Hollow pattern mould system and method for producing multi-color area pattern article efficiently

A technology of pattern templates and color patterns, applied in manufacturing tools, supply devices, etc., can solve problems such as chaotic and imprecise patterns, inability to produce natural stone, difficulty in mass production, etc., and achieve the effect of enhancing the three-dimensional sense of visual hierarchy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

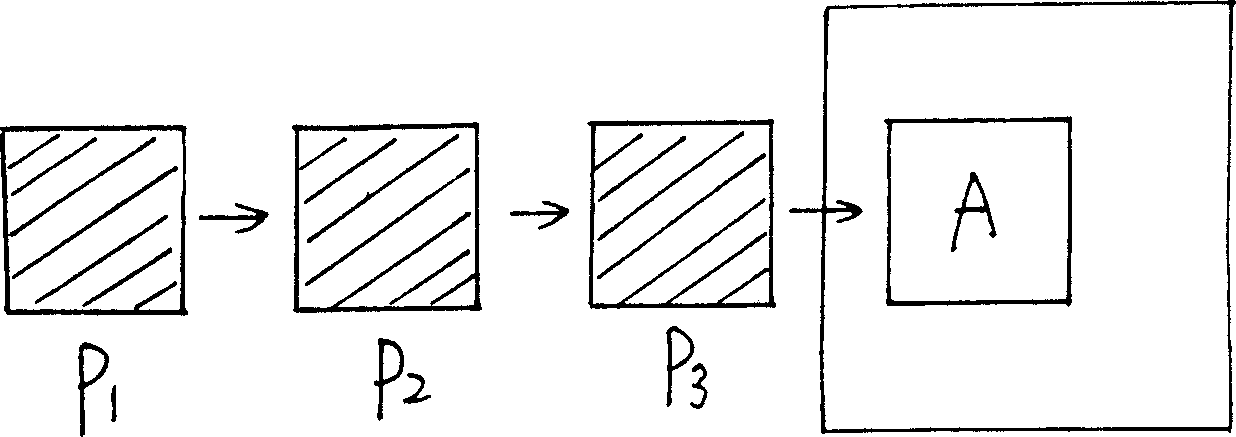

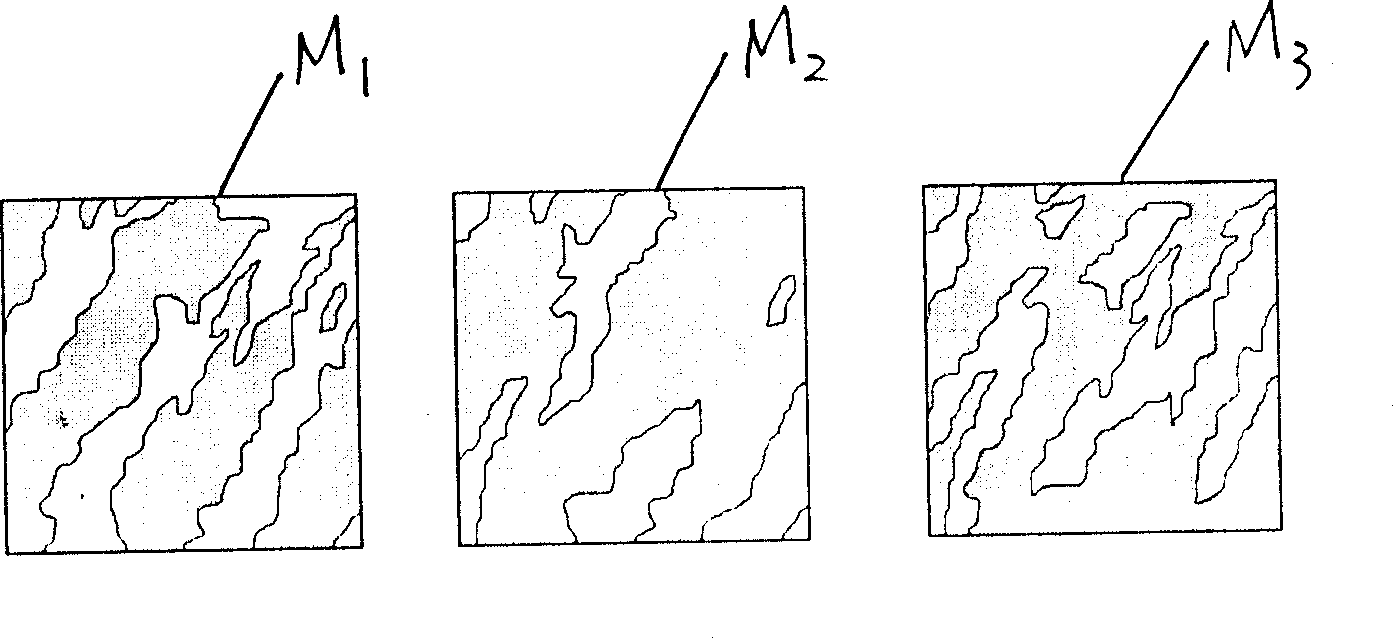

[0231]In the first embodiment, a ceramic imitation large flower green marble pattern product with a size of 600 mm × 600 mm for the purpose of making dark green, light green with light transmission characteristics, and black is an example. , its manufacturing process includes the following steps:

[0232] (1), prepare a drying kiln, a firing kiln, a ceramic press required for the production of porcelain tiles, and a product size that can be stamped in the stamping area of the press through circular motion The circular track made of 0.5mm thick stainless steel belt with consistent frame is used as the carrier for carrying the color pattern raw material.

[0233] (2) Prepare three different colored porcelain powders: dark green, black, and light green with light-transmitting characteristics.

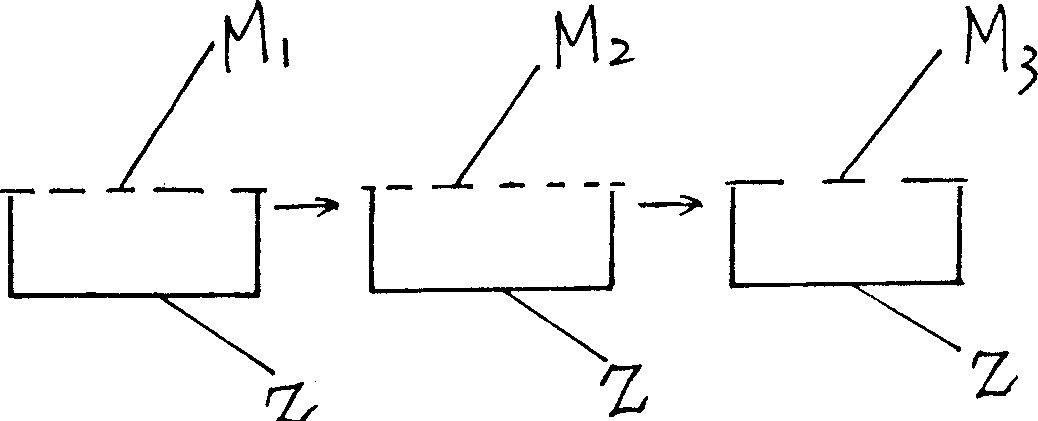

[0234] (3) Prepare and install a set of hollow pattern mold system for efficiently producing multi-color area pattern products next to the ceramic press, including:

[0235] Firstly, p...

no. 2 example

[0246] In the second embodiment, taking the 600mm × 600mm porcelain fine pattern product imitating large flower green marble pattern for the purpose of making dark green, light green and black three pattern color zones as an example, the manufacturing process includes the following steps:

[0247] (1) Prepare a drying kiln, a firing kiln, a ceramic press machine for the production of porcelain tiles, as well as the required stamping dies, distribution carts, and powder pushing racks.

[0248] (2) Prepare three different colored porcelain powders of dark green, light green and black.

[0249] (3) Prepare and install a set of hollow pattern mold system for efficiently producing multi-color area pattern products next to the ceramic press, including:

[0250] First, prepare 3 empty hole pattern templates that are respectively used for the first piece through dark green, the second piece through light green, and the third piece through black pattern raw materials with different hol...

no. 3 example

[0272] In the third embodiment, taking the resin-containing artificial stone product imitating the large flower green marble pattern of the size of 600mm * 600mm for the purpose of making dark green, light green, and black three pattern color zones as an example, the manufacturing process includes the following steps:

[0273] (1) Prepare the vacuum pumps required for the production of resin-containing artificial stone products, multiple heating box equipment, vibration equipment, and a framed frame with a size slightly larger than 600mm×600mm as a carrier for the raw materials for making resin-containing artificial stone products Glass plate and conveyor belt.

[0274] (2), prepare dark green, light green, black three kinds of different colors respectively containing unsaturated resin 30%, light calcium carbonate powder 70% to be the pattern raw material of making resin-containing artificial stone in slurry state.

[0275] (3) Prepare and install a set of hollow pattern mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com