Method for producing 3D patterns on glass surface and etching solution for method

A technology of glass surface and production method, applied in the field of etching solution, can solve the problems of inability to accurately grasp the processing precision of patterns, and achieve the effect of a soft and warm environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

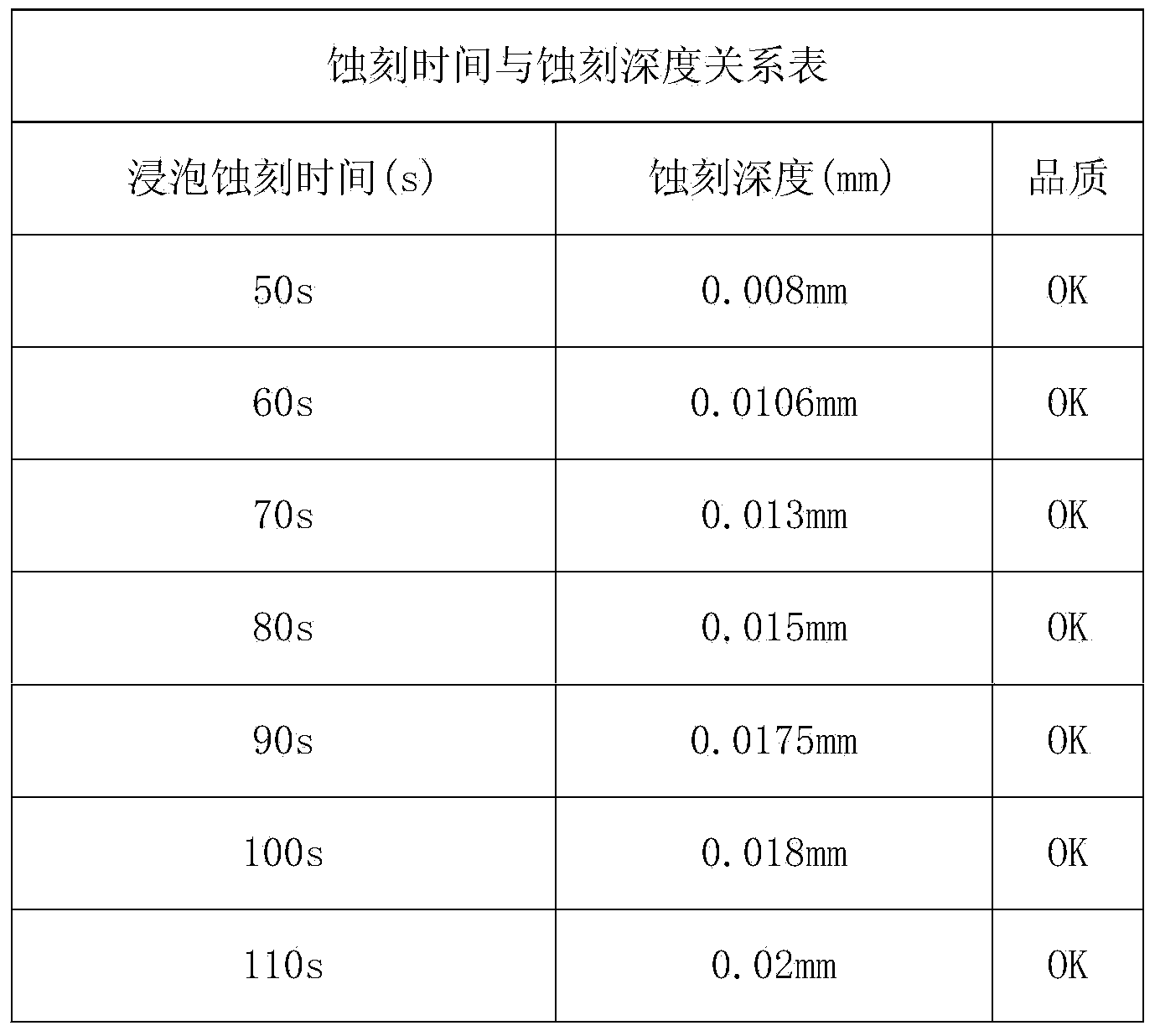

[0020] A method for producing a 3D pattern on a glass surface, comprising the following steps: a. First cleaning the flat glass surface before and after tempering, and printing on the glass surface to be made with a 3D pattern by using a corrosion-resistant ink through a screen screen with a pattern designed in advance pattern, dry it, the surface of the back of the glass that does not need to be patterned is all silk-screened with corrosion-resistant ink, and dried;

[0021] b. Put the screen-printed glass into the etching solution according to the depth of the pattern. The composition and proportion of the etching solution are prepared by weight percentage, 75 parts of water, 5 parts of catalyst, 20 parts of hydrofluoric acid, and the temperature of the etching solution is constant. 27 degrees Celsius; the catalyst here uses a concentration of 65% sulfuric acid.

[0022] c. Take out the processed glass and put it into water to clean the etching solution on the glass;

[002...

Embodiment 2

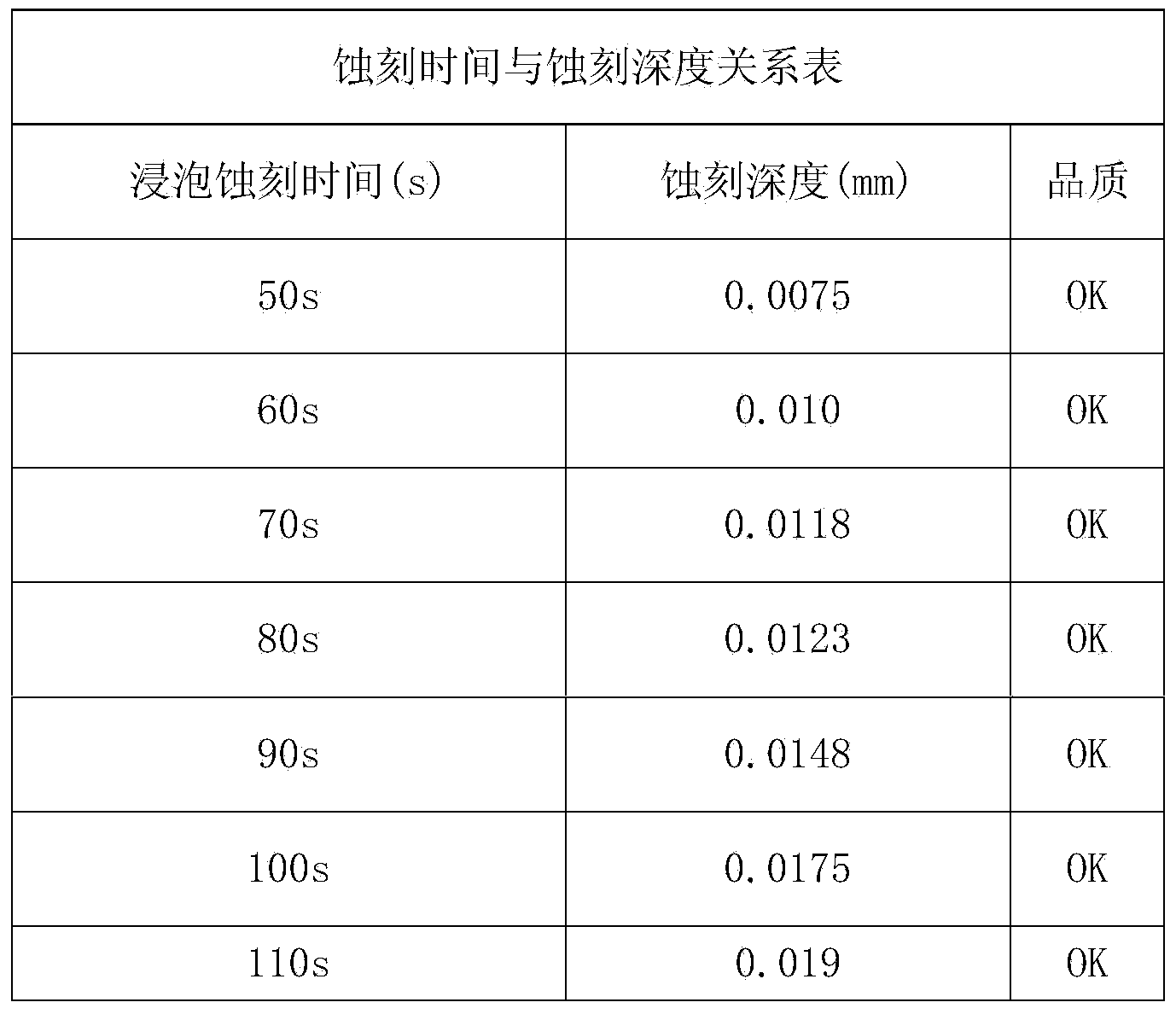

[0027] A method for producing a 3D pattern on a glass surface, comprising the following steps: a. First cleaning the flat glass surface before and after tempering, and printing on the glass surface to be made with a 3D pattern by using a corrosion-resistant ink through a screen screen with a pattern designed in advance pattern, dry it, the surface of the back of the glass that does not need to be patterned is all silk-screened with corrosion-resistant ink, and dried;

[0028] b. Put the screen-printed glass into the etching solution according to the depth of the pattern. The composition and proportion of the etching solution are prepared by weight percentage, 70 parts of water, 15 parts of catalyst, 15 parts of hydrofluoric acid, and the temperature of the etching solution is constant. 27 degrees Celsius; the catalyst here is sulfuric acid with a concentration of 70%.

[0029] c. Take out the processed glass and put it into water to clean the etching solution on the glass;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com