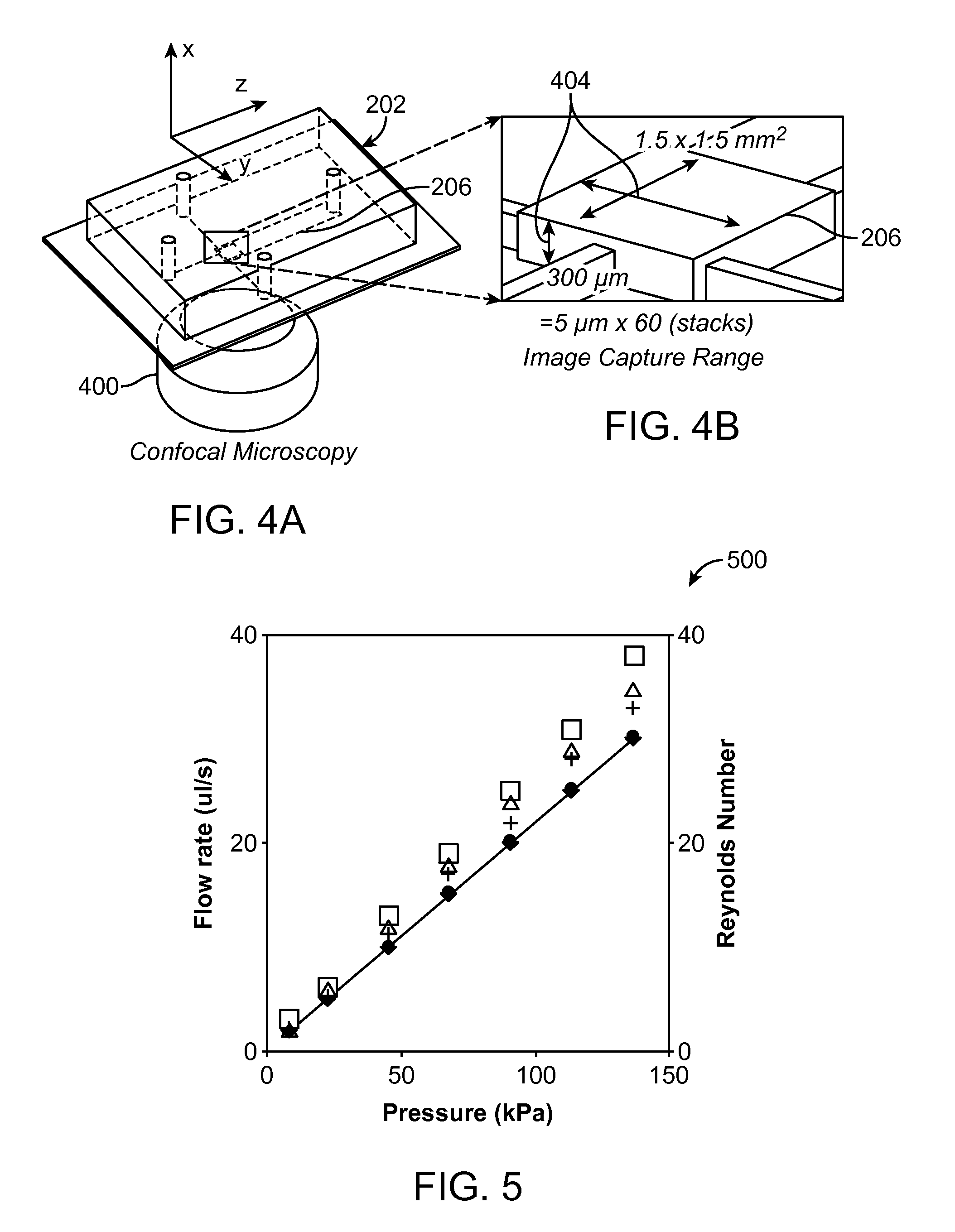

3D Chemical Pattern Control in 2D Fluidics Devices

InactiveUS20130014828A1Chemical/physical/physico-chemical microreactorsLaboratory glasswares3d patterningEngineering

Methods of controllably creating three-dimensional (3D) combined-flow-interface patterns in multi-lane fluidic devices, and systems, apparatuses and software therefor. In one example, the 3D-pattern is created and varied as a function of one or more of the geometry of the inlets to a main fluidic channel in which the 3D-pattern is formed, the Reynolds number of the flows, the dimensions of the main fluidic channel and the inlets, and the spacing of adjacent inlets. In one embodiment particularly disclosed, differing 3D combined-flow-interface patterns are created using a three-lane fluidic device having a fixed inlet geometry. In another embodiment particularly disclosed, differing 3D combined-flow-interface patterns are created using a five-lane fluidic device having a fixed inlet geometry that can be used to effectively mimic variable inlet geometries.

Owner:CARNEGIE MELLON UNIV

Process for printing and securing three-dimensional pattern on non-fibrous substrates and article comprising non-fibrous surface having three-dimensional pattern thereon

ActiveUS20150266334A1Envelopes/bags making machineryLayered products3d patterningBiomedical engineering

A process for creating a stable 3D pattern on a non-fibrous substrate comprises depositing a heat-expandable composition on the substrate; causing the disposed composition to expand in volume, thereby forming a 3D pattern having a perimeter; causing the composition to solidify; and applying a varnish coating over the pattern's perimeter and an area of the substrate adjacent thereto such that the varnish covers a sealing region extending at least 0.5 mm from the perimeter on both sides thereof. An article of manufacture comprises a non-fibrous outer surface having a 3D decorative pattern applied thereto and coated with a varnish coating covering a sealing region extending at least 0.5 mm from the pattern's perimeter on both sides thereof.

Owner:THE PROCTER & GAMBLE COMPANY

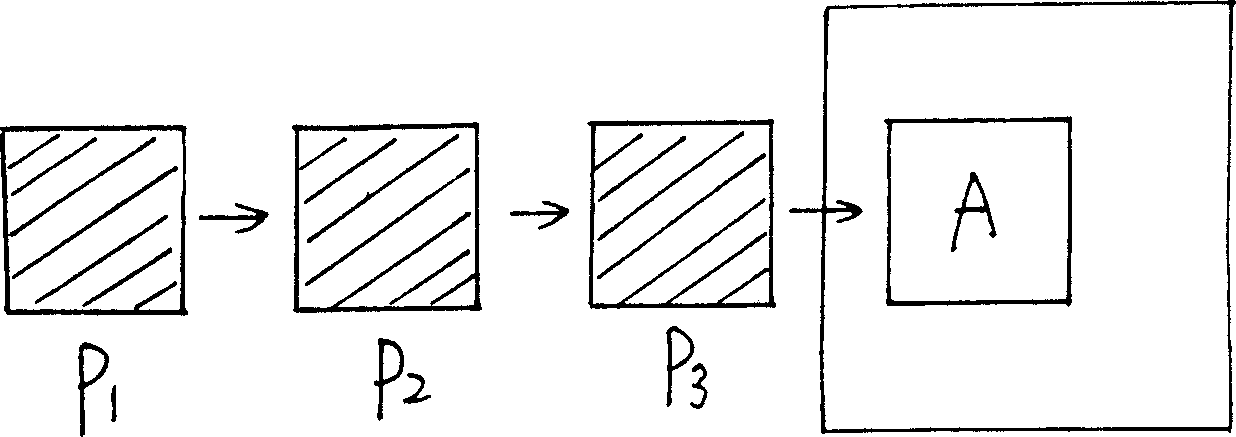

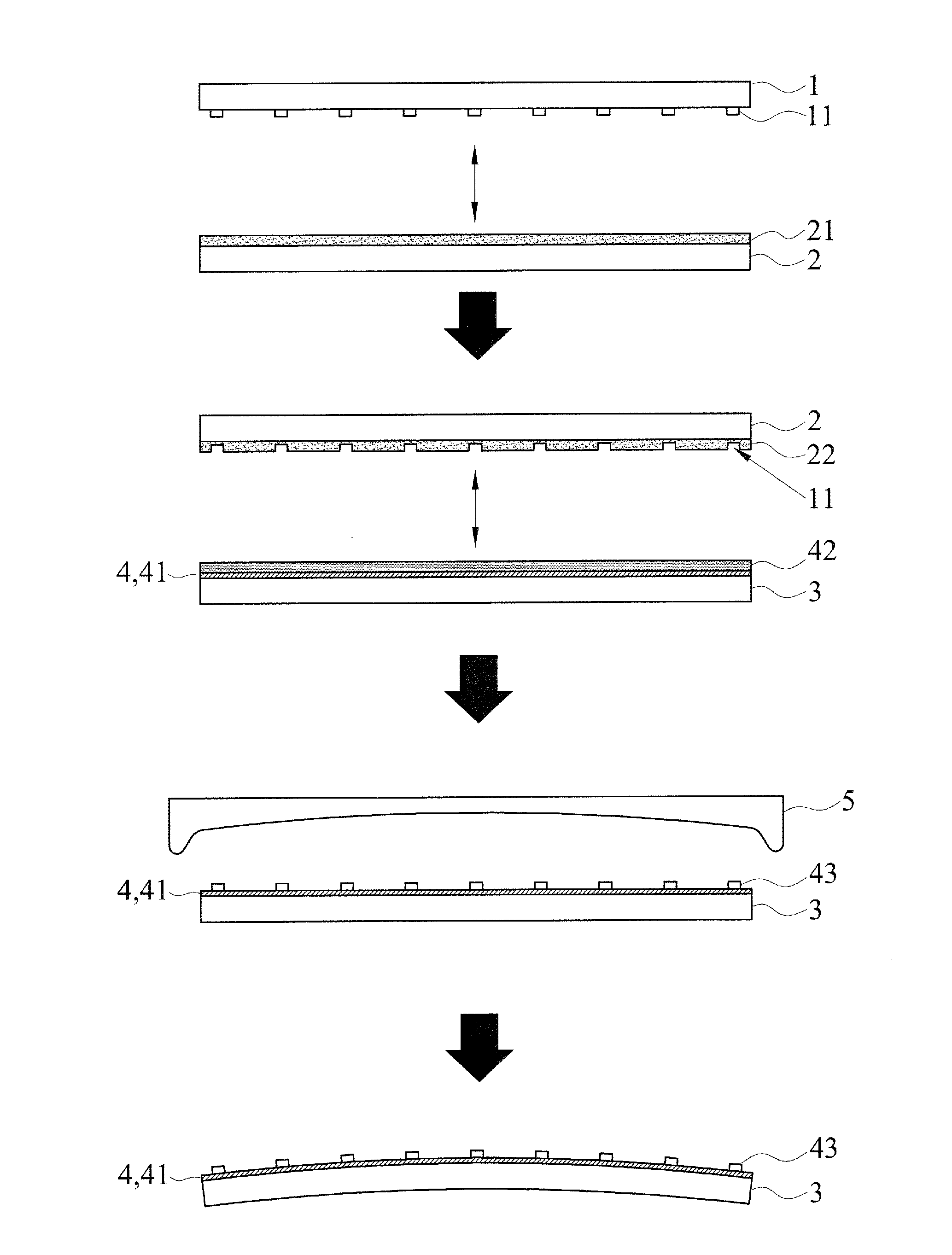

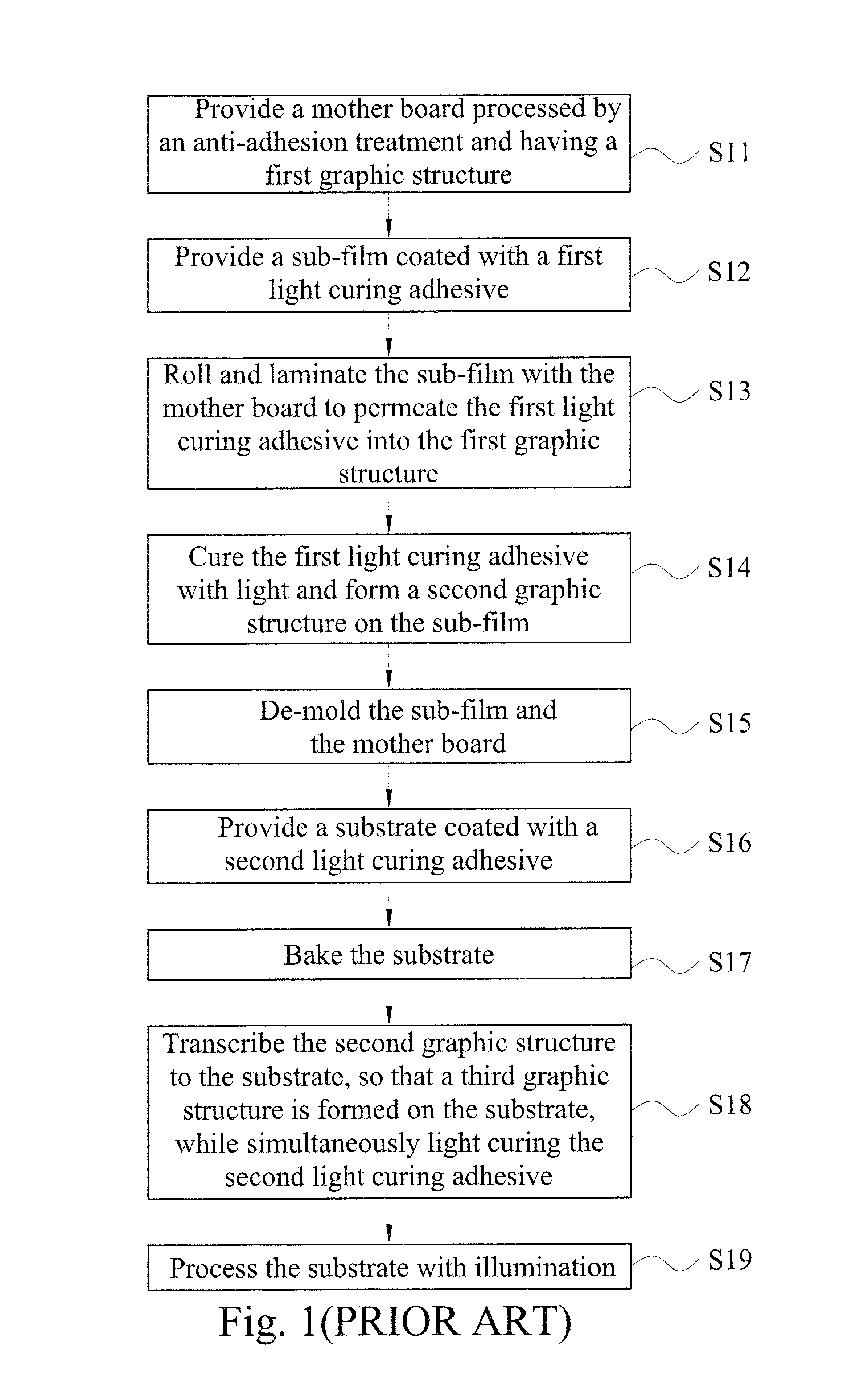

Multi-layer 3D pattern manufacturing method and manufacturing apparatus thereof

InactiveUS20150020959A1Increased transcription rateImprove aestheticsLamination plant layoutMechanical working/deformationScreen printing3d patterning

A multi-layer 3D pattern manufacturing method includes the steps of forming a color film on a surface of a substrate or a third pattern structure by providing a chromogenic material by lithography, gravure, flexographic printing, screen printing and physical vapor deposition in a transcribed printing process. Using the color film to match with different 3D pattern structures to form a multilayer 3D pattern which can be applied to the housing of various different electronic products not only can improve the aesthetic appearance, it can also enclose the color film within the 3D pattern to prevent the 3D pattern from falling off or fading; thus, the lifetime of the pattern can be improved.

Owner:IMPRINTING LITHOGRAPHY DECORATION TECH

Color filter using surface plasmon and liquid crystal display device

InactiveUS8593595B2Raise the ratioHigh color reproductionOptical filtersNon-linear optics3d patterningLiquid-crystal display

Discussed are a color filter using a surface plasmon and a liquid crystal display (LCD) device, the color filter capable of enhancing a transmittance ratio of an LC panel by having a 3D pattern structure of a transmissive pattern for selectively transmitting light of a specific wavelength, and capable of simplifying entire processes. According to the color filter using a surface plasmon and the LCD device, not only three colors of RGB but also multi-colors can be implemented, and color reproduction can be enhanced by optimizing arrangement of the transmissive pattern according to the number of colors to be implemented.

Owner:LG DISPLAY CO LTD

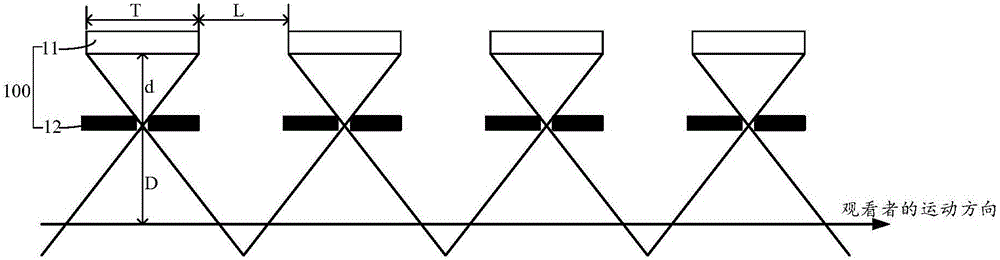

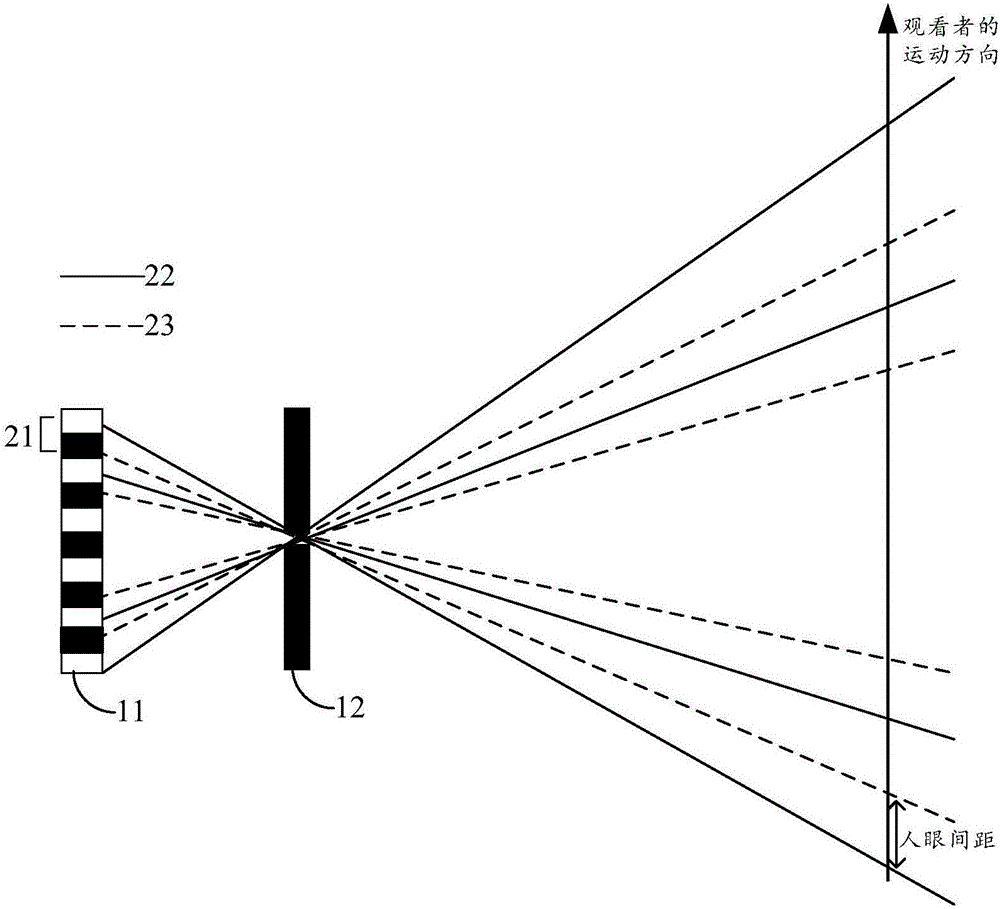

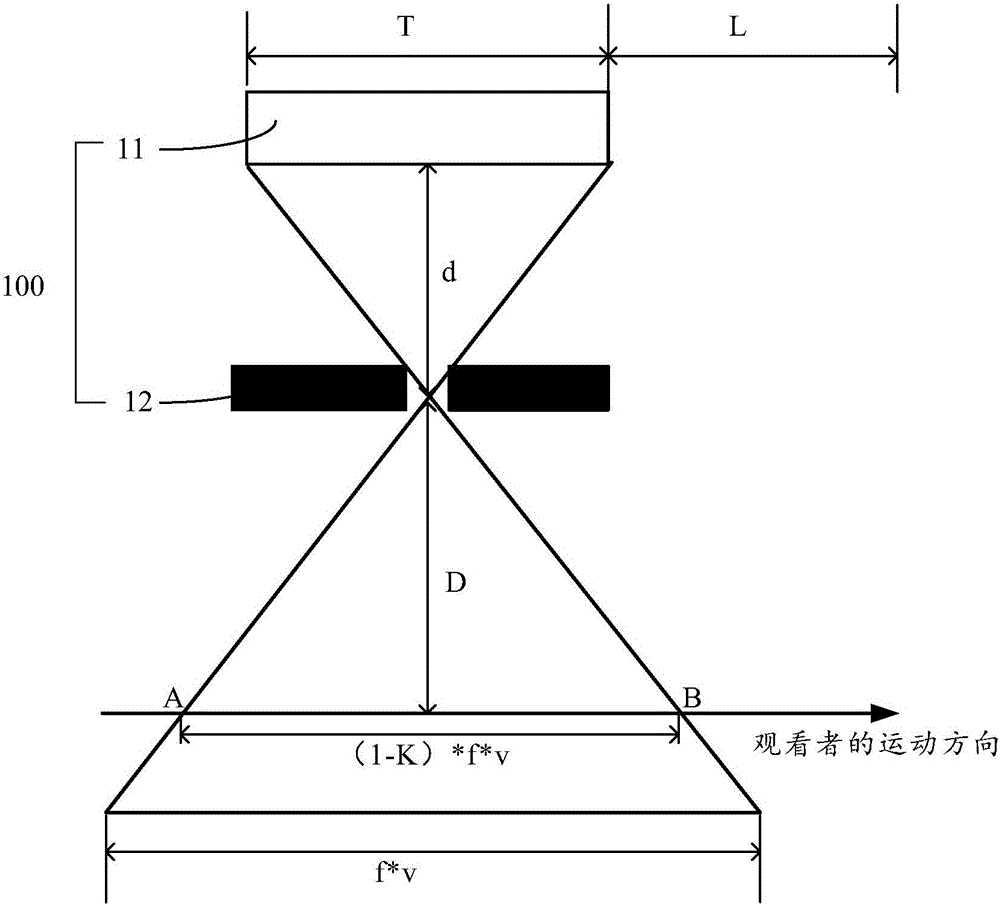

3D display method and system

The embodiment of the invention, which relates to the display field, provides a 3D display method and system. When a watcher moves relative to a display device, the watcher can watch a stable 3D pattern during the relative movement process. The system comprises N display devices arranged successively along the moving direction of the watcher, wherein the display devices include 3D display panels and slit devices that are arranged at light-emitting sides of the 3D display panel and are opposite to the 3D display panels. The distances between the 3D display panels and the slits of the slit devices are d and the distances between the watcher and the slits of the slit devices are D; and the d and D meet the following formula: d / D= T / (T+L)*(1-K), wherein the T expresses widths of the 3D display panels along the moving direction of the watcher, the L expresses the distances between the adjacent display devices, and the K expresses black frame insertion proportions of all frames in the 3D display panels. The method can be applied to a 3D display process.

Owner:BOE TECH GRP CO LTD +1

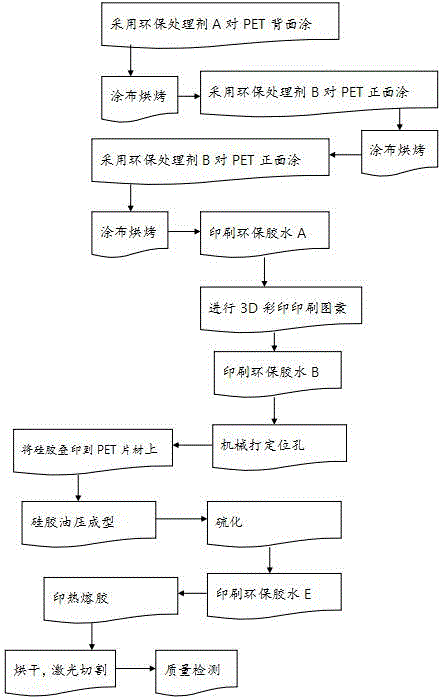

Silica gel and cloth 3D pattern trademark label in-mold forming transfer printing process

InactiveCN106515242AAchieve effectPattern printingOther printing apparatus3d patterningEnvironmental resistance

The invention provides a silica gel and cloth 3D pattern trademark label in-mold forming transfer printing process. The process includes the following steps that an environment-friendly treating agent A is adopted for coating the PET back face, and coating and roasting are performed; an environment-friendly treating agent B is adopted for coating the PET front face, and coating and roasting are performed; the environment-friendly treating agent B is adopted for coating the PET front face, and coating and roasting are further performed; a printing press is adopted for 3D color printing of printing patterns; environment-friendly glue A is printed, and roasting is conducted; environment-friendly glue B is printed, and roasting is conducted; location holes are mechanically drilled; a special lamination machine is adopted for overprinting silica gel onto a PET sheet after the step S10; silica gel oil pressure forming is carried out; vulcanization is performed; environment-friendly glue E is printed on the silica gel, hot melt glue is also printed, and drying, laser cutting and quality inspection are performed; and the 3D patterns are transferred onto a silica gel product during silica gel oil pressure forming, and the patterns can be formed on the product in times of mold stripping without deformation. The definition is high and abrasion resistance is good. Production efficiency is greatly improved, the production cycle is shortened, and production cost is reduced.

Owner:东莞市松烁硅胶科技有限公司

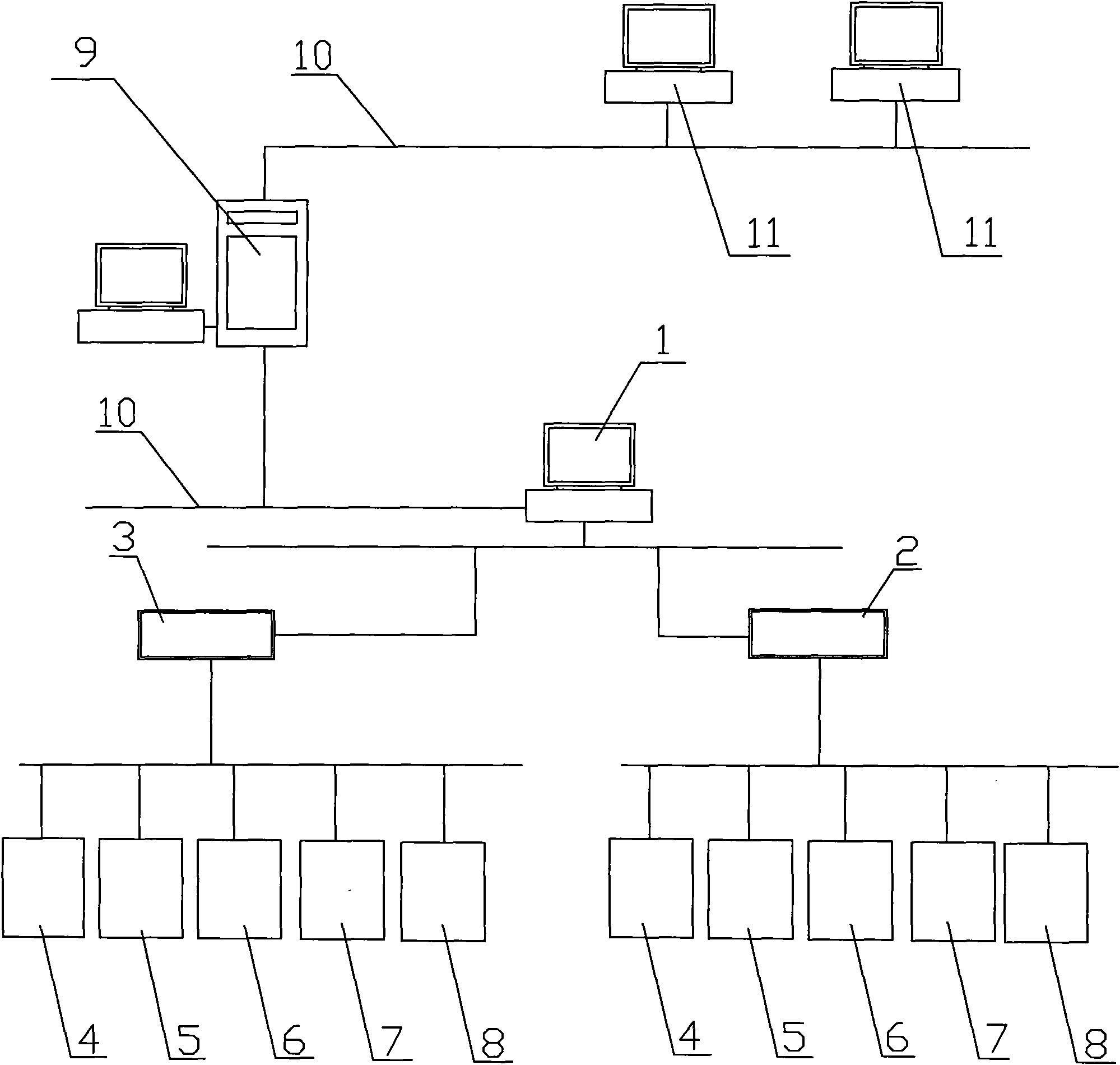

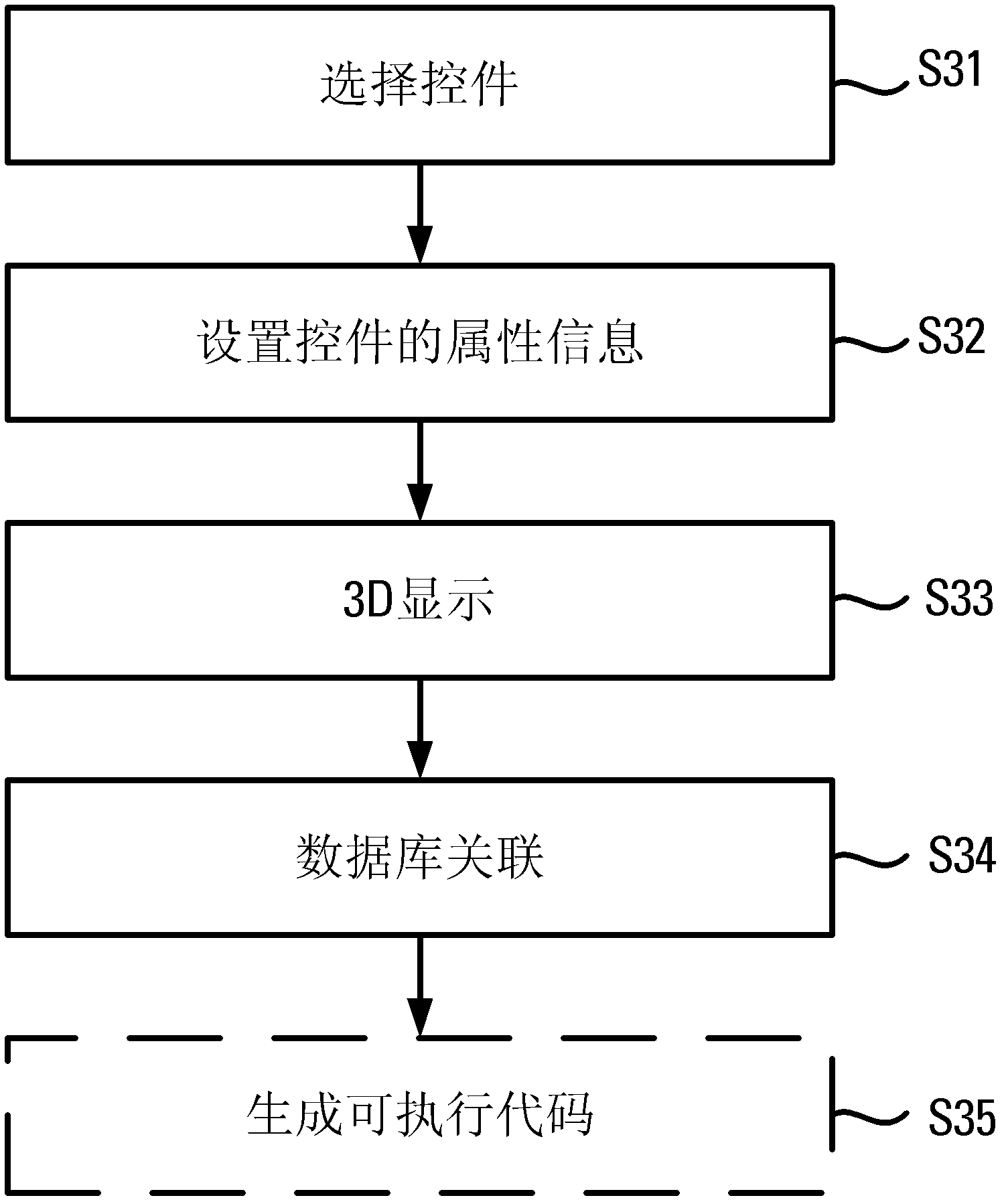

Device and method for designing material tracking system

The invention discloses a device and method for designing a material tracking system. The device comprises a control storage unit, a situation designing unit, a three-dimensional (3D) engine unit and a data base relevance unit. At least one control is stored in the control storage unit, each control standardizes one component in a production line to be a 3D object, and each control has attribute information. One or a plurality of controls are selected from the control storage unit, and corresponding attribute information is set for each selected control so as to form a production line situation. The 3D engine unit displays a 3D pattern image of the production line situation according to the selected control provided by the situation design unit and the attribute information of the selected control. By means of the data base relevance unit, the attribute information of each control is relevant to data reflecting a corresponding component condition in the production line in the material data base so that the data in the material data base is used for updating the attribute information of each control.

Owner:SIEMENS CHINA

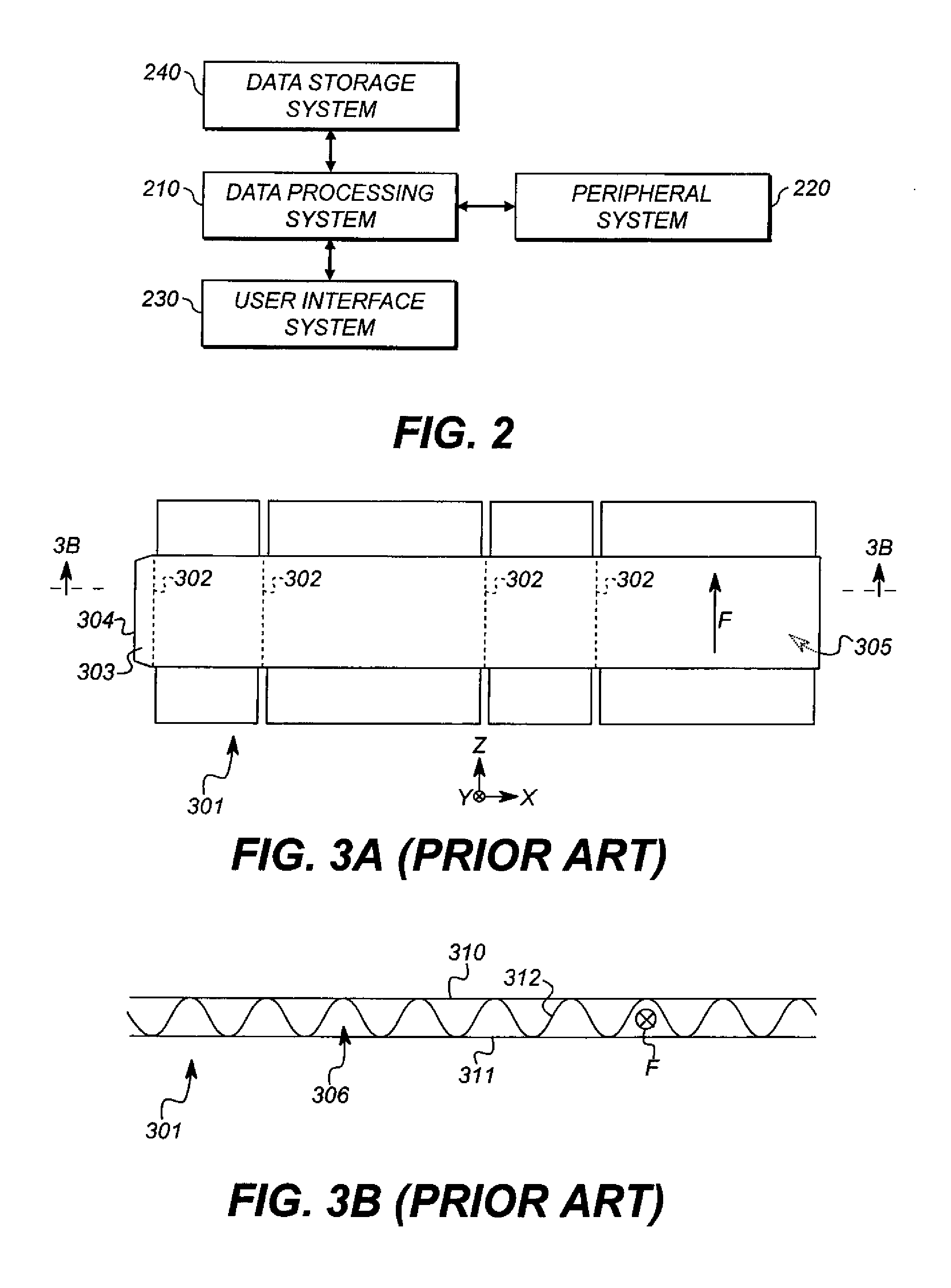

Forming a 3D structural element

InactiveUS20130292049A1Precise positioningReduce quality problemsLamination ancillary operationsLamination3d patterningBiomedical engineering

A structural element is formed. A 3D aim toner pattern is received. Using a processor, the 3D pattern is automatically sliced into a plurality of 2D aim toner patterns and corresponding thicknesses. A sheet is received. Toner corresponding to a selected one of the 2D aim toner patterns is deposited on the received sheet. The deposited toner is fixed to have substantially the thickness corresponding to the selected one of the 2D aim toner patterns. The receiving through fixing steps are repeated until each of the 2D aim toner patterns has been deposited onto a sheet. The sheets are fixed the together to form the structural element having toner corresponding to the 3D pattern.

Owner:EASTMAN KODAK CO

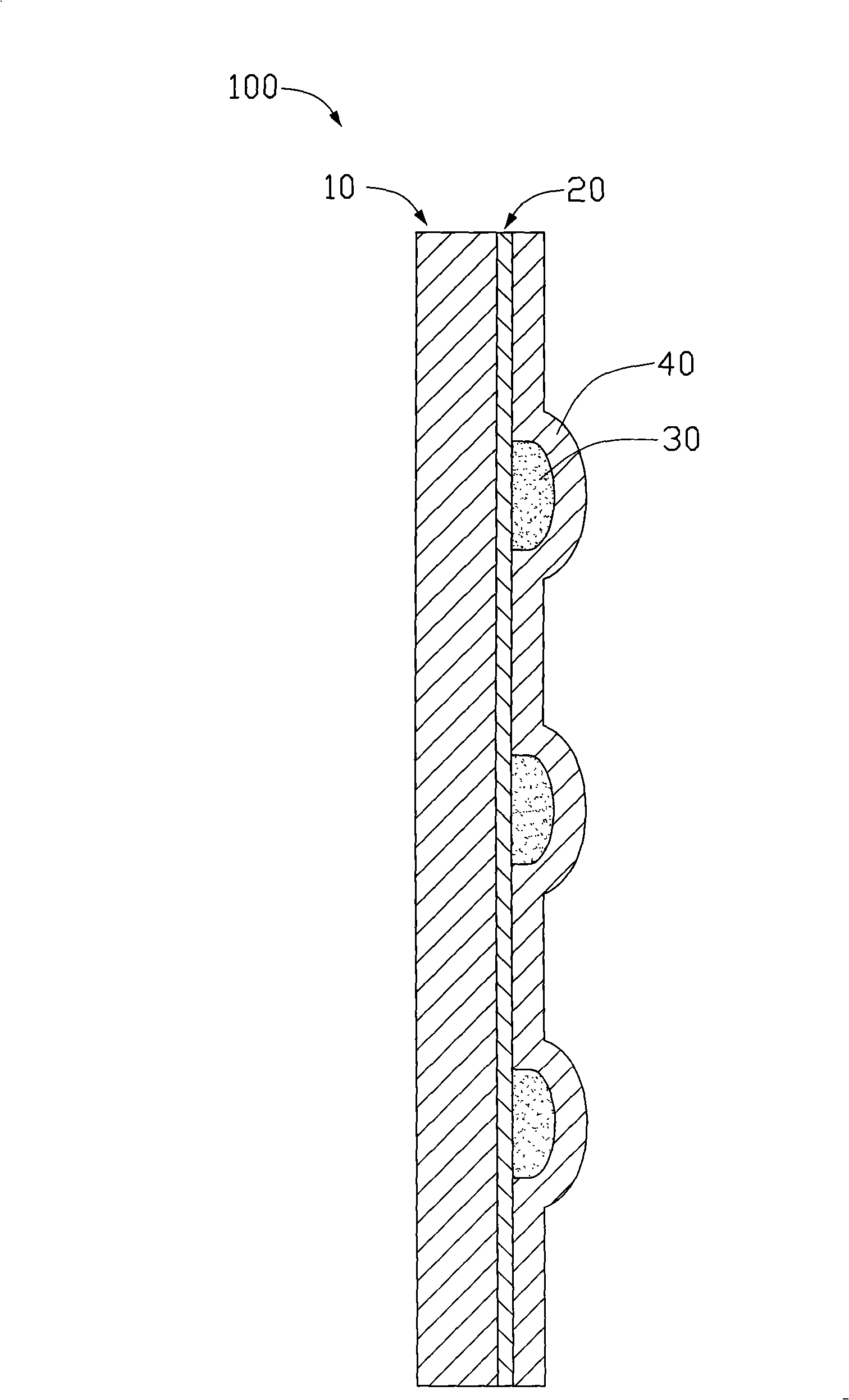

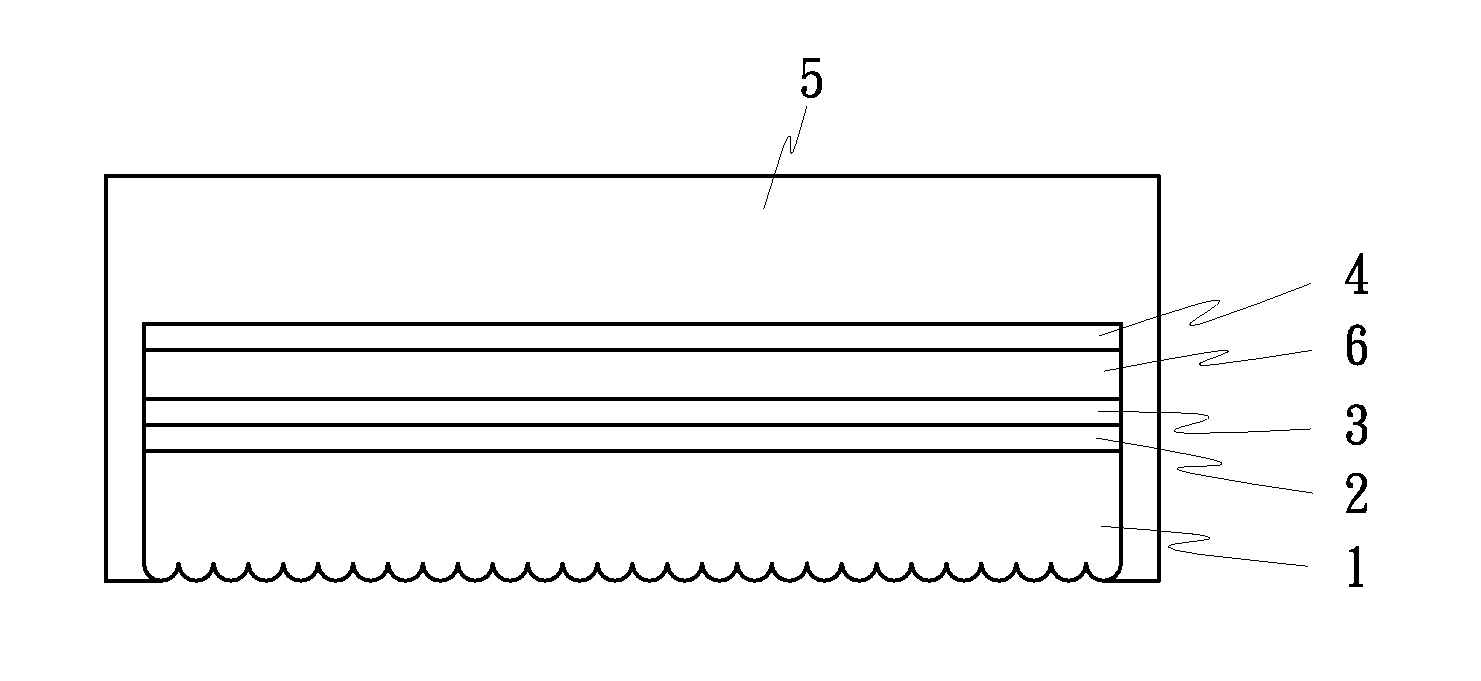

In mold film with a 2d/3d pattern

InactiveUS20090148674A1Improve mechanical propertiesImprove physical strengthStampsSynthetic resin layered products3d patterningGrating

Both in mold film and in mold label with a 2D or 3D pattern include a base layer, which has a flat inner surface and an outer surface that can be a 2D visual surface or 3D grating surface, a pattern layer printed on the inner surface of the base layer to show a 2D or 3D pattern, a protective layer prepared from a polymer material having high temperature resistance, acid resistance and alkali resistance characteristics and printed on the pattern layer, and an adhesion layer covered on the protective layer. In an alternate form, an anti-EMI layer is sandwiched between the protective layer and the adhesion layer for electromagnetic interference protection.

Owner:ULT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com