Diffraction optics element scan etching device with etch deepness on-line detection mechanism

A diffractive optical element and detection mechanism technology, applied in the field of science, can solve problems such as inability to realize online detection of etching depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

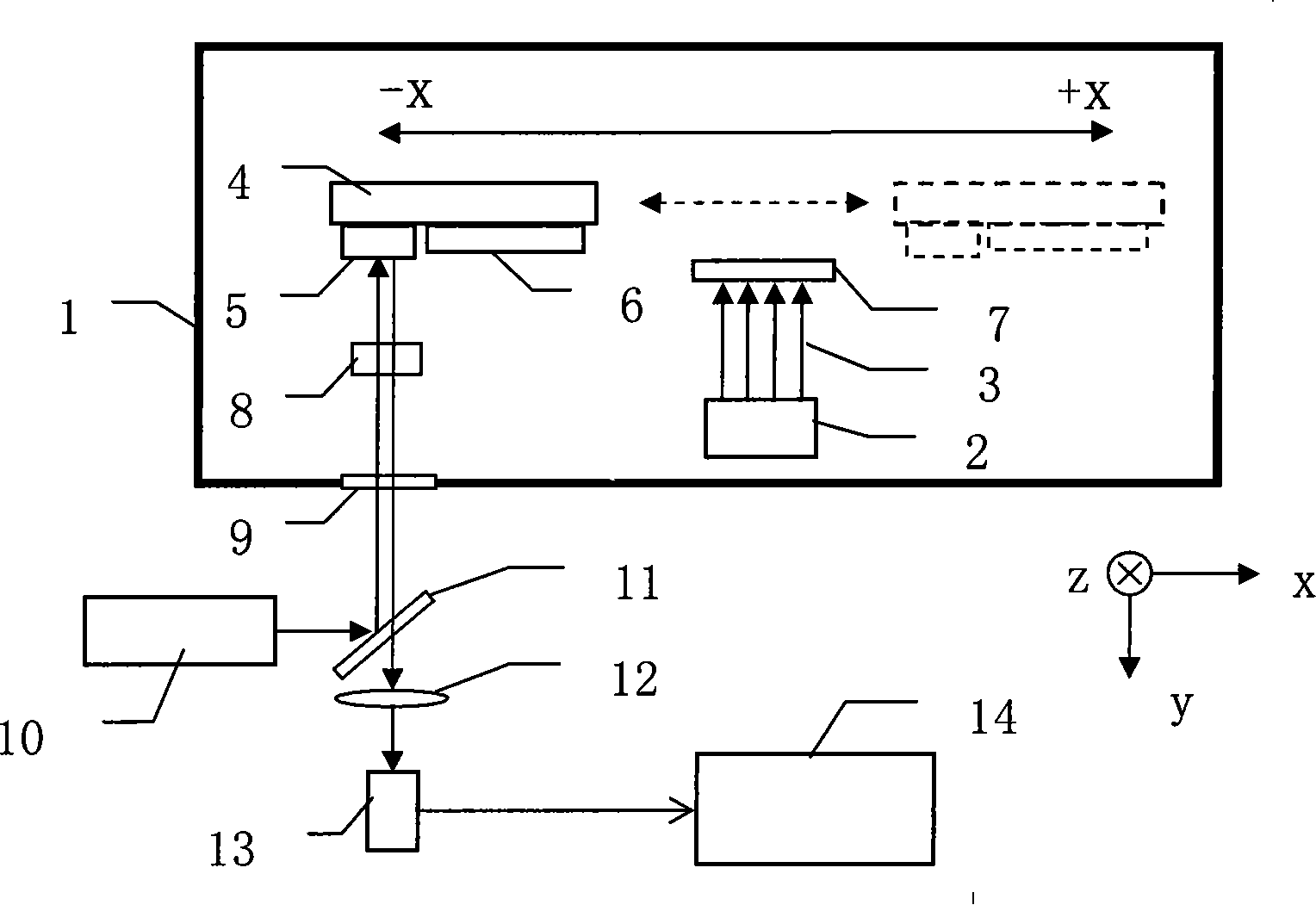

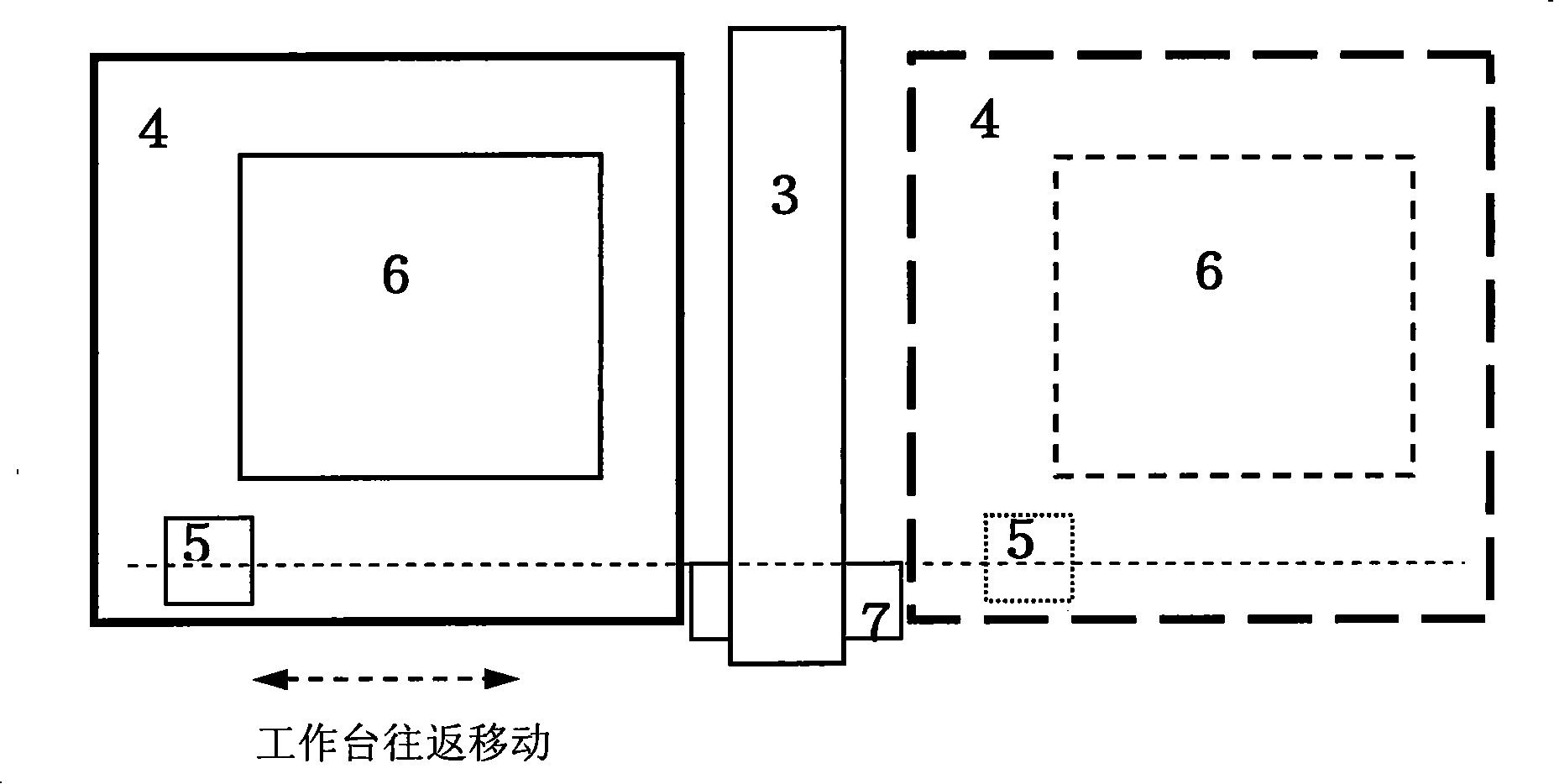

[0049] see Figure 1 and figure 2, The diffractive optical element scanning etching device with an etching depth on-line detection mechanism includes a vacuum chamber 1 with an observation window, an ion source 2, an ion beam stop 3, and a translation table 4, and the work table of the translation table 4 is to be etched. The optical element 6, the translation workbench 4 can translate along the +x and -x directions, the incident direction of the ion beam is perpendicular to the work surface of the workbench, that is, the direction of the ion beam emitted by the ion source is approximately parallel to the normal line of the workbench, Its observation window 9 is basically parallel to the normal direction of the working surface of the translation workbench. The accompanying sheet 5 and the optical element (formal substrate) 6 to be etched are fixed on the working surface of the workbench, and the graphite baffle 7 is fixed at a suitable position on the ion beam stop to block ...

Embodiment 2

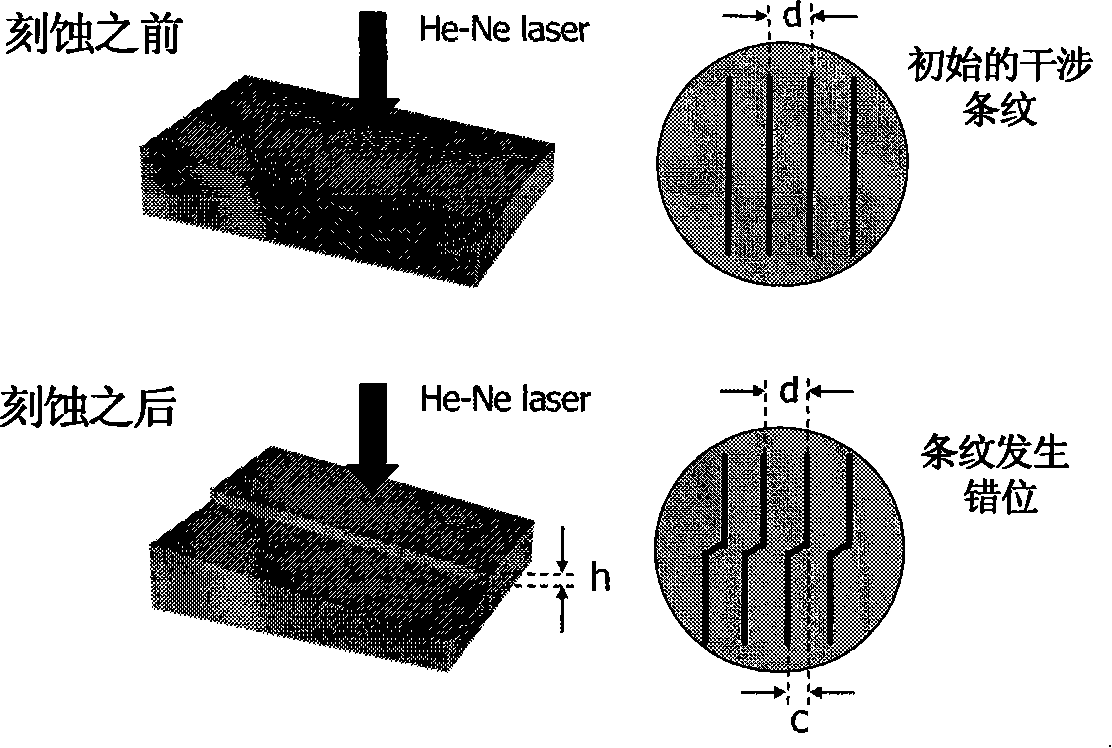

[0060] The structure of the diffractive optical element scanning etching device with an etching depth on-line detection mechanism is the same as in Embodiment 1, wherein the material of the optical element 6 to be etched is fused silica, and a phase-type Ronchi grating with a target etching depth of 690±15 nm.

[0061] The accompanying sheet 5 used in the detection is the same as that used in Example 1, which is a circular sheet with a diameter of 25mm and a thickness of about 3mm, and the material is fused silica; the linear density of its equal-thickness stripes is about 10 lines / cm; The etching depth corresponding to the fringe interval is about 217 nanometers, so when the dislocation ratio of equal-thickness fringes of the companion sheet reaches about 3.180 ((690±15) / 217≈3.180±0.069), the etching should be stopped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com